Experimental Investigation on Flexural Behaviour of Sustainable Reinforced Concrete Beam with a Smart Mortar Layer

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Casting of Specimen

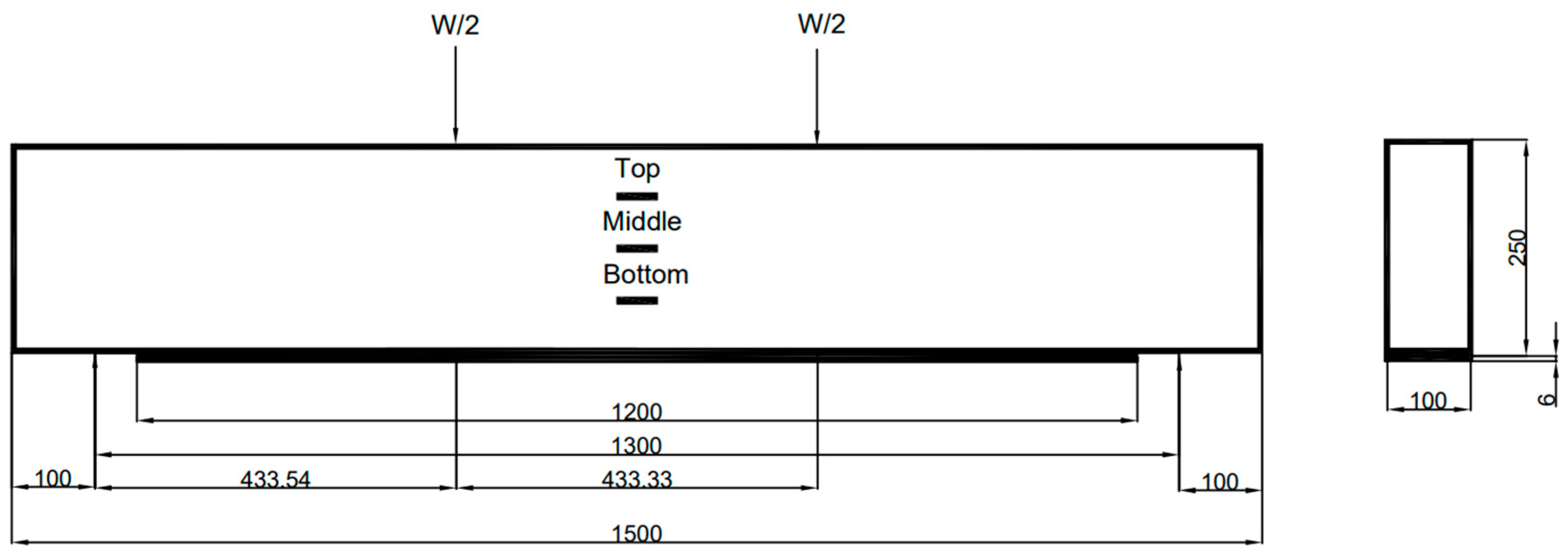

2.3. Test Method

3. Discussion and Findings

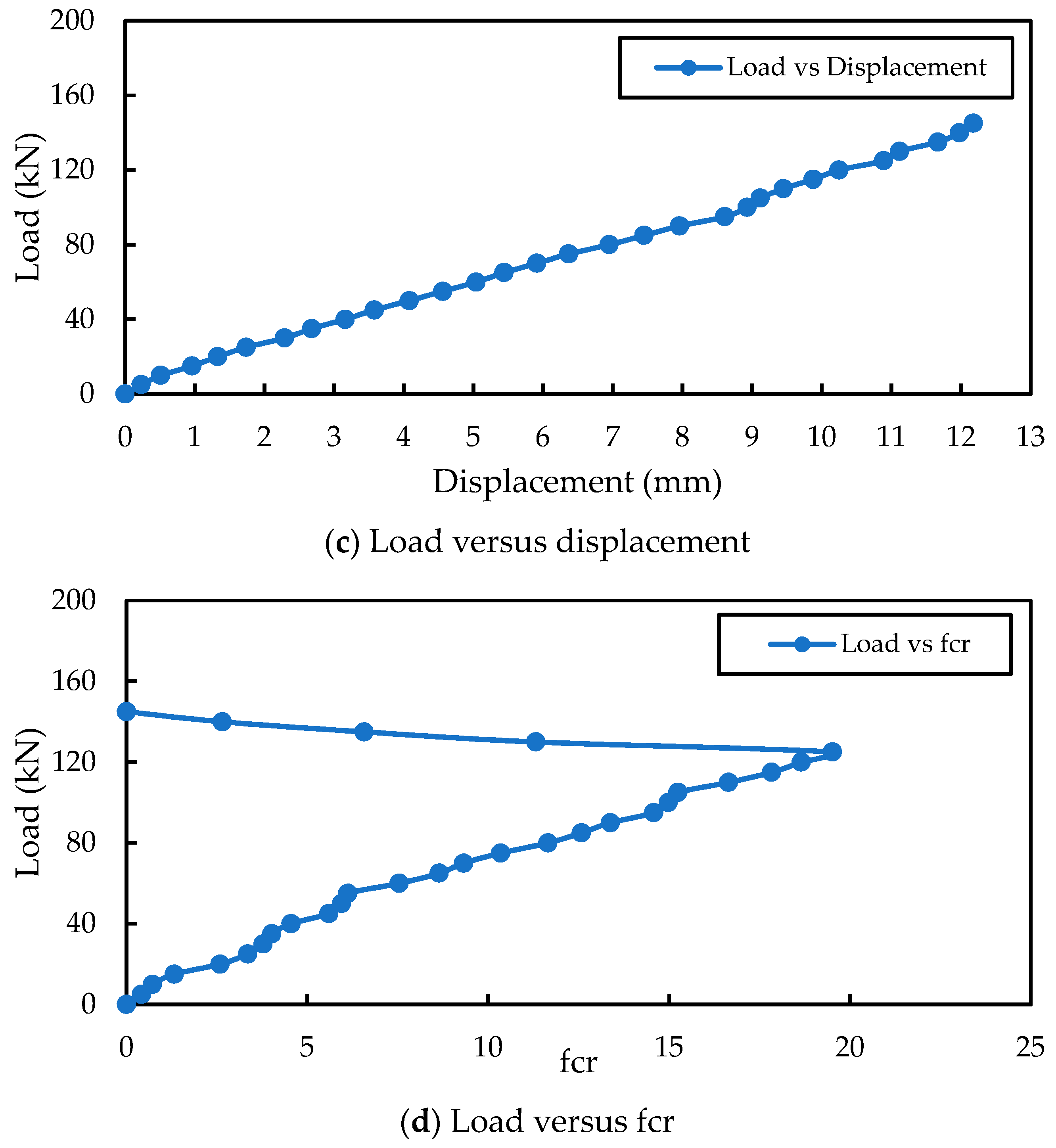

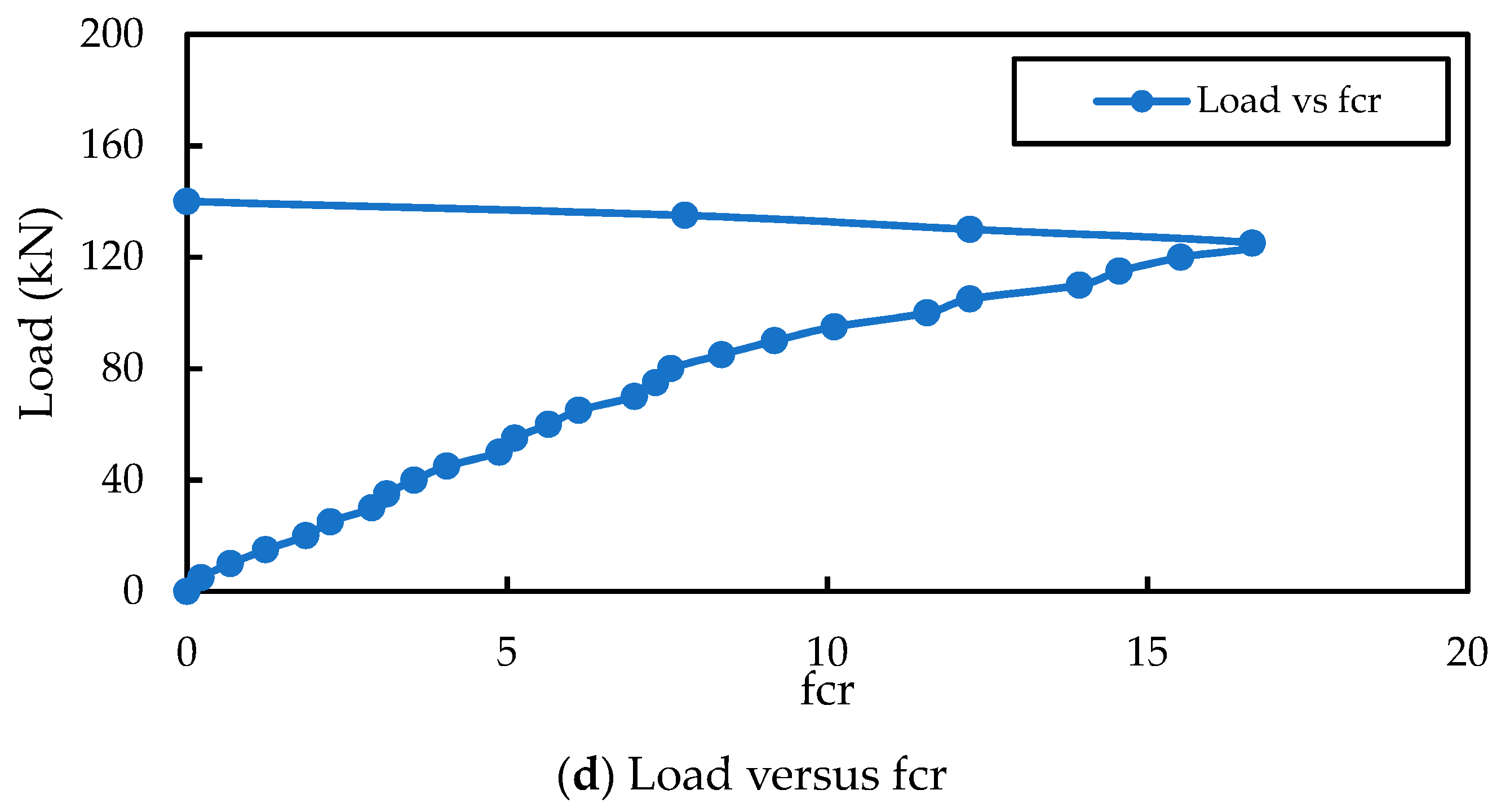

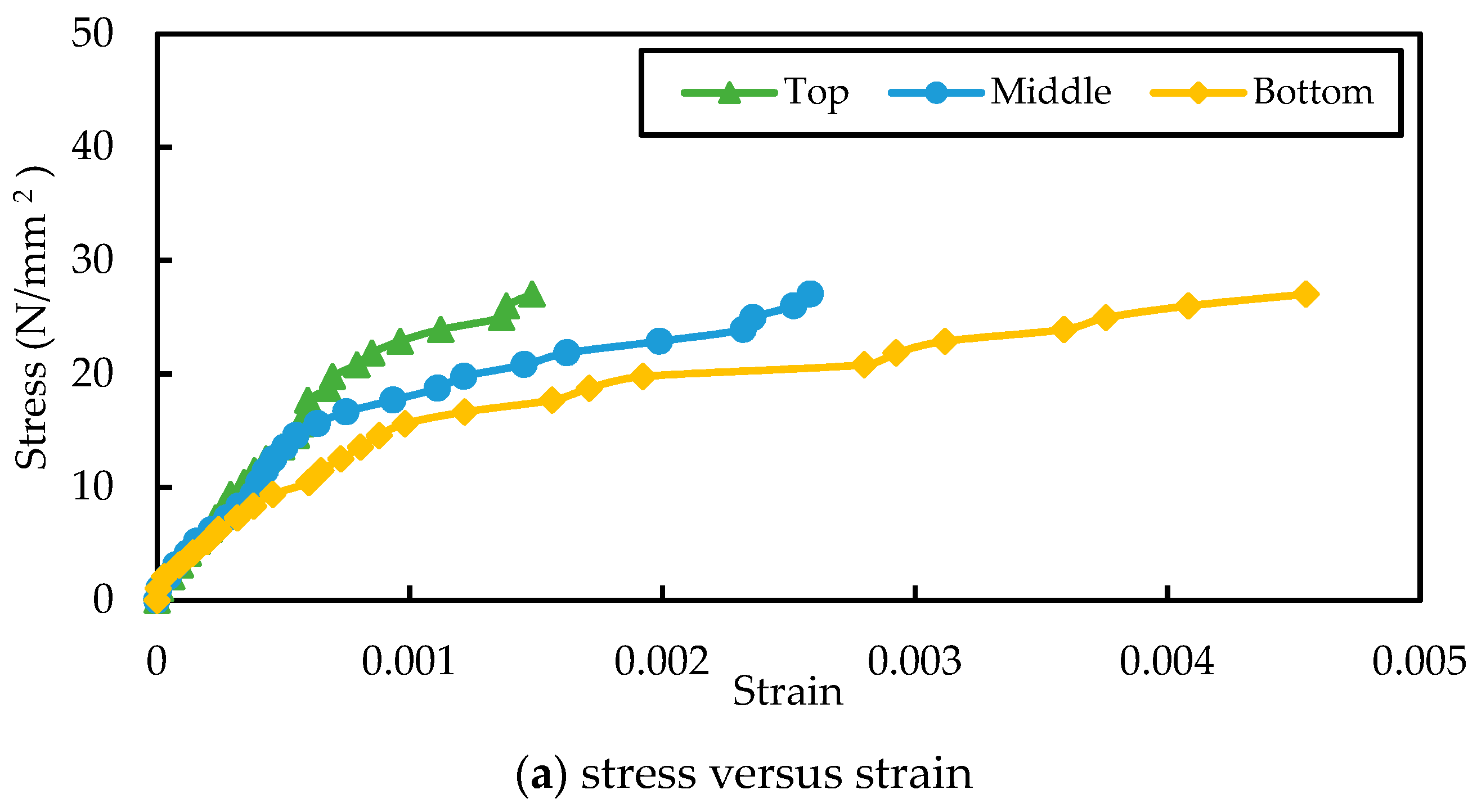

3.1. A New Brass Fibre Added Mortar Layer Is Cast on a New 1.5-m-Long Beam

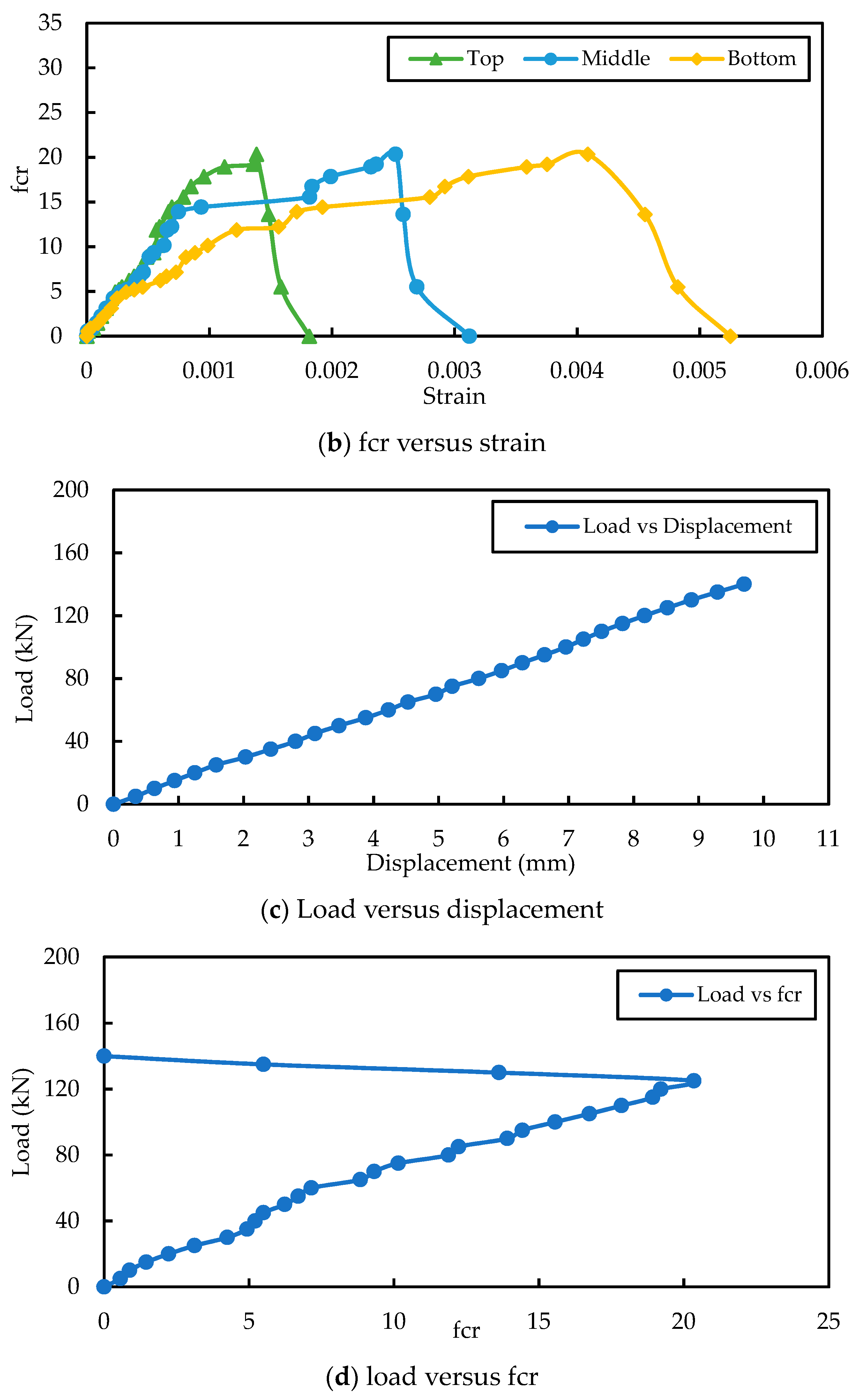

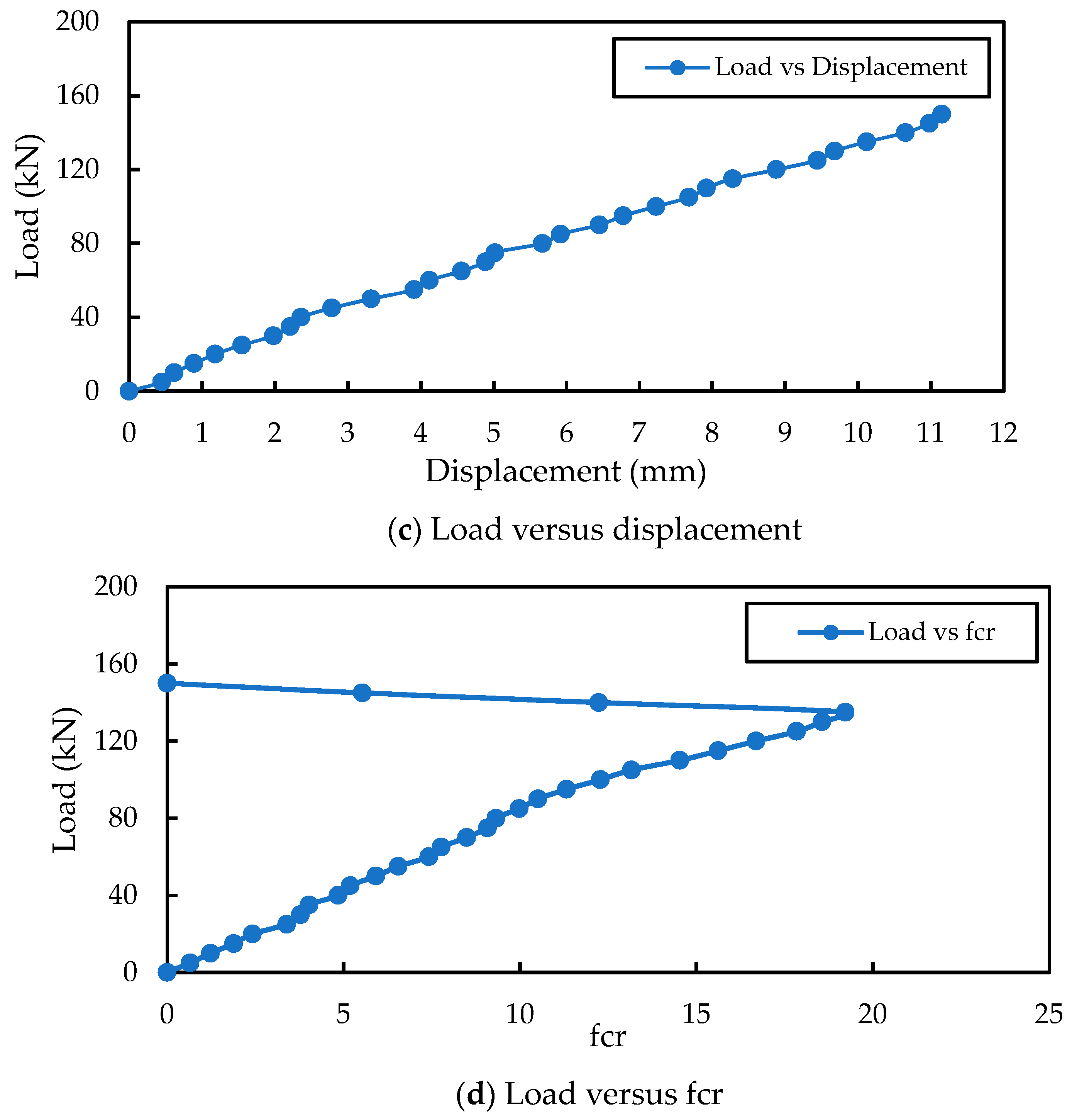

3.2. A Fresh Mortar Layer of Brass Fibres Was Cast on an Existing 1.5-m-Long Beam

