Correlation of Microstructural Features within Short Carbon Fiber/ABS Manufactured via Large-Area Additive- Manufacturing Beads

Abstract

:1. Introduction

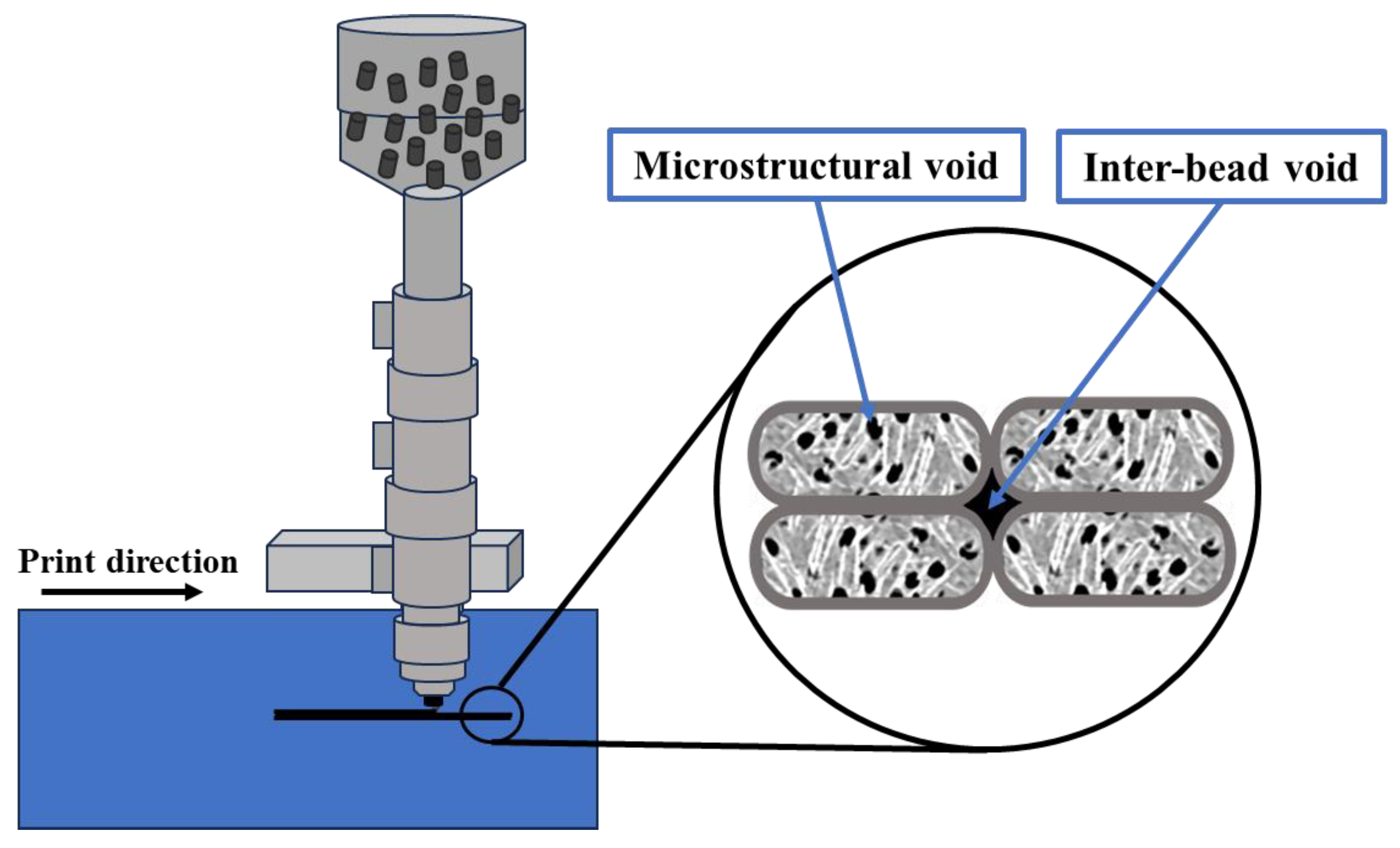

2. Materials and Methods

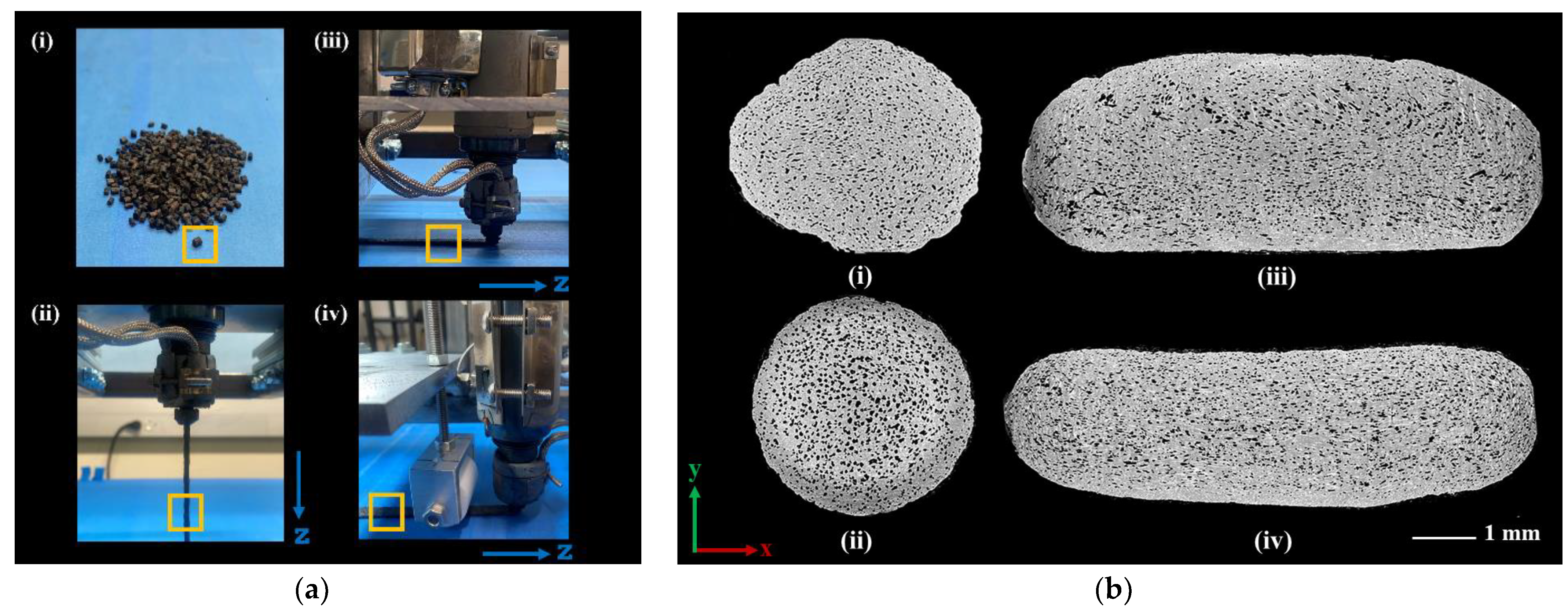

2.1. Sample Preparation

- (i)

- SCF/ABS pellet as received to assess our incoming feedstock

- (ii)

- Single freely extruded strand to assess the effect of the LAAM extrusion process

- (iii)

- Regularly extrusion/deposited single bead to assess the effect of the LAAM extrusion/deposition process

- (iv)

- Single bead with roller compression following extrusion/deposition to assess the effect of a post-extrusion/deposition forming process

