Microhardness and Compressive Strength of Bulk Fill Glass Hybrid Material and Other Direct Restorative Materials

Abstract

1. Introduction

2. Materials and Methods

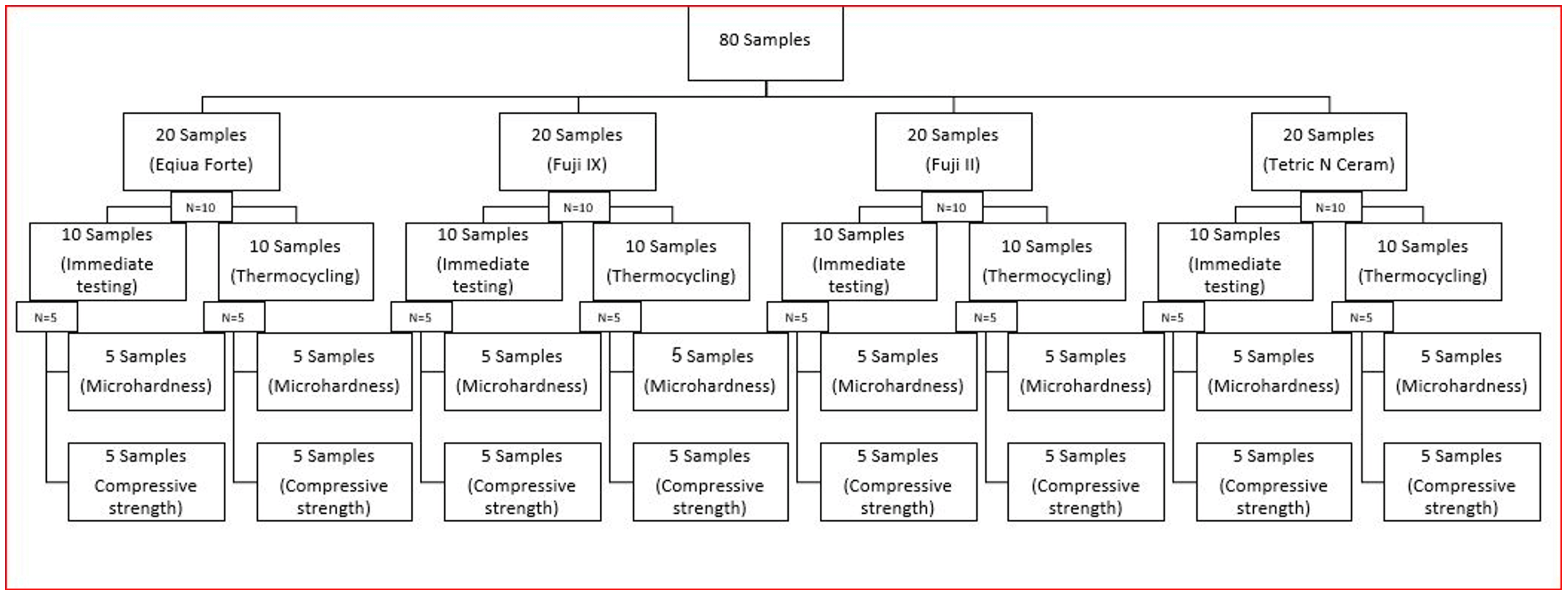

2.1. Study Design

2.2. Specimen Preparation

2.3. Compressive Strength Testing

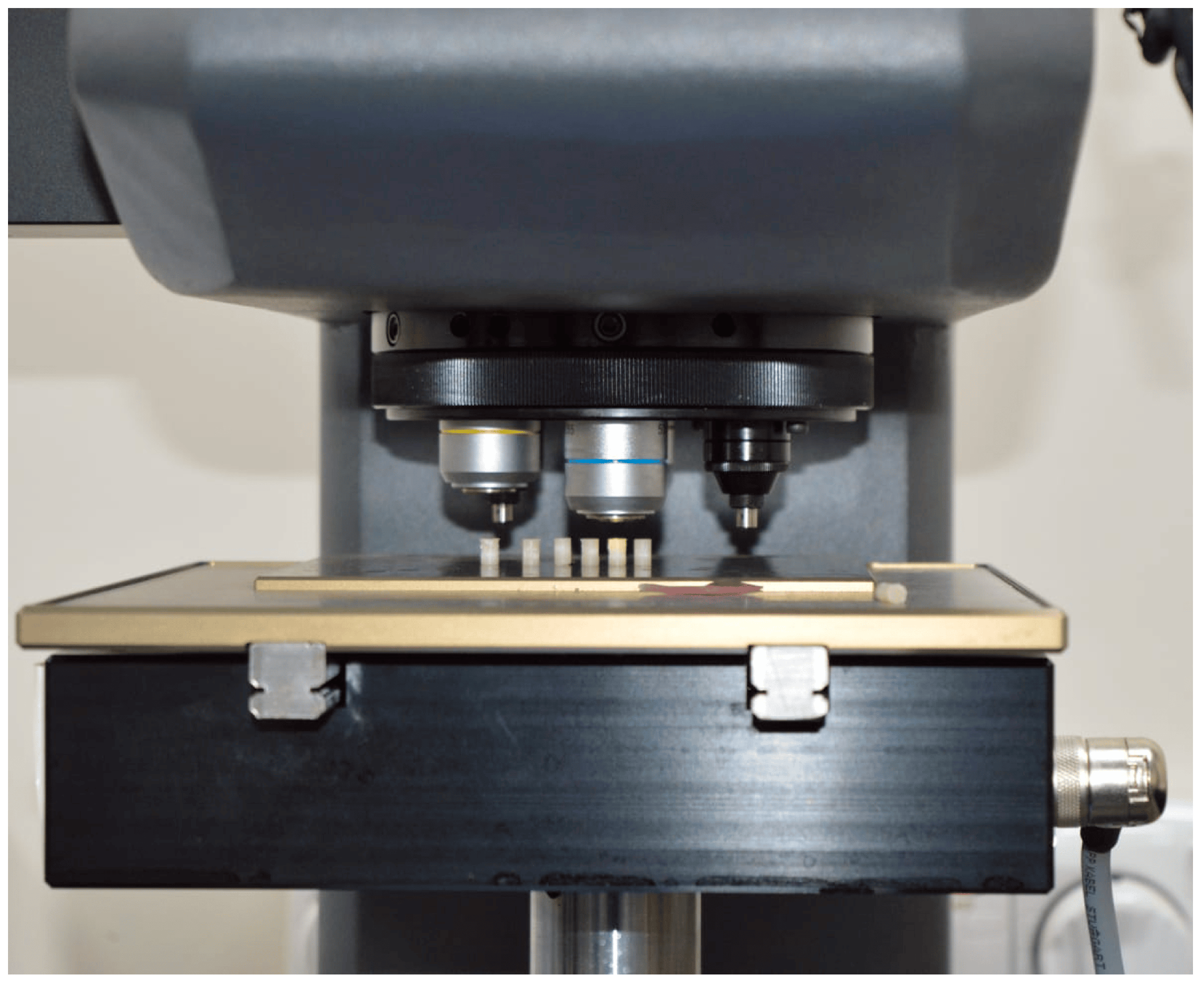

2.4. Microhardness Testing

2.5. Statistical Analysis

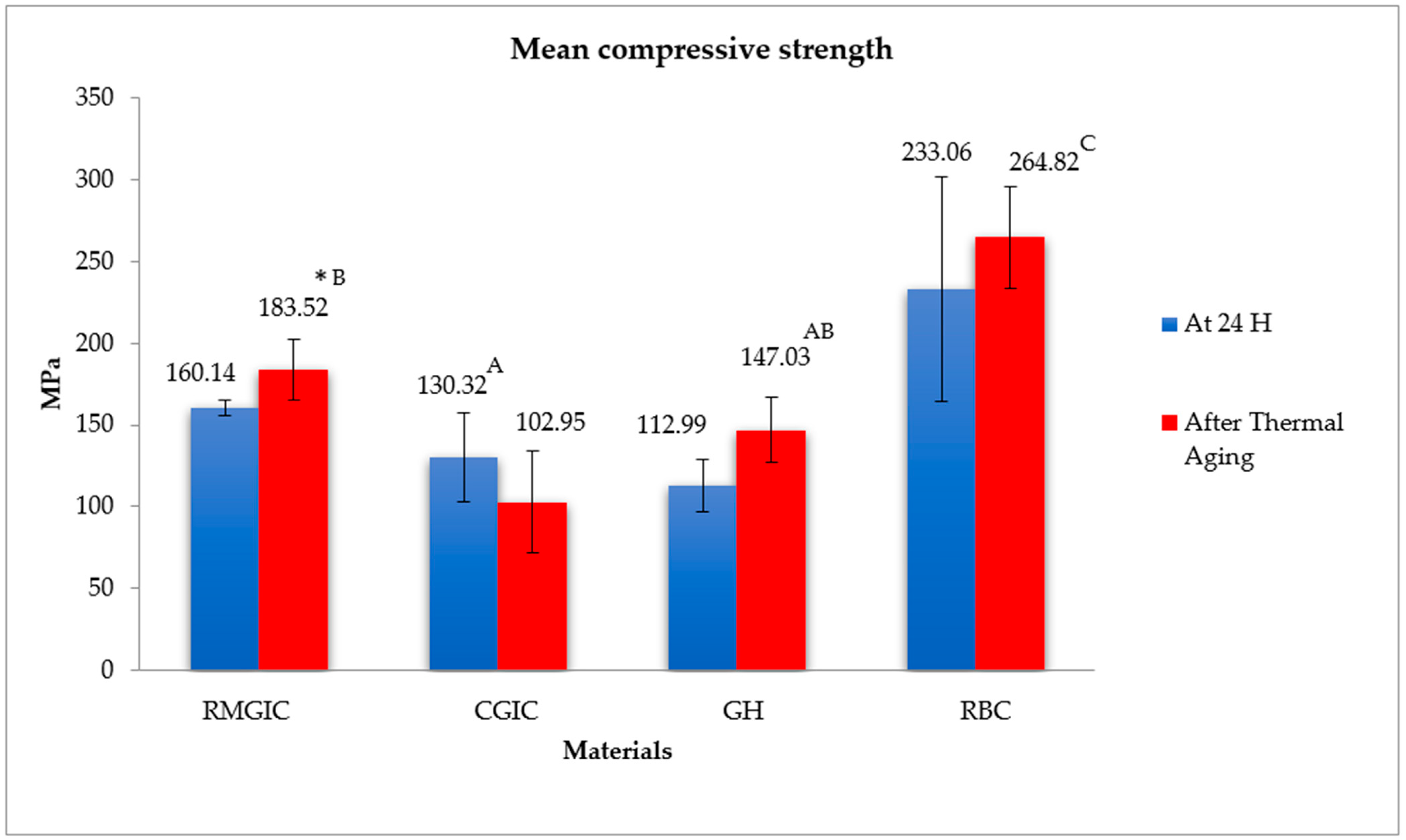

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Skorulska, A.; Piszko, P.; Rybak, Z.; Szymonowicz, M.; Dobrzyński, M. Review on polymer, ceramic