Advanced Asphalt Mixtures for Tropical Climates Incorporating Pellet-Type Slaked Lime and Epoxy Resin

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Slaked Lime

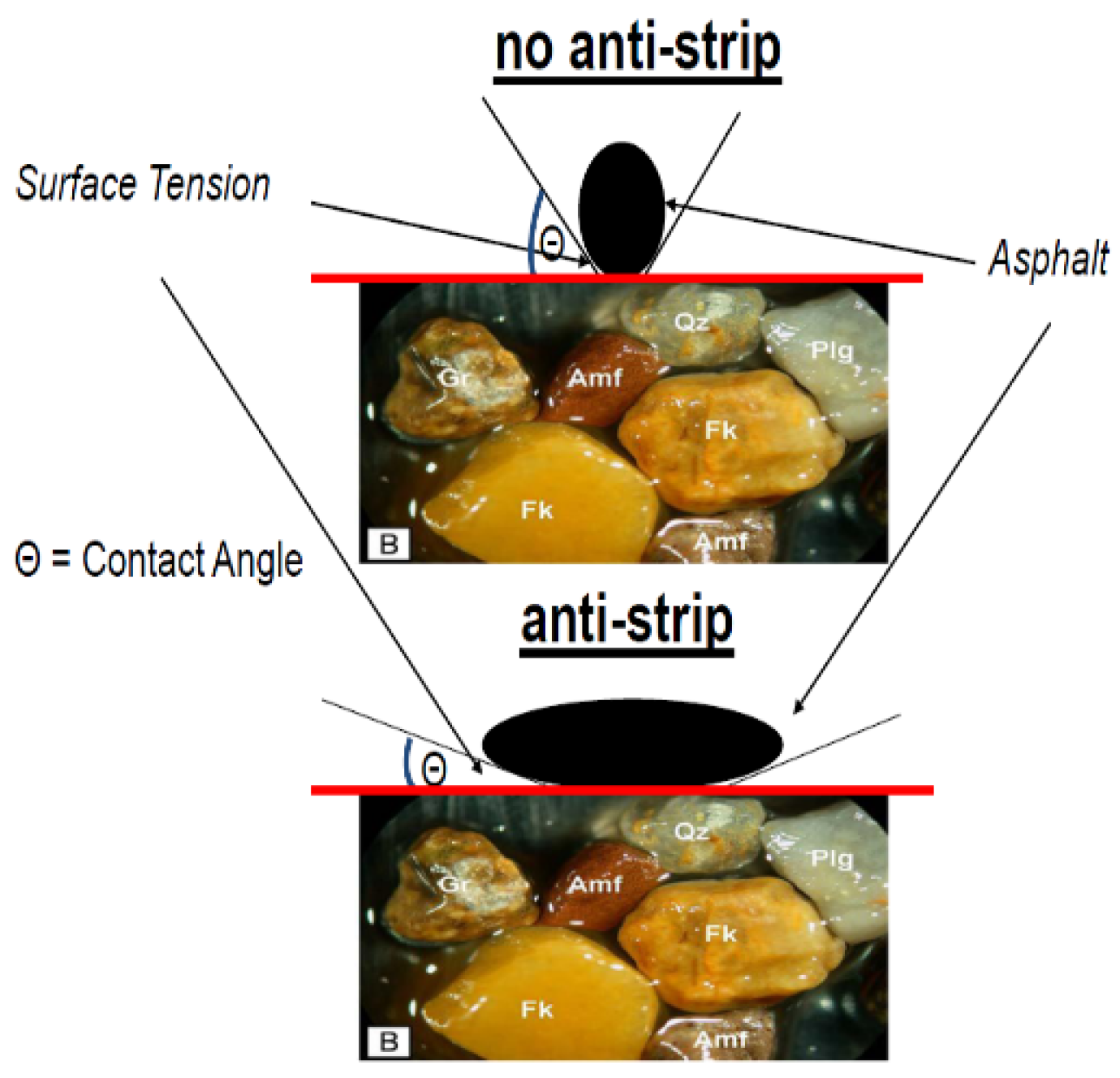

2.1.2. Anti-Stripping Technology

2.1.3. Pellet-Type Slaked Lime for Asphalt Durability

2.1.4. Design and Advantages of Pellet-Type Stripping Agent for Warm Mix Asphalt

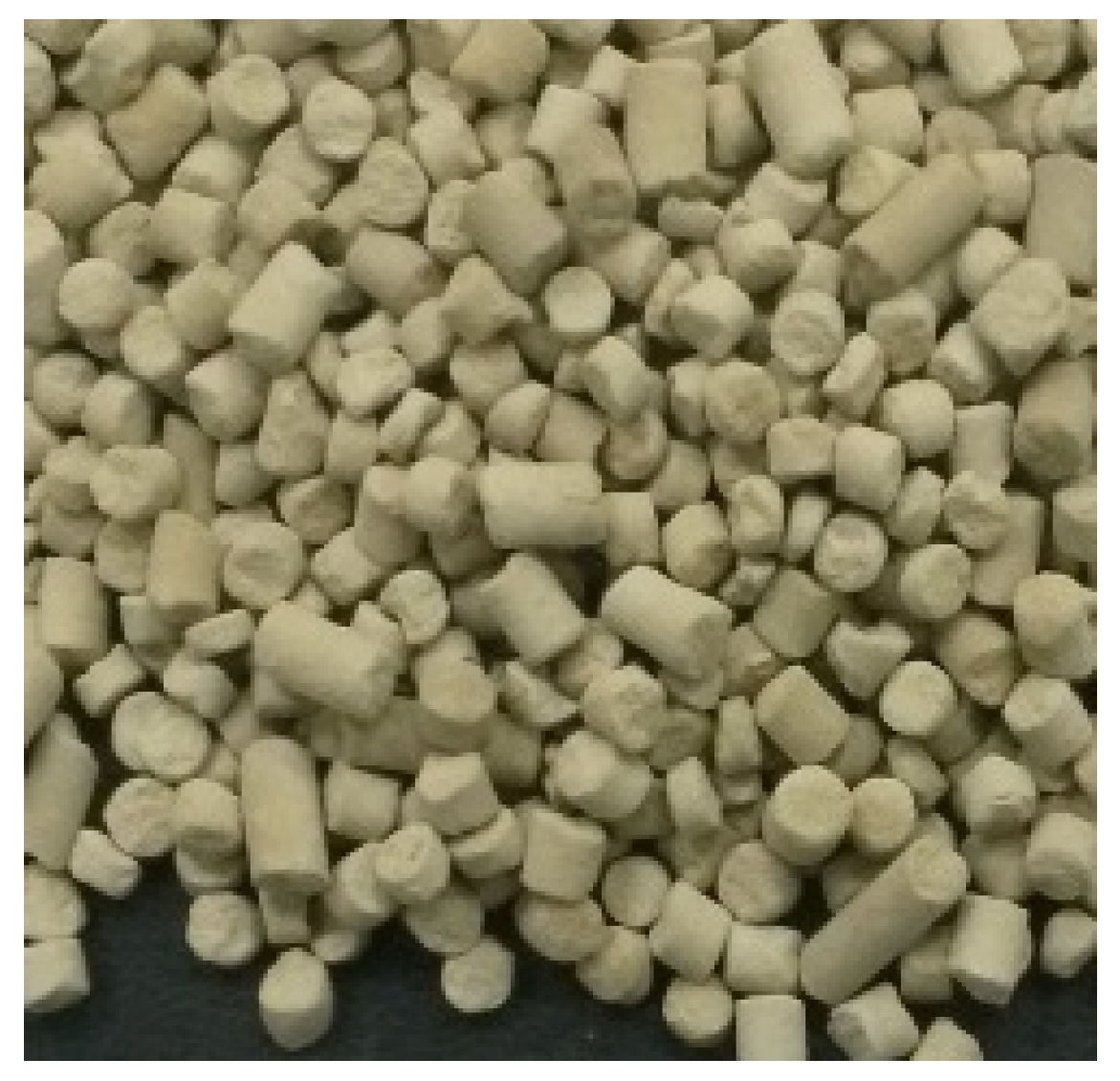

- In this method, slaked lime (Ca(OH)2) is combined with a liquid emulsifier in a ratio of 20:80 by weight, where the emulsifier consists of wax, vegetable oil, surfactants, and water. The mixture is extruded into pellets, which are subsequently cooled and dried to ensure structural stability. This extrusion process creates uniform pellets with consistent size and shape, allowing for easier handling, storage, and integration into asphalt mixtures. The extrusion ensures that the slaked lime is evenly coated with the emulsifier, reducing dust generation and improving distribution in the asphalt matrix.

- The liquid emulsifier is composed of 8% ethylene wax, 3% olive oil, 5% mineral oil, and 7% fatty acid amine surfactants, with the remaining 77% consisting of water. These proportions were determined based on trials to achieve optimal pellet stability, moisture resistance, and ease of mixing. The emulsifier serves to bind the slaked lime particles together, forming stable pellets that resist crumbling and ensure even distribution during asphalt mixing.

- Each constituent material plays a critical role in the formulation. Slaked lime (Ca(OH)2) acts as the primary anti-stripping agent, improving moisture resistance by enhancing the bond between the binder and aggregate. Wax (ethylene) provides structural stability to the pellets, preventing them from disintegrating during storage and handling, and ensuring that they maintain their shape during mixing. Vegetable oil (olive oil) enhances the flexibility and workability of the pellets, ensuring they remain stable during the asphalt production process. Mineral oil acts as a lubricant to ease the extrusion process and improve the consistency of the pellets. Surfactants (fatty acid amine) assist in reducing the surface tension between the binder and aggregate, enhancing the adhesive properties of the asphalt mixture and improving the dispersion of slaked lime throughout the asphalt.

