Bolt-Hole Elongation of Woven Carbon-Epoxy Composite Plates and Joints Using the Digital Image Correlation Technique

Abstract

1. Introduction

2. Materials and Methods

Experimental Procedure

3. Results and Discussion

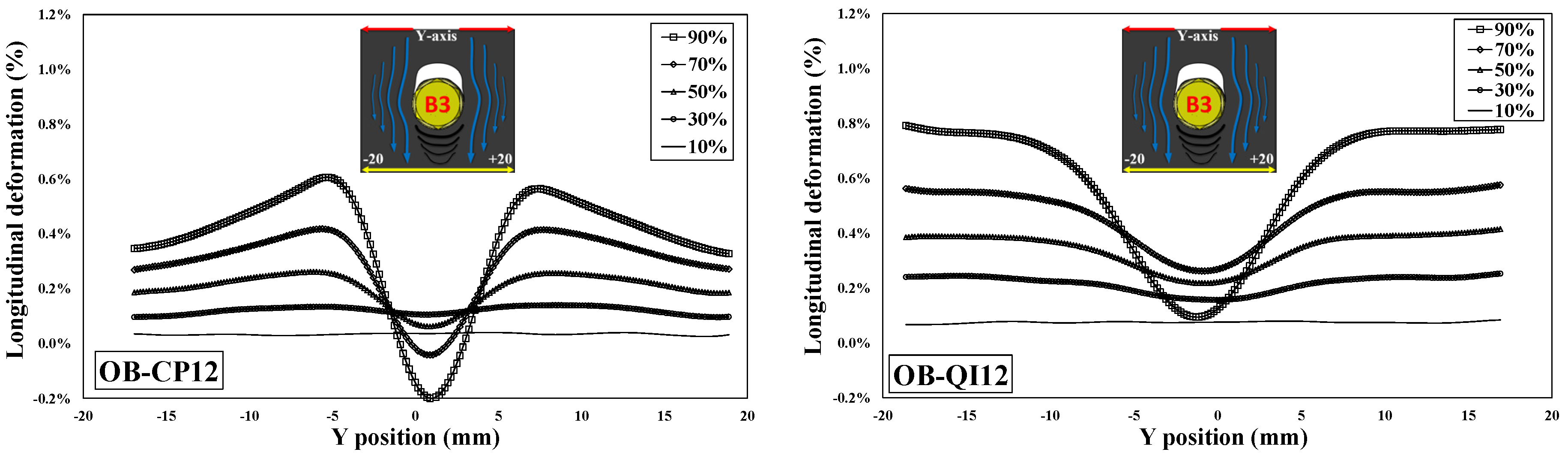