3.3. Brass Fibre Added Mortar Layer Pasted on Existing Beam of Length 1.5 m with Araldite Paste

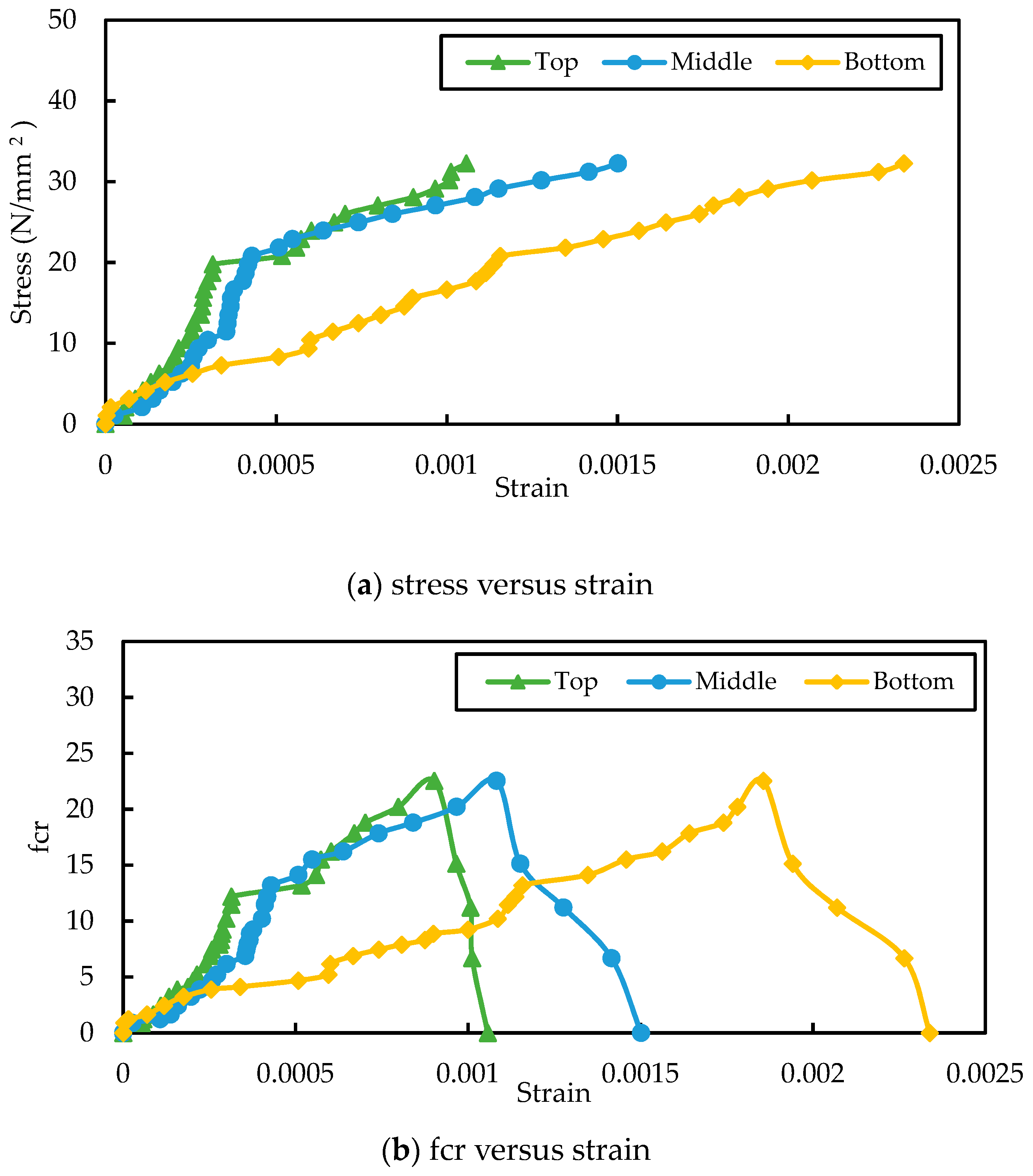

3.4. Hybrid Brass Carbon Fresh Mortar Layer Cast on a Fresh Concrete Beam of Length 1.5 m

3.5. Hybrid Brass–Carbon Fibre Added Fresh Mortar Layer Cast on an Existing Concrete Beam of Length 1.5 m

3.6. Hybrid Brass–Carbon Fibre-Added Mortar Layer Pasted on Existing Concrete Beam with Araldite Paste of Length 1.5 m

4. Discussion of Results

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Arya, C.; Clarke, J.L.; Kay, E.A.; O’Regan, P.D. Design guidance for strengthening concrete structures using fiber composite materials: A review. Eng. Struct. 2001, 24, 889–900. [Google Scholar] [CrossRef]

