Polypropylene Composites Reinforced with Lignocellulose Nanocrystals of Corncob: Thermal and Mechanical Properties

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Organosolv Pulping of Corncob

2.3. Lignocellulose Nanocrystals

2.4. Composites Preparation

2.5. LCNC/PP Composites Characterization

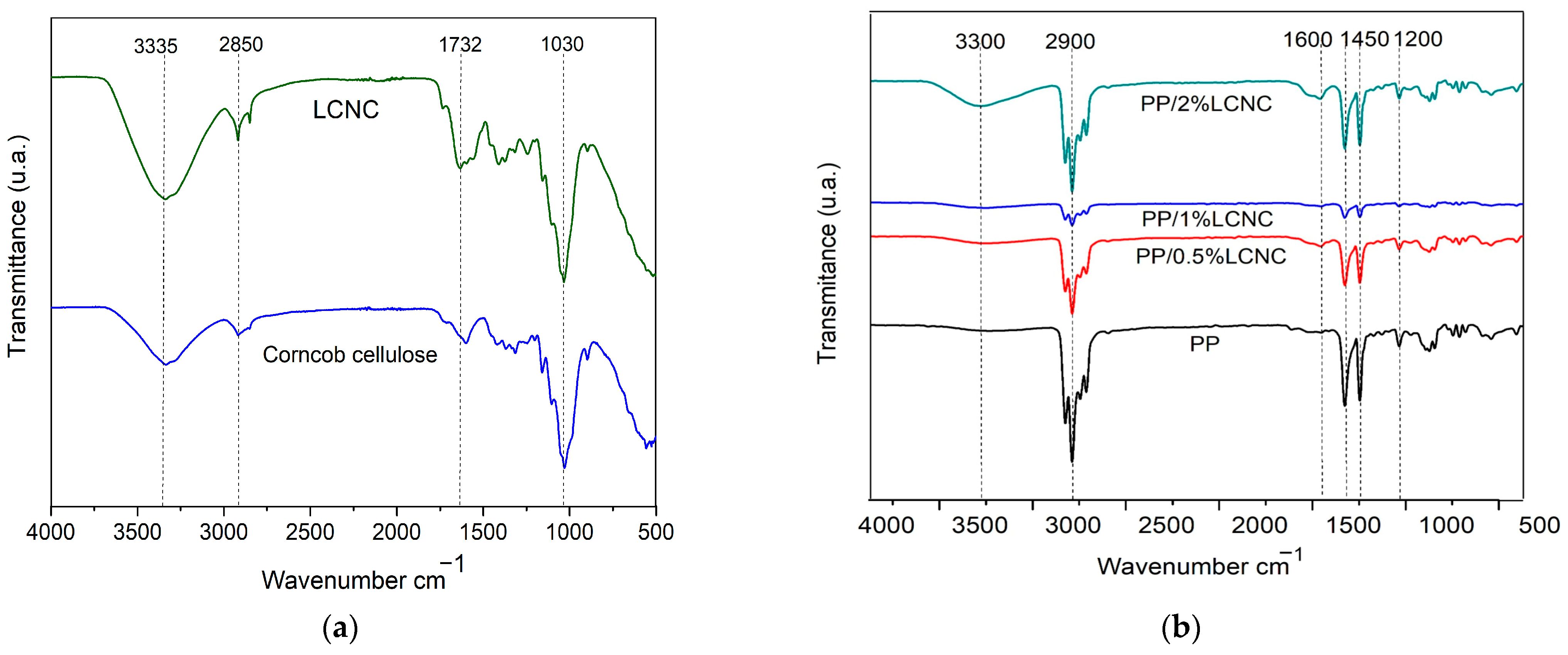

- Fourier-transform infrared spectroscopy (FTIR): FTIR analysis was carried out to determine the main functional groups on the LCNC/PP composite. The FTIR spectra were collected at a resolution of 4 cm−1 in transmission mode (4000–400 cm−1) using a FTIR spectrophotometer Alpha, Bruker (Germany, Berlin). The spectra were plotted using Origin Pro 2019 software.

- Thermogravimetric analysis (TGA): The LCNC/PP composite was analyzed using a TGA-Q500 thermogravimetric analyzer (TA Instruments, New Castle, DE, USA) to study its thermal behavior. It was equipped with Universal Analysis 2000 software (version 4.5A, TA Instruments). Samples were heated from 30 °C to 600 °C at 10 °C/min under nitrogen. The spectra were plotted using Origin Pro 2019 software.

