A Study to Investigate the Influence of Machining Parameters on Delamination in the Abrasive Waterjet Machining of Jute-Fiber-Reinforced Polymer Composites: An Integrated Taguchi and Response Surface Methodology (RSM) Optimization to Minimize Delamination

Abstract

:1. Introduction

2. Methods and Methodology

2.1. Material Preparation

2.2. Machining Process

2.3. Measurement of Delamination

3. Results and Analysis

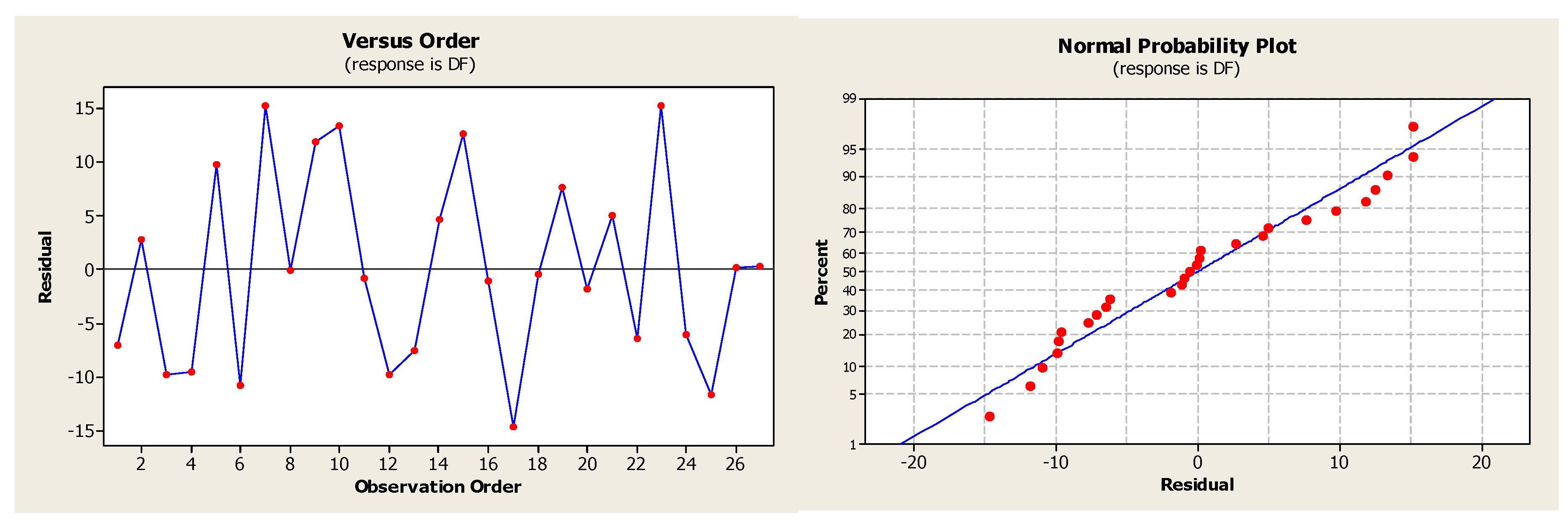

3.1. Regression Equation for the Delamination

3.2. Main Effect Plots for Data Means and Signal-to-Noise Ratio