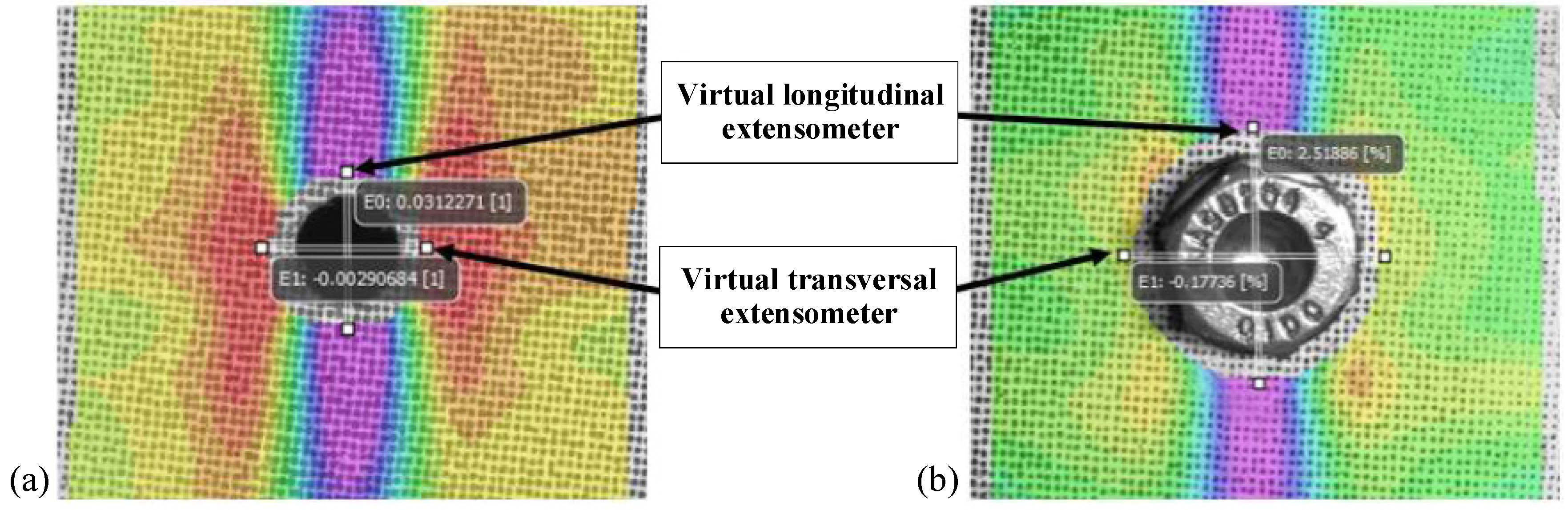

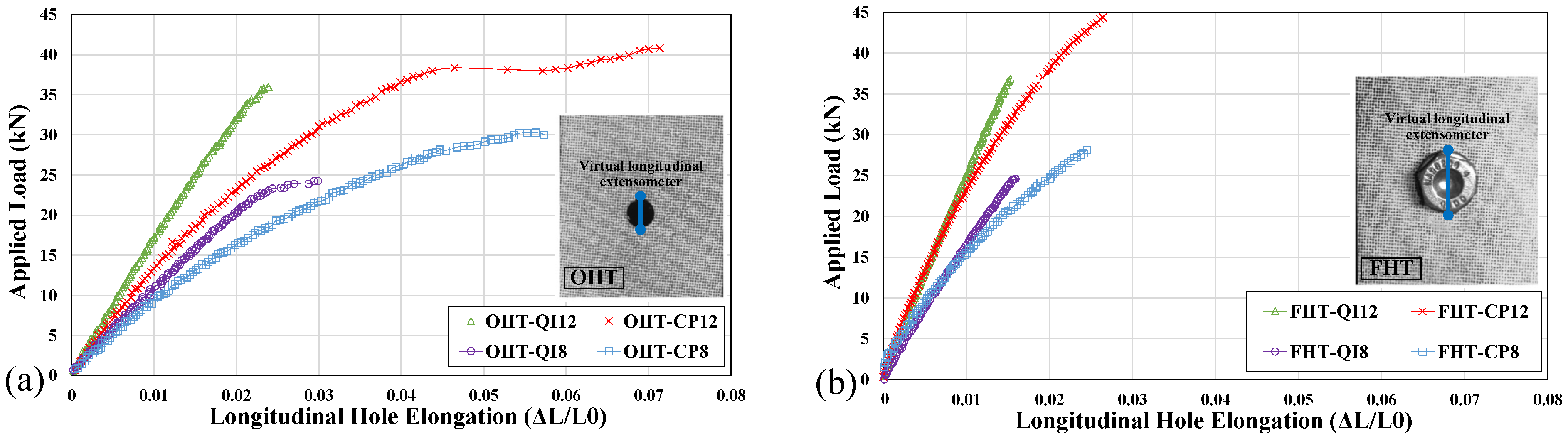

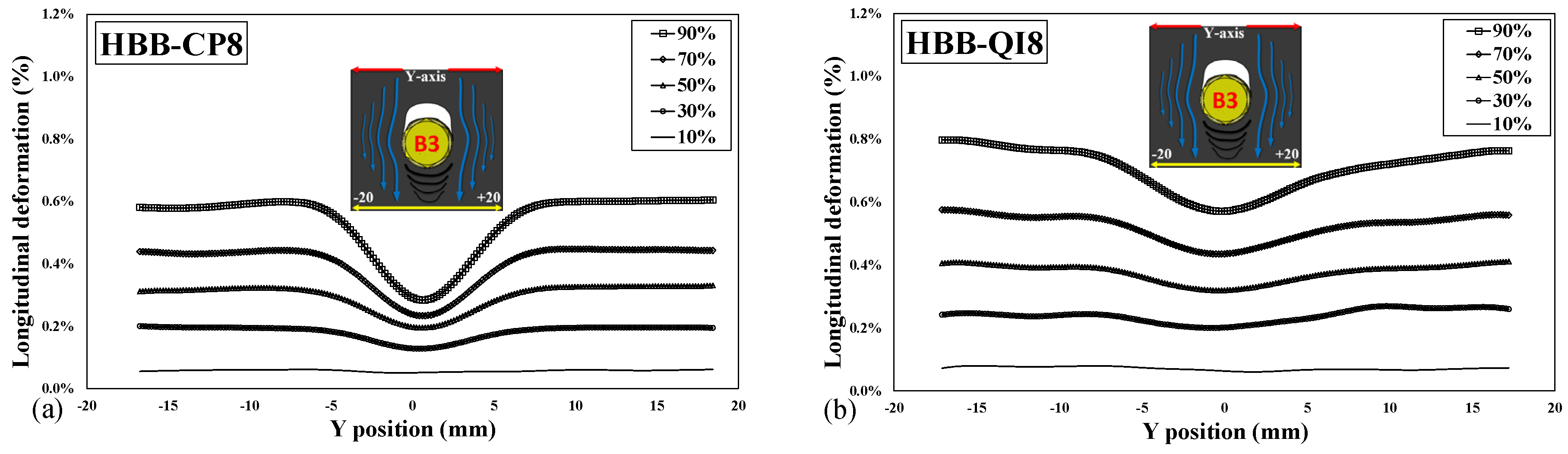

3.1. Hole Deformation

- The clamped bolt upholds the geometric integrity of the hole because FHT laminates have a lower THC than OHT laminates.