- The optimal particle size for the pellets was determined through experimental trials, with a target size of approximately 3–5 mm in diameter. This size was chosen to ensure that the pellets could be evenly distributed in the asphalt mixture without segregation. Additionally, this size range ensures that the slaked lime within the pellets remains effective in enhancing moisture resistance without causing mixing issues or negatively affecting the workability of the asphalt. The particle size was also optimized to ensure minimal dust generation during handling and mixing.

- The pellet-type particles possess several key characteristics. First, they have structural stability, maintaining their integrity during storage, handling, and mixing, ensuring that they do not break down prematurely. Second, they allow uniform dispersion, as they are designed to disperse evenly throughout the asphalt mixture, ensuring consistent moisture resistance across the entire pavement structure.

2.1.5. Decomposition and Dispersion of Pellet-Type Material During Hot Mixing

- The pellet-type material is specifically designed to fully decompose during the hot mixing process. At typical asphalt production temperatures, ranging between 135 °C and 160 °C, the emulsifier components in the pellet, such as wax, vegetable oil, surfactants, and water, melt and break down. This allows the slaked lime to be released and evenly dispersed within the asphalt mixture. As the emulsifier decomposes, it facilitates the uniform integration of the slaked lime, ensuring that its beneficial properties, particularly in enhancing moisture resistance, are effectively retained without any remnants of the pellet structure remaining.

- To evaluate the dispersion of the slaked lime after the decomposition of the pellets, several tests were conducted. Visual and microscopic inspections of the asphalt mixture confirmed the complete dissolution of the pellets, with no residual material detected. Additionally, key performance indicators such as the Tensile Strength Ratio and Hamburg Wheel Tracking tests were used to assess the effectiveness of the dispersion. The uniform improvements in moisture resistance and rutting resistance observed across multiple samples demonstrate that the slaked lime was well-dispersed throughout the mixture. The consistent high performance in these tests supports the conclusion that the pellet material fully decomposes and integrates evenly into the asphalt matrix.

