Development of Sugarcane Bagasse Ash Blended Cementitious Composites Reinforced with Carbon Nanotubes and Polypropylene Fibers

Abstract

:1. Introduction

2. Methodology

2.1. Materials

2.2. Magnetic Stirring and Sonication of CNTs

2.3. Mix Design

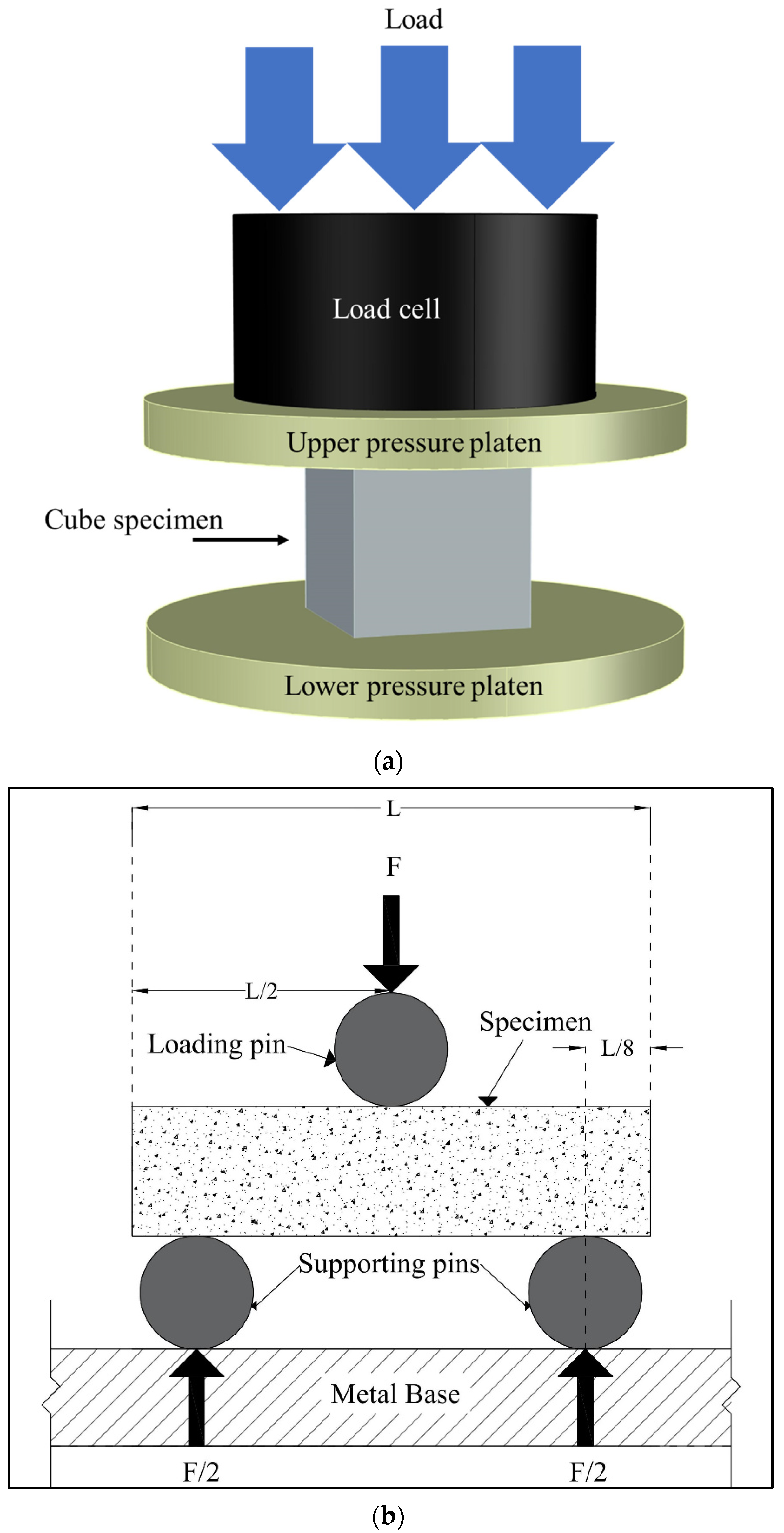

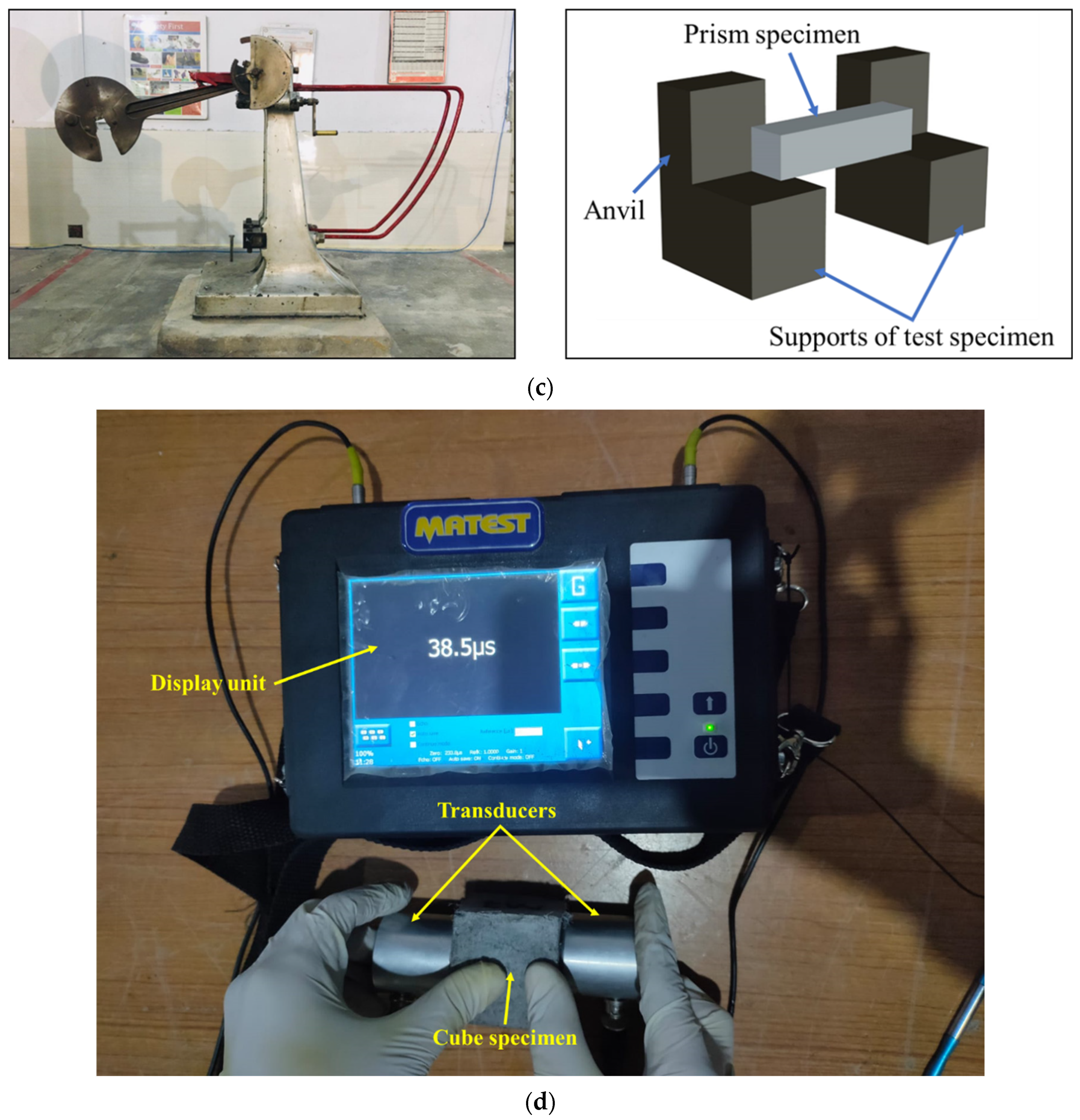

2.4. Test Methods

3. Results and Discussion

3.1. Compressive Strength Test

3.2. Flexural Strength Test

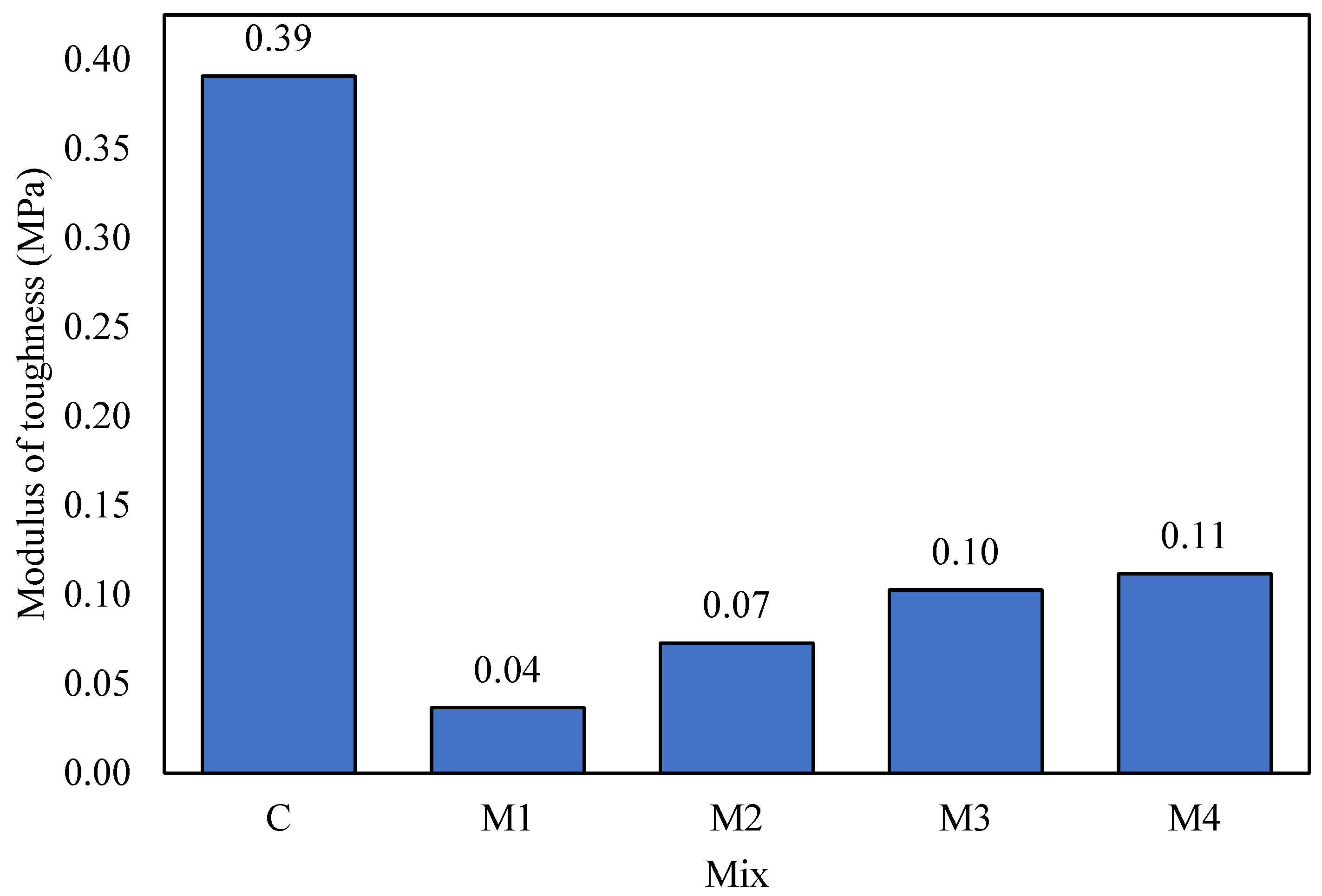

3.3. Impact Strength Test

3.4. Water Absorption Test

3.5. UPV Test

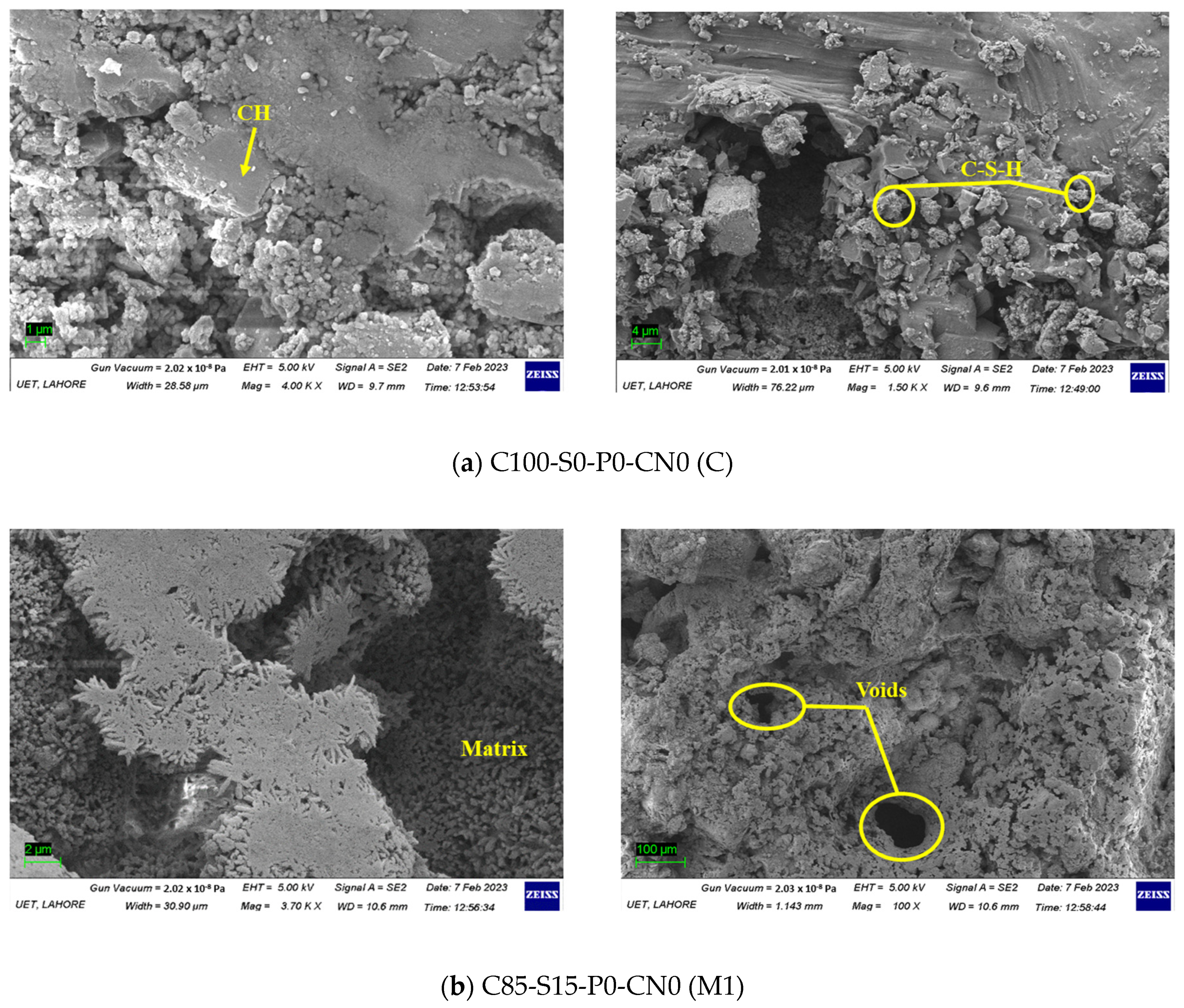

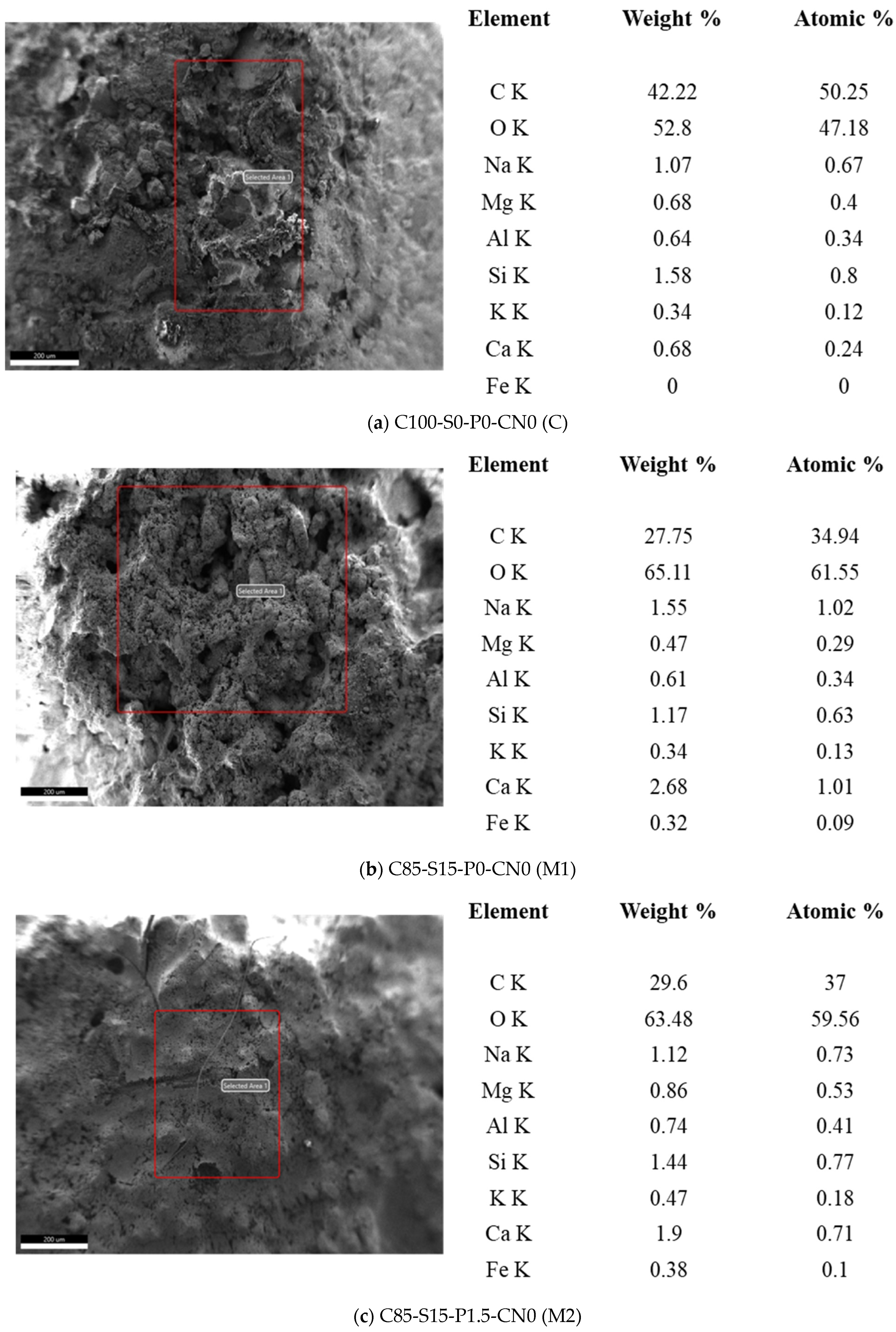

3.6. Microstructural Analysis

4. Conclusions

- The partial replacement of OPC with SCBA led to decline in the compressive and flexural strengths, which were effectively compensated by PP fibers. Initially, the inclusion of 0.04% MW-CNTs posed challenges owing to their hydrophilic nature, resulting in a compromised hydration process and subsequent reduction in the strength. However, in the mix with 0.08% CNTs, higher compressive and flexural strengths of 15.30 MPa and 0.98 MPa were obtained, respectively, which can be used in general construction works such as masonry units, load-bearing walls, and other reinforced structural elements. This revealed that the incorporation of 15% SCBA, 1.5% PP fiber, and 0.08% CNTs by weight of the binder in the development of cementitious composites can play a substantial role in enhancing the sustainability and economy of the construction sector.