and composite materials for cad/cam indirect restorations in dentistry—Application, mechanical characteristics and comparison. Materials 2021, 14, 1592. [Google Scholar] [CrossRef] [PubMed]

- Rueggeberg, F.A. State-of-the-art: Dental photocuring—A review. Dent. Mater. 2011, 27, 39–52. [Google Scholar] [CrossRef]

- Elfakhri, F.; Alkahtani, R.; Li, C.; Khaliq, J. Influence of filler characteristics on the performance of dental composites: A comprehensive review. Ceram. Int. 2022, 48 Pt A, 27280–27294. [Google Scholar] [CrossRef]

- Banava, S.; Salehyar, S. In vitro Comparative Study of Compressive Strength of Different Types of Composite Resins in Different Periods of Time. Iran. J. Pharm. Sci. 2008, 4, 69–74. [Google Scholar]

- Francisconi, L.F.; Scaffa, P.M.; de Barros, V.R.; Coutinho, M.; Francisconi, P.A. Glass ionomer cements and their role in the restoration of non-carious cervical lesions. J. Appl. Oral Sci. 2009, 17, 364–369. [Google Scholar] [CrossRef] [PubMed]

- Sakaguchi, R.L.; Powers, J.M. Craig’s Restorative Dental Materials-e-Book; Elsevier Health Sciences: Amsterdam, The Netherlands, 2011. [Google Scholar]