2.1.6. Epoxy Resin Used in Asphalt

2.1.7. Preparation and Mix Design of Modified Asphalt Concrete Mixtures

2.1.8. Development of Dry–Wet Cycle

2.2. Laboratory Tests

2.2.1. TSR Test

2.2.2. Indirect Tension Strength Test

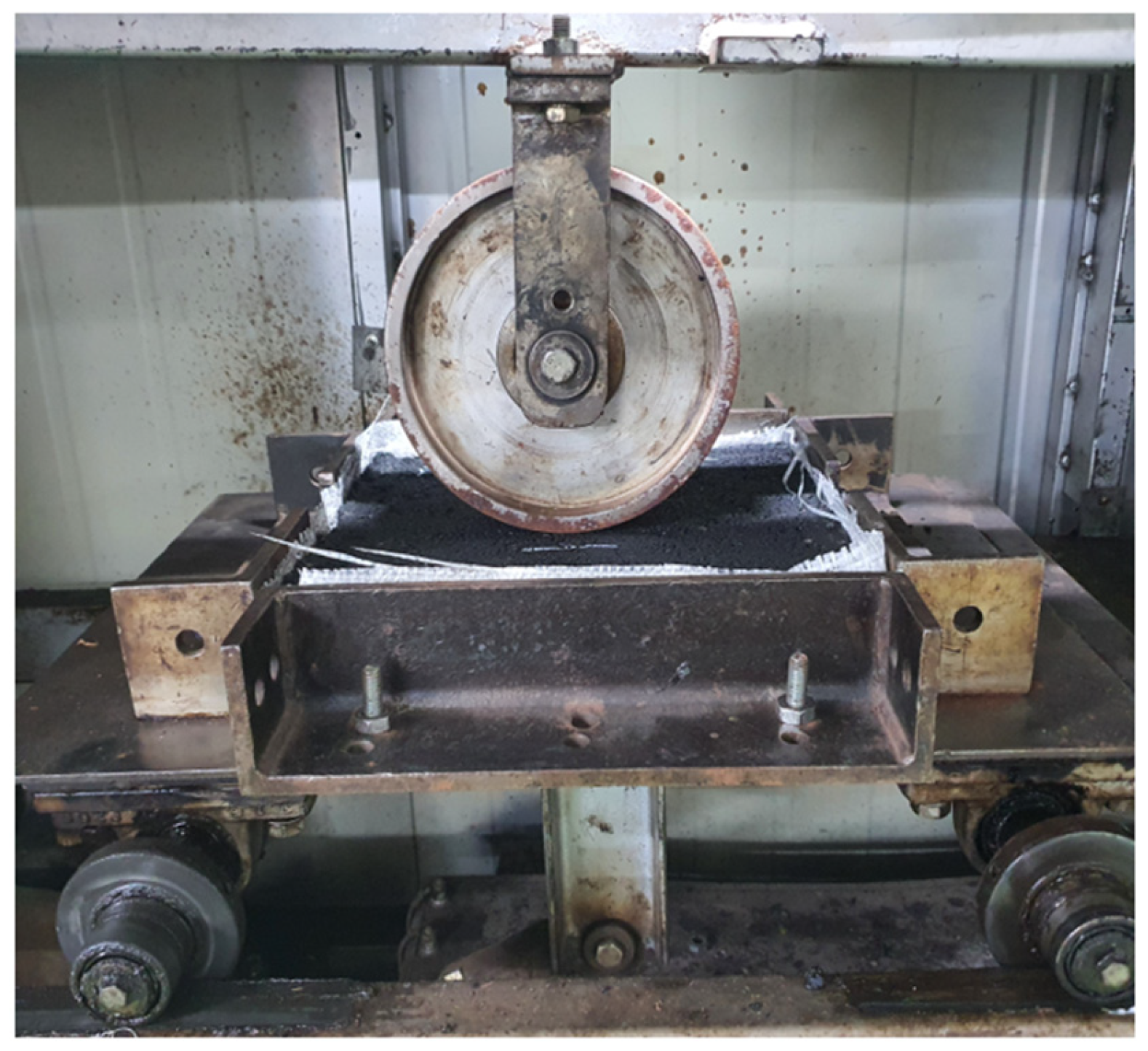

2.2.3. HWT Test

2.2.4. Cantabro Test

2.2.5. Dynamic Modulus Test

3. Results and Discussions

3.1. TSR Test Results

3.2. ITS Test Results

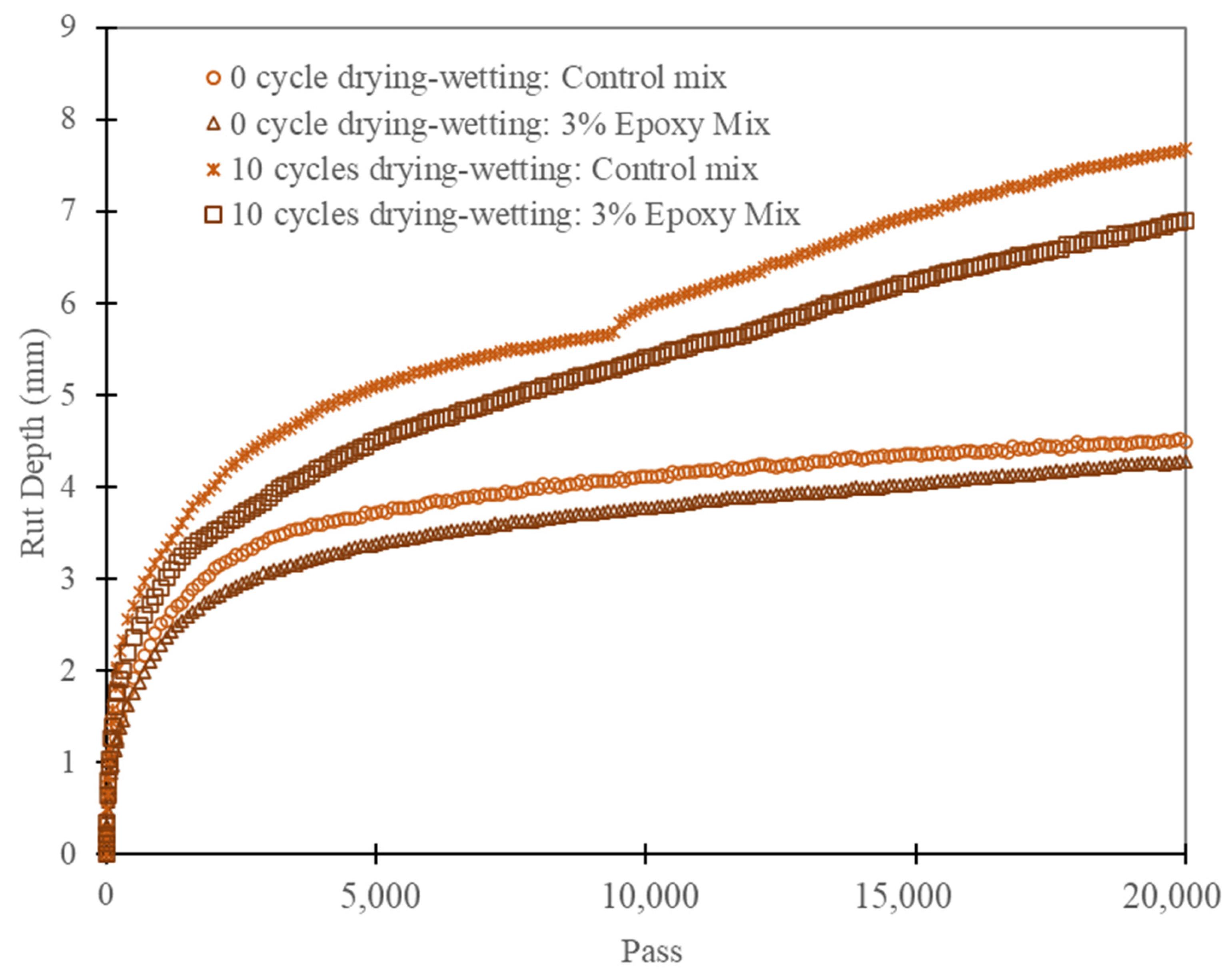

3.3. HWT Test Results

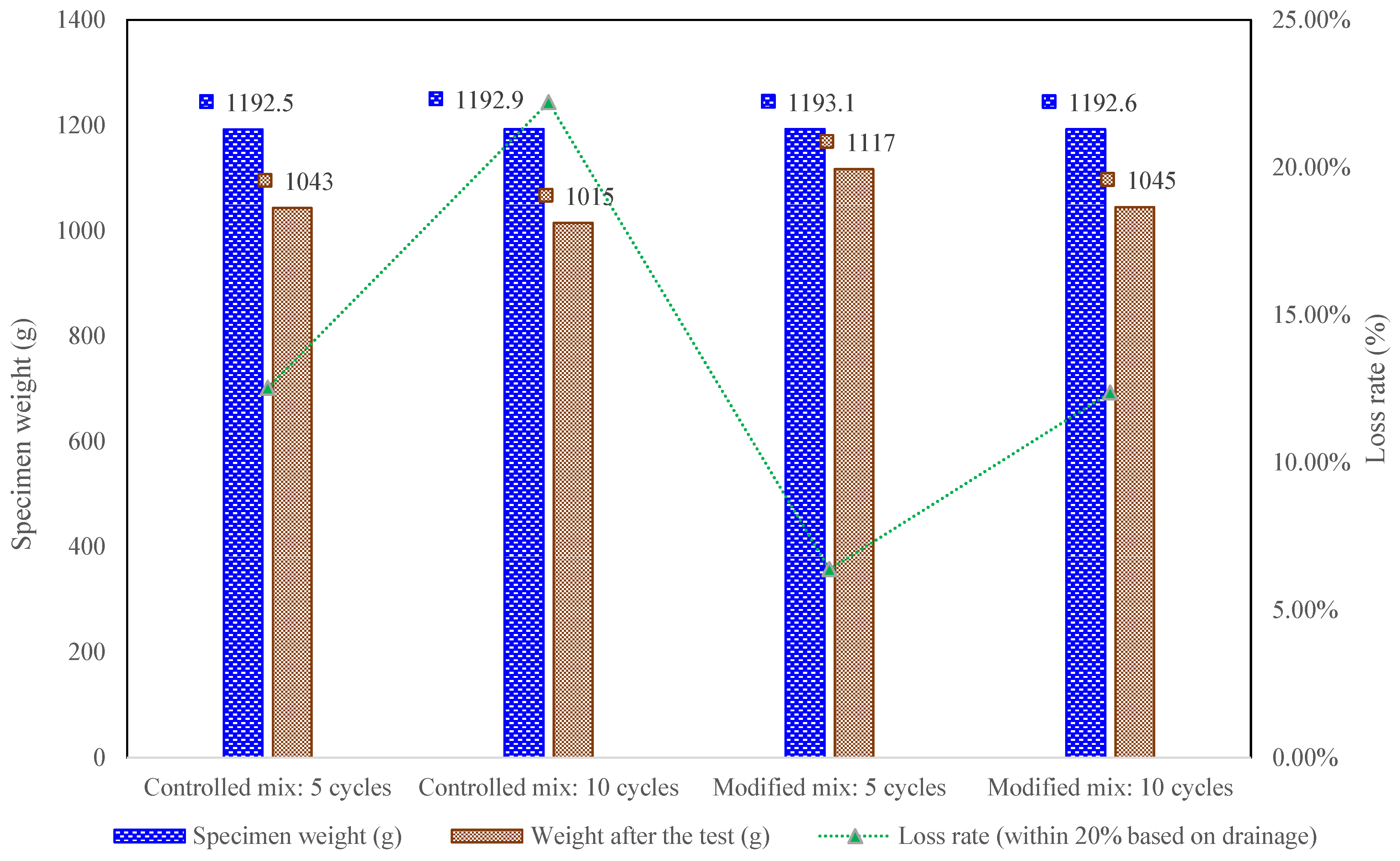

3.4. Cantabro Test Results

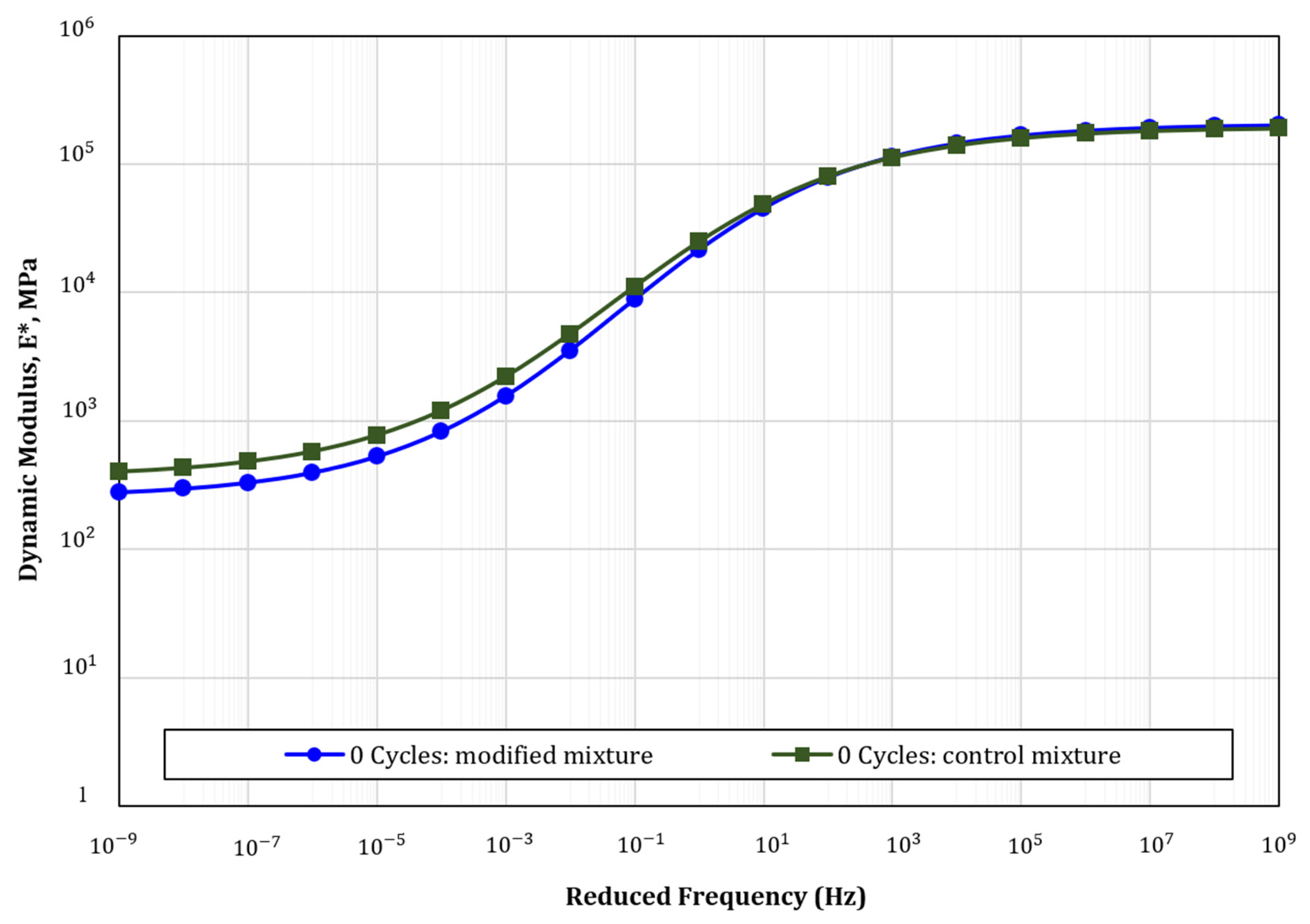

3.5. Dynamic Modulus Test Results

3.6. Discussion on Anti-Stripping Effects of Pellet-Type Slaked Lime and Hydrated Lime Powder

3.7. Discussion on Mechanisms of Epoxy Resin in Enhancing Asphalt Mixtures

4. Conclusions

- The TSR test results demonstrated that the modified asphalt mixture with 3% epoxy resin maintained significantly higher moisture resistance compared to the control. Initially, at 0 cycles, the modified mixture had a TSR value of 90%, whereas the control had 84%. Following 10 drying–wetting cycles, the changed mixture’s TSR value was 80%, while the control mixture’s value was 75%, indicating a 6.67% increase in moisture resistance.

