Study on the Conventional Uniaxial Mechanical Properties and Micro-Mechanism of Sandstone under Dry–Wet Cycles

Abstract

:1. Introduction

1.1. Sample Processing

1.2. Test Procedure

1.3. Experimental Plan

2. Test Results and Analysis

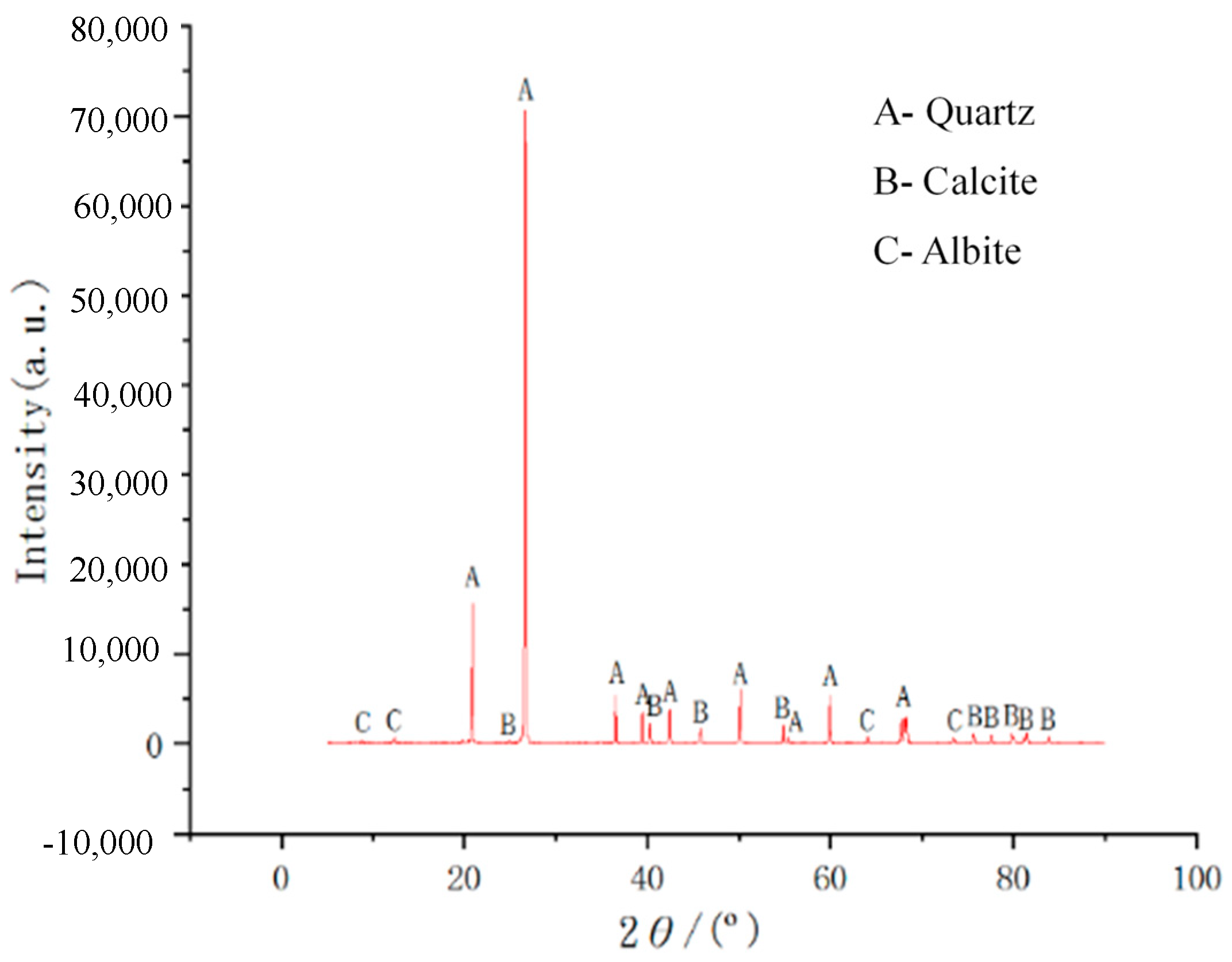

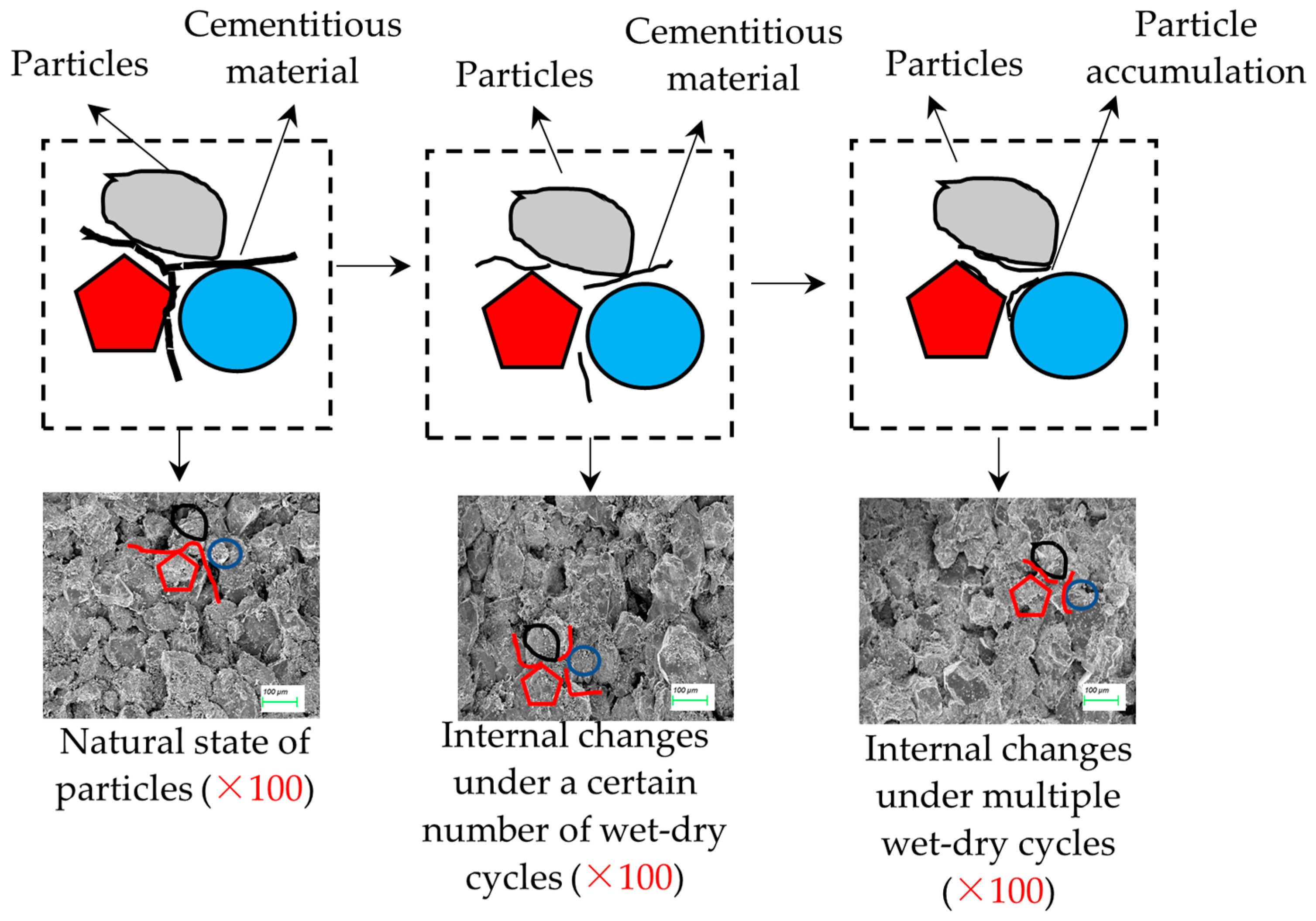

2.1. Analysis of Microcosmic Characteristics of Samples after Drying and Wetting Cycles

2.2. Change in the Physical Properties of the Sample

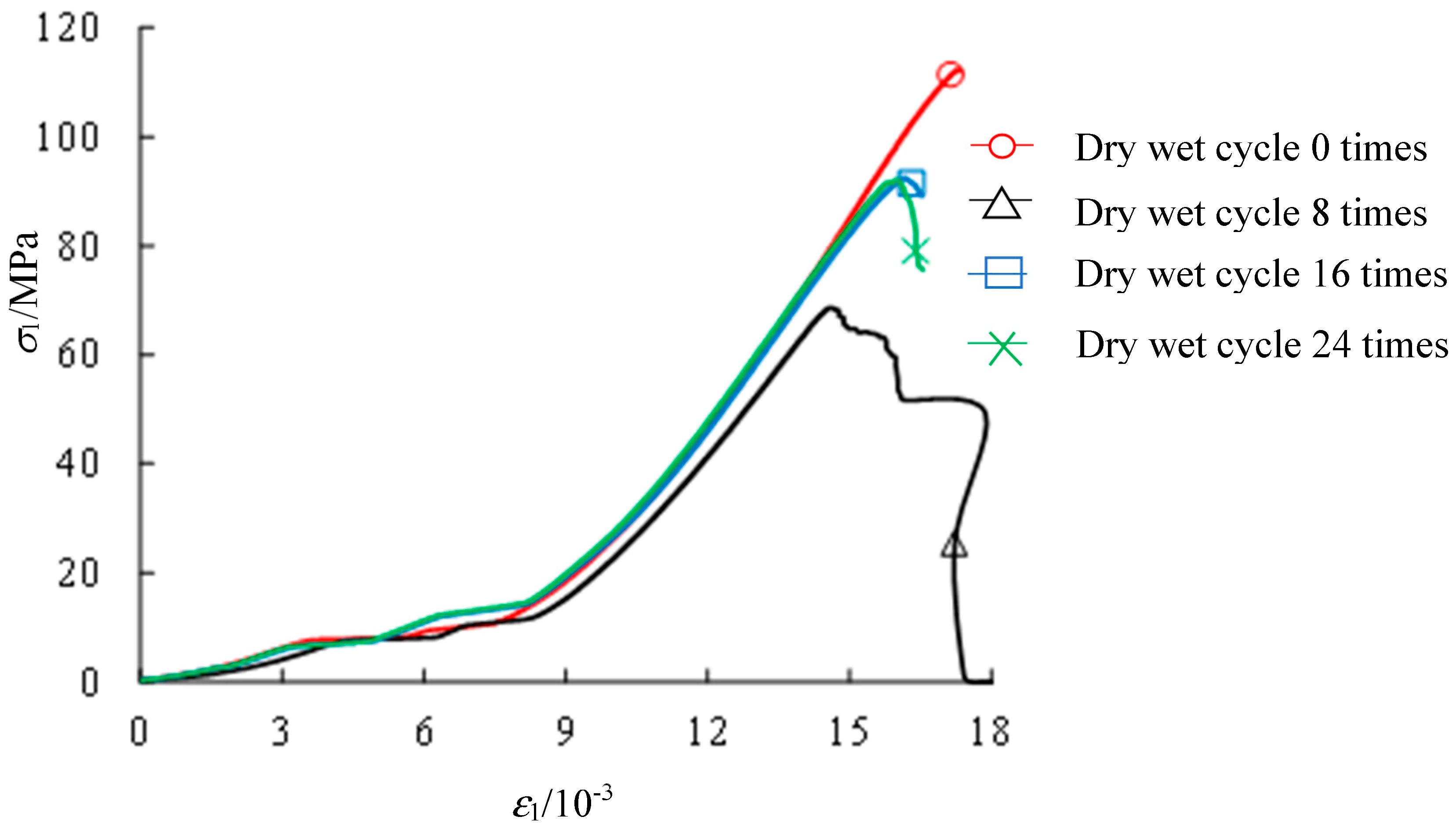

