Mechanical Characterization of Recyclable and Non-Recyclable Bio-Epoxy Resins for Aerospace Applications

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

2.3. Experimental Techniques

2.3.1. Differential Scanning Calorimeter Tests

2.3.2. Tensile Tests

2.3.3. Bending Tests

2.3.4. Fracture Toughness Tests

2.3.5. Compression Tests

3. Results and Discussion

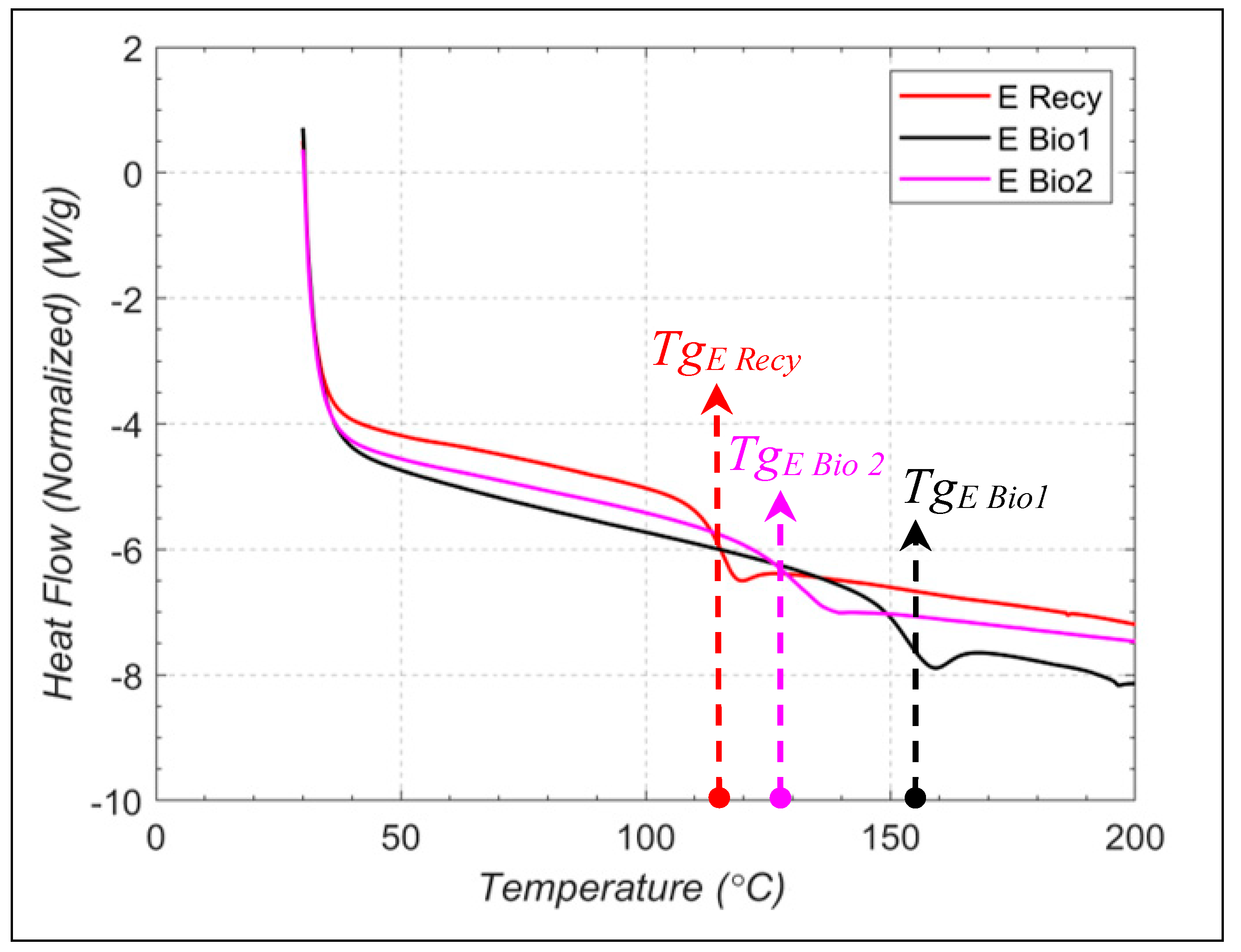

3.1. Glass Transition Temperature

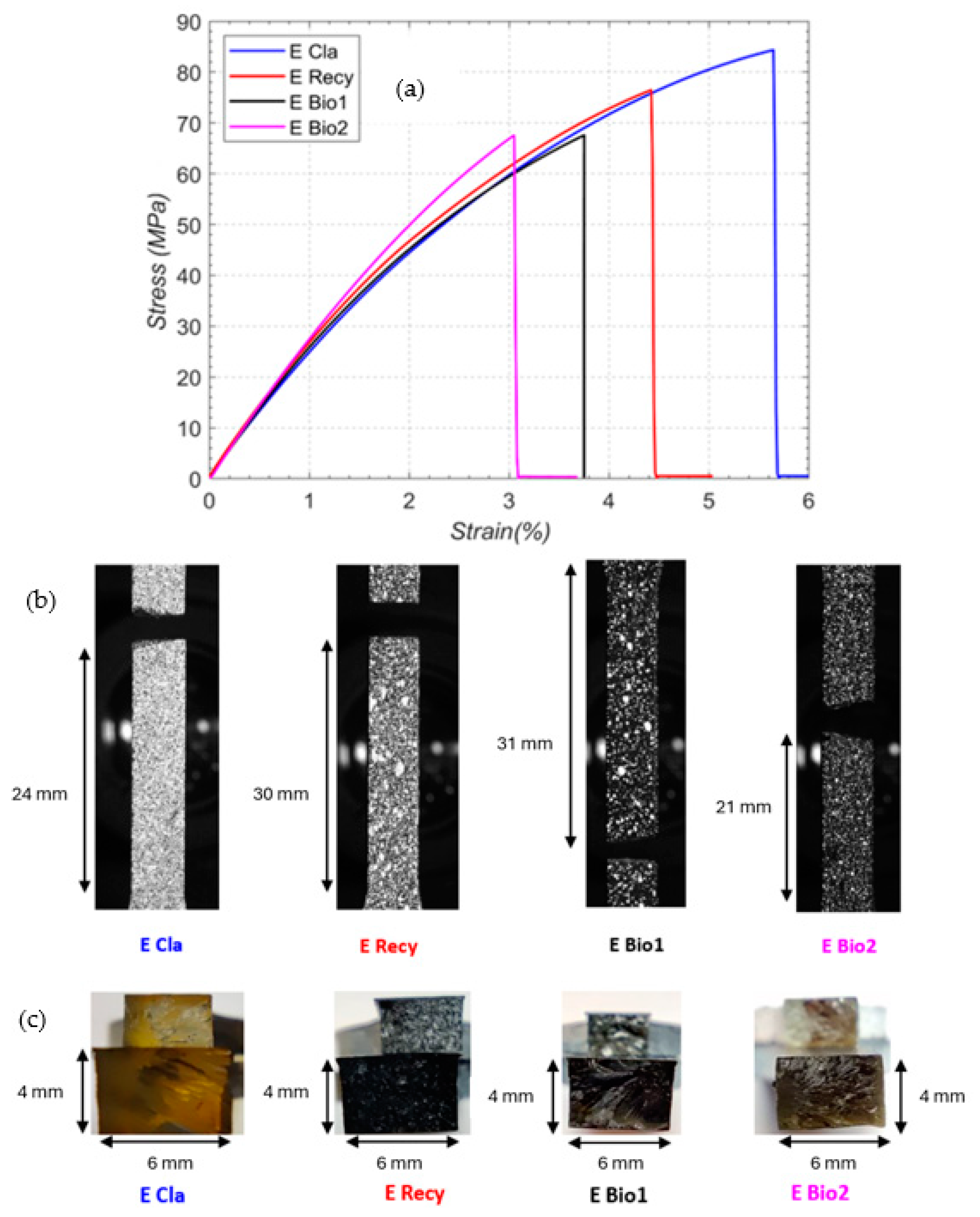

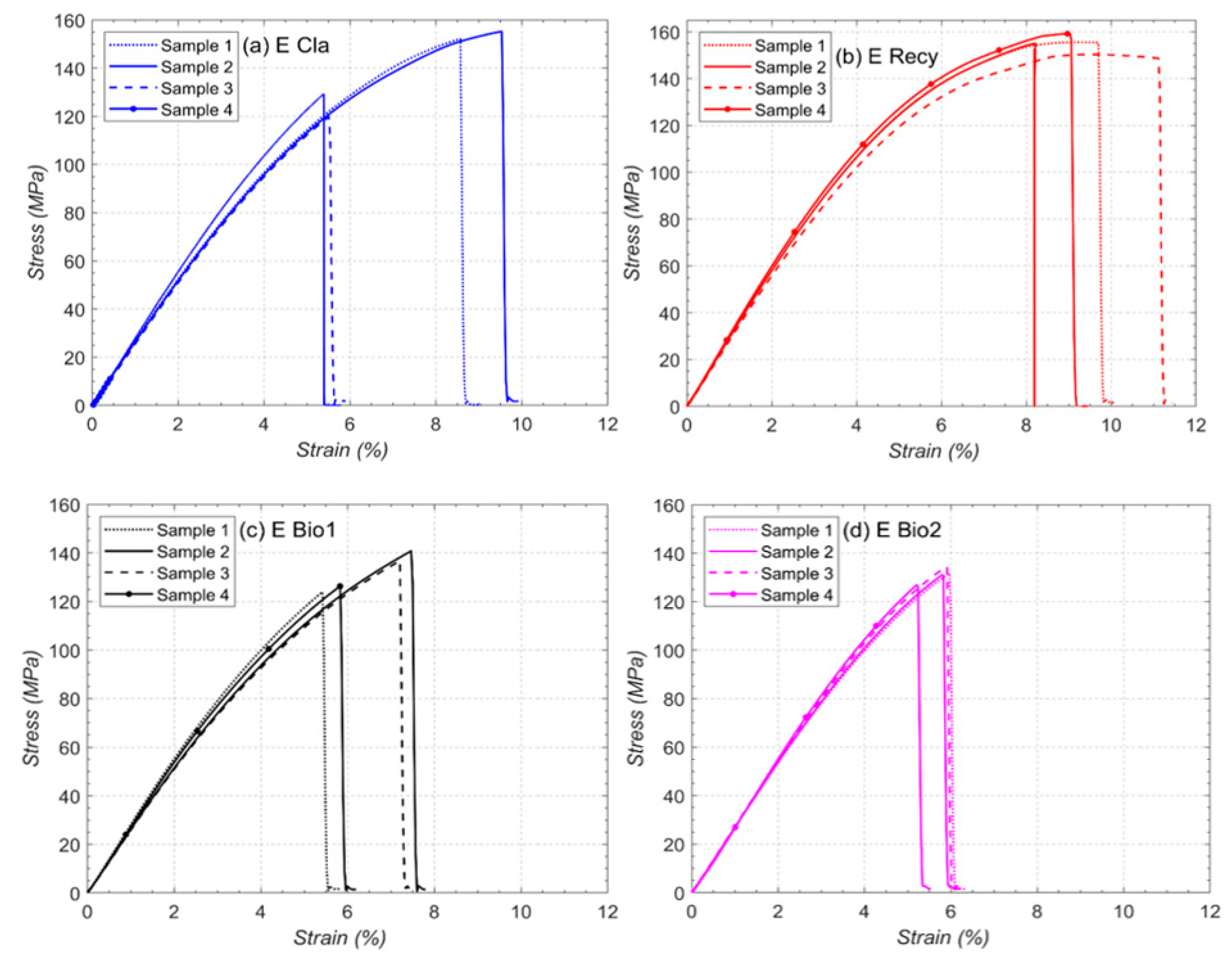

3.2. Tensile Test

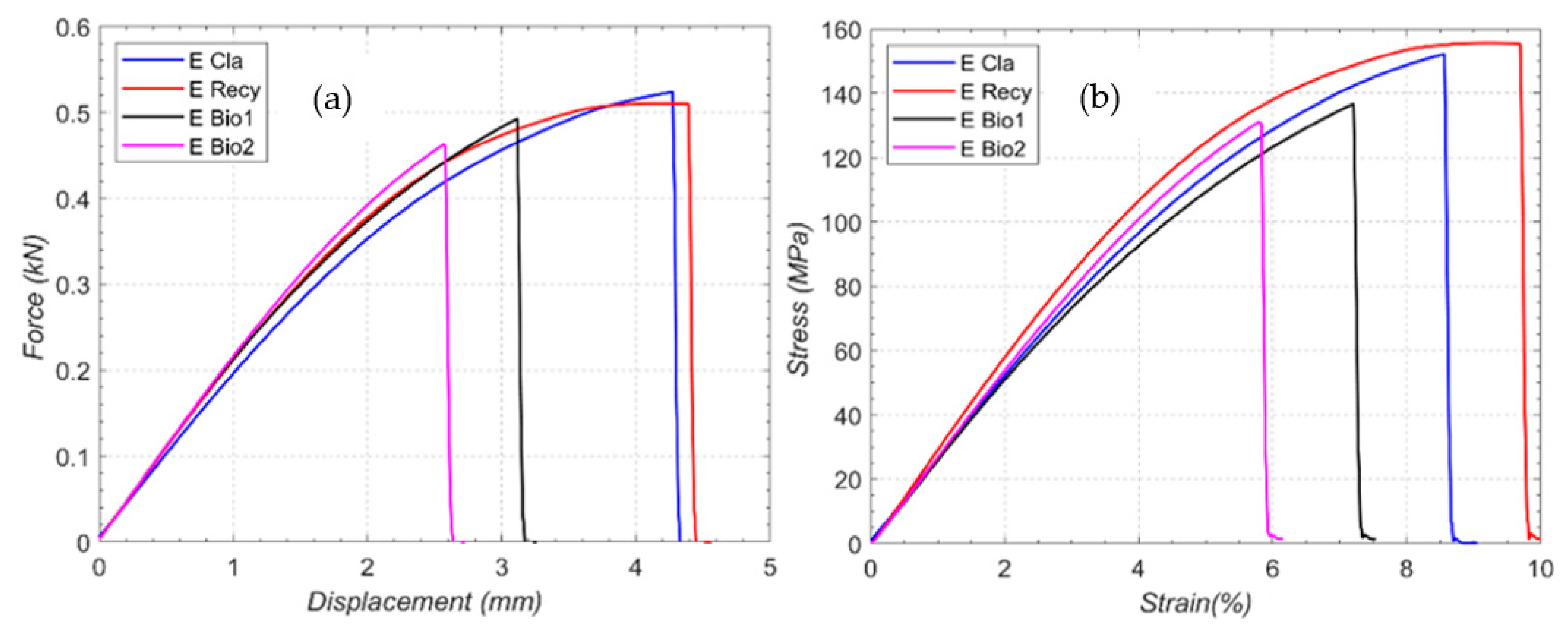

