Fractographic Investigation of Cryogenic Temperature Mode-II Delamination Behavior of Filament Wound CFRP Laminates with Varied Resin Systems

Abstract

:1. Introduction

2. Materials and Methods

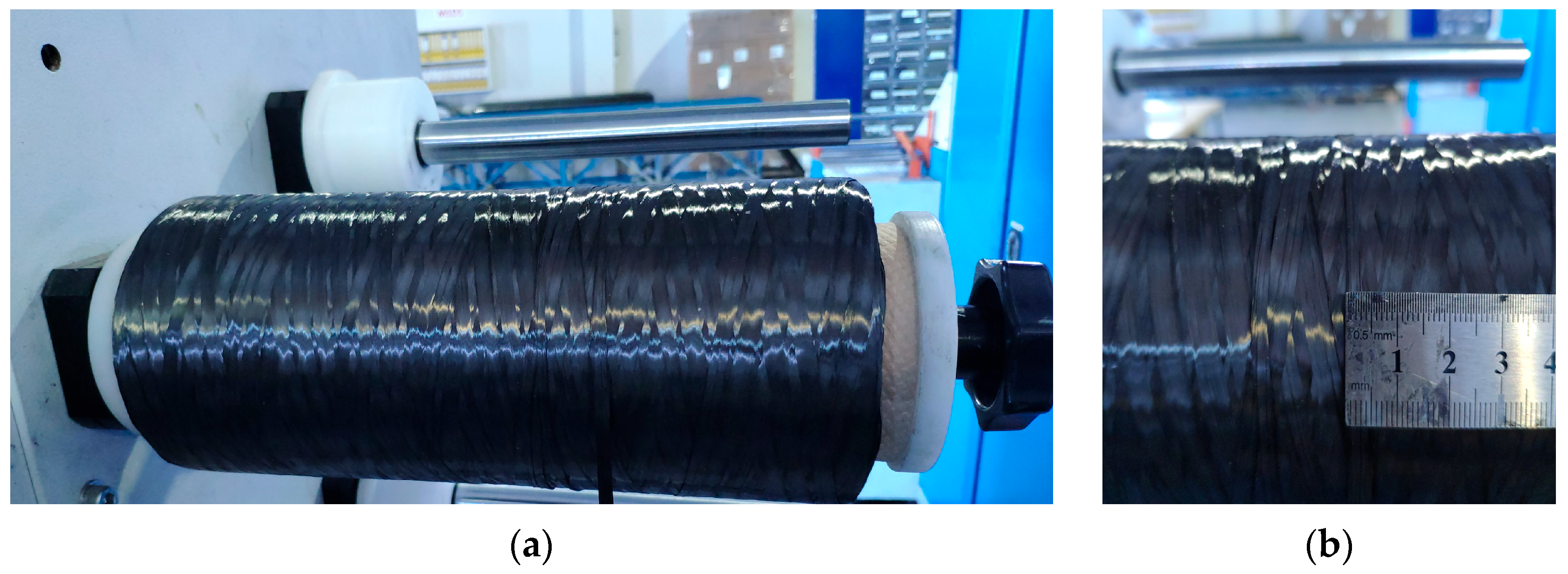

2.1. Materials

2.2. Specimen Preparation

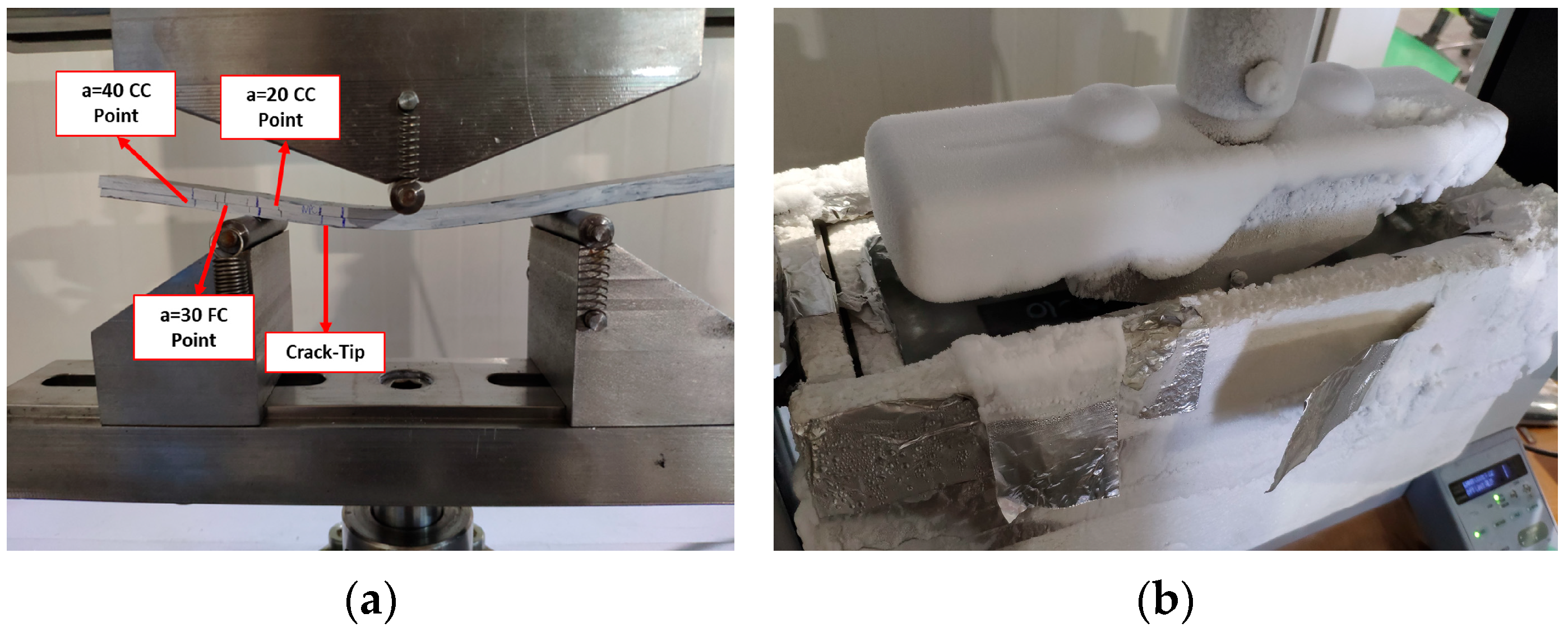

2.3. Mechanical Tests

2.4. Microscopy

3. Results

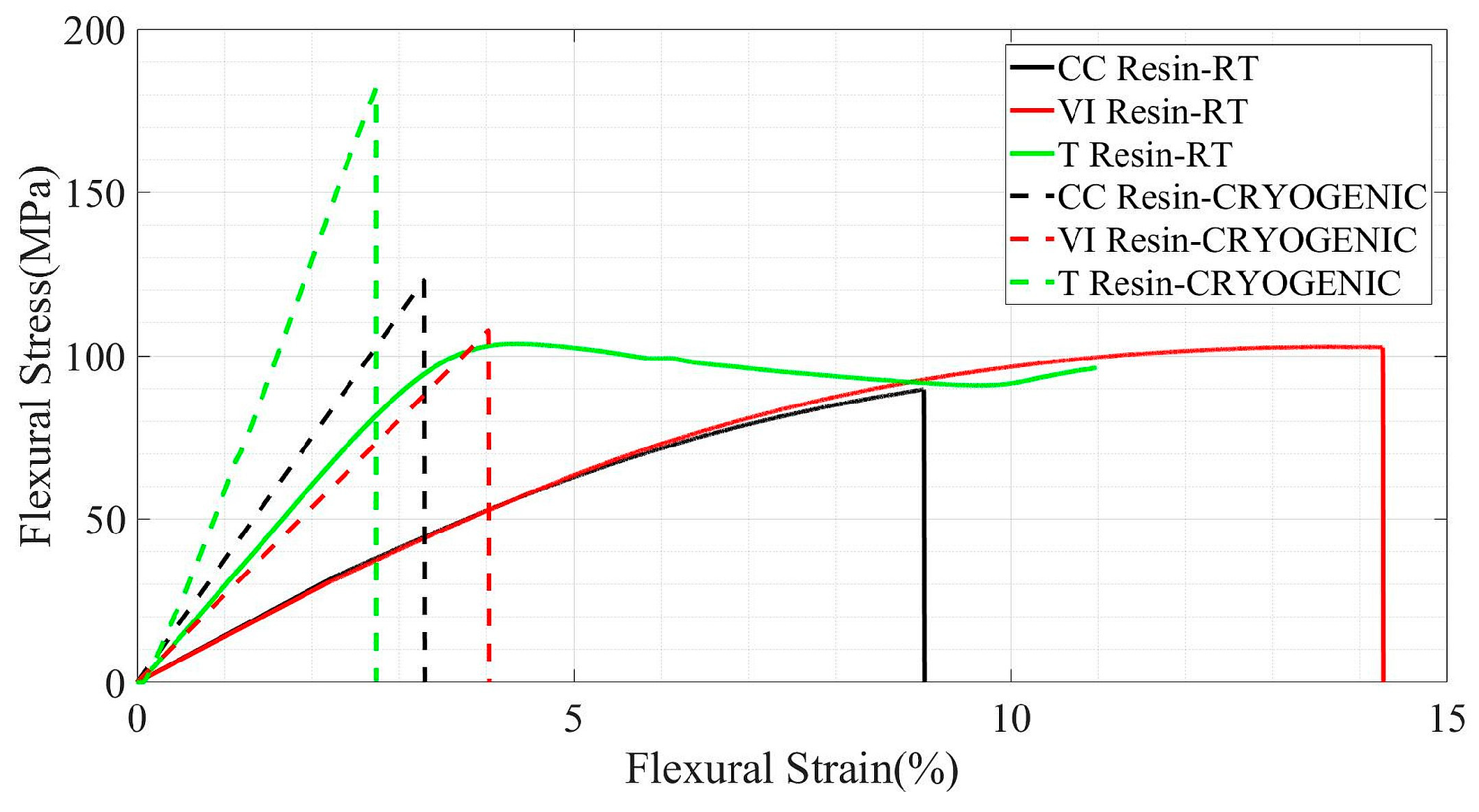

3.1. Three-Point Bending Tests

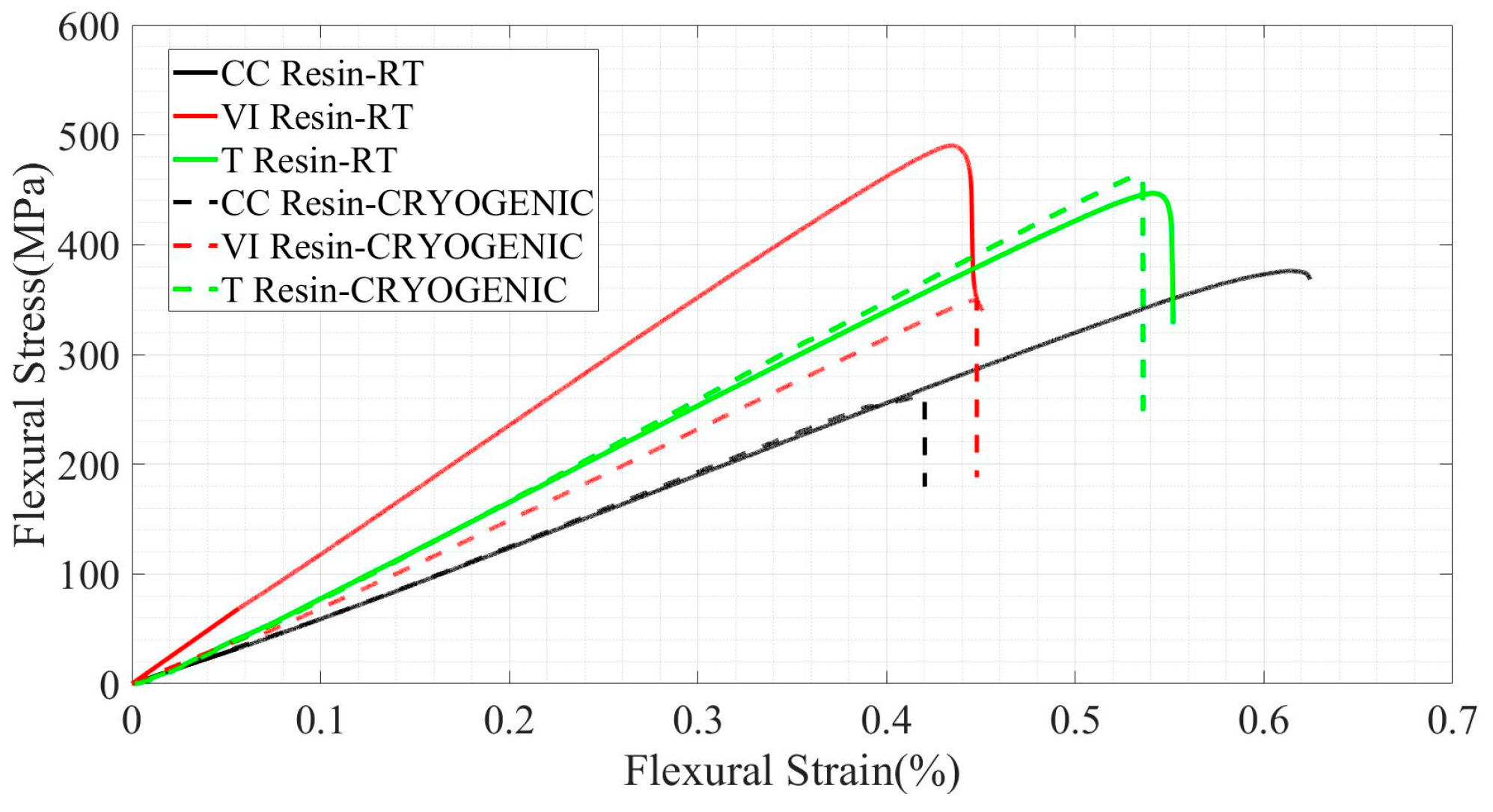

3.2. End-Notched Flexure Tests

4. Discussion

4.1. Macro-Scale Interpretation of the Main Mode of Failure

4.2. Crack Propagation Surfaces and Resin Morphologies

4.2.1. Pre-Crack Region (Crack Initiation Zone)

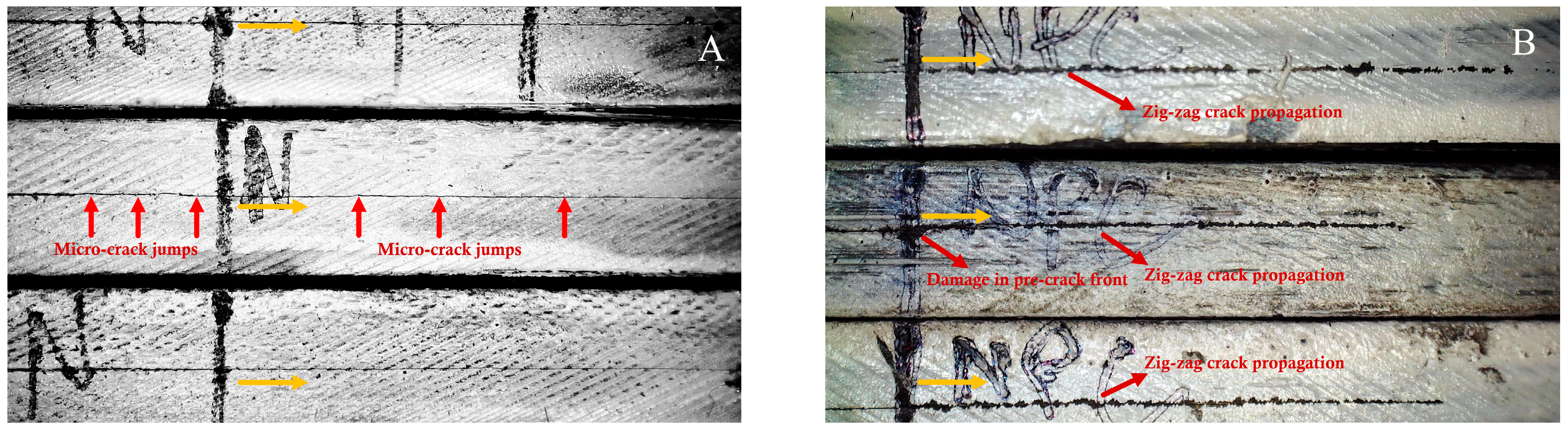

4.2.2. Far-Crack Region (Crack Propagation Zone)

