Ultrasonic Attenuation of Carbon-Fiber Reinforced Composites

Abstract

1. Introduction

2. Materials and Experimental Procedures

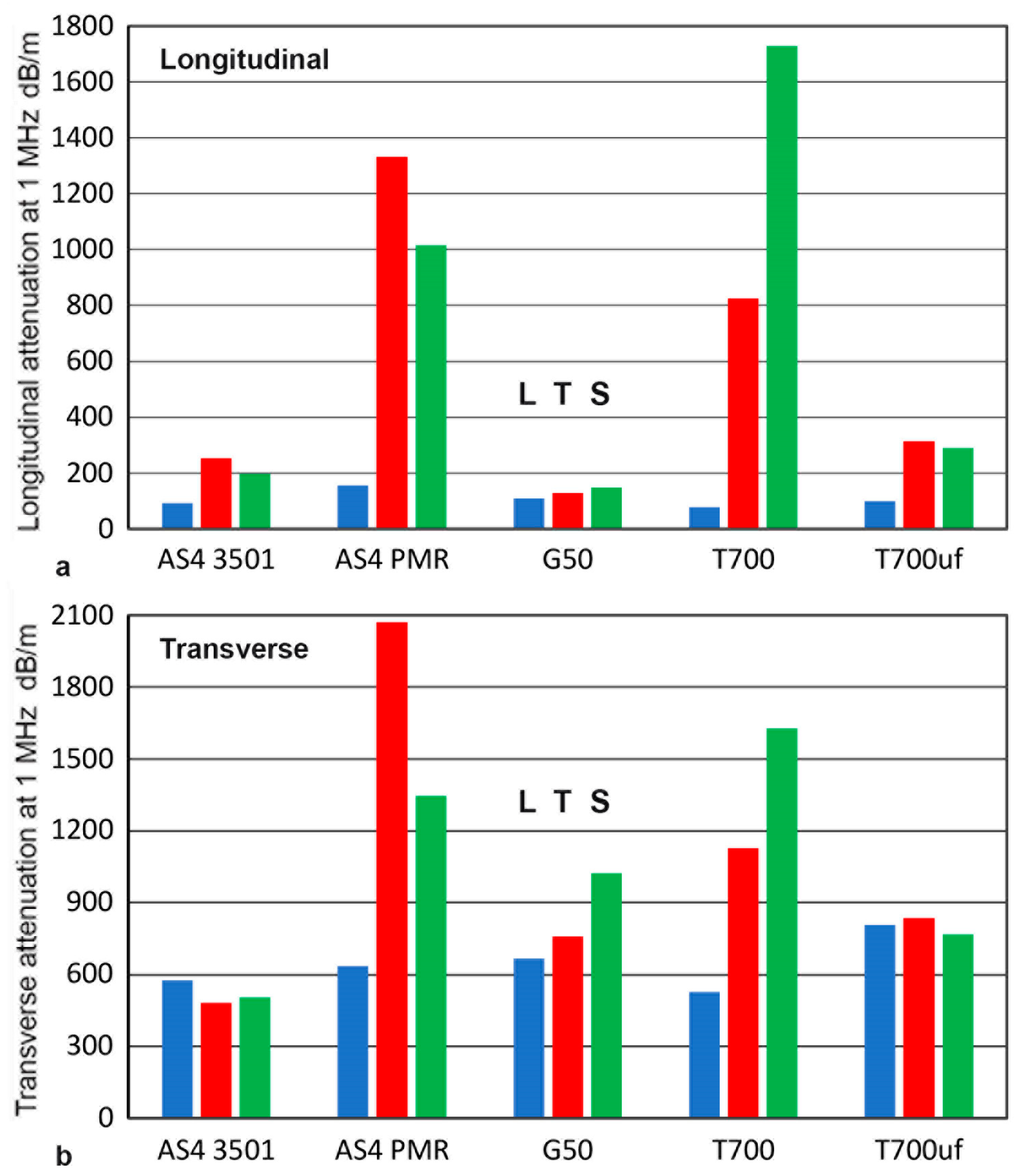

3. Results and Discussion

4. Conclusions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Test. | Material | Cd | C3 | v | η | Cdt | C3t | vt | ηt | Cdt/Cd | ηt/η | Thickness | Density | Notes |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No | dB/m /MHz | dB/m /MHz3 | mm/µs | dB/m /MHz | dB/m /MHz3 | mm/µs | mm | Mg/m3 | ||||||