- Gao, B.; Kim, J.K.; Leung, C.K.Y. Experimental investigation of taper ended FRP strips in FRP strengthened RC beams. In Proceedings of the 4th International Conference on Advanced Composite Materials in Bridges and Structures, Calgary, AB, Canada, 20–23 July 2004. [Google Scholar]

- Khalifa, A.; Nanni, A. Rehabilitation of rectangular simply supported RC beams with shear deficiencies using CFRP composites. Constr. Build. Mater. 2002, 16, 135–146. [Google Scholar] [CrossRef]

- Pesic, N.; Pilakoutas, K. Concrete beams with externally bonded flexural FRP-reinforcement: Analytical investigation of debonding failure. Compos. Part B Eng. 2003, 34, 327–338. [Google Scholar] [CrossRef] [Green Version]

- Mohammad Noh, N. Effectiveness of RC Beams Strengthened with Near Surface Mounted (NSM) Fiber Reinforced Polymer (FRP) Bars and Externally Bonded (EB) FRP Sheets. Master’s Thesis, Universiti Teknologi MARA, Shah Alam, Malaysia, 2003. [Google Scholar]

- Gao, B.; Kim, J.K.; Leung, C.K.Y. Optimization of tapered end design for FRP strips bonded to RC beams. Compos. Sci. Technol. 2005, 66, 1266–1273. [Google Scholar] [CrossRef]

- Ceroni, F.; Pecce, M.; Mattys, S.; Taerwe, L. Debonding strength and anchorage devices for reinforced concrete elements strengthened with FRP sheets. Compos. Part B Eng. 2007, 30, 429–441. [Google Scholar] [CrossRef]