4.2.3. Effect of LN2 on Multi-Scaled Interactions

5. Conclusions

- The three-point bending tests on the neat epoxy specimens demonstrated that cryogenic temperatures led to a decrease in the elongation and an increase in the strength and stiffness due to embrittlement. It became apparent that the neat epoxy’s performance may not accurately reflect the cryogenic performance of the composites due to the dominant influence of fiber/matrix interactions on the damage behavior. Consequently, experimental efforts focusing on single-fiber tow/resin interactions may be favored.

- The mode-II delamination behavior was notably affected by inherent resin bagging and tow undulation problems associated with conventional wet winding. Their presence caused complex 3D crack propagation. Tow movement at room temperature provided resin ductility, contributing to an increase in the GIIc levels through a tow interlocking mechanism.

- Matrix shear failure, fiber/matrix debonding and even fiber fracture events were observed during crack propagation at room temperature.

- Under cryogenic temperatures, the dominant failure mode shifted towards fiber/matrix debonding, characterized by visible zig-zag crack propagation, as seen from side views of the specimens.

- The VI resin, with the lowest mixture viscosity, suffered from a wetting problem that increased the contribution of the undulated fiber architecture (tow interlocking). This mechanism explained the similar GIIc values measured at both room and cryogenic temperatures, with the embrittlement events observed for the neat resin system having a limited impact on the laminate behavior.

- The CC resin system, with a moderate mixture viscosity, enabled better wetting of the interlaminar plane. This was associated with the pre-crack insertion process, where the overall winding process was temporarily halted. The combination of the undulated fiber architecture and matrix phase contributed to the highest GIIc levels measured at room temperature. However, this case also experienced the most significant GIIc reduction under cryogenic temperatures, which may be attributed to resin embrittlement. The fractographic analyses suggested that nanoscale matrix cracking, fiber shear fracturing and fiber/matrix debonding events collectively contributed the ultimate fracture.

