From Waste to Strength: Unveiling the Mechanical Properties of Peanut-Shell-Based Polymer Composites

Abstract

:1. Introduction

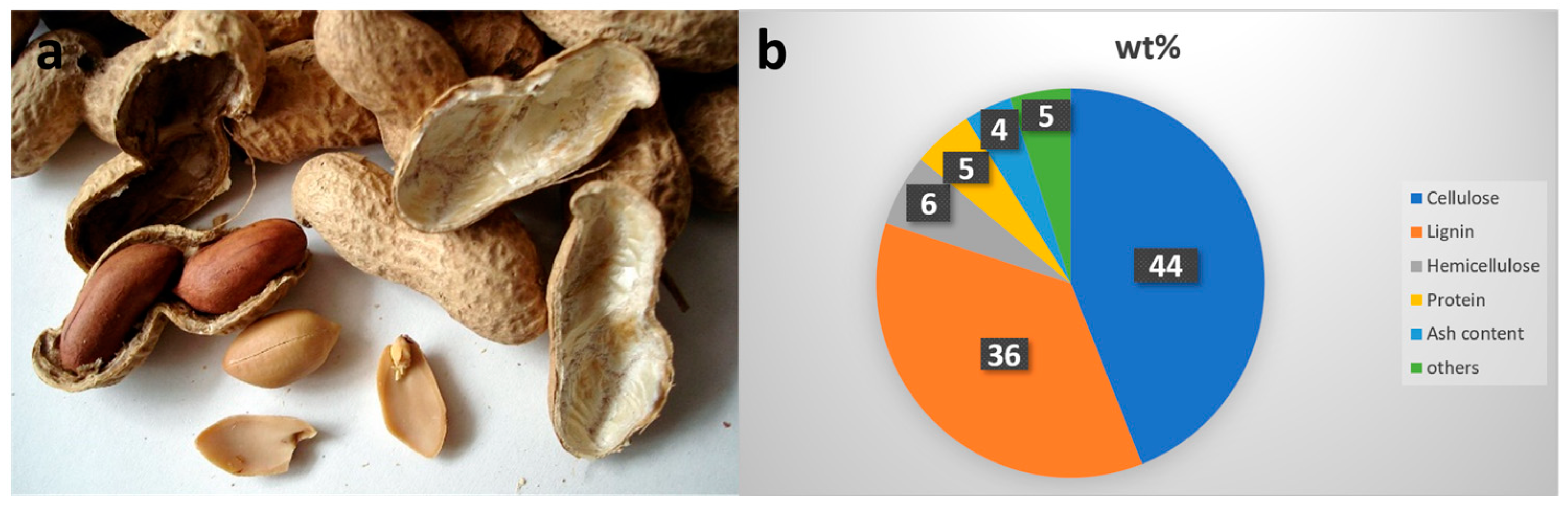

2. Composition of Peanut Shell

3. Preparation of Peanut Shell Powder

4. Various Extracts of Peanut Shell

4.1. Synthesis of Peanut Shell Fiber

4.2. Synthesis of Biocarbon

4.3. Synthesis of Peanut Shell Ash

4.4. Synthesis of Cellulose

5. Preparation of PSP-Reinforced Polymer Composites

5.1. PSP-Reinforced Thermoplastic Composites

5.2. PSP-Reinforced Thermosetting Composites

6. Preparation of PSP-Derived Biocarbon-Reinforced Polymer Composites

7. Mechanical Properties

8. Biodegradability

9. Current Challenges and Future Directions

10. Potential Applications

11. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hsissou, R.; Seghiri, R.; Benzekri, Z.; Hilali, M.; Ra, M.; Elhar, A. Polymer composite materials: A comprehensive review. Compos. Struct. 2021, 262, 113640. [Google Scholar] [CrossRef]

- Tien, H.; Kuan, N.; Tan, M.Y.; Shen, Y.; Yahya, M.Y. Mechanical properties of particulate organic natural filler-reinforced polymer composite: A review. Compos. Adv. Mater. 2021, 30, 26349833211007502. [Google Scholar] [CrossRef]

- Khan, M.Z.R.; Srivastava, S.K.; Gupta, M.K. Tensile and flexural properties of natural fiber reinforced polymer composites: A review. J. Reinf. Plast. Compos. 2018, 37, 1435–1455. [Google Scholar] [CrossRef]

- Valino, A.D.; Dizon, J.R.C.; Espera, A.H.; Chen, Q.; Messman, J.; Advincula, R.C. Advances in 3D printing of thermoplastic polymer composites and nanocomposites. Prog. Polym. Sci. 2019, 98, 101162. [Google Scholar] [CrossRef]

- Chandra Dubey, S.; Mishra, V.; Sharma, A. A review on polymer composite with waste material as reinforcement. Mater. Today Proc. 2021, 47, 2846–2851. [Google Scholar] [CrossRef]

- Sun, X.; Sun, H.; Li, H.; Peng, H. Developing polymer composite materials: Carbon nanotubes or graphene? Adv. Mater. 2013, 25, 5153–5176. [Google Scholar] [CrossRef]