- The impact strength was decreased due to the poor energy absorption capabilities of SCBA. However, CNTs and PP fibers, with their toughness and energy absorption capabilities, improved the impact resistance of the specimens.

- The water absorption and UPV served as indicators of the porosity in the developed specimens. The inclusion of SCBA produced a porous structure, whereas PP fibers densified the cementitious matrix. CNTs initially increased the porosity and then filled the nanopores as their concentration was increased.

- From SEM and EDS, it was observed that, owing to their hydrophilic nature, MW-CNTs, can hinder the hydration activity of the binder; however, an optimum concentration of CNTs can result in the formation of a denser cement–sand matrix and high-stiffness C-S-H.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Andrew, R.M. Global CO2 emissions from cement production, 1928–2018. Earth Syst. Sci. Data 2019, 11, 1675–1710. [Google Scholar] [CrossRef]

- Heede, R. Tracing anthropogenic carbon dioxide and methane emissions to fossil fuel and cement producers, 1854–2010. Clim. Chang. 2014, 122, 229–241. [Google Scholar] [CrossRef]

- Malhotra, V.M. Making Concrete “Greener” with Fly Ash. Concr. Int. 1999, 21, 61–66. [Google Scholar]

- Nie, S.; Zhou, J.; Yang, F.; Lan, M.; Li, J.; Zhang, Z.; Chen, Z.; Xu, M.; Li, H.; Sanjayan, J.G. Analysis of theoretical carbon dioxide emissions from cement production: Methodology and application. J. Clean. Prod. 2022, 334, 130270. [Google Scholar] [CrossRef]

- Malhotra, V.M. Introduction: Sustainable Development and Concrete Technology. Concr. Int. 2002, 24, 22. [Google Scholar]

- Pade, C.; Guimaraes, M. The CO2 uptake of concrete in a 100 year perspective. Cem. Concr. Res. 2007, 37, 1348–1356. [Google Scholar] [CrossRef]

- Mindess, S.; Young, F.; Darwin, D. Concrete, 2nd ed.; Prentice-Hall: Upper Saddle River, NJ, USA, 2003. [Google Scholar]

- Gupta, S.; Chaudhary, S. State of the art review on supplementary cementitious materials in India—II: Characteristics of SCMs, effect on concrete and environmental impact. J. Clean. Prod. 2022, 357, 131945. [Google Scholar] [CrossRef]

- Cherki El Idrissi, A.; Paris, M.; Rozière, E.; Deneele, D.; Darson, S.; Loukili, A. Alkali-activated grouts with incorporated fly ash: From NMR analysis to mechanical properties. Mater. Today Commun. 2018, 14, 225–232. [Google Scholar] [CrossRef]

