Physical, Mechanical and Structural Characteristics of Sulfur Concrete with Bitumen Modified Sulfur and Fly Ash

Abstract

1. Introduction

- -

- The determination of the optimal sulfur content as a binder component in the composition of the sulfur concrete;

- -

- The selection of the optimal content of the filler in the form of fly ash;

- -

- The determination of the optimal dosages of the mineral aggregates;

- -

- The modification of the sulfur, with the help of the bitumen additive, and the selection of the most effective content of this additive;

- -

- The determination of the characteristics of various compositions of sulfur concrete and obtaining dependencies based on them;

- -

- The study of the structural features of the resulting sulfur concrete.

2. Materials and Methods

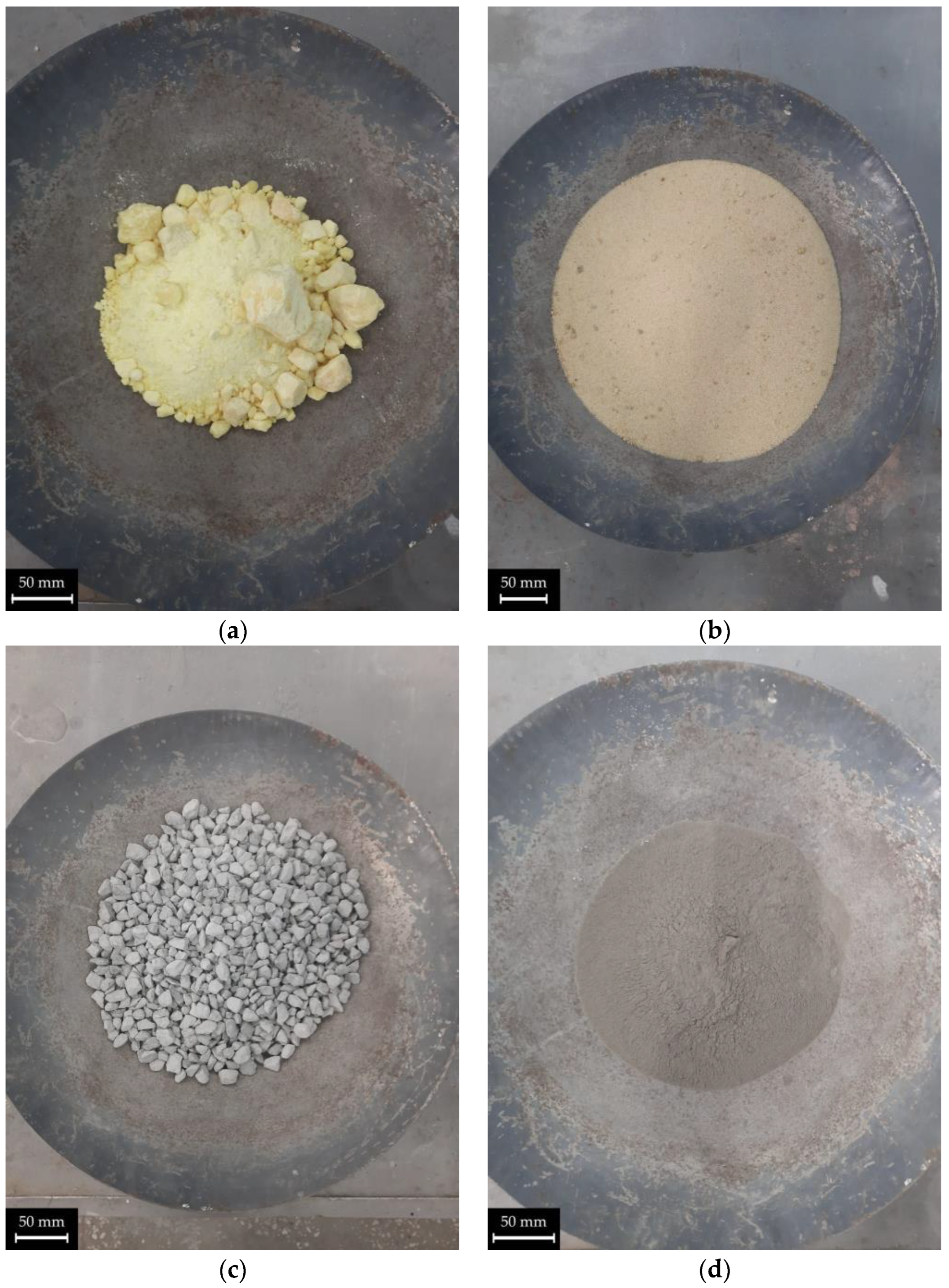

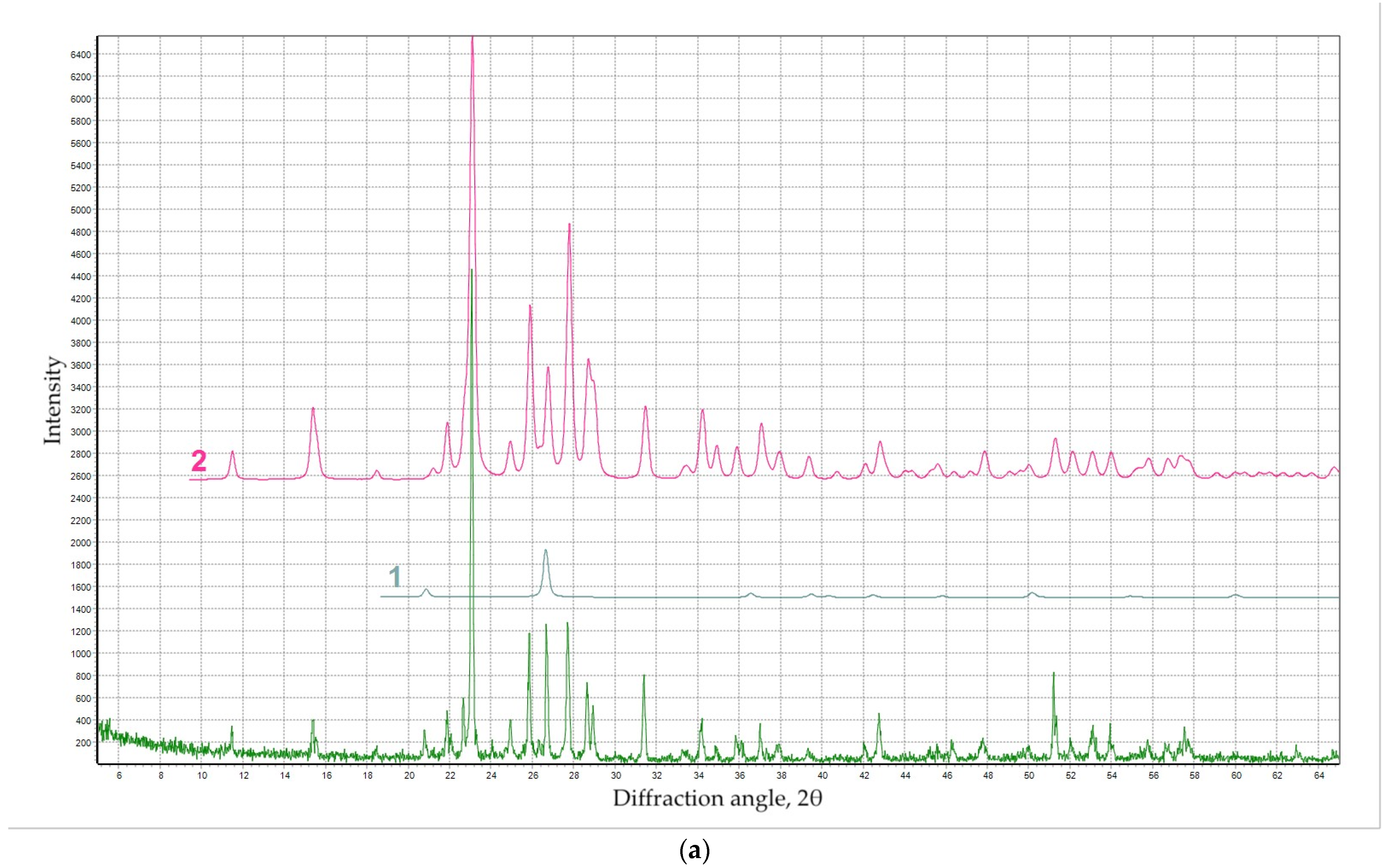

2.1. Materials

- -

- Technical sulfur (TS) (Novoshakhtinsk oil products plant, Novoshakhtinsk, Russia);