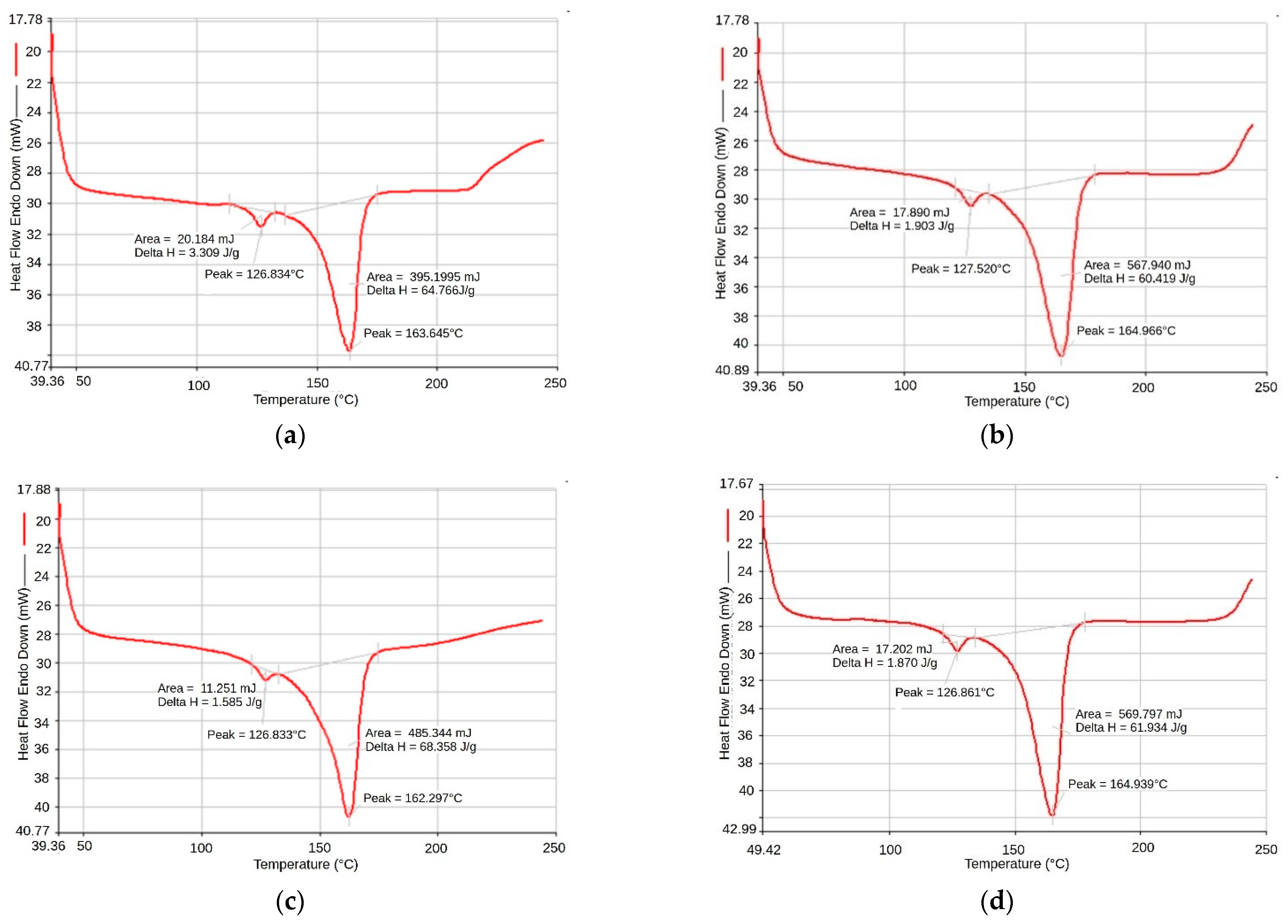

- Differential scanning calorimetry (DSC): To study the thermal transitions of pure PP and the PP/LCNC composite, the differential scanning calorimetry technique was used using the Perkin Elmer DSC equipment, Pyris DSC-6 (USA, TX, San Antonio), National University of Costa Rica, with a heating rate of 20 °C/min from room temperature to 250 °C in a nitrogen atmosphere. This energy difference was recorded as a spike on the DSC scan, indicating the temperature and energy of the transition.