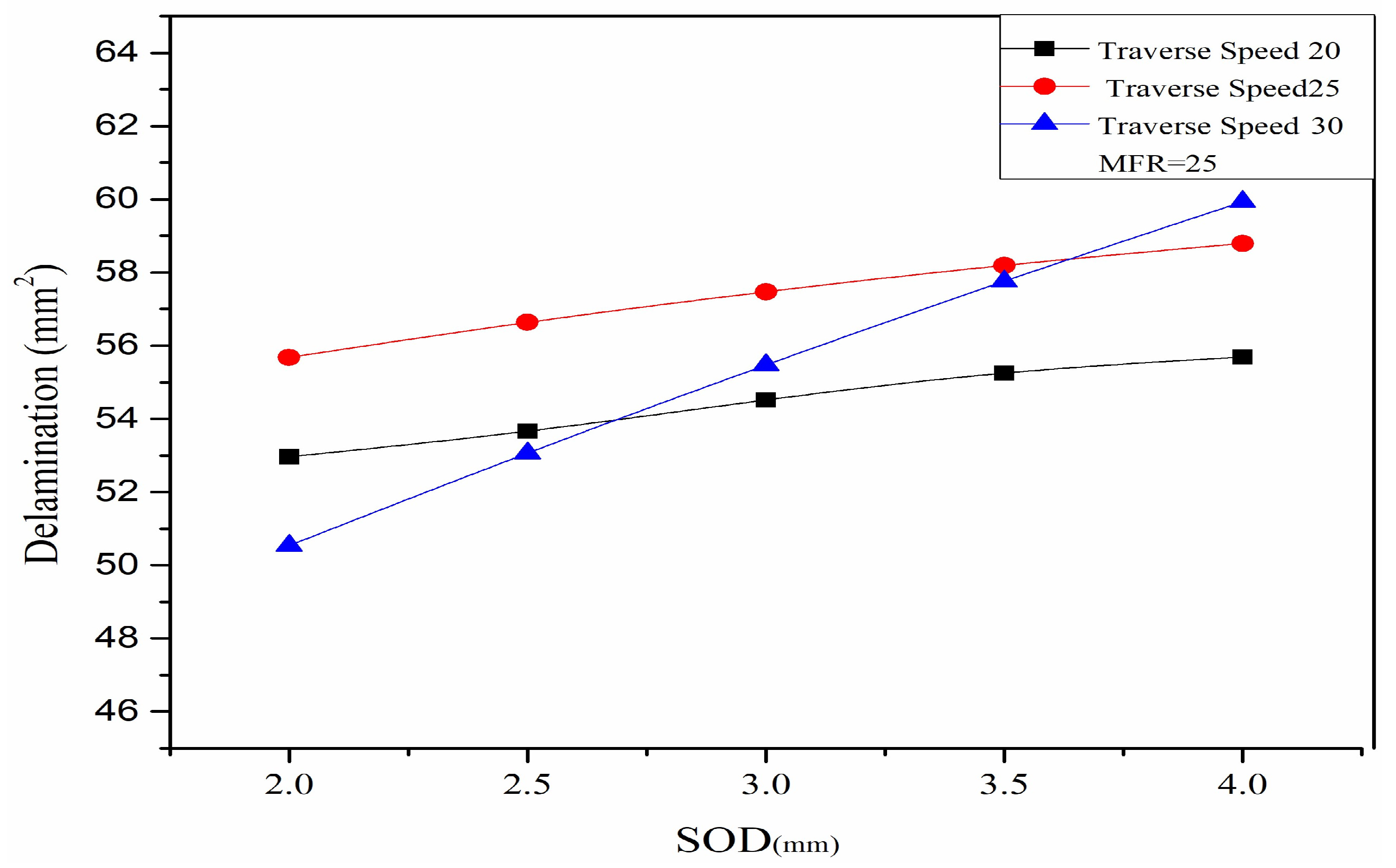

3.3. Interaction Plots for Data Means and Signal-to-Noise Ratio

3.4. Analysis of Variance and Response Tables

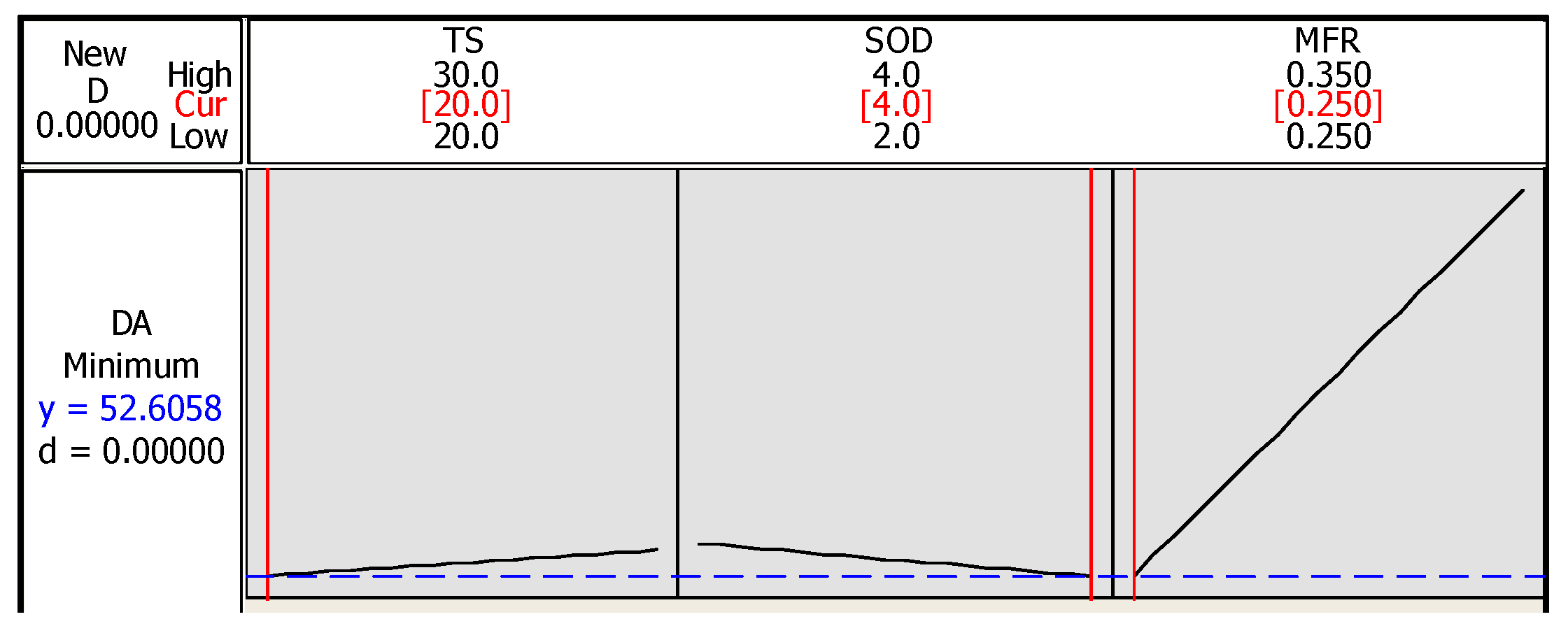

3.5. Optimization through Optimization Plot

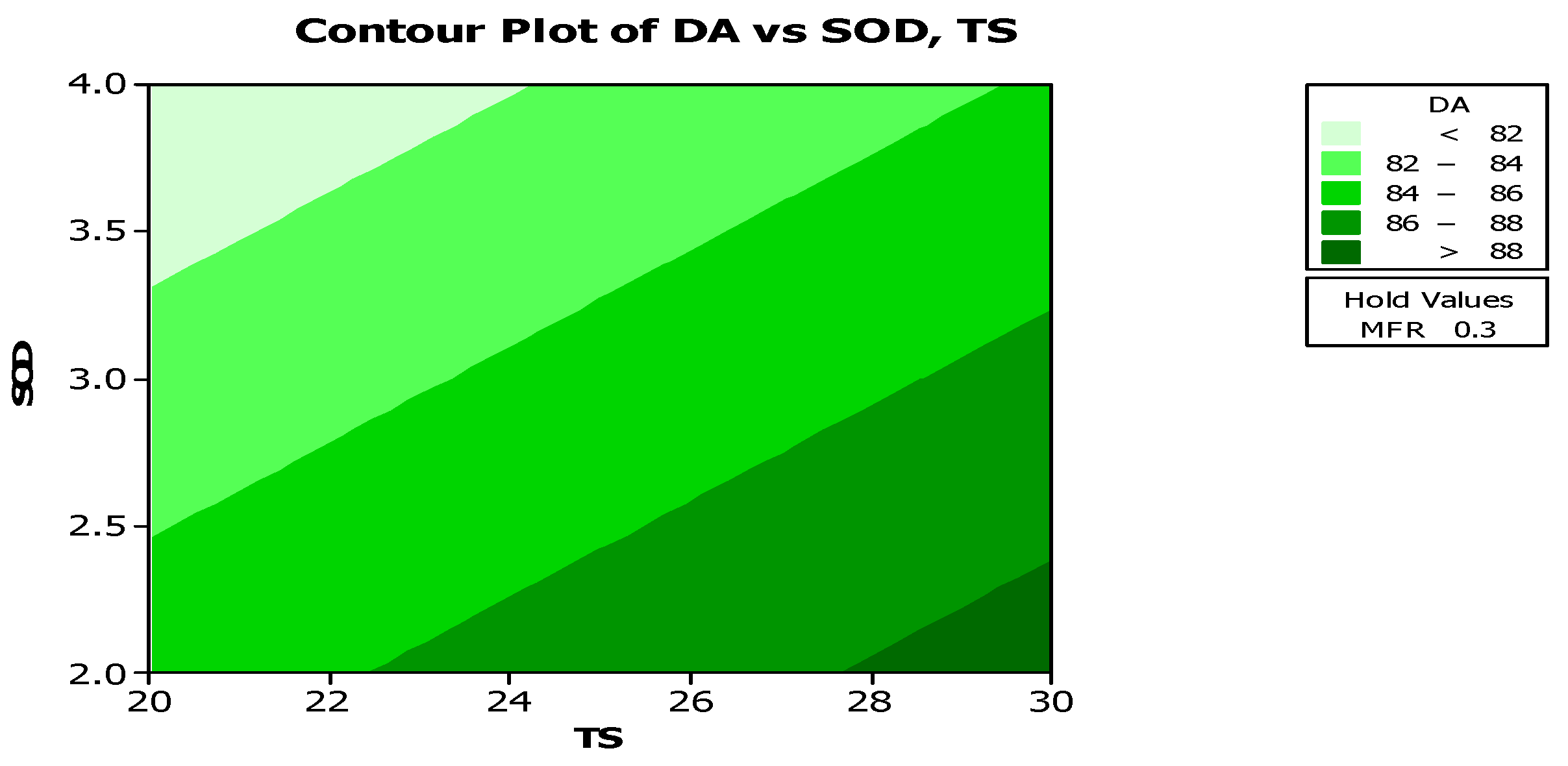

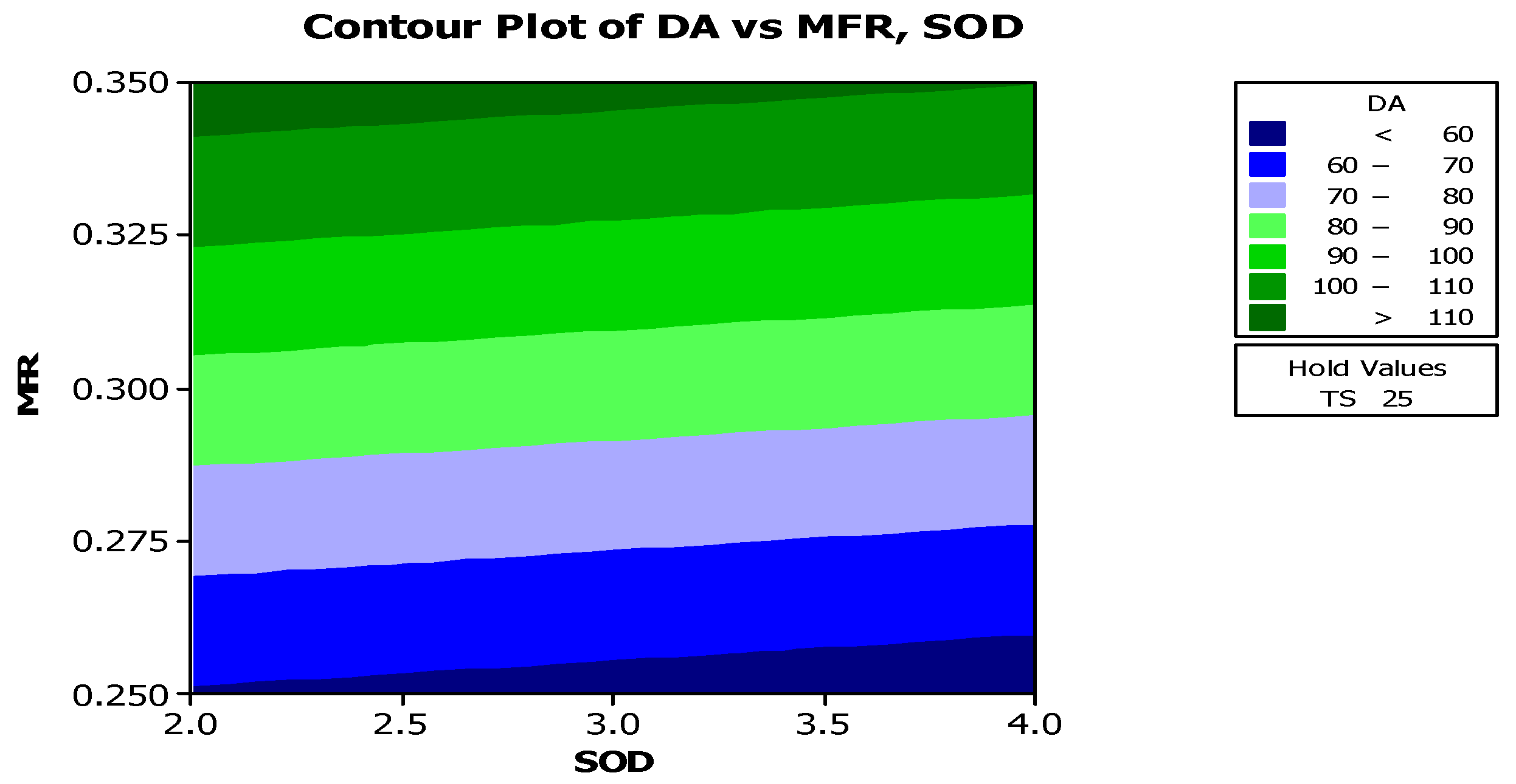

3.6. Optimization Using Contour Plots

3.7. Prediction of Intermediate Values of DA

3.8. Prediction of Fiber Orientation Influence on Delamination

4. Conclusions

- Traverse speed (TS) of 20 mm/min;