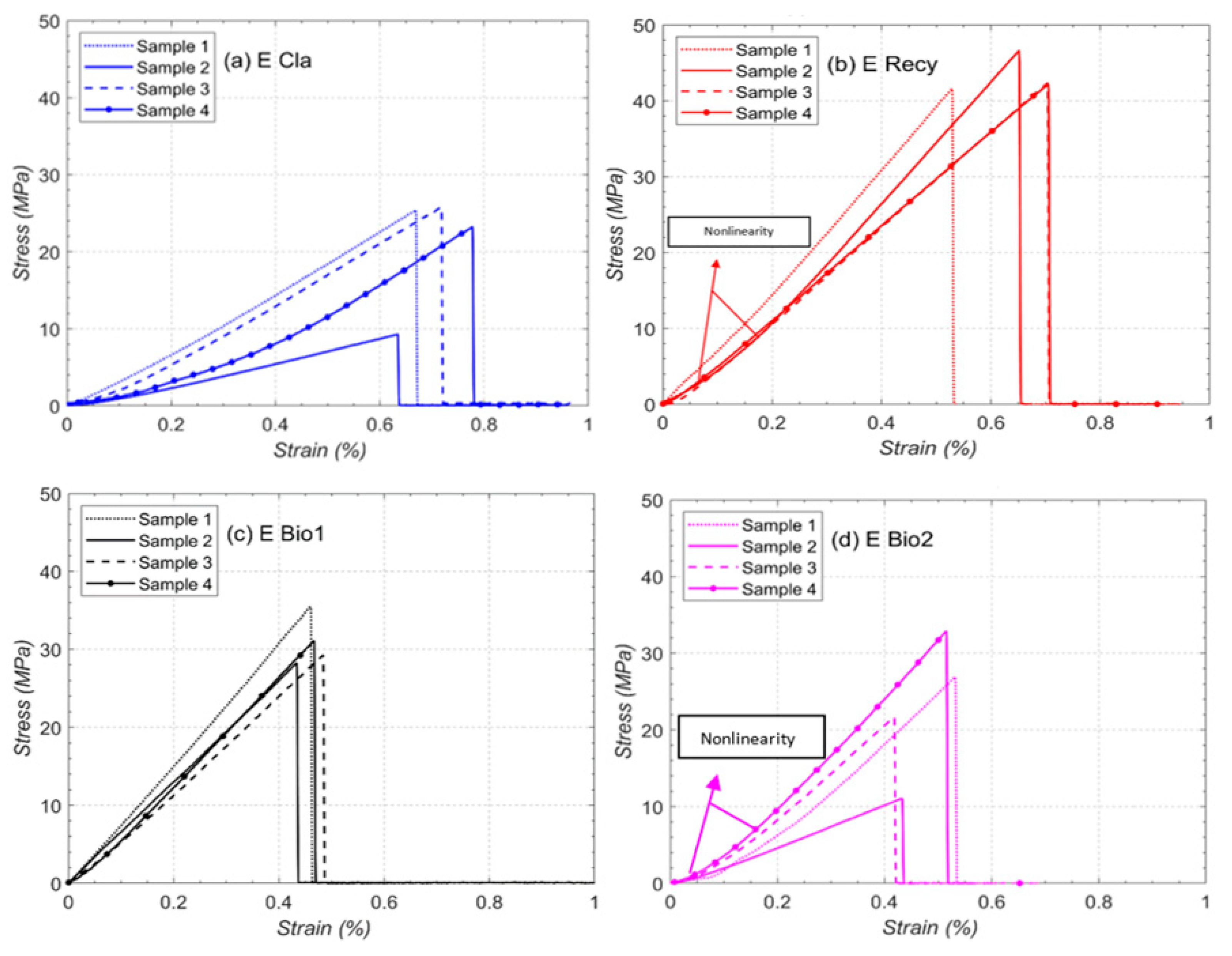

3.3. Bending

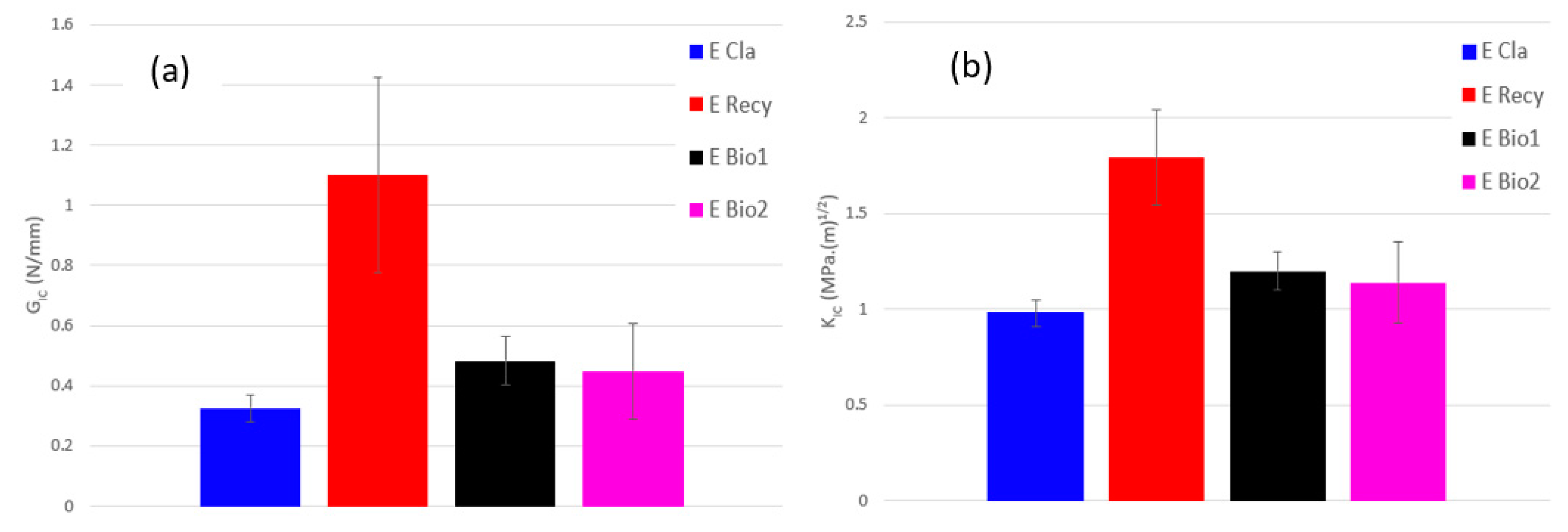

3.4. Fracture Toughness

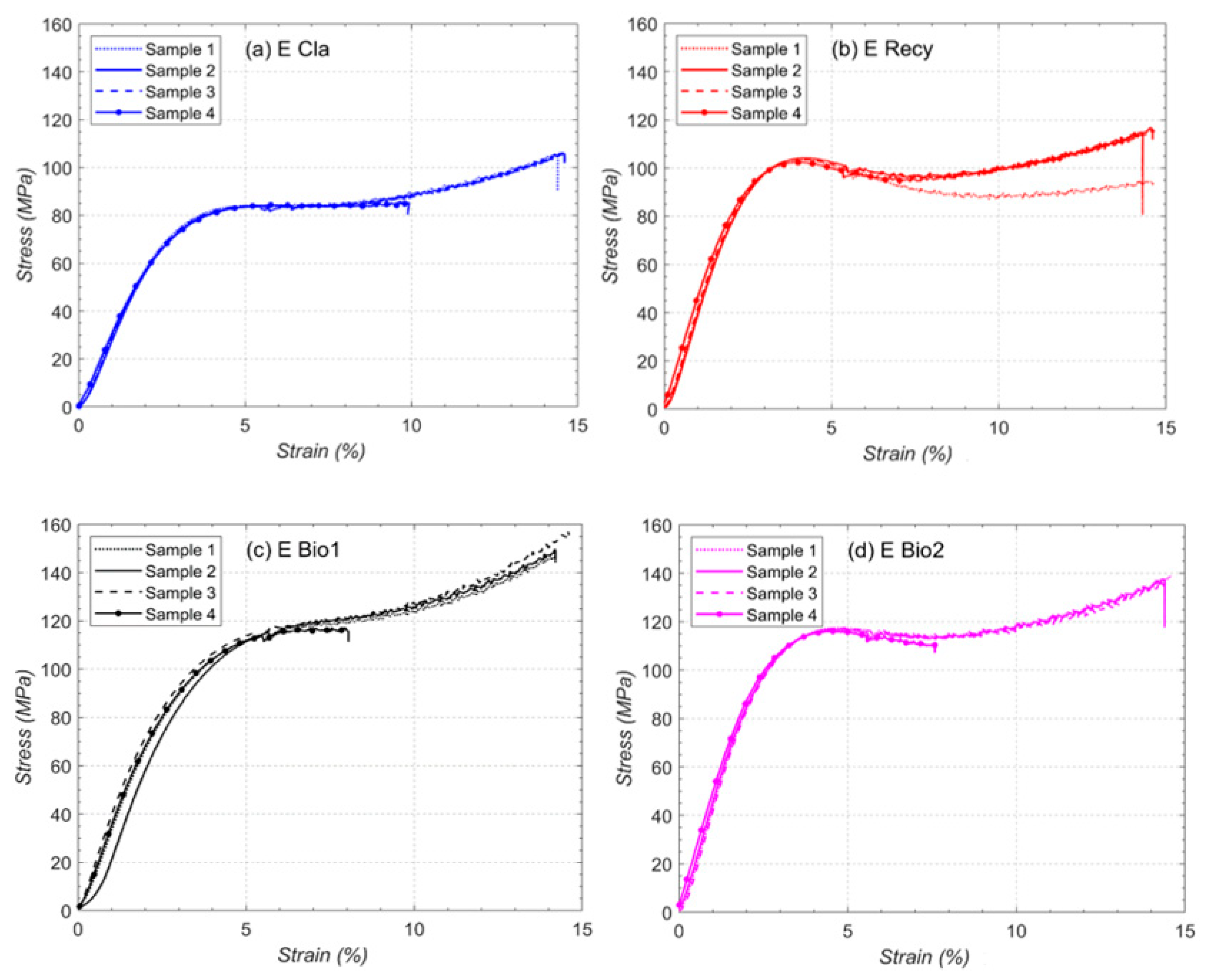

3.5. Compression

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Argon, A.S.; Cohen, R.E.; Mower, T.M. Mechanisms of Toughening Brittle Polymers. Mater. Sci. Eng. A 1994, 176, 79–90. [Google Scholar] [CrossRef]

- Domun, N.; Hadavinia, H.; Zhang, T.; Sainsbury, T.; Liaghat, G.H.; Vahid, S. Improving the Fracture Toughness and The Strength of Epoxy Using Nanomaterials—A Review of The Current Status. Nanoscale 2015, 7, 10294–10329. [Google Scholar] [CrossRef] [PubMed]

- Gojny, F.H.; Wichmann, M.H.G.; Fiedler, B.; Schulte, K. Influence of Different Carbon Nanotubes on The Mechanical Properties of Epoxy Matrix Composites—A Comparative Study. Compos. Sci. Technol. 2005, 65, 2300–2313. [Google Scholar] [CrossRef]