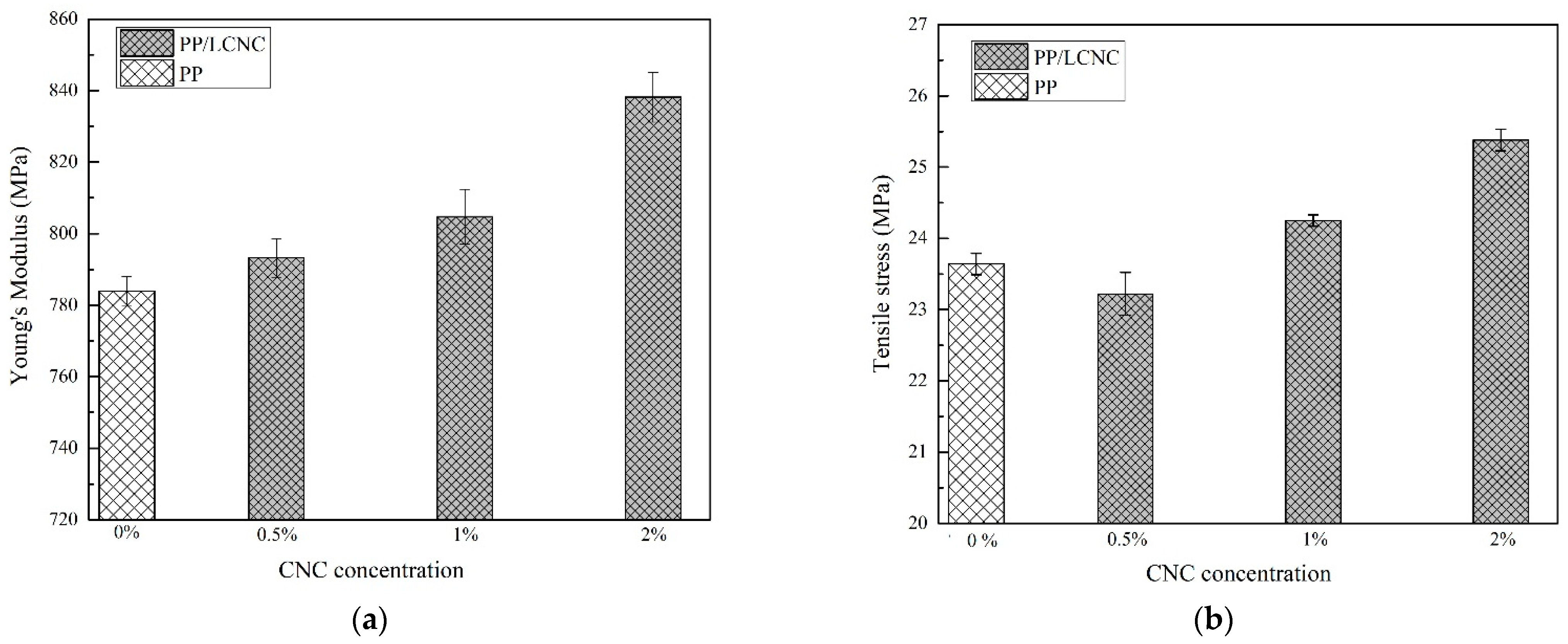

- Mechanical properties: Tensile tests were measured on the Instron Model 3345 Universal Testing Machine (USA, IL, Glenview) with a 1 kN load cell. The standard used was ASTM D638 type IV specimen [31]. The crosshead speed was set at 5 mm/min and room temperature. Reported values for the modulus, strength, and elongation at break were based on the average of at least five samples. Bending tests were carried out according to the ASTM D790 standard, which uses three points, two support and one on the top [32], for which the plates obtained after thermo-compression were taken and cut into rectangular specimens according to the standard and placed in the Instron Model 4411 Universal Testing Equipment, where they were vertically deformed at a constant temperature and constant speed with a minimum of 5 repetitions per trial.