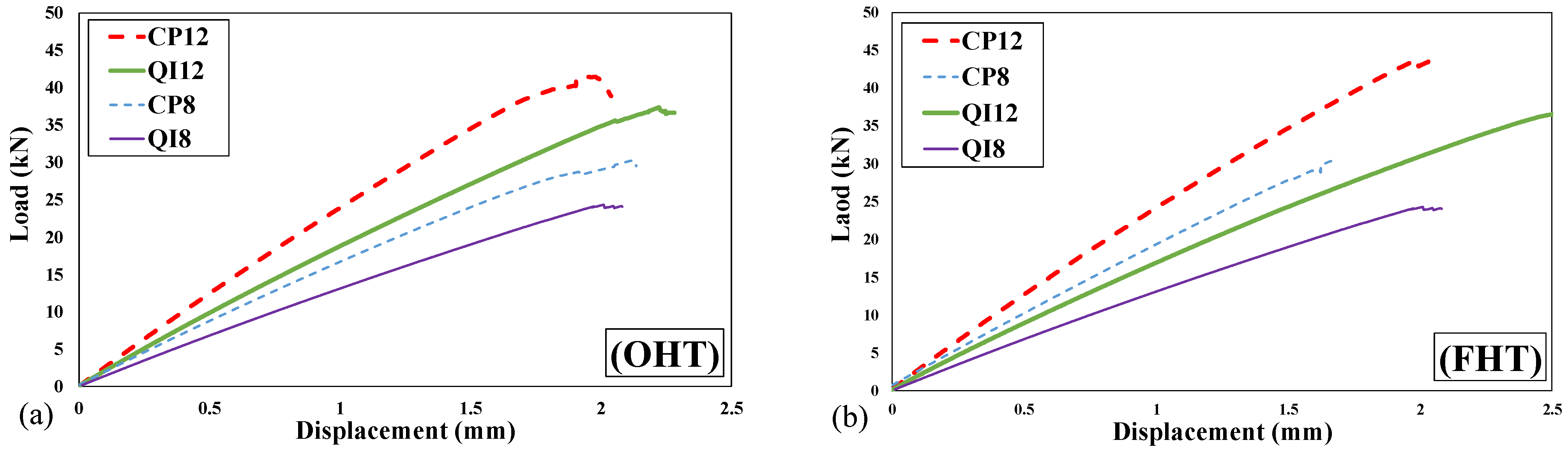

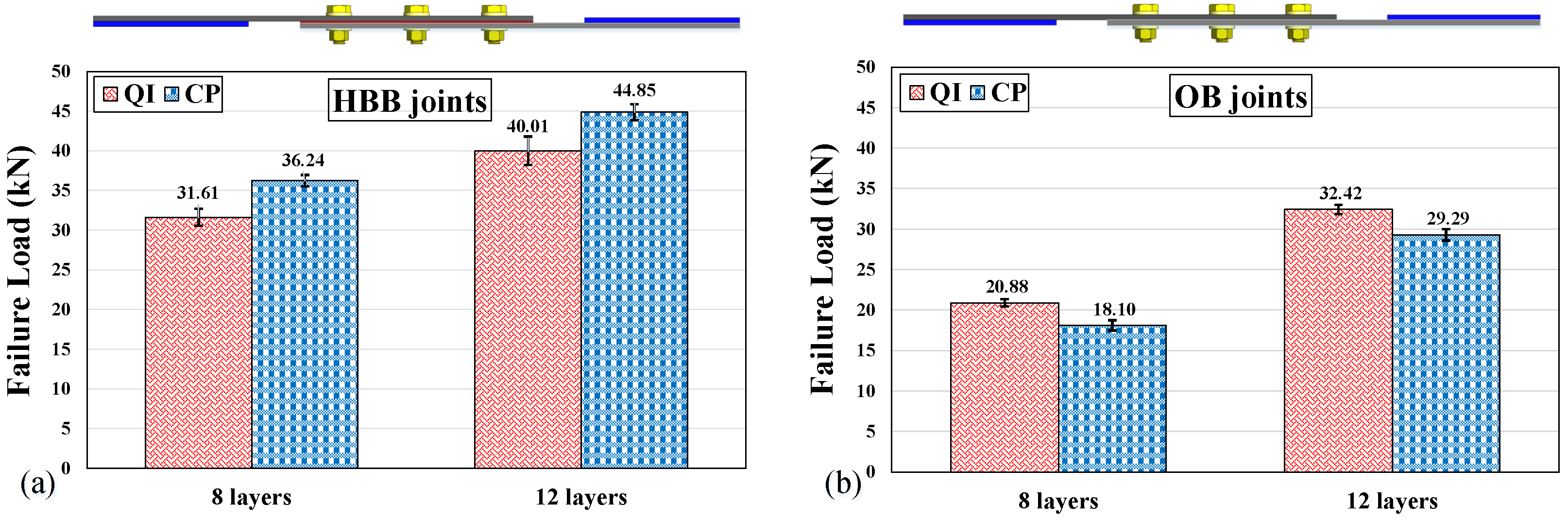

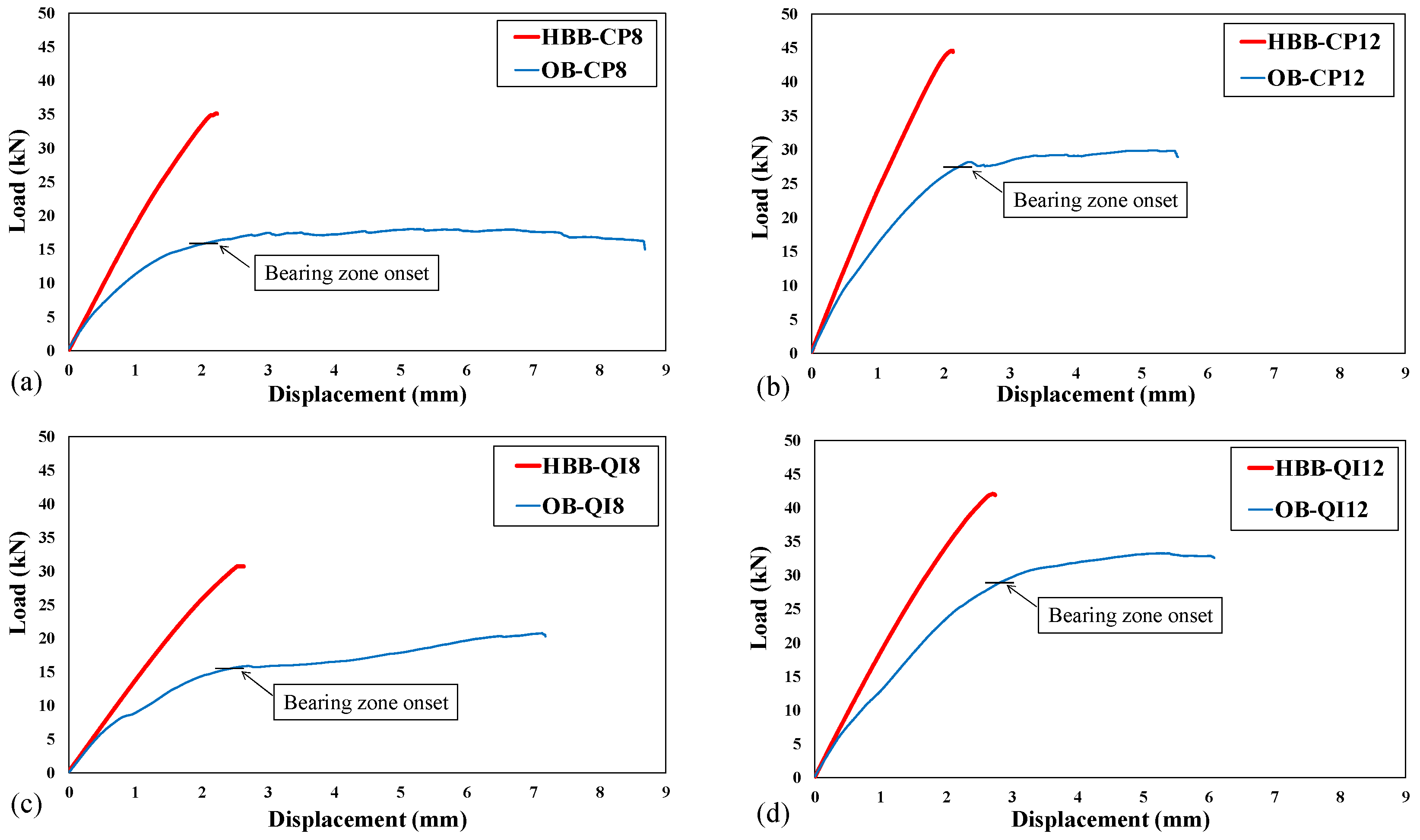

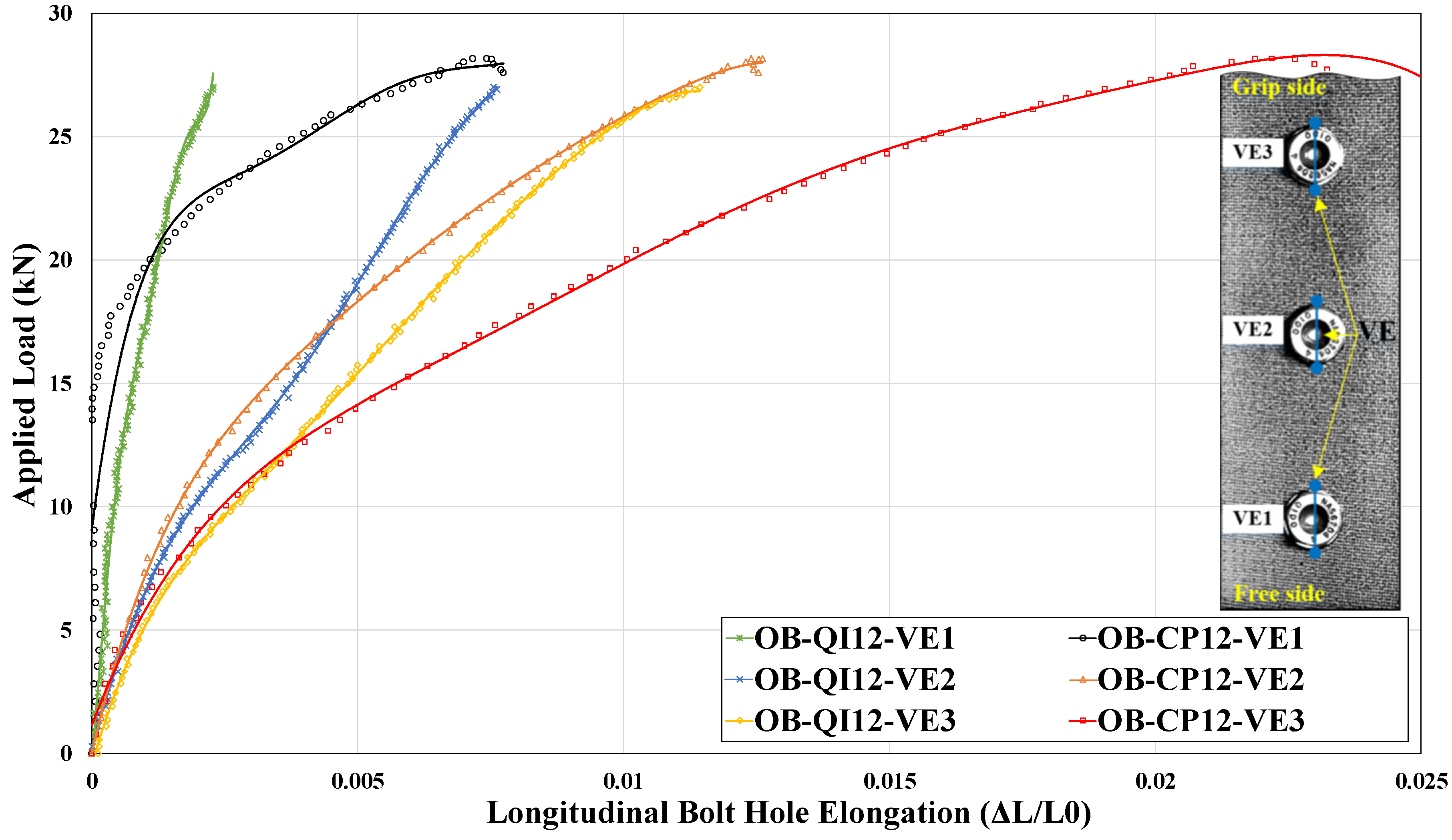

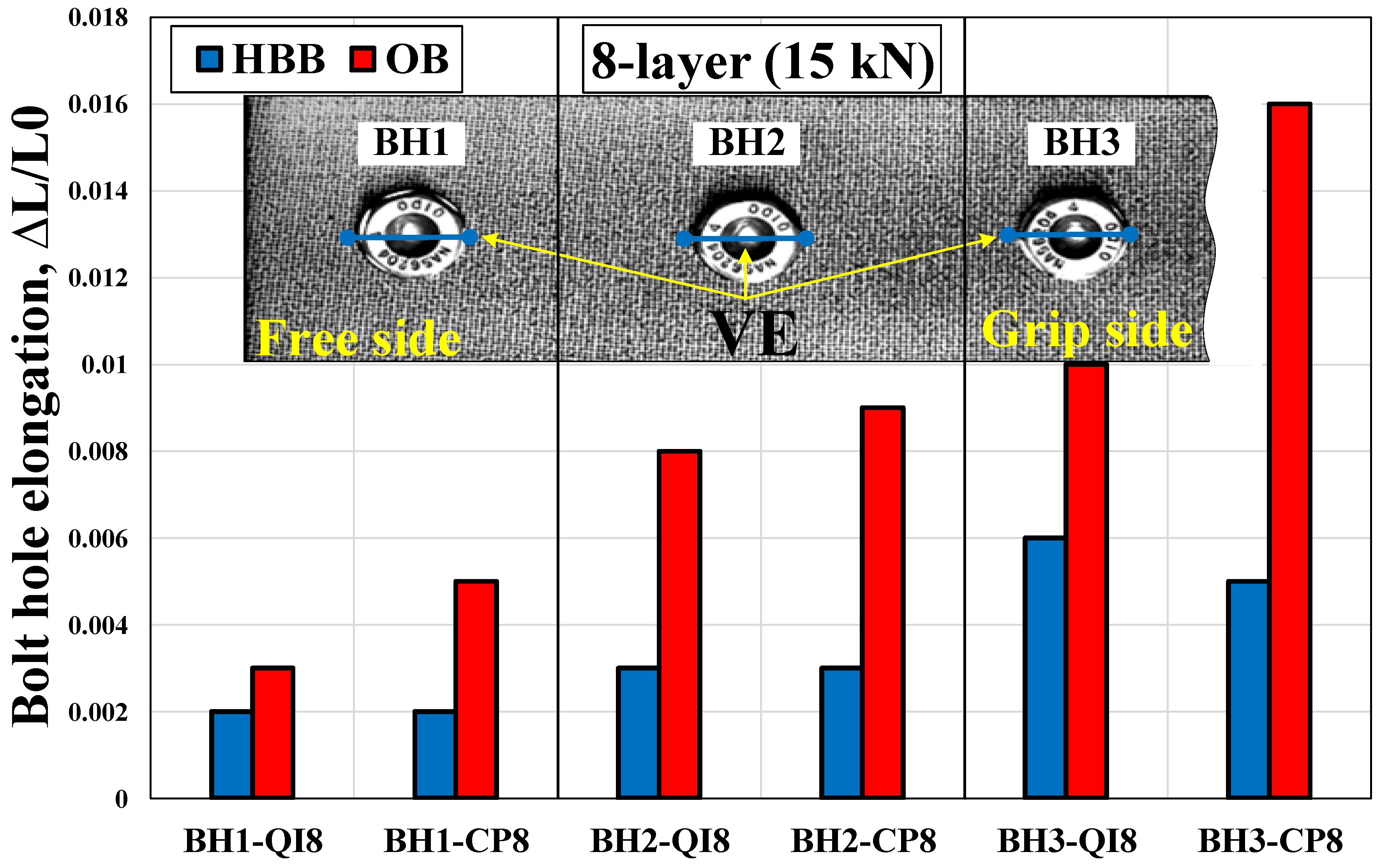

3.2. Bolt-Hole Elongation (BHE) in Joints

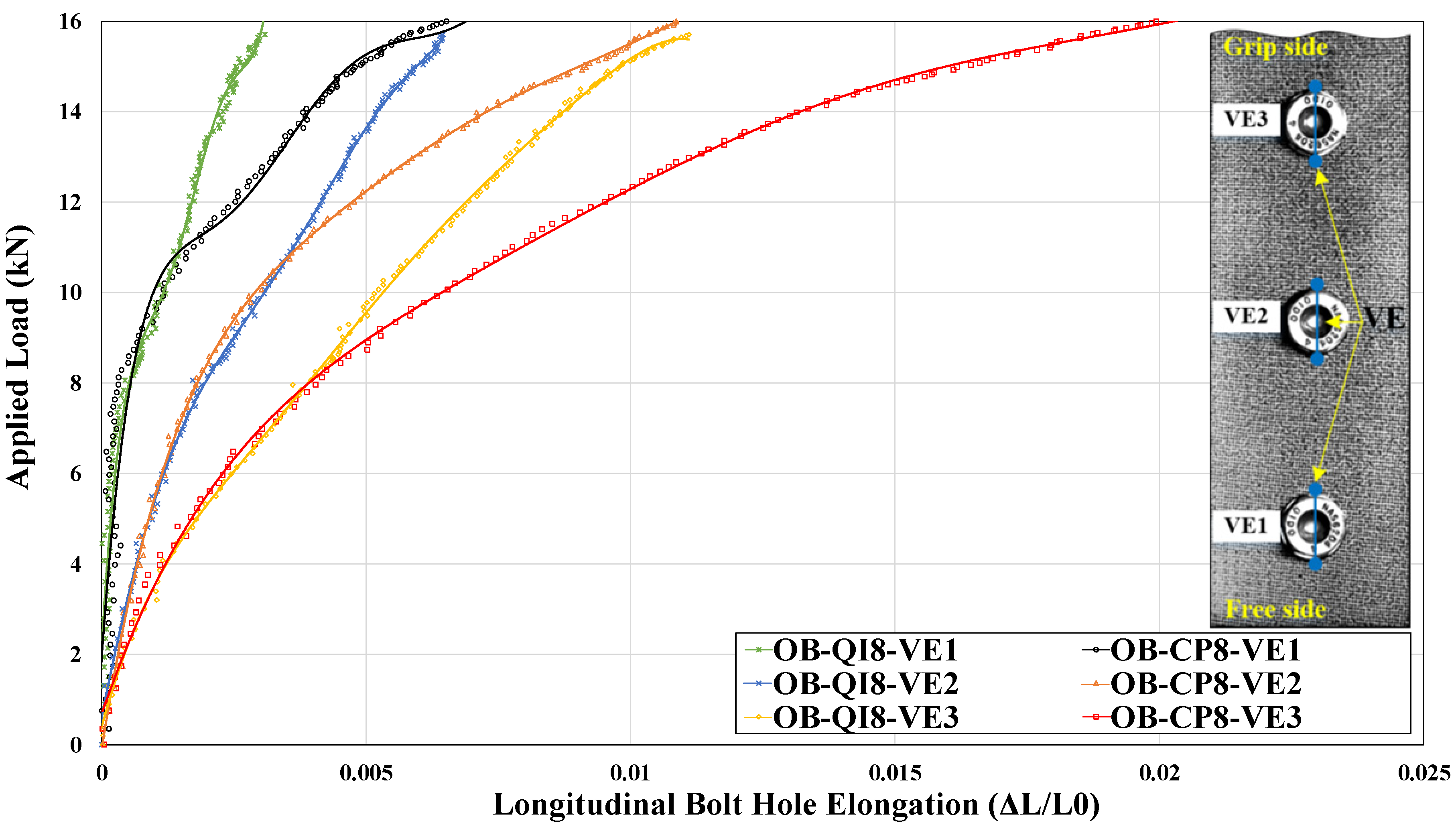

3.2.1. BHE of Only-Bolted (OB) Joints

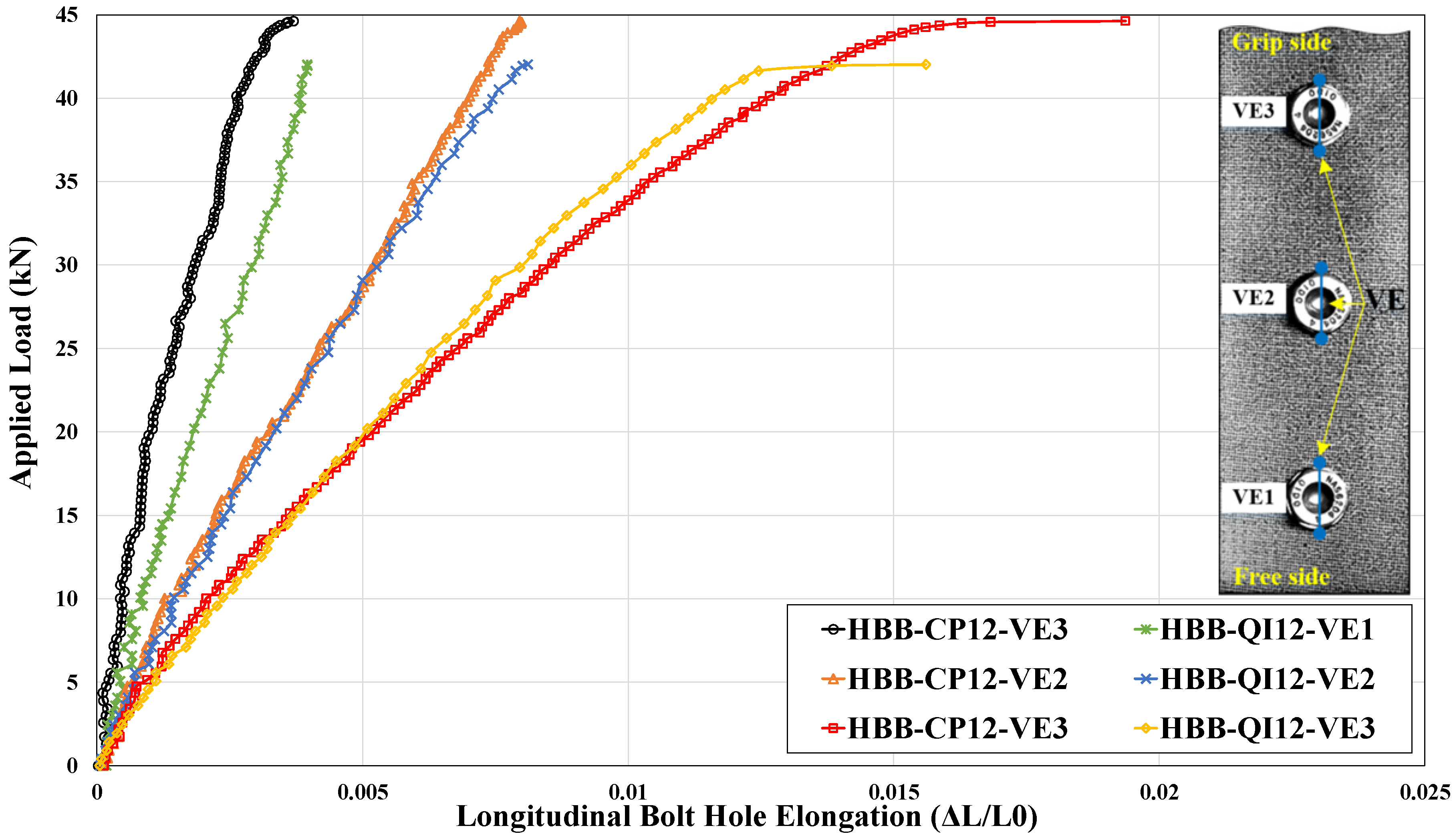

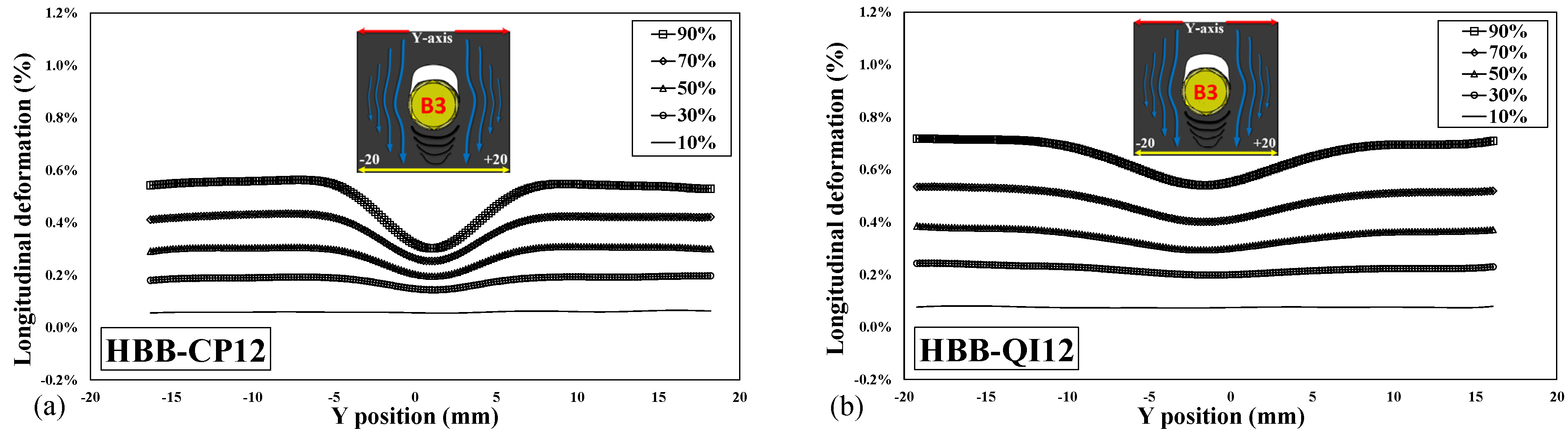

3.2.2. BHE of Hybrid-Bolted-Bonded (HBB) Joints

3.2.3. BHE in OB versus HBB: CP and QI

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Caldwell, S.P.; Radford, D.W. Composite Single Lap Shear Joint Integrity Monitoring via Embedded Electromechanical Impedance Sensors. J. Compos. Sci. 2023, 7, 53. [Google Scholar] [CrossRef]

- Joy Mathavan, J.; Hassan, M.H.; Xu, J.; Franz, G. Hole Quality Observation in Single-Shot Drilling of CFRP/Al7075-T6 Composite Metal Stacks Using Customized Twist Drill Design. J. Compos. Sci. 2022, 6, 378. [Google Scholar] [CrossRef]