| R15 | CFRP AS4 UD L | 91.0 | 9.32 | 3.11 × 10–2 | 531 | 2.15 | 4.18 × 10–2 | 5.84 | 1.35 | 36.6 | 1.53 | pol = ⊥F | ||

| R15a | CFRP AS4 UD L | 91.0 | 9.32 | 3.11 × 10–2 | 621 | 2.15 | 4.89 × 10–2 | 6.82 | 1.57 | 29.5 | 1.53 | pol = ⊥F | ||

| R16 | CFRP AS4 UD T | 247 | 4.937 | 3.16 | 2.86 × 10–2 | 451 | 2.09 | 3.45 × 10–2 | 1.83 | 1.21 | 24.3 | 1.53 | pol = //F | |

| R16a | CFRP AS4 UD T | 247 | 4.937 | 3.16 | 2.86 × 10–2 | 512 | 1.58 | 2.96 × 10–2 | 2.07 | 1.04 | 20.0 | 1.53 | pol = ⊥F | |

| R17 | CFRP AS4 UD S | 196 | 3.15 | 2.26 × 10–2 | 461 | 2.04 | 3.45 × 10–2 | 2.35 | 1.52 | 20.0 | 1.53 | pol = //F | ||

| R17a | CFRP AS4 UD S | 196 | 3.15 | 2.26 × 10–2 | 546 | 1.58 | 3.16 × 10–2 | 2.79 | 1.40 | 28.0 | 1.53 | pol = ⊥F | ||

| R37 | CFRP AS4 XP L | 301 | 8.24 | 9.09 × 10–2 | 571 | 2.16 | 4.52 × 10–2 | 1.90 | 0.50 | 28.0 | 1.53 | pol = //F | ||

| R37a | CFRP AS4 XP L | 301 | 8.24 | 9.09 × 10–2 | 482 | 1.82 | 3.21 × 10–2 | 1.60 | 0.35 | 17.4 | 1.53 | pol = ⊥F | ||

| R38 | CFRP AS4 XP S | 298 | 3.20 | 3.49 × 10–2 | 645 | 1.76 | 4.16 × 10–2 | 2.16 | 1.19 | 26.0 | 1.53 | pol = //F | ||

| R39 | CFRP AS4 QI L | 384 | 7.74 | 1.09 × 10–1 | 704 | 3.95 | 1.02 × 10–1 | 1.83 | 0.94 | 26.0 | 1.53 | pol = //F | ||

| R39a | CFRP AS4 QI L | 384 | 7.74 | 1.09 × 10–1 | 694 | 1.83 | 4.65 × 10–2 | 1.81 | 0.43 | 17.7 | 1.53 | pol = ⊥F | ||

| R40 | CFRP AS4 QI S | 306 | 3.18 | 3.57 × 10–2 | 922 | 1.77 | 5.98 × 10–2 | 3.01 | 1.68 | 24.3 | 1.53 | pol = //F | ||

| R18 | CFRP G50 UD L | 110 | 11.30 | 4.55 × 10–2 | 667 | 2.04 | 5.00 × 10–2 | 6.06 | 1.09 | 13.3 | 1.58 | pol = ⊥F | ||

| R21 | CFRP G50 UD T | 129 | 2.83 | 1.30 × 10–2 | 603 | 2.16 | 4.77 × 10–2 | 4.67 | 3.63 | 29.0/19.9 | 1.58 | pol = //F | ||

| R21a | CFRP G50 UD T | 129 | 2.83 | 1.30 × 10–2 | 366 | 550.0 | 1.36 | 1.82 × 10–2 | 2.84 | 1.40 | 29.0/19.9 | 1.58 | pol = ⊥F | |