- Stand-off distance (SOD) of 4 mm;

- Abrasive mass flow rate (MFR) of 0.25 kg/min.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Perek, A.; Radomska-Zalas, A.; Fejdek-Beida-Frank Pude, A. Process optimization by applying the response surface methodology (rsm) to the abrasive suspension water jet cutting of phenolic composites. Facta Univ. Mech. Eng. 2022, 1, 1–16. [Google Scholar]

- Ramulu, M.; Arola, D. Water jet and abrasive water jet cutting of unidirectional graphite/epoxy composite. Composites 1993, 24, 299–308. [Google Scholar] [CrossRef]

- Ho-Cheng, H. A failure analysis of water jet drilling in composite laminates. Int. J. Mach. Tools Manuf. 1990, 30, 423–429. [Google Scholar] [CrossRef]

- Shanmugam, D.K.; Nguyen, T.; Wang, J. A study of delamination on graphite/epoxy composites in abrasive water jet machining. Compos. Part A Appl. Sci. Manuf. 2008, 39, 923–929. [Google Scholar] [CrossRef]

- Demiral, M.; Abbassi, F.; Saracyakupoglu, T.; Habibi, M. Damage analysis of a CFRP cross-ply laminate subjected to abrasive water jet cutting. Alex. Eng. J. 2022, 61, 7669–7684. [Google Scholar] [CrossRef]

- Schwartzentruber, J.; Papini, M.; Spelt, J.K. Characterizing and modeling delamination of carbon-fiber epoxy laminates during abrasive waterjet cutting. Compos. Part A Appl. Sci. Manuf. 2018, 112, 299–314. [Google Scholar] [CrossRef]

- Dhakal, H.N.; Ismail, S.O.; Ojo, S.O.; Paggi, M.; Smith, J.R. Abrasive water jet drilling of advanced sustainable bio-fibre-reinforced polymer/hybrid composites: A comprehensive analysis of machining-induced damage responses. Int. J. Adv. Manuf. Technol. 2018, 99, 2833–2847. [Google Scholar] [CrossRef]