- The T resin system, with the highest mixture viscosity, likewise offered good wetting. Parallel to the VI resin system, the GIIc values of the T resin system remained stable under cryogenic conditions. The fractographic analyses indicated better fiber/matrix adhesion under cryogenic temperatures. This fact simultaneously allowed for an equal contribution of the matrix phase during mode-II crack propagation. Notably, typical shear hackles inherent to mode-II crack propagation were observed on the fracture surfaces of the samples tested under cryogenic conditions. This situation was not present in any of the other resins due to the fact that the damage progression under cryogenic temperatures was always initiated by fiber/matrix debonding followed by other failure events.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Abumeri, G.H.; Kosareo, D.N.; Roche, J.M. Cryogenic Composite Tank Design for next Generation Launch Technology. In Proceedings of the 40th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit, Fort Lauderdale, FL, USA, 11–14 July 2004. [Google Scholar]

- Mallick, K.; Cronin, J.; Ryan, K.; Arzberger, S.; Munshi, N.; Paul, C.; Welsh, J.S. An Integrated Systematic Approach to Linerless Composite Tank Development. In Proceedings of the Collection of Technical Papers—46th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference, Austin, TX, USA, 18–21 April 2005; Volume 5, pp. 3553–3569. [Google Scholar]

- Chen, D.; Li, J.; Yuan, Y.; Gao, C.; Cui, Y.; Li, S.; Liu, X.; Wang, H.; Peng, C.; Wu, Z. A Review of the Polymer for Cryogenic Application: Methods, Mechanisms and Perspectives. Polymers 2021, 13, 320. [Google Scholar] [CrossRef] [PubMed]

- Adams, D.S.; Bowles, D.E.; Herakovich, C.T. Thermally Induced Transverse Cracking in Graphite-Epoxy Cross-Ply Laminates. J. Reinf. Plast. Compos. 1986, 5, 152–169. [Google Scholar] [CrossRef]

- Bechel, V.T.; Kim, R.Y. Damage Trends in Cryogenically Cycled Carbon/Polymer Composites. Compos. Sci. Technol. 2004, 64, 1773–1784. [Google Scholar] [CrossRef]

- Nguyen, B.N.; Simmons, K.L. A Multiscale Modeling Approach to Analyze Filament-Wound Composite Pressure Vessels. J. Compos. Mater. 2013, 47, 2113–2123. [Google Scholar] [CrossRef]

- Pereira, A.B.; De Morais, A.B. Mode II Interlaminar Fracture of Glass/Epoxy Multidirectional Laminates. Compos. Part A Appl. Sci. Manuf. 2004, 35, 265–272. [Google Scholar] [CrossRef]

- Choi, S.; Sankar, B.V. Micromechanical Analysis of Composite Laminates at Cryogenic Temperatures. J. Compos. Mater. 2006, 40, 1077–1091. [Google Scholar] [CrossRef]

- Azeem, M.; Ya, H.H.; Kumar, M.; Stabla, P.; Smolnicki, M.; Gemi, L.; Khan, R.; Ahmed, T.; Ma, Q.; Sadique, M.R.; et al. Application of Filament Winding Technology in Composite Pressure Vessels and Challenges: A Review. J. Energy Storage 2022, 49, 103468. [Google Scholar] [CrossRef]

- Shindo, Y.; Takeda, T.; Narita, F.; Saito, N.; Watanabe, S.; Sanada, K. Delamination Growth Mechanisms in Woven Glass Fiber Reinforced Polymer Composites under Mode II Fatigue Loading at Cryogenic Temperatures. Compos. Sci. Technol. 2009, 69, 1904–1911. [Google Scholar] [CrossRef]

- Flanagan, M.; Grogan, D.M.; Goggins, J.; Appel, S.; Doyle, K.; Leen, S.B.; Ó Brádaigh, C.M. Permeability of Carbon Fibre PEEK Composites for Cryogenic Storage Tanks of Future Space Launchers. Compos. Part A Appl. Sci. Manuf. 2017, 101, 173–184. [Google Scholar] [CrossRef]

- Grogan, D.M.; Ó Brádaigh, C.M.; McGarry, J.P.; Leen, S.B. Damage and Permeability in Tape-Laid Thermoplastic Composite Cryogenic Tanks. Compos. Part A Appl. Sci. Manuf. 2015, 78, 390–402. [Google Scholar] [CrossRef]

