Experimental Investigation of Aloe Vera-Treated False Banana (Ensete Ventricosum) Fibre-Reinforced Polypropylene Composite

Abstract

1. Introduction

2. Material and Methods

2.1. Test Material

2.2. Experimental Design

2.3. Preparation of Composite Plates

2.4. Mechanical Testing

3. Results and Discussion

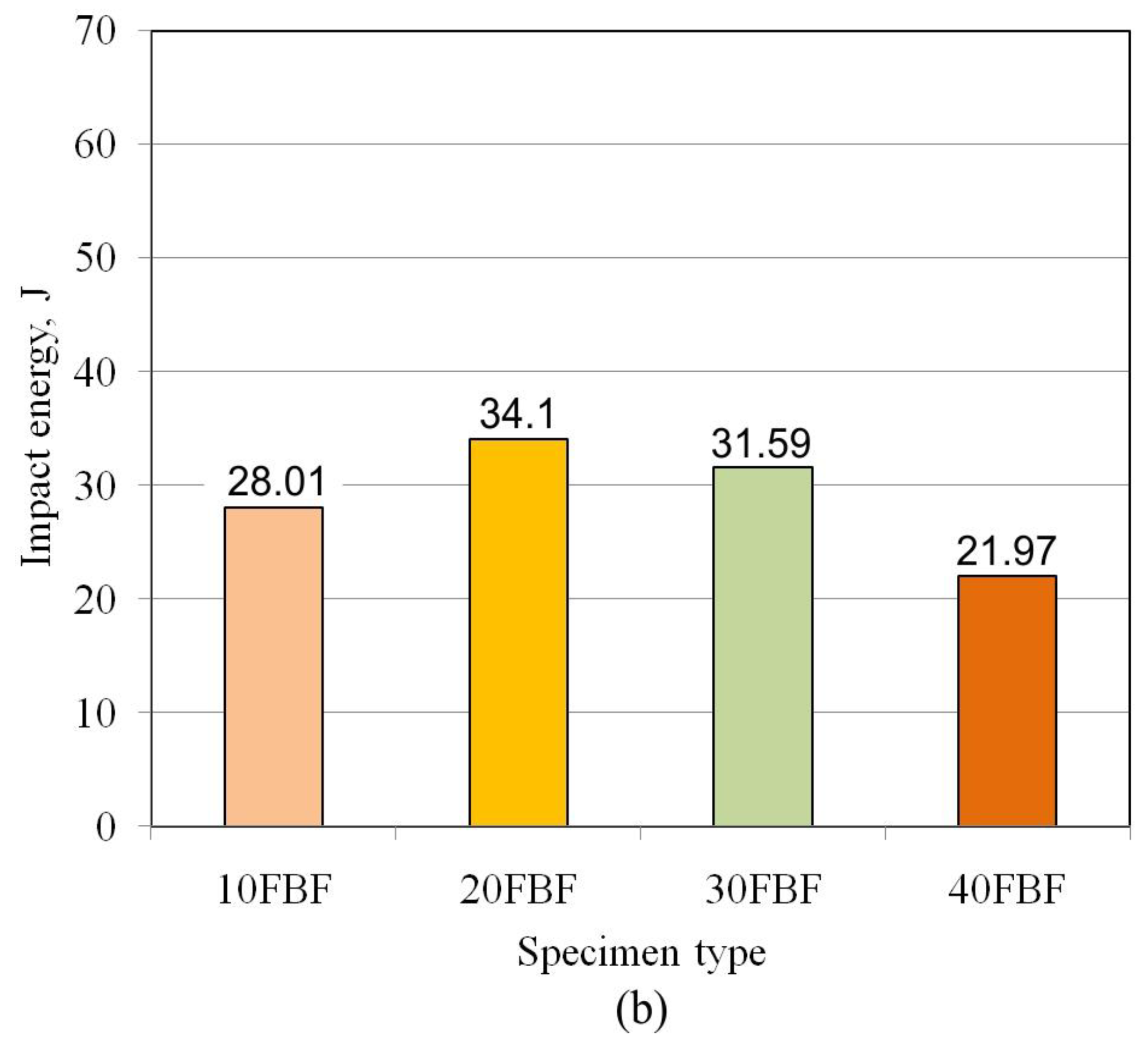

