Investigation of Solar Air Collectors with Carbon-Nanotube-Based Turbulators and Pin Fin Arrangements

Abstract

:1. Introduction

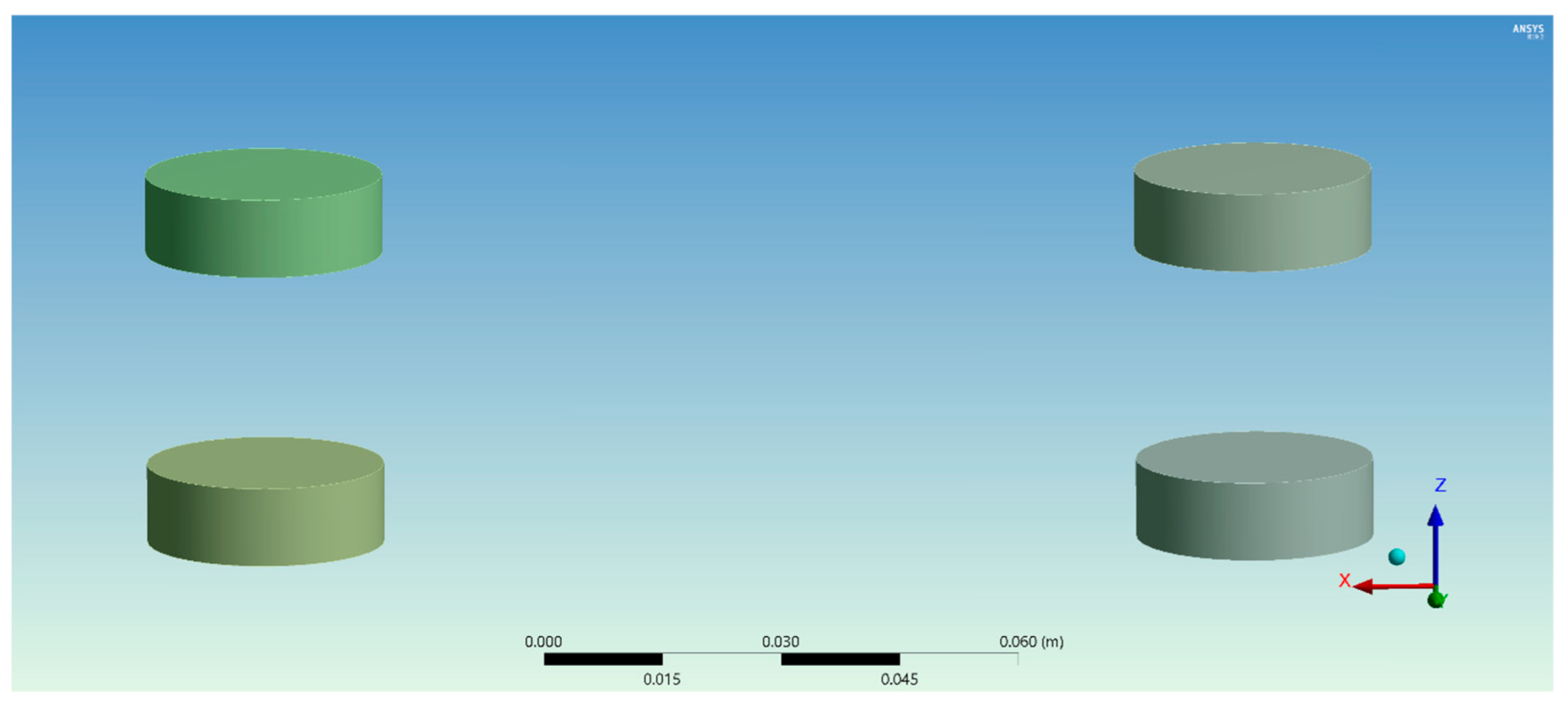

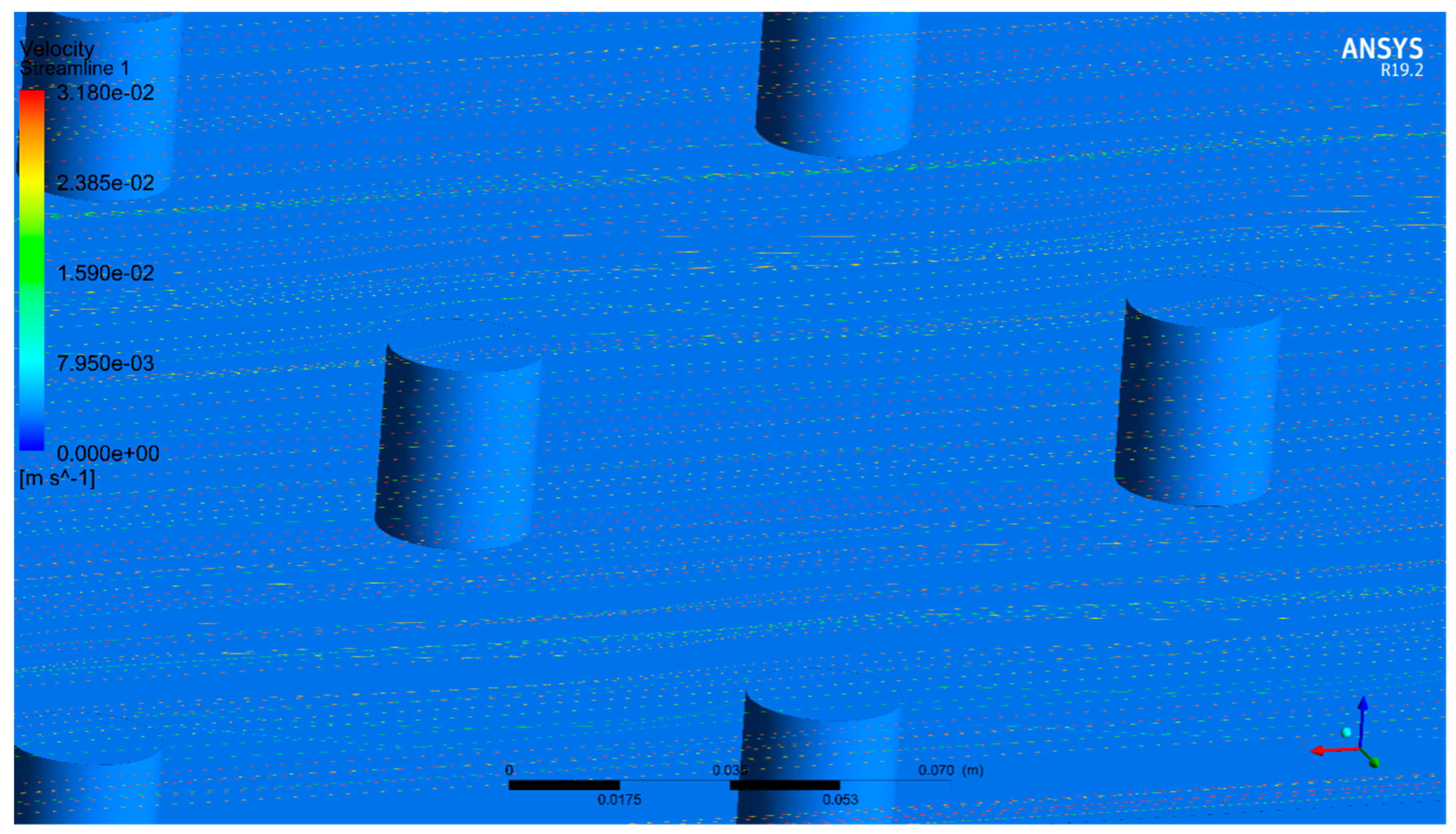

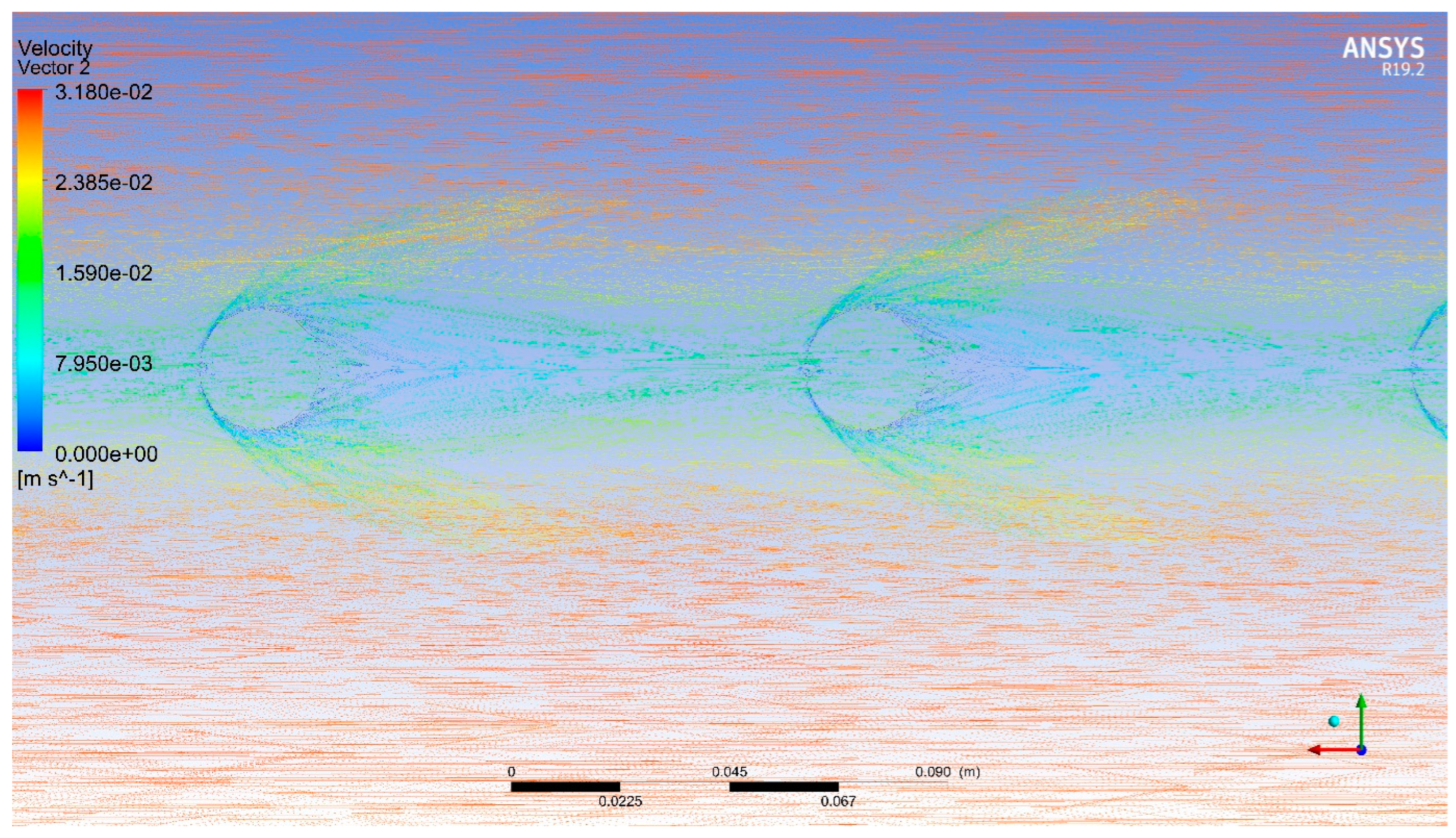

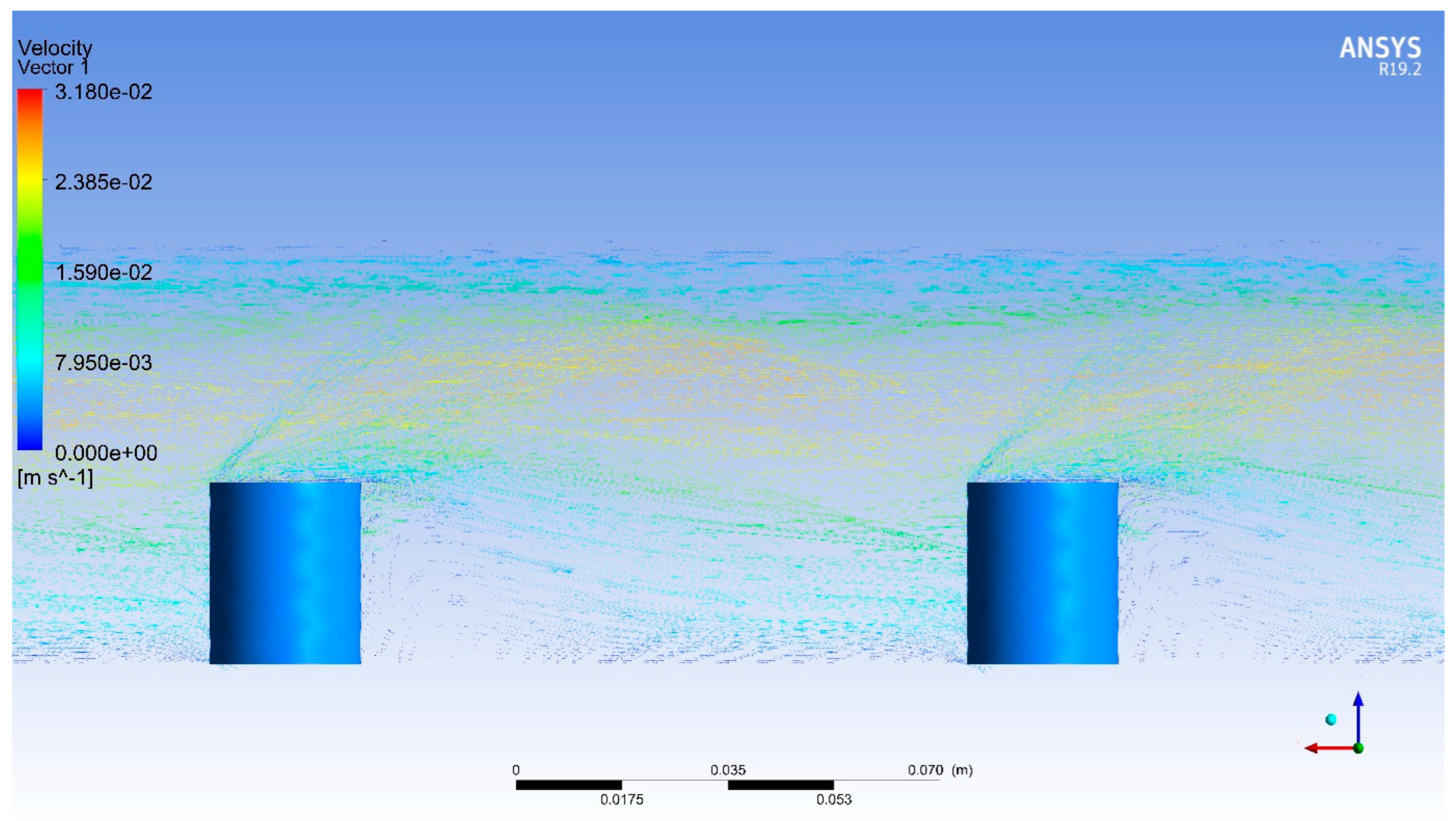