- -

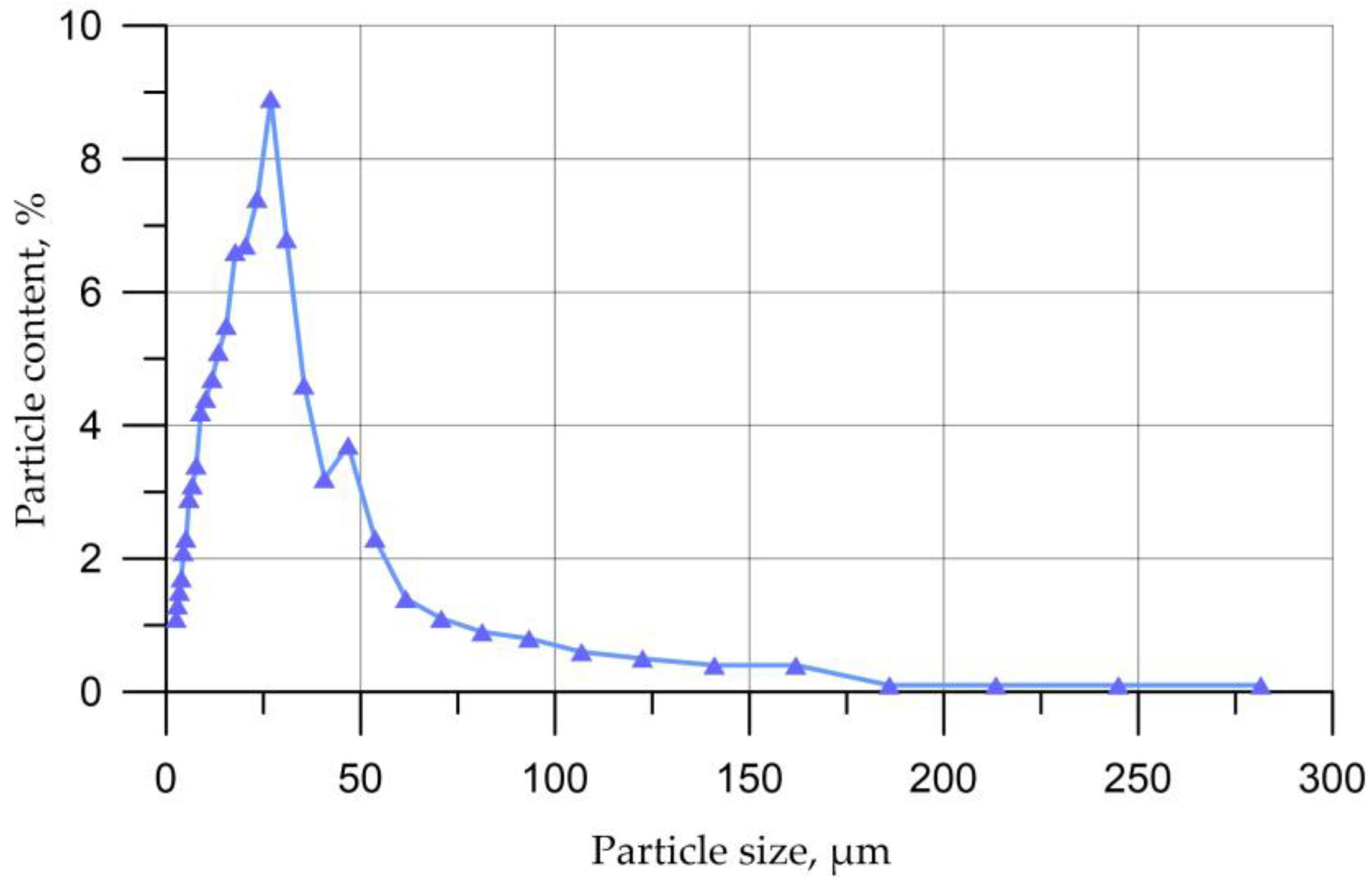

- Fly ash (FA) (Novocherkaskaya GRES, Novocherkassk, Russia);

- -

- Crushed sandstone (CS) (RostMed, Kamensk, Russia);

- -

- Career sand (S) (DON-RESURS, Kagalnik, Russia).