| R22 | CFRP G50 UD S | 148 | 2.79 | 1.51 × 10–2 | 995 | 1.84 | 6.71 × 10–2 | 6.72 | 4.43 | 28.9 | 1.58 | pol = ⊥F | ||

| R22a | CFRP G50 UD S | 148 | 2.79 | 1.51 × 10–2 | 1050 | 1.30 | 5.00 × 10–2 | 7.10 | 3.31 | 28.9 | 1.58 | pol = ⊥F | ||

| R36 | CFRP G50 XP S | 213 | 2.68 | 2.09 × 10–2 | 709 | 1.62 | 4.20 × 10–2 | 3.33 | 2.01 | 4.7 | 1.58 | pol = //F | ||

| R23 | CFRP AS4 PMR UD L | 155 | 11.33 | 6.43 × 10–2 | 637 | 1.52 | 3.55 × 10–2 | 4.11 | 0.49 | 14.5 | 1.45 | pol = ⊥F | ||

| R24 | CFRP AS4 PMR UD T | 1052 | 279.0 | 2.17 | 8.36 × 10–2 | 1037 | 1.60 | 6.08 × 10–2 | 0.99 | 0.73 | 19.0 | 1.45 | pol = //F | |

| R24a | CFRP AS4 PMR UD T | 1052 | 279.0 | 2.17 | 8.36 × 10–2 | 790 | 2314 | 1.12 | 3.24 × 10–2 | 0.75 | 0.39 | 19.0 | 1.45 | pol = ⊥F |

| R25 | CFRP AS4 PMR UD S | 865 | 151.4 | 2.30 | 7.30 × 10–2 | 1308 | 1.74 | 8.34 × 10–2 | 1.51 | 1.14 | 18.5 | 1.45 | pol = //F | |

| R25a | CFRP AS4 PMR UD S | 865 | 151.4 | 2.30 | 7.30 × 10–2 | 911 | 473.1 | 1.11 | 3.71 × 10–2 | 1.05 | 0.51 | 18.5 | 1.45 | pol = ⊥F |

| R41 | CFRP AS4 PMR QI L | 1205 | 7.25 | 3.20 × 10–1 | 923 | 3.38 | 1.14 × 10–1 | 0.77 | 0.36 | 16.6 | 1.45 | pol = //F | ||

| R41a | CFRP AS4 PMR QI L | 1205 | 7.25 | 3.20 × 10–1 | 1033 | 1.62 | 6.13 × 10–2 | 0.86 | 0.19 | 16.6 | 1.45 | pol = ⊥F | ||

| R42 | CFRP AS4 PMR QI S | 384 | 2.93 | 4.12 × 10–2 | 516 | 1.66 | 3.14 × 10–2 | 1.34 | 0.76 | 14.9 | 1.45 | pol = //F | ||

| R43 | CFRP AS4 PPS QI L | 1267 | 7.97 | 3.70 × 10–2 | 635 | 1996 | 3.78 | 8.80 × 10–2 | 0.50 | 2.38 | 5.26 | 1.48 | pol = //F | |

| R43a | CFRP AS4 PPS QI L | 1267 | 7.97 | 3.70 × 10–2 | 1584 | 1.33 | 7.72 × 10–2 | 1.25 | 2.09 | 5.26 | 1.48 | pol = ⊥F | ||

| R44 | CFRP AS4 PPS QI L | 970 | 7.13 | 2.53 × 10–1 | 546 | 1536 | 3.24 | 6.48 × 10–2 | 0.56 | 0.26 | 29.3 | 1.48 | pol = //F | |

| R44a | CFRP AS4 PPS QI L | 970 | 7.13 | 2.53 × 10–1 | 1041 | 1.36 | 5.19 × 10–2 | 1.07 | 0.20 | 29.3 | 1.48 | pol = ⊥F | ||

| R45 | CFRP AS4 PPS QI S | 1758 | 2.32 | 1.49 × 10–1 | 692 | 1.27 | 3.22 × 10–2 | 0.39 | 0.22 | 2.6 | 1.48 | pol = //F | ||