- Xiong, G.J.; Jiang, X.; Liu, J.W.; Chen, L. A way for preventing tension delamination of concrete cover in midspan of FRP strengthened beams. Constr. Build. Mater. 2005, 21, 402–408. [Google Scholar] [CrossRef]

- Al-Saidy, A.H.; Al-Harthy, A.S.; Al-Jabri, K.S.; Abdul-Halim, M.; Al Shidi, N.M. Structural performance of corroded RC beams repaired with CFRP sheets. Compos. Struct. 2010, 92, 1931–1938. [Google Scholar] [CrossRef]

- El-Ghandour, A.A. Experimental and analytical of CFRP flexural and shear strengthening efficiencies of RC beams. Constr. Build. Mater. 2011, 25, 1419–1429. [Google Scholar] [CrossRef]

- Buyle-Bodin, F. Use of carbon fiber textile to control premature failure of reinforced concrete beams strengthened with bonded CFRP plates. J. Ind. Text. 2010, 33, 145–157. [Google Scholar] [CrossRef]

- Arafah, A.M. Factors affecting the reliability of reinforced concrete beams. WIT Trans. Ecol. Environ. 2000, 45, 379–387. [Google Scholar]

- Khalel, R.I. Torsional behavior of high-strength reinforced concrete beams. J. Eng. Sustain. Dev. 2013, 17, 317–332. [Google Scholar]

- Jagana, R.; Kumar, C.V. High strength concrete. Int. J. Eng. Sci. Res. Technol. 2017, 6, 394–407. [Google Scholar]

- Rashid, M.A.; Mansur, M.A. Reinforced high-strength concrete beams in flexure. ACI Struct. J. 2005, 102, 462. [Google Scholar]