- Moshaverinia, M.; Navas, A.; Jahedmanesh, N.; Shah, K.C.; Moshaverinia, A.; Ansari, S. Comparative evaluation of the physical properties of a reinforced glass ionomer dental restorative material. J. Prosthet. Dent. 2019, 122, 154–159. [Google Scholar] [CrossRef] [PubMed]

- Ramos, N.B.P.; Felizardo, K.R.; Berger, S.B.; Guiraldo, R.D.; Lopes, M.B. Comparative study of physical-chemical properties of bioactive glass ionomer cement. Braz. Dent. J. 2024, 35, e245728. [Google Scholar] [CrossRef] [PubMed]

- Yeslam, H.E.; Hasanain, F.A. Evaluation of the Strength of a Novel Bioactive Hybrid Glass Restorative Material. J. Biochem. Technol. 2023, 14, 61–65. [Google Scholar] [CrossRef]

- Mulay, S.; Galankar, K.; Varadarajan, S.; Gupta, A.A. Evaluating fluoride uptake of dentin from different restorative materials at various time intervals—In vitro study. J. Oral Biol. Craniofacial Res. 2022, 12, 216–222. [Google Scholar] [CrossRef]

- Brzović-Rajić, V.; Miletić, I.; Gurgan, S.; Peroš, K.; Verzak, Ž.; Ivanišević-Malčić, A. Fluoride Release from Glass Ionomer with Nano Filled Coat and Varnish. Acta Stomatol. Croat. 2018, 52, 307–313. [Google Scholar] [CrossRef]

- Messer-Hannemann, P.; Böttcher, H.; Henning, S.; Schwendicke, F.; Effenberger, S. Concept of a Novel Glass Ionomer Restorative Material with Improved Mechanical Properties. J. Funct. Biomater. 2023, 14, 534. [Google Scholar] [CrossRef] [PubMed]

- Sidhu, S.K.; Nicholson, J.W. A Review of Glass-Ionomer Cements for Clinical Dentistry. J. Funct. Biomater. 2016, 7, 16. [Google Scholar] [CrossRef] [PubMed]

- Francois, P.; Fouquet, V.; Attal, J.P.; Dursun, E. Commercially Available Fluoride-Releasing Restorative Materials: A Review and a Proposal for Classification. Materials 2020, 13, 2313. [Google Scholar] [CrossRef]

- Neti, B.; Sayana, G.; Muddala, L.; Raju, S.; Yarram, A.; Gvd, H. Fluoride releasing restorative materials: A review. Int. J. Dent. Mater. 2020, 2, 19–23. [Google Scholar] [CrossRef]

- Jalalian, B.; Golkar, P.; Paktinat, A.; Ahmadi, E.; Panahande, S.A.; Omrani, L.R. Degree of Conversion of Resin-Modified Glass Ionomer Cement Containing Hydroxyapatite Nanoparticles. Front. Dent. 2019, 16, 415–420. [Google Scholar] [CrossRef]

- Sidhu, S. Glass-ionomer cement restorative materials: A sticky subject? Aust. Dent. J. 2011, 56, 23–30. [Google Scholar] [CrossRef]

- Al-Angari, S.; Hara, A.; Chu, T.-M.; Platt, J.; Eckert, G.; Cook, N. Physicomechanical properties of a zinc-reinforced glass ionomer restorative material. J. Oral Sci. 2014, 56, 11–16. [Google Scholar] [CrossRef][Green Version]

- Ferracane, J.L.; Sidhu, S.K.; Melo, M.A.S.; Yeo, I.-S.L.; Diogenes, A.; Darvell, B.W. Bioactive dental materials: Developing, promising, confusing. JADA Found. Sci. 2023, 2, 100022. [Google Scholar]

- Joshi, G.; Heiss, M. Glass-Hybrid Technology for Long-Term Restorations. Compend. Contin. Educ. Dent. 2021, 42, 2–5. [Google Scholar]

- Williams, D.F. Biocompatibility pathways and mechanisms for bioactive materials: The bioactivity zone. Bioact. Mater. 2022, 10, 306–322. [Google Scholar] [CrossRef]

- Spagnuolo, G. Bioactive Dental Materials: The Current Status. Materials 2022, 15, 2016. [Google Scholar] [CrossRef] [PubMed]