| R46 | CFRP AS4 PPS QI S | 1935 | 2.33 | 1.65 × 10–1 | 645 | 1.27 | 3.00 × 10–2 | 0.33 | 0.18 | 15.5 | 1.48 | pol = ⊥F | ||

| R47 | CFRP XN50 QI L | 553 | 10.83 | 2.19 × 10–1 | 18.1 | 1.57 | ||||||||

| R48 | CFRP XN50 QI T | 508 | 9.08 | 1.69 × 10–1 | 1288 | 2.77 | 1.31 × 10–1 | 2.54 | 0.77 | 3.45 | 1.57 | pol = //F | ||

| R48a | CFRP XN50 QI T | 508 | 9.08 | 1.65 × 10–1 | 994 | 1.41 | 6.16 × 10–2 | 1.96 | 0.36 | 3.45 | 1.57 | pol = ⊥F | ||

| R49 | CFRP XN50 QI S | 383 | 2.63 | 3.70 × 10–2 | 1341 | 1.27 | 6.93 × 10–2 | 3.50 | 1.88 | 3.43 | 1.57 | pol = //F | ||

| R26 | CFRP T700 UD L | 76.6 | 9.19 | 2.57 × 10–2 | 527 | 1.95 | 3.77 × 10–2 | 6.88 | 1.47 | 23.8 | 1.48 | pol = ⊥F | ||

| R27 | CFRP T700 UD T | 825 | 2.91 | 8.80 × 10–2 | 661 | 1.92 | 4.65 × 10–2 | 0.80 | 0.53 | 18.9 | 1.48 | pol = //F | ||

| R27 | CFRP T700 UD T | 825 | 2.91 | 8.80 × 10–2 | 1596 | 1.38 | 8.07 × 10–2 | 1.95 | 0.92 | 18.9 | 1.48 | pol = ⊥F | ||

| R28 | CFRP T700 UD S | 1733 | 2.66 | 1.69 × 10–1 | 1400 | 1.89 | 9.70 × 10–2 | 0.81 | 0.54 | 15.5 | 1.48 | pol = //F | ||

| R28a | CFRP T700 UD S | 1733 | 2.66 | 1.69 × 10–1 | 1857 | 1.64 | 1.12 × 10–1 | 1.07 | 0.66 | 15.5 | 1.48 | pol = ⊥F | ||

| R50 | CFRP T700uf UD L | 99.5 | 9.50 | 3.46 × 10–2 | 807 | 1.99 | 5.88 × 10–2 | 8.11 | 1.70 | 13.4 | 1.55 | pol = //F | ||

| R51 | CFRP T700uf UD T | 315 | 3.04 | 3.51 × 10–2 | 701 | 1.97 | 5.11 × 10–2 | 2.23 | 1.46 | 12.4 | 1.55 | pol = //F | ||

| R51a | CFRP T700uf UD T | 315 | 3.04 | 3.51 × 10–2 | 968 | 1.50 | 5.28 × 10–2 | 3.07 | 1.51 | 12.4 | 1.55 | pol = ⊥F | ||

| R52 | CFRP T700uf UD S | 289 | 3.05 | 3.23 × 10–2 | 886 | 1.97 | 6.40 × 10–2 | 3.07 | 1.98 | 4.57 | 1.55 | pol = //F | ||

| R52a | CFRP T700uf UD S | 289 | 3.05 | 3.23 × 10–2 | 645 | 1.54 | 3.64 × 10–2 | 2.23 | 1.12 | 4.57 | 1.55 | pol = ⊥F | ||

| R53 | CFRP T300 XP S | 333 | 3.48 | 4.25 × 10–2 | 2040 | 2.00 | 1.50 × 10–1 | 6.13 | 3.53 | 7.7 | 1.51 | pol = //F | ||

| R1 | GRP rod L | 74.6 | 4.96 | 1.36 × 10–2 | 478 | 1.71 | 3.00 × 10–2 | 6.41 | 2.21 | 33.5 | 1.97 | pol = ⊥F | ||