3. Results and Discussion

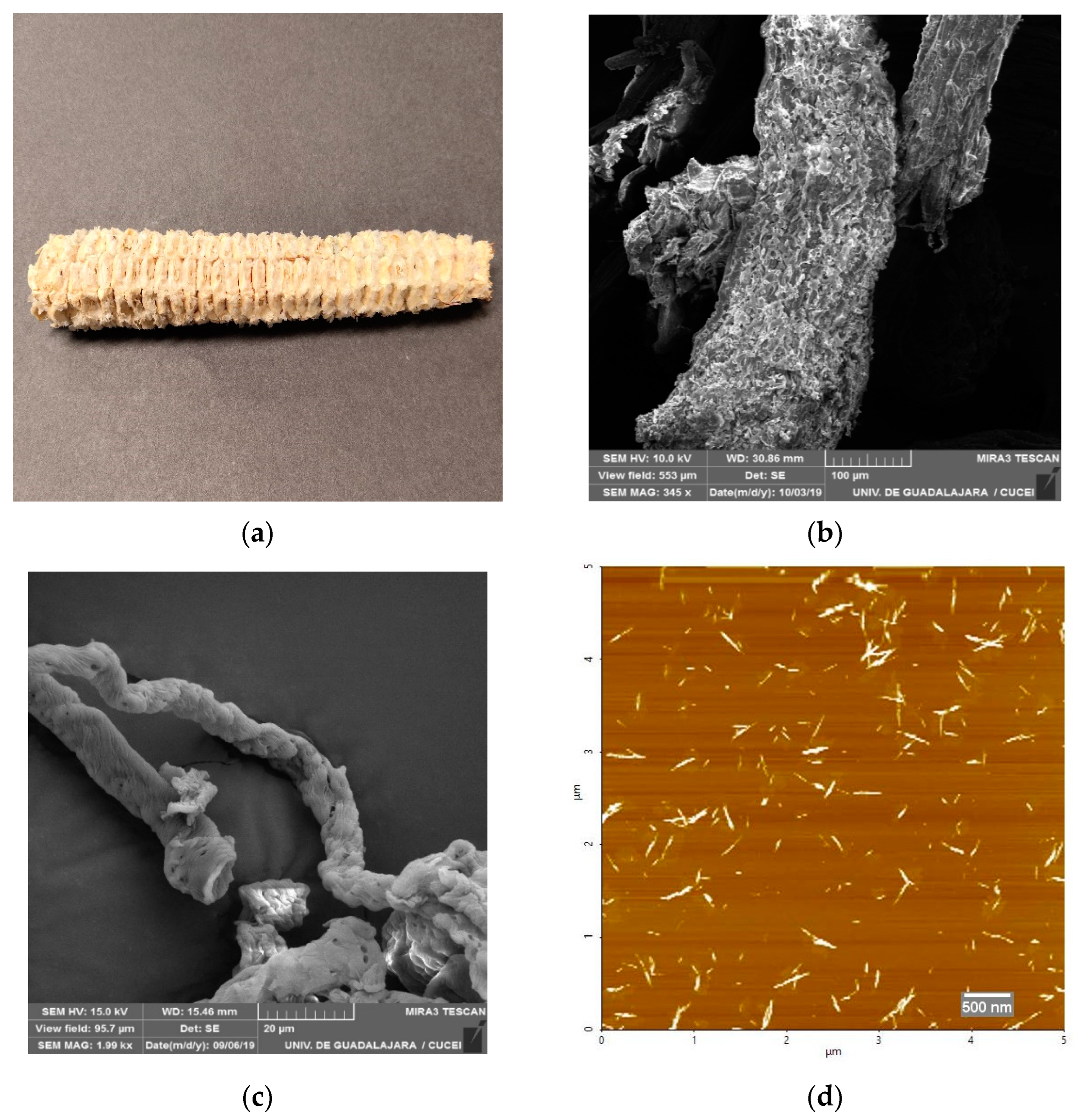

3.1. Morphology of Corncob Fibers from Macro to Nano

3.2. Infra-Red Spectroscopy with Fourier Transform (FT-IR)

3.3. Thermal Stability Analysis (TGA)

3.4. Analysis of Thermal Transitions (DSC)

3.5. Tensile Tests

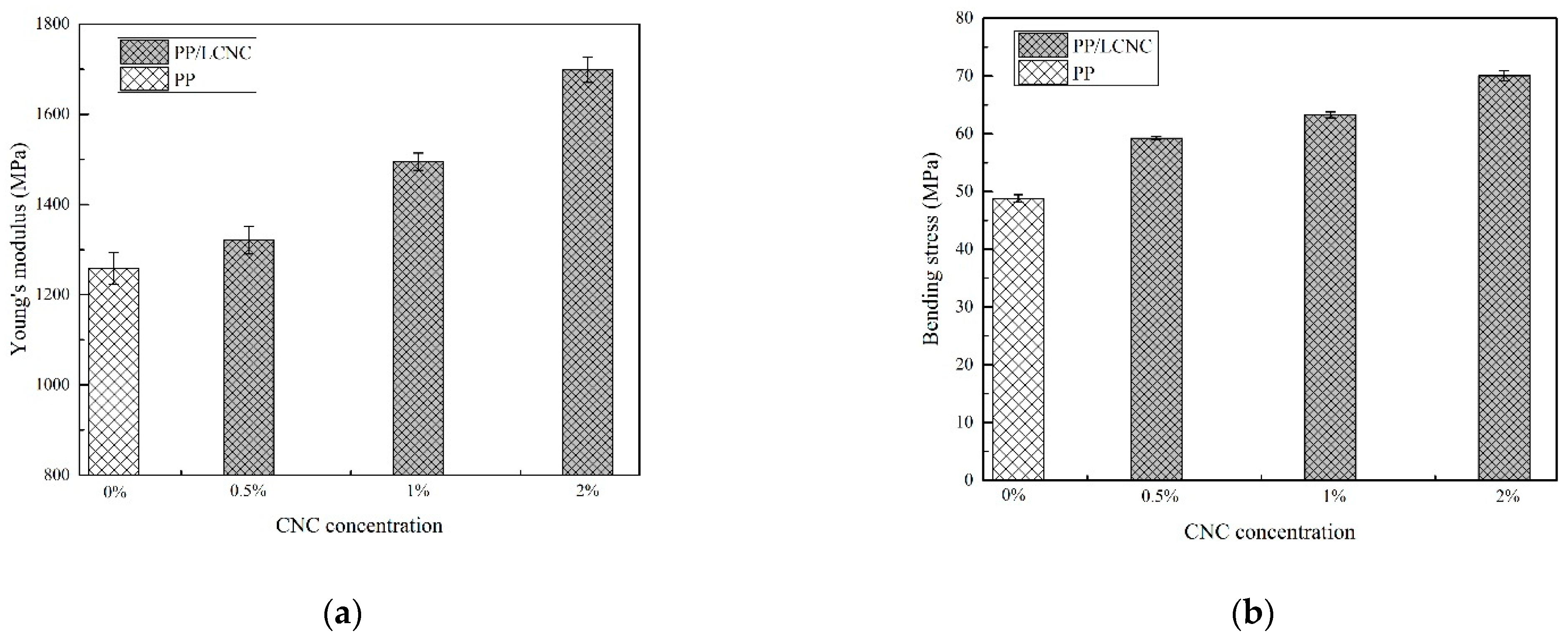

3.6. Bending Tests

4. Conclusions

- The presence of residual lignin in the unbleached cellulose of corncob generates functionalization on the surface of the LCNCs, one by residual lignin and the other by the ester groups of the sulfate ions (-OSO3-) introduced after hydrolysis with sulfuric acid due to the esterification between the surface hydroxyls of unbleached cellulose and sulfuric acid.

- This functionalization by residual lignin and the ester groups improved the interaction between LCNCs and polypropylene, improving the thermal and mechanical properties in the composite material.

- In general, all concentrations of LCNC in composite material showed to be thermally stable for processing, but it is noteworthy that the melting enthalpies was increased by adding 2% of LCNC compared to pure PP.

- Based on the results obtained from the mechanical tests, it was possible to demonstrate that the composite is resistant to traction and bending compared to pure recycled PP. Young’s modulus and bending strengths increase as the percentage of LCNC increases, and the tensile strength acts similarly to Young’s modulus.