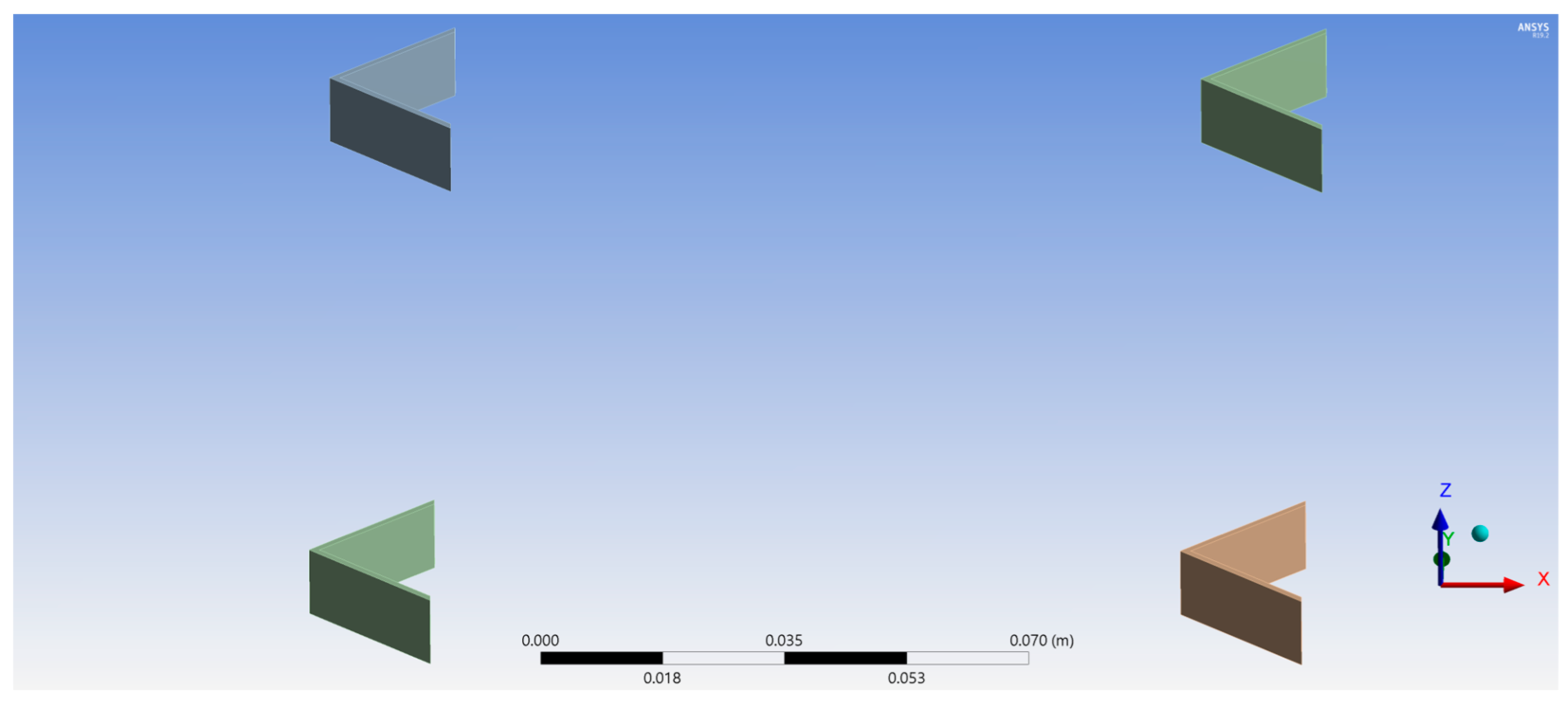

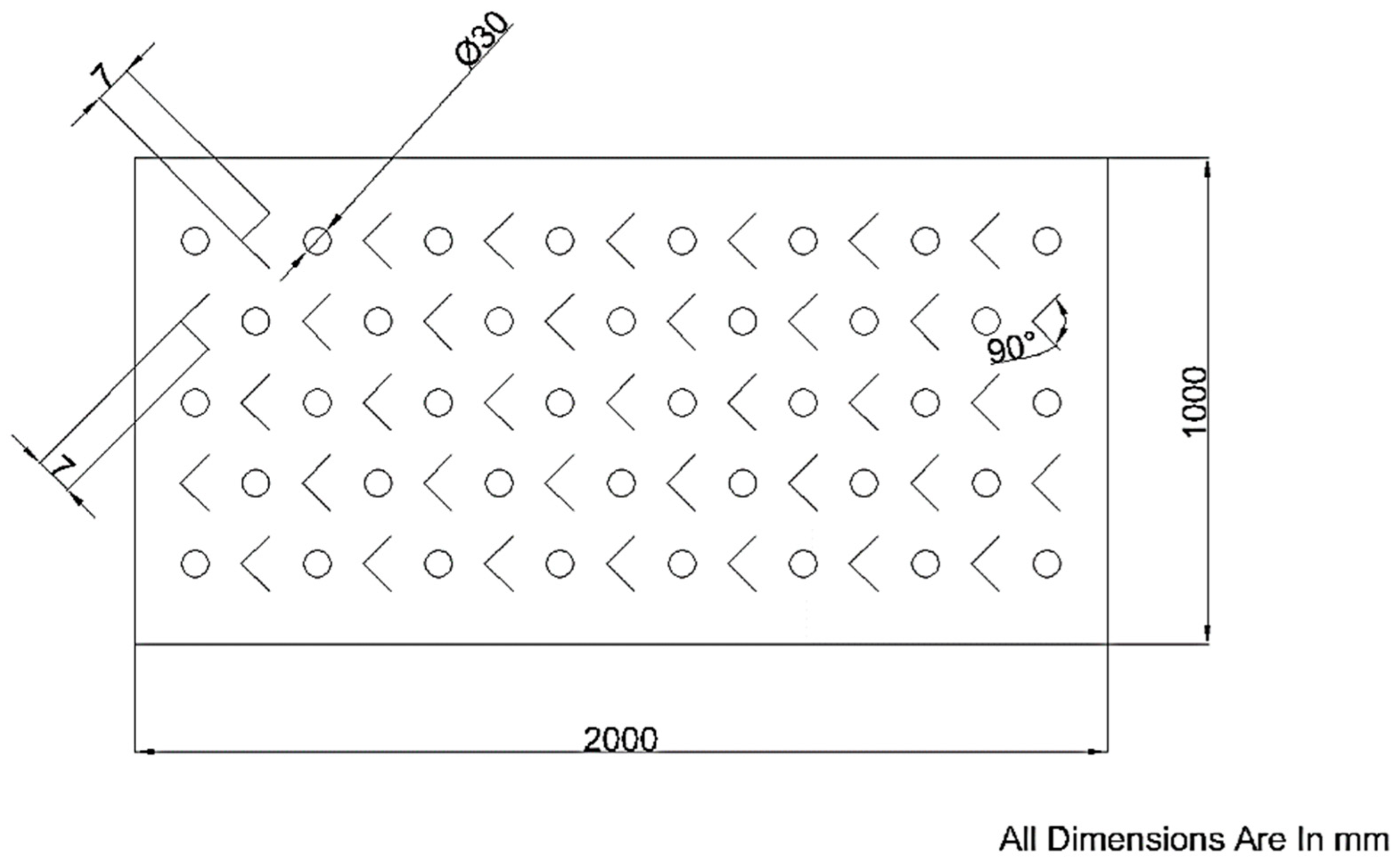

2. CFD Modelling

2.1. Solar Thermal Collector Parameters

2.2. Governing Equations

2.3. Performance Parameters

2.4. Boundary Conditions and Solver Settings

- The SIMPLE scheme is adopted to calculate the flow problem. This method couples the velocity and pressure corrections to apply mass conservation in order to calculate the pressure field;

- The residual values are set to a threshold of below 10−6 to achieve convergence in the solution;

- The pressure is formulated using the weighted body force method.