- Mousavinezhad, S.; Gonzales, G.J.; Toledo, W.K.; Garcia, J.M.; Newtson, C.M.; Allena, S. A Comprehensive Study on Non-Proprietary Ultra-High-Performance Concrete Containing Supplementary Cementitious Materials. Materials 2023, 16, 2622. [Google Scholar] [CrossRef]

- Nili, M.; Afroughsabet, V. The effects of silica fume and polypropylene fibers on the impact resistance and mechanical properties of concrete. Constr. Build. Mater. 2010, 24, 927–933. [Google Scholar] [CrossRef]

- Prošek, Z.; Nežerka, V.; Hlůžek, R.; Trejbal, J.; Tesárek, P.; Karra’a, G. Role of lime, fly ash, and slag in cement pastes containing recycled concrete fines. Constr. Build. Mater. 2019, 201, 702–714. [Google Scholar] [CrossRef]

- Ray, T.; Ranjan Mohanta, N.; Hitesh Kumar, M.; Saikrishna Macharyulu, I.; Samantaray, S. Study of effect of temperature on behavior of alkali activated slag concrete. Mater. Today Proc. 2021, 43, 1352–1357. [Google Scholar] [CrossRef]

- Ashraf, M.; Iqbal, M.F.; Rauf, M.; Ashraf, M.U.; Ulhaq, A.; Muhammad, H.; Liu, Q. Developing a Sustainable Concrete Incorporating Bentonite Clay and Silica Fume: Mechanical and Durability Performance. J. Clean. Prod. 2022, 337, 130315. [Google Scholar] [CrossRef]

- Amin, M.N.; Ahmad, A.; Shahzada, K.; Khan, K.; Jalal, F.E.; Qadir, M.G. Mechanical and microstructural performance of concrete containing high-volume of bagasse ash and silica fume. Sci. Rep. 2022, 12, 5719. [Google Scholar] [CrossRef] [PubMed]

