Mechanical Properties of Post-Cured Eggshell-Filled Glass-Fibre-Reinforced Polymer Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material Selection

2.2. Processing of Filler Material

2.2.1. Processing for Uncarbonised Eggshell Filler

2.2.2. Processing for Carbonised Eggshell Filler

2.3. Fabrication of Composites

2.4. Post-Curing of Composites

2.5. Tensile Test

2.6. Flexural Test

2.7. Microscopic Analysis

3. Results and Discussion

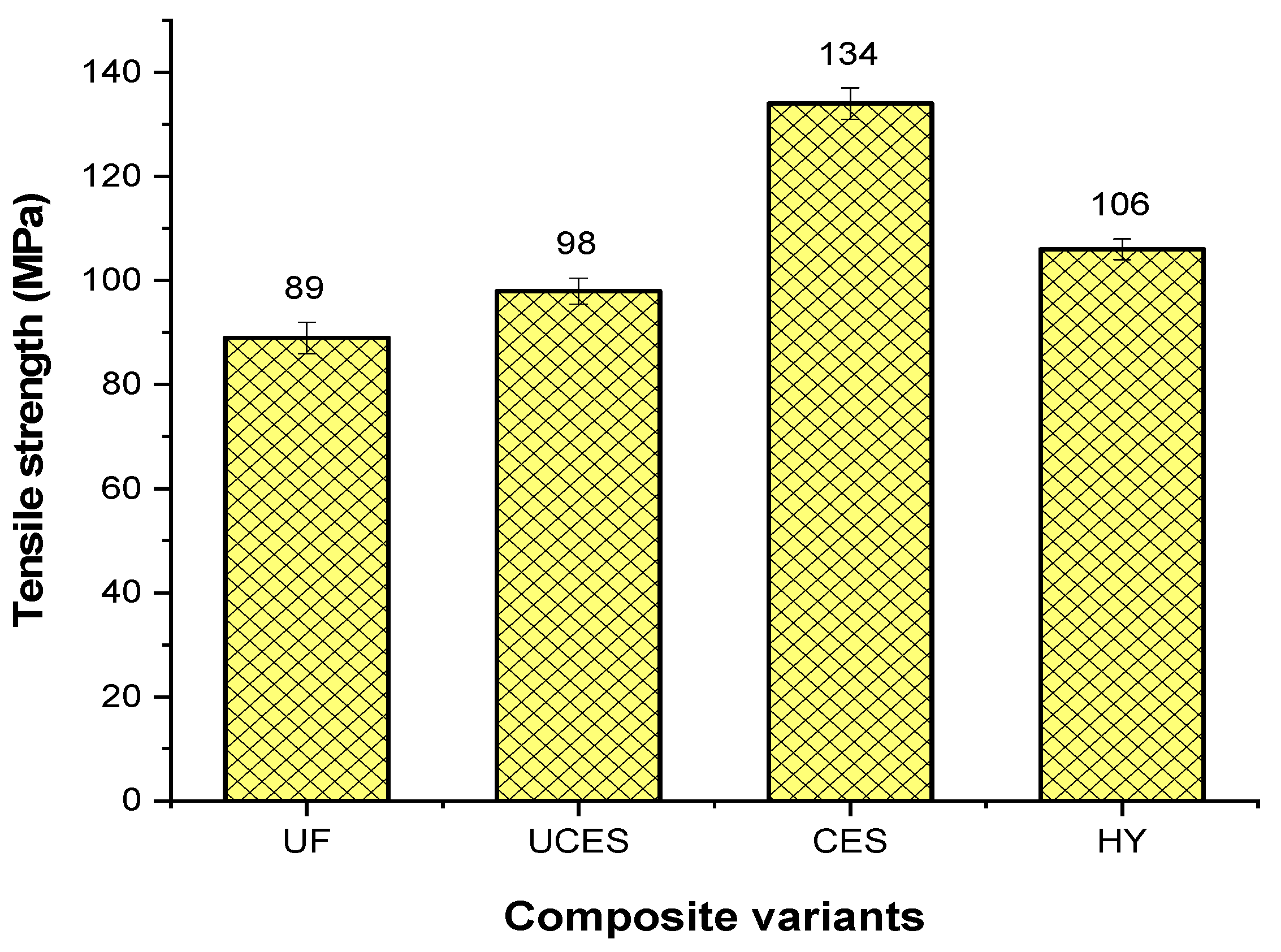

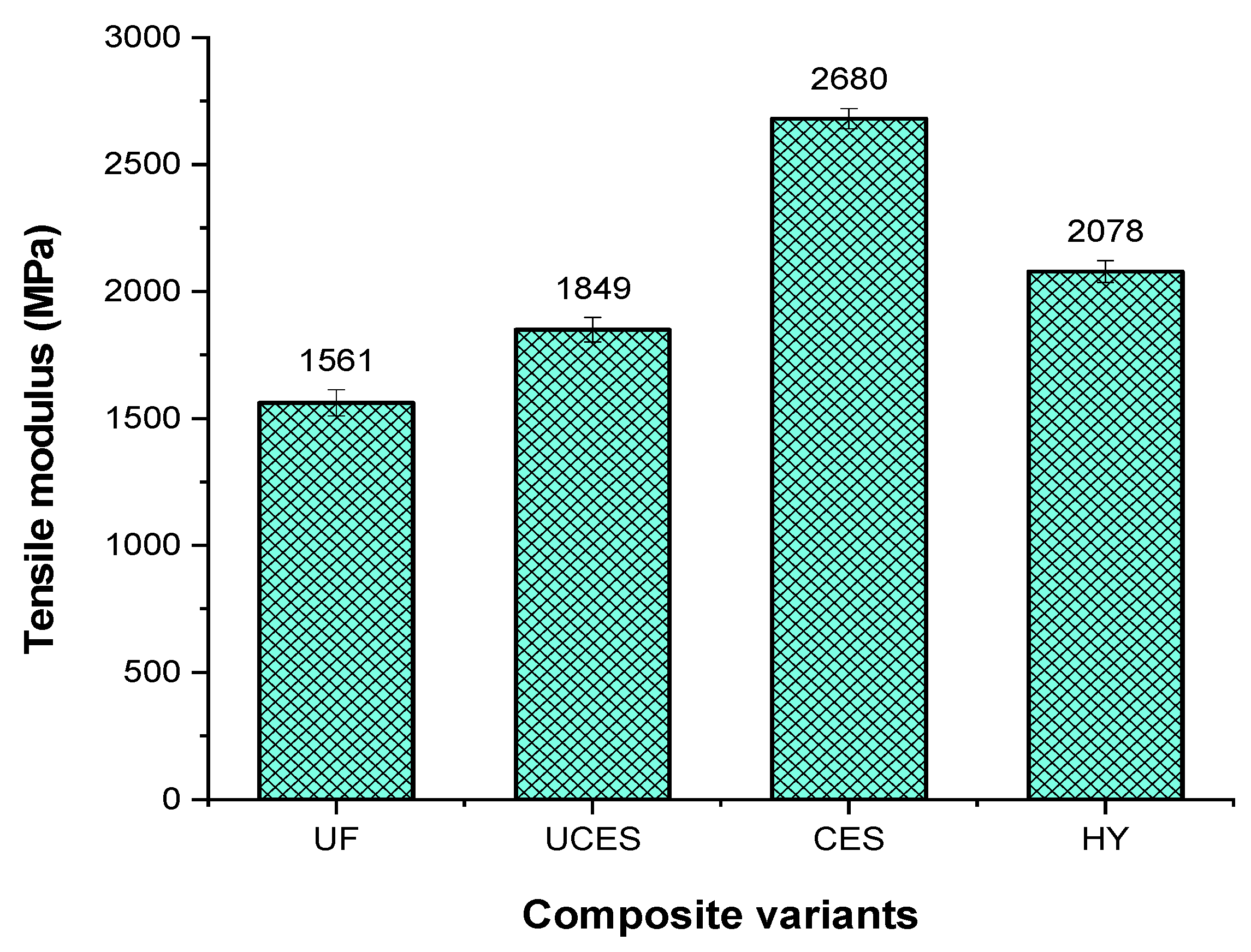

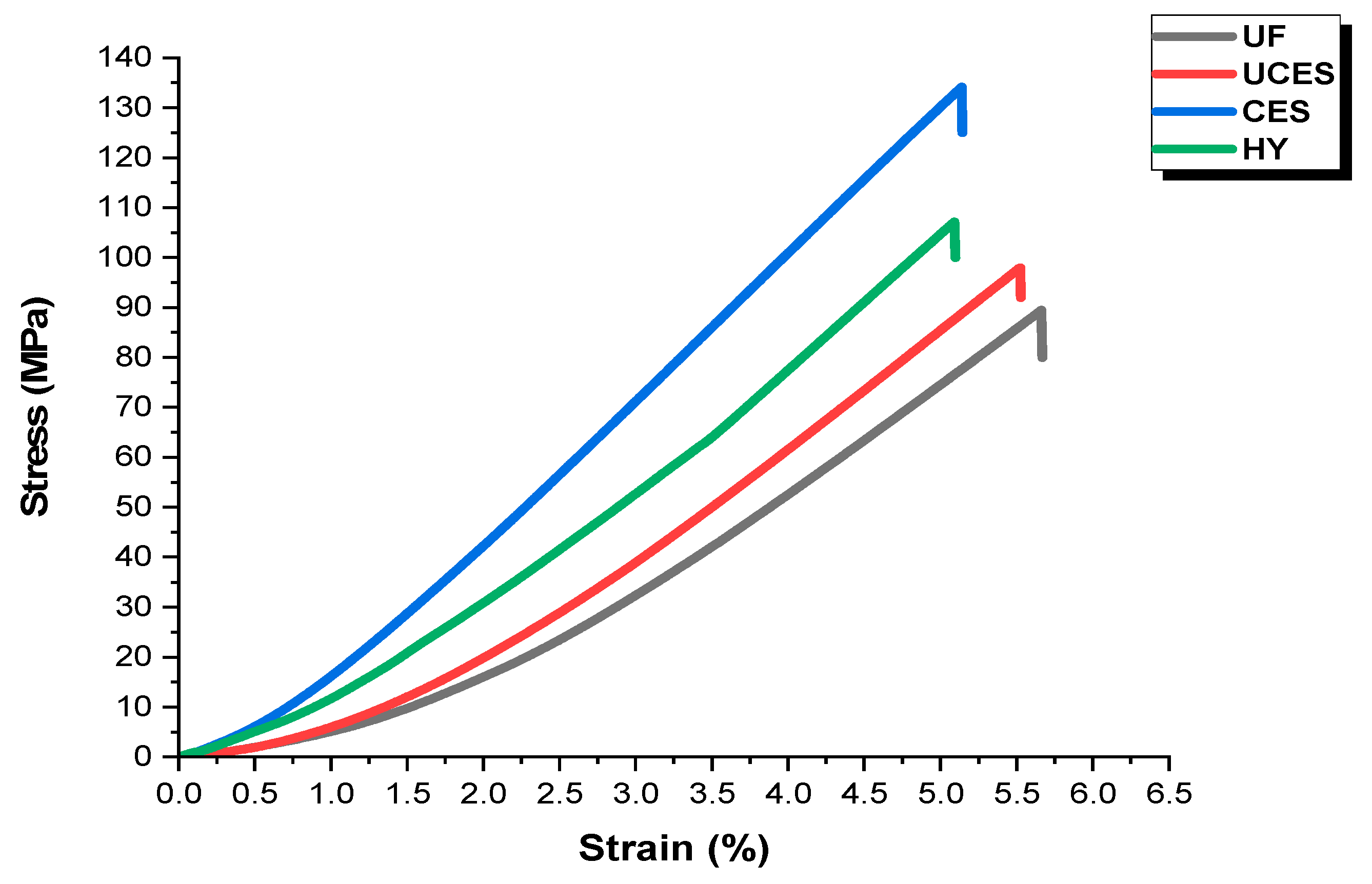