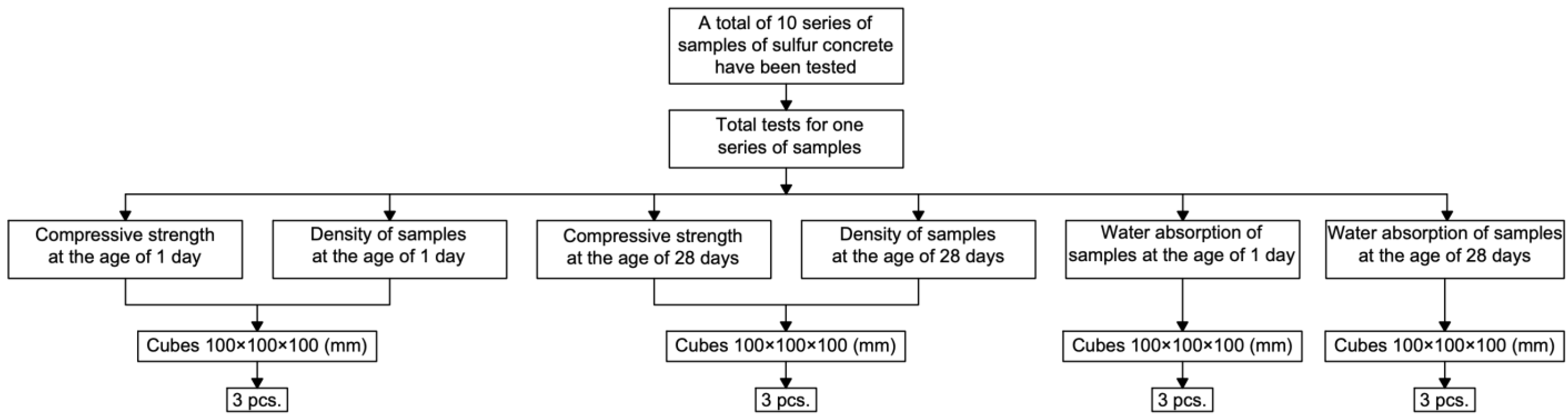

2.2. Methods

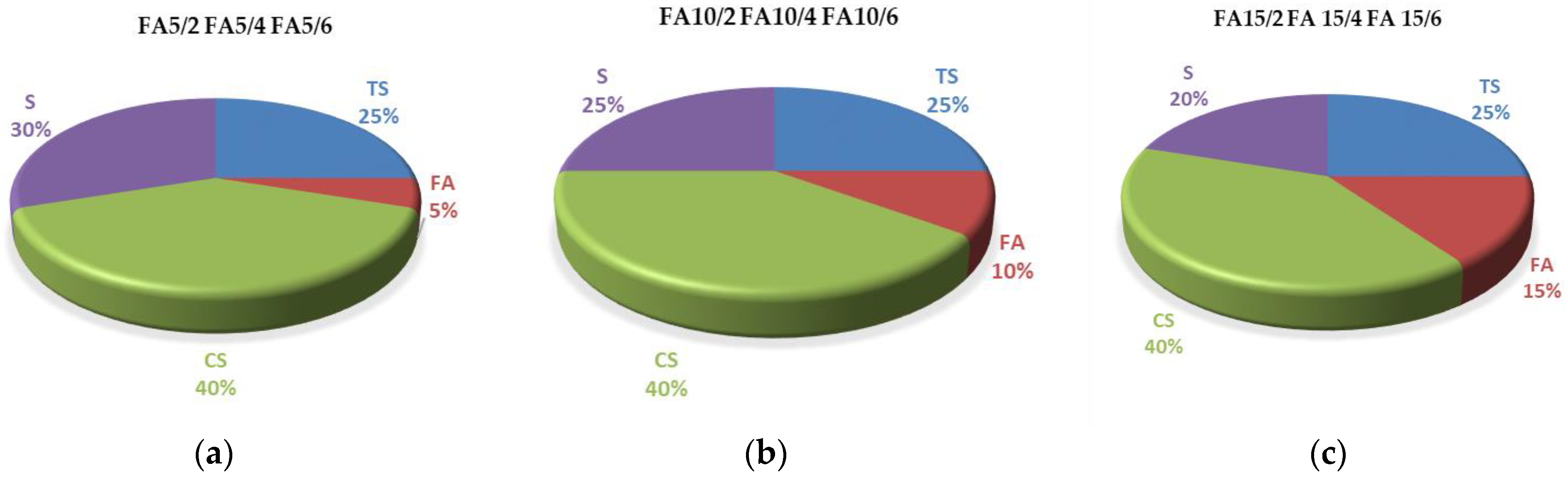

- (a)

- Technical sulfur (TS), as the main component of sulfur concrete, in an amount of 25% by weight of all dry components of sulfur concrete;

- (b)

- Fly ash (FA) at 0%, 5%, 10% and 15% by weight of all dry sulfur concrete components depending on the composition of the sulfur concrete mixture.

- -

- Portable thermometer megeon 26300 (MEGEON, Moscow, Russia);

- -

- Cube shapes 2FK-100 (RNPO RusPribor, St. Petersburg, Russia);

- -

- Drying cabinet ShS-80-01 SPU (Smolensk SKTB SPU, Smolensk, Russia);

- -

- Laboratory vibration platform (IMash, Armavir, Russia).