2.3. The Stress–Strain Curves of Samples with Different Wetting and Drying Cycles

2.4. Strength Characteristics

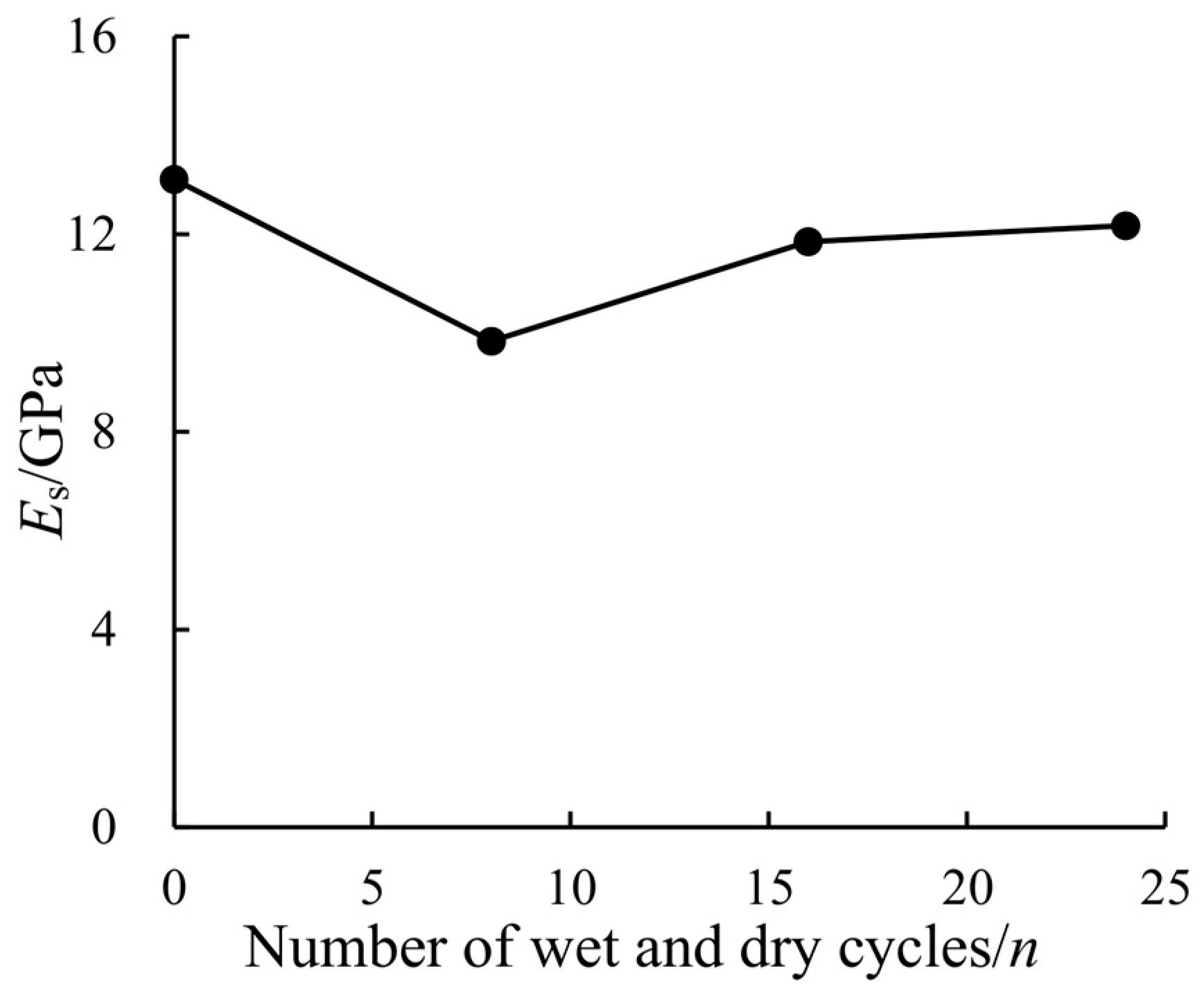

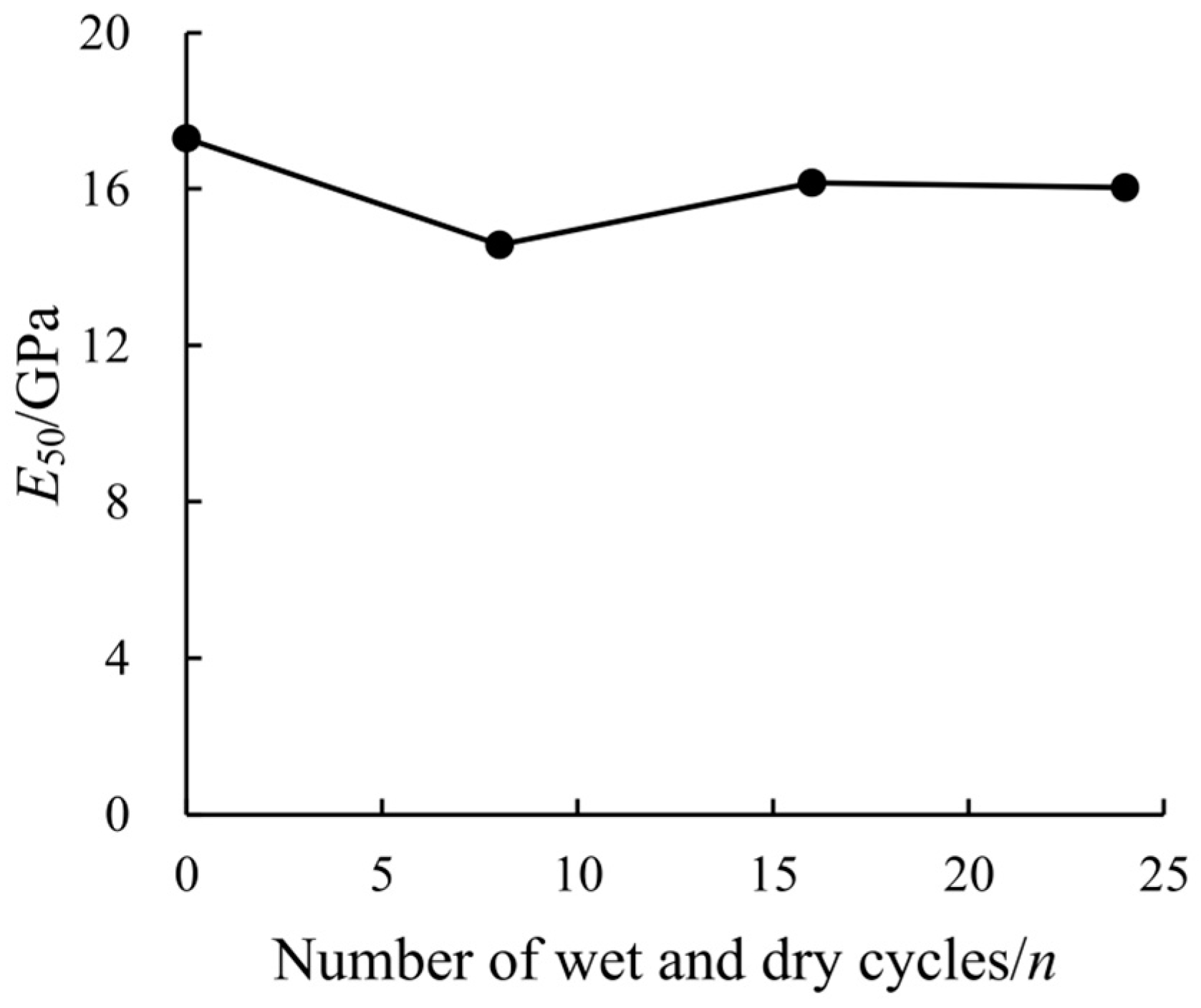

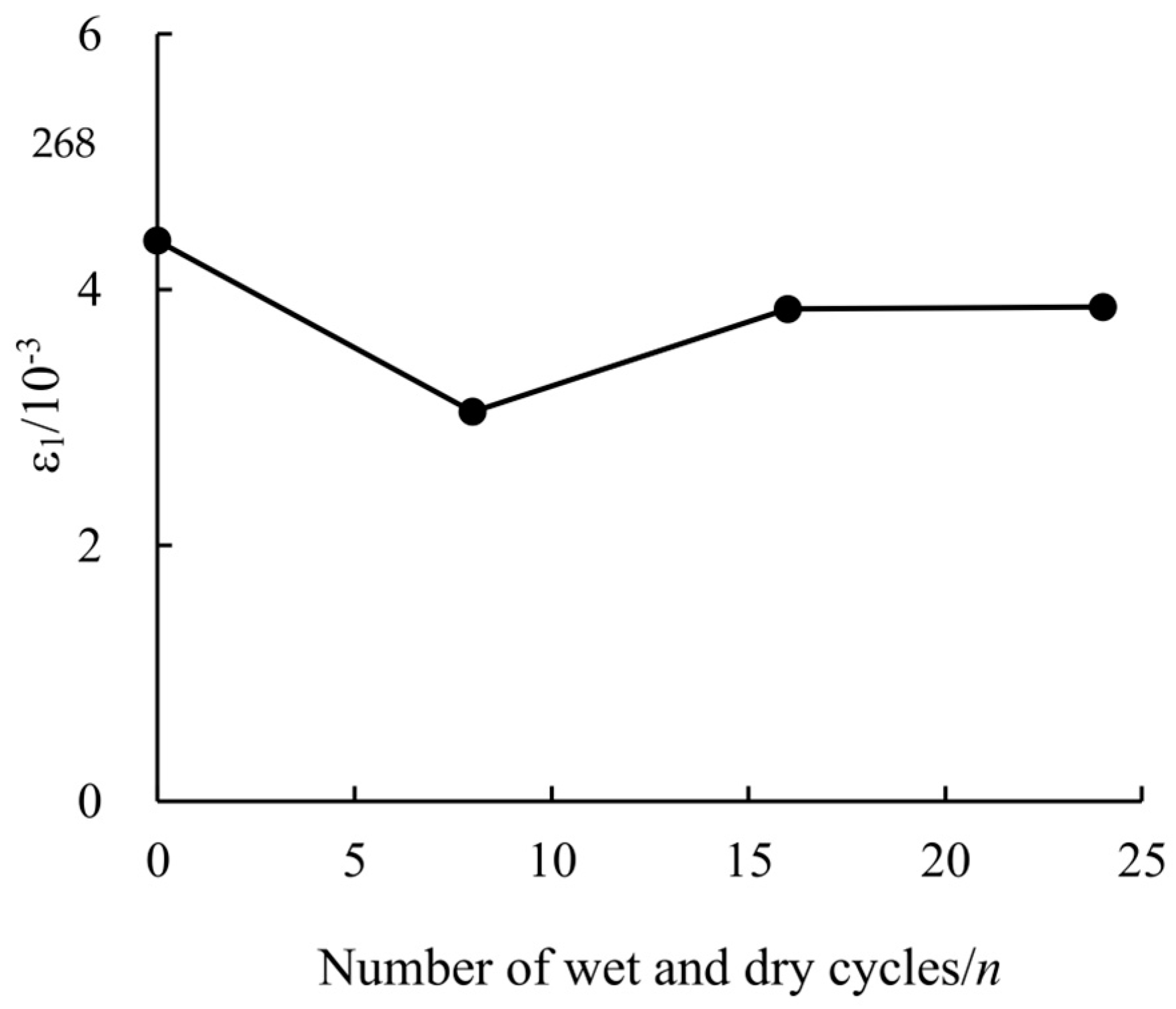

2.5. Deformation Feature

2.6. Analysis of the Failure Mode

3. Discussion

4. Conclusions and Suggestions

4.1. Conclusions

- (1)

- The intergranular connection of sandstone is a stratified structure, and the intergranular connection between the underlayer structures gradually becomes loose under the action of drying and wetting circulation. When the circulation reaches a certain extent, certain particle deposition occurs between the stratified structures inside the sample. After the drying and wetting cycle, the drying quality of the sample gradually decreases, and the water absorption quality gradually increases. The internal components of sandstone appear to dissolve under the action of water, and certain pores are formed inside.