3.1. Tensile Test Results

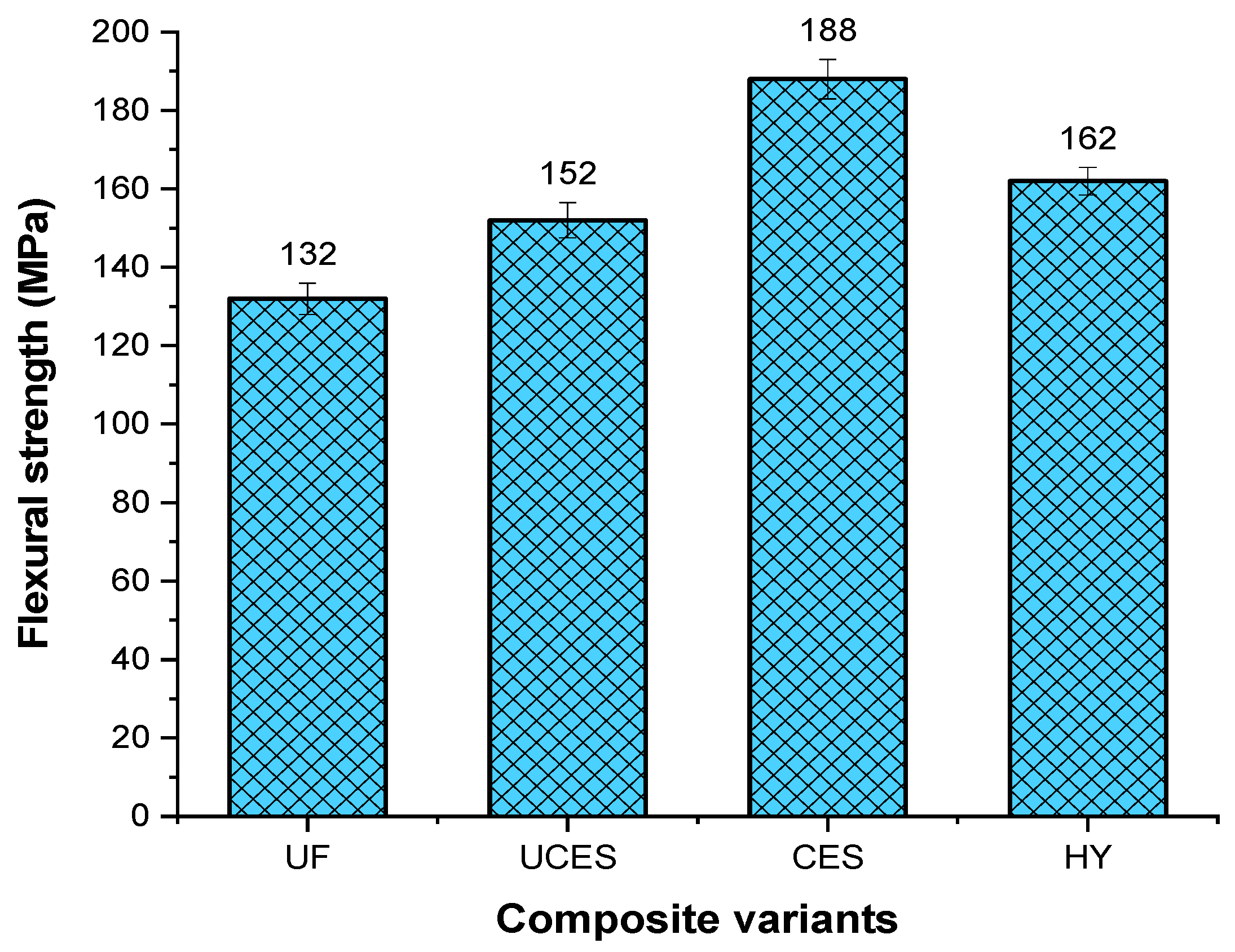

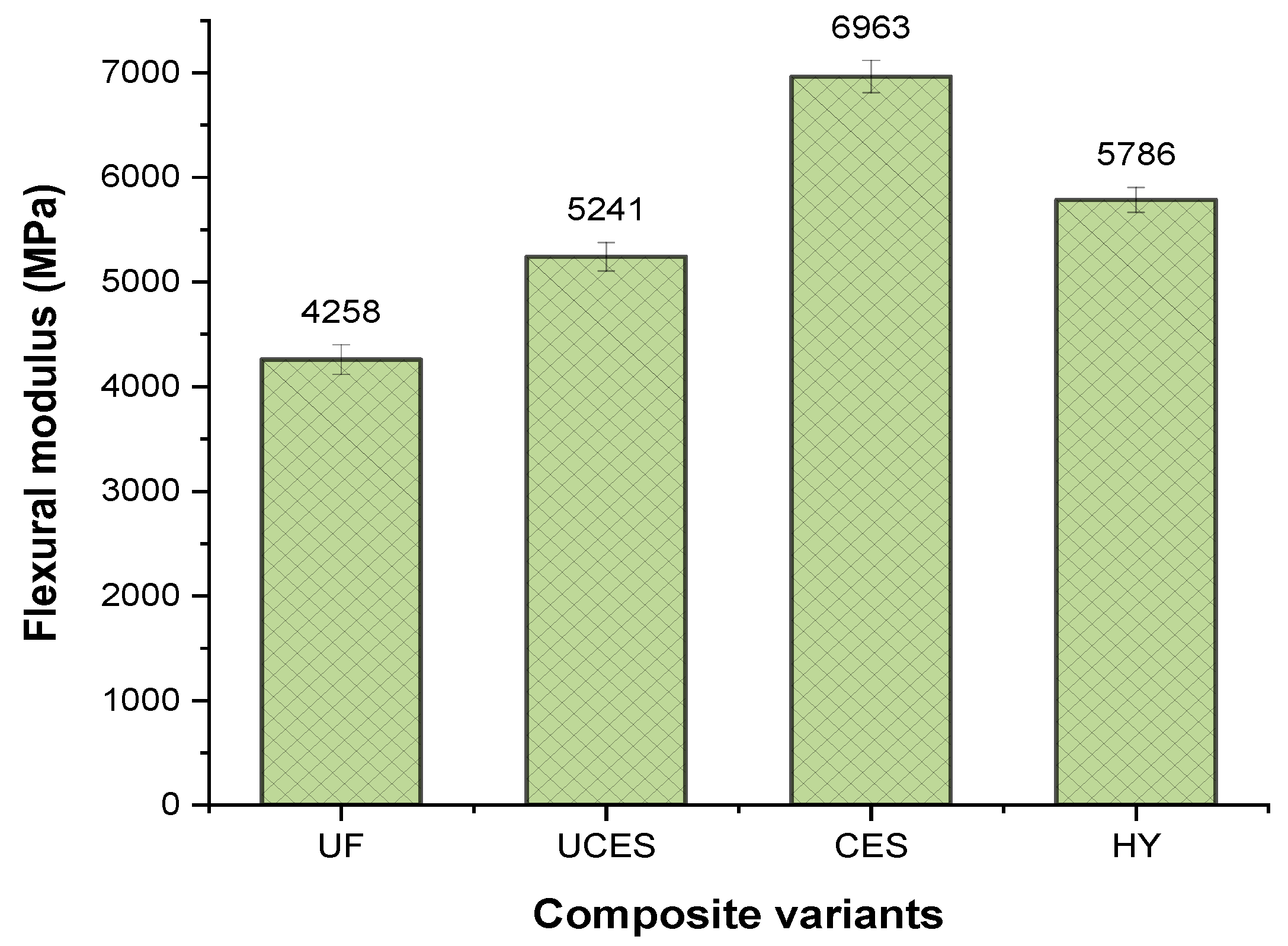

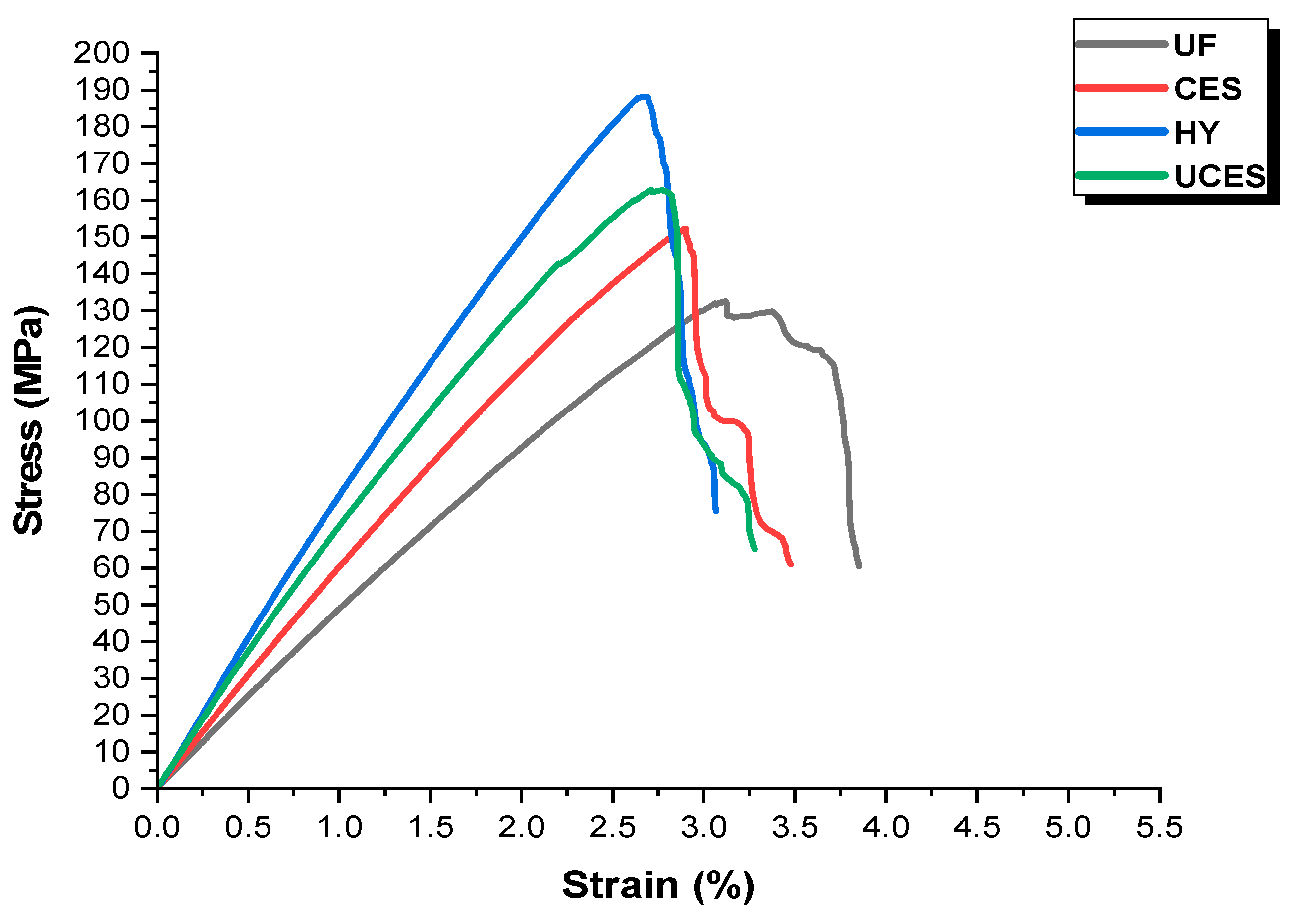

3.2. Flexural Test Results

3.3. Modes of Failure

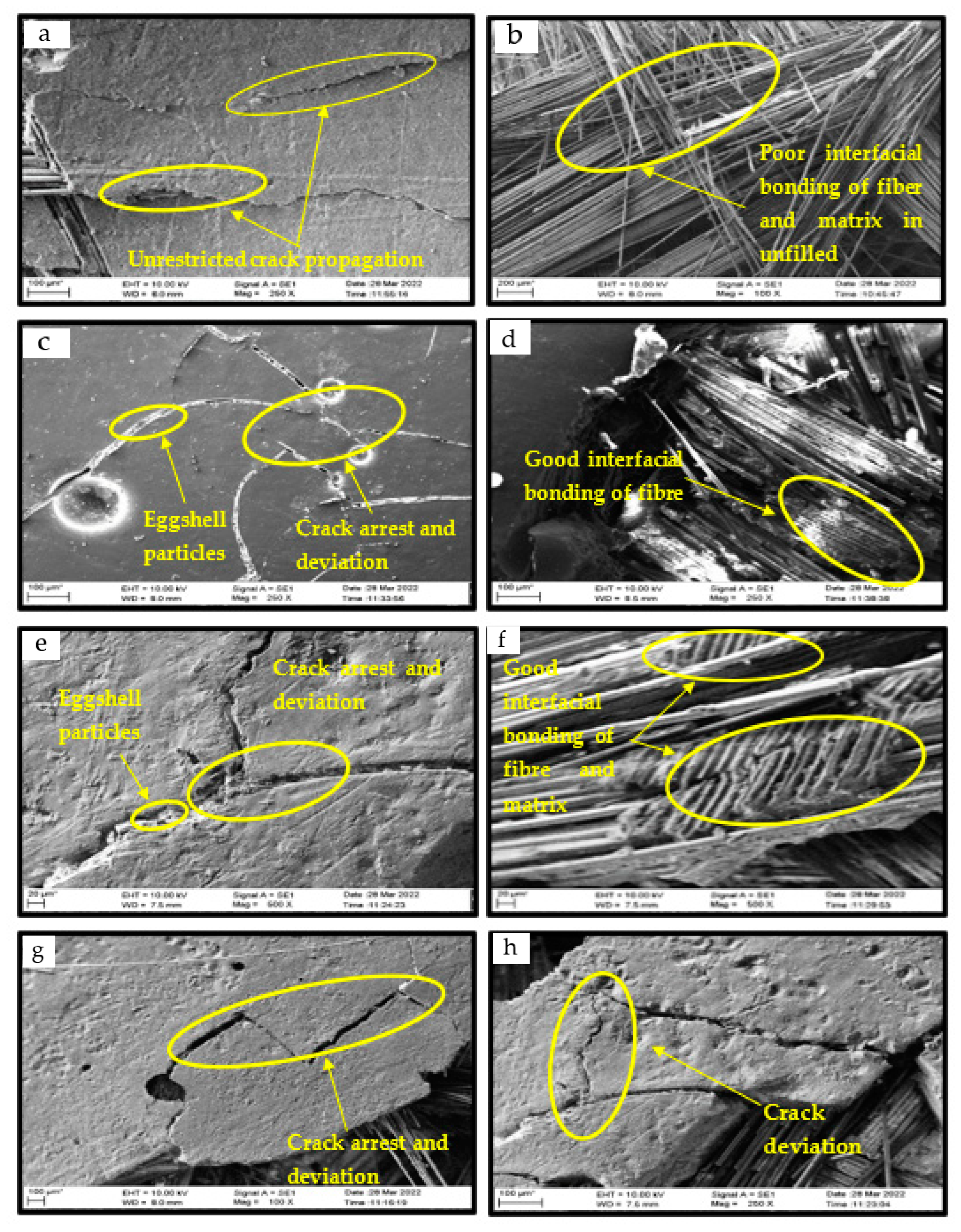

3.4. Microscopic Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yang, J.; Liu, Y.; Liu, S.; Li, L.; Zhang, C.; Liu, T. Conducting polymer composites: Material synthesis and applications in electrochemical capacitive energy storage. Mater. Chem. Front. 2017, 1, 251–268. [Google Scholar] [CrossRef]