- The HWT test results showed superior rutting resistance for the modified mixture. After 20,000 passes under 0 drying–wetting cycles, the modified mixture had a rut depth of 4.27 mm, whereas the control mixture had a rut depth of 4.49 mm, indicating a 4.9% reduction in rut depth for the modified mixture. After 10 drying–wetting cycles, the rut depth for the modified mixture was 6.89 mm, whereas the control reached 7.67 mm, indicating a 10.16% improvement in rutting resistance for the modified mixture.

- Under double load conditions designed to simulate heavy traffic loads, the modified mixture showed significantly better performance. The rut depth for the modified mixture after 20,000 passes was 16 mm, compared to 22 mm for the control, highlighting a substantial 27.27% improvement in rutting resistance under heavy loading.

- The Cantabro test results highlighted the enhanced resistance to abrasion and aggregate loss in the modified mixture. After 5 drying–wetting cycles, the modified mixture had a mass loss of 6.38%, significantly lower than the control mixture’s 12.53%. After 10 cycles, the modified mixture maintained a mass loss of 12.37%, compared to 22.21% for the control mixture. This indicates a substantial 44.29% improvement in resistance to abrasion and aggregate loss for the modified mixture.

- The dynamic modulus test results showcased the viscoelastic properties of the modified mixture under different frequencies and temperatures. At low frequency (simulating hot weather conditions with slow traffic), the epoxy-modified mixture exhibited a modulus of 460 MPa, compared to 720 MPa for the control mixture, indicating greater flexibility. At high frequency (simulating cold weather conditions or high traffic speeds), the modified mixture had a modulus of 277,476 MPa compared to 341,462 MPa for the control, suggesting better stress absorption and reduced likelihood of cracking. After 10 drying–wetting cycles, the modified mixture’s dynamic modulus values increased, reflecting enhanced stiffness and durability under repeated moisture exposure.

- Despite the promising results, this study is limited by the use of simulated tropical climate conditions and laboratory tests, which may not fully replicate real-world environments and long-term performance.