| R4 | GRP rod S | 173 | 5.946 | 3.07 | 1.95 × 10–2 | 952 | 1.64 | 5.70 × 10–2 | 5.50 | 2.94 | 6.3 | 1.97 | pol = ⊥F | |

| R4a | GRP rod S | 173 | 5.946 | 3.07 | 1.95 × 10–2 | 944 | 1.76 | 6.10 × 10–2 | 5.46 | 3.13 | 6.3 | 1.97 | pol = //F | |

| R5 | GRP L | 121 | 5.06 | 2.24 × 10–2 | 650 | 1.80 | 4.30 × 10–2 | 5.37 | 1.91 | 7.0 | 2.07 | pol = //F | ||

| R13 | GRP XP L | 202 | 4.15 | 3.07 × 10–1 | 1740 | 1.99 | 1.27 × 10–1 | 8.61 | 0.41 | 7.0 | 1.81 | pol = //F | ||

| R14 | GRP XP S | 441 | 2.84 | 4.59 × 10–1 | 3030 | 1.65 | 1.83 × 10–1 | 6.87 | 3.99 | 2.2 | 1.81 | pol = //F | ||

| R34 | KFRP S | 1090 | 2.72 | 1.08 × 10–1 | 1630 | 1.32 | 7.90 × 10–2 | 1.50 | 0.73 | 9.2 | 1.34 | pol = //F | ||

| O1 | PMMA | 91.4 | 2.74 | 9.18 × 10–³ | 253 | 1.40 | 1.30 × 10–2 | 2.77 | 1.42 | 1.18 | ||||

| O9 | Epoxy1 | 274 | 2.75 | 2.76 × 10–2 | 1030 | 1.38 | 5.21 × 10–2 | 3.76 | 1.89 | 9.1 | 1.39 | |||

| O42 | Epoxy2 | 582 | 2.69 | 5.74 × 10–2 | 1750 | 1.24 | 7.95 × 10–2 | 3.01 | 1.39 | 2.9 | 1.22 |

References

- Kundu, T. (Ed.) Ultrasonic Nondestructive Evaluation, Engineering and Biological Material Characterization; CRC Press: Boca Raton, FL, USA, 2003; 848p. [Google Scholar]

- Giurgiutiu, V. Structural Health Monitoring of Aerospace Composites; Academic Press: New York, NY, USA, 2015; 470p. [Google Scholar]

- Rizzo, P.; Milazzo, A. (Eds.) European Workshop on Structural Health Monitoring; Special Collection of 2020 Papers—Volume 1; Springer Nature: Cham, Switzerland, 2021; 969p. [Google Scholar] [CrossRef]

- Howell, P.A. (Ed.) Nondestructive Evaluation (NDE) Methods and Capabilities Handbook; NASA/TM−2020-220568/Volume I; Langley Research Center: Hampton, VA, USA, 2020; 198p. [Google Scholar]

- Mehdikhani, M.; Gorbatikh, L.; Verpoest, I.; Lomov, S.V. Voids in fiber-reinforced polymer composites: A review on their formation, characteristics, and effects on mechanical performance. J. Compos. Mater. 2019, 53, 1579–1669. [Google Scholar] [CrossRef]

- Ashrith, H.S.; Jeevan, T.P.; Xu, J. A review on the fabrication and mechanical characterization of fibrous composites for engineering applications. J. Compos. Sci. 2023, 7, 252. [Google Scholar] [CrossRef]

- Philibert, M.; Yao, K.; Gresil, M.; Soutis, C. Lamb waves-based technologies for structural health monitoring of composite structures for aircraft applications. Eur. J. Mater. 2022, 2, 436–474. [Google Scholar] [CrossRef]

- Stone, D.E.; Clarke, B. Ultrasonic attenuation as a measure of void content in carbon-fibre reinforced plastics. Non-Destr. Test. 1975, 8, 137–145. [Google Scholar] [CrossRef]

- Martin, B.G. Ultrasonic wave propagation in fiber-reinforced solids containing voids. J. Appl. Phys. 1977, 48, 3368–3373. [Google Scholar] [CrossRef]