- Rosso, P.; Ye, L.; Friedrich, K.; Sprenger, S. A Toughened Epoxy Resin by Silica Nanoparticle Reinforcement. J. Appl. Polym. Sci. 2006, 100, 1849–1855. [Google Scholar] [CrossRef]

- Kamar, N.T.; Drzal, L.T.; Lee, A.; Askeland, P. Nanoscale Toughening of Carbon Fiber Reinforced/Epoxy Polymer Composites (CFRPs) Using A Triblock Copolymer. Polymer 2017, 111, 36–47. [Google Scholar] [CrossRef]

- Hull, D. A Unified Approach to Progressive Crushing of Fibre-Reinforced Composite Tubes. Compos. Sci. Technol. 1991, 40, 377–421. [Google Scholar] [CrossRef]

- Di Mauro, C.; Tran, T.-N.; Graillot, A.; Mija, A. Enhancing the Recyclability of a Vegetable Oil-Based Epoxy Thermoset Through Initiator Influence. ACS Sustain. Chem. Eng. 2020, 8, 7690–7700. [Google Scholar] [CrossRef]

- Walley, S.M.; Field, J.E. Strain Rate Sensitivity of Polymers in Compression from Low to High Rates. DYMAT J. 1994, 1, 211–227. [Google Scholar]

- Yekani Fard, M.; Liu, Y.; Chattopadhyay, A. A Simplified Approach for Flexural Behavior of Epoxy Resin Materials. J. Strain Anal. Eng. Des. 2012, 47, 18–31. [Google Scholar] [CrossRef]

- Gilat, A.; Goldberg, R.K.; Roberts, G.D. Strain Rate Sensitivity of Epoxy Resin in Tensile and Shear Loading. J. Aerosp. Eng. 2007, 20, 75–89. [Google Scholar] [CrossRef]

- Littell, J.D.; Ruggeri, C.R.; Goldberg, R.K.; Roberts, G.D.; Arnold, W.A.; Binienda, W.K. Measurement of Epoxy Resin Tension, Compression, and Shear Stress–Strain Curves over a Wide Range of Strain Rates Using Small Test Specimens. J. Aerosp. Eng. 2008, 21, 162–173. [Google Scholar] [CrossRef]

- Jordan, J.L.; Foley, J.R.; Siviour, C.R. Mechanical Properties of Epon 826/DEA Epoxy. Mech. Time-Depend. Mater. 2008, 12, 249–272. [Google Scholar] [CrossRef]

- Abdellaoui, H.; Raji, M.; Bouhfid, R.; el kacem Qaiss, A. Investigation of The Deformation Behavior of Epoxy-Based Composite Materials. In Failure Analysis in Biocomposites, Fibre-Reinforced Composites and Hybrid Composites; Woodhead Publishing: Sawston, UK, 2019; pp. 29–49. [Google Scholar] [CrossRef]

- Chen, W.; Lu, F.; Cheng, M. Tension And Compression Tests of Two Polymers Under Quasi-Static and Dynamic Loading. Polym. Test. 2002, 21, 113–121. [Google Scholar] [CrossRef]

- Fard, M.Y.; Liu, Y.; Chattopadhyay, A. Analytical Solution for Flexural Response of Epoxy Resin Materials. J. Aerosp. Eng. 2012, 25, 395–408. [Google Scholar] [CrossRef]

- Allaer, K.; De Baere, I.; Van Paepegem, W.; Degrieck, J. Direct Fracture Toughness Determination of a Ductile Epoxy Polymer from Digital Image Correlation Measurements on a Single Edge Notched Bending Sample. Polym. Test. 2015, 42, 199–207. [Google Scholar] [CrossRef]

- Shirodkar, N.; Cheng, S.; Seidel, G.D. Enhancement of Mode I Fracture Toughness Properties of Epoxy Reinforced with Graphene Nanoplatelets and Carbon Nanotubes. Compos. Part B 2021, 224, 109177. [Google Scholar] [CrossRef]

- Rahmani, H.; Najafi, S.H.M.; Ashori, A. Mechanical Performance of Epoxy/Carbon Fiber Laminated Composites. J. Reinf. Plast. Compos. 2014, 33, 733–740. [Google Scholar] [CrossRef]

- Liu, T.; Hao, C.; Wang, L.; Li, Y.; Liu, W.; Xin, J.; Zhang, J. A Self-Healable High Glass Transition Temperature Bioepoxy Material Based on Vitrimer Chemistry. Macromolecules 2018, 51, 5577–5585. [Google Scholar] [CrossRef]

- Yu, K.; Taynton, P.; Zhang, W.; Dunn, M.L.; Qi, H.J. Reprocessing and Recycling of Thermosetting Polymers Based on Bond Exchange Reactions. RSC Adv. 2014, 4, 10108–10117. [Google Scholar] [CrossRef]

- Baruah, R.; Kumar, A.; Ujjwal, R.R.; Kedia, S.; Ranjan, A.; Ojha, U. Recyclable Thermosets Based on Dynamic Amidation and Aza-Michael Addition Chemistry. Macromolecules 2016, 49, 7814–7824. [Google Scholar] [CrossRef]

- Lu, L.; Pan, J.; Li, G. Recyclable High Performance Epoxy Based on Transesterification Reaction. J. Mater. Chem. A 2017, 5, 21505–21513. [Google Scholar] [CrossRef]