- The interaction between LCNC and PP is good, and there is an accommodation of the filler in the polymer matrix, which implies better mechanical properties.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tian, H.; Wu, L.; Qin, H.; Li, X.; Zhao, X.; Zhao, W.; Xue, F.; Zhao, S.; Li, L.; Zeng, W. Composite materials combined with stem cells promote kidney repair and regeneration. Compos. Part B Eng. 2024, 275, 111278. [Google Scholar] [CrossRef]

- Yadav, R.; Singh, M.; Shekhawat, D.; Lee, S.-Y.; Park, S.-J. The role of fillers to enhance the mechanical, thermal, and wear characteristics of polymer composite materials: A review. Compos. Part A Appl. Sci. Manuf. 2023, 175, 107775. [Google Scholar] [CrossRef]

- Nahar, S.; Khan, R.A.; Dey, K.; Sarker, B.; Das, A.K.; Ghoshal, S. Comparative studies of mechanical and interfacial properties between jute and bamboo fiber-reinforced polypropylene-based composites. J. Thermoplast. Compos. Mater. 2012, 25, 15–32. [Google Scholar] [CrossRef]

- Varshney, D.; Debnath, K.; Singh, I. Mechanical characterization of polypropylene (PP) and polyethylene (PE) based natural fiber reinforced composites. Int. J. Surf. Eng. Mater. Technol. 2014, 4, 16–23. [Google Scholar]