- Azmir, M.A.; Ahsan, A.K.; Rahmah, A. Effect of abrasive water jet machining parameterson aramid fibre reinforced plastics composite. Int. J. Mater. Form. 2009, 2, 37–44. [Google Scholar] [CrossRef]

- Ibraheem, H.M.A.; Iqbal, A.; Hashemipour, M. Numerical optimization of the hole making in GFRP composites using abrasive water jet machining process. J. Chin. Inst. Eng. 2015, 38, 66–76. [Google Scholar] [CrossRef]

- Vigneshwaran, S.; Uthayakumar, M.; Arumugaprabu, V. Abrasive Water Jet Machining of Fiber-Reinforced Composite Materials. J. Reinf. Plast. Compos. 2018, 37, 230–237. [Google Scholar] [CrossRef]

- Xiao, S.; Wang, P.; Gao, H.; Soulat, D. A Study of Abrasive Waterjet Multi-Pass Cutting on Kerf Quality of Carbon Fiber-Reinforced Plastics. Int. J. Adv. Manuf. Technol. 2019, 105, 4527–4537. [Google Scholar] [CrossRef]

- Dhanawade, A.; Kumar, P.; Kumar, S. Experimental Study on Abrasive Water Jet Machining of Carbon Epoxy Composite. Adv. Mater. Process. Technol. 2020, 6, 40–53. [Google Scholar] [CrossRef]

- Kant, R.; Dhami, S.S. Investigating Process Parameters of Abrasive Water Jet Machine Using EN31. Mater. Manuf. Process. 2021, 36, 1597–1603. [Google Scholar] [CrossRef]

- Kechagias, J.; Petropoulos, G.; Vaxevanidis, N. Application of Taguchi Design for Quality Characterization of Abrasive Water Jet Machining of TRIP Sheet Steels. Int. J. Adv. Manuf. Technol. 2012, 62, 635–643. [Google Scholar] [CrossRef]

- Kale, A.; Singh, S.K.; Sateesh, N.; Subbiah, R. A Review on Abrasive Water Jet Machining Process and Its Process Parameters. Mater. Today 2020, 26, 1032–1036. [Google Scholar] [CrossRef]

- Wang, J. Abrasive Waterjet Machining of Polymer Matrix Composites—Cutting Performance, Erosive Process and Predictive Models. Int. J. Adv. Manuf. Technol. 1999, 15, 757–768. [Google Scholar] [CrossRef]

- Iyer, N.P.; Kumar, N.A. Investigation of Abrasive water jet machining parameters of Bismaleimide composites. Mater. Manuf. Process. 2022, 37, 1642–1651. [Google Scholar] [CrossRef]

- Jeykrishnan, J.; Ramnath, B.V.; Vignesh, S.S.; Sridharan, P.; Saravanan, B. Optimization of Process Parameters in Abrasive Water Jet Machining/Cutting (AWJM) of Nickel Alloy Using Traditional Analysis to Minimize Kerf Taper Angle. Mater. Today 2019, 16, 392–397. [Google Scholar] [CrossRef]

- Ravikumar, K.; Sreebalaji, V.S.; Pridhar, T. Characterization and optimization of Abrasive Water Jet Machining parameters of aluminum/tungsten carbide composites. Measurement 2018, 117, 57–66. [Google Scholar] [CrossRef]

- Manoj, M.; Jinu, G.R.; Muthuramalingam, T. Multi Response Optimization of AWJM Process Parameters on Machining TiB2 Particles Reinforced Al7075 Composite Using Taguchi-DEAR Methodology. Silicon 2018, 10, 2287–2293. [Google Scholar] [CrossRef]

- Shanmugam, D.K.; Wang, J.; Liu, H. Minimisation of kerf tapers in abrasive waterjet machining of alumina ceramics using a compensation technique. Int. J. Mach. Tools Manuf. 2008, 48, 1527–1534. [Google Scholar] [CrossRef]

- Lemma, E.; Chen, L.; Siores, E.; Wang, J. Optimising the AWJ cutting process of ductile materials using nozzle oscillation technique. Int. J. Mach. Tools Manuf. 2002, 42, 781–789. [Google Scholar] [CrossRef]