- Yokozeki, T.; Ogasawara, T.; Aoki, T.; Ishikawa, T. Experimental Evaluation of Gas Permeability through Damaged Composite Laminates for Cryogenic Tank. Compos. Sci. Technol. 2009, 69, 1334–1340. [Google Scholar] [CrossRef]

- Nishijima, S.; Honda, Y.; Okada, T. Application of the Positron Annihilation Method for Evaluation of Organic Materials for Cryogenic Use. Cryogenics 1995, 35, 779–781. [Google Scholar] [CrossRef]

- Pozdnyakov, A.O.; Brzhezinskaya, M.M.; Vinogradov, A.S.; Friedrich, K. NEXAFS Spectra of Polymer-Nanocarbon Composites. In Proceedings of the Fullerenes Nanotubes and Carbon Nanostructures, Phoenix, AZ, USA, 18–23 May 2008; Volume 16. [Google Scholar]

- Shen, X.J.; Liu, Y.; Xiao, H.M.; Feng, Q.P.; Yu, Z.Z.; Fu, S.Y. The Reinforcing Effect of Graphene Nanosheets on the Cryogenic Mechanical Properties of Epoxy Resins. Compos. Sci. Technol. 2012, 72, 1581–1587. [Google Scholar] [CrossRef]

- He, Y.; Zhang, L.; Chen, G.; Li, X.; Yao, D.; Lee, J.H.; Zhang, Y. Surface Functionalized Carbon Nanotubes and Its Effects on the Mechanical Properties of Epoxy Based Composites at Cryogenic Temperature. Polym. Bull. 2014, 71, 2465–2485. [Google Scholar] [CrossRef]

- Tudela, M.; Kim, R. Impact Damage Response of Composite Materials at LOX/Cryogenic Temperatures. In Proceedings of the Collection of Technical Papers—AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference, Austin, TX, USA, 18–21 April 2005; Volume 7. [Google Scholar]

- Liu, X.; Sun, T.; Wu, Z.; He, H. Mode II Interlaminar Fracture Toughness of Unidirectional Fiber-Reinforced Polymer Matrix Composites with Synthetic Boehmite Nanosheets at Room Temperature and Low Temperature. J. Compos. Mater. 2018, 52, 945–952. [Google Scholar] [CrossRef]

- Zhao, Y.; Chen, Z.K.; Liu, Y.; Xiao, H.M.; Feng, Q.P.; Fu, S.Y. Simultaneously Enhanced Cryogenic Tensile Strength and Fracture Toughness of Epoxy Resins by Carboxylic Nitrile-Butadiene Nano-Rubber. Compos. Part A Appl. Sci. Manuf. 2013, 55, 178–187. [Google Scholar] [CrossRef]

- Kim, B.C.; Park, S.W.; Lee, D.G. Fracture Toughness of the Nano-Particle Reinforced Epoxy Composite. Compos. Struct. 2008, 86, 69–77. [Google Scholar] [CrossRef]

- Coronado, P.; Argüelles, A.; Viña, J.; Viña, I. Influence of Low Temperatures on the Phenomenon of Delamination of Mode I Fracture in Carbon-Fibre/Epoxy Composites under Fatigue Loading. Compos. Struct. 2014, 112, 188–193. [Google Scholar] [CrossRef]

- Bechel, V.T.; Negilski, M.; James, J. Limiting the Permeability of Composites for Cryogenic Applications. Compos. Sci. Technol. 2006, 66, 2284–2295. [Google Scholar] [CrossRef]

- Rousseau, J.; Perreux, D.; Verdière, N. The Influence of Winding Patterns on the Damage Behaviour of Filament-Wound Pipes. Compos. Sci. Technol. 1999, 59, 1439–1449. [Google Scholar] [CrossRef]

- Torres Arellano, M.; Crouzeix, L.; Douchin, B.; Collombet, F.; Hernández Moreno, H.; González Velázquez, J. Strain Field Measurement of Filament-Wound Composites at ±55° Using Digital Image Correlation: An Approach for Unit Cells Employing Flat Specimens. Compos. Struct. 2010, 92, 2457–2464. [Google Scholar] [CrossRef]

- Hernández-Moreno, H.; Douchin, B.; Collombet, F.; Choqueuse, D.; Davies, P. Influence of Winding Pattern on the Mechanical Behavior of Filament Wound Composite Cylinders under External Pressure. Compos. Sci. Technol. 2008, 68, 1015–1024. [Google Scholar] [CrossRef]

- Zhang, Y.; Xia, Z.; Ellyin, F. Two-Scale Analysis of a Filament-Wound Cylindrical Structure and Application of Periodic Boundary Conditions. Int. J. Solids Struct. 2008, 45, 5322–5336. [Google Scholar] [CrossRef]