3.1. Impact Test

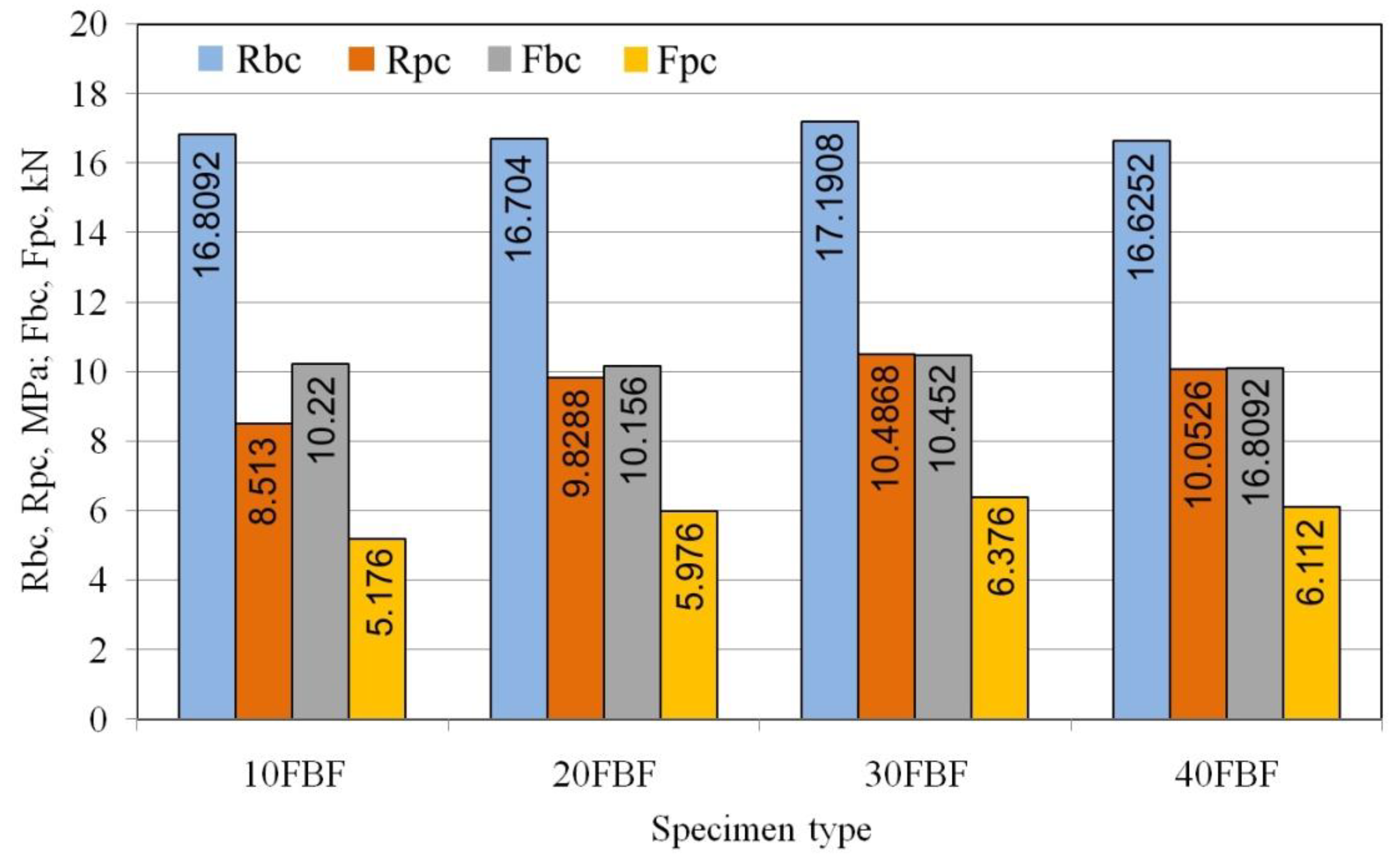

3.2. Compression Test

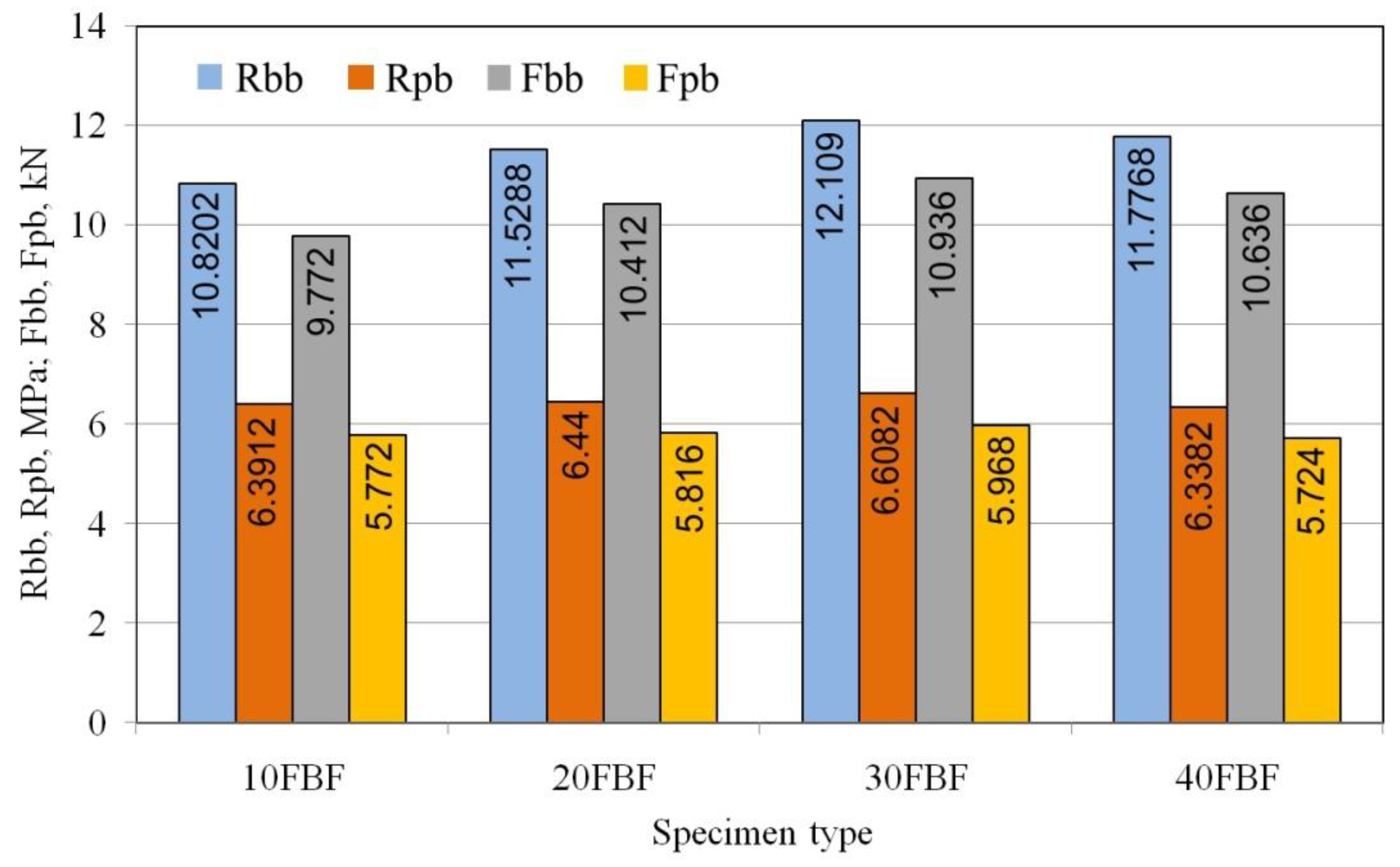

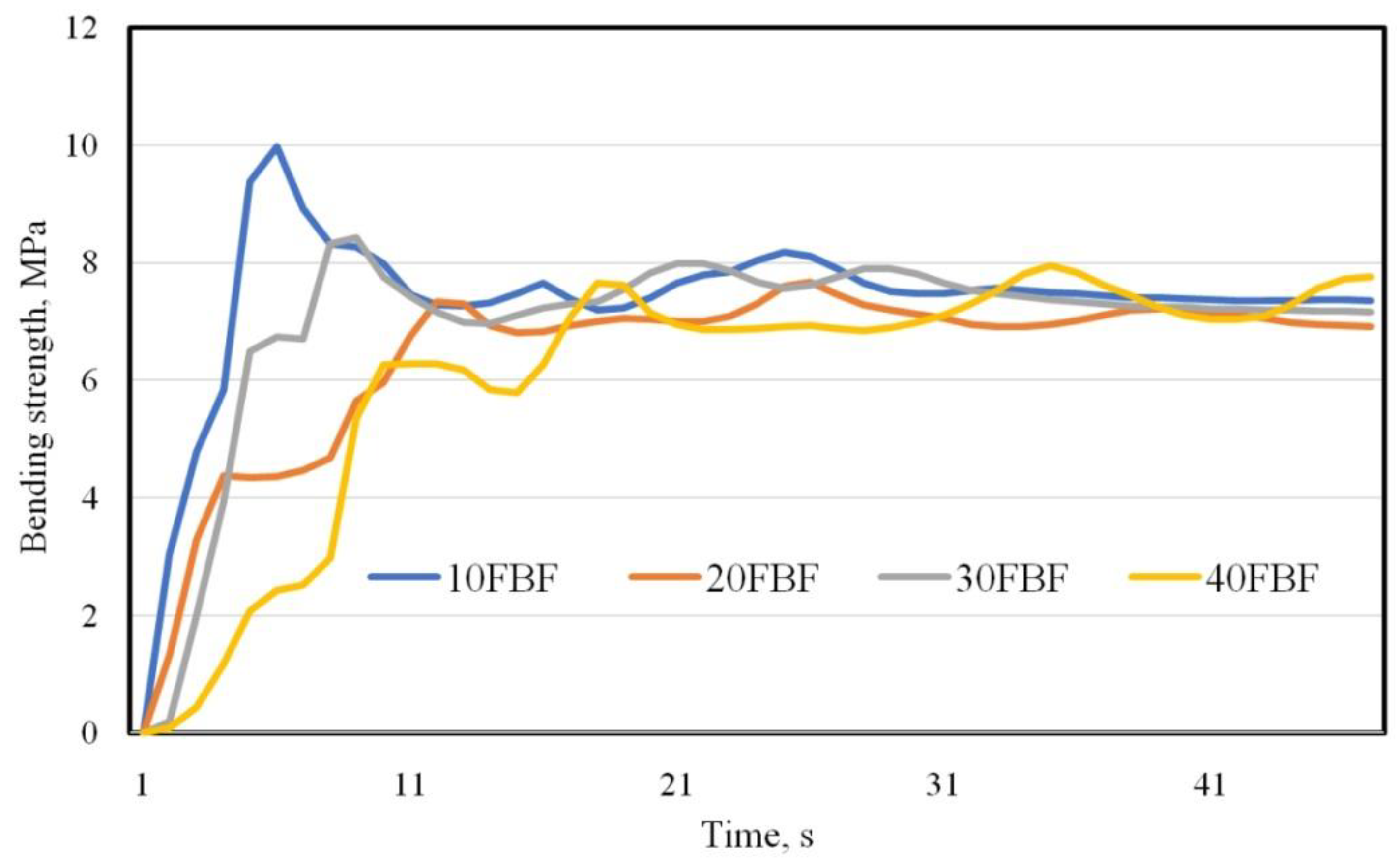

3.3. Three-Point Bending Test

4. Conclusions

- The mechanical properties of chopped FBF-reinforced PP composites were enhanced by the Aloe Vera treatment.