- Mohammadi, M.; Taban, E.; Tan, W.H.; Che Din, N.B.; Putra, A.; Berardi, U. Recent progress in natural fiber reinforced composite as sound absorber material. J. Build. Eng. 2024, 84, 108514. [Google Scholar] [CrossRef]

- Zhiltsova, T.; Campos, J.; Costa, A.; Oliveira, M.S.A. Sustainable Polypropylene-Based Composites with Agro-Waste Fillers: Thermal, Morphological, Mechanical Properties and Dimensional Stability. Materials 2024, 17, 696. [Google Scholar] [CrossRef]

- Song, D.; Wang, B.; Tao, W.; Wang, X.; Zhang, W.; Dai, M.; Li, J.; Zhou, Z. Synergistic reinforcement mechanism of basalt fiber/cellulose nanocrystals/polypropylene composites. Nanotechnol. Rev. 2022, 11, 3020–3030. [Google Scholar] [CrossRef]

- Wang, X.; Wang, P.; Liu, S.; Crouse, J.; Gardner, D.J.; Via, B.; Gallagher, T.; Elder, T.; Peng, Y. Material properties of spray-dried cellulose nanocrystal reinforced homopolymer polypropylene composites. Polym. Compos. 2023. [Google Scholar] [CrossRef]

- Teruel, R.; Alcalá, N.; Crespo, C.; Laspalas, M. Machine learning model and input batch management tool for the composition of new recycled polypropylene plastic material with reduced variability in target properties. J. Clean. Prod. 2024, 435, 140390. [Google Scholar] [CrossRef]

- Prado, K.S.; Strangl, M.; Pereira, S.R.; Tiboni, A.R.; Ortner, E.; Spinacé, M.A.S.; Buettner, A. Odor characterization of post-consumer and recycled automotive polypropylene by different sensory evaluation methods and instrumental analysis. Waste Manag. 2020, 115, 36–46. [Google Scholar] [CrossRef]

- Khoshkava, V.; Kamal, M.R. Effect of cellulose nanocrystals (CNC) particle morphology on dispersion and rheological and mechanical properties of polypropylene/CNC nanocomposites. ACS Appl. Mater. Interfaces 2014, 6, 8146–8157. [Google Scholar] [CrossRef]

- Bagheriasl, D.; Carreau, P.J.; Dubois, C.; Riedl, B. Effect of cellulose nanocrystals (CNCs) on crystallinity, mechanical and rheological properties of polypropylene/CNCs nanocomposites. AIP Conf. Proc. 2015, 1664, 070010. [Google Scholar] [CrossRef]

- Sojoudiasli, H.; Heuzey, M.-C.; Carreau, P.J. Mechanical and morphological properties of cellulose nanocrystal-polypropylene composites. Polym. Compos. 2018, 39, 3605–3617. [Google Scholar] [CrossRef]

- Agarwal, J.; Mohanty, S.; Nayak, S.K. Valorization of pineapple peel waste and sisal fiber: Study of cellulose nanocrystals on polypropylene nanocomposites. J. Appl. Polym. Sci. 2020, 137, 49291. [Google Scholar] [CrossRef]

- Gwon, J.-G.; Cho, H.-J.; Lee, D.; Choi, D.-H.; Lee, S.; Wu, Q.; Lee, S.-Y. Physicochemical and mechanical properties of polypropylene-cellulose nanocrystal nanocomposites: Effects of manufacturing process and chemical grafting. BioResources 2018, 13, 1619–1636. [Google Scholar] [CrossRef]

- Huang, J.; Xu, C.; Wu, D.; Lv, Q. Transcrystallization of polypropylene in the presence of polyester/cellulose nanocrystal composite fibers. Carbohydr. Polym. 2017, 167, 105–114. [Google Scholar] [CrossRef] [PubMed]

- Bagheriasl, D.; Carreau, P.J.; Dubois, C.; Riedl, B. Properties of polypropylene and polypropylene/poly(ethylene-co-vinyl alcohol) blend/CNC nanocomposites. Compos. Sci. Technol. 2015, 117, 357–363. [Google Scholar] [CrossRef]

- Ghabezi, P.; Farahani, M.; Hosseini Fakhr, M. Experimental investigation of nano-alumina effect on the filling time in VARTM process. J. Fundam. Appl. Sci. 2016, 8, 925. [Google Scholar] [CrossRef]