- Mehrabian, M.; Boukhili, R. 3D-DIC strain field measurements in bolted and hybrid bolted-bonded joints of woven carbon-epoxy composites. Compos. Part B Eng. 2021, 218, 108875. [Google Scholar] [CrossRef]

- Vangrimde, B.; Boukhili, R. Analysis of the bearing response test for polymer matrix composite laminates: Bearing stiffness measurement and simulation. Compos. Struct. 2002, 56, 359–374. [Google Scholar] [CrossRef]

- Sawicki, A.J.; Minguet, P.J. Failure mechanisms in compression-loaded composite laminates containing open and filled holes. J. Reinf. Plast. Compos. 1999, 18, 1708–1728. [Google Scholar] [CrossRef]

- Sola, C.; Castanié, B.; Michel, L.; Lachaud, F.; Delabie, A.; Mermoz, E. Bearing fatigue of composite laminates: Damage monitoring and fatigue life prediction. Compos. Part B Eng. 2017, 110, 487–496. [Google Scholar] [CrossRef]

- Saleh, M.N.; Wang, Y.; Yudhanto, A.; Joesbury, A.; Potluri, P.; Lubineau, G.; Soutis, C. Investigating the potential of using off-Axis 3D woven composites in composite joints’ applications. Appl. Compos. Mater. 2017, 24, 377–396. [Google Scholar] [CrossRef]

- Hu, J.; Zhang, K.; Cheng, H.; Liu, P.; Zou, P.; Song, D. Stress analysis and damage evolution in individual plies of notched composite laminates subjected to in-plane loads. Chin. J. Aeronaut. 2017, 30, 447–460. [Google Scholar] [CrossRef]

- Chen, H.-S. The static and fatigue strength of bolted joints in composites with hygrothermal cycling. Compos. Struct. 2001, 52, 295–306. [Google Scholar] [CrossRef]

- Starikov, R.; Schön, J. Fatigue resistance of composite joints with countersunk composite and metal fasteners. Int. J. Fatigue 2002, 24, 39–47. [Google Scholar] [CrossRef]

- Starikov, R.; Schön, J. Quasi-static behaviour of composite joints with protruding-head bolts. Compos. Struct. 2001, 51, 411–425. [Google Scholar] [CrossRef]