- Azcune, I.; Odriozola, I. Aromatic Disulfide Crosslinks in Polymer Systems: Self-Healing, Reprocessability, Recyclability and More. Eur. Polym. J. 2016, 84, 147–160. [Google Scholar] [CrossRef]

- Cicala, G.; Pergolizzi, E.; Piscopo, F.; Carbone, D.; Recca, G. Hybrid Composites Manufactured by Resin Infusion with a Fully Recyclable Bioepoxy Resin. Compos. Part B 2018, 132, 69–76. [Google Scholar] [CrossRef]

- Ruiz de Luzuriaga, A.; Martin, R.; Markaide, N.; Rekondo, A.; Cabañero, G.; Rodríguez, J.; Odriozola, I. Epoxy resin with exchangeable disulfide crosslinks to obtain reprocessable, repairable and recyclable fiber-reinforced thermoset composites. Mater. Horiz. 2016, 3, 241–247. [Google Scholar] [CrossRef]

- Cicala, G.; Mannino, S.; La Rosa, A.D.; Banatao, D.R.; Pastine, S.J.; Kosinski, S.T.; Scarpa, F. Hybrid biobased recyclable epoxy composites for mass production. Polym. Compos. 2018, 39, E2217–E2225. [Google Scholar] [CrossRef]

- La Rosa, A.D.; Blanco, I.; Banatao, D.R.; Pastine, S.J.; Björklund, A.; Cicala, G. Innovative Chemical Process for Recycling Thermosets Cured with Recyclamines® by Converting Bio-Epoxy Composites in Reusable Thermoplastic—An LCA Study. Materials 2018, 11, 353. [Google Scholar] [CrossRef] [PubMed]

- Auvergne, R.; Caillol, S.; David, G.; Boutevin, B.; Pascault, J.-P. Biobased Thermosetting Epoxy: Present and Future. Chem. Rev. 2014, 114, 1082–1115. [Google Scholar] [CrossRef] [PubMed]

- Mashouf Roudsari, G.; Mohanty, A.K.; Misra, M. Green Approaches to Engineer Tough Biobased Epoxies: A Review. ACS Sustain. Chem. Eng. 2017, 5, 9528–9541. [Google Scholar] [CrossRef]

- Mustapha, R.; Rahmat, A.R.; Majid, R.A.; Mustapha, S.N.H. Vegetable Oil-Based Epoxy Resins and Their Composites with Bio-Based Hardener: A Short Review. Polym.-Plast. Technol. Mater. 2019, 58, 1311–1326. [Google Scholar] [CrossRef]

- Johnson, R.D.J.; Arumugaprabu, V.; Rajasekar, E.; Santhosh, G.; Saravanakumar, M. Mechanical Property Studies on Environmentally Friendly Bio Epoxy Resin. Mater. Today Proc. 2018, 5, 6815–6820. [Google Scholar] [CrossRef]

- Vinod, A.; Sanjay, M.R.; Siengchin, S. Fatigue and Thermo-Mechanical Properties of Chemically Treated Morinda Citrifolia Fiber-Reinforced Bio-Epoxy Composite: A Sustainable Green Material for Cleaner Production. J. Clean. Prod. 2021, 326, 129411. [Google Scholar] [CrossRef]

- Mattar, N.; Hübner, F.; Demleitner, M.; Brückner, A.; Langlois, V.; Renard, E.; Ruckdäschel, H.; Anda, A.R. Multiscale Characterization of Creep and Fatigue Crack Propagation Resistance of Fully Bio-Based Epoxy-Amine Resins. ACS Appl. Polym. Mater. 2021, 3, 5134–5144. [Google Scholar] [CrossRef]

- Terry, J.S.; Taylor, A.C. The Properties and Suitability of Commercial Bio-Based Epoxies for Use in Fiber-Reinforced Composites. J. Appl. Polym. Sci. 2021, 138, 50417. [Google Scholar] [CrossRef]

- ASTM D6866; Standard Test Methods for Determining the Biobased Content of Solid, Liquid, and Gaseous Samples Using Radiocarbon Analysis. ASTM International: West Conshohocken, PA, USA, 2024.

- ISO 11357-2; Plastics—Differential Scanning Calorimetry (DSC)—Part 2: Determination of Glass Transition Temperature and Step Height. International Organization for Standardization: Geneva, Switzerland, 2020.

- ASTM D638-14; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2014. [CrossRef]

- ISO 178; Plastics—Determination of Flexural Properties. Bristish Standards Institution (BSI): London, UK, 2019.

- ASTM D5045-14; Standard Test Methods for Plane-Strain Fracture Toughness and Strain Energy Release Rate of Plastic Materials. ASTM International: West Conshohocken, PA, USA, 2014. [CrossRef]

- Mishra, K.; Brassart, L.; Singh, A. Rate Dependent Fracture Behavior of Highly Cross-Linked Epoxy Resin. Eng. Fail. Anal. 2022, 140, 106558. [Google Scholar] [CrossRef]

- ASTM D695-15; Standard Test Method for Compressive Properties of Rigid Plastics. ASTM International: West Conshohocken, PA, USA, 2015. [CrossRef]

- Raponi, O.; Raponi, R.; Barbana, G.; DiBenedetto, R.; Junior, A. Development of a Simple Dielectric Analysis Module for Online Cure Monitoring of a Commercial Epoxy Resin Formulation. Mater. Res. 2017, 20, 291–297. [Google Scholar] [CrossRef]