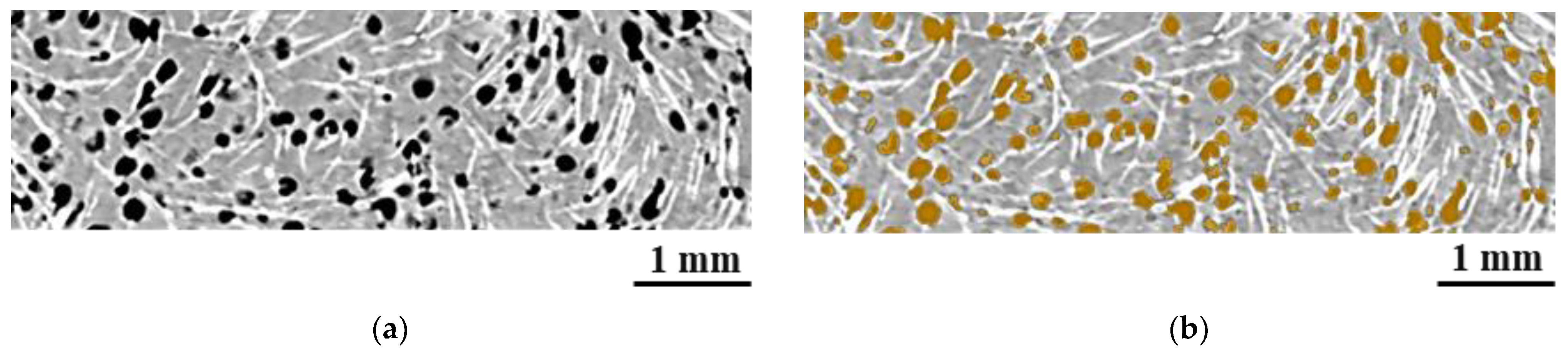

2.2. µCT Image Acquisition Technique

2.3. µCT Image Processing

3. Results

3.1. Sample-Average Properties