- Reynolds, W.N.; Wilkinson, S.J. The analysis of fibre-reinforced porous composite materials by the measurement of ultrasonic wave velocities. Ultrasonics 1978, 16, 159–163. [Google Scholar] [CrossRef]

- Williams, J.H., Jr.; Lee, S.S.; Nayeb-Hashemi, H. Ultrasonic wave propagation loss factor in composite in terms of constituent properties. J. Nondestruct. Eval. 1980, 1, 191–199. [Google Scholar] [CrossRef]

- Prosser, W.H. Ultrasonic Characterization of the Nonlinear Elastic Properties of Unidirectional Graphite/Epoxy Composites; NASA-CR-4100; National Aeronautics and Space Administration, Scientific and Technical Information Division: Washington, DC, USA, 1987; 184p. [Google Scholar]

- Jeong, H.; Hsu, D.K. Experimental analysis of porosity-induced ultrasonic attenuation and velocity change in carbon composites. Ultrasonics 1995, 33, 195–203. [Google Scholar] [CrossRef]

- Jeong, H. Effects of voids on the mechanical strength and ultrasonic attenuation of laminated composites. J. Compos. Mater. 1997, 31, 276–292. [Google Scholar] [CrossRef]

- Datta, S.K. Scattering of elastic waves by a distribution of inclusions. Arch. Mech. 1976, 28, 317. [Google Scholar]

- Datta, S.K. A Self-Consistent Approach to Multiple Scattering by Elastic Ellipsoidal Inclusions. J. Appl. Mech. 1977, 44, 657–662. [Google Scholar] [CrossRef]

- Kinra, V.; Petraitis, M.; Datta, S.K. Ultrasonic wave propagation in a random particulate composite. Int. J. Solids Struct. 1990, 16, 301–312. [Google Scholar] [CrossRef]

- Castaings, M.; Hosten, B. Air-coupled measurement of plane wave, ultrasonic plate transmission for characterising anisotropic, viscoelastic materials. Ultrasonics 2000, 38, 781–786. [Google Scholar] [CrossRef]

- Castaings, M.; Hosten, B.; Kundu, T. Inversion of ultrasonic, plane-wave transmission data in composite plates to infer viscoelastic material properties. NDT E Int. 2000, 33, 377–392. [Google Scholar] [CrossRef]

- Mouritz, A.P. Ultrasonic and interlaminar properties of highly porous composites. J. Compos. Mater. 2000, 34, 218–239. [Google Scholar] [CrossRef]

- Biwa, S. Independent scattering and wave attenuation in viscoelastic composites. Mech. Mater. 2001, 33, 635–647. [Google Scholar] [CrossRef]

- Biwa, S.; Watanabe, Y.; Ohno, N. Modelling of ultrasonic attenuation in unidirectional FRP. J. Soc. Mater. Sci. Jpn. 2001, 50, 62–68. [Google Scholar] [CrossRef][Green Version]

- Neau, G.; Lowe, M.J.S.; Deschamps, M. Propagation of Lamb waves in anisotropic and absorbing plates: Theoretical derivation and experiments. AIP Conf. Proc. 2002, 615, 1062–1069. [Google Scholar]

- Quintanilla, F.H.; Fan, Z.; Lowe, M.; Craster, R.V. Guided waves’ dispersion curves in anisotropic viscoelastic single- and multi-layered media. Proc. R. Soc. A Math. Phys. Eng. Sci. 2015, 471, 20150268. [Google Scholar] [CrossRef]

- Ishii, Y.; Biwa, S.; Kuraishi, A. Influence of porosity on ultrasonic wave velocity, attenuation and interlaminar interface echoes in composite laminates: Finite element simulations and measurements. Compos. Struct. 2016, 152, 645–653. [Google Scholar] [CrossRef]

- Cobbs, S.D.; Bond, G.G. Development of porosity standards for CYCOM 5320-1 Out-of-autoclave composite laminates. In Proceedings of the SAMPE 2012, Baltimore, MD, USA, 21–24 May 2012. 15p. [Google Scholar]