- Fu, H.; Xu, H.; Liu, Y.; Yang, Z.; Kormakov, S.; Wu, D.; Sun, J. Overview of Injection Molding Technology for Processing Polymers and Their Composites. ES Mater. Manuf. 2020, 8, 3–23. [Google Scholar] [CrossRef]

- Banat, D.; Mania, R.J. Progressive failure analysis of thin-walled Fibre Metal Laminate columns subjected to axial compression. Thin-Walled Struct. 2018, 122, 52–63. [Google Scholar] [CrossRef]

- Shahabaz, S.M.; Sharma, S.; Shetty, N.; Shetty, S.D.; Gowrishankar, M.C. Influence of Temperature on Mechanical Properties and Machining of Fibre Reinforced Polymer Composites: A Review. ES Mater. Manuf. 2021, 16, 26–46. [Google Scholar] [CrossRef]

- Kilickap, E. Optimization of cutting parameters on delamination based on Taguchi method during drilling of GFRP composite. Expert Syst. Appl. 2010, 37, 6116–6122. [Google Scholar] [CrossRef]

- Dixit, D.; Pal, R.; Kapoor, G.; Stabenau, M. Lightweight composite materials processing. In Lightweight Ballistic Composites: Military and Law-Enforcement Applications: Second Edition, 2nd ed.; Bhatnagar, A., Ed.; Woodhead Publishing: Sawston, UK, 2016; pp. 157–216. [Google Scholar]