3. Results and Discussion

4. Conclusions

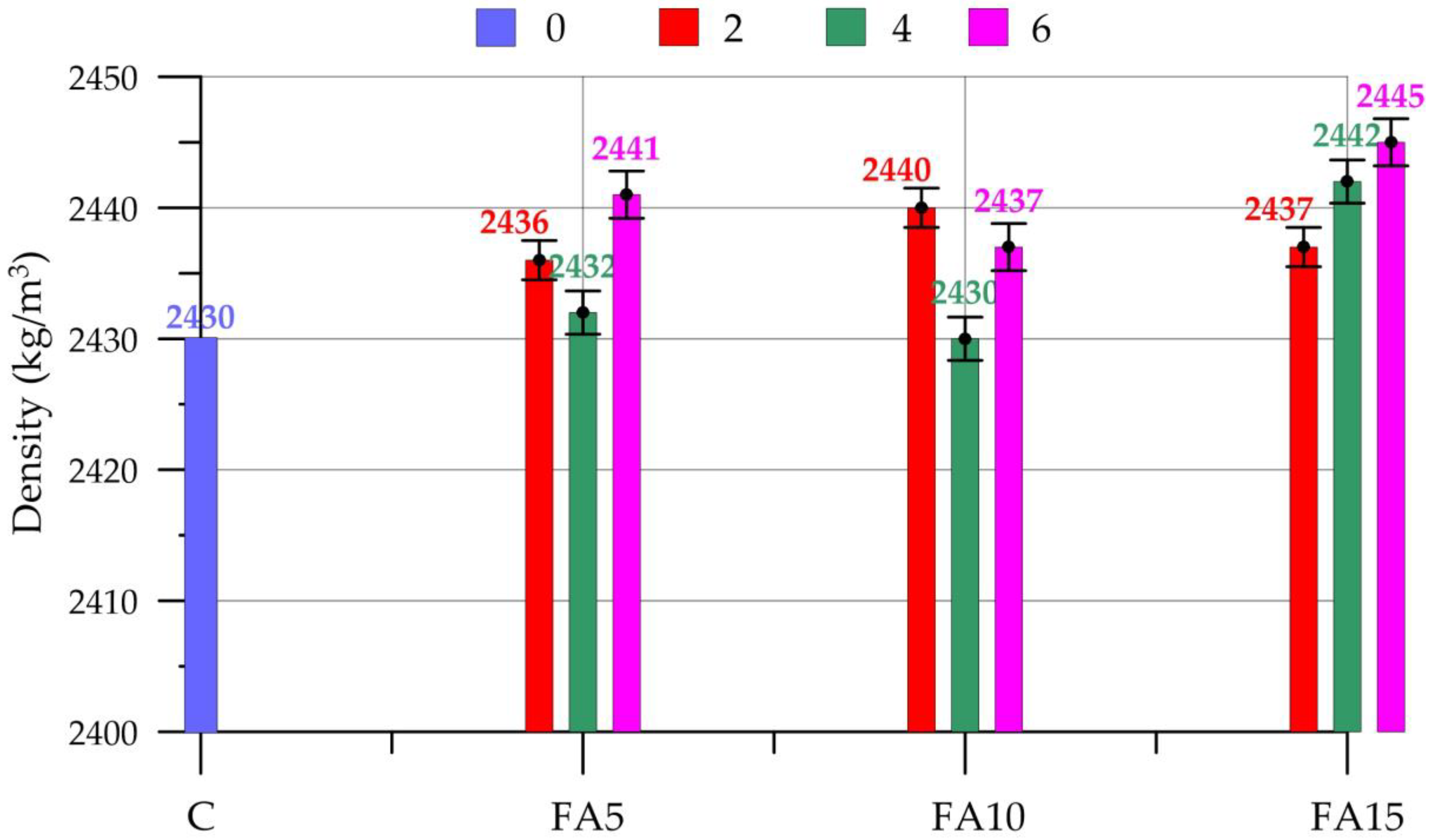

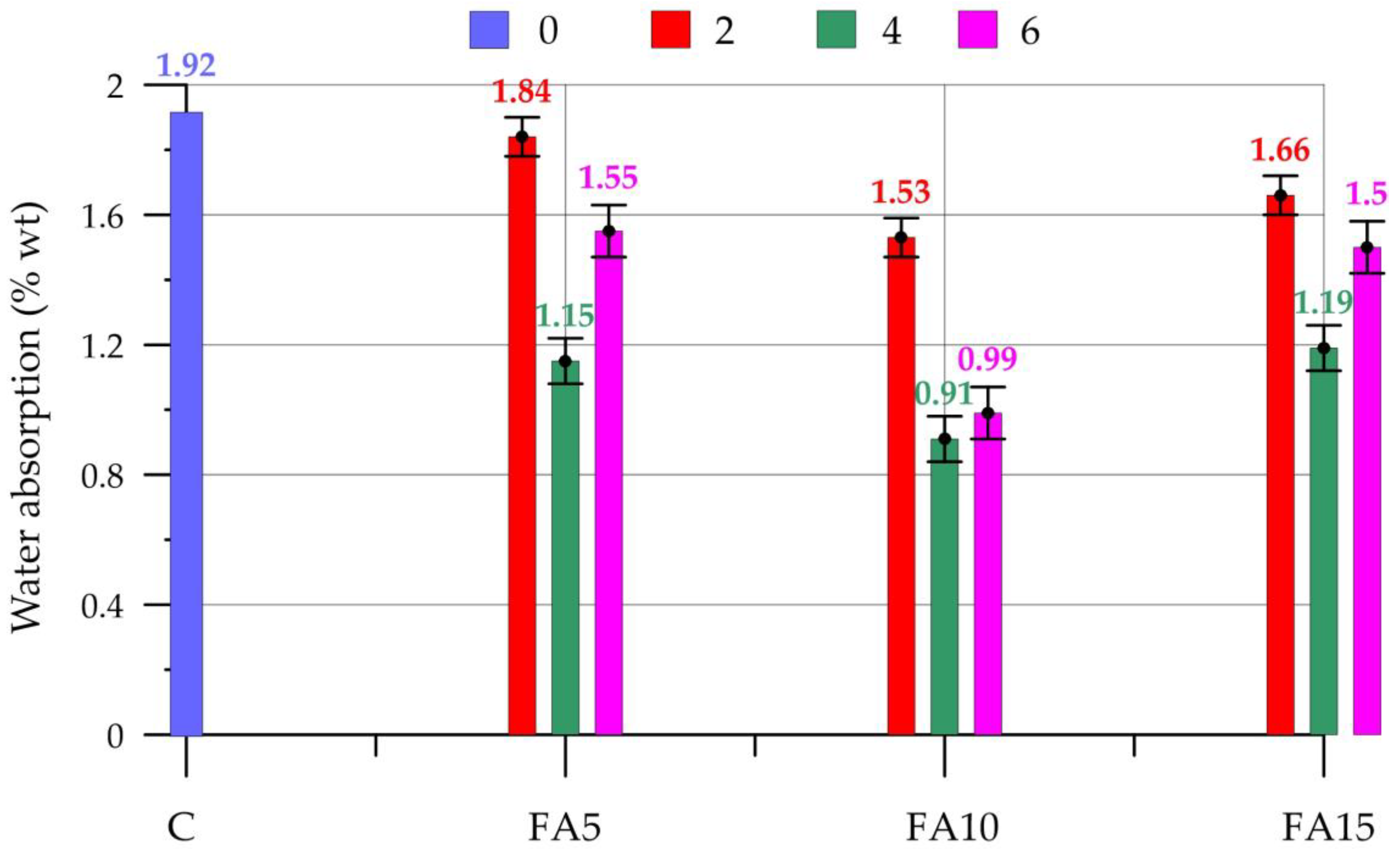

- (1)

- The optimal composition of modified sulfur concrete after 28 days, which showed the best compressive strength (24.8 MPa) and water absorption (0.9%), contains 25% sulfur modified with 4% bitumen by weight, 10% fly ash, 40% crushed stone and 25% sand.

- (2)

- The optimal composition of the modified sulfur concrete made it possible to increase the compressive strength up to 78% and reduce the water absorption to 53%.

- (3)

- The characteristics of the sulfur concrete samples after 28 days of hardening differ slightly from the values after 1 day of hardening: density—up to 0.6% more, compressive strength—up to 1.7% more and water absorption—up to 1.8% less.

- (4)

- The formulation solutions considered in this study do not significantly affect the change in the density of sulfur concrete. The density of all compositions, including the control one, varied from 2429 kg/m3 to 2445 kg/m3.

- (5)