- Ghabezi, P.; Farahani, M.; Hosseini Fakhr, M.; Abroshan, H. Investigation of Mechanical Behavior of Alfa and Gamma Nano- Alumina/Epoxy Composite Made By Vartm. Int. J. Adv. Biotechnol. Res. 2016, 7, 731–736. [Google Scholar]

- Görbe, Á.; Varga, L.J.; Bárány, T. Development of nanoparticle-filled polypropylene-based single polymer composite foams. Heliyon 2023, 9, e19638. [Google Scholar] [CrossRef]

- Shojaeiarani, J.; Bajwa, D.S.; Chanda, S. Cellulose nanocrystal based composites: A review. Compos. Part C Open Access 2021, 5, 100164. [Google Scholar] [CrossRef]

- Trache, D.; Thakur, V.K.; Boukherroub, R. Cellulose Nanocrystals/Graphene Hybrids—A Promising New Class of Materials for Advanced Applications. Nanomaterials 2020, 10, 1523. [Google Scholar] [CrossRef]

- Sabaruddin, F.A.; Paridah, M.T.; Sapuan, S.M.; Ilyas, R.A.; Lee, S.H.; Abdan, K.; Mazlan, N.; Roseley, A.S.; Abdul Khalil, H.P.S. The Effects of Unbleached and Bleached Nanocellulose on the Thermal and Flammability of Polypropylene-Reinforced Kenaf Core Hybrid Polymer Bionanocomposites. Polymers 2020, 13, 116. [Google Scholar] [CrossRef] [PubMed]

- Santos Ventura, E.M.; Alfredo, E.Á.M.; Gutiérrez Becerra, A.; Sulbarán-Rangel, B. Unbleached cellulose from waste corncob for isolation of cellulose nanocrystals. Emerg. Mater. Res. 2020, 9, 1258–1265. [Google Scholar] [CrossRef]

- Peng, Y.; Nair, S.S.; Chen, H.; Yan, N.; Cao, J. Effects of Lignin Content on Mechanical and Thermal Properties of Polypropylene Composites Reinforced with Micro Particles of Spray Dried Cellulose Nanofibrils. ACS Sustain. Chem. Eng. 2018, 6, 11078–11086. [Google Scholar] [CrossRef]

- ISO 1133; Plastics—Determination of Melt Flow Rate (MFR) and Melt Volume Flow Rate (MVR) of Thermoplastics. ISO: Geneva, Switzerland, 2012.

- ISO 1183; Plastics—Methods for Determining the Density of Non-Cellular Plastics—Part 1: Immersion Method, Liquid Pycnometer Method and Titration Method. ISO: Geneva, Switzerland, 2019.

- Gutiérrez-Hernández, J.M.; Escalante, A.; Murillo-Vázquez, R.N.; Delgado, E.; González, F.J.; Toríz, G. Use of Agave tequilana-lignin and zinc oxide nanoparticles for skin photoprotection. J. Photochem. Photobiol. B Biol. 2016, 163, 156–161. [Google Scholar] [CrossRef]

- Hernández, J.A.; Romero, V.H.; Escalante, A.; Toríz, G.; Rojas, O.J.; Sulbarán, B.C. Agave tequilana bagasse as source of cellulose nanocrystals via organosolv treatment. BioResources 2018, 13, 3603–3614. [Google Scholar] [CrossRef]

- Cranston, E.D.; Gray, D.G. Formation of cellulose-based electrostatic layer-by-layer films in a magnetic field. Sci. Technol. Adv. Mater. 2006, 7, 319. [Google Scholar] [CrossRef]

- ASTM D638-22; Standard Test Method for Tensile Properties of Plastics. ASTM: West Conshohocken, PA, USA, 2022.

- ASTM D790-17; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM: West Conshohocken, PA, USA, 2017.

- Lin, N.; Dufresne, A. Surface chemistry, morphological analysis and properties of cellulose nanocrystals with gradiented sulfation degrees. Nanoscale 2014, 6, 5384–5393. [Google Scholar] [CrossRef] [PubMed]

- Bilatto, S.; Marconcini, J.M.; Mattoso, L.H.C.; Farinas, C.S. Lignocellulose nanocrystals from sugarcane straw. Ind. Crops Prod. 2020, 157, 112938. [Google Scholar] [CrossRef]

- Liang, F.; Song, Y.; Huang, C.; Zhang, J.; Chen, B. Preparation and performance evaluation of a lignin-based solid acid from acid hydrolysis lignin. Catal. Commun. 2013, 40, 93–97. [Google Scholar] [CrossRef]

- Yang, H.; Yan, R.; Chen, H.; Lee, D.H.; Zheng, C. Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 2007, 86, 1781–1788. [Google Scholar] [CrossRef]