- Vaxevanidis, N.M.; Markopoulos, A.; Petropoulos, G. Artificial neural network modelling of surface quality characteristics in abrasive water jet machining of trip steel sheet. J. Intell. Manuf. 2008, 19, 283–292. [Google Scholar]

- Kalirasu, S.; Rajani, N.; Rajesh, S.; Gopikumar, S.; Arunkumar, K.; Mukesh Vaidya, C.M. Surface Quality of Jute Fibre Reinforced Epoxy Composite by Abrasive Waterjet Machining. Int. J. Recent Technol. Eng. 2019, 8, 196–199. [Google Scholar]

| Sl. No. | Traverse Speed (TS) mm/min | Standoff Distance (SOD) mm | Abrasive Mass Flow Rate (MFR) kg/min |

|---|---|---|---|

| 1 | 20 | 2 | 0.25 |

| 2 | 25 | 3 | 0.30 |

| 3 | 30 | 4 | 0.35 |

| Exp. No. | TS (mm/min) | SOD (mm) | MFR (Kg/min) | DA (mm2) |

|---|---|---|---|---|

| 1 | 20 | 2 | 25 | 50.120 |

| 2 | 25 | 2 | 25 | 61.880 |

| 3 | 30 | 2 | 25 | 51.253 |

| 4 | 20 | 3 | 25 | 43.990 |

| 5 | 25 | 3 | 25 | 65.158 |

| 6 | 30 | 3 | 25 | 46.458 |

| 7 | 20 | 4 | 25 | 65.001 |

| 8 | 25 | 4 | 25 | 51.661 |

| 9 | 30 | 4 | 25 | 65.440 |

| 10 | 20 | 2 | 30 | 99.859 |

| 11 | 25 | 2 | 30 | 87.468 |

| 12 | 30 | 2 | 30 | 80.480 |

| 13 | 20 | 3 | 30 | 75.090 |

| 14 | 25 | 3 | 30 | 89.232 |

| 15 | 30 | 3 | 30 | 99.104 |

| 16 | 20 | 4 | 30 | 77.860 |

| 17 | 25 | 4 | 30 | 66.252 |

| 18 | 30 | 4 | 30 | 82.327 |

| 19 | 20 | 2 | 35 | 123.260 |

| 20 | 25 | 2 | 35 | 115.664 |

| 21 | 30 | 2 | 35 | 124.496 |

| 22 | 20 | 3 | 35 | 105.450 |

| 23 | 25 | 3 | 35 | 129.006 |

| 24 | 30 | 3 | 35 | 109.627 |

| 25 | 20 | 4 | 35 | 96.446 |

| 26 | 25 | 4 | 35 | 110.236 |

| 27 | 30 | 4 | 35 | 112.225 |

| Predictor | Coef | SE Coef | T | P |

|---|---|---|---|---|

| Constant | −88.88 | 18.91 | −4.70 | 0.000 |

| Speed | 0.3815 | 0.4498 | 0.85 | 0.405 |

| SOD | −3.724 | 2.249 | −1.66 | 0.111 |

| MFR | 5.8383 | 0.4498 | 12.98 | 0.000 |

| Source | DA | Seq SS | Adj SS | Adj MS | F | P |

|---|---|---|---|---|---|---|

| TS | 1 | 65.5 | 65.5 | 65.5 | 0.72 | 0.405 |

| SOD | 1 | 249.6 | 249.6 | 249.6 | 2.74 | 0.111 |

| MFR | 1 | 15,338.7 | 15,338.7 | 15,338.7 | 168.49 | 0.000 |

| Error | 23 | 2093.9 | 2093.9 | 91.0 | ||

| Total | 26 | 17,747.7 |

| Level | TS | SOD | MFR |

|---|---|---|---|

| 1 | 81.90 | 88.28 | 55.66 |

| 2 | 86.28 | 84.79 | 84.19 |

| 3 | 85.71 | 80.83 | 114.05 |

| Delta | 4.39 | 7.45 | 58.38 |

| Rank | 3 | 2 | 1 |

| Run Order | TS mm/min | SOD mm | MFR kg/min | DA for 45° (mm2) | DA for 90° (mm2) |