- Ravishankar, B.; Nayak, S.K.; Kader, M.A. Hybrid composites for automotive applications—A review. J. Reinf. Plast. Compos. 2019, 38, 835–845. [Google Scholar] [CrossRef]

- Parveez, B.; Kittur, M.I.; Badruddin, I.A.; Kamangar, S.; Hussien, M.; Umarfarooq, M.A. Scientific Advancements in Composite Materials for Aircraft Applications: A Review. Polymers 2022, 14, 5007. [Google Scholar] [CrossRef]

- Soutis, C. Aerospace Engineering Requirements in Building with Composites; Elsevier Ltd.: Oxford, UK, 2019; ISBN 9780081026793. [Google Scholar]

- Khalid, M.Y.; Arif, Z.U.; Ahmed, W.; Arshad, H. Evaluation of tensile properties of fiber metal laminates under different strain rates. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2022, 236, 556–564. [Google Scholar] [CrossRef]

- Kumar Sharma, A.; Bhandari, R.; Sharma, C.; Krishna Dhakad, S.; Pinca-Bretotean, C. Polymer matrix composites: A state of art review. Mater. Today Proc. 2022, 57, 2330–2333. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, X.; Fang, Z.; Huang, Y.; Xu, H.; Liu, Y.; Wu, D.; Zhuang, J.; Sun, J. Recent advances in preparation, mechanisms, and applications of thermally conductive polymer composites: A review. J. Compos. Sci. 2020, 4, 180. [Google Scholar] [CrossRef]

- Rajak, D.K.; Pagar, D.D.; Kumar, R.; Pruncu, C.I. Recent progress of reinforcement materials: A comprehensive overview of composite materials. J. Mater. Res. Technol. 2019, 8, 6354–6374. [Google Scholar] [CrossRef]

- Okan, M.; Aydin, H.M.; Barsbay, M. Current approaches to waste polymer utilization and minimization: A review. J. Chem. Technol. Biotechnol. 2019, 94, 8–21. [Google Scholar] [CrossRef] [Green Version]

- Khalid, M.Y.; Arif, Z.U.; Hossain, M.; Umer, R. Recycling of wind turbine blades through modern recycling technologies: A road to zero waste. Renew. Energy Focus 2023, 44, 373–389. [Google Scholar] [CrossRef]

- Mandala, R.; Bannoth, A.P.; Akella, S.; Rangari, V.K.; Kodali, D. A short review on fused deposition modeling 3D printing of bio-based polymer nanocomposites. J. Appl. Polym. Sci. 2022, 139, 51904. [Google Scholar] [CrossRef]

- Nagarajan, K.J.; Balaji, A.N.; Basha, K.S.; Ramanujam, N.R.; Kumar, R.A. International Journal of Biological Macromolecules Effect of agro waste α-cellulosic micro fi ller on mechanical and thermal behavior of epoxy composites. Int. J. Biol. Macromol. 2020, 152, 327–339. [Google Scholar] [CrossRef]

- Afolalu, S.A.; Salawu, E.Y.; Ogedengbe, T.S.; Joseph, O.O.; Okwilagwe, O.; Emetere, M.E.; Yusuf, O.O.; Noiki, A.; Akinlabi, S. Bio-Agro Waste Valorization and its Sustainability in the Industry: A Review. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1107, 012140. [Google Scholar] [CrossRef]

- Khieng, T.K.; Debnath, S.; Ting Chaw Liang, E.; Anwar, M.; Pramanik, A.; Basak, A.K. A review on mechanical properties of natural fibre reinforced polymer composites under various strain rates. J. Compos. Sci. 2021, 5, 130. [Google Scholar] [CrossRef]

- Arzumanova, N.B. Polymer biocomposites based on agro waste: Part iii. shells of various nuts as natural filler for polymer composites. New Mater. Compd. Appl. 2021, 5, 19–44. [Google Scholar]

- Pradhan, S.; Prakash, V.; Acharya, S.K. Bio waste (Pistacia vera nut shell) filled polymer composites for tribological applications. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2021, 236, 334–344. [Google Scholar] [CrossRef]

- Liminana, P.; Garcia-Sanoguera, D.; Quiles-Carrillo, L.; Balart, R.; Montanes, N. Development and characterization of environmentally friendly composites from poly(butylene succinate) (PBS) and almond shell flour with different compatibilizers. Compos. Part B Eng. 2018, 144, 153–162. [Google Scholar] [CrossRef]

- Jose, A.S.; Athijayamani, A.; Jani, S.P. A review on the mechanical properties of bio waste particulate reinforced polymer composites. Mater. Today Proc. 2020, 37, 1757–1760. [Google Scholar] [CrossRef]

- Suhot, M.A.; Hassan, M.Z.; Aziz, S.A.; Md Daud, M.Y. Recent progress of rice husk reinforced polymer composites: A review. Polymers 2021, 13, 2391. [Google Scholar] [CrossRef]

- Jagadeesh, P.; Puttegowda, M.; Thyavihalli Girijappa, Y.G.; Rangappa, S.M.; Siengchin, S. Effect of natural filler materials on fiber reinforced hybrid polymer composites: An Overview. J. Nat. Fibers 2022, 19, 4132–4147. [Google Scholar] [CrossRef]

- Zhang, Q.; Cai, H.; Yi, W.; Lei, H.; Liu, H.; Wang, W.; Ruan, R. Biocomposites from Organic Solid Wastes Derived. Materials 2020, 13, 3923. [Google Scholar] [CrossRef] [PubMed]

- Laxmi, S.; Sahu, R.M.; Kumar, T. Groundnut benefits: Trend and growth situation in Madhyapradesh, India. Plant Arch. 2019, 19, 2753–2758. [Google Scholar]

- USDA’s Foreign Agricultural Service. Available online: https://www.fas.usda.gov/ (accessed on 1 July 2023).