- Tsioptsias, C.; Leontiadis, K.; Tzimpilis, E.; Tsivintzelis, I. Polypropylene nanocomposite fibers: A review of current trends and new developments. J. Plast. Film Sheeting 2021, 37, 283–311. [Google Scholar] [CrossRef]

- Monti, M.; Scrivani, M.T.; Gianotti, V. Effect of SEBS and OBC on the Impact Strength of Recycled Polypropylene/Talc Composites. Recycling 2020, 5, 9. [Google Scholar] [CrossRef]

- Majewsky, M.; Bitter, H.; Eiche, E.; Horn, H. Determination of microplastic polyethylene (PE) and polypropylene (PP) in environmental samples using thermal analysis (TGA-DSC). Sci. Total Environ. 2016, 568, 507–511. [Google Scholar] [CrossRef] [PubMed]

- Gray, N.; Hamzeh, Y.; Kaboorani, A.; Abdulkhani, A. Influence of cellulose nanocrystal on strength and properties of low density polyethylene and thermoplastic starch composites. Ind. Crops Prod. 2018, 115, 298–305. [Google Scholar] [CrossRef]

- Habibi, Y.; Lucia, L.A.; Rojas, O.J. Cellulose nanocrystals: Chemistry, self-assembly, and applications. Chem. Rev. 2010, 110, 3479–3500. [Google Scholar] [CrossRef]

| Composite PP/LCNC’s | % Polypropylene | % LCNC |

|---|---|---|

| PP | 100 | 0 |

| PP/0.5%LCNC | 99.5 | 0.5 |

| PP/1%LCNC | 99 | 1 |

| PP/2%LCNC | 98 | 2 |

| Composite | Initial Degradation Temperature (°C) | Final Degradation Temperature (°C) | Degradation Temperature with 50% Mass Loss (°C) | % Residual Mass at 600 °C | DTG T Max (°C) |

|---|---|---|---|---|---|

| PP | 406 | 497 | 473 | 10.81 | 483 |

| PP/0.5%LCNC | 443 | 500 | 482 | 11.53 | 488 |

| PP/1%LCNC | 438 | 502 | 483 | 11.58 | 490 |

| PP/2%LCNC | 424 | 500 | 475 | 11.92 | 486 |

| Composite | Enthalpy ΔHf (J/g) | Crystallinity (%) | First Endothermic Peak (°C) | Second Endothermic Peak (°C) |

|---|---|---|---|---|

| PP | 64.786 | 53.03 | 126.834 | 163.645 |

| PP/0.5%LCNC | 60.419 | 49.47 | 127.520 | 164.966 |

| PP/1%LCNC | 68.358 | 55.97 | 126.833 | 162.297 |

| PP/2%LCNC | 61.934 | 50.71 | 126.861 | 164.939 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Santos-Ventura, E.M.; Escalante-Álvarez, M.A.; González-Nuñez, R.; Esquivel-Alfaro, M.; Sulbarán-Rangel, B. Polypropylene Composites Reinforced with Lignocellulose Nanocrystals of Corncob: Thermal and Mechanical Properties. J. Compos. Sci. 2024, 8, 125. https://doi.org/10.3390/jcs8040125

Santos-Ventura EM, Escalante-Álvarez MA, González-Nuñez R, Esquivel-Alfaro M, Sulbarán-Rangel B. Polypropylene Composites Reinforced with Lignocellulose Nanocrystals of Corncob: Thermal and Mechanical Properties. Journal of Composites Science. 2024; 8(4):125. https://doi.org/10.3390/jcs8040125

Chicago/Turabian StyleSantos-Ventura, Edgar Mauricio, Marcos Alfredo Escalante-Álvarez, Rubén González-Nuñez, Marianelly Esquivel-Alfaro, and Belkis Sulbarán-Rangel. 2024. "Polypropylene Composites Reinforced with Lignocellulose Nanocrystals of Corncob: Thermal and Mechanical Properties" Journal of Composites Science 8, no. 4: 125. https://doi.org/10.3390/jcs8040125

APA StyleSantos-Ventura, E. M., Escalante-Álvarez, M. A., González-Nuñez, R., Esquivel-Alfaro, M., & Sulbarán-Rangel, B. (2024). Polypropylene Composites Reinforced with Lignocellulose Nanocrystals of Corncob: Thermal and Mechanical Properties. Journal of Composites Science, 8(4), 125. https://doi.org/10.3390/jcs8040125