- The maximum bending strength was recorded at about 12.1 MPa for the Aloe Vera-treated chopped FBF-reinforced PP composite with 30 wt.% of FBF. The maximum bending strength of about 9.9 MPa for untreated composites was recorded for the composite with 10 wt.% of FBF.

- The maximum impact energy (about 60.6 J) was recorded for the Aloe Vera-treated composite containing 30 wt.% of FBF. For the non-Aloe Vera-treated composite with the same FBF content, the impact energy was about twice as low (31.59 J).

- The maximum average compressive strength (about 17.19 MPa) was found for specimen of Aloe Vera gel-treated composite containing 30 wt.% of FBF.

- When the FBF content increases, the mechanical properties of the Aloe Vera-treated FBFRPP composites increase until a chopped FBF content of 30 wt.% is reached, but beyond an FBF content of 30 wt.%, the mechanical properties decrease. This implies that the fibre weight fraction truly affects the mechanical properties of the composites tested.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Aboudi, J.; Arnold, S.; Bednarczyk, B. Micromechanics of Composite Materials: A Generalized Multiscale Analysis Approach, 1st ed.; Academic Press: Cambridge, MA, USA, 2013. [Google Scholar]

- Campbell, F.C. Chapter 1: Introduction to Composite Materials. In Structural Composite Materials; ASM International: Detroit, MI, USA, 2010. [Google Scholar]

- Mallick, P.K. Fibre Reinforced Composite, Material and Manufacturing Design, 3rd ed.; University of Michigan: Deaborn, MI, USA, 2007. [Google Scholar]

- Trzepieciński, T.; Najm, S.M.; Pepelnjak, T.; Bensaid, K.; Szpunar, M. Incremental Sheet Forming of Metal-Based Composites Used in Aviation and Automotive Applications. J. Compos. Sci. 2022, 6, 295. [Google Scholar] [CrossRef]

- Trzepieciński, T.; Najm, S.M.; Sbayti, M.; Belhadjsalah, H.; Szpunar, M.; Lemu, H.G. New Advances and Future Possibilities in Forming Technology of Hybrid Metal-Polymer Composites Used in Aerospace Applications. J. Compos. Sci. 2021, 5, 217. [Google Scholar] [CrossRef]

- Japan Polypropylene’s Polypropylene Manufacturing Technology. 2017. Available online: https://www.m-chemical.co.jp/en/petrochem-license/technologies/pdf/Introduction_JPP_Polypropylene_Process.pdf (accessed on 5 May 2023).

- Natural Composite Products. Available online: http://www.archidemat.com/naturalne-wyroby-kompozytowe/ (accessed on 11 May 2023).

- Janowski, G.; Frącz, W.; Bąk, Ł.; Trzepieciński, T. The Effect of the Extrusion Method on Processing and Selected Properties of Poly(3-hydroxybutyric-co-3-hydroxyvaleric Acid)-Based Biocomposites with Flax and Hemp Fibers. Polymers 2022, 14, 5370. [Google Scholar] [CrossRef] [PubMed]

- Mizera, Č.; Herák, D.; Müller, M.; Hrabě, P. Mechanical behaviour of polymeric composite with fibres of false banana (Ensete ventricosum). Agron. Res. 2015, 13, 680–689. [Google Scholar]

- Getu, A. Process Ability Enhancement of False Banana Fiber. Master’s Thesis, Bahir Dar University, Bahir Dar, Ethiopia, 2012. [Google Scholar]

- Chomsa, M.D. In Vitro Propagation of Enset (Ensete Ventricosum (Welw.) Cheesman). Master’s Thesis, University of Natal, Pietermaritzburg, South Africa, 2003. [Google Scholar]

- Ketema, S. Investigating the Mechanical Properties of False Banana Fiber Reinforced Polypropylene Composite for Panel Application. Master’s Thesis, Bahir Dar University, Bahir Dar, Ethiopia, 2021. [Google Scholar]