- Sorita, G.D.; Leimann, F.V.; Ferreira, S.R.S. Biorefinery approach: Is it an upgrade opportunity for peanut by-products? Trends Food Sci. Technol. 2020, 105, 56–69. [Google Scholar] [CrossRef]

- Perea-Moreno, M.A.; Manzano-Agugliaro, F.; Hernandez-Escobedo, Q.; Perea-Moreno, A.J. Peanut shell for energy: Properties and its potential to respect the environment. Sustainability 2018, 10, 3254. [Google Scholar] [CrossRef] [Green Version]

- Xu, Z.; Xiao, X.; Fang, P.; Ye, L.; Huang, J.; Wu, H.; Tang, Z.; Chen, D. Comparison of combustion and pyrolysis behavior of the peanut shells in air and N2: Kinetics, thermodynamics and gas emissions. Sustainability 2020, 12, 464. [Google Scholar] [CrossRef] [Green Version]

- Yin, L.; Hu, Q.; Mondal, S.; Xu, J.; Ouyang, G. Peanut shell-derived biochar materials for effective solid-phase microextraction of polycyclic aromatic hydrocarbons in environmental waters. Talanta 2019, 202, 90–95. [Google Scholar] [CrossRef]

- Shahi, N.; Wang, P.; Adhikari, S.; Min, B.; Rangari, V.K. Biopolymers Fractionation and Synthesis of Nanocellulose/Silica Nanoparticles from Agricultural Byproducts. ACS Sustain. Chem. Eng. 2021, 9, 6284–6295. [Google Scholar] [CrossRef]

- Hou, C.T.; Shaw, J.F. Biocatalysis and agricultural biotechnology. Biocatal. Agric. Biotechnol. 2009, 20, 1–407. [Google Scholar] [CrossRef]

- Ge, S.; Wu, Y.; Peng, W.; Xia, C.; Mei, C.; Cai, L.; Shi, S.Q.; Sonne, C.; Lam, S.S.; Tsang, Y.F. High-pressure CO2 hydrothermal pretreatment of peanut shells for enzymatic hydrolysis conversion into glucose. Chem. Eng. J. 2020, 385, 123949. [Google Scholar] [CrossRef]

- Nwaze, I.O.; Akubueze, E.U. Suitability of Groundnut Shells for Bioethanol Production using Saccharomyces cerevisae. J. Mater. Sci. Res. Rev. 2023, 11, 34–39. [Google Scholar]

- Kim, M.; Lee, D.J.; Jung, S.; Chang, S.X.; Lin, K.Y.A.; Bhatnagar, A.; Kwon, E.E.; Tsang, Y.F. Valorization of peanut wastes into a catalyst in production of biodiesel. Int. J. Energy Res. 2022, 46, 1299–1312. [Google Scholar] [CrossRef]

- Gupta, A.D. Extraction of Cellulose and Biofuel Production From Groundnut Shells and Its Application To Increase Crop Yield. World J. Pharm. Pharm. Sci. 2017, 6, 1820–1831. [Google Scholar] [CrossRef] [Green Version]

- Yallappa, S.; Deepthi, D.R.; Yashaswini, S.; Hamsanandini, R.; Chandraprasad, M.; Ashok Kumar, S.; Hegde, G. Natural biowaste of Groundnut shell derived nano carbons: Synthesis, characterization and itsin vitro antibacterial activity. Nano-Struct. Nano-Objects 2017, 12, 84–90. [Google Scholar] [CrossRef]

- Yaro, S.A.; Olajide, O.S.; Asuke, F.; Popoola, A.P.I. Synthesis of groundnut shell nanoparticles: Characterization and particle size determination. Int. J. Adv. Manuf. Technol. 2017, 91, 1111–1116. [Google Scholar] [CrossRef]

- Kouadri, I.; Seghir, B.B.; Hemmami, H.; Zeghoud, S. Extraction of Silica from Different Sources of Agricultural Waste. Asian J. Res. Chem. 2023, 16, 98–102. [Google Scholar] [CrossRef]

- Sareena, C.; Sreejith, M.P.; Ramesan, M.T.; Purushothaman, E. Biodegradation behaviour of natural rubber composites reinforced with natural resource fillers—Monitoring by soil burial test. J. Reinf. Plast. Compos. 2014, 33, 412–429. [Google Scholar] [CrossRef]

- Maleki, S.S.; Mohammadi, K.; Ji, K.S. Characterization of Cellulose Synthesis in Plant Cells. Sci. World J. 2016, 2016, 8641373. [Google Scholar] [CrossRef] [Green Version]