- Girard, C.; Dano, M.-L.; Picard, A.; Gendron, G. Bearing behavior of mechanically fastened joints in composite laminates—Part I: Strength and local strains. Mech. Adv. Mater. Struct. 2003, 10, 1–21. [Google Scholar] [CrossRef]

- Lawlor, V.P.; Mccarthy, M.A.; Stanley, W. An experimental study of bolt–hole clearance effects in double-lap, multi-bolt composite joints. Compos. Struct. 2005, 71, 176–190. [Google Scholar] [CrossRef]

- Subramanian, C.; Senthilvelan, S. Effect of reinforced fiber length on the joint performance of thermoplastic leaf spring. Mater. Des. 2010, 31, 3733–3741. [Google Scholar] [CrossRef]

- Wei, J.; Jiao, G.; Jia, P.; Huang, T. The effect of interference fit size on the fatigue life of bolted joints in composite laminates. Compos. Part B Eng. 2013, 53, 62–68. [Google Scholar] [CrossRef]

- Li, J.; Zhang, K.; Li, Y.; Liu, P.; Xia, J. Influence of interference-fit size on bearing fatigue response of single-lap carbon fiber reinforced polymer/Ti alloy bolted joints. Tribol. Int. 2016, 93, 151–162. [Google Scholar] [CrossRef]

- Nezhad, H.Y.; Egan, B.; Merwick, F.; McCarthy, C.T. Bearing damage characteristics of fibre-reinforced countersunk composite bolted joints subjected to quasi-static shear loading. Compos. Struct. 2017, 166, 184–192. [Google Scholar] [CrossRef]

- Giannopoulos, I.K.; Doroni-Dawes, D.; Kourousis, K.I.; Yasaee, M. Effects of bolt torque tightening on the strength and fatigue life of airframe FRP laminate bolted joints. Compos. Part B Eng. 2017, 125, 19–26. [Google Scholar] [CrossRef]

- Liu, F.; Lu, X.; Zhao, L.; Zhang, J.; Hu, N.; Xu, J. An interpretation of the load distributions in highly torqued single-lap composite bolted joints with bolt-hole clearances. Compos. Part B Eng. 2018, 138, 194–205. [Google Scholar] [CrossRef]

- Zhang, K.; Li, H.; Cheng, H.; Luo, B.; Liu, P. Combined effects of seawater ageing and fatigue loading on the bearing performance and failure mechanism of CFRP/CFRP single-lap bolted joints. Compos. Struct. 2020, 234, 111677. [Google Scholar] [CrossRef]

