Analysis of Ballistic Impact of 7.62 mm FMJ M80 Rifle Projectile into Twaron/UHMWPE Composite Armor

Abstract

:1. Introduction

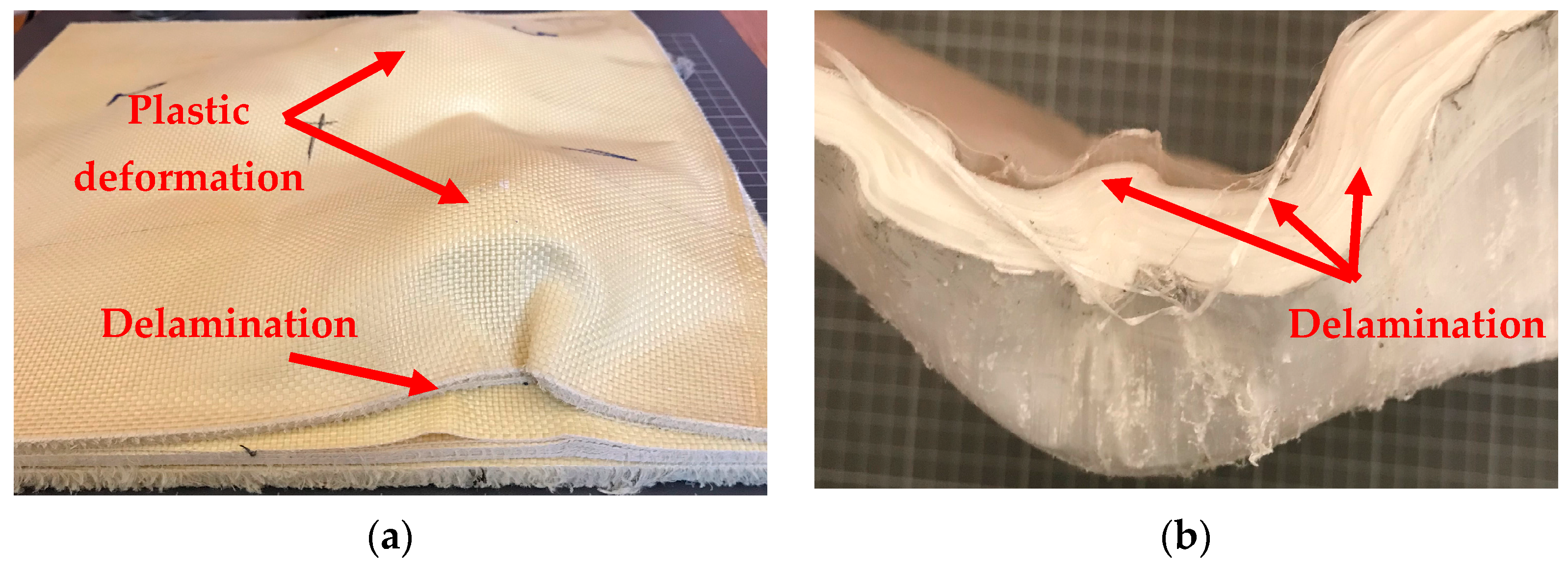

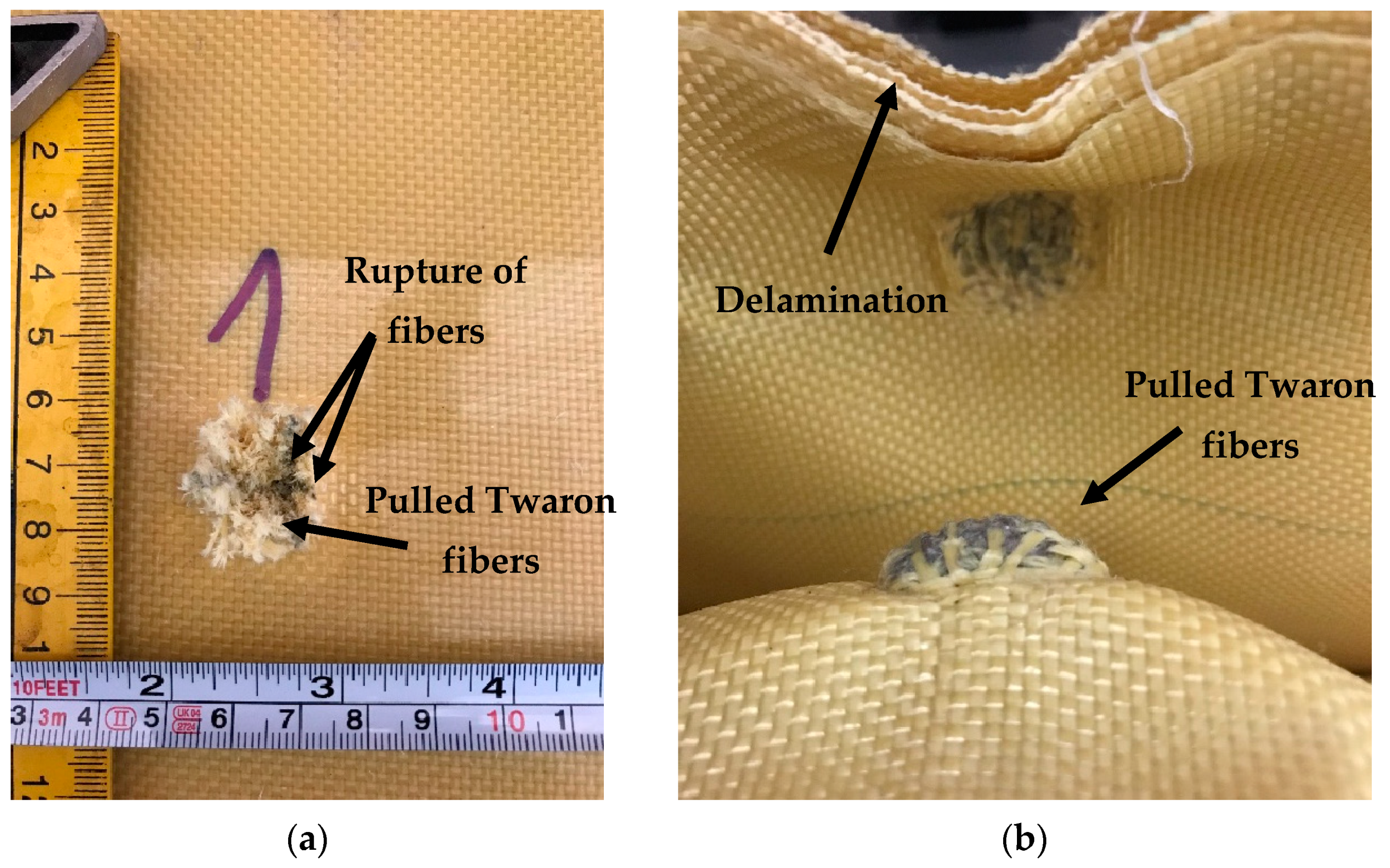

2. Materials and Methods

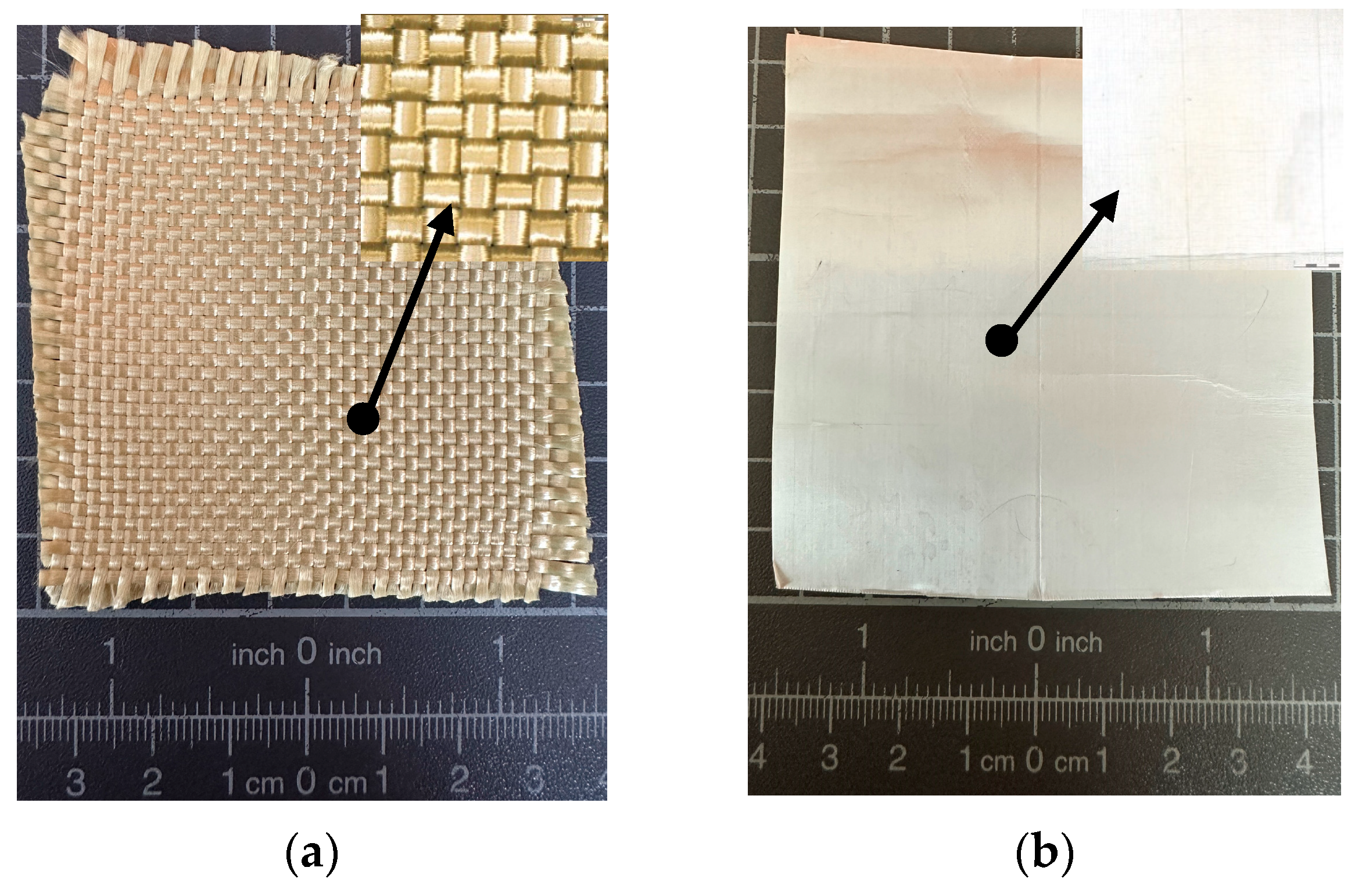

2.1. Material Properties of Composite Armor

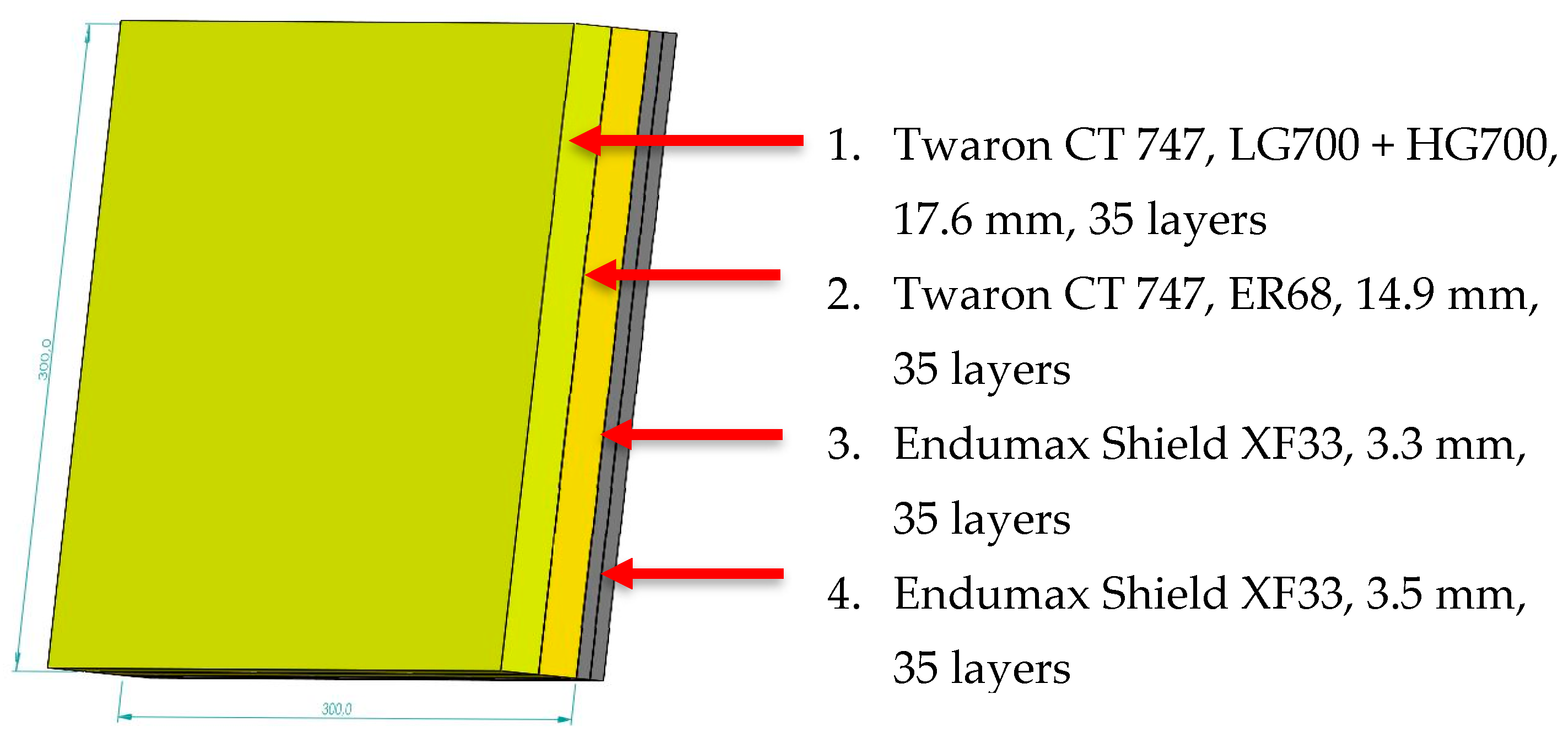

2.2. Manufacture of Composite Armor Twaron/UHMWPE

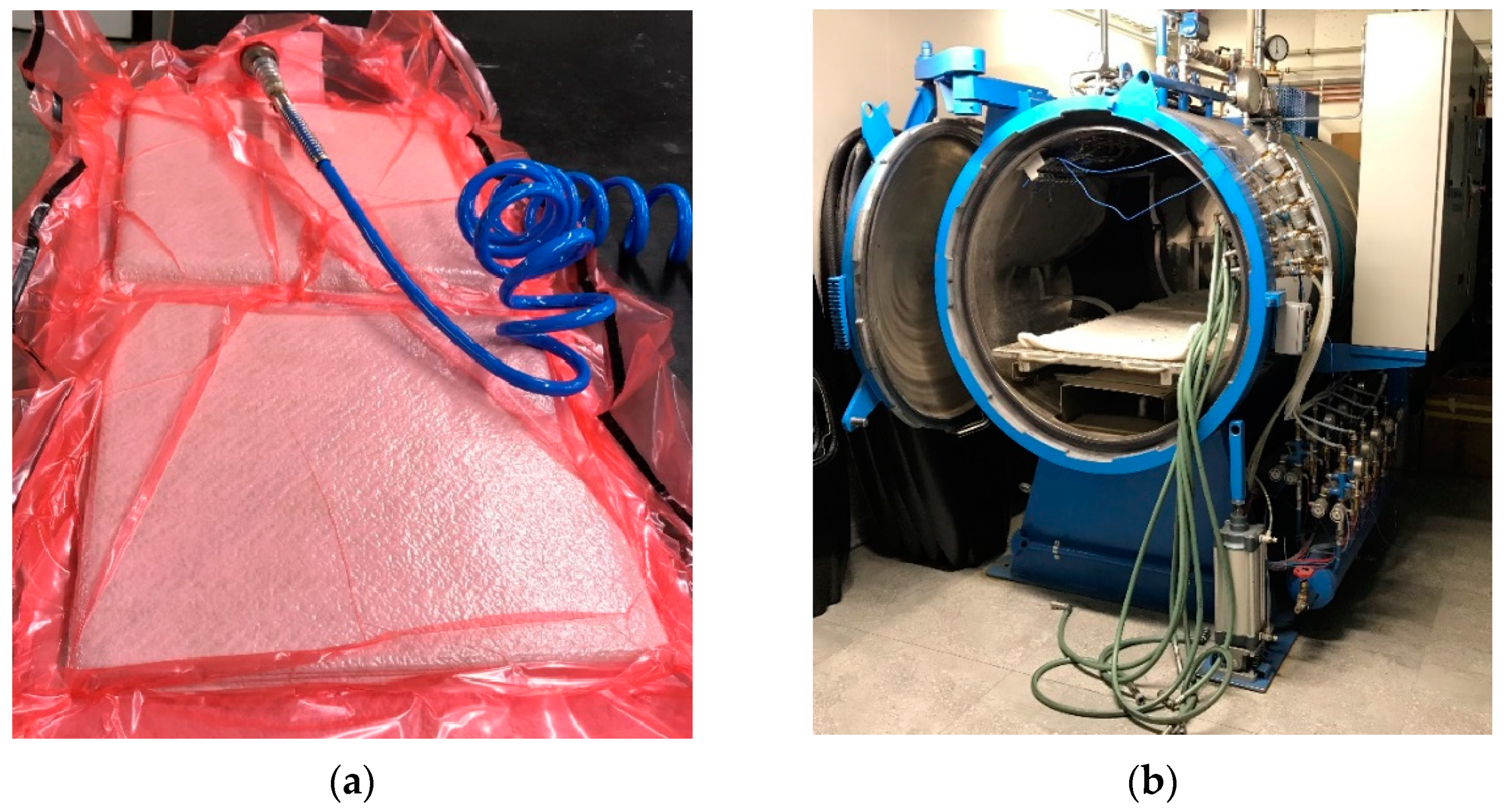

2.2.1. VARTM Technology

2.2.2. Autoclave Technology

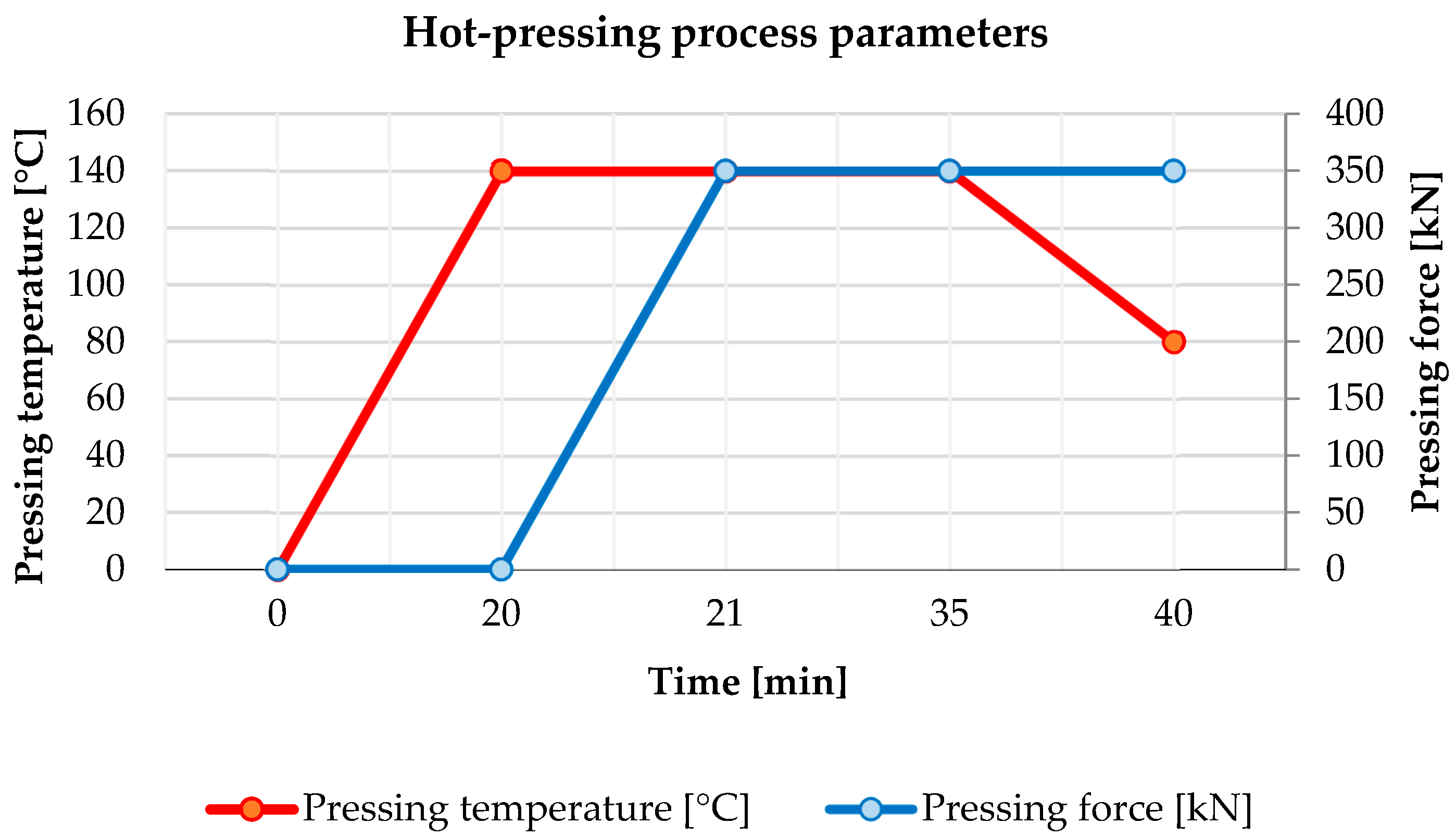