- Zaghloul, M.M.Y.; Mohamed, Y.S.; El-Gamal, H. Fatigue and tensile behaviors of fiber-reinforced thermosetting composites embedded with nanoparticles. J. Compos. Mater. 2019, 53, 709–718. [Google Scholar] [CrossRef]

- Nurdina, A.K.; Mariatti, M.; Samayamutthirian, P. Effect of single-mineral filler and hybrid-mineral filler additives on the properties of polypropylene composites. J. Vinyl Addit. Technol. 2009, 15, 20–28. [Google Scholar] [CrossRef]

- Sun, J.; Zhang, X.; Du, Q.; Murugadoss, V.; Wu, D.; Guo, Z. The Contribution of Conductive Network Conversion in Thermal Conductivity Enhancement of Polymer Composite: A Theoretical and Experimental Study. ES Mater. Manuf. 2021, 13, 53–65. [Google Scholar] [CrossRef]

- Baghban, M.H.; Vahid, S.; Tosee, R.; Valerievich, K.A.; Faridmehr, I. Mechanical Properties of Self-Compacting Lightweight Concrete Containing Organic Waste Ash. Eng. Sci. 2022, 20, 275–283. [Google Scholar] [CrossRef]

- Hiremath, P.; Shettar, M.; Gowrishankar, M.C. Investigation on mechanical and physical properties of GFRP-Egg shell powder hybrid composites. Indian J. Sci. Technol. 2016, 9, 1–6. [Google Scholar] [CrossRef]