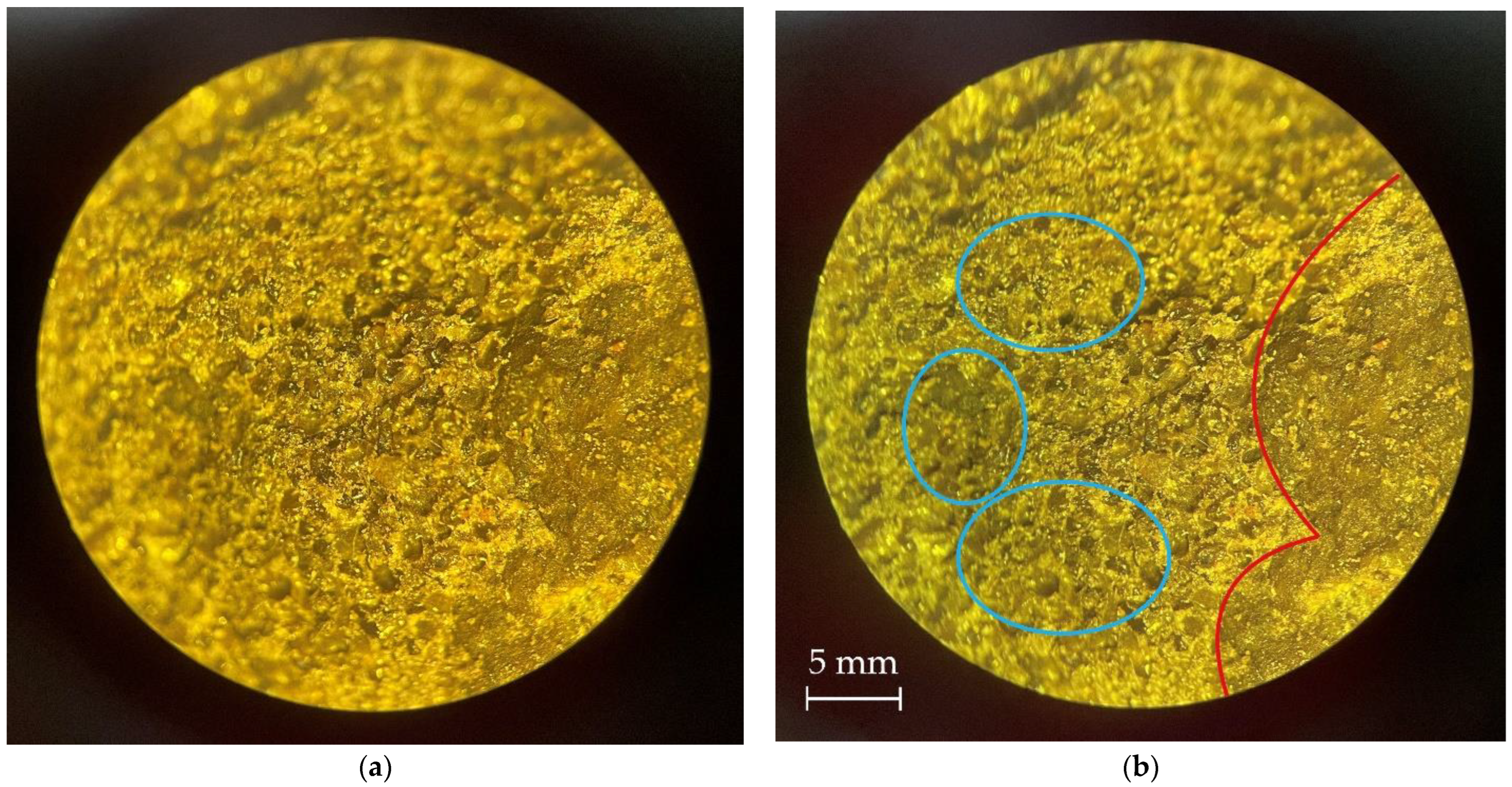

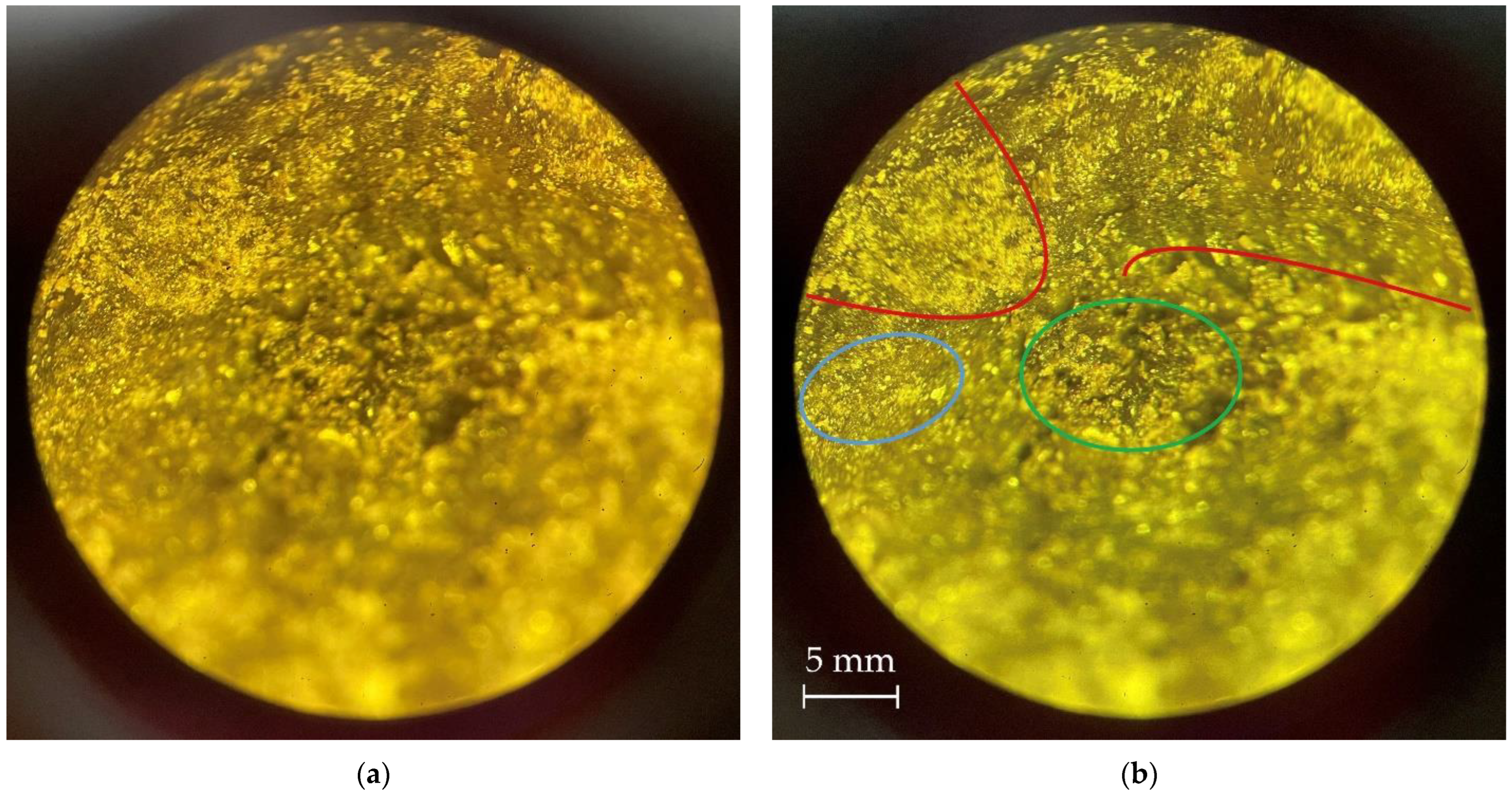

- The structure of the sulfur concrete samples of the control composition contains a sufficiently large number of shrinkage cavities, which directly affect its strength and water absorption. In this case, the sulfur evenly envelops the fine aggregate particles and forms a homogeneous phase boundary. There are practically no shrinkage cavities in a sample of the sulfur concrete of the optimal composition, the packing of filler particles, sulfur and aggregates is dense, and sulfur itself, as a binder, fairly evenly envelops the fine aggregate particles and sticks them together.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Piotr, S.; Agnieszka, B.; Henryk, B.; Andrzej, G. Quantitative Evaluation and Leaching Behavior of Cobalt Immobilized in Sulfur Polymer Concrete Composites Based on Lignite Fly Ash, Slag and Phosphogypsum. J. Clean. Prod. 2019, 222, 92–102. [Google Scholar] [CrossRef]

- Uzzal, H.; Chi, P.; Irene, L.; Jack, C. Comparative LCA on Using Waste Materials in the Cement Industry: A Hong Kong Case Study. Resour. Conserv. Recycl. 2017, 120, 199–208. [Google Scholar] [CrossRef]

- Dowan, K.; Byungran, L.; Jonggyu, L.; Cheagun, P. A Study on the Applicability of Bio-Sulfur as a Cement Admixture. Appl. Sci. 2022, 12, 9793. [Google Scholar] [CrossRef]

- Kenzhebek, A.; Nazerke, B.; Ina, P.; Jolanta, P. The Effect of Mechanical Activation of Fly Ash on Cement-Based Materials Hydration and Hardened State Properties. Materials 2023, 16, 2959. [Google Scholar] [CrossRef]

- Ahmad, M. Effect of Aggregate on the Performance of Fly-Ash-Based Geopolymer Concrete. Buildings 2023, 13, 769. [Google Scholar] [CrossRef]

- Beskopylny, A.; Shcherban, E.; Stel’makh, S.; Mailyan, L.; Meskhi, B.; Varavka, V.; Chernil’nik, A.; Pogrebnyak, A. Improved Fly Ash Based Structural Foam Concrete with Polypropylene Fiber. J. Compos. Sci. 2023, 7, 76. [Google Scholar] [CrossRef]

- Yao, J.; Yao, S.; Huang, S.; Ni, T.; Jiang, C.; Yang, Y.; Kong, D. The Influence of Fly Ash on the Tensile Creep Prediction of High-Strength Concrete at Early Ages. Materials 2023, 16, 1337. [Google Scholar] [CrossRef]

- Duan, Y.; Wang, Q.; Long, Z.; Wang, X. Investigating the Impact of Fly Ash on the Strength and Micro-Structure of Concrete during Steam Curing and Subsequent Stages. Materials 2023, 16, 1326. [Google Scholar] [CrossRef]

- Stel’makh, S.A.; Shcherban’, E.M.; Beskopylny, A.; Mailyan, L.R.; Meskhi, B.; Beskopylny, N.; Zherebtsov, Y. Development of High-Tech Self-Compacting Concrete Mixtures Based on Nano-Modifiers of Various Types. Materials 2022, 15, 2739. [Google Scholar] [CrossRef]

- Abubakr, A.; Soliman, A. Impact Behaviour of Steel-Fibre-Reinforced Alkali-Activated Slag Concrete Exposed to Elevated Temperatures. Materials 2023, 16, 4096. [Google Scholar] [CrossRef]

- Shi, K.; Deng, H.; Hu, J.; Zhou, J.; Cai, X.; Liu, Z. Effects of Steel Slag Powder Content and Curing Condition on the Performance of Alkali-Activated Materials Based UHPC Matrix. Materials 2023, 16, 3875. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.; Ma, Q.; Chen, Y.; Liu, Z.; Zhou, H. Thermal-Related Stress–Strain Behavior of Alkali Activated Slag Concretes under Compression. Materials 2023, 16, 3470. [Google Scholar] [CrossRef] [PubMed]

- Sivakumar, P.; Villagrán-Zaccardi, Y.; Lapauw, N.; Gruyaert, E.; Matthys, S.; Belie, N. Durability Performance of Hybrid Binder Concretes Containing Non-Ferrous Slag and Recycled Aggregates. Sustainability 2023, 15, 6338. [Google Scholar] [CrossRef]

- Esparham, A.; Vatin, N.; Kharun, M.; Hematibahar, M. A Study of Modern Eco-Friendly Composite (Geopolymer) Based on Blast Furnace Slag Compared to Conventional Concrete Using the Life Cycle Assessment Approach. Infrastructures 2023, 8, 59. [Google Scholar] [CrossRef]

- Beskopylny, A.N.; Shcherban’, E.M.; Stel’makh, S.A.; Mailyan, L.R.; Meskhi, B.; Evtushenko, A.; Varavka, V.; Beskopylny, N. Nano-Modified Vibrocentrifuged Concrete with Granulated Blast Slag: The Relationship between Mechanical Properties and Micro-Structural Analysis. Materials 2022, 15, 4254. [Google Scholar] [CrossRef]

- Kurda, R. Effect of Silica Fume on Engineering Performance and Life Cycle Impact of Jute-Fibre-Reinforced Concrete. Sustainability 2023, 15, 8465. [Google Scholar] [CrossRef]