- Future research should focus on field trials to validate these findings, assess long-term durability under actual traffic and environmental conditions, and explore the cost-effectiveness and scalability of implementing the pellet-type materials on a larger scale. Additionally, investigating the environmental impact and lifecycle sustainability of these materials will provide a more comprehensive understanding of their benefits and potential limitations.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, Q.; Yang, S.; Chen, G. Regional Variations of Climate Change Impacts on Asphalt Pavement Rutting Distress. Transp. Res. Part D Transp. Environ. 2024, 126, 103968. [Google Scholar] [CrossRef]

- Liu, T.; Yang, S.; Liao, B.; Yang, E.; Jiang, X. Contribution of Climate Change and Traffic Load on Asphalt Pavement Carbon Emissions. J. Clean. Prod. 2024, 434, 140553. [Google Scholar] [CrossRef]

- Liu, T.; Yang, S.; Jiang, X.; Liao, B.; Castillo-Camarena, E.A. Adaptation Measures for Asphalt Pavements to Climate Change in China. J. Clean. Prod. 2023, 415, 137861. [Google Scholar] [CrossRef]

- Yao, L.; Leng, Z.; Ni, F.; Lu, G.; Jiang, J. Adaptive Maintenance Strategies to Mitigate Climate Change Impacts on Asphalt Pavements. Transp. Res. Part D Transp. Environ. 2024, 126, 104026. [Google Scholar] [CrossRef]

- Swarna, S.T.; Hossain, K.; Bernier, A. Climate Change Adaptation Strategies for Canadian Asphalt Pavements; Part 2: Life Cycle Assessment and Life Cycle Cost Analysis. J. Clean. Prod. 2022, 370, 133355. [Google Scholar] [CrossRef]

- Jwaida, Z.; Dulaimi, A.; Mydin, M.A.O.; Özkılıç, Y.O.; Jaya, R.P.; Ameen, A. The Use of Waste Polymers in Asphalt Mixtures: Bibliometric Analysis and Systematic Review. J. Compos. Sci. 2023, 7, 415. [Google Scholar] [CrossRef]

- Wang, X.; Huang, Y.; Geng, L.; Li, M.; Han, H.; Li, K.; Xu, Q.; Ding, Y.; Zhang, T. Multiscale Performance of Composite Modified Cold Patch Asphalt Mixture for Pothole Repair. Constr. Build. Mater. 2023, 371, 130729. [Google Scholar] [CrossRef]

- Hafezzadeh, R.; Autelitano, F.; Giuliani, F. Asphalt-Based Cold Patches for Repairing Road Potholes—An Overview. Constr. Build. Mater. 2021, 306, 124870. [Google Scholar] [CrossRef]

- Xiao, R.; Zhang, M.; Zhong, J.; Baumgardner, G.L.; Huang, B. Waste Plastic Powder Coating on Acidic Aggregates: A New Hydrophobic Coating Technology to Build Moisture-Resistant Asphalt Mixtures. Transp. Res. Rec. 2023. [Google Scholar] [CrossRef]

- Hesami, E.; Mehdizadeh, G. Study of the Amine-Based Liquid Anti-Stripping Agents by Simulating Hot Mix Asphalt Plant Production Process. Constr. Build. Mater. 2017, 157, 1011–1017. [Google Scholar] [CrossRef]

- Rahman, M.N.; Castro, S.; Noorvand, H.; Kaloush, K.; Mamlouk, M.; Ozer, H. Effect of Low Dosage Fiber Reinforcement on Cracking Performance of Asphalt Concrete. Constr. Build. Mater. 2024, 411, 134380. [Google Scholar] [CrossRef]

- Chen, Y.; Huang, J.; Muhammad, Y.; Zhao, Z.; Fan, S.; Luo, W.; Li, J. Study on the Performance and Mechanism of Carbon Nanomaterials Incorporated SBS Composite Modified Asphalt. Constr. Build. Mater. 2023, 389, 131795. [Google Scholar] [CrossRef]

- Li, Z.; Guo, T.; Chen, Y.; Zhang, T.; Tang, D.; Hao, M.; Zhao, X.; Liu, J. Study on Road Performance of Polyurethane Cold-Recycled Mixture. Polymers 2023, 15, 1958. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Hou, D.; Li, Z.; Wang, H.; Dong, S. Evaluation of the Thermal Stability and Micro-Modification Mechanism of SBR/PP-Modified Asphalt. Polymers 2024, 16, 456. [Google Scholar] [CrossRef] [PubMed]

- Gong, Y.; Wu, S.; Bi, H.; Tian, L. Study on Thermal Stability and Fatigue Properties of SBS/CNT-Modified Asphalt Sealant. Polymers 2023, 15, 3968. [Google Scholar] [CrossRef]

- Gupta, L.; Bellary, A. Comparative Study on the Behavior of Bituminous Concrete Mix and Warm Mix Asphalt Prepared Using Lime and Zycotherm as Additive. Mater. Today Proc. 2018, 5, 2074–2081. [Google Scholar] [CrossRef]

- Syrmanova, K.; Kaldybekova, Z.; Agabekova, A.; Baizhanova, S. Influence of the Chemical Composition of Kulantau Vermiculite on the Structure of Modified Bitumen Compositions. J. Compos. Sci. 2024, 8, 118. [Google Scholar] [CrossRef]

- Sadeghi, P.; Goli, A.; Fini, E. Carbon Sequestration via Bituminous Composites Containing Recycled High-Density Polyethylene. J. Compos. Sci. 2024, 8, 100. [Google Scholar] [CrossRef]

- Taherkhani, H.; Tajdini, M. Comparing the Effects of Nano-Silica and Hydrated Lime on the Properties of Asphalt Concrete. Constr. Build. Mater. 2019, 218, 308–315. [Google Scholar] [CrossRef]

- Park, S.S.; Park, J.W.; Yoon, K.B.; Park, I.S.; Woo, S.W.; Lee, D.E. Evaluation of Compressive Strength and Thermal Conductivity of Sand Stabilized with Epoxy Emulsion and Polymer Solution. Polymers 2022, 14, 1964. [Google Scholar] [CrossRef]