- Schmalz, G.; Hickel, R.; Price, R.B.; Platt, J.A. Bioactivity of Dental Restorative Materials: FDI Policy Statement. Int. Dent. J. 2023, 73, 21–27. [Google Scholar] [CrossRef] [PubMed]

- Schwendicke, F.; Rossi, J.G.; Krois, J.; Basso, M.; Peric, T.; Turkun, L.S.; Miletić, I. Cost-effectiveness of glass hybrid versus composite in a multi-country randomized trial. J. Dent. 2021, 107, 103614. [Google Scholar] [CrossRef] [PubMed]

- Miletić, I.; Baraba, A.; Krmek, S.J.; Perić, T.; Marković, D.; Basso, M.; Ozkaya, C.A.; Kemaloglu, H.; Turkun, L.S. Clinical performance of a glass-hybrid system in comparison with a resin composite in two-surface class II restorations: A 5-year randomised multi-centre study. Clin. Oral Investig. 2024, 28, 104. [Google Scholar] [CrossRef]

- François, P.; Remadi, A.; Le Goff, S.; Abdel-Gawad, S.; Attal, J.P.; Dursun, E. Flexural properties and dentin adhesion in recently developed self-adhesive bulk-fill materials. J. Oral Sci. 2021, 63, 139–144. [Google Scholar] [CrossRef]

- Poornima, P.; Koley, P.; Kenchappa, M.; Nagaveni, N.B.; Bharath, K.P.; Neena, I.E. Comparative evaluation of compressive strength and surface microhardness of EQUIA Forte, resin-modified glass-ionomer cement with conventional glass-ionomer cement. J. Indian Soc. Pedod. Prev. Dent. 2019, 37, 265–270. [Google Scholar] [CrossRef]

- Uyumaz, F.; Abaklı İnci, M.; Özer, H. Could bulk fill glass hybrid restorative materials replace composite resins in treating permanent teeth? A randomized controlled clinical trial. J. Esthet. Restor. Dent. 2024, 36, 702–709. [Google Scholar] [CrossRef]

- ISO 9917-1:2007; Dentistry: Water-Based Cements. International Organization for Standardization: Geneva, Switzerland, 2007.

- Alqasabi, S.Y.; Sulimany, A.M.; Almohareb, T.; Alayad, A.S.; Bawazir, O.A. The Effect of Different Coating Agents on the Microhardness, Water Sorption, and Solubility of EQUIA Forte® HT. Coatings 2024, 14, 751. [Google Scholar] [CrossRef]

- Bilge, K.; Aşar, E.; Ipek, İ. Evaluation of Flexural Strength and Microhardness of Different Type Glass Ionomer Cements. Eur. Ann. Dent. Sci. 2024, 51, 10–14. [Google Scholar] [CrossRef]

- Gale, M.S.; Darvell, B.W. Thermal cycling procedures for laboratory testing of dental restorations. J. Dent. 1999, 27, 89–99. [Google Scholar] [CrossRef]

- Alsafi, A.M.; Taher, N.M. Microhardness and surface roughness of resin infiltrated bleached enamel surface using atomic force microscopy: An in vitro study. Saudi Dent. J. 2023, 35, 692–698. [Google Scholar] [CrossRef] [PubMed]

- Saadat, M.; Moradian, M.; Mirshekari, B. Evaluation of the Surface Hardness and Roughness of a Resin-Modified Glass Ionomer Cement Containing Bacterial Cellulose Nanocrystals. Int. J. Dent. 2021, 2021, 8231473. [Google Scholar] [CrossRef] [PubMed]

- Basheer, R.R.; Hasanain, F.A.; Abuelenain, D.A. Evaluating flexure properties, hardness, roughness and microleakage of high-strength injectable dental composite: An in vitro study. BMC Oral Health 2024, 24, 546. [Google Scholar] [CrossRef] [PubMed]

- Asaad, R.; Kotb Salem, S. Wear, Microhardness and Fracture Toughness of Different CAD/CAM Ceramics. Egypt. Dent. J. 2021, 67, 485–495. [Google Scholar] [CrossRef]

- Asafarlal, S. Comparative Evaluation of Microleakage, Surface Roughness and Hardness of Three Glass Ionomer Cements—Zirconomer, Fujii IX Extra GC and Ketac Molar: An In Vitro Study. Dentistry 2017, 7, 1000427. [Google Scholar] [CrossRef]