- Fu, X.; Ma, E.; Chung, D.D.L.; Anderson, W.A. Self-monitoring in carbon fiber reinforced mortar by reactance measurement. Cem. Concr. Res. 1997, 27, 845–852. [Google Scholar] [CrossRef]

- Fu, X.; Chung, D.D.L. Effect of curing age on the self-monitoring behavior of carbon fiber reinforced mortar. Cem. Concr. Res. 1997, 27, 1313–1318. [Google Scholar] [CrossRef]

- Chung, D.D.L. Self-monitoring structural materials. Mater. Sci. Eng. 1998, 22, 57–78. [Google Scholar] [CrossRef]

- Teomete, E.; Kocyigit, O.I. Tensile strain sensitivity of steel fiber reinforced cement matrix composites tested by split tensile test. Constr. Build. Mater. 2013, 47, 962–968. [Google Scholar] [CrossRef]

- Teomete, E. Transverse strain sensitivity of steel fiber reinforced cement composites tested by compression and split tensile tests. Constr. Build. Mater. 2014, 55, 136–145. [Google Scholar] [CrossRef]

- Teomete, E. Measurement of crack length sensitivity and strain gage factor of carbon fiber reinforced cement matrix composites. Measurement 2015, 74, 21–30. [Google Scholar] [CrossRef]

- Teomete, E. The effect of temperature and moisture on electrical resistance, strain sensitivity and crack sensitivity of steel fiber reinforced smart cement composite. Smart Mater. Struct. 2016, 25, 075024. [Google Scholar] [CrossRef]

- Han, B.; Zhang, K.; Yu, X.; Kwon, E.; Jinping, O.U. Nickel particle based self-sensing pavement for vehicle detection. Measurement 2011, 44, 1645–1650. [Google Scholar] [CrossRef]

- Han, B.; Yu, Y.; Han, B.Z.; Ou, J.P. Development of a wireless stress/strain measurement system integrated with pressure-sensitive nickel powder-filled cement-based sensors. Sens. Actuators A 2008, 147, 536–543. [Google Scholar] [CrossRef]

- Han, B.; Han, B.Z.; Ou, J.P. Experimental study on use of nickel powder-filled Portland cement-based composite for fabrication of piezoresistive sensors with high sensitivity. Sens. Actuators A 2009, 149, 51–55. [Google Scholar] [CrossRef]

- Sun, M.; Liew, R.J.Y.; Zhang, M.H.; Li, W. Development of cement-based strain sensor for health monitoring of ultra-high strength concrete. Constr. Build. Mater. 2014, 65, 630–637. [Google Scholar] [CrossRef]

- Baeza, F.J.; Galao, O.; Zornoza, E.; Garcés, P. Multifunctional cement composites strain and damage sensors applied on reinforced concrete (RC) structural elements. Materials 2013, 6, 841–855. [Google Scholar] [CrossRef] [Green Version]

- Xiao, H.; Li, H.; Ou, J.P. Strain sensing properties of cement-based sensors embedded at various stress zones in a bending concrete beam. Sens. Actuators A 2011, 167, 581–587. [Google Scholar] [CrossRef]

- Kumar, D.R.; Thirumurugan, V.; Satyanarayanan, K.S. Experimental study on optimization of smart mortar with the addition of brass fibres. Mater. Today Proc. 2021, 50, 388–393. [Google Scholar] [CrossRef]

- Durairaj, R.; Varatharajan, T.; Srinivasan, S.K.; Gurupatham, B.G.A.; Roy, K. An Experimental Study on Electrical Properties of Self-Sensing Mortar. J. Compos. Sci. 2022, 6, 208. [Google Scholar] [CrossRef]

- Sevim, O.; Jiang, Z.; Ozbulut, O.E. Effects of graphene nanoplatelets type on self-sensing properties of cement mortar composites. Constr. Build. Mater. 2022, 359, 129488. [Google Scholar] [CrossRef]

- Erman, D.; Egemen, T. Cross tension and compression loading and large-scale testing of strain and damage sensing smart concrete. Constr. Build. Mater. 2022, 316, 125784. [Google Scholar]

- Cheng, A.; Lin, W.-T. Electrical resistance and self-sensing properties of pressure-sensitive materials with graphite filler in Kuralon fiber concrete. Mater. Sci. 2022, 40, 223–239. [Google Scholar] [CrossRef]

- Dong, W.; Li, W. Application of intrinsic self-sensing cement-based sensor for traffic detection of human motion and vehicle speed. Constr. Build. Mater. 2022, 355, 129130. [Google Scholar] [CrossRef]

- Bellic, A.; Mobili, A. Commercial and recycled carbon/steel fibers for fiber-reinforced cement mortars with high electrical conductivity overlay panel. Cem. Concr. Compos. 2020, 109, 103569. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, K.; Wang, S.; Wang, Z.; Yang, Z.; Shumuye, E.D.; Gong, X. Effect of Elevated Temperature on Mechanical Properties of High-Volume Fly Ash-Based Geopolymer Concrete, Mortar and Paste Cured at Room Temperature. Polymers 2021, 13, 1473. [Google Scholar] [CrossRef]