- (2)

- The stress–strain curves of the samples show four stages. The peak strength decreases first and then increases with the number of cycles. The change in the elastic modulus and deformation modulus is similar to the change in the peak strength with the number of cycles. This is related to the peak strain variation in the connection between the layered structures in the sandstone, and the drying and wetting cycle does not increase the ductility of the rock.

- (3)

- The samples with different numbers of drying and wetting cycles exhibit typical axial tensile failure under uniaxial action. The tensile cracks on the surface of the samples show an increasing trend with increasing drying and wetting cycles. The sandstone surface exhibits block spalling when the number of drying and wetting cycles is less (8 times).

4.2. Suggestions

- (1)

- This article only considers the mechanical characteristics under uniaxial loading, while rocks in nature are often in a certain confining pressure environment. Therefore, experiments on rock mechanical properties under different confining pressures and dry–wet cycling can be conducted to obtain more reliable patterns.

- (2)

- The liquid used for dry–wet cycling in this study is water, while the water encountered in actual engineering often contains acidity and alkalinity. Therefore, further research and improvement are needed to obtain research parameters that are more in line with actual conditions.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, B.Y.; Zhang, J.H.; Sun, G.L. Deformation and Shear Strength of Rockfill Materials Composed of Soft Siltstones Subjected to Stress, Cyclical Drying/Wetting and Temperature Variations. Eng. Geol. 2015, 190, 87–97. [Google Scholar] [CrossRef]

- Huang, X.; Pang, J.; Zou, J. Study on the Effect of Dry–Wet Cycles on Dynamic Mechanical Properties of Sandstone Under Sulfuric Acid Solution. Rock Mech. Rock Eng. 2022, 55, 1253–1269. [Google Scholar] [CrossRef]

- Huang, X.; Pang, J. Study on the Change of Physical Properties of Sandstone under Action of Acidic Drying-Wetting Cycles and Discrete Element Simulation. Bull. Eng. Geol. Environ. 2021, 80, 7773–7790. [Google Scholar] [CrossRef]

- Yang, J.; Mu, Z.; Yang, S.Q.; Tian, W.L. Experimental investigation of microscopic crack development and damage characteristics of sandstone based on acoustic emission characteristic parameters. Geomech. Geophys. Geo-Energ. Geo-Resour. 2022, 8, 51. [Google Scholar] [CrossRef]

- Qiao, L.; Wan, Z.; Huang, A. Alteration of Mesoscopic Properties and Mechanical Behavior of Sandstone Due to Hydro-Physical and Hydro-Chemical Effects. Rock Mech. Rock Eng. 2016, 50, 255–267. [Google Scholar] [CrossRef]

- Yao, H.; Zhang, Z.; Li, D. Experimental Study on the Permeability Characteristics of Sandstone in Different Chemical Solutions. Ksce J. Civ. Eng. 2018, 22, 3271–3277. [Google Scholar] [CrossRef]

- Yao, H.; Ma, D.; Xiong, J. Study on the Influence of Different Aqueous Solutions on the Mechanical Properties and Microstructure of Limestone. J. Test. Eval. A Multidiscip. Forum Appl. Sci. Eng. 2021, 49, 3776–3794. [Google Scholar] [CrossRef]

- Li, X.; Peng, K.; Peng, J.; Hou, D. Experimental Investigation of Cyclic Wetting-Drying Effect on Mechanical Behavior of a Medium-Grained Sandstone. Eng. Geol. 2021, 293, 106335. [Google Scholar] [CrossRef]

- Liu, X.; Li, Y.; Wang, W. Study on Mechanical Properties and Energy Characteristics of Carbonaceous Shale with Different Fissure Angles under Dry–Wet Cycles. Bull. Eng. Geol. Environ. 2022, 81, 319. [Google Scholar] [CrossRef]