2.2.3. Hot−Pressing Technology

2.3. Testing of Manufactured Composite Panels

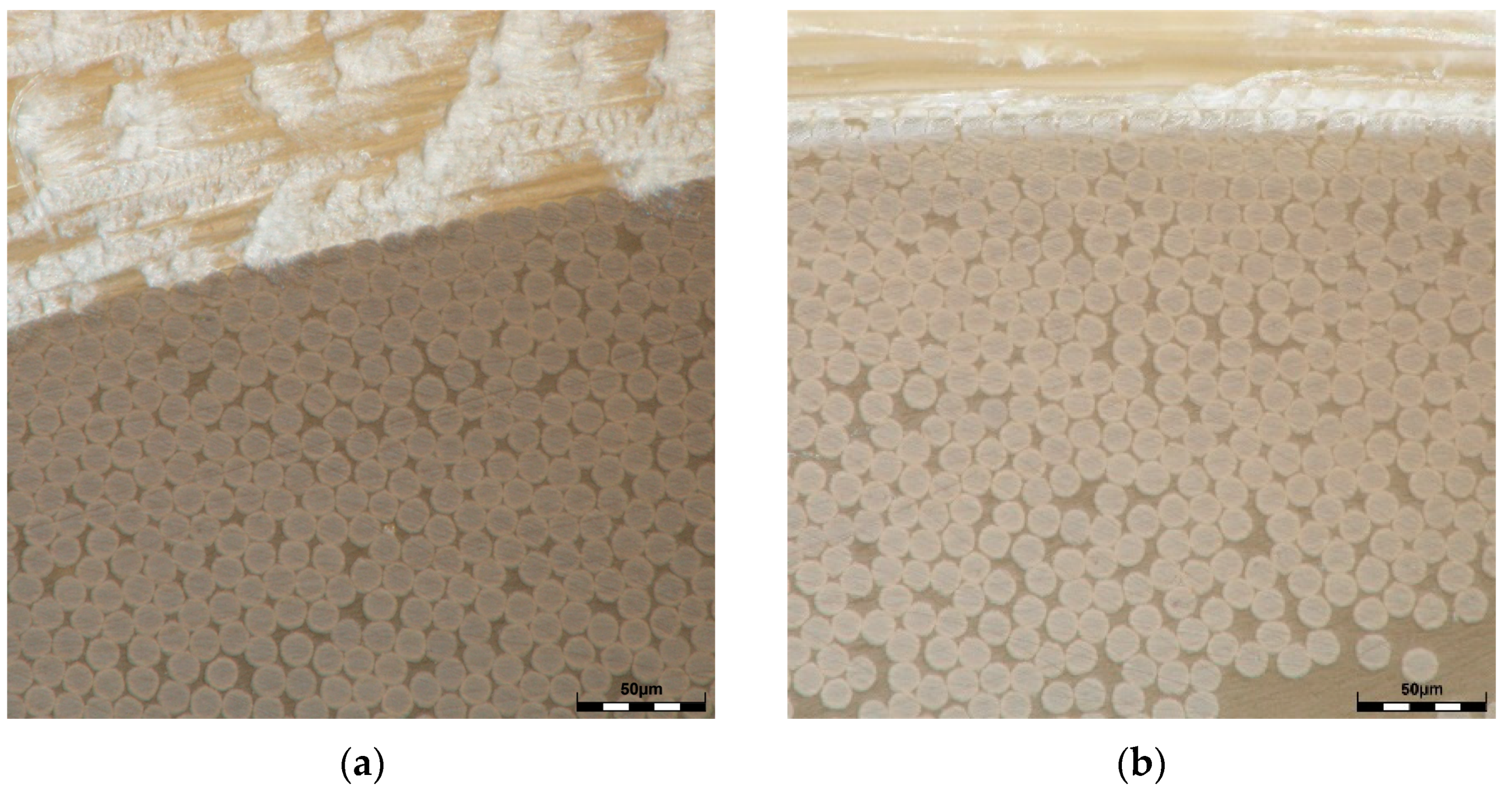

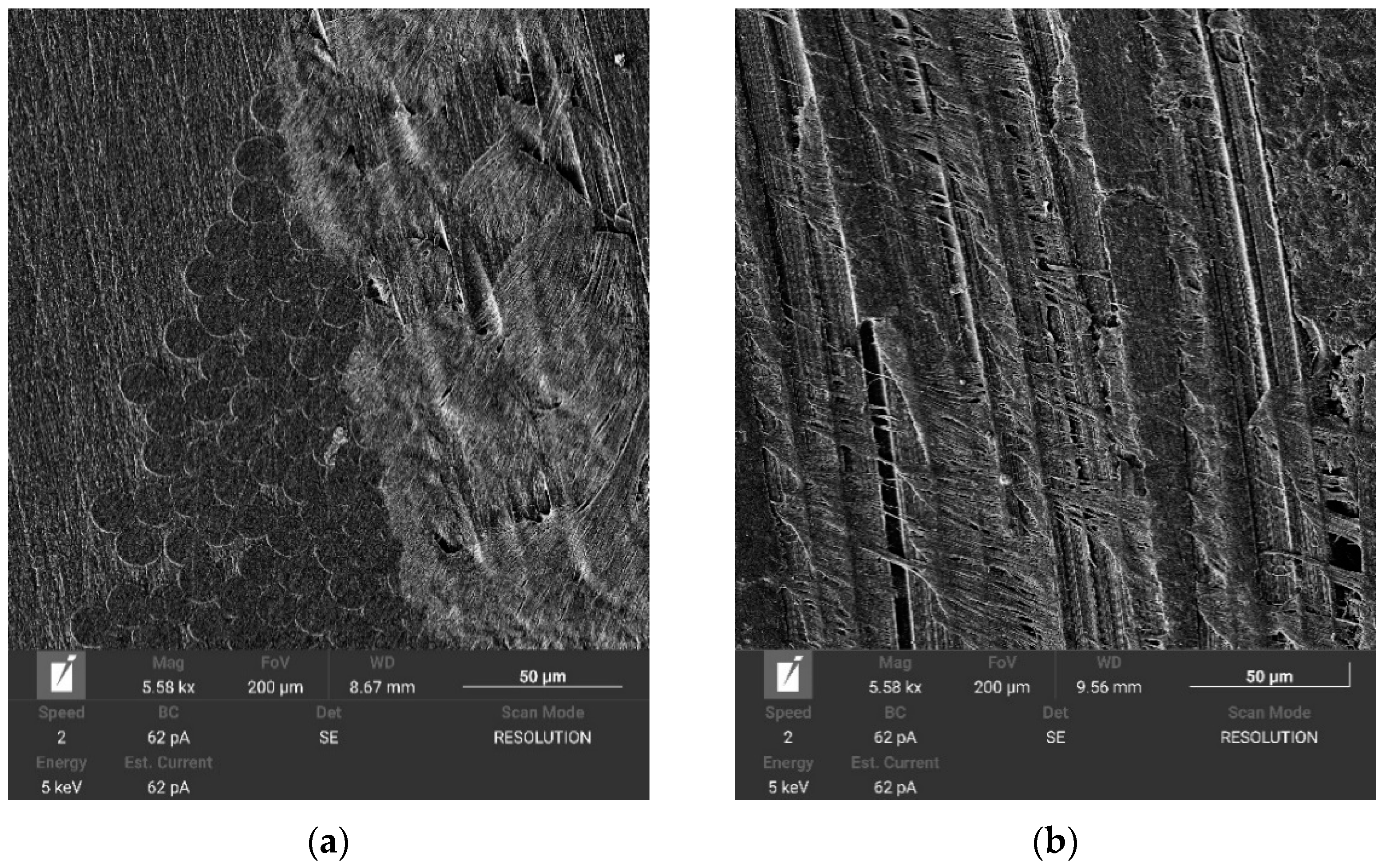

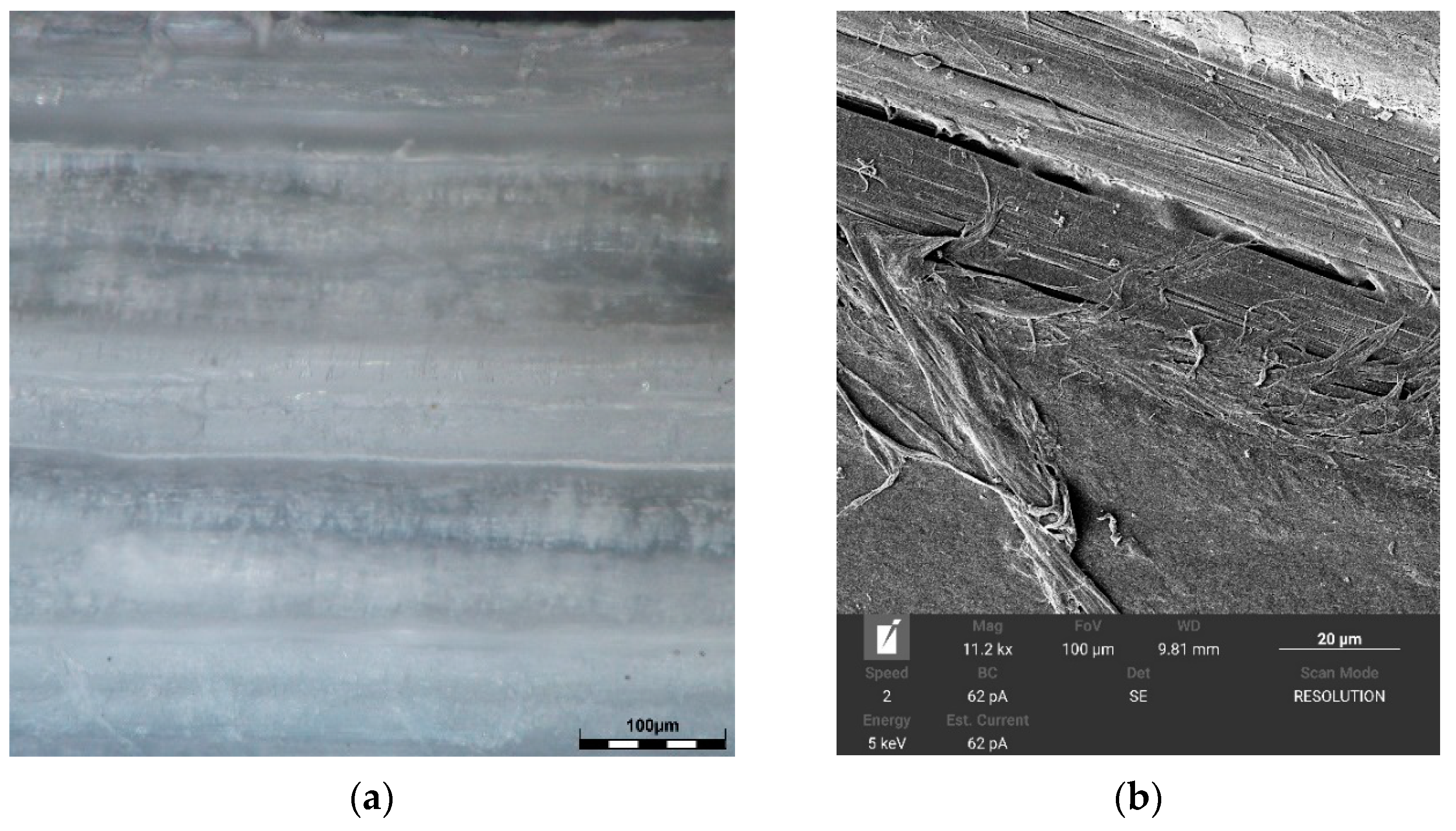

2.3.1. Surface Hardness and Microstructure of Composite Panels

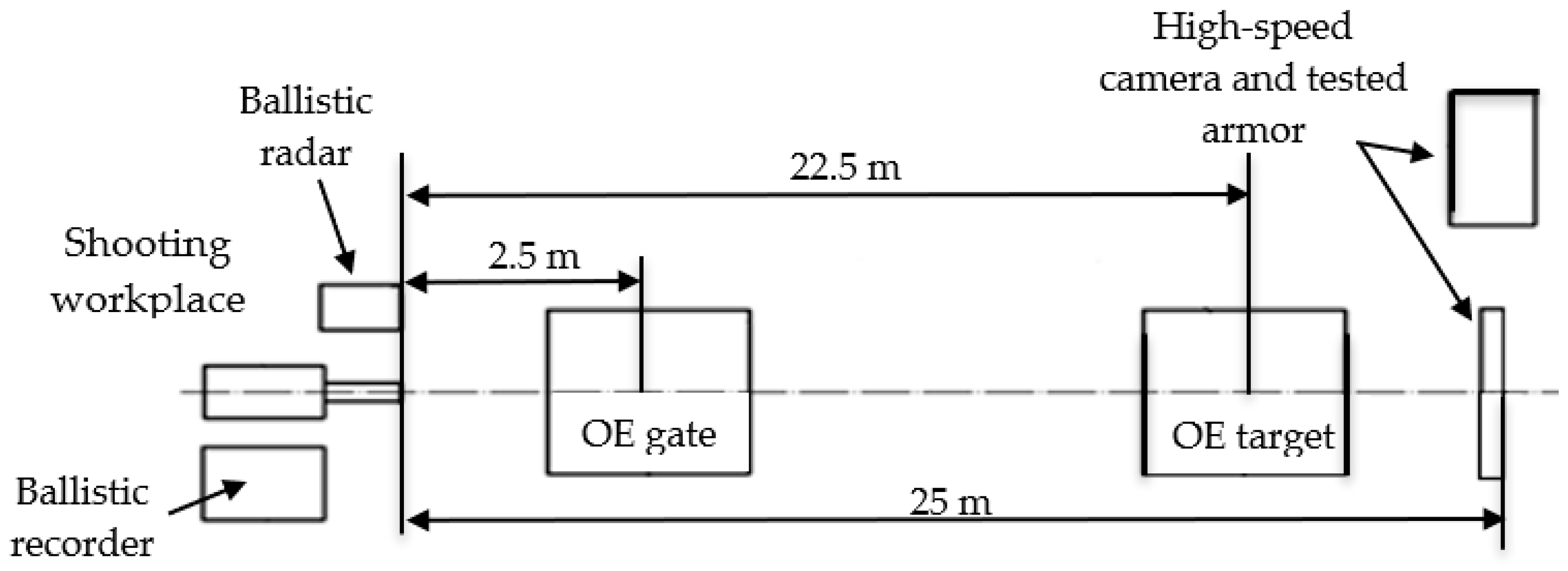

2.3.2. Ballistic Testing of Composite Panels

3. Results and Discussion

3.1. Surface Hardness of Composite Panels

3.2. Ballistic Testing Results

4. Conclusions

- Change of armor composition in the context of experimentally obtained results

- 2.