- Smarzewski, P. Mechanical and Microstructural Studies of High Performance Concrete with Condensed Silica Fume. Appl. Sci. 2023, 13, 2510. [Google Scholar] [CrossRef]

- Amir, V.; Riaz, S.; Ahmed, H.; Raza, S.; Shohan, A.; Alsulamy, S. Synergistic Effect of Micro-Silica and Recycled Tyre Steel Fiber on the Properties of High-Performance Recycled Aggregate Concrete. Sustainability 2023, 15, 8642. [Google Scholar] [CrossRef]

- Montoya, A.; Chung, C.-W.; Kim, J.-H. High Performance Concretes with Highly Reactive Rice Husk Ash and Silica Fume. Materials 2023, 16, 3903. [Google Scholar] [CrossRef]

- Bušić, R.; Miličević, I.; Dokšanović, T.; Grubišić, M. Durability Performance and Thermal Resistance of Structural Self-Compacting Concrete Improved with Waste Rubber and Silica Fume. Buildings 2023, 13, 1331. [Google Scholar] [CrossRef]

- Meskhi, B.; Beskopylny, A.N.; Stel’makh, S.A.; Shcherban’, E.M.; Mailyan, L.R.; Beskopylny, N.; Chernil’nik, A.; El’shaeva, D. Insulation Foam Concrete Nanomodified with Microsilica and Reinforced with Polypropylene Fiber for the Improvement of Characteristics. Polymers 2022, 14, 4401. [Google Scholar] [CrossRef] [PubMed]

- Beskopylny, A.; Stel’makh, S.A.; Shcherban’, E.M.; Mailyan, L.R.; Meskhi, B. Nano Modifying Additive Micro Silica Influence on Integral and Differential Characteristics of Vibrocentrifuged Concrete. J. Build. Eng. 2022, 51, 104235. [Google Scholar] [CrossRef]

- Tisdale, K.A.; Maladeniya, C.P.; Lopez, C.V.; Tennyson, A.G.; Smith, R.C. Sustainable Composites from Waste Sulfur, Terpenoids, and Pozzolan Cements. J. Compos. Sci. 2023, 7, 35. [Google Scholar] [CrossRef]

- Maladeniya, C.P.; Smith, R.C. Influence of Component Ratio on Thermal and Mechanical Properties of Terpenoid-Sulfur Composites. J. Compos. Sci. 2021, 5, 257. [Google Scholar] [CrossRef]

- Fediuk, R.; Mugahed Amran, Y.H.; Mosaberpanah, M.A.; Danish, A.; El-Zeadani, M.; Klyuev, S.V.; Vatin, N. A Critical Review on the Properties and Applications of Sulfur-Based Concrete. Materials 2020, 13, 4712. [Google Scholar] [CrossRef]

- Gulzar, M.; Rahim, A.; Ali, B.; Khan, A. An Investigation on Recycling Potential of Sulfur Concrete. J. Build. Eng. 2021, 38, 102175. [Google Scholar] [CrossRef]

- Meskhi, B.; Beskopylny, A.N.; Stel’makh, S.A.; Shcherban’, E.M.; Mailyan, L.R.; Shilov, A.A.; El’shaeva, D.; Shilova, K.; Karalar, M.; Aksoylu, C.; et al. Analytical Review of Geopolymer Concrete: Retrospective and Current Issues. Materials 2023, 16, 3792. [Google Scholar] [CrossRef]

- Shcherban’, E.M.; Stel’makh, S.A.; Beskopylny, A.; Mailyan, L.R.; Meskhi, B. Increasing the Corrosion Resistance and Durability of Geopolymer Concrete Structures of Agricultural Buildings Operating in Specific Conditions of Aggressive Environments of Livestock Buildings. Appl. Sci. 2022, 12, 1655. [Google Scholar] [CrossRef]

- Sauceda-Oloño, P.Y.; Borbon-Almada, A.C.; Gaxiola, M.; Smith, A.D.; Tennyson, A.G.; Smith, R.C. Thermal and Mechanical Properties of Recyclable Composites Prepared from Bio-Olefins and Industrial Waste. J. Compos. Sci. 2023, 7, 248. [Google Scholar] [CrossRef]

- Dehestani, M.; Teimortashlu, E.; Molaei, M.; Ghomian, M.; Firoozi, S.; Aghili, S. Experimental Data on Compressive Strength and Durability of Sulfur Concrete Modified by Styrene and Bitumen. Data Br. 2017, 13, 137–144. [Google Scholar] [CrossRef]

- Gamal, M.; El-Dieb, A.; Mohamed, A.-M.; Sawy, K. Performance of Modified Sulfur Concrete Exposed to Aactual Sewerage Environment with Variable Temperature, Humidity and Gases. J. Build. Eng. 2017, 11, 1–8. [Google Scholar] [CrossRef]

- Dugarte, M.; Martinez-Arguelles, G.; Torres, J. Experimental Evaluation of Modified Sulfur Concrete for Achieving Sustainability in Industry Applications. Sustainability 2018, 11, 70. [Google Scholar] [CrossRef]

- Mohammed, S.; Poornima, V. Strength and Durability Study of Sulphur Concrete with Replaced Fine Aggregate. Mater. Today Proc. 2018, 5, 23888–23897. [Google Scholar] [CrossRef]

- Al-Otaibi, S.; Al-Aibani, A.; Al-Bahar, S.; Abdulsalam, M.; Al-Fadala, S. Potential for Producing Concrete Blocks Using Sulphur Polymeric Concrete in Kuwait. J. King Saud Univ. Eng. Sci. 2019, 31, 327–331. [Google Scholar] [CrossRef]

- Bae, S.G.; Gwon, S.W.; Kim, S.W.; Cha, S.W. Physical Properties of Sulfur Concrete with Modified Sulfur Binder. J. Korean Soc. Civ. Eng. 2014, 34, 763–771. [Google Scholar] [CrossRef][Green Version]

- Moon, J.; Kalb, P.; Milian, L.; Northrup, P. Characterization of a Sustainable Sulfur Polymer Concrete Using Activated Fillers. Cem. Concr. Compos. 2016, 67, 20–29. [Google Scholar] [CrossRef]

- Yang, C.; Lv, X.; Tian, X.; Wang, Y.; Komarneni, S. An Investigation on the Use of Electrolytic Manganese Residue as Filler in Sulfur Concrete. Constr. Build. Mater. 2014, 73, 305–310. [Google Scholar] [CrossRef]

- Khavari, B.; Shekarriz, M.; Aminnejad, B.; Lork, A.; Vahdani, S. Laboratory Evaluation and Optimization of Mechanical Properties of Sulfur Concrete Reinforced with Micro and Macro Steel Fibers via Response Surface Methodology. Constr. Build. Mater. 2023, 384, 131434. [Google Scholar] [CrossRef]

- Dobrosmyslov, S.; Zadov, V.; Nazirov, R.; Nagibin, G.; Voronin, A.; Simunin, M.; Fadeev, Y.; Khartov, S. High Strength Construction Material Based on Sulfur Binder Obtained by Physical Modification. Buildings 2022, 12, 1012. [Google Scholar] [CrossRef]

- GOST 10180-2012; Concretes. Methods for Strength Determination Using Reference Specimens. Gost Standard: Moscow, Russia, 2012. Available online: http://docs.cntd.ru/document/1200100908 (accessed on 30 June 2023).

- EN 12390-1:2021; Testing Hardened Concrete—Part 1: Shape, Dimensions and Other Requirements of Specimens and Moulds. iTeh Standards: Etobicoke, ON, Canada, 2021. Available online: https://standards.iteh.ai/catalog/standards/cen/d1c9ccee-2e5a-425e-a964-961da95d2f99/en-12390-1-2021 (accessed on 30 June 2023).