- Sajid, Z.; Karuppanan, S.; Sallih, N.; Kee, K.; Shah, S. Role of washer size in mitigating adverse effects of bolt-hole clearance in a single-lap, single-bolt basalt composite joint. Compos. Struct. 2021, 266, 113802. [Google Scholar] [CrossRef]

- Torres-Arellano, M.; Bolom-Martínez, M.d.J.; Franco-Urquiza, E.A.; Pérez-Mora, R.; Jiménez-Arévalo, O.A.; Olivier, P. Bearing Strength and Failure Mechanisms of Riveted Woven Carbon Composite Joints. Aerospace 2021, 8, 105. [Google Scholar] [CrossRef]

- Cao, Y.; Zuo, D.; Zhao, Y.; Cao, Z.; Zhi, J.; Zheng, G.; Tay, T.E. Experimental investigation on bearing behavior and failure mechanism of double-lap thin-ply composite bolted joints. Compos. Struct. 2021, 261, 113565. [Google Scholar] [CrossRef]

- Gamdani, F.; Boukhili, R.; Vadean, A. Tensile behavior of hybrid multi-bolted/bonded joints in composite laminates. Int. J. Adhes. Adhes. 2019, 95, 102426. [Google Scholar] [CrossRef]

- ASTM D3039/D3039M-14; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM D5766-D5766M-11; Standard Test Method for Open-hole Tensile Strength of Polymer Matrix Composite Laminates. ASTM International: West Conshohocken, PA, USA, 2011.

- ASTM-D6742/D6742M-12; Standard Practice for Filled-Hole Tension and Compression Testing of Polymer Matrix Composite Laminates. ASTM International: West Conshohocken, PA, USA, 2012.

- ASTM-D5961/D5961M-13; Standard Test Method for Bearing Response of Polymer Matrix Composite Laminates. ASTM International: West Conshohocken, PA, USA, 2013.

- Gamdani, F.; Boukhili, R.; Vadean, A. Fatigue behavior of hybrid multi-bolted-bonded single-lap joints in woven composite plates. Int. J. Fatigue 2022, 158, 106738. [Google Scholar] [CrossRef]

- Gamdani, F.; Boukhili, R.; Vadean, A. Tensile strength of open-hole, pin-loaded and multi-bolted single-lap joints in woven composite plates. Mater. Des. 2015, 88, 702–712. [Google Scholar] [CrossRef]

- Tomblin, J.; Seneviratne, W. Laminate Statistical Allowable Generation for Fiber-Reinforced Composite Materials: Lamina Variability Method; Office of Aviation Research and Development, Federal Aviation Administration, Department of Aerospace Engineering, Wichita State University: Wichita, KS, USA, 2009. [Google Scholar]

- Portanova, M.A.; Masters, J. Standard Methods for Filled Hole Tension Testing of Textile Composites; NASA Contractor Report; Lockheed Martin Engineering and Sciences Company: Hampton, VA, USA, 1995; p. 198263. [Google Scholar]

- Lim, J.B.; Nethercot, D. Stiffness prediction for bolted moment-connections between cold-formed steel members. J. Constr. Steel Res. 2004, 60, 85–107. [Google Scholar] [CrossRef]

- Mehrabian, M.; Boukhili, R. Quantifying of secondary bending effect in multi-bolt single-lap carbon-epoxy composite joints via 3D-DIC. Compos. Sci. Technol. 2020, 200, 108453. [Google Scholar] [CrossRef]

- Skorupa, A.; Skorupa, M. Differences between the Fatigue Behaviour of Longitudinal Lap Joints in a Pressurized Fuselage and Laboratory Lap Joint Specimens; Riveted Lap Joints in Aircraft Fuselage; Springer: Berlin/Heidelberg, Germany, 2012; pp. 11–26. [Google Scholar]

| Code | Lay-up | Plies | Average Thickness, t mm, | Unnotched, TS MPa, (STD) | Open-Hole, OHT MPa, (STD) | Filled-Hole, FHT MPa, (STD) |

|---|---|---|---|---|---|---|

| CP8 | [(0/90)/(0/90)/(0/90)/(0/90)]s | 8 | 1.65 | 854 (29.80) | 455 (9.82) | 420 (0.95) |

| QI8 | [(0/90)/(±45)/(0/90)/(±45)]s | 8 | 592 (9.12) | 384 (6.76) | 366 (0.30) | |

| CP12 | [(0/90)/(0/90)/(0/90)/(0/90)/(0/90)/(0/90)]s | 12 | 2.63 | 800 (15.26) | 406 (8.40) | 442 (1.03) |

| QI12 | [(0/90)/(±45)/(0/90)/(±45)/(0/90)/(±45)]s | 12 | 579 (9.00) | 364 (7.98) | 358 (1.18) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mehrabian, M.; Lakis, A., Jr.; Boukhili, R. Bolt-Hole Elongation of Woven Carbon-Epoxy Composite Plates and Joints Using the Digital Image Correlation Technique. J. Compos. Sci. 2024, 8, 180. https://doi.org/10.3390/jcs8050180

Mehrabian M, Lakis A Jr., Boukhili R. Bolt-Hole Elongation of Woven Carbon-Epoxy Composite Plates and Joints Using the Digital Image Correlation Technique. Journal of Composites Science. 2024; 8(5):180. https://doi.org/10.3390/jcs8050180

Chicago/Turabian StyleMehrabian, Masoud, Aouni Lakis, Jr., and Rachid Boukhili. 2024. "Bolt-Hole Elongation of Woven Carbon-Epoxy Composite Plates and Joints Using the Digital Image Correlation Technique" Journal of Composites Science 8, no. 5: 180. https://doi.org/10.3390/jcs8050180

APA StyleMehrabian, M., Lakis, A., Jr., & Boukhili, R. (2024). Bolt-Hole Elongation of Woven Carbon-Epoxy Composite Plates and Joints Using the Digital Image Correlation Technique. Journal of Composites Science, 8(5), 180. https://doi.org/10.3390/jcs8050180