- Samaratunga, D.; Severino, J.V.; Kenderian, K. Ultrasonic evaluation of porosity in out-of-autoclave carbon fiber–reinforced polymer composite material. Mater. Eval. 2021, 79, 1169–1178. [Google Scholar] [CrossRef]

- Song, J.; Kim, S.; Kim, S.; Cho, Y.; Kim, Y.H. Lamb wave propagation on a unidirectional CFRP plate: Comparison of FEM simulations, experiments, and analytical calculations. J. Mech. Sci. Technol. 2021, 35, 3863–3869. [Google Scholar] [CrossRef]

- Ono, K. Review on structural health evaluation with acoustic emission. Appl. Sci. 2018, 8, 958. [Google Scholar] [CrossRef]

- Ono, K. A comprehensive report on ultrasonic attenuation of engineering materials, including metals, ceramics, polymers, fiber-reinforced composites, wood, and rocks. Appl. Sci. 2020, 10, 2230. [Google Scholar] [CrossRef]

- Ono, K. Dynamic viscosity and transverse ultrasonic attenuation of engineering materials. Appl. Sci. 2020, 10, 5265. [Google Scholar] [CrossRef]

- Ono, K. Ultrasonic attenuation of ceramic and inorganic materials using the through-transmission method. Appl. Sci. 2022, 12, 13026. [Google Scholar] [CrossRef]

- ASTM C1332-18; Standard Practice for Measurement of Ultrasonic Attenuation Coefficients of Advanced Ceramics by Pulse-Echo Contact Technique. ASTM International: West Conshohocken, PA, USA, 2018; 12p.

- Ono, K. Experimental determination of Lamb-wave attenuation coefficients. Appl. Sci. 2022, 12, 6735. [Google Scholar] [CrossRef]

- Lowe, M. Disperse|Research Groups|Imperial College London. Available online: https://www.imperial.ac.uk/non-destructive-evaluation/products-and-services/disperse/ (accessed on 27 January 2022).

- Lin, D.; Ni, R.; Adams, R. Prediction and measurement of the vibrational damping parameters of carbon and glass fibre-reinforced plastics plates. J. Compos. Mater. 1984, 18, 132–152. [Google Scholar] [CrossRef]

- Berthelot, J.-M.; Assarar, M.; Sefrani, Y.; El-Mahi, A. Damping analysis of composite materials and structures. Compos. Struct. 2008, 85, 189–204. [Google Scholar] [CrossRef]

- Treviso, A.; Van Genechten, B.; Mundo, D.; Tournour, M. Damping in composite materials: Properties and models. Compos. Part B 2015, 78, 144–152. [Google Scholar] [CrossRef]

- Murayama, T. Dynamic Mechanical Analysis of Polymeric Material; Elsevier: Amsterdam, The Netherlands, 1978; 231p. [Google Scholar]

- Menard, K.P. Dynamic Mechanical Analysis: A Practical Introduction; CRC Press: Boca Raton, FL, USA, 2008; 240p. [Google Scholar]

- Kishi, H.; Kuwata, M.; Matsuda, S.; Asami, T.; Murakami, A. Damping properties of thermoplastic-elastomer interleaved carbon fiber-reinforced epoxy composites. Compos. Sci. Technol. 2004, 64, 2517–2523. [Google Scholar] [CrossRef]

- Gao, Y.; Li, Y.; Hong, Y.; Zhang, H.; He, X. Modeling of the damping properties of unidirectional carbon fibre composites. Polym. Polym. Compos. 2011, 19, 119–122. [Google Scholar] [CrossRef]

- Stark, W.; Jaunich, M.; McHugh, J. Dynamic mechanical analysis (DMA) of epoxy carbon-fibre prepregs partially cured in a discontinued autoclave analogue process. Polym. Test. 2015, 41, 140–148. [Google Scholar] [CrossRef]

- Rueppel, M.; Rion, J.; Dransfeld, C.; Fischer, C.; Masania, K. Damping of carbon fibre and flax fibre angle-ply composite laminates. Compos. Sci. Technol. 2017, 146, 1–9. [Google Scholar] [CrossRef]