- Increasing ballistic resistance of layered composite armor

- 3.

- Method of damage evaluation of composite armor

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Miao, W.D.; Li, F.; Zeng, W.; Zheng, X.J. Key Technologies for Adaptive Change Design of Armored Vehicle in Response to Complex Environment. Adv. Mater. Res. 2014, 926–930, 1724–1728. [Google Scholar] [CrossRef]

- Vala, M.; Žalud, Z.; Neumann, V. Teorie a Kostrukce Bojových a Speciálních Vozidel. Vol. Díl III, Bezpečnost a Zkoušení Vozidel; Univerzita Obrany: Brno, Czech Republic, 2017; ISBN 978-80-7582-023-5. [Google Scholar]

- Rolc, S.; Buchar, J.; Křesťan, J.; Krátký, J.; Řídký, R. Pancéřová Ochrana; Academia: Praha, Czech Republic; Gerstner: Dayton, OH, USA, 2022; ISBN 978-80-200-3100-6. [Google Scholar]

- De Oliveira Braga, F.; Lima, É.P., Jr.; de Sousa Lima, E.; Monteiro, S.N. The Effect of Thickness on Aramid Fabric Laminates Subjected to 7.62 mm Ammunition Ballistic Impact. Mater. Res. 2017, 20 (Suppl. S2), 676–680. [Google Scholar] [CrossRef]

- Yadav, R.; Naebe, M.; Wang, X.; Kandasubramanian, B. Body Armor Materials: From Steel to Contemporary