- Liu, R.; Liu, G.; Yousaf, B.; Abbas, Q. Operating conditions-induced changes in product yield and characteristics during thermal-conversion of peanut shell to biochar in relation to economic analysis. J. Clean. Prod. 2018, 193, 479–490. [Google Scholar] [CrossRef]

- Usman, M.A.; Momohjimoh, I.; Gimba, A.S.B. Effect of Groundnut Shell Powder on the Mechanical Properties of Recycled Polyethylene and Its Biodegradability. J. Miner. Mater. Charact. Eng. 2016, 04, 228–240. [Google Scholar] [CrossRef] [Green Version]

- Usman, M.A.; Momohjimoh, I.; Usman, A.O. Mechanical, physical and biodegradability performances of treated and untreated groundnut shell powder recycled polypropylene composites. Mater. Res. Express 2020, 7, 035302. [Google Scholar] [CrossRef]

- Jacob, J.; Mamza, P.A.; Ahmed, A.S.; Yaro, S.A. Effect of groundnut shell powder on the viscoelastic properties of recycled high density polyethylene composites. Bayero J. Pure Appl. Sci. 2018, 11, 139–144. [Google Scholar]

- Jacob, J.; Mamza, P.A.P.; Ahmed, A.S.; Yaro, S.A. Mechanical and Dynamic Mechanical Characterization of Groundnut Shell Powder Filled Recycled High Density Polyethylene Composites. Sci. World J. 2019, 14, 92–97. [Google Scholar]

- Zaaba, N.F.; Ismail, H.; Jaafar, M. The effects of modifying peanut shell powder with polyvinyl alcohol on the properties of recycled polypropylene and peanut shell powder composites. BioResources 2014, 9, 2128–2142. [Google Scholar] [CrossRef] [Green Version]

- Zaaba, N.F.; Ismail, H. Comparative study of irradiated and non-irradiated recycled polypropylene/peanut shell powder composites under the effects of natural weathering degradation. BioResources 2018, 13, 487–505. [Google Scholar] [CrossRef]

- Zaaba, N.F.; Ismail, H. The Influence of Different Compounding Sequence and Peanut Shell Powder Loading on Properties of Polylactic Acid/Thermoplastic Corn Starch Biocomposites. J. Vinyl Addit. Technol. 2020, 26, 413–422. [Google Scholar] [CrossRef]

- Chamaiporn Yamoum, R.M. Effect of Peanut Shell Content on Mechanical, Thermal, and Biodegradable Properties of Peanut Shell/Polylactic Acid Biocomposites. Polym. Compos. 2015, 38, 682–690. [Google Scholar] [CrossRef]

- Fadhil, H. Flexural and Impact Properties of Epoxy Composites Reinforced with Peanut Shell Particles. Eng. Technol. J. 2020, 38, 1026–1033. [Google Scholar] [CrossRef]

- Prabhakar, M.N.; Shah, A.U.R.; Rao, K.C.; Song, J. Il Mechanical and thermal properties of epoxy composites reinforced with waste peanut shell powder as a bio-filler. Fibers Polym. 2015, 16, 1119–1124. [Google Scholar] [CrossRef]

- Sareena, C.; Ramesan, M.T.; Purushothaman, E. Utilization of Peanut Shell Powder as a Novel Filler in Natural Rubber. J. Appl. Polym. Sci. 2012, 125, 2322–2334. [Google Scholar] [CrossRef]

- Chatterjee, A.; Singh, H. Development and Characterization of Peanut Shell Flour–Polypropylene Composite. J. Inst. Eng. Ser. D 2019, 100, 147–153. [Google Scholar] [CrossRef]

- Bai, S.; Wang, T.; Tian, Z.; Cao, K.; Li, J. Facile preparation of porous biomass charcoal from peanut shell as adsorbent. Sci. Rep. 2020, 10, 147–153. [Google Scholar] [CrossRef] [PubMed]

- Wu, M.F.; Hsiao, C.H.; Lee, C.Y.; Tai, N.H. Flexible Supercapacitors Prepared Using the Peanut-Shell-Based Carbon. ACS Omega 2020, 5, 14417–14426. [Google Scholar] [CrossRef]

- Khalid, M.Y.; Arif, Z.U. Novel biopolymer-based sustainable composites for food packaging applications: A narrative review. Food Packag. Shelf Life 2022, 33, 100892. [Google Scholar] [CrossRef]

- Adeosun, S.; Taiwo, O.; Akpan, E.; Gbenebor, O.; Gbagba, S.; Olaleye, S. Mechanical characteristics of groundnut shell particle reinforced polylactide nano fibre. Rev. Mater. 2016, 21, 482–491. [Google Scholar] [CrossRef] [Green Version]

- Fang, Z.; Gao, Y.; Bolan, N.; Shaheen, S.M.; Xu, S.; Wu, X.; Xu, X.; Hu, H.; Lin, J.; Zhang, F.; et al. Conversion of biological solid waste to graphene-containing biochar for water remediation: A critical review. Chem. Eng. J. 2020, 390, 124611. [Google Scholar] [CrossRef]