2.5. Grid Impedance Test

3. Results and Discussion

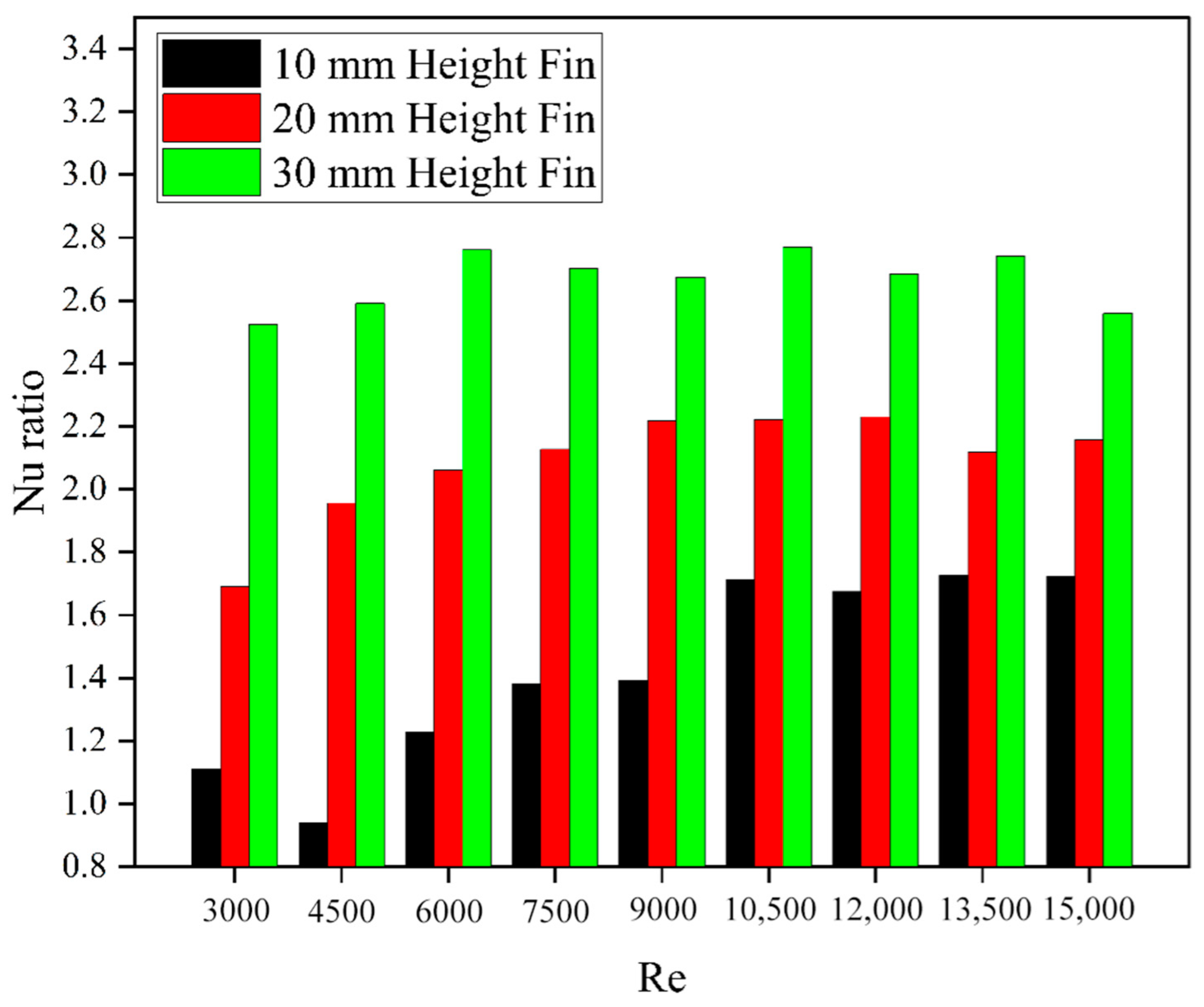

3.1. Effect of CNT Pin Fin Models with Different Heights

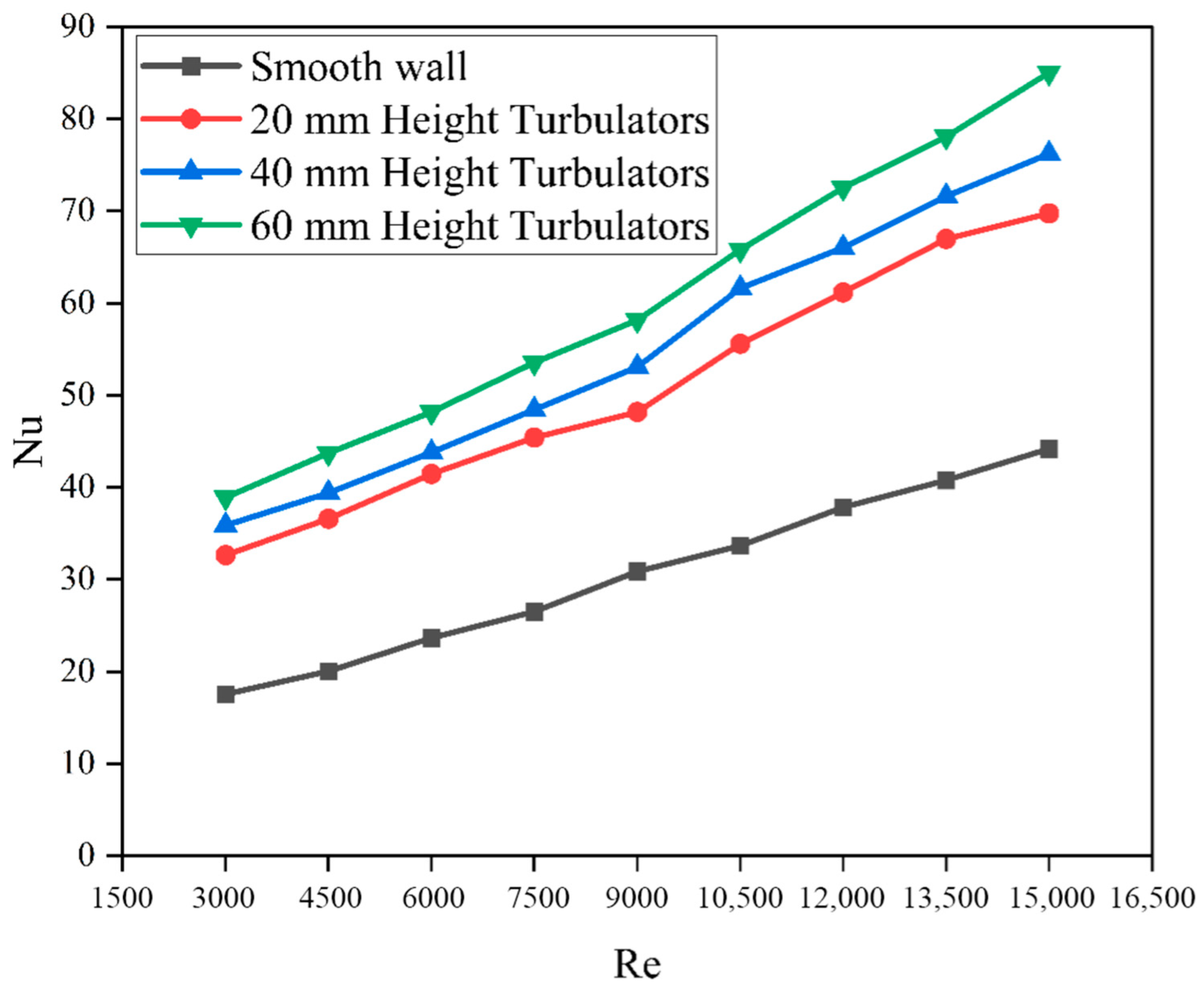

3.2. Effect of Different Heights in CNT Turbulator Model

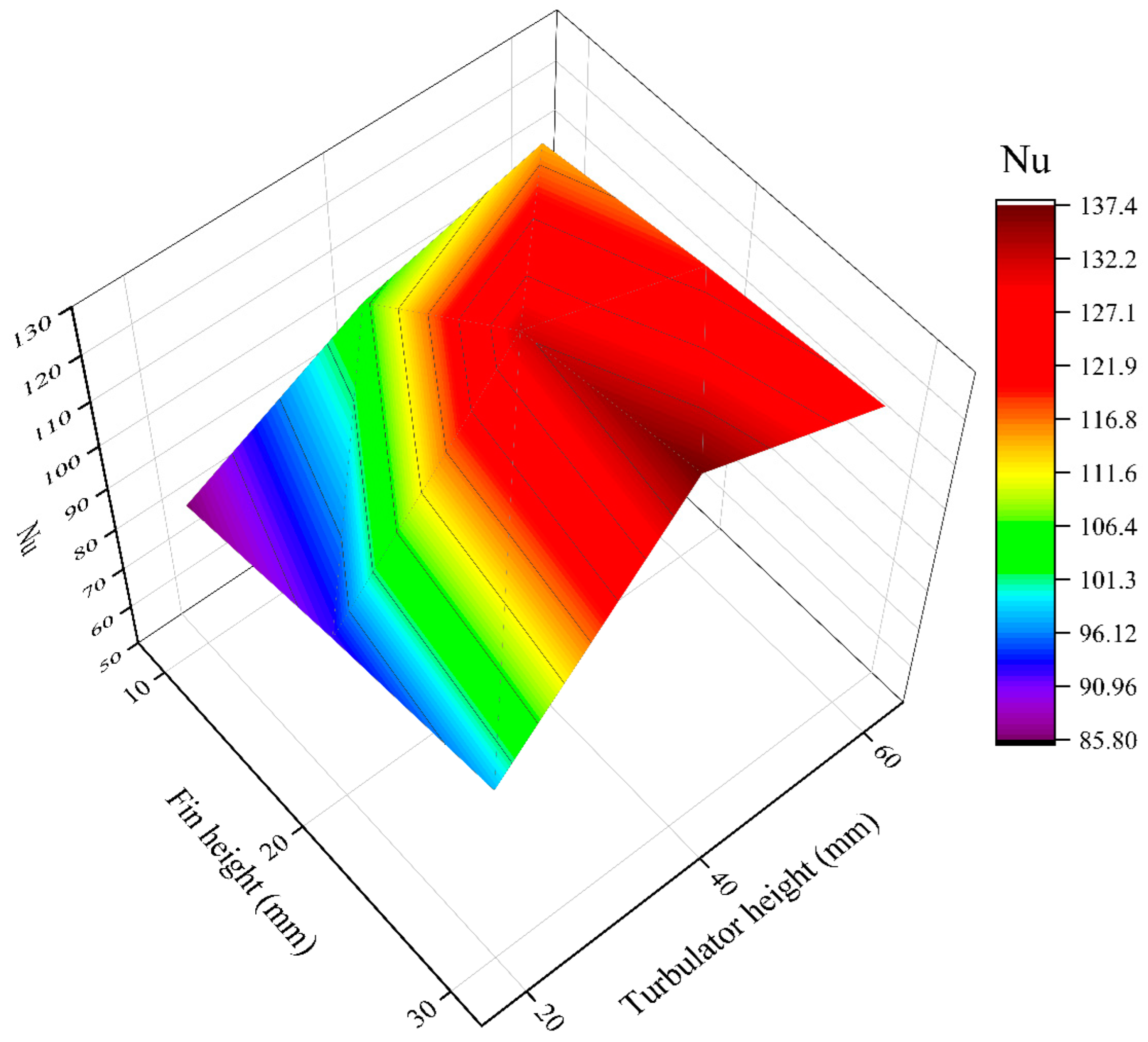

3.3. Effect of Different Heights of CNT Pin Fins and Turbulators

3.4. Effect of Different Heights of CNT Pin Fin and Turbulator Model on Pressure Drop

4. Comparative Analysis

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Thermal efficiency | |

| Qu | Energy gain |

| IT | Incident solar thermal rays |

| Ap | Base plate surface area |

| Pumping power | |

| Mass flow rate | |

| Re | Reynold’s Number |

| Density | |

| Temperature | |

| Keff | Thermal conductivity |

| K | Turbulence kinetic energy |

| Dynamic viscosity | |

| Specific energy | |

| Specific enthalpy | |

| Hourly solar radiation | |

| Nu | Nusselt number |

| Prandtl number | |

| Dh | Hydraulic diameter |

| L | Base plate length |

References

- IEA. Renewables 2022; IEA: Paris, France, 2022. [Google Scholar]