- Ciardiello, R.; Benelli, A.; Paolino, D.S. Static and Impact Properties of Flax-Reinforced Polymers Prepared with Conventional Epoxy and Sustainable Resins. Polymers 2024, 16, 190. [Google Scholar] [CrossRef]

- Yukun, L.; Kai, H.; Hongjun, Y.; Liulei, H.; Licheng, G. Experimentally Validated Phase-Field Fracture Modeling of Epoxy Resins. Compos. Struct. 2022, 279, 114806. [Google Scholar] [CrossRef]

- Goldberg, O.; Greenfeld, I.; Wagner, D. Efficient Toughening of Short-Fiber Composites Using Weak Magnetic Fields. Materials 2020, 13, 2415. [Google Scholar] [CrossRef]

| Properties | 5052 Epoxy (Non-Bio) | 5544 Epoxy (Recyclable) | 5551 Epoxy (Bio-Epoxy) | 5561 Epoxy (Bio-Epoxy) |

|---|---|---|---|---|

| Nomenclature | E Cla | E Recy | E Bio1 | E Bio2 |

| Hardener | Aradur 5020 | THR9351 | TH9297 | TH7389 |

| Mixing ratio (by wt.) (a) | 100:38 | 100:26 | 100:32 | 100:19 |

| Curing conditions (a) | 23 °C/24 h + 50 °C/15 h | 80 °C/25 min + 140 °C/4 h | 25 °C/24 h + 80 °C/4 h + 140 °C/4 h | 80 °C/25 min + 140 °C/6 h |

| Bio-content (%) (a)(b) | - | 27 | 33 | 48.9 |

| Parameters | Tensile | Bending | Toughness | Compression |

|---|---|---|---|---|

| Thickness (B, mm) | 4 | 4 | 4 | 12.7 |

| Length (l, mm) | 115 | 50 | 35 | 35.4 |

| Total width (W, mm) | 19 | 4 | 8 | 12.7 |

| Loading speed (mm/min) | 5 | 1.75 | 1 | 1.3 |

| Properties | 5052 Epoxy E Cla (Non-Bio) | 5544 Epoxy E Recy (Recyclable Bio) | 5551 Epoxy E Bio1 (Bio-Epoxy) | 5561 Epoxy E Bio2 (Bio-Epoxy) |

|---|---|---|---|---|

| Glass transition temperature (°C) | 106 (a) | 117 | 156 | 128 |

| Supplier and Reference | Bio-Based Content (%) | Tg (°C) | Etension (GPa) | Tensile Strength (MPa) | KIC (MPa·m1/2) |

|---|---|---|---|---|---|

| Aditya Birla 5544 E Recy | 27 | 110-124 | 3.07 | 74.0 | 4.50 |

| Aditya Birla 5551 E Bio1 | 33 | 147-165 | 2.81 | 62.0 | 3.13 |

| Aditya Birla 5561 E Bio2 | 48.9 | 121-135 | 2.93 | 62.3 | 3.14 |

| Cardolite Formulite 2500A | 46.8 | 71.9 | 2.29 | 48.0 | 0.59 |

| Cardolite Formulite 2500A | 36.6 | 98.7 | 3.09 | 68.0 | 0.68 |

| Entropy Resins SuperSap INR | 19 | 118.4 | 3.23 | 67.8 | 0.96 |

| Gurit AMPRO BIO | 40 | 66.5 | 2.2 | 42.6 | 0.64 |

| Resoltech 1800 ECO | 33 | 59.3 | 2.38 | 37.7 | 0.81 |

| Sicomim greepoxy 56 | 43 | 75.1 | 3.45 | 72.5 | 0.94 |

| Sicomim greepoxy 56 | 42 | 78.4 | 3.28 | 65.6 | 2.16 |

| Sicomim Infugreen 810 | 29 | 75.4 | 3.57 | 75.7 | 1.14 |

| Sicomim Infugreen 810 | 31 | 81.8 | 3.09 | 61.6 | 2.39 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mezeix, L.; Gupta, P.; Bouvet, C.; Wongtimnoi, K. Mechanical Characterization of Recyclable and Non-Recyclable Bio-Epoxy Resins for Aerospace Applications. J. Compos. Sci. 2024, 8, 191. https://doi.org/10.3390/jcs8050191

Mezeix L, Gupta P, Bouvet C, Wongtimnoi K. Mechanical Characterization of Recyclable and Non-Recyclable Bio-Epoxy Resins for Aerospace Applications. Journal of Composites Science. 2024; 8(5):191. https://doi.org/10.3390/jcs8050191

Chicago/Turabian StyleMezeix, Laurent, Prateek Gupta, Christophe Bouvet, and Komkrisd Wongtimnoi. 2024. "Mechanical Characterization of Recyclable and Non-Recyclable Bio-Epoxy Resins for Aerospace Applications" Journal of Composites Science 8, no. 5: 191. https://doi.org/10.3390/jcs8050191

APA StyleMezeix, L., Gupta, P., Bouvet, C., & Wongtimnoi, K. (2024). Mechanical Characterization of Recyclable and Non-Recyclable Bio-Epoxy Resins for Aerospace Applications. Journal of Composites Science, 8(5), 191. https://doi.org/10.3390/jcs8050191