|---|---|---|---|---|---|

| 1 | 20 | 2 | 0.30 | 75.090 | 127.660 |

| 2 | 25 | 4 | 0.35 | 110.236 | 154.010 |

| 3 | 25 | 2 | 0.35 | 115.664 | 115.833 |

| 4 | 25 | 4 | 0.30 | 66.252 | 138.520 |

| 5 | 25 | 3 | 0.30 | 89.232 | 73.957 |

| 6 | 30 | 3 | 0.30 | 99.104 | 72.660 |

| 7 | 25 | 4 | 0.25 | 51.661 | 88.220 |

| 8 | 25 | 3 | 0.35 | 129.006 | 140.560 |

| 9 | 25 | 2 | 0.30 | 61.880 | 72.060 |

| 10 | 20 | 3 | 0.25 | 43.990 | 56.192 |

| 11 | 25 | 3 | 0.25 | 65.158 | 46.709 |

| 12 | 20 | 2 | 0.25 | 50.120 | 66.737 |

| 13 | 20 | 3 | 0.30 | 99.859 | 125.678 |

| 14 | 30 | 3 | 0.35 | 109.627 | 93.921 |

| 15 | 30 | 2 | 0.30 | 80.480 | 121.293 |

| 16 | 20 | 3 | 0.35 | 105.450 | 122.060 |

| 17 | 30 | 3 | 0.25 | 46.458 | 68.470 |

| 18 | 30 | 4 | 0.25 | 65.440 | 51.032 |

| 19 | 20 | 4 | 0.25 | 65.001 | 66.596 |

| 20 | 20 | 2 | 0.35 | 123.260 | 103.322 |

| 21 | 20 | 4 | 0.30 | 77.860 | 97.725 |

| 22 | 25 | 2 | 0.25 | 87.468 | 84.074 |

| 23 | 30 | 4 | 0.35 | 112.225 | 123.928 |

| 24 | 30 | 4 | 0.30 | 82.327 | 112.040 |

| 25 | 30 | 2 | 0.25 | 51.253 | 56.395 |

| 26 | 30 | 2 | 0.35 | 124.496 | 77.843 |

| 27 | 20 | 4 | 0.35 | 96.446 | 105.950 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Murthy, B.R.N.; Rao U, S.; Naik, N.; Potti, S.R.; Nambiar S, S. A Study to Investigate the Influence of Machining Parameters on Delamination in the Abrasive Waterjet Machining of Jute-Fiber-Reinforced Polymer Composites: An Integrated Taguchi and Response Surface Methodology (RSM) Optimization to Minimize Delamination. J. Compos. Sci. 2023, 7, 475. https://doi.org/10.3390/jcs7110475

Murthy BRN, Rao U S, Naik N, Potti SR, Nambiar S S. A Study to Investigate the Influence of Machining Parameters on Delamination in the Abrasive Waterjet Machining of Jute-Fiber-Reinforced Polymer Composites: An Integrated Taguchi and Response Surface Methodology (RSM) Optimization to Minimize Delamination. Journal of Composites Science. 2023; 7(11):475. https://doi.org/10.3390/jcs7110475

Chicago/Turabian StyleMurthy, B. R. N., Sathish Rao U, Nithesh Naik, Srinivasa Rao Potti, and Sandeep Nambiar S. 2023. "A Study to Investigate the Influence of Machining Parameters on Delamination in the Abrasive Waterjet Machining of Jute-Fiber-Reinforced Polymer Composites: An Integrated Taguchi and Response Surface Methodology (RSM) Optimization to Minimize Delamination" Journal of Composites Science 7, no. 11: 475. https://doi.org/10.3390/jcs7110475

APA StyleMurthy, B. R. N., Rao U, S., Naik, N., Potti, S. R., & Nambiar S, S. (2023). A Study to Investigate the Influence of Machining Parameters on Delamination in the Abrasive Waterjet Machining of Jute-Fiber-Reinforced Polymer Composites: An Integrated Taguchi and Response Surface Methodology (RSM) Optimization to Minimize Delamination. Journal of Composites Science, 7(11), 475. https://doi.org/10.3390/jcs7110475