- Dinesh, A.; Rubina, I.; Asmin Varsha, N.; Dhevdharshini, M.; Ramesh, C. Evaluation of the readiness of clay bricks with partially replaced rice husk ash. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Jagadesh, P.; Ramachandramurthy, A.; Murugesan, R.; Sarayu, K. Micro-analytical studies on sugar cane bagasse ash. Sadhana 2015, 40, 1629–1638. [Google Scholar] [CrossRef]

- Mehmood, A.; Irfan-ul-Hassan, M.; Yaseen, N. Role of industrial by-products and metakaolin in the development of sustainable geopolymer blends: Upscaling from laboratory-scale to pilot-scale. J. Build. Eng. 2022, 62, 105279. [Google Scholar] [CrossRef]

- Su, Q.; Xu, J. Mechanical properties of concrete containing glass sand and rice husk ash. Constr. Build. Mater. 2023, 393, 132053. [Google Scholar] [CrossRef]

- Yaseen, N.; Sahar, U.; Bahrami, A.; Mazhar Saleem, M.; Ayyan Iqbal, M.; Saddique, I. Synergistic impacts of fly ash and sugarcane bagasse ash on performance of polyvinyl alcohol fiber-reinforced engineered cementitious composites. Results Mater. 2023, 20, 100490. [Google Scholar] [CrossRef]

- Yaseen, N.; Irfan-ul-Hassan, M.; Saeed, A.-R.; Rizwan, S.A.; Afzal, M. Sustainable Development and Performance Assessment of Clay-Based Geopolymer Bricks Incorporating Fly Ash and Sugarcane Bagasse Ash. J. Mater. Civ. Eng. 2022, 34, 04022036. [Google Scholar] [CrossRef]

- Zareei, S.A.; Ameri, F.; Bahrami, N. Microstructure, Strength, and Durability of Eco-Friendly Concretes Containing Sugarcane Bagasse Ash. Constr. Build. Mater. 2018, 184, 258–268. [Google Scholar] [CrossRef]

- Memon, S.A.; Javed, U.; Shah, M.I.; Hanif, A. Use of Processed Sugarcane Bagasse Ash in Concrete as Partial Replacement of Cement: Mechanical and Durability Properties. Buildings 2022, 12, 1769. [Google Scholar] [CrossRef]

- Payá, J.; Monzó, J.; Borrachero, M.V.; Tashima, M.M.; Soriano, L. Bagasse Ash. In Waste and Supplementary Cementitious Materials in Concrete; Elsevier: Amsterdam, The Netherlands, 2018; pp. 559–598. [Google Scholar] [CrossRef]

- Ribeiro, D.V.; Morelli, M.R. Effect of Calcination Temperature on the Pozzolanic Activity of Brazilian Sugar Cane Bagasse Ash (SCBA). Mater. Res. 2014, 17, 974–981. [Google Scholar] [CrossRef]

- Torres Agredo, J.; Mejía de Gutiérrez, R.; Escandón Giraldo, C.E.; González Salcedo, L.O. Characterization of Sugar Cane Bagasse Ash as Supplementary Material for Portland Cement. Ing. Investig. 2014, 34, 5–10. [Google Scholar] [CrossRef]

- Saad Agwa, I.; Zeyad, A.M.; Tayeh, B.A.; Adesina, A.; de Azevedo, A.R.G.; Amin, M.; Hadzima-Nyarko, M. A Comprehensive Review on the Use of Sugarcane Bagasse Ash as a Supplementary Cementitious Material to Produce Eco-Friendly Concretes. Mater. Today Proc. 2022, 65, 688–696. [Google Scholar] [CrossRef]

- Bahurudeen, A.; Kanraj, D.; Gokul Dev, V.; Santhanam, M. Performance Evaluation of Sugarcane Bagasse Ash Blended Cement in Concrete. Cem. Concr. Compos. 2015, 59, 77–88. [Google Scholar] [CrossRef]

- Khan, M.I.; Abdy Sayyed, M.A.; Ali, M.M.A. Examination of Cement Concrete Containing Micro Silica and Sugarcane Bagasse Ash Subjected to Sulphate and Chloride Attack. Mater. Today Proc. 2021, 39, 558–562. [Google Scholar] [CrossRef]

- Thomas, B.S.; Yang, J.; Bahurudeen, A.; Abdalla, J.A.; Hawileh, R.A.; Hamada, H.M.; Nazar, S.; Jittin, V.; Ashish, D.K. Sugarcane Bagasse Ash as Supplementary Cementitious Material in Concrete—A Review. Mater. Today Sustain. 2021, 15, 100086. [Google Scholar] [CrossRef]

- Akbar, A.; Farooq, F.; Shafique, M.; Aslam, F.; Alyousef, R.; Alabduljabbar, H. Sugarcane Bagasse Ash-Based Engineered Geopolymer Mortar Incorporating Propylene Fibers. J. Build. Eng. 2021, 33, 101492. [Google Scholar] [CrossRef]

- Latifi, M.R.; Biricik, Ö.; Mardani Aghabaglou, A. Effect of the Addition of Polypropylene Fiber on Concrete Properties. J. Adhes. Sci. Technol. 2022, 36, 345–369. [Google Scholar] [CrossRef]

- Berenguer, R.A.; Capraro, A.P.B.; Farias de Medeiros, M.H.; Carneiro, A.M.P.; de Oliveira, R.A. Sugar Cane Bagasse Ash as a Partial Substitute of Portland Cement: Effect on Mechanical Properties and Emission of Carbon Dioxide. J. Environ. Chem. Eng. 2020, 8, 103655. [Google Scholar] [CrossRef]

- Irshidat, M.R.; Al-Nuaimi, N.; Rabie, M. Hybrid Effect of Carbon Nanotubes and Polypropylene Microfibers on Fire Resistance, Thermal Characteristics and Microstructure of Cementitious Composites. Constr. Build. Mater. 2021, 266, 121154. [Google Scholar] [CrossRef]

- Kavya Sameera, V.; Keshav, L. Properties and Performance of Steel Fiber Reinforced Concrete Beam Structure—Review. Mater. Today Proc. 2022, 66, 916–919. [Google Scholar] [CrossRef]