Biomimetic Systems. RSC Adv. 2016, 6, 115145–115174. [Google Scholar] [CrossRef]

- Bhatnagar, A. (Ed.) Lightweight Ballistic Composites: Military and Law-Enforcement Applications; Woodhead Publishing: Cambridge, UK, 2016. [Google Scholar]

- Nunes, S.G.; Scazzosi, R.; Manes, A.; Amico, S.C.; de Amorim Júnior, W.F.; Giglio, M. Influence of Projectile and Thickness on the Ballistic Behavior of Aramid Composites: Experimental and Numerical Study. Int. J. Impact Eng. 2019, 132, 103307. [Google Scholar] [CrossRef]

- Oliveira, M.S.; Pereira, A.C.; da Costa Garcia Filho, F.; da Luz, F.S.; de Oliveira Braga, F.; Nascimento, L.F.C.; Lima, É.P., Jr.; da Cruz Demosthenes, L.C.; Monteiro, S.N. Fique Fiber-Reinforced Epoxy Composite for Ballistic Armor against 7.62 mm Ammunition. In Green Materials Engineering; Springer International Publishing: Cham, Switzerland, 2019; pp. 193–199. [Google Scholar] [CrossRef]

- Prochazka, J.; Pokorny, Z.; Jasenak, J.; Majerik, J.; Neumann, V. Possibilities of the Utilization of Ferritic Nitrocarburizing on Case-Hardening Steels. Materials 2021, 14, 3714. [Google Scholar] [CrossRef]