- Tucci, F.; Vedernikov, A. Design Criteria for Pultruded Structural Elements. Encycl. Mater. Compos. 2021, 3, 51–68. [Google Scholar]

- Vedernikov, A.; Safonov, A.; Tucci, F.; Carlone, P.; Akhatov, I. Analysis of Spring-in Deformation in L-shaped Profiles Pultruded at Different Pulling Speeds: Mathematical Simulation and Experimental Results. In Proceedings of the ESAFORM 2021, 4th International ESAFORM Conference on Material Forming, Liège, Belgium, 14–16 April 2021. [Google Scholar]

- Minchenkov, K.; Vedernikov, A. Effects of the quality of pre-consolidated materials on the mechanical properties and morphology of thermoplastic pultruded flat laminates. Compos. Commun. 2022, 35, 101281. [Google Scholar] [CrossRef]

- Zhou, P.; Li, C. Durability study on the interlaminar shear behavior of glass-fibre reinforced polypropylene (GFRPP) bars for marine applications. Constr. Build. Mater. 2022, 349, 128694. [Google Scholar] [CrossRef]

- Madenci, E.; Özkılıç, Y.O.; Aksoylu, C.; Safonov, A. The Effects of Eccentric Web Openings on the Compressive Performance of Pultruded GFRP Boxes Wrapped with GFRP and CFRP Sheets. Polymers 2022, 14, 4567. [Google Scholar] [CrossRef]

- Ozkilic, Y.O.; Gemi, L.; Madenci, E.; Aksoylu, C.; Kalkan, İ. Effect of the GFRP wrapping on the shear and bending Behavior of RC beams with GFRP encasement. Steel Compos. Struct. 2022, 45, 193–204. [Google Scholar]

- IS 456-2000; Indian Standard Plain and Reinforced Concrete Code of Practice. Bureau of Indian Standards: New Delhi, India, 2000.

- IS 2250-1981; Indian Standard Code of Practice for Preparation and Use of Masonry Mortars. Bureau of Indian Standards: New Delhi, India, 1981.

| Cement (kg/m3) | Fine Aggregate (kg/m3) | Coarse Aggregate (kg/m3) | Water (kg/m3) |

|---|---|---|---|

| 428.48 | 888.94 | 924.64 | 171.39 |

| Cement (kg/m3) | Fine Aggregate (kg/m3) | Water (kg/m3) | Superplasticizer (kg/m3) | Silica Fume (kg/m3) |

|---|---|---|---|---|

| 468 | 1427.5 | 234 | 7.02 | 70.20 |

| S. No. | Beam | Variations Provided |

|---|---|---|

| 1 | Beam-1-FB-FM-BF | By incorporating brass fibres into the mortar mixture, a fresh mortar layer was cast on a fresh beam. |

| 2 | Beam-2-EB-FM-BF | By including brass fibres in the mortar mixture, a fresh mortar layer was cast on the top of the existing beam. |

| 3 | Beam-3-EB-EM-BF | Brass fibres were included in the mortar mixture, and a separate layer of cast mortar was placed over the existing beam. |

| 4 | Beam-4-FB-FM-HBC | By incorporating hybrid brass carbon fibres into the mortar mixture, a fresh mortar layer was cast on a fresh beam. |

| 5 | Beam-5-EB-FM-HBC | Hybrid brass-carbon fibres are added to the mortar mixture before casting a new mortar layer over an existing beam. |

| 6 | Beam-6-EB-EM-HBC | Hybrid brass carbon fibres were added to the mortar mixture, and a separate layer of cast mortar was applied to the existing beam with Araldite paste. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Durairaj, R.; Varatharajan, T.; Srinivasan, S.K.; Gurupatham, B.G.A.; Roy, K. Experimental Investigation on Flexural Behaviour of Sustainable Reinforced Concrete Beam with a Smart Mortar Layer. J. Compos. Sci. 2023, 7, 132. https://doi.org/10.3390/jcs7040132

Durairaj R, Varatharajan T, Srinivasan SK, Gurupatham BGA, Roy K. Experimental Investigation on Flexural Behaviour of Sustainable Reinforced Concrete Beam with a Smart Mortar Layer. Journal of Composites Science. 2023; 7(4):132. https://doi.org/10.3390/jcs7040132

Chicago/Turabian StyleDurairaj, Ramkumar, Thirumurugan Varatharajan, Satyanarayanan Kachabeswara Srinivasan, Beulah Gnana Ananthi Gurupatham, and Krishanu Roy. 2023. "Experimental Investigation on Flexural Behaviour of Sustainable Reinforced Concrete Beam with a Smart Mortar Layer" Journal of Composites Science 7, no. 4: 132. https://doi.org/10.3390/jcs7040132

APA StyleDurairaj, R., Varatharajan, T., Srinivasan, S. K., Gurupatham, B. G. A., & Roy, K. (2023). Experimental Investigation on Flexural Behaviour of Sustainable Reinforced Concrete Beam with a Smart Mortar Layer. Journal of Composites Science, 7(4), 132. https://doi.org/10.3390/jcs7040132