- Jradi, M.; Riffat, S. Medium Temperature Concentrators for Solar Thermal Applications. Int. J. Low-Carbon Technol. 2014, 9, 214–224. [Google Scholar] [CrossRef] [Green Version]

- Zhang, D.; Li, J.; Gao, Z.; Wang, L.; Nan, J. Thermal Performance Investigation of Modified Flat Plate Solar Collector with Dual-Function. Appl. Therm. Eng. 2016, 108, 1126–1135. [Google Scholar] [CrossRef] [Green Version]

- Tasmin, N.; Farjana, S.H.; Hossain, M.R.; Golder, S.; Mahmud, M.A.P. Integration of Solar Process Heat in Industries: A Review. Clean Technol. 2022, 4, 97–131. [Google Scholar] [CrossRef]

- Sreekumar, A. Techno-Economic Analysis of a Roof-Integrated Solar Air Heating System for Drying Fruit and Vegetables. Energy Convers. Manag. 2010, 51, 2230–2238. [Google Scholar] [CrossRef]

- Sánchez, M.M.; Lucas, M.; MartÍnez, P.; Sánchez, A.; Viedma, A. Climatic Solar Roof: An Ecological Alternative to Heat Dissipation in Buildings. Sol. Energy 2002, 73, 419–432. [Google Scholar] [CrossRef]

- Amer, B.M.A.; Hossain, M.A.; Gottschalk, K. Design and Performance Evaluation of a New Hybrid Solar Dryer for Banana. Energy Convers. Manag. 2010, 51, 813–820. [Google Scholar] [CrossRef]

- Saxena, A.; Agarwal, N.; Srivastava, G. Design and Performance of a Solar Air Heater with Long Term Heat Storage. Int. J. Heat Mass Transf. 2013, 60, 8–16. [Google Scholar] [CrossRef]

- Liu, F.; Wang, J.; Liu, Y.; Wang, F.; Chen, Y.; Du, Q.; Sun, F.; Yang, N. Natural Convection Characteristics of Honeycomb Fin with Different Hole Cells for Battery Phase-Change Material Cooling Systems. J. Energy Storage 2022, 51, 104578. [Google Scholar] [CrossRef]

- Xue, Y.; Ge, Z.; Du, X.; Yang, L. On the Heat Transfer Enhancement of Plate Fin Heat Exchanger. Energies 2018, 11, 1398. [Google Scholar] [CrossRef] [Green Version]

- Singh, H.; Alam, T.; Haque Siddiqui, M.I.; Ashraf Ali, M.; Sagar, D. Experimental Investigation of Heat Transfer Augmentation Due to Obstacles Mounted in Solar Air Heater Duct. Exp. Heat Transf. 2022, 35, 1–20. [Google Scholar] [CrossRef]

- Eismann, R.; Hummel, S.; Giovannetti, F. A Thermal-Hydraulic Model for the Stagnation of Solar Thermal Systems with Flat-Plate Collector Arrays. Energies 2021, 14, 733. [Google Scholar] [CrossRef]

- Dhaundiyal, A.; Gebremicheal, G.H. The Stack Effect on the Thermal-Fluid Behaviour of a Solar Collector. Energies 2022, 15, 1188. [Google Scholar] [CrossRef]

- Prasad, B.N.; Kumar, A.; Singh, K.D.P. Optimization of Thermo Hydraulic Performance in Three Sides Artificially Roughened Solar Air Heaters. Sol. Energy 2015, 111, 313–319. [Google Scholar] [CrossRef]

- Kumar, B.V.; Manikandan, G.; Kanna, P.R.; Taler, D.; Taler, J.; Nowak-Ocłoń, M.; Mzyk, K.; Toh, H.T. A Performance Evaluation of a Solar Air Heater Using Different Shaped Ribs Mounted on the Absorber Plate—A Review. Energies 2018, 11, 3104. [Google Scholar] [CrossRef] [Green Version]

- Singh, V.P.; Jain, S.; Karn, A.; Kumar, A.; Dwivedi, G.; Meena, C.S.; Dutt, N.; Ghosh, A. Recent Developments and Advancements in Solar Air Heaters: A Detailed Review. Sustainability 2022, 14, 12149. [Google Scholar] [CrossRef]

- Alam, T.; Kim, M.-H. A Critical Review on Artificial Roughness Provided in Rectangular Solar Air Heater Duct. Renew. Sustain. Energy Rev. 2017, 69, 387–400. [Google Scholar] [CrossRef]

- Qi, R.; Chen, F.; Xu, L.; Yu, J.; Chen, X. Effects of Reynolds Number on the Overall Characteristics of Flow and Heat Transfer in the Long Micro-Tube with Dimples. Processes 2022, 10, 2696. [Google Scholar] [CrossRef]

- Li, H.; Kottke, V. Analysis of Local Shellside Heat and Mass Transfer in the Shell-and-Tube Heat Exchanger with Disc-and-Doughnut Baffles. Int. J. Heat Mass Transf. 1999, 42, 3509–3521. [Google Scholar] [CrossRef]

- Habib, M.A.; Mobarak, A.M.; Attya, A.M.; Aly, A.Z. An Experimental Investigation of Heat-Transfer and Flow in Channels with Streamwise-Periodic Flow. Energy 1992, 17, 1049–1058. [Google Scholar] [CrossRef]

- Skullong, S.; Thianpong, C.; Jayranaiwachira, N.; Promvonge, P. Experimental and Numerical Heat Transfer Investigation in Turbulent Square-Duct Flow through Oblique Horseshoe Baffles. Chem. Eng. Process. Process Intensif. 2016, 99, 58–71. [Google Scholar] [CrossRef]

- Liou, T.-M.; Hwang, J.-J. Turbulent Heat Transfer Augmentation and Friction in Periodic Fully Developed Channel Flows. J. Heat Transfer 1992, 114, 56–64. [Google Scholar] [CrossRef]

- Chang, W.; Wang, Y.; Li, M.; Luo, X.; Ruan, Y.; Hong, Y.; Zhang, S. The Theoretical and Experimental Research on Thermal Performance of Solar Air Collector with Finned Absorber. Energy Procedia 2015, 70, 13–22. [Google Scholar] [CrossRef] [Green Version]

- Hu, J.; Liu, K.; Guo, M.; Zhang, G.; Chu, Z.; Wang, M. Performance Improvement of Baffle-Type Solar Air Collector Based on First Chamber Narrowing. Renew. Energy 2019, 135, 701–710. [Google Scholar] [CrossRef]