- Zaghloul, M.M.Y.; Zaghloul, M.M.Y.; Zaghloul, M.M.Y. Developments in polyester composite materials—An in-depth review on natural fibres and nano fillers. Compos. Struct. 2021, 278, 114698. [Google Scholar] [CrossRef]

- Fuseini, M.; Zaghloul, M.M.Y. Qualitative and statistical approaches of the electrophoretic deposition kinetics of polyaniline copper coating. Prog. Org. Coat. 2022, 171, 107015. [Google Scholar] [CrossRef]

- Boronat, T.; Fombuena, V.; Garcia-Sanoguera, D.; Sanchez-Nacher, L.; Balart, R. Development of a biocomposite based on green polyethylene biopolymer and eggshell. Mater. Des. 2015, 68, 177–185. [Google Scholar] [CrossRef]

- Naik, N.; Shivamurthy, B.; Thimmappa, B.H.S.; Gupta, A.; Guo, J.Z.; Seok, I. A Review on processing methods and characterization techniques of Green Composites. Eng. Sci. 2022, 20, 80–99. [Google Scholar] [CrossRef]

- Jagadeesh, P.; Thyavihalli Girijappa, Y.G.; Puttegowda, M.; Rangappa, S.M.; Siengchin, S. Effect of natural filler materials on fiber reinforced hybrid polymer composites: An Overview. J. Nat. Fibers 2022, 19, 4132–4147. [Google Scholar] [CrossRef]

- Oliveira, D.A.; Benelli, P.; Amante, E.R. A literature review on adding value to solid residues: Egg shells. J. Clean. Prod. 2013, 46, 42–47. [Google Scholar] [CrossRef]

- Nolasco, E.; Jundt, E.; Kramp, M.M.; Dutta, E.; Nishijima, N.; Oda, Y.; Handa, A.; Xu, C.; Zhang, Y.; Majumder, K. Application of Dried Egg White to Enhance the Textural Properties of Fresh and Frozen Pancakes. ES Food Agrofor. 2020, 2, 50–57. [Google Scholar] [CrossRef]

- Murugan, S.; Munusamy, Y.; Ismail, H. Effects of chicken eggshell filler size on the processing, mechanical and thermal properties of PVC matrix composite. Plast Rubber Compos. 2017, 46, 42–51. [Google Scholar] [CrossRef]

- Zaghloul, M.M.Y.M. Mechanical properties of linear low-density polyethylene fire-retarded with melamine polyphosphate. J. Appl. Polym. Sci. 2018, 135, 46770. [Google Scholar] [CrossRef]

- Zaghloul, M.M.Y.; Zaghloul, M.M.Y. Influence of flame retardant magnesium hydroxide on the mechanical properties of high density polyethylene composites. J. Reinf. Plast. Compos. 2017, 36, 1802–1816. [Google Scholar] [CrossRef]

- Chandrappa, D.R.K.; Kamath, M.S.S. The Egg shell as a filler in composite materials-a review. J. Mech. Energy Eng. 2021, 4, 335–340. [Google Scholar] [CrossRef]

- Zieleniewska, M.; Leszczyński, M.K.; Szczepkowski, L.; Krzyżowska, M.; Bień, K.; Ryszkowska, J. Development and applicational evaluation of the rigid polyurethane foam composites with egg shell waste. Polym. Degrad. Stab. 2016, 132, 78–86. [Google Scholar] [CrossRef]

- Aruniit, A.; Kers, J.; Krumme, A.; Poltimäe, T.; Tall, K. Preliminary study of the influence of post curing parameters to the particle reinforced composite’s mechanical and physical properties. Medziagotyra 2012, 18, 256–261. [Google Scholar] [CrossRef]

- Chavan, V.R.; Dinesh, K.R.; Veeresh, K.; Algur, V.; Shettar, M. Influence of post curing on GFRP hybrid composite. MATEC Web Conf. 2018, 144, 02011. [Google Scholar] [CrossRef]

- Rozylo, P.; Debski, H. Effect of eccentric loading on the stability and load-carrying capacity of thin-walled composite profiles with top-hat section. Compos. Struct. 2020, 245, 112388. [Google Scholar] [CrossRef]

- Panchal, M.; Raghavendra, G.; Reddy, A.R.; Omprakash, M.; Ojha, S. Experimental investigation of mechanical and erosion behavior of eggshell nanoparticulate epoxy biocomposite. Polym. Polym. Compos. 2021, 29, 897–908. [Google Scholar] [CrossRef]

- Yew, M.C.; Ramli Sulong, N.H.; Yew, M.K.; Amalina, M.A.; Johan, M.R. Eggshells: A novel bio-filler for intumescent flame-retardant coatings. Prog. Org. Coat. 2015, 81, 116–124. [Google Scholar] [CrossRef]

- Jie, L.; Emayaruba, S.; Dassan, G.B.; Zainol, M.S.; Anjang, A. Tensile and Compressive Properties of Glass Fiber-Reinforced Polymer Hybrid Composite with Eggshell Powder. Arab. J. Sci. Eng. 2020, 45, 5783–5791. [Google Scholar]

- Hassan, S.B.; Aigbodion, V.S.; Patrick, S.N. Development of Polyester/Eggshell Particulate Composites. Tribol. Ind. 2012, 34, 217–225. [Google Scholar]