- Mian, H.H.; Rahman, H. Influence of Mosaic Patterns on the Structural Integrity of Filament Wound Composite Pressure Vessels. Int. J. Struct. Integr. 2011, 2, 345–356. [Google Scholar] [CrossRef]

- Pai, S.P.; Jensen, D.W. Influence of Fiber Undulations on Buckling of Thin Filament-Wound Cylinders in Axial Compression. J. Aerosp. Eng. 2001, 14, 12–20. [Google Scholar] [CrossRef]

- Pourahmadi, E.; Taheri-Behrooz, F. The Influence of Fiber Bundle Width on the Mechanical Properties of Filament-Wound Cylindrical Structures. Int. J. Mech. Sci. 2020, 178, 105617. [Google Scholar] [CrossRef]

- Shen, C.; Han, X. Damage and Failure Analysis of Filament Wound Composite Structure Considering Fibre Crossover and Undulation. Adv. Compos. Lett. 2018, 27, 55–70. [Google Scholar] [CrossRef]

- Barcikowski, M.; Rybkowska, K. Mode II Fracture Characterization of Toughened Epoxy Resin Composites. Int. J. Fract. 2022, 234, 223–233. [Google Scholar] [CrossRef]

- Abd Rased, M.F.; Yoon, S.H. Experimental Study on Effects of Asymmetrical Stacking Sequence on Carbon Fiber/Epoxy Filament Wound Specimens in DCB, ENF, and MMB Tests. Compos. Struct. 2021, 264, 113749. [Google Scholar] [CrossRef]

- De Morais, A.B.; Silva, J.F.; Marques, A.T.; De Castro, P.T. Mode II Interlaminar Fracture of Filament Wound Angle-Ply Specimens. Appl. Compos. Mater. 2002, 9, 117–129. [Google Scholar] [CrossRef]

- Bonhomme, J.; Argüelles, A.; Viña, J.; Viña, I. Fractography and Failure Mechanisms in Static Mode I and Mode II Delamination Testing of Unidirectional Carbon Reinforced Composites. Polym. Test. 2009, 28, 612–617. [Google Scholar] [CrossRef]

- Li, S.; Chen, D.; Yuan, Y.; Gao, C.; Cui, Y.; Wang, H.; Liu, X.; Liu, M.; Wu, Z. Influence of Flexible Molecular Structure on the Cryogenic Mechanical Properties of Epoxy Matrix and Carbon Fiber/Epoxy Composite Laminate. Mater. Des. 2020, 195, 109028. [Google Scholar] [CrossRef]

- Choi, S.; Sankar, B.V. Fracture Toughness of Transverse Cracks in Graphite/Epoxy Laminates at Cryogenic Conditions. Compos. Part B Eng. 2007, 38, 193–200. [Google Scholar] [CrossRef]

- ASTM D790-17; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2002; pp. 1–12.

- ASTM D7905; Standard Test Method for Determination of the Mode II Interlaminar Fracture Toughness of Unidirectional Fiber-Reinforced Polymer Matrix Composites. ASTM International: West Conshohocken, PA, USA, 2014; pp. 1–18.

- ISO 1268-5; Fibre-Reinforced Plastics—Methods of Producing Test Plates—Part 5: Filament Winding. ISO (International Organization for Standardization): Geneva, Switzerland, 2015; Volume 10406-1:20, pp. 3–6.

- Srivastava, V.K.; Gries, T.; Veit, D.; Quadflieg, T.; Mohr, B.; Kolloch, M. Effect of Nanomaterial on Mode I and Mode II Interlaminar Fracture Toughness of Woven Carbon Fabric Reinforced Polymer Composites. Eng. Fract. Mech. 2017, 180, 73–86. [Google Scholar] [CrossRef]

- Peng, C.; Li, J.; Wu, Z.; Peng, W.; Zhou, D. Investigating into the Liquid Oxygen Compatibility of a Modified Epoxy Resin Containing Silicon/Phosphorus and Its Mechanical Behavior at Cryogenic Temperature. RSC Adv. 2016, 6, 38300–38309. [Google Scholar] [CrossRef]

- Feng, Q.; Yang, J.; Liu, Y.; Xiao, H.; Fu, S. Simultaneously Enhanced Cryogenic Tensile Strength, Ductility and Impact Resistance of Epoxy Resins by Polyethylene Glycol. J. Mater. Sci. Technol. 2014, 30, 90–96. [Google Scholar] [CrossRef]

- Ward, I.M.; Pinnock, P.R. The Mechanical Properties of Solid Polymers. Br. J. Appl. Phys. 1966, 17, 3–32. [Google Scholar] [CrossRef]