- EN 12390-2:2019; Testing Hardened Honcrete—Part 2: Making and Curing Specimens for Strength Tests. iTeh Standards: Etobicoke, ON, Canada, 2019. Available online: https://standards.iteh.ai/catalog/standards/cen/ae7e6a86-1cbc-455e-8b2a-8964be9087f9/en-12390-2-2019 (accessed on 30 June 2023).

- EN 12390-3:2019; Testing Hardened Honcrete—Part 3: Compressive Strength of Test Specimens. iTeh Standards: Etobicoke, ON, Canada, 2019. Available online: https://standards.iteh.ai/catalog/standards/cen/7eb738ef-44af-436c-ab8e-e6561571302c/en-12390-3-2019 (accessed on 30 June 2023).

- EN 12390-4:2019; Testing Hardened Concrete—Part 4: Compressive Strength—Specification for Testing Machines. iTeh Standards: Etobicoke, ON, Canada, 2019. Available online: https://standards.iteh.ai/catalog/standards/cen/10b1c613-819b-42d7-8f94-480cd37a666a/en-12390-4-2019 (accessed on 30 June 2023).

- EN 12390-5:2019; Testing Hardened Honcrete—Part 5: Flexural Strength of Test Specimens. iTeh Standards: Etobicoke, ON, Canada, 2019. Available online: https://standards.iteh.ai/catalog/standards/cen/5653c2c7-55a9-4bcb-8e13-5b1dfb0e3baf/en-12390-5-2019 (accessed on 30 June 2023).

- GOST 12730.1-2020; Concretes. Methods of Determination of Density. Gost Standard: Moscow, Russia, 2020. Available online: https://docs.cntd.ru/document/1200177299 (accessed on 30 June 2023).

- EN 12390-7:2019; Testing Hardened Honcrete—Part 7: Density of Hardened Concrete. iTeh Standards: Etobicoke, ON, Canada, 2019. Available online: https://standards.iteh.ai/catalog/standards/cen/811a0cf3-55e3-495a-b06e-5c302d5f2806/en-12390-7-2019 (accessed on 30 June 2023).

- GOST 12730.3-2020; Concretes. Method of Determination of Water Absorption. Gost Standard: Moscow, Russia, 2020. Available online: https://docs.cntd.ru/document/1200177301 (accessed on 30 June 2023).

- BS 1881-122:2011+A1:2020; Testing Concrete Method for Determination of Water Absorption. European Standards: Plzen, Czech Republic, 2020. Available online: https://www.en-standard.eu/bs-1881-122-2011-a1-2020-testing-concrete-method-for-determination-of-water-absorption/ (accessed on 30 June 2023).

- GOST 8735-88; Sand for construction work. Testing methods. Gost Standard: Moscow, Russia, 2020. Available online: https://docs.cntd.ru/document/1200003348 (accessed on 2 August 2023).

- ISO 3262-21:2023(en); Extenders—Specifications and methods of test—Part 21: Silica sand (Unground Natural Quartz). International Organization for Standardization: London, UK, 2023. Available online: https://www.iso.org/obp/ui/en/#iso:std:iso:3262:-21:ed-2:v1:en (accessed on 2 August 2023).

- Lazovskaya, I.; Jakubowski, S.; Hlukhau, D.; Lazouski, Y. Serobeton as a Perspective Building Material. Vestn. Polotskogo Gos. Univ. 2017, 8, 53–57. [Google Scholar]

- Khademi, A.G.; Imani, H. Comparison of Sulfur Concrete, Cement Concrete and Cement-sulfur Concrete and their Properties and Application. Curr. World Environ. 2015, 10, 63–68. Available online: https://www.cwejournal.org/pdf/vol10noSI1/CWE_Vol10_Spl(1)_p_201-207.pdf (accessed on 24 August 2023). [CrossRef]

- Ciak, N.; Jankowski, D.; Ciak, M.J. The Role of Microfillers in Shaping the Sulphur Concrete Performance. Tech. Sci./Univ. Warm. Mazury Olszt. 2015, 18, 171–178. Available online: https://www.infona.pl/resource/bwmeta1.element.baztech-59bfc8f7-f3f5-4ad3-9eb2-b35c0c67fc39 (accessed on 24 August 2023).

- Yusupova, A.; Baraeva, L.; Medvedeva, G.; Bobryshev, A. Technology and Properties of High-strength Sulfur Concrete Modified with Organometallophosphate Compounds. Mater. Today Proc. 2021, 38, 1648–1652. [Google Scholar] [CrossRef]

- Shin, M.; Kim, K.; Gwon, S.-W.; Cha, S. Durability of Sustainable Sulfur Concrete with Fly Ash and Recycled Aggregate Against Chemical and Weathering Environments. Constr. Build. Mater. 2014, 69, 167–176. [Google Scholar] [CrossRef]