- Kern, L.S.; Hine, P.J.; Gusev, A.A. Optimizing the damping properties of unidirectional composites by incorporating carbon fibers with a thin viscoelastic coating. Compos. Struct. 2019, 208, 879–890. [Google Scholar] [CrossRef]

- Fairlie, G.; Njuguna, J. Damping properties of flax/carbon hybrid epoxy/fibre-reinforced composites for automotive semi-structural applications. Fibers 2020, 8, 64. [Google Scholar] [CrossRef]

- Gong, L.; Zhang, F.; Peng, X.; Scarpa, F.; Huang, Z.; Tao, G.; Liu, H.-Y.; Zhou, H.; Zhou, H. Improving the damping properties of carbon fiber reinforced polymer composites by interfacial sliding of oriented multilayer graphene oxide. Compos. Sci. Technol. 2022, 224, 109309. [Google Scholar] [CrossRef]

- Ono, K.; Cho, H.; Vallen, H.; M’Closkey, R.T. Transmission sensitivities of contact ultrasonic transducers and their applications. Sensors 2021, 21, 4396. [Google Scholar] [CrossRef]

- Lee, T.; Lakes, R.S.; Lal, A. Resonant ultrasound spectroscopy for measurement of mechanical damping: Comparison with broadband viscoelastic spectroscopy. Rev. Sci. Instrum. 2000, 71, 2855–2861. [Google Scholar] [CrossRef]

| Fiber | Ef GPa | Matrix | Lay-Ups | Fiber Volume | Size mm | Supplier |

|---|---|---|---|---|---|---|

| AS4 | 235 | 3501-6 epoxy | UD | 56.8% | 29.5 × 24.3 × 20.0 | NASA Langley |

| AS4 | 235 | 3501-6 epoxy | XP | 56.8% | 28.0 × 17.4 × 26.0 | NASA Langley |

| AS4 | 235 | 3501-6 epoxy | QI | 56.8% | 26.0 × 17.7 × 23.0 | NASA Langley |

| G50 | 360 | F584 epoxy | UD | 60.0% | 29.0 × 19.9 × 28.9 | Hexcel/UCLA |

| G50 | 360 | F584 epoxy | XP | 60.0% | 91 × 45 × 4.7 | Hexcel/UCLA |

| AS4 | 235 | PMR15 | UD | 58.4% | 14.5 × 19.0 × 18.5 | Rohr Industries |

| AS4 | 235 | PMR15 | QI | 58.4% | 16.6 × 16.6 × 14.9 | Rohr Industries |

| AS4 | 235 | PPS | QI | 63.6% | 29.3 × 22.0 × 15.5 | Rohr Industries |

| XN50 | 490 | C25 epoxy | QI | 56.0% | 18.1 × 19.4 × 14.0 | Nippon Oil |

| T700 | 230 | 2501 epoxy | UD | 48.2% | 23.7 × 18.8 × 15.6 | Toray/UCLA |

| T700 | 230 | UF3369 epoxy | UD | 59.7% | 13.2 × 12.2 × 13.5 | Toray/UCLA |

| T300 | 230 | epoxy | XP | 59.0% | 127 × 127 × 7.7 | Northrup |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ono, K. Ultrasonic Attenuation of Carbon-Fiber Reinforced Composites. J. Compos. Sci. 2023, 7, 479. https://doi.org/10.3390/jcs7110479

Ono K. Ultrasonic Attenuation of Carbon-Fiber Reinforced Composites. Journal of Composites Science. 2023; 7(11):479. https://doi.org/10.3390/jcs7110479

Chicago/Turabian StyleOno, Kanji. 2023. "Ultrasonic Attenuation of Carbon-Fiber Reinforced Composites" Journal of Composites Science 7, no. 11: 479. https://doi.org/10.3390/jcs7110479

APA StyleOno, K. (2023). Ultrasonic Attenuation of Carbon-Fiber Reinforced Composites. Journal of Composites Science, 7(11), 479. https://doi.org/10.3390/jcs7110479