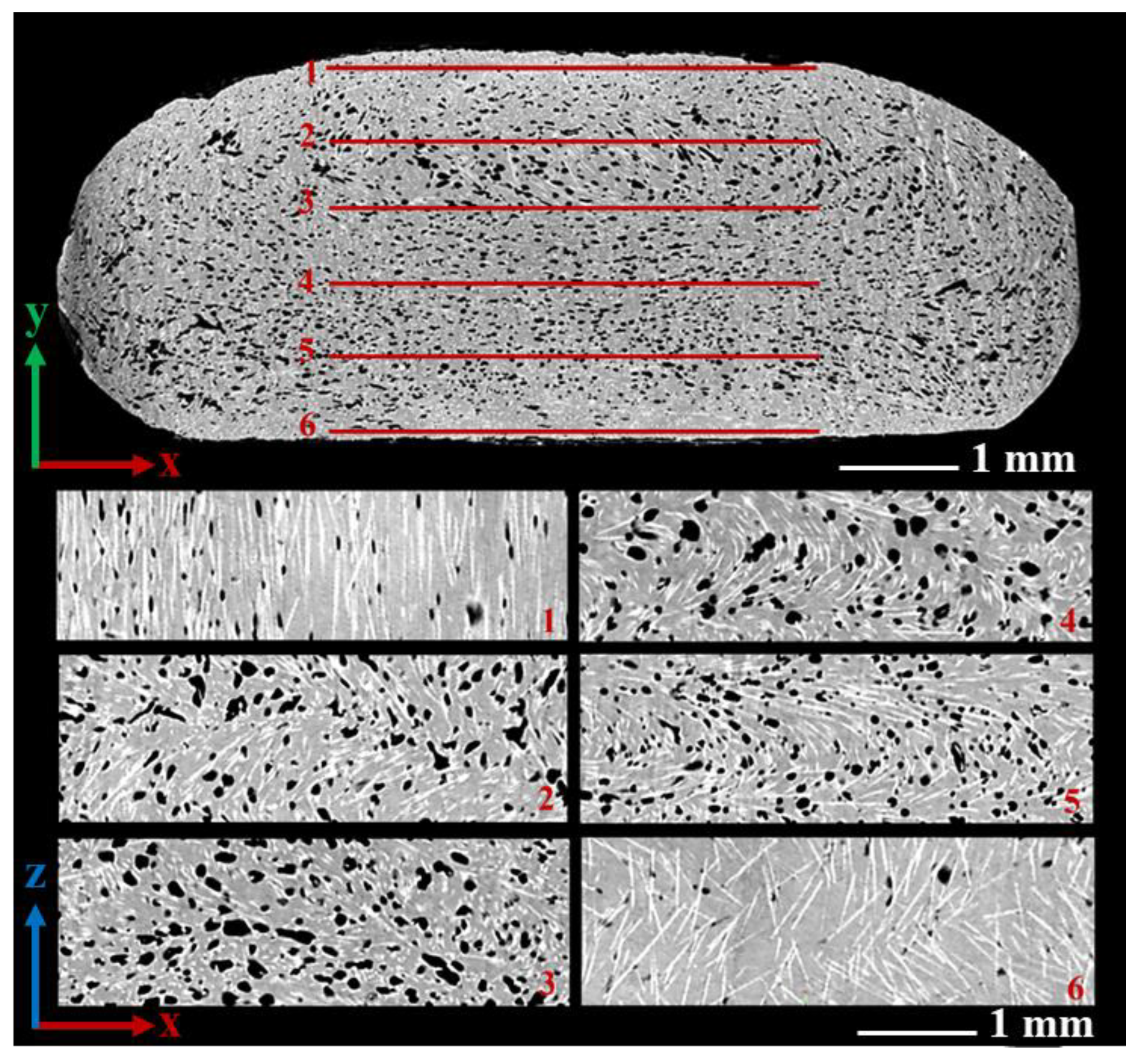

3.1.1. Void Volume Fraction and Distribution

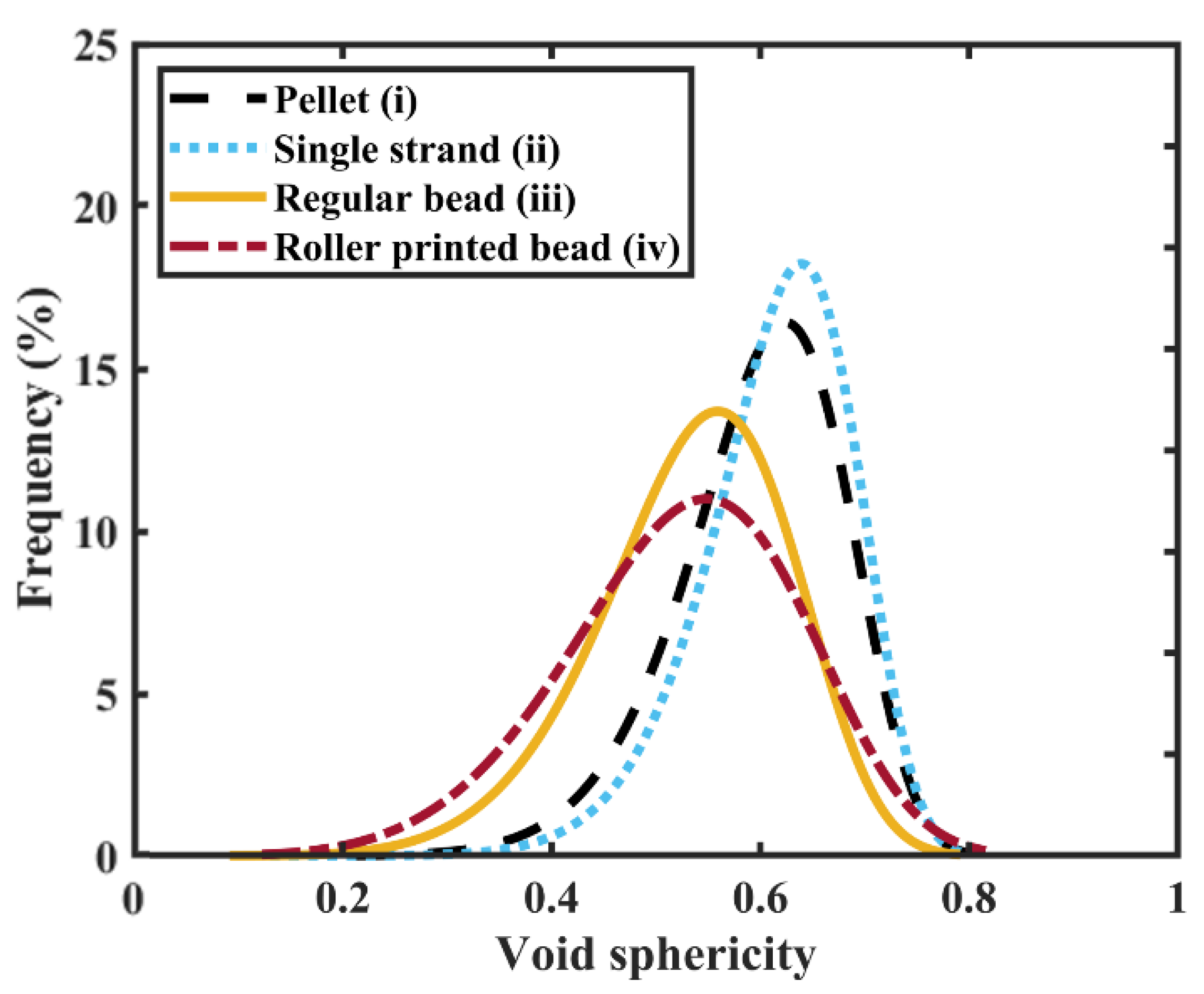