- Lee, J.S.; Lee, S.Y.; Bae, Y.S.; Le, T.H.M. Development of Pavement Material Using Crumb Rubber Modifier and Graphite Nanoplatelet for Pellet Asphalt Production. Polymers 2023, 15, 727. [Google Scholar] [CrossRef] [PubMed]

- Kong, L.; Su, S.; Wang, Z.; Wu, P.; Zhang, Y.; Chen, Z.; Ren, D.; Ai, C. Microscale Mechanism and Key Factors of Waterborne Epoxy Resin Emulsified Asphalt Enhancing Interlayer Bonding Performance and Shear Resistance of Bridge Deck Pavement. Constr. Build. Mater. 2024, 419, 135570. [Google Scholar] [CrossRef]

- Gao, Y.; Jin, J.; Liu, S.; Du, Y.; Qian, G.; Mao, J.; Zhu, Y. Performance Evaluation of New Epoxy Resin-Based Composite Phase Change Materials and Their Asphalt Mixture. J. Traffic Transp. Eng. (Engl. Ed.) 2024, 11, 507–522. [Google Scholar] [CrossRef]

- Lee, S.Y.; Yun, Y.M.; Minh Le, T.H. Influence of Performance-Graded Binders on Enhancing Asphalt Mixture Performance with Epoxy Resin and Crumb Rubber Powder. Case Stud. Constr. Mater. 2023, 19, e02628. [Google Scholar] [CrossRef]

- Kim, K.N.; Le, T.H.M. Feasibility of Pellet Material Incorporating Anti-Stripping Emulsifier and Slaked Lime for Pothole Restoration. Buildings 2023, 13, 1305. [Google Scholar] [CrossRef]

- Rafiq, W.; Napiah, M.B.; Sutanto, M.H.; Alaloul, W.S.; Zabri, Z.N.B.; Khan, M.I.; Musarat, M.A. Investigation on Hamburg Wheel-Tracking Device Stripping Performance Properties of Recycled Hot-Mix Asphalt Mixtures. Materials 2020, 13, 4704. [Google Scholar] [CrossRef]

- Ye, Y.; Hao, Y.; Zhuang, C.; Shu, S.; Lv, F. Evaluation on Improvement Effect of Different Anti-Stripping Agents on Pavement Performance of Granite–Asphalt Mixture. Materials 2022, 15, 915. [Google Scholar] [CrossRef]

- Okubo, H.; Yao, S. Restoring Mechanism of Mechanical Properties of Recycled Polyethylene Pellet Moldings by a Repelletizing Treatment Using a Twin-Screw Extruder. J. Mater. Cycles Waste Manag. 2021, 23, 1152–1176. [Google Scholar] [CrossRef]

- Renken, P.; Büchler, S.; Falchetto, A.C.; Wang, D.; Wistuba, M.P. Warm Mix Asphalt-a German Case Study. Asph. Paving Technol. Assoc. Asph. Paving Technol. Tech. Sess. 2018, 87, 685–714. [Google Scholar] [CrossRef]

- Barraj, F.; Khatib, J.; Castro, A.; Elkordi, A. Effect of Chemical Warm Mix Additive on the Properties and Mechanical Performance of Recycled Asphalt Mixtures. Buildings 2022, 12, 874. [Google Scholar] [CrossRef]

- Advanced Asphalt Technologies, LLC. NCHRP 673 A Manual for Design of Hot-Mix Asphalt with Commentary; NCHRP: Washington, DC, USA, 2011. [Google Scholar] [CrossRef]

- Babangida Attahiru, Y.; Mohamed, A.; Eltwati, A.; Burga, A.A.; Ibrahim, A.; Nabade, A.M. Effect of Waste Cooking Oil on Warm Mix Asphalt Block Pavement—A Comprehensive Review. Phys. Chem. Earth 2023, 129, 103310. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, J.; Wang, Z.; Long, S.; Jiang, S.; Liu, G. Preparation and Performance Characterization of a Novel High-Performance Epoxy Resin Modified Reactive Liquid Asphalt. Constr. Build. Mater. 2020, 263, 120113. [Google Scholar] [CrossRef]

- Cong, P.; Luo, W.; Xu, P.; Zhang, Y. Chemical and Physical Properties of Hot Mixing Epoxy Asphalt Binders. Constr. Build. Mater. 2019, 198, 1–9. [Google Scholar] [CrossRef]

- Yao, X.; Tan, L.; Xu, T. Preparation, Properties and Compound Modification Mechanism of Waterborne Epoxy Resin/Styrene Butadiene Rubber Latex Modified Emulsified Asphalt. Constr. Build. Mater. 2022, 318, 126178. [Google Scholar] [CrossRef]

- Lee, S.Y.; Kwak, D.Y.; Le, T.H.M. Laboratory Evaluation on the Aging Susceptibility of Reclaimed Asphalt Bitumen Containing Low-Viscosity Binder and Cooking Oil Waste. Results Eng. 2023, 19, 101260. [Google Scholar] [CrossRef]

- Lou, K.; Xiao, P.; Kang, A.; Wu, Z.; Dong, X. Effects of Asphalt Pavement Characteristics on Traffic Noise Reduction in Different Frequencies. Transp. Res. Part D Transp. Environ. 2022, 106, 103259. [Google Scholar] [CrossRef]

- Zhang, W. Effect of Tack Coat Application on Interlayer Shear Strength of Asphalt Pavement: A State-of-the-Art Review Based on Application in the United States. Int. J. Pavement Res. Technol. 2017, 10, 434–445. [Google Scholar] [CrossRef]

- Alnadish, A.M.; Singh, N.S.S.; Alawag, A.M. Applications of Synthetic, Natural, and Waste Fibers in Asphalt Mixtures: A Citation-Based Review. Polymers 2023, 15, 1004. [Google Scholar] [CrossRef]

- Luca, J.; Mrawira, D. New Measurement of Thermal Properties of Superpave Asphalt Concrete. J. Mater. Civ. Eng. 2005, 17, 72–79. [Google Scholar] [CrossRef]

- Al-Khateeb, G.G.; Al-Suleiman Obaidat, T.I.; Khedaywi, T.S.; Elayan, M.S. Studying Rutting Performance of Superpave Asphalt Mixtures Using Unconfined Dynamic Creep and Simple Performance Tests. Road Mater. Pavement Des. 2018, 19, 315–333. [Google Scholar] [CrossRef]

- ASTM C127; Standard Test Method for Density, Relative Density (Specific Gravity), and Absorption of Coarse Aggregate. ASTM: West Conshohocken, PA, USA, 2004; pp. 1–5.