- Chu, X.X.; Wu, Z.X.; Huang, R.J.; Zhou, Y.; Li, L.F. Mechanical and Thermal Expansion Properties of Glass Fibers Reinforced PEEK Composites at Cryogenic Temperatures. Cryogenics 2010, 50, 84–88. [Google Scholar] [CrossRef]

- Johannesson, T.; Sjöblom, P.; Seldén, R. The Detailed Structure of Delamination Fracture Surfaces in Graphite/Epoxy Laminates. J. Mater. Sci. 1984, 19, 1171–1177. [Google Scholar] [CrossRef]

- Wang, Z.; Almeida, J.H.S.; St-Pierre, L.; Wang, Z.; Castro, S.G.P. Reliability-Based Buckling Optimization with an Accelerated Kriging Metamodel for Filament-Wound Variable Angle Tow Composite Cylinders. Compos. Struct. 2020, 254, 112821. [Google Scholar] [CrossRef]

- Koschmieder, M.; Michaeli, W. On-Line Tow Width Measurement in Filament Winding. Int. SAMPE Symp. Exhib. 2000, 45, 1417. [Google Scholar]

| Epoxy System | Pot Life at 23 °C (hours) | Nominal Curing Cycle | Resin Viscosity (cPs) | Hardener Viscosity (cPs) | Measured Tg * (°C) | Data Sheet Tg (°C) |

|---|---|---|---|---|---|---|

| MARKUT 5025 (CC resin) | 2–3 | 1 day 23 °C+ 4 h 100 °C | 1000–1500 at 5 °C | 40–60 at 25 °C | 98.8 | 118–124 |

| BASAT 11546 (VI resin) | 4.5 | 1 h 80 °C+ 4 h 120 °C | 1200–1400 at 25 °C | 10–30 at 25 °C | 109.3 | 115–120 |

| CTD 7.1 Toughened Epoxy Resin (T resin) | 3.5 | 2 h 80 °C | 1500–5000 at 50 °C | 12 at 25 °C | 66.3 | 80 |

| Resin Type | Test Environment | σflex | εflex | Eflex | GIIc (kJ/m2) | Vf |

|---|---|---|---|---|---|---|

| (MPa) | (%) | (MPa) | ||||

| CC Resin | RT | 83.4 ± 8.8 | 8.4 ± 1.6 | 1012.2 ± 123.1 | 1.74 ± 0.17 | 0.5 |

| LN2 | 139.7 ± 32.7 | 3.8 ± 0.9 | 3643 ± 63.2 | 0.88 ± 0.05 | ||

| VI Resin | RT | 100.5 ± 3.7 | 13.2 ± 1.1 | 764.8 ± 61.1 | 0.97 ± 0.21 | 0.55 |

| LN2 | 146.1 ± 26.0 | 4.6 ± 0.8 | 3180.2 ± 89.6 | 0.94 ± 0.08 | ||

| T Resin | RT | 101.8 ± 6.8 | 4.7 ± 0.4 | 2243.0 ± 322.0 | 1.27 ± 0.09 | 0.45 |

| LN2 | 170.9 ± 28.2 | 2.7 ± 0.3 | 6331.7 ± 578.2 | 1.22 ± 0.12 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ufuk, R.; Bilge, K.; Kıral, B.E.; Ereke, M.; Karabeyoğlu, A. Fractographic Investigation of Cryogenic Temperature Mode-II Delamination Behavior of Filament Wound CFRP Laminates with Varied Resin Systems. J. Compos. Sci. 2023, 7, 450. https://doi.org/10.3390/jcs7110450

Ufuk R, Bilge K, Kıral BE, Ereke M, Karabeyoğlu A. Fractographic Investigation of Cryogenic Temperature Mode-II Delamination Behavior of Filament Wound CFRP Laminates with Varied Resin Systems. Journal of Composites Science. 2023; 7(11):450. https://doi.org/10.3390/jcs7110450

Chicago/Turabian StyleUfuk, Recep, Kaan Bilge, Barış Emre Kıral, Murat Ereke, and Arif Karabeyoğlu. 2023. "Fractographic Investigation of Cryogenic Temperature Mode-II Delamination Behavior of Filament Wound CFRP Laminates with Varied Resin Systems" Journal of Composites Science 7, no. 11: 450. https://doi.org/10.3390/jcs7110450

APA StyleUfuk, R., Bilge, K., Kıral, B. E., Ereke, M., & Karabeyoğlu, A. (2023). Fractographic Investigation of Cryogenic Temperature Mode-II Delamination Behavior of Filament Wound CFRP Laminates with Varied Resin Systems. Journal of Composites Science, 7(11), 450. https://doi.org/10.3390/jcs7110450