- Dhyani, V.; Bhaskar, T. A comprehensive review on the pyrolysis of lignocellulosic biomass. Renew. Energy 2018, 129, 695–716. [Google Scholar] [CrossRef]

- Jirimali, H.; Singh, J.; Boddula, R.; Lee, J.-K.; Singh, V. Nano-Structured Carbon: Its Synthesis from Renewable Agricultural Sources and Important Applications. Materials 2022, 15, 3969. [Google Scholar] [CrossRef]

- Gürkan, E.H.; İlyas, B. Adsorption of copper, and zinc onto novel Ca- alginate-biochar composite prepared by biochars produced from pyrolysis of groundnut husk. Int. J. Phytoremediat. 2022, 24, 1350–1363. [Google Scholar] [CrossRef]

- Hu, X.; Gholizadeh, M. Biomass pyrolysis: A review of the process development and challenges from initial researches up to the commercialisation stage. J. Energy Chem. 2019, 39, 109–143. [Google Scholar] [CrossRef] [Green Version]

- SriBala, G.; Carstensen, H.H.; Van Geem, K.M.; Marin, G.B. Measuring Biomass Fast Pyrolysis Kinetics: State of the Art. Wiley Interdiscip. Rev. Energy Environ. 2019, 8, e326. [Google Scholar] [CrossRef]

- Varma, A.K.; Singh, S.; Rathore, A.K.; Thakur, L.S.; Shankar, R.; Mondal, P. Investigation of kinetic and thermodynamic parameters for pyrolysis of peanut shell using thermogravimetric analysis. Biomass Convers. Biorefinery 2022, 12, 4877–4888. [Google Scholar] [CrossRef]

- Jung, K.W.; Hwang, M.J.; Ahn, K.H.; Ok, Y.S. Kinetic study on phosphate removal from aqueous solution by biochar derived from peanut shell as renewable adsorptive media. Int. J. Environ. Sci. Technol. 2015, 12, 3363–3372. [Google Scholar] [CrossRef] [Green Version]

- Pawar, A.; Panwar, N.L. Experimental investigation on biochar from groundnut shell in a continuous production system. Biomass Convers. Biorefin. 2022, 12, 1093–1103. [Google Scholar] [CrossRef]

- Picard, M.; Thakur, S.; Misra, M.; Mielewski, D.F.; Mohanty, A.K. Biocarbon from peanut hulls and their green composites with biobased poly(trimethylene terephthalate) (PTT). Sci. Rep. 2020, 10, 3310. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Aryee, A.A.; Mpatani, F.M.; Kani, A.N.; Dovi, E.; Han, R.; Li, Z.; Qu, L. A review on functionalized adsorbents based on peanut husk for the sequestration of pollutants in wastewater: Modification methods and adsorption study. J. Clean. Prod. 2021, 310, 127502. [Google Scholar] [CrossRef]

- González-García, P. Activated carbon from lignocellulosics precursors: A review of the synthesis methods, characterization techniques and applications. Renew. Sustain. Energy Rev. 2018, 82, 1393–1414. [Google Scholar] [CrossRef]

- Bedane, A.H.; Guo, T.X.; Eić, M.; Xiao, H. Adsorption of volatile organic compounds on peanut shell activated carbon. Can. J. Chem. Eng. 2019, 97, 238–246. [Google Scholar] [CrossRef] [Green Version]

- Guo, F.; Jiang, X.; Li, X.; Peng, K.; Guo, C.; Rao, Z. Carbon electrode material from peanut shell by one-step synthesis for high performance supercapacitor. J. Mater. Sci. Mater. Electron. 2019, 30, 914–925. [Google Scholar] [CrossRef]

- Xiao, Z.; Chen, W.; Liu, K.; Cui, P.; Zhan, D. Porous biomass carbon derived from peanut shells as electrode materials with enhanced electrochemical performance for supercapacitors. Int. J. Electrochem. Sci. 2018, 13, 5370–5381. [Google Scholar] [CrossRef]

- Nuilek, K.; Simon, A.; Baumli, P. Influence of KOH on the carbon nanostructure of peanut shell. Resolut. Discov. 2018, 3, 29–32. [Google Scholar] [CrossRef]

- Jiang, X.; Guo, F.; Jia, X.; Liang, S.; Peng, K.; Qian, L. Synthesis of biomass-based porous graphitic carbon combining chemical treatment and hydrothermal carbonization as promising electrode materials for supercapacitors. Ionics 2020, 26, 3655–3668. [Google Scholar] [CrossRef]

- Muthu Balasubramanian, M.; Subramani, M.; Murugan, D.; Ponnusamy, S. Groundnut shell–derived porous carbon-based supercapacitor with high areal mass loading using carbon cloth as current collector. Ionics 2020, 26, 6297–6308. [Google Scholar] [CrossRef]

- Lv, W.; Wen, F.; Xiang, J.; Zhao, J.; Li, L.; Wang, L.; Liu, Z.; Tian, Y. Peanut shell derived hard carbon as ultralong cycling anodes for lithium and sodium batteries. Electrochim. Acta 2015, 176, 533–541. [Google Scholar] [CrossRef]