- Verma, V.; Mathur, S.; Sachdev, V.; Singh, D. Evaluation of compressive strength, shear bond strength, and microhardness values of glass-ionomer cement Type IX and Cention N. J. Conserv. Dent. 2020, 23, 550–553. [Google Scholar] [CrossRef]

- Bala, O.; Arisu, H.D.; Yikilgan, I.; Arslan, S.; Gullu, A. Evaluation of surface roughness and hardness of different glass ionomer cements. Eur. J. Dent. 2012, 6, 79–86. [Google Scholar] [CrossRef]

- Hasanain, F.A. Effect of Ageing, Staining and Polishing on the Colour Stability of a Single, a Group Shade and Nano Fill Dental Composite: An In-vitro Study. J. Clin. Diagn. Res. 2022, 16, 26–30. [Google Scholar] [CrossRef]

- Yeslam, H.E.; Alharbi, S.; Albalawi, W.; Hasanain, F.A. The effect of thermal aging on flexural strength of CAD/CAM hybrid and polymeric materials. Mater. Res. Express 2023, 10, 095402. [Google Scholar] [CrossRef]

- Birant, S.; Ozcan, H.; Koruyucu, M.; Seymen, F. Assesment of the compressive strength of the current restorative materials. Pediatr. Dent. J. 2021, 31, 80–85. [Google Scholar] [CrossRef]

- Mozaffar, A.; Jamal, U.; Sharma, A.; Imteyaz, S.; Zeya, T. Comparative Evaluation of the Compressive Strength of A Ceramic Reinforced Glass Ionomer and Resin High Strength Glass Ionomer Cement with A Nanohybrid Composite Material: An In Vitro Study. J. Res. Adv. Dent. 2021, 11, 2–148. [Google Scholar]

- Vaid, D.S.; Shah, N.C.; Bilgi, P.S. One year comparative clinical evaluation of EQUIA with resin-modified glass ionomer and a nanohybrid composite in noncarious cervical lesions. J. Conserv. Dent. JCD 2015, 18, 449. [Google Scholar] [CrossRef] [PubMed]

- Gorseta, K.; Skrinjaric, T.; Glavina, D. The Effect of Heating and Ultrasound on the Shear Bond Strength of Glass Ionomer Cement. Coll. Antropol. 2012, 36, 1307–1312. [Google Scholar] [PubMed]

- Yeslam, H.E. Flexural Behavior of Biocompatible High-Performance Polymer Composites for CAD/CAM Dentistry. J. Compos. Sci. 2023, 7, 270. [Google Scholar] [CrossRef]

- Joshi, K.H.; Gonapa, P.; Tiriveedi, R.; Chowdhury, D.D.; Aggarwal, A.; Mishra, S.; Babaji, P. Assessment of Flexural and Compressive Strengths of EQUIA, GC Gold Hybrid, and Conventional GIC Restorative Materials. J. Pharm. Bioallied Sci. 2023, 15 (Suppl. 6), S1175–S1177. [Google Scholar] [CrossRef]

- Ilie, N. Maturation of restorative glass ionomers with simplified application procedure. J. Dent. 2018, 79, 46–52. [Google Scholar] [CrossRef] [PubMed]

- Šalinović, I.; Stunja, M.; Schauperl, Z.; Verzak, Ž.; Ivanišević Malčić, A.; Brzović Rajić, V. Mechanical Properties of High Viscosity Glass Ionomer and Glass Hybrid Restorative Materials. Acta Stomatol. Croat. 2019, 53, 125–131. [Google Scholar] [CrossRef]

- Brzović Rajić, V.; Ivanišević Malčić, A.; Bilge Kütük, Z.; Gurgan, S.; Jukić, S.; Miletić, I. Compressive Strength of New Glass Ionomer Cement Technology based Restorative Materials after Thermocycling and Cyclic Loading. Acta Stomatol. Croat. 2019, 53, 318–325. [Google Scholar] [CrossRef]