- ASTM Standard D5821; Standard Test Method for Determining the Percentage of Fractured Particles in Coarse Aggregate. ASTM: West Conshohocken, PA, USA, 2017; pp. 1–6.

- ASTM C131/C131M-14; Standard Test Method for Resistance to Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in the Los Angeles Machine. ASTM: West Conshohocken, PA, USA, 2014; Volume 4, pp. 5–8.

- ASTM D 4791; Flat Particles, Elongated Particles, or Flat and Elongated Particles in Coarse Aggregate. ASTM: West Conshohocken, PA, USA, 1999; Volume 4, pp. 1–4.

- ASTM D24; Standard Specification for Mineral Filler for Bituminous Paving Mixtures. ASTM: West Conshohocken, PA, USA, 2001; Volume 4, pp. 1–2.

- AASHTO T 283; Standard Method of Test for Resistance of Compacted Asphalt Mixtures to Moisture-Induced Damage. ASTM: West Conshohocken, PA, USA, 2018; Volume 3, pp. 1–8.

- ASTM D6931; Standard Test Method for Indirect Tensile (IDT) Strength of Bituminous Mixtures. ASTM: West Conshohocken, PA, USA, 2017; pp. 1–5.

- AASHTO T 324; Standard Method of Test for Hamburg Wheel-Track Testing of Compacted Asphalt Mixtures. AASHTO Association: Washington, DC, USA, 2022.

- KS F 2492; Cantabro Test Method for Drainage Asphalt Mixtures. Korean National Standard: Maengdong-myeon, Republic of Korea, 2022.

- AASHTO TP62-2017; Standard Method of Test for Determining Dynamic Modulus of Hot Mix Asphalt (HMA). AASHTO Association: Washington, DC, USA, 2017.

| Property | Description |

|---|---|

| Chemical composition | Ca(OH)2 |

| Appearance | Fine white powder |

| pH value | 11 |

| Specific gravity | 2.24 |

| Solubility in water | Slightly soluble (1.73 g/L at 20 °C) |

| Bulk density | 0.5–0.8 g/cm3 |

| Particle size distribution | Typically <75 µm |

| Moisture content | ≤2% |

| Heat of hydration | Exothermic reaction when mixed with water, releasing heat |

| Calcium content | ≥90% |

| Impurities | ≤2% (includes magnesium oxide, silicon dioxide, and iron oxide) |

| Neutralizing value | 120–135 (compared to pure calcium carbonate with a value of 100) |

| Component | Control Mix | Modified Mix with Epoxy Resin |

|---|---|---|

| Wax | 8.0 (Ethylene) | 6.0 (Ethylene) |

| Vegetable oil | 3.0 (Olive) | 1.5 (Olive) |

| Mineral oil | 5.0 | 4.5 |

| Surfactants (Fatty acid amine) | 7.0 | 6.0 |

| Additive | 0.2 | 0.2 |

| Water | 76.8 | 78.8 |

| Epoxy resin | - | 3.0 |

| Property | Control Mix | Modified Mix with Epoxy Resin |

|---|---|---|

| Exterior | Milky liquid | Milky liquid |

| Stability | 7 days or less | 15 days or less |

| Condition | Liquid | Liquid |

| Smell | Odorless | Slightly resinous |

| Active ingredient | 24% | 27% |

| Materials | Properties | Value |

|---|---|---|

| Aggregate | Bulk specific gravity [42] | 2.65 |

| Moisture absorption [42] | 0.150% | |

| Aggregate impact value [43] | 21.4% | |

| Los Angeles abrasion loss [44] | 23.8% | |

| Shape index [45] | 10.2% | |

| Mineral filler | Bulk density [46] | 2.45 |

| Fineness modulus [46] | 0.85% |

| Sieve Size (mm) | Percentage Passing (%) |

|---|---|

| 19.0 | 100 |

| 12.5 | 95.3 |

| 9.5 | 82.7 |

| 4.75 | 60.2 |

| 2.36 | 42.5 |

| 1.18 | 28.3 |

| 0.600 | 18.9 |

| 0.300 | 12.7 |

| 0.150 | 7.4 |

| 0.075 | 4.8 |

| Material | Slaked Lime AC Mixture (2%) | Modified Mixture with Epoxy Resin (3%) |

|---|---|---|

| Slaked lime content (%) | 2.0 | 1.0 |

| Epoxy resin content (%) | - | 3.0 |

| Mixing temperature (°C) | 155 | 135 |

| Aggregate (g) | 499.8 | 504.9 |

| Anti-stripping agent (g) | 10.0 | 5.1 |

| Asphalt (g) | 16 | 16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, S.-Y.; Le, T.H.M. Advanced Asphalt Mixtures for Tropical Climates Incorporating Pellet-Type Slaked Lime and Epoxy Resin. J. Compos. Sci. 2024, 8, 442. https://doi.org/10.3390/jcs8110442

Lee S-Y, Le THM. Advanced Asphalt Mixtures for Tropical Climates Incorporating Pellet-Type Slaked Lime and Epoxy Resin. Journal of Composites Science. 2024; 8(11):442. https://doi.org/10.3390/jcs8110442

Chicago/Turabian StyleLee, Sang-Yum, and Tri Ho Minh Le. 2024. "Advanced Asphalt Mixtures for Tropical Climates Incorporating Pellet-Type Slaked Lime and Epoxy Resin" Journal of Composites Science 8, no. 11: 442. https://doi.org/10.3390/jcs8110442

APA StyleLee, S.-Y., & Le, T. H. M. (2024). Advanced Asphalt Mixtures for Tropical Climates Incorporating Pellet-Type Slaked Lime and Epoxy Resin. Journal of Composites Science, 8(11), 442. https://doi.org/10.3390/jcs8110442