- Owuamanam, S.; Cree, D. Progress of bio-calcium carbonate waste eggshell and seashell fillers in polymer composites: A review. J. Compos. Sci. 2020, 4, 70. [Google Scholar] [CrossRef]

- Kowshik, S.; Sharma, S.; Rao, S.U.; Shettar, M.; Hiremath, P.; Upadhyaya, A. Investigation on the Effects of Uncarbonised, Carbonised and Hybrid Eggshell Filler Addition on the Mechanical Properties of Glass Fibre/Polyester Composites. Eng. Sci. 2022, 18, 121–131. [Google Scholar] [CrossRef]

- Babu, K.; Balasubramanian, N. Role, effect, and influences of micro and nano-fillers on various properties of polymer matrix composites for microelectronics: A review. Polym. Adv. Technol. 2018, 29, 1568–1585. [Google Scholar] [CrossRef]

| Property | Unit | E-Glass Fibre |

|---|---|---|

| Density | g/cm3 | 2.54 |

| Tensile strength | MPa | 3425 |

| Tensile elongation | % | 2.75 |

| Modulus of elasticity | GPa | 75 |

| Fibre diameter | µm | 11 |

| Chemical composition | %(weight) | 51.6 SiO2 |

| 15.9 Al2O3 | ||

| 9.6 B2O3 | ||

| 5.5 MgO | ||

| 16.6 CaO | ||

| 0.8 Other |

| Property | Unit | Unsaturated Polyester |

|---|---|---|

| Density | g/cm3 | 1.2 |

| Tensile strength | MPa | 62 |

| Tensile elongation | % | 2 |

| Modulus of elasticity | GPa | 3.2 |

| Flexural strength | MPa | 40 |

| Composite Variant | Glass Fibre (wt.%) | Polyester (wt.%) | Uncarbonised Eggshell (wt.%) | Carbonised Eggshell (wt.%) |

|---|---|---|---|---|

| Unfilled (UF) | 34 | 66 | 0 | 0 |

| Uncarbonised eggshell filled (UCES) | 34 | 56 | 10 | 0 |

| Carbonised eggshell filled (CES) | 34 | 56 | 0 | 10 |

| Hybrid eggshell filled (HY) | 34 | 56 | 5 | 5 |

| Specimen Number (Top to Bottom) | Mode of Failure as per the ASTM Standard | First Character (Failure Type) | Second Character (Failure Area) | Third Character (Failure Location) |

|---|---|---|---|---|

| 1 | LAT | Lateral | At grip | Top |

| 2 | AGM | Angular | Gauge | Middle |

| 3 | LGM | Lateral | Gauge | Middle |

| 4 | LAT | Lateral | At grip | Top |

| 5 | LGM | Lateral | Gauge | Middle |

| Specimen Number (Top to Bottom) | Mode of Failure as per the ASTM Standard | First Character (Failure Type) | Second Character (Failure Area) | Third Character (Failure Location) |

|---|---|---|---|---|

| 1 | AAT | Angular | At grip | Top |

| 2 | AGM | Angular | Gauge | Middle |

| 3 | AGM | Angular | Gauge | Middle |

| 4 | LGM | Lateral | Gauge | Middle |

| 5 | LGM | Lateral | Gauge | Middle |

| Specimen Number (Top to Bottom) | Mode of Failure as per the ASTM Standard | First Character (Failure Type) | Second Character (Failure Area) | Third Character (Failure Location) |

|---|---|---|---|---|

| 1 | AGM | Angular | Gauge | Middle |

| 2 | AGM | Angular | Gauge | Middle |

| 3 | AGM | Angular | Gauge | Middle |

| 4 | LAT | Lateral | At grip | Top |

| 5 | LGM | Lateral | Gauge | Middle |

| Specimen Number (Top to Bottom) | Mode of Failure as per the ASTM Standard | First Character (Failure Type) | Second Character (Failure Area) | Third Character (Failure Location) |

|---|---|---|---|---|

| 1 | LGM | Lateral | Gauge | Middle |

| 2 | LGM | Lateral | Gauge | Middle |

| 3 | LGM | Lateral | Gauge | Middle |

| 4 | LAT | Lateral | At grip | Top |

| 5 | LGM | Lateral | Gauge | Middle |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kowshik, S.; Sharma, S.; Rao, S.; Shettar, M.; Hiremath, P. Mechanical Properties of Post-Cured Eggshell-Filled Glass-Fibre-Reinforced Polymer Composites. J. Compos. Sci. 2023, 7, 49. https://doi.org/10.3390/jcs7020049

Kowshik S, Sharma S, Rao S, Shettar M, Hiremath P. Mechanical Properties of Post-Cured Eggshell-Filled Glass-Fibre-Reinforced Polymer Composites. Journal of Composites Science. 2023; 7(2):49. https://doi.org/10.3390/jcs7020049

Chicago/Turabian StyleKowshik, Suhas, Sathyashankara Sharma, Sathish Rao, Manjunath Shettar, and Pavan Hiremath. 2023. "Mechanical Properties of Post-Cured Eggshell-Filled Glass-Fibre-Reinforced Polymer Composites" Journal of Composites Science 7, no. 2: 49. https://doi.org/10.3390/jcs7020049