- Shen, L.; Yao, X.; Di Luzio, G.; Jiang, M.; Han, Y. Mix Optimization of Hybrid Steel and Polypropylene Fiber-Reinforced Concrete for Anti-Thermal Spalling. J. Build. Eng. 2023, 63, 105409. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, L.; Cao, K.; Sun, L. Review on the Durability of Polypropylene Fibre-Reinforced Concrete. Adv. Civ. Eng. 2021, 2021, 6652077. [Google Scholar] [CrossRef]

- Sohaib, N.; Seemab, F.; Sana, G.; Mamoon, R. Using Polypropylene Fibers in Concrete to Achieve Maximum Strength; Institute of Research Engineers and Doctors, LLC: New York, NY, USA, 2018; pp. 37–42. [Google Scholar] [CrossRef]

- Mazaheripour, H.; Ghanbarpour, S.; Mirmoradi, S.H.; Hosseinpour, I. The Effect of Polypropylene Fibers on the Properties of Fresh and Hardened Lightweight Self-Compacting Concrete. Constr. Build. Mater. 2011, 25, 351–358. [Google Scholar] [CrossRef]

- Akarsh, P.K.; Shrinidhi, D.; Marathe, S.; Bhat, A.K. Graphene Oxide as Nano-Material in Developing Sustainable Concrete—A Brief Review. Mater. Today Proc. 2022, 60, 234–246. [Google Scholar] [CrossRef]

- Carmichael, M.J.; Arulraj, G.P. Impact Resistance of Concrete with Nano Materials. Mater. Today Proc. 2021, 37 Pt 2, 677–684. [Google Scholar] [CrossRef]

- Kotop, M.A.; El-Feky, M.S.; Alharbi, Y.R.; Abadel, A.A.; Binyahya, A.S. Engineering Properties of Geopolymer Concrete Incorporating Hybrid Nano-Materials. Ain. Shams. Eng. J. 2021, 12, 3641–3647. [Google Scholar] [CrossRef]

- Liew, K.M.; Kai, M.F.; Zhang, L.W. Carbon Nanotube Reinforced Cementitious Composites: An Overview. Compos. Part A Appl. Sci. Manuf. 2016, 91, 301–323. [Google Scholar] [CrossRef]

- Wu, H.; Wang, C.; Yang, D.; Ma, Z. Utilizing Nano-SiO2 for Modifying the Microstructure, Strength and Transport Properties of Sustainable Cementitious Materials with Waste Concrete Powder. J. Build. Eng. 2023, 63, 105522. [Google Scholar] [CrossRef]

- Khan, S.A.; Ghazi, S.M.U.; Amjad, H.; Imran, M.; Khushnood, R.A. Emerging Horizons in 3D Printed Cement-Based Materials with Nanomaterial Integration: A Review. Constr. Build. Mater. 2024, 411, 134815. [Google Scholar] [CrossRef]

- Han, B.; Sun, S.; Ding, S.; Zhang, L.; Yu, X.; Ou, J. Review of Nanocarbon-Engineered Multifunctional Cementitious Composites. Compos. Part A Appl. Sci. Manuf. 2015, 70, 69–81. [Google Scholar] [CrossRef]

- Konsta-Gdoutos, M.S.; Aza, C.A. Self Sensing Carbon Nanotube (CNT) and Nanofiber (CNF) Cementitious Composites for Real Time Damage Assessment in Smart Structures. Cem. Concr. Compos. 2014, 53, 162–169. [Google Scholar] [CrossRef]

- Xie, X.L.; Mai, Y.W.; Zhou, X.P. Dispersion and Alignment of Carbon Nanotubes in Polymer Matrix: A Review. Mater. Sci. Eng. R Rep. 2005, 49, 89–112. [Google Scholar] [CrossRef]

- Daghash, S.M.; Soliman, E.M.; Kandil, U.F.; Reda Taha, M.M. Improving Impact Resistance of Polymer Concrete Using CNTs. Int. J. Concr. Struct. Mater. 2016, 10, 539–553. [Google Scholar] [CrossRef]

- Xu, S.; Liu, J.; Li, Q. Mechanical Properties and Microstructure of Multi-Walled Carbon Nanotube-Reinforced Cement Paste. Constr. Build. Mater. 2015, 76, 16–23. [Google Scholar] [CrossRef]

- Konsta-Gdoutos, M.S.; Metaxa, Z.S.; Shah, S.P. Highly Dispersed Carbon Nanotube Reinforced Cement Based Materials. Cem. Concr. Res. 2010, 40, 1052–1059. [Google Scholar] [CrossRef]

- Mohsen, M.O.; Taha, R.; Abu Taqa, A.; Shaat, A. Optimum Carbon Nanotubes’ Content for Improving Flexural and Compressive Strength of Cement Paste. Constr. Build. Mater. 2017, 150, 395–403. [Google Scholar] [CrossRef]

- Nuaklong, P.; Boonchoo, N.; Jongvivatsakul, P.; Charinpanitkul, T.; Sukontasukkul, P. Hybrid Effect of Carbon Nanotubes and Polypropylene Fibers on Mechanical Properties and Fire Resistance of Cement Mortar. Constr. Build. Mater. 2021, 275, 122189. [Google Scholar] [CrossRef]

- Andrade Neto, J.D.S.; Santos, T.A.; Pinto, S.d.A.; Dias, C.M.R.; Ribeiro, D.V. Effect of the Combined Use of Carbon Nanotubes (CNT) and Metakaolin on the Properties of Cementitious Matrices. Constr. Build. Mater. 2021, 271, 121903. [Google Scholar] [CrossRef]

- Asil, M.B.; Ranjbar, M.M. Hybrid Effect of Carbon Nanotubes and Basalt Fibers on Mechanical, Durability, and Microstructure Properties of Lightweight Geopolymer Concretes. Constr. Build. Mater. 2022, 357, 129352. [Google Scholar] [CrossRef]

- Han, G.; Xiang, J.; Jing, H.; Wei, X.; Gao, Y.; Chen, W. Carbon Nanotubes Assisted Fly Ash for Cement Reduction on the Premise of Ensuring the Stability of the Grouting Materials. Constr. Build. Mater. 2023, 368, 130476. [Google Scholar] [CrossRef]