- Tomul, F.; Arslan, Y.; Kabak, B.; Trak, D.; Kendüzler, E.; Lima, E.C.; Tran, H.N. Peanut shells-derived biochars prepared from different carbonization processes: Comparison of characterization and mechanism of naproxen adsorption in water. Sci. Total Environ. 2020, 726, 137828. [Google Scholar] [CrossRef]

- Alshabib, M.; Oluwadamilare, M.A.; Tanimu, A.; Abdulazeez, I.; Alhooshani, K.; Ganiyu, S.A. Experimental and DFT investigation of ceria-nanocomposite decorated AC derived from groundnut shell for efficient removal of methylene-blue from wastewater effluent. Appl. Surf. Sci. 2021, 536, 147749. [Google Scholar] [CrossRef]

- Sujatha, E.R.; Dharini, K.; Bharathi, V. Influence of groundnut shell ash on strength and durability properties of clay. Geomech. Geoengin. 2016, 11, 20–27. [Google Scholar] [CrossRef]

- Lakshumu Naidu, A.; Kona, S. Experimental Study of the Mechanical Properties of Banana Fiber and Groundnut Shell Ash Reinforced Epoxy Hybrid Composite. Int. J. Eng. Trans. A Basics 2018, 31, 659–665. [Google Scholar] [CrossRef]

- Bano, S.; Negi, Y.S. Studies on cellulose nanocrystals isolated from groundnut shells. Carbohydr. Polym. 2017, 157, 1041–1049. [Google Scholar] [CrossRef]

- Liu, X.; Dong, H.Z.; Hou, H.X. Preparation and characterization of cellulose nanocrystals from peanut shells. Mod. Food Sci. Technol. 2015, 31, 466–473. [Google Scholar] [CrossRef]

- Jayaraj, K.; Christy, J.S.; Pius, A. Green Composite Film for Food Packaging Applications. Adv. Appl. Math. Sci. 2020, 20, 245–260. [Google Scholar]

- Punnadiyil, R.K.; Sreejith, M.P.; Purushothaman, E. Isolation of microcrystalline and nano cellulose from peanut shells. J. Chem. Pharm. Sci. 2016, 974, 2115. [Google Scholar]

- Das, C.; Tamrakar, S.; Kiziltas, A.; Xie, X. Incorporation of biochar to improve mechanical, thermal and electrical properties of polymer composites. Polymers 2021, 13, 2663. [Google Scholar] [CrossRef]

- Obasi, H.C. Peanut Husk Filled Polyethylene Composites: Effects of Filler Content and Compatibilizer on Properties. J. Polym. 2015, 2015, 189289. [Google Scholar] [CrossRef] [Green Version]

- García, E.; Louvier-Hernández, J.F.; Cervantes-Vallejo, F.J.; Flores-Martínez, M.; Hernández, R.; Alcaraz-Caracheo, L.A.; Hernández-Navarro, C. A Mechanical, dynamic and tribological characterization of HDPE/peanut shell composites. Polym. Test. 2021, 98, 107075. [Google Scholar] [CrossRef]

- Guna, V.; Ilangovan, M.; Rather, M.H.; Giridharan, B.V.; Prajwal, B.; Vamshi Krishna, K.; Venkatesh, K.; Reddy, N. Groundnut shell/rice husk agro-waste reinforced polypropylene hybrid biocomposites. J. Build. Eng. 2020, 27, 100991. [Google Scholar] [CrossRef]

- Potadar, O.V.; Kadam, G.S. Preparation and Testing of Composites using Waste Groundnut Shells and Coir Fibres. Procedia Manuf. 2018, 20, 91–96. [Google Scholar] [CrossRef]

- Ikladious, N.E.; Shukry, N.; El-Kalyoubi, S.F.; Asaad, J.N.; Mansour, S.H.; Tawfik, S.Y.; Abou-Zeid, R.E. Eco-friendly composites based on peanut shell powder / unsaturated polyester resin. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2019, 233, 955–964. [Google Scholar] [CrossRef]

- Raju, G.U.; Kumarappa, S.; Gaitonde, V.N. Mechanical and physical characterization of agricultural waste reinforced polymer composites. J. Mater. Environ. Sci. 2012, 3, 907–916. [Google Scholar]

- Patnaik, P.K.; Mishra, S.K.; Swain, P.T.R.; Sameer; Panda, D. Effect of Groundnut Shell Particulate Content on Physical and Mechanical Behavior of Jute–Epoxy Hybrid Composite. J. Inst. Eng. Ser. E 2022, 103, 65–72. [Google Scholar] [CrossRef]

- Zaaba, N.F.; Ismail, H.; Jaafar, M. Recycled Polypropylene/Peanut Shell Powder (RPP/PSP) Composites: Property Comparison before and after Electron Beam Irradiation. Polym. Compos. 2018, 39, 3048–3056. [Google Scholar] [CrossRef]

- Olajide, O.S.; Yaro, S.A.; Asuke, F.; Aponbiede, O. Experimental correlation between process parameters and tensile strength of polylactic acid/groundnut shell nanoparticle biocomposites. Int. J. Adv. Manuf. Technol. 2017, 93, 717–726. [Google Scholar] [CrossRef]