- Kunte, S.; Shah, S.B.; Patil, S.; Shah, P.; Patel, A.; Chaudhary, S. Comparative Evaluation of Compressive Strength and Diametral Tensile Strength of Conventional Glass Ionomer Cement and a Glass Hybrid Glass Ionomer Cement. Int. J. Clin. Pediatr. Dent. 2022, 15, 398–401. [Google Scholar] [CrossRef]

- Kim, K.H.; Ong, J.L.; Okuno, O. The effect of filler loading and morphology on the mechanical properties of contemporary composites. J. Prosthet. Dent. 2002, 87, 642–649. [Google Scholar] [CrossRef]

- Li, Y.; Swartz, M.L.; Phillips, R.W.; Moore, B.K.; Roberts, T.A. Effect of filler content and size on properties of composites. J. Dent. Res. 1985, 64, 1396–1401. [Google Scholar] [CrossRef] [PubMed]

- Moshaverinia, A.; Roohpour, N.; Chee, W.; Schricker, S. A review of powder modifications in conventional glass-ionomer dental cements. J. Mater. Chem. 2010, 21, 1319–1328. [Google Scholar] [CrossRef]

| Material Name | Abbreviation | Material Type | Manufacturer | Composition |

|---|---|---|---|---|

| Fuji IX | CGIC | Conventional glass ionomer | GC Europe N.V., Leuven, Belgium | Powder: 95% fluoroaluminosilicate glass, 5% polyacrylic acid. Liquid: 50% distilled water, 40% polyacrylic acid and tartaric acid, 10% polybasic carboxylic acid. |

| Equia Forte | GH | Glass hybrid | GC Europe N.V., Leuven, Belgium | Powder: 95% strontium-fluoroaluminosilicate glass, 5% polyacrylic acid. Liquid: 40% aqueous polyacrylic acid. |

| Fuji II | RMGIC | Resin-modified glass ionomer | GC Europe N.V., Leuven, Belgium | Powder: 100% fluoroaluminosilicate glass. Liquid: 35% 2-Hydroxyethyl methacrylate (HEMA), 25% distilled water, 24% polyacrylic acid, 6% tartaric acid and 0.10% camphorquinone bisphenol A-glycidyl methacrylate (Bis-GMA) and traces of triethylene glycol dimethacrylate (TEGDMA). |

| Tetric-N-Ceram Bulk Fill | RBC | Nanohybrid bulk fill resin-based composite | Ivoclar Vivadent Inc., Schaan, Liechtenstein | Monomers: 20% bisphenol-A glycidyl methacrylate (Bis-GMA), ethoxylated bisphenol-A-glycidyl methacrylate (Bis-EMA), urethane dimethacrylate (UDMA). Fillers: 81% Barium glass, ytterbium trifluoride, mixed oxide, silicon dioxide, prepolymers. Initiators: <1 wt.% Camphorquinone. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abuzinadah, A.J.; Merdad, Y.M.A.; Aldharrab, R.S.; Almutairi, W.A.; Yeslam, H.E.; Hasanain, F.A. Microhardness and Compressive Strength of Bulk Fill Glass Hybrid Material and Other Direct Restorative Materials. J. Compos. Sci. 2024, 8, 508. https://doi.org/10.3390/jcs8120508

Abuzinadah AJ, Merdad YMA, Aldharrab RS, Almutairi WA, Yeslam HE, Hasanain FA. Microhardness and Compressive Strength of Bulk Fill Glass Hybrid Material and Other Direct Restorative Materials. Journal of Composites Science. 2024; 8(12):508. https://doi.org/10.3390/jcs8120508

Chicago/Turabian StyleAbuzinadah, Ahmed J., Yasser M. A. Merdad, Reem S. Aldharrab, Wejdan A. Almutairi, Hanin E. Yeslam, and Fatin A. Hasanain. 2024. "Microhardness and Compressive Strength of Bulk Fill Glass Hybrid Material and Other Direct Restorative Materials" Journal of Composites Science 8, no. 12: 508. https://doi.org/10.3390/jcs8120508

APA StyleAbuzinadah, A. J., Merdad, Y. M. A., Aldharrab, R. S., Almutairi, W. A., Yeslam, H. E., & Hasanain, F. A. (2024). Microhardness and Compressive Strength of Bulk Fill Glass Hybrid Material and Other Direct Restorative Materials. Journal of Composites Science, 8(12), 508. https://doi.org/10.3390/jcs8120508