- Hu, P.; Cheng, Y.; Zhang, P.; Liu, J.; Yang, H.; Chen, J. A Metal/UHMWPE/SiC Multi-Layered Composite Armor against Ballistic Impact of Flat-Nosed Projectile. Ceram. Int. 2021, 47, 22497–22513. [Google Scholar] [CrossRef]

- Viliš, J.; Pokorný, Z.; Zouhar, J.; Jopek, M. Ballistic Resistance of Composite Materials Tested by Taylor Anvil Test. Manuf. Technol. 2022, 22, 610–616. [Google Scholar] [CrossRef]

- Hub, J.; Komenda, J. Ballistic’s Resistance of Steel Plate Hardox upon Impact of Non Penetrating Projectiles. Adv. Mil. Technol. 2009, 4, 79–91. [Google Scholar]

- De Oliveira Braga, F.; Bolzan, L.T.; Lima, É.P., Jr.; Monteiro, S.N. Performance of Natural Curaua Fiber-Reinforced Polyester Composites under 7.62 mm Bullet Impact as a Stand-Alone Ballistic Armor. J. Mater. Res. Technol. 2017, 6, 323–328. [Google Scholar] [CrossRef]

- Da Cruz Demosthenes, L.C.; Da Luz, F.S.; Nascimento, L.F.C.; Monteiro, S.N. Buriti Fabric Reinforced Epoxy Composites as a Novel Ballistic Component of a Multilayered Armor System. Sustainability 2022, 14, 10591. [Google Scholar] [CrossRef]

- Scazzosi, R.; De Souza, S.D.B.; Amico, S.C.; Giglio, M.; Manes, A. Experimental and Numerical Evaluation of the Perforation Resistance of Multi-Layered Alumina/Aramid Fiber Ballistic Shield Impacted by an Armor Piercing Projectile. Compos. Part B Eng. 2022, 230, 109488. [Google Scholar] [CrossRef]

- Mujiyono, M.; Nurhadiyanto, D.; Mukhammad, A.F.H.; Riyadi, T.W.B.; Wahyudi, K.; Kholis, N.; Wulandari, A.P.; Hassan, S.A. Damage Formations of Ramie Fiber Composites Multilayer Armour System under High-Velocity Impacts. East.–Eur. J. Enterp. Technol. 2023, 1, 16–25. [Google Scholar] [CrossRef]

- Al-Furjan, M.S.H.; Shan, L.; Shen, X.; Zarei, M.S.; Hajmohammad, M.H.; Kolahchi, R. A Review on Fabrication Techniques and Tensile Properties of Glass, Carbon, and Kevlar Fiber Reinforced Rolymer Composites. J. Mater. Res. Technol. 2022, 19, 2930–2959. [Google Scholar] [CrossRef]

- Bracco, P.; Bellare, A.; Bistolfi, A.; Affatato, S. Ultra-High Molecular Weight Polyethylene: Influence of the Chemical, Physical and Mechanical Properties on the Wear Behavior. A Review. Materials 2017, 10, 791. [Google Scholar] [CrossRef]

- Li, Y.; Fan, H.; Gao, X.-L. Ballistic Helmets: Recent Advances in Materials, Protection Mechanisms, Performance, and Head Injury Mitigation. Compos. B Eng. 2022, 238, 109890. [Google Scholar] [CrossRef]

- Dharmavarapu, P.; Reddy, S. Aramid Fibre as Potential Reinforcement for Polymer Matrix Composites: A Review. Emergent Mater. 2022, 5, 1561–1578. [Google Scholar] [CrossRef]

- Priyanka, P.; Dixit, A.; Mali, H.S. High Strength Kevlar Fiber Reinforced Advanced Textile Composites. Iran. Polym. J. 2019, 28, 621–638. [Google Scholar] [CrossRef]

- Ari, A.; Karahan, M.; Kopar, M.; Ahrari, M. The Effect of Manufacturing Parameters on Various Composite Plates under Ballistic Impact. Polym. Polym. Compos. 2022, 30, 096739112211448. [Google Scholar] [CrossRef]

- Twaron CT 747; Teijin Limited; Ballistic Materials Handbook. Japan: Tokyo, Osaka. Available online: https://www.teijinaramid.com/sites/default/files/2023-07/Twaron-Prepreg-CT-736-CT-777-Von-Roll-TA00112-English-20.pdf (accessed on 12 July 2023).

- Endumax Shield XF33; Teijin Limited; Ballistic Materials Handbook. Japan: Tokyo, Osaka. Available online: https://www.teijinaramid.com/sites/default/files/2023-07/Endumax-Film-Shield-Fabric-Panel-Laminate-TA00113-English-20210521.pdf (accessed on 12 July 2023).

- Kuentzer, N.; Simacek, P.; Advani, S.G.; Walsh, S. Correlation of Void Distribution to VARTM Manufacturing Techniques. Compos. Part A Appl. Sci. Manuf. 2007, 38, 802–813. [Google Scholar] [CrossRef]

- Bender, D.; Schuster, J.; Heider, D. Flow Rate Control during Vacuum-Assisted Resin Transfer Molding (VARTM) Processing. Compos. Sci. Technol. 2006, 66, 2265–2271. [Google Scholar] [CrossRef]

- Kostopoulos, V.; Masouras, A.; Baltopoulos, A.; Vavouliotis, A.; Sotiriadis, G.; Pambaguian, L. A Critical Review of Nanotechnologies for Composite Aerospace Structures. CEAS Space J. 2017, 9, 35–57. [Google Scholar] [CrossRef]

- Zouhar, J.; Slaný, M.; Sedlák, J.; Joska, Z.; Pokorný, Z.; Barényi, I.; Majerík, J.; Fiala, Z. Application of Carbon–Flax Hybrid Composite in High Performance Electric Personal Watercraft. Polymers 2022, 14, 1765. [Google Scholar] [CrossRef]

- Hassan, M.H.; Othman, A.R.; Kamaruddin, S. A Review on the Manufacturing Defects of Complex-Shaped Laminate in Aircraft Composite Structures. Int. J. Adv. Manuf. Technol. 2017, 91, 4081–4094. [Google Scholar] [CrossRef]

- Budelmann, D.; Schmidt, C.; Meiners, D. Prepreg Tack: A Review of Mechanisms, Measurement, and Manufacturing Implication. Polym. Compos. 2020, 41, 3440–3458. [Google Scholar] [CrossRef]

- Asim, M.; Jawaid, M.; Saba, N.; Ramengmawii; Nasir, M.; Sultan, M.T.H. Processing of Hybrid Polymer Composites—A Review. In Hybrid Polymer Composite Materials; Elsevier: Amsterdam, The Netherlands, 2017; pp. 1–22. [Google Scholar] [CrossRef]

- Sapozhnikov, S.B.; Kudryavtsev, O.A.; Zhikharev, M.V. Fragment Ballistic Performance of Homogenous and Hybrid Thermoplastic Composites. Int. J. Impact Eng. 2015, 81, 8–16. [Google Scholar] [CrossRef]

- Pandya, K.S.; Pothnis, J.R.; Ravikumar, G.; Naik, N.K. Ballistic Impact Behavior of Hybrid Composites. Mater. Eng. 2013, 44, 128–135. [Google Scholar] [CrossRef]

- ASTM D1415; Standard Test Method for Rubber Property—International Hardness. American Society for Testing Materials: West Conshohocken, PA, USA, 2018.