- Berhanu, H.; Kiflie, Z.; Miranda, I.; Lourenço, A.; Ferreira, J.; Feleke, S.S.; Yimam, A.; Pereira, H. Characterization of crop residues from false banana /Ensete ventricosum/ in Ethiopia in view of a full-resource valorization. PLoS ONE 2018, 13, e0199422. [Google Scholar] [CrossRef]

- Gairola, S.P.; Tyagi, Y.; Gupta, N. Mechanical properties evaluation of banana fibre reinforced polymer composites: A review. Acta Innov. 2022, 42, 59–70. [Google Scholar] [CrossRef]

- Mizera, Č.; Herák, D.; Hrabe, P.; Muller, M.; Kabutey, A. Effect of length of false banana fibers /Ensete ventricosum/ on mechanical behavior under tensile loading. Sci. Agric. Bohem. 2016, 47, 90–96. [Google Scholar]

- Mizera, Č.; Hrabě, P.; Müller, M.; Herák, D. Creep behaviour of the polymer composite with false banana’s fibres (Ensete Ventricosum). Manuf. Technol. 2016, 16, 188–192. [Google Scholar] [CrossRef]

- Godara, S. Effect of chemical modification of fiber surface on natural fiber composites: A review. Mater. Today Proc. 2019, 18, 3428–3434. [Google Scholar]

- Li, X.; Tabil, L.G.; Panigrahi, S. Chemical treatments of natural fibre for use in natural fibre-reinforced composites: A review. J. Polym. Environ. 2007, 15, 25–33. [Google Scholar] [CrossRef]

- Chandekar, H.; Chaudhari, V.; Waigaonkar, S. A review of jute fiber reinforced polymer composites. Mater. Today Proc. 2020, 26, 2079–2082. [Google Scholar] [CrossRef]

- Adeniyi, A.G.; Onifade, D.V.; Ighalo, J.O.; Adeoye, A.S. A review of coir fiber reinforced polymer composites. Compos. Part B Eng. 2019, 176, 107305. [Google Scholar] [CrossRef]

- Siddique, S.H.; Faisal, S.; Zahid, B.; Wang, C. Tensile properties of bagasse fiber composites. Mehran Univ. Res. J. Eng. Technol. 2021, 40, 502–511. [Google Scholar] [CrossRef]

- Senthilkumar, K.; Saba, N.; Rajini, N.; Chandrasekar, M.; Jawaid, M.; Siengchin, S.; Alotman, O.Y. Mechanical properties evaluation of sisal fibre reinforced polymer composites: A review. Constr. Build. Mater. 2018, 174, 713–729. [Google Scholar] [CrossRef]

- Daniel-Mkpume, C.C.; Ugochukwu, C.; Okonkwo, E.G.; Fayomi, O.S.I.; Obiorah, S.M. Effect of Luffa cylindrica fiber and particulate on the mechanical properties of epoxy. Int. J. Adv. Manuf. Technol. 2019, 102, 3439–3444. [Google Scholar] [CrossRef]

- Rokbi, M.; Osmani, H.; Imad, A.; Benseddiq, N. Effect of chemical treatment on flexure properties of natural fibre-reinforced polyester composite. Procedia Eng. 2011, 10, 2092–2097. [Google Scholar] [CrossRef]

- Asmelash, T.G. The types of aloe species and their multi-function in southern Ethiopia the cases of hammer district. Int. J. Environ. Sci. Nat. Resour. 2017, 3, 555619. [Google Scholar]

- Barbosa, R.; Villarreal, A.; Rodriguez, C.; De Leon, H.; Gilkerson, R.; Lozano, K. Aloe Vera extract-based composite nanofibers for wound dressing applications. Mater. Sci. Eng. C 2021, 124, 112061. [Google Scholar] [CrossRef]

- Chaitanya, S.; Singh, I. Novel Aloe Vera fiber reinforced biodegradable composites—Development and characterization. J. Reinf. Plast. Compos. 2016, 36, 1411–1423. [Google Scholar] [CrossRef]