- Pączkowski, P.; Puszka, A.; Gawdzik, B. Effect of Eco-Friendly Peanut Shell Powder on the Chemical Resistance, Physical, Thermal, and Thermomechanical Properties of Unsaturated Polyester Resin Composites. Polymers 2021, 13, 3690. [Google Scholar] [CrossRef]

- Balaji, N.; Natrayan, L.; Kaliappan, S.; Patil, P.P.; Sivakumar, N.S. Annealed peanut shell biochar as potential reinforcement for aloe vera fiber-epoxy biocomposite: Mechanical, thermal conductivity, and dielectric properties. Biomass Convers. Biorefin. 2022. [Google Scholar] [CrossRef]

- Zaaba, N.F.; Ismail, H.; Jaafar, M. Effect of peanut shell powder content on the properties of recycled polypropylene (RPP)/peanut shell powder (PSP) composites. BioResources 2013, 8, 5826–5841. [Google Scholar] [CrossRef] [Green Version]

- Cañigueral, N.; Vilaseca, F.; Méndez, J.A.; López, J.P.; Barberà, L.; Puig, J.; Pèlach, M.A.; Mutjé, P. Behavior of biocomposite materials from flax strands and starch-based biopolymer. Chem. Eng. Sci. 2009, 64, 2651–2658. [Google Scholar] [CrossRef]

- Rodríguez-Llamazares, S.; Rivas, B.L.; Pérez, M.; Perrin-Sarazin, F.; Maldonado, A.; Venegas, C. The Effect of Clay Type and of Clay–Masterbatch Product in the Preparation of Polypropylene/Clay Nanocomposites. J. Appl. Polym. Sci. 2011, 122, 2013–2025. [Google Scholar] [CrossRef]

- Zaman, H.U.; Khan, R.A. Preparation and Evaluation of Polypropylene-Peanut Shell Flour Eco-Friendly Composites with and without Cloisite 30B. Int. J. Adv. Sci. Eng. 2022, 9, 2658–2668. [Google Scholar] [CrossRef]

- Okonji, P.C.; Nwobi-Okoye, C.C.; Atanmo, P.N. Experimental study of the feasibility of using groundnut shell ash and ant hill powder in foundry application. J. Chin. Adv. Mater. Soc. 2018, 6, 270–281. [Google Scholar] [CrossRef]

- Zaaba, N.F.; Jaafar, M.; Ismail, H. The Effect of Alkaline Peroxide Pre-Treatment on Properties of Peanut Shell Powder Filled Recycled Polypropylene Composites. J. Eng. Sci. 2017, 13, 75–87. [Google Scholar] [CrossRef]

- Meng, W.; Shi, J.; Zhang, X.; Lian, H.; Wang, Q.; Peng, Y. Effects of peanut shell and skin extracts on the antioxidant ability, physical and structure properties of starch-chitosan active packaging films. Int. J. Biol. Macromol. 2020, 152, 137–146. [Google Scholar] [CrossRef]

- Anand Raj, L.F.A.; Shanmugapriya, R.; Jeslin, J. Biosynthesis of cellulose microfibre from peanut shell for the preparation of bio-nanocomposite films for food-packaging application. Bull. Mater. Sci. 2019, 42, 63. [Google Scholar] [CrossRef] [Green Version]

- Sheng, D.D.C.V.; Ramegowda, N.S.; Guna, V.; Reddy, N. Groundnut shell and coir reinforced hybrid bio composites as alternative to gypsum ceiling tiles. J. Build. Eng. 2022, 57, 104892. [Google Scholar] [CrossRef]

- Ekpenyong, N.E.; Ekong, S.A.; Nathaniel, E.U.; Emem, J.; Okorie, U.S.; Robert, U.W.; Akpabio, I.A. Thermal Response and Mechanical Properties of Groundnut Shells ’ Composite Boards. Res. J. Sci. Technol. 2023, 3, 42–57. [Google Scholar]

- Robert, U.W.; Etuk, S.E.; Agbasi, O.E.; Ekong, S.A.; Nathaniel, E.U.; Anonaba, A.; Nnana, L.A. Valorisation of Waste Carton Paper, Melon Seed Husks, and Groundnut Shells to Thermal Insulation Panels for Structural Applications. Polytechnica 2021, 4, 97–106. [Google Scholar] [CrossRef]

- Wei, X.; Wan, S.; Jiang, X.; Wang, Z.; Gao, S. Peanut-Shell-like Porous Carbon from Nitrogen-Containing Poly-N-phenylethanolamine for High-Performance Supercapacitor. ACS Appl. Mater. Interfaces 2015, 7, 22238–22245. [Google Scholar] [CrossRef] [PubMed]

| Rank | Country | World Production | Production (1000 MT) |

|---|---|---|---|

| 1 | China | 37% | 18,300 |

| 2 | India | 13% | 6650 |

| 3 | Nigeria | 9% | 4500 |

| 4 | USA | 5% | 2526 |

| 5 | Sudan | 5% | 2500 |

| Polymer Matrix | Filler | Filler Size | Filler % | Fabrication Method | Reference |

|---|---|---|---|---|---|

| Recycled polyethylene | Alkali-treated groundnut shell powder | 0–300 and 300–600 µm | 20 and 25 | Melt mixing using two-roll mill | [45] |