- Chaichan, M.T.; Abaas, K.I.; Kazem, H.A. Design and Assessment of Solar Concentrator Distillating System Using Phase Change Materials (PCM) Suitable for Desertic Weathers. Desalin. Water Treat. 2016, 57, 14897–14907. [Google Scholar] [CrossRef]

- Kumar Nougriaya, S.; Chopra, M.K.; Gupta, B.; Baredar, P. Stepped Solar Still: A Review on Designs Analysis. Mater. Today Proc. 2021, 46, 5647–5660. [Google Scholar] [CrossRef]

- Yadav, A.S.; Bhagoria, J.L. A Numerical Investigation of Square Sectioned Transverse Rib Roughened Solar Air Heater. Int. J. Therm. Sci. 2014, 79, 111–131. [Google Scholar] [CrossRef]

- Promthaisong, P.; Eiamsa-ard, S. Fully Developed Periodic and Thermal Performance Evaluation of a Solar Air Heater Channel with Wavy-Triangular Ribs Placed on an Absorber Plate. Int. J. Therm. Sci. 2019, 140, 413–428. [Google Scholar] [CrossRef]

- Nagaraj, M.; Reddy, M.K.; Honnesara Sheshadri, A.K.; Karanth, K.V. Numerical Analysis of an Aerofoil Fin Integrated Double Pass Solar Air Heater for Thermal Performance Enhancement. Sustainability 2023, 15, 591. [Google Scholar] [CrossRef]

- Renteria, J.D.; Nika, D.L.; Balandin, A.A. Graphene Thermal Properties: Applications in Thermal Management and Energy Storage. Appl. Sci. 2014, 4, 525–547. [Google Scholar] [CrossRef] [Green Version]

- Abdelkader, T.K.; Zhang, Y.; Gaballah, E.S.; Wang, S.; Wan, Q.; Fan, Q. Energy and Exergy Analysis of a Flat-Plate Solar Air Heater Coated with Carbon Nanotubes and Cupric Oxide Nanoparticles Embedded in Black Paint. J. Clean. Prod. 2020, 250, 119501. [Google Scholar] [CrossRef]

- Esmaeili, Z.; Akbarzadeh, S.; Rashidi, S.; Valipour, M.S. Effects of Hybrid Nanofluids and Turbulator on Efficiency Improvement of Parabolic Trough Solar Collectors. Eng. Anal. Bound. Elem. 2023, 148, 114–125. [Google Scholar] [CrossRef]

- Ebrahim Momin, A.-M.; Saini, J.S.; Solanki, S.C. Heat Transfer and Friction in Solar Air Heater Duct with V-Shaped Rib Roughness on Absorber Plate. Int. J. Heat Mass Transf. 2002, 45, 3383–3396. [Google Scholar] [CrossRef]

- Saini, S.K.; Saini, R.P. Development of Correlations for Nusselt Number and Friction Factor for Solar Air Heater with Roughened Duct Having Arc-Shaped Wire as Artificial Roughness. Sol. Energy 2008, 82, 1118–1130. [Google Scholar] [CrossRef]

- Hans, V.S.; Saini, R.P.; Saini, J.S. Heat Transfer and Friction Factor Correlations for a Solar Air Heater Duct Roughened Artificially with Multiple V-Ribs. Sol. Energy 2010, 84, 898–911. [Google Scholar] [CrossRef]

- Aharwal, K.R.; Gandhi, B.K.; Saini, J.S. Heat Transfer and Friction Characteristics of Solar Air Heater Ducts Having Integral Inclined Discrete Ribs on Absorber Plate. Int. J. Heat Mass Transf. 2009, 52, 5970–5977. [Google Scholar] [CrossRef]

- Singh, S.; Chander, S.; Saini, J.S. Heat Transfer and Friction Factor Correlations of Solar Air Heater Ducts Artificially Roughened with Discrete V-down Ribs. Energy 2011, 36, 5053–5064. [Google Scholar] [CrossRef]

- Hans, V.S.; Gill, R.S.; Singh, S. Heat Transfer and Friction Factor Correlations for a Solar Air Heater Duct Roughened Artificially with Broken Arc Ribs. Exp. Therm. Fluid Sci. 2017, 80, 77–89. [Google Scholar] [CrossRef]

- Jaurker, A.R.; Saini, J.S.; Gandhi, B.K. Heat Transfer and Friction Characteristics of Rectangular Solar Air Heater Duct Using Rib-Grooved Artificial Roughness. Sol. Energy 2006, 80, 895–907. [Google Scholar] [CrossRef]

- Pandey, N.K.; Bajpai, V.K. Varun Experimental Investigation of Heat Transfer Augmentation Using Multiple Arcs with Gap on Absorber Plate of Solar Air Heater. Sol. Energy 2016, 134, 314–326. [Google Scholar] [CrossRef]

- Bhattacharyya, S.; Chattopadhyay, H.; Guin, A.; Benim, A.C. Investigation of Inclined Turbulators for Heat Transfer Enhancement in a Solar Air Heater. Heat Transf. Eng. 2019, 40, 1451–1460. [Google Scholar] [CrossRef]

- Chamoli, S.; Thakur, N.S. Heat Transfer Enhancement in Solar Air Heater with V-Shaped Perforated Baffles. J. Renew. Sustain. Energy 2013, 5, 23122. [Google Scholar] [CrossRef]

- Sahu, M.M.; Bhagoria, J.L. Augmentation of Heat Transfer Coefficient by Using 90° Broken Transverse Ribs on Absorber Plate of Solar Air Heater. Renew. Energy 2005, 30, 2057–2073. [Google Scholar] [CrossRef]

- Ramani, B.M.; Gupta, A.; Kumar, R. Performance of a Double Pass Solar Air Collector. Sol. Energy 2010, 84, 1929–1937. [Google Scholar] [CrossRef]

- Lin, W.; Gao, W.; Liu, T. A Parametric Study on the Thermal Performance of Cross-Corrugated Solar Air Collectors. Appl. Therm. Eng. 2006, 26, 1043–1053. [Google Scholar] [CrossRef]