- Kordkheili, H.Y.; Hiziroglu, S.; Farsi, M. Physical and Mechanical Properties of Cement Composites Manufactured from Carbon Nanotubes and Bagasse Fiber. Mater. Des. 2012, 33, 395–398. [Google Scholar] [CrossRef]

- Manzur, T.; Yazdani, N. Optimum Mix Ratio for Carbon Nanotubes in Cement Mortar. KSCE J. Civ. Eng. 2015, 19, 1405–1412. [Google Scholar] [CrossRef]

- ASTM C128; Standard Test Method for Relative Density (Specific Gravity) and Absorption of Fine Aggregate. ASTM International: West Conshohocken, PA, USA, 2016. [CrossRef]

- ASTM C33; Standard Specification for Concrete Aggregate. ASTM International: West Conshohocken, PA, USA, 2023. [CrossRef]

- Chia, L.; Huang, Y.; Xia, W.; Lu, P.; Zhang, D. Carbon Nanotube (CNT) Reinforced Cementitious Composites Using Carboxymethyl Cellulose (CMC) Treatment for Enhanced Dispersion, Mechanical, and Piezoresistive Properties. Constr. Build. Mater. 2023, 377, 131104. [Google Scholar] [CrossRef]

- Hu, Y.; Luo, D.; Li, P.; Li, Q.; Sun, G. Fracture Toughness Enhancement of Cement Paste with Multi-Walled Carbon Nanotubes. Constr. Build. Mater. 2014, 70, 332–338. [Google Scholar] [CrossRef]

- Sáez de Ibarra, Y.; Gaitero, J.J.; Erkizia, E.; Campillo, I. Atomic Force Microscopy and Nanoindentation of Cement Pastes with Nanotube Dispersions. Phys. Status Solidi (a) 2006, 203, 1076–1081. [Google Scholar] [CrossRef]

- Sobolkina, A.; Mechtcherine, V.; Khavrus, V.; Maier, D.; Mende, M.; Ritschel, M.; Leonhardt, A. Dispersion of Carbon Nanotubes and Its Influence on the Mechanical Properties of the Cement Matrix. Cem. Concr. Compos. 2012, 34, 1104–1113. [Google Scholar] [CrossRef]

- Zhang, P.; Su, J.; Guo, J.; Hu, S. Influence of Carbon Nanotube on Properties of Concrete: A Review. Constr. Build. Mater. 2023, 369, 130388. [Google Scholar] [CrossRef]

- De Almeida Carísio, P.; Dos Santos Mendonça, Y.G.; Soares, C.F.T.; Reales, O.A.M.; de Moraes Rego Fairbairn, E.; Filho, R.D.T. Dispersion of Carbon Nanotubes with Different Types of Superplasticizer as a Dispersing Agent for Self-Sensing Cementitious Materials. Appl. Sci. 2021, 11, 8452. [Google Scholar] [CrossRef]

- Karimipour, A.; Ghalehnovi, M.; de Brito, J.; Attari, M. The Effect of Polypropylene Fibres on the Compressive Strength, Impact and Heat Resistance of Self-Compacting Concrete. Structures 2020, 25, 72–87. [Google Scholar] [CrossRef]

- ASTM C109; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars. ASTM International: West Conshohocken, PA, USA, 2017. [CrossRef]

- ASTM C348-20; Standard Test Method for Flexural Strength of Hydraulic-Cement Mortars. ASTM International: West Conshohocken, PA, USA, 2021. [CrossRef]

- ASTM E23; Standard Test Methods for Notched Bar Impact Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2018. [CrossRef]

- ASTM C1403-00; Standard Test Method for Rate of Water Absorption of Masonry Mortars. ASTM International: West Conshohocken, PA, USA, 2017. [CrossRef]

- ASTM C597-16; Standard Test Method for Pulse Velocity Through Concrete. ASTM International: West Conshohocken, PA, USA, 2016. [CrossRef]

- Srinivasan, R.; Sathiya, K. Experimental Study on Bagasse Ash in Concrete. Int. J. Serv. Learn. Eng. Humanit. Eng. Soc. Entrep. 2010, 5, 60–66. [Google Scholar] [CrossRef]

- Chi, M. Effects of Sugar Cane Bagasse Ash as a Cement Replacement on Properties of Mortars. Sci. Eng. Compos. Mater. 2012, 19, 279–285. [Google Scholar] [CrossRef]

- Jagadesh, P.; Ramachandramurthy, A.; Murugesan, R. Evaluation of Mechanical Properties of Sugar Cane Bagasse Ash Concrete. Constr. Build. Mater. 2018, 176, 608–617. [Google Scholar] [CrossRef]

- Afroughsabet, V.; Ozbakkaloglu, T. Mechanical and durability properties of high-strength concrete containing steel and polypropylene fibers. Constr. Build. Mater. 2015, 94, 73–82. [Google Scholar] [CrossRef]

- Musso, S.; Tulliani, J.-M.; Ferro, G.; Tagliaferro, A. Influence of Carbon Nanotubes Structure on the Mechanical Behavior of Cement Composites. Compos. Sci. Technol. 2009, 69, 1985–1990. [Google Scholar] [CrossRef]

- Wang, J.; Li, Y.; Qiu, Z.; Zhang, Y. Experimental Research on Compressive Properties of Recycling Polypropylene (PP) Fiber Recycled Coarse Aggregate Concrete. J. Build. Eng. 2023, 76, 107403. [Google Scholar] [CrossRef]

- ASTM C270; Standard Specification for Mortar for Unit Masonry. ASTM International: West Conshohocken, PA, USA, 2014. [CrossRef]

- Razeman, N.A.; Itam, Z.; Beddu, S.; Izam, N.S.M.N.; Ramli, M.Z.; Syamsir, A.; Mohamad, D.; Kamal, N.L.M.; Usman, F.; Asyraf, M.R.M. A Review on The Compressive Strength and Workability of Concrete with Agricultural Waste Ash as Cement Replacement Material. IOP Conf. Ser. Earth Environ. Sci. 2023, 1135, 012058. [Google Scholar] [CrossRef]

- Batool, F.; Masood, A.; Ali, M. Characterization of Sugarcane Bagasse Ash as Pozzolan and Influence on Concrete Properties. Arab. J. Sci. Eng. 2020, 45, 3891–3900. [Google Scholar] [CrossRef]