- Qi, H.J.; Joyce, K.; Boyce, M.C. Durometer Hardness and the Stress-Strain Behavior of Elastomeric Materials. Rubber Chem. Technol. 2003, 76, 419–435. [Google Scholar] [CrossRef]

- ČSN 39 5360; Zkoušky Odolnosti Ochranných Prostředků—Zkoušky Odolnosti Proti Střelám, Střepinám a Bodným Zbraním—Technické Požadavky a Zkoušky. Česká Agentura pro Standardizaci: Praha, Czech Republic, 2018.

- NIJ STANDARD-0101.06; Ballistic Resistance of Body Armor. National Institute of Justice. National Institute of Justice: Washington, DC, USA, 2008.

- VPAM APR 2006; General Basis for Ballistic Material, Construction and Product Testing: Requirements, Test Levels and Test Procedures. Association of Test Laboratories for Bullet Resistant Materials and Constructions: Rijswijk, The Netherlands, 2014. Available online: https://www.vpam.eu/pruefrichtlinien/aktuell/apr-2006/ (accessed on 30 November 2014).

- AEP-55, STANAG 4569; Protection Levels for Occupants of Logistic and Light Armored Vehicles. Part 1–4: General—Annex A, First Edition. NATO: Brussels, Belgium, 2005; Volume 1.

- ČOS 130027; Balistická Odolnost Osobních Ochranných Prostředků při Ohrožení Střepinami—Modifikovaná Metoda. Úřad pro Obrannou Standardizaci, Katalogizaci a Státní Ověřování Jakosti: Praha, Czech Republic, 2022. Available online: https://oos-data.army.cz/cos/cos/130027.pdf (accessed on 15 July 2023).

- Viliš, J.; Pokorný, Z.; Zouhar, J. Testing the Ballistic Resistance of Composite Materials. In Proceedings of the 31st International Conference on Metallurgy and Materials, Brno, Czech Republic, 18–19 May 2022; TANGER Ltd.: Ostrava, Czech Republic, 2022; pp. 656–661. [Google Scholar] [CrossRef]

- Viliš, J.; Pokorný, Z.; Zouhar, J.; Vítek, R.; Procházka, J. Evaluation of Ballistic Resistance of Thermoplastic and Thermoset Composite Panels. J. Phys. Conf. Ser. 2022, 2382, 012024. [Google Scholar] [CrossRef]

| Materials | Thickness [mm] | Area Density [g/m2] | Young’s Modulus [GPa] | Composite Density [kg/m3] |

|---|---|---|---|---|

| Twaron CT 747 | 0.62 | 410 | 115 | 1450 |

| Endumax Shield XF33 | 0.16 | 146 | 170 | 970 |

| Panels | Dimension [mm] | Thickness [mm] | Weight [kg] | Number of Layers |

|---|---|---|---|---|

| Twaron CT 747, LG700 + HG700 | 300 × 300 | 17.6 | 2.02 | 35 |

| Twaron CT 747, ER68 | 300 × 300 | 14.9 | 1.56 | 35 |

| Endumax Shield XF33 | 300 × 300 | 3.3 | 0.26 | 20 |

| Endumax Shield XF33 | 300 × 300 | 3.5 | 0.27 | 20 |

| Surface Hardness Shore D, num. m. | Twaron CT 747, ER68 | Twaron CT 747, LG700 + HG700 | Endumax Shield XF33 |

|---|---|---|---|

| 1. | 78.3 | 83.0 | 69.8 |

| 2. | 84.3 | 85.9 | 71.8 |

| 3. | 81.5 | 86.0 | 71.5 |

| 4. | 83.8 | 85.6 | 71.5 |

| 5. | 83.9 | 85.9 | 71.2 |

| 6. | 82.1 | 86.7 | 71.0 |

| 7. | 82.9 | 86.1 | 70.1 |

| 8. | 82.7 | 85.8 | 71.7 |

| 9. | 80.3 | 87.3 | 71.6 |

| 10. | 82.0 | 84.3 | 72.0 |

| Average value | 82.2 ± 1.73 | 85.7 ± 1.15 | 71.2 ± 0.69 |

| Cartridge Type | Projectile Weight [g] | Projectile Velocity [±15 m/s] |

|---|---|---|

| 7.62 × 51 mm NATO FMJ M80 | 9.55 | 833.00 |

| S. n. | Armor Configuration, See Figure 13 | v0 [m/s] | v25 [m/s] | EK0 [J] | EK25 [J] | Penetration |

|---|---|---|---|---|---|---|

| 1. | Twaron/UHMWPE | 867.7 | 841.3 | 3595.1 | 3379.7 | No |

| 2. | 858.2 | 833.8 | 3516.8 | 3319.7 | No | |

| 3. | 876.5 | 852.6 | 3668.4 | 3471.1 | No |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Viliš, J.; Neumann, V.; Vítek, R.; Zouhar, J.; Pokorný, Z.; Marek, M. Analysis of Ballistic Impact of 7.62 mm FMJ M80 Rifle Projectile into Twaron/UHMWPE Composite Armor. J. Compos. Sci. 2023, 7, 390. https://doi.org/10.3390/jcs7090390

Viliš J, Neumann V, Vítek R, Zouhar J, Pokorný Z, Marek M. Analysis of Ballistic Impact of 7.62 mm FMJ M80 Rifle Projectile into Twaron/UHMWPE Composite Armor. Journal of Composites Science. 2023; 7(9):390. https://doi.org/10.3390/jcs7090390

Chicago/Turabian StyleViliš, Jindřich, Vlastimil Neumann, Roman Vítek, Jan Zouhar, Zdeněk Pokorný, and Milan Marek. 2023. "Analysis of Ballistic Impact of 7.62 mm FMJ M80 Rifle Projectile into Twaron/UHMWPE Composite Armor" Journal of Composites Science 7, no. 9: 390. https://doi.org/10.3390/jcs7090390

APA StyleViliš, J., Neumann, V., Vítek, R., Zouhar, J., Pokorný, Z., & Marek, M. (2023). Analysis of Ballistic Impact of 7.62 mm FMJ M80 Rifle Projectile into Twaron/UHMWPE Composite Armor. Journal of Composites Science, 7(9), 390. https://doi.org/10.3390/jcs7090390