| Component Name | Property | Actual Value |

|---|---|---|

| TS | Bulk density (kg/m3) | 1347 |

| Sulfur mass fraction (%) | 99.95 | |

| Ash content (%) | 0.02 | |

| Mass fraction of organic substances (%) | 0.01 | |

| Mass fraction of acids in terms of sulfuric acid (%) | 0.002 | |

| Mass fraction of water (%) | 0.018 | |

| FA | Bulk density (kg/m3) | 1180 |

| Na2O | 0.65 | |

| MgO | 2.49 | |

| Al2O3 | 24.2 | |

| SiO2 | 48.45 | |

| K2O | 1.25 | |

| CaO | 7.3 | |

| TiO2 | 0.92 | |

| MnO | 0.069 | |

| Fe2O3 | 9.88 | |

| V2O5 | 0.02 | |

| Gr2O3 | 0.01 | |

| Stotal | 0.26 | |

| CO2 | 0.1 | |

| P2O5 | 1.71 | |

| Cu | 0.012 | |

| Zn | 0.019 | |

| Loss on ignition at 950 °C | 2.66 | |

| CS | Particle size (mm) | 5–20 |

| Bulk density (kg/m3) | 1385 | |

| Apparent density (kg/m3) | 2567 | |

| Resistance to fragmentation (wt %) | 12.0 | |

| The content of lamellar and acicular grains (wt %) | 8.4 | |

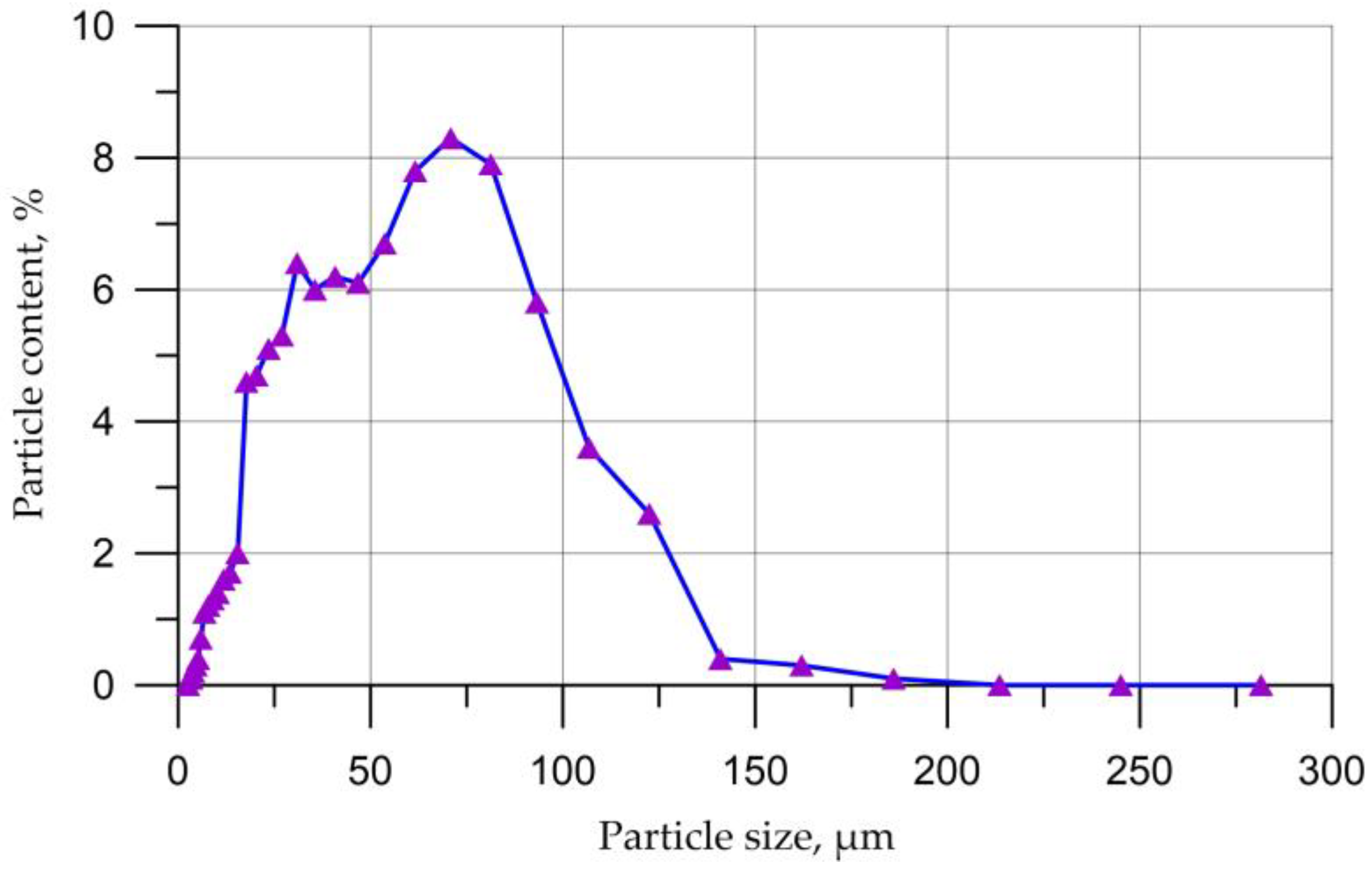

| S | Fineness modulus | 1.65 |

| Bulk density (kg/m3) | 1462 | |

| The content of dust and clay particles (%) | 0.14 | |

| Content of clay in lumps (%) | 0.11 | |

| Organic and contaminant content | No |

| Composition Type | Concrete Mixture Proportion per 1 m3 | ||||

|---|---|---|---|---|---|

| TS (kg/m3) | FA (kg/m3) | CS (kg/m3) | S (kg/m3) | Bitumen (kg/m3) | |

| C | 605 | 0 | 968 | 847 | 0 |

| FA5/2 | 605 | 121 | 968 | 726 | 12.1 |

| FA10/2 | 605 | 242 | 968 | 605 | 12.1 |

| FA15/2 | 605 | 363 | 968 | 484 | 12.1 |

| FA5/4 | 605 | 121 | 968 | 726 | 24.2 |

| FA10/4 | 605 | 242 | 968 | 605 | 24.2 |

| FA15/4 | 605 | 363 | 968 | 484 | 24.2 |

| FA5/6 | 605 | 121 | 968 | 726 | 36.3 |

| FA10/6 | 605 | 242 | 968 | 605 | 36.3 |

| FA15/6 | 605 | 363 | 968 | 484 | 36.3 |

| Residues on Sieves (%) | Sieve Diameter (mm) | |||||

|---|---|---|---|---|---|---|

| 2.5 | 1.25 | 0.63 | 0.315 | 0.16 | <0.16 | |

| Partial | 3.6 | 7.9 | 8.2 | 10.8 | 68.4 | 1.1 |

| Total | 3.6 | 11.5 | 19.7 | 30.5 | 98.9 | |

| Composition | C | FA5/2 | FA10/2 | FA15/2 | FA5/4 | FA10/4 | FA15/4 | FA5/6 | FA10/6 | FA15/6 |

|---|---|---|---|---|---|---|---|---|---|---|

| Compressive strength growth (%) | 1.4 | 2.4 | 1.1 | 0.6 | 1.0 | 0.8 | 1.0 | 1.3 | 0.5 | 1.7 |

| Composition | K | FA5/2 | FA10/2 | FA15/2 | FA5/4 | FA10/4 | FA15/4 | FA5/6 | FA10/6 | FA15/6 |

|---|---|---|---|---|---|---|---|---|---|---|

| Water absorption reduction (%) | 1.1 | 0.5 | 1.3 | 1.2 | 1.8 | 1.1 | 1.7 | 1.3 | 2.1 | 0.7 |

| Characteristics of Sulfur Concrete | The Content of FA (% wt) in the Composition of the Sulfur Concrete Mixture | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 5 | 10 | 15 | |||||||

| Bitumen Additive Content (% by Weight of Sulfur) | |||||||||

| 2 | 4 | 6 | 2 | 4 | 6 | 2 | 4 | 6 | |

| Density after 1 day (kg/m3) | −0.04 | −0.12 | 0.08 | −0.12 | 0.12 | 0.25 | 0.04 | 0.21 | −0.08 |

| Density after 28 days (kg/m3) | 0.25 | 0.08 | 0.45 | 0.41 | 0 | 0.29 | 0.29 | 0.49 | 0.62 |

| Compressive strength after 1 day (MPa) | 2.2 | 48.0 | 11.7 | 29.9 | 79.6 | 58.4 | 12.4 | 42.3 | 26.3 |

| Compressive strength after 28 days (MPa) | 7.2 | 47.5 | 11.5 | 29.5 | 78.4 | 56.8 | 11.5 | 41.7 | 26.6 |

| Water absorption after 1 day (MPa) | −4.2 | −40.1 | −19.3 | −20.3 | −52.6 | −48.4 | −13.5 | −38.0 | −21.9 |

| Water absorption after 28 days (MPa) | −3.7 | −40.5 | −19.5 | −20.5 | −52.6 | −48.9 | −13.7 | −38.4 | −21.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stel’makh, S.A.; Shcherban’, E.M.; Beskopylny, A.N.; Mailyan, L.R.; Meskhi, B.; Shilov, A.A.; Evtushenko, A.; Chernil’nik, A.; El’shaeva, D.; Karalar, M.; et al. Physical, Mechanical and Structural Characteristics of Sulfur Concrete with Bitumen Modified Sulfur and Fly Ash. J. Compos. Sci. 2023, 7, 356. https://doi.org/10.3390/jcs7090356

Stel’makh SA, Shcherban’ EM, Beskopylny AN, Mailyan LR, Meskhi B, Shilov AA, Evtushenko A, Chernil’nik A, El’shaeva D, Karalar M, et al. Physical, Mechanical and Structural Characteristics of Sulfur Concrete with Bitumen Modified Sulfur and Fly Ash. Journal of Composites Science. 2023; 7(9):356. https://doi.org/10.3390/jcs7090356

Chicago/Turabian StyleStel’makh, Sergey A., Evgenii M. Shcherban’, Alexey N. Beskopylny, Levon R. Mailyan, Besarion Meskhi, Alexandr A. Shilov, Alexandr Evtushenko, Andrei Chernil’nik, Diana El’shaeva, Memduh Karalar, and et al. 2023. "Physical, Mechanical and Structural Characteristics of Sulfur Concrete with Bitumen Modified Sulfur and Fly Ash" Journal of Composites Science 7, no. 9: 356. https://doi.org/10.3390/jcs7090356

APA StyleStel’makh, S. A., Shcherban’, E. M., Beskopylny, A. N., Mailyan, L. R., Meskhi, B., Shilov, A. A., Evtushenko, A., Chernil’nik, A., El’shaeva, D., Karalar, M., Özkılıç, Y. O., & Aksoylu, C. (2023). Physical, Mechanical and Structural Characteristics of Sulfur Concrete with Bitumen Modified Sulfur and Fly Ash. Journal of Composites Science, 7(9), 356. https://doi.org/10.3390/jcs7090356