- Rukzon, S.; Chindaprasirt, P. Utilization of Bagasse Ash in High-Strength Concrete. Mater. Des. 2012, 34, 45–50. [Google Scholar] [CrossRef]

- Karahan, O.; Atiş, C.D. The Durability Properties of Polypropylene Fiber Reinforced Fly Ash Concrete. Mater. Des. 2011, 32, 1044–1049. [Google Scholar] [CrossRef]

- Ikpong, A.A. The Relationship between the Strength and Non-Destructive Parameters of Rice Husk Ash Concrete. Cem. Concr. Res. 1993, 23, 387–398. [Google Scholar] [CrossRef]

- Parihar, H.S.; Shanker, R.; Singh, V. Effect of Variation of Steel Reinforcement on Ultrasonic Pulse Velocity Prediction in Concrete Beam. Mater. Today Proc. 2022, 65, 1486–1490. [Google Scholar] [CrossRef]

- Kirchheim, A.P.; Fernàndez-Altable, V.; Monteiro, P.J.M.; Dal Molin, D.C.C.; Casanova, I. Analysis of Cubic and Orthorhombic C3A Hydration in Presence of Gypsum and Lime. J. Mater. Sci. 2009, 44, 2038–2045. [Google Scholar] [CrossRef]

- Lu, B.; Drissi, S.; Liu, J.; Hu, X.; Song, B.; Shi, C. Effect of Temperature on CO2 Curing, Compressive Strength and Microstructure of Cement Paste. Cem. Concr. Res. 2022, 157, 106827. [Google Scholar] [CrossRef]

- Maljaee, H.; Paiva, H.; Madadi, R.; Tarelho, L.A.C.; Morais, M.; Ferreira, V.M. Effect of Cement Partial Substitution by Waste-Based Biochar in Mortars Properties. Constr. Build. Mater. 2021, 301, 124074. [Google Scholar] [CrossRef]

- Méducin, F.; Bresson, B.; Lequeux, N.; Noirfontaine, M.D.; Zanni, H. Calcium Silicate Hydrates Investigated by Solid-state High Resolution 1H and 29Si Nuclear Magnetic Resonance. Cem. Concr. Res. 2007, 37, 631–638. [Google Scholar] [CrossRef]

- Tang, H.; Wu, X.; Xian, H.; Zhu, J.; Wei, J.; Liu, H.; He, H. Heterogeneous Nucleation and Growth of CaCO3 on Calcite (104) and Aragonite (110) Surfaces: Implications for the Formation of Abiogenic Carbonate Cements in the Ocean. Minerals 2020, 10, 294. [Google Scholar] [CrossRef]

- Wang, T.; Yi, Z.; Song, J.; Zhao, C.; Guo, R.; Gao, X. An Industrial Demonstration Study on CO2 Mineralization Curing for Concrete. iScience 2022, 25, 104261. [Google Scholar] [CrossRef]

- Le, D.H.; Sheen, Y.N. Assessment of Properties of Mortars Modified with Sugarcane Bagasse Ash Processed by Heating at Different Temperatures as Cement Replacement. Eur. J. Environ. Civ. Eng. 2022, 27, 393–415. [Google Scholar] [CrossRef]

- Kazmi, S.M.S.; Munir, M.J.; Patnaikuni, I.; Wu, Y.F. Pozzolanic Reaction of Sugarcane Bagasse Ash and Its Role in Controlling Alkali Silica Reaction. Constr. Build. Mater. 2017, 148, 231–240. [Google Scholar] [CrossRef]

| CaO | MgO | SiO2 | SO3 | Al2O3 | Fe2O3 | LOI | |

|---|---|---|---|---|---|---|---|

| OPC | 62.32 | 2.75 | 20.53 | 2.47 | 5.10 | 2.96 | 1.58 |

| SCBA | 2.24 | 1.80 | 69.80 | 0.46 | 1.15 | 1.95 | 19.30 |

| Mixes | Short Descriptions of Mixes | OPC | SCBA | Sand | Water | CNTs | PP Fibers | HRWR |

|---|---|---|---|---|---|---|---|---|

| C | C100-S0-P0-CN0 | 666.67 | 0 | 1833.3 | 323.3 | 0 | 0 | 53.3 |

| M1 | C85-S15-P0-CN0 | 566.67 | 100 | 1833.3 | 323.3 | 0 | 0 | 53.3 |

| M2 | C85-S15-P1.5-CN0 | 566.67 | 100 | 1833.3 | 323.3 | 0 | 10 | 53.3 |

| M3 | C85-S15-P1.5-CN0.04 | 566.67 | 100 | 1833.3 | 323.3 | 0.27 | 10 | 53.3 |

| M4 | C85-S15-P1.5-CN0.08 | 566.67 | 100 | 1833.3 | 323.3 | 0.53 | 10 | 53.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Iqbal, M.A.; Sahar, U.U.; Bahrami, A.; Yaseen, N.; Siddique, I. Development of Sugarcane Bagasse Ash Blended Cementitious Composites Reinforced with Carbon Nanotubes and Polypropylene Fibers. J. Compos. Sci. 2024, 8, 94. https://doi.org/10.3390/jcs8030094

Iqbal MA, Sahar UU, Bahrami A, Yaseen N, Siddique I. Development of Sugarcane Bagasse Ash Blended Cementitious Composites Reinforced with Carbon Nanotubes and Polypropylene Fibers. Journal of Composites Science. 2024; 8(3):94. https://doi.org/10.3390/jcs8030094

Chicago/Turabian StyleIqbal, Muhammad Ayyan, Umbreen Us Sahar, Alireza Bahrami, Noor Yaseen, and Iffat Siddique. 2024. "Development of Sugarcane Bagasse Ash Blended Cementitious Composites Reinforced with Carbon Nanotubes and Polypropylene Fibers" Journal of Composites Science 8, no. 3: 94. https://doi.org/10.3390/jcs8030094

APA StyleIqbal, M. A., Sahar, U. U., Bahrami, A., Yaseen, N., & Siddique, I. (2024). Development of Sugarcane Bagasse Ash Blended Cementitious Composites Reinforced with Carbon Nanotubes and Polypropylene Fibers. Journal of Composites Science, 8(3), 94. https://doi.org/10.3390/jcs8030094