- Huang, Z.; Zhang, H.; Feng, X.; Zhang, J. Damage and Constitutive Study of Siltstone under Dry-Wet Cycle and Confining Pressure. Huazhong Keji Daxue Xuebao Ziran Kexue Ban J. Huazhong Univ. Sci. Technol. Nat. Sci. Ed. 2022, 50, 122–128. [Google Scholar] [CrossRef]

- Che, Y.; Song, Y.; Yang, H.; Chen, J.; Meng, C.; Zhang, J. Damage Behaviour of Sandstone Induced by Combination of Dry–Wet Cycles and Acidic Environment. Environ. Earth Sci. 2023, 82, 19. [Google Scholar] [CrossRef]

- Ma, D.; Yao, H.; Xiong, J.; Zhu, D.; Lu, J. Experimental Study on the Deterioration Mechanism of Sandstone under the Condition of Wet-Dry Cycles. KSCE J. Civ. Eng. 2022, 26, 2685–2694. [Google Scholar] [CrossRef]

- Gautam, T.P.; Shakoor, A. Slaking Behavior of Clay-Bearing Rocks during a One-Year Exposure to Natural Climatic Conditions. Eng. Geol. 2013, 166, 17–25. [Google Scholar] [CrossRef]

- Ramandi, H.L.; Mostaghimi, P.; Armstrong, R.T.; Saadatfar, M.; Pinczewski, W.V. Porosity and Permeability Characterization of Coal: A Micro-Computed Tomography Study. Int. J. Coal Geol. 2016, 154–155, 57–68. [Google Scholar] [CrossRef]

- Yang, X.; Wang, J.; Zhu, C.; He, M.; Gao, Y. Effect of Wetting and Drying Cycles on Microstructure of Rock Based on SEM. Environ. Earth Sci. 2019, 78, 183. [Google Scholar] [CrossRef]

- Zhou, Z.; Cai, X.; Chen, L.; Cao, W.; Zhao, Y.; Xiong, C. Influence of Cyclic Wetting and Drying on Physical and Dynamic Compressive Properties of Sandstone. Eng. Geol. 2017, 220, 1–12. [Google Scholar] [CrossRef]

- Ma, Q.; Yu, P.; Yuan, P. Experimental Study on Creep Properties of Deep Siltstone under Cyclic Wetting and Drying. Chin. J. Rock Mech. Eng. 2018, 37, 8. [Google Scholar] [CrossRef]

- Du, B.; Bai, H.; Ma, Z.; Li, M.; Wu, G. Experimental Study on the Dynamic Tensile Properties of Red-Sandstone after Cyclic Wetting and Drying. Chin. J. Rock Mech. Eng. 2018, 37, 9. [Google Scholar] [CrossRef]

| Sample Number | Number of Drying and Wetting Cycles/n | Loading Method | Loading Rate |

|---|---|---|---|

| 1-1 | 1 | stress control | 1 KN/s |

| 2-1 | 8 | ||

| 3-1 | 16 | ||

| 4-1 | 24 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Peng, S.; Yang, Y. Study on the Conventional Uniaxial Mechanical Properties and Micro-Mechanism of Sandstone under Dry–Wet Cycles. J. Compos. Sci. 2023, 7, 494. https://doi.org/10.3390/jcs7120494

Zhang J, Peng S, Yang Y. Study on the Conventional Uniaxial Mechanical Properties and Micro-Mechanism of Sandstone under Dry–Wet Cycles. Journal of Composites Science. 2023; 7(12):494. https://doi.org/10.3390/jcs7120494

Chicago/Turabian StyleZhang, Jinsong, Shilong Peng, and Yudi Yang. 2023. "Study on the Conventional Uniaxial Mechanical Properties and Micro-Mechanism of Sandstone under Dry–Wet Cycles" Journal of Composites Science 7, no. 12: 494. https://doi.org/10.3390/jcs7120494

APA StyleZhang, J., Peng, S., & Yang, Y. (2023). Study on the Conventional Uniaxial Mechanical Properties and Micro-Mechanism of Sandstone under Dry–Wet Cycles. Journal of Composites Science, 7(12), 494. https://doi.org/10.3390/jcs7120494