- Narendiranath, B.T.; Tarun, K.S.; Bandaru, S.; Vattikuti, M. Comparative study on orientation of fibers in epoxy composites reinforced with aloe-vera and palmyra fibers. Int. J. Mech. Eng. Technol. 2018, 9, 747–760. [Google Scholar]

- Hadi, A.; Nawab, A.; Alam, F.; Zehra, K. Sustainable food packaging films based on alginate and aloe vera. Polym. Eng. Sci. 2022, 62, 2111–2118. [Google Scholar] [CrossRef]

- ASTM D695–15; Standard Test Method for Compressive Properties of Rigid Plastics. ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM D 7264/D 7264M-07; Standard Test Method for Flexural Properties of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2015.

- Kabir, M.L.; Wang, H.; Lau, K.Y.; Cardona, F. Chemical treatments on plant-based natural fibre reinforced polymer composites: An overview. Compos. Part B Eng. 2012, 43, 2883–2892. [Google Scholar] [CrossRef]

- Sullins, T.; Pillay, S.; Komus, A.; Ning, H. Hemp fiber reinforced polypropylene composites: The effects of material treatments. Compos. Part B Eng. 2017, 114, 15–22. [Google Scholar] [CrossRef]

- Müller, M.; Valášek, P.; Ruggiero, A. Strength characteristics of untreated short-fibre composites from the plant Ensete ventricosum. BioResources 2017, 12, 255–269. [Google Scholar] [CrossRef]

- Chandramohan, D.; Kumar, A.J.P. Experimental data on the properties of natural fibre particle reinforced polymer composite material. Data Brief 2017, 13, 460–468. [Google Scholar] [CrossRef] [PubMed]

- Gebre, T.; Raj, J. Fabrication and study of mechanical properties for false banana and bamboo fibers reinforced bio-composites. Int. J. Adv. Res. Sci. Eng. 2016, 5, 338–351. [Google Scholar]

| Specimen Type | Content, wt.% | |

|---|---|---|

| PP | FBF | |

| 10FBF | 90 | 10 |

| 20FBF | 80 | 20 |

| 30FBF | 70 | 30 |

| 40FBF | 60 | 40 |

| Specimen Type | Average Impact Energy, J | Advantage of Aloe Vera Treatment over Non-Treatment with Respect to the Increase in Impact Energy | |

|---|---|---|---|

| Aloe Vera-Treated FBF | FBF Treated Only with NaOH and Acetic Acid | ||

| 10FBF | 40.34 | 28.01 | 44% greater |

| 20FBF | 53.59 | 34.10 | 57.15% greater |

| 30FBF | 60.58 | 31.59 | 91.77% greater |

| 40FBF | 52.58 | 21.97 | 142.5% grater |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shimels, H.G.; Ketema, S.; Trzepieciński, T.; Batu, T. Experimental Investigation of Aloe Vera-Treated False Banana (Ensete Ventricosum) Fibre-Reinforced Polypropylene Composite. J. Compos. Sci. 2023, 7, 288. https://doi.org/10.3390/jcs7070288

Shimels HG, Ketema S, Trzepieciński T, Batu T. Experimental Investigation of Aloe Vera-Treated False Banana (Ensete Ventricosum) Fibre-Reinforced Polypropylene Composite. Journal of Composites Science. 2023; 7(7):288. https://doi.org/10.3390/jcs7070288

Chicago/Turabian StyleShimels, Hailu G., Sisay Ketema, Tomasz Trzepieciński, and Temesgen Batu. 2023. "Experimental Investigation of Aloe Vera-Treated False Banana (Ensete Ventricosum) Fibre-Reinforced Polypropylene Composite" Journal of Composites Science 7, no. 7: 288. https://doi.org/10.3390/jcs7070288

APA StyleShimels, H. G., Ketema, S., Trzepieciński, T., & Batu, T. (2023). Experimental Investigation of Aloe Vera-Treated False Banana (Ensete Ventricosum) Fibre-Reinforced Polypropylene Composite. Journal of Composites Science, 7(7), 288. https://doi.org/10.3390/jcs7070288