| Materials | Density | Thermal Conductivity | Specific Heat | Viscosity |

|---|---|---|---|---|

| (kg/m3) | (W/mK) | (J/kg.K) | (kg/ms) | |

| Air | Equation (8) | Equation (9) | 1006.34 | Equation (10) |

| Glass cover | 2500 | 1.2 | 800 | - |

| Aluminium | 2719 | 202.4 | 871 | - |

| CNT | 1740 | 3000 | 570 | - |

| Parameters | Boundary Condition |

|---|---|

| Absorber top surface | Wall |

| Glass cover | Wall |

| Absorber side | Wall |

| Air inlet | Velocity inlet |

| Air outlet | Pressure outlet |

| Residuals | 10−6 |

| Run | Pin Fin Height (mm) | Turbulator Height (mm) |

|---|---|---|

| 1 | 10 | 20 |

| 2 | 20 | 20 |

| 3 | 30 | 20 |

| 4 | 10 | 40 |

| 5 | 20 | 40 |

| 6 | 30 | 40 |

| 7 | 10 | 60 |

| 8 | 20 | 60 |

| 9 | 30 | 60 |

| Author | Modifications |

|---|---|

| Momin et al. [33] | Continuous V-shape rib |

| Saini et al. [34] | Continuous arc shape |

| Hans et al. [35] | Multi V shape |

| Aharwal et al. [36] | Inclined ribs with gap |

| Singh et al. [37] | V ribs with gap |

| Hans et al. [38] | Arc-shape with gap |

| Kumar et al. [39] | Multi-V ribs with gap |

| Pandey et al. [40] | Multi arc rib with gap |

| Bhattacharyya et al. [41] | Inclined turbulators |

| Chamoli et al. [42] | V-down shaped perforated baffles |

| Present work | Pin fin |

| Present work | Turbulators |

| Present work | Pin fin and Turbulators (PFT) |

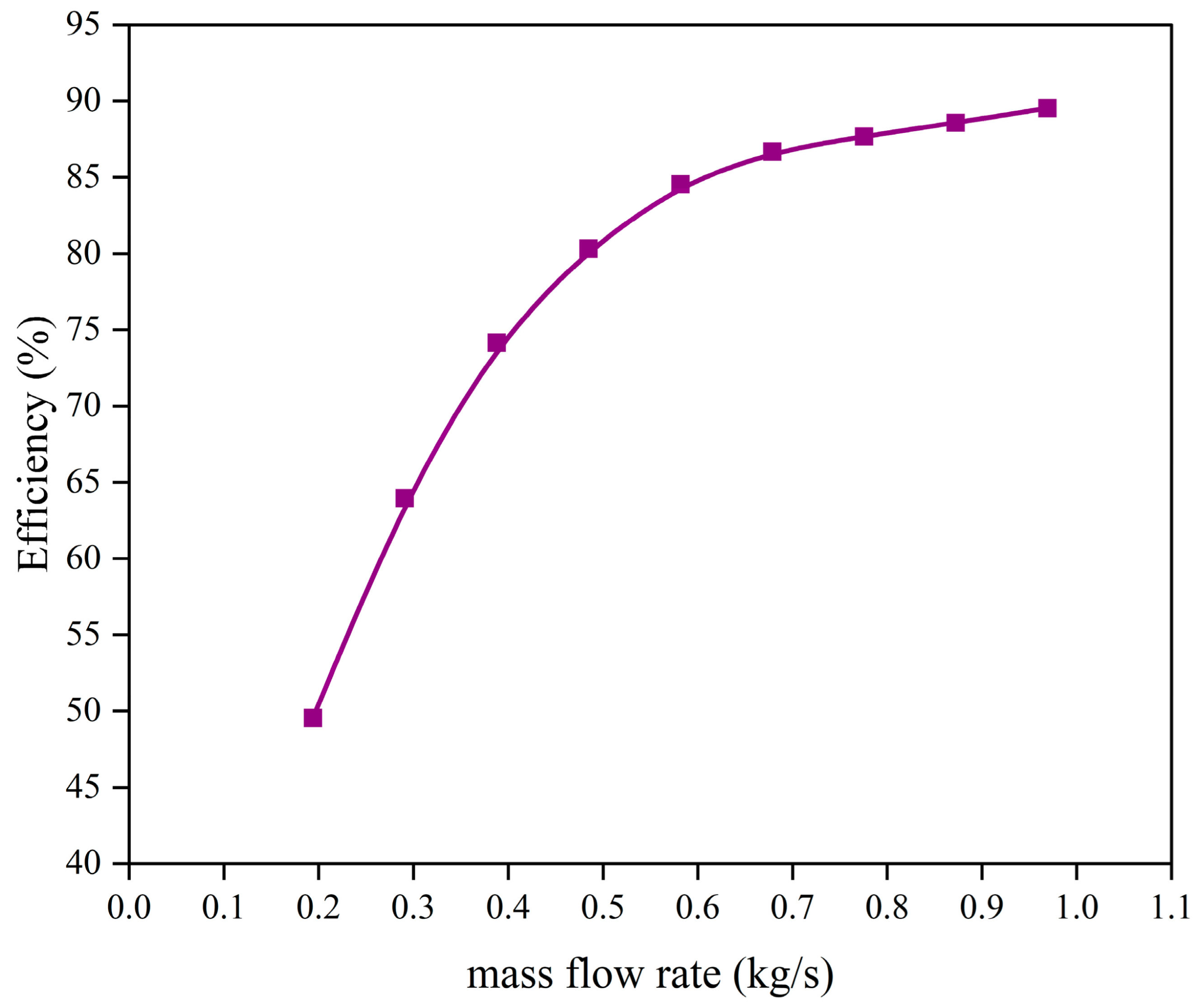

| Author | Modifications | Reynold’s Number (Re) | Mass Flux (kg/m2 s) | Thermal Efficiency (%) |

|---|---|---|---|---|

| Sahu et al. [43] | Transverse Ribs (TR) | 3000–12,000 | - | 83.5 |

| Ramani et al. [44] | Porous Material (PM) | 612–10,300 | 1.233–6.122 | 78.2 |

| Lin et al. [45] | Wavelike absorbing plate parallel to the flow direction (WLF) | 4600–5200 | 0.001–0.25 | 55.92 |

| Lin et al. [45] | Wavelike absorbing plate perpendicular to the flow direction (WPF) | 4600–5200 | 0.001–0.25 | 57.04 |

| Lin et al. [45] | Cross-corrugated absorbing plates (CCP) | 4600–5200 | 0.001–0.25 | 40.21 |

| Present work | Pin fin | 3000–15,000 | 2.75–13.845 | 81.79 |

| Present work | Turbulators | 3000–15,000 | 2.75–13.845 | 86.65 |

| Present work | Pin fin and Turbulators (PFT) | 3000–15,000 | 2.75–13.845 | 89.54 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Appadurai, M.; Raj, E.F.I.; Ram, V.; Gnaniah, A.M.; Salkuti, S.R.; Kim, S.-C. Investigation of Solar Air Collectors with Carbon-Nanotube-Based Turbulators and Pin Fin Arrangements. J. Compos. Sci. 2023, 7, 322. https://doi.org/10.3390/jcs7080322

Appadurai M, Raj EFI, Ram V, Gnaniah AM, Salkuti SR, Kim S-C. Investigation of Solar Air Collectors with Carbon-Nanotube-Based Turbulators and Pin Fin Arrangements. Journal of Composites Science. 2023; 7(8):322. https://doi.org/10.3390/jcs7080322

Chicago/Turabian StyleAppadurai, M., E. Fantin Irudaya Raj, Vishal Ram, Augustine Mathu Gnaniah, Surender Reddy Salkuti, and Seong-Cheol Kim. 2023. "Investigation of Solar Air Collectors with Carbon-Nanotube-Based Turbulators and Pin Fin Arrangements" Journal of Composites Science 7, no. 8: 322. https://doi.org/10.3390/jcs7080322

APA StyleAppadurai, M., Raj, E. F. I., Ram, V., Gnaniah, A. M., Salkuti, S. R., & Kim, S.-C. (2023). Investigation of Solar Air Collectors with Carbon-Nanotube-Based Turbulators and Pin Fin Arrangements. Journal of Composites Science, 7(8), 322. https://doi.org/10.3390/jcs7080322