| Recycled HDPE | Alkali-treated groundnut shell powder | 150 µm | 0–25 | Melt mixing | [48] |

| PLA | Peanut shell with stabilizer | 13.46 ± 6.8 µm of diameter and 66.8 ± 13.2 µm | 10–40 | Melt compounding | [51] |

| Epoxy resin | Groundnut shell powder | 121.6 µm | 2–8 | Hand lay-up | [53] |

| Epoxy resin | Alkali-treated peanut shell powder | 200–300 µm | 5–15 gm | Mixing and curing | [54] |

| Polypropylene | Peanut shell husk + maleated polyethylene (MAPE) | <300 µm | 10–50 | Kinetic mixer followed by injection molding | [56] |

| HDPE | Peanut shell fiber | <127 µm | 2–10% | Melt extrusion | [90] |

| Unsaturated polyester/styrene-mixture resin | Untreated peanut shell particles Alkali-treated Silane-treated | <0.5 mm | 0–40 and 25–55 | Mixing and curing | [93] |

| Vinyl ester resin | Alkali-treated peanut shell powder | 600 µm | 20–60 | Mixing and curing | [94] |

| Epoxy resin | Groundnut shell particles + jute fabric | 100–200 µm | 5–20 | Hand lay-up | [95] |

| Recycled polypropylene | Groundnut shell particles | 66.84 µm | 10–40 | Melt blending, compression molding, and irradiated with electron beam | [96] |

| PLA + polyethylene glycol (PEG) | Groundnut-shell-powder ash | 50–100 nm | 10–30 | Melt extrusion | [97] |

| Unsaturated polyester resin | Groundnut shell powder | 0.10–0.25 mm | 0–30 | Stirring and curing | [98] |

| Polymer Matrix | Peanut Shell Filler | Optimum Filler wt.% | Tensile Strength MPa | Elongation at Break % | Young’s Modulus | Flexural Strength | Impact Strength (kJ/m2) | Reference |

|---|---|---|---|---|---|---|---|---|

| Recycled polyethylene | Alkali-treated groundnut shell powder | 20 | 7.7 | - | 120 | [46] | ||

| Recycled HDPE | Alkali-treated peanut shell powder | 20 | 25–30 | - | 77.73 | [48] | ||

| PLA | Peanut shell with stabilizer | 30 10 | 67.02 ± 0.46 | 7.83 ± 1.09 | 2261.42 ±31.73 | 8.40 ± 0.50 | [52] | |

| Epoxy resin | Groundnut shell powder | 6 4 | 150–160 | 6 | [53] | |||

| Epoxy resin | Alkali-treated peanut shell powder | 15 gm | 35.56 | 1960 | [54] | |||

| Polypropylene | Peanut shell husk + maleated polyethylene (MAPE) | 10 | 26 | 29 | [56] | |||

| LDPE | Peanut husk Compatibilized peanut husk Peanut husk Compatibilized peanut husk | 5 5 20 20 | 15 19 | 11 13 - | 2 GPa 2.3 GPa | 27 MPa 31 MPa | [89] | |

| HDPE | Peanut shell fiber | 8 2 | 23.53 ± 0.20 | - | 1260.91 ± 256.25 | - | [90] | |

| Unsaturated polyester/styrene mixture resin | Alkali-treated peanut shell particles Silane-treated Alkali-treated | 35 | 35–40 >40 | [93] | ||||

| Vinyl ester resin | Alkali-treated peanut shell powder | 40 50 | 28.09 | 1872.65 | 42.91 | [94] | ||

| Epoxy resin | Groundnut shell particles + jute fabric | 15 | 24.92 | 35.04 | [95] | |||

| Recycled polypropylene | Groundnut shell particles | 10 40 | 25 | 4 | 1300 | [96] | ||

| PLA + polyethylene glycol (PEG) | Groundnut-shell-powder ash | 20 | 114.87 | 8.61 | 2305.361 MPa | [97] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mandala, R.; Hegde, G.; Kodali, D.; Kode, V.R. From Waste to Strength: Unveiling the Mechanical Properties of Peanut-Shell-Based Polymer Composites. J. Compos. Sci. 2023, 7, 307. https://doi.org/10.3390/jcs7080307

Mandala R, Hegde G, Kodali D, Kode VR. From Waste to Strength: Unveiling the Mechanical Properties of Peanut-Shell-Based Polymer Composites. Journal of Composites Science. 2023; 7(8):307. https://doi.org/10.3390/jcs7080307

Chicago/Turabian StyleMandala, Radhika, Gurumurthy Hegde, Deepa Kodali, and Venkateswara R. Kode. 2023. "From Waste to Strength: Unveiling the Mechanical Properties of Peanut-Shell-Based Polymer Composites" Journal of Composites Science 7, no. 8: 307. https://doi.org/10.3390/jcs7080307

APA StyleMandala, R., Hegde, G., Kodali, D., & Kode, V. R. (2023). From Waste to Strength: Unveiling the Mechanical Properties of Peanut-Shell-Based Polymer Composites. Journal of Composites Science, 7(8), 307. https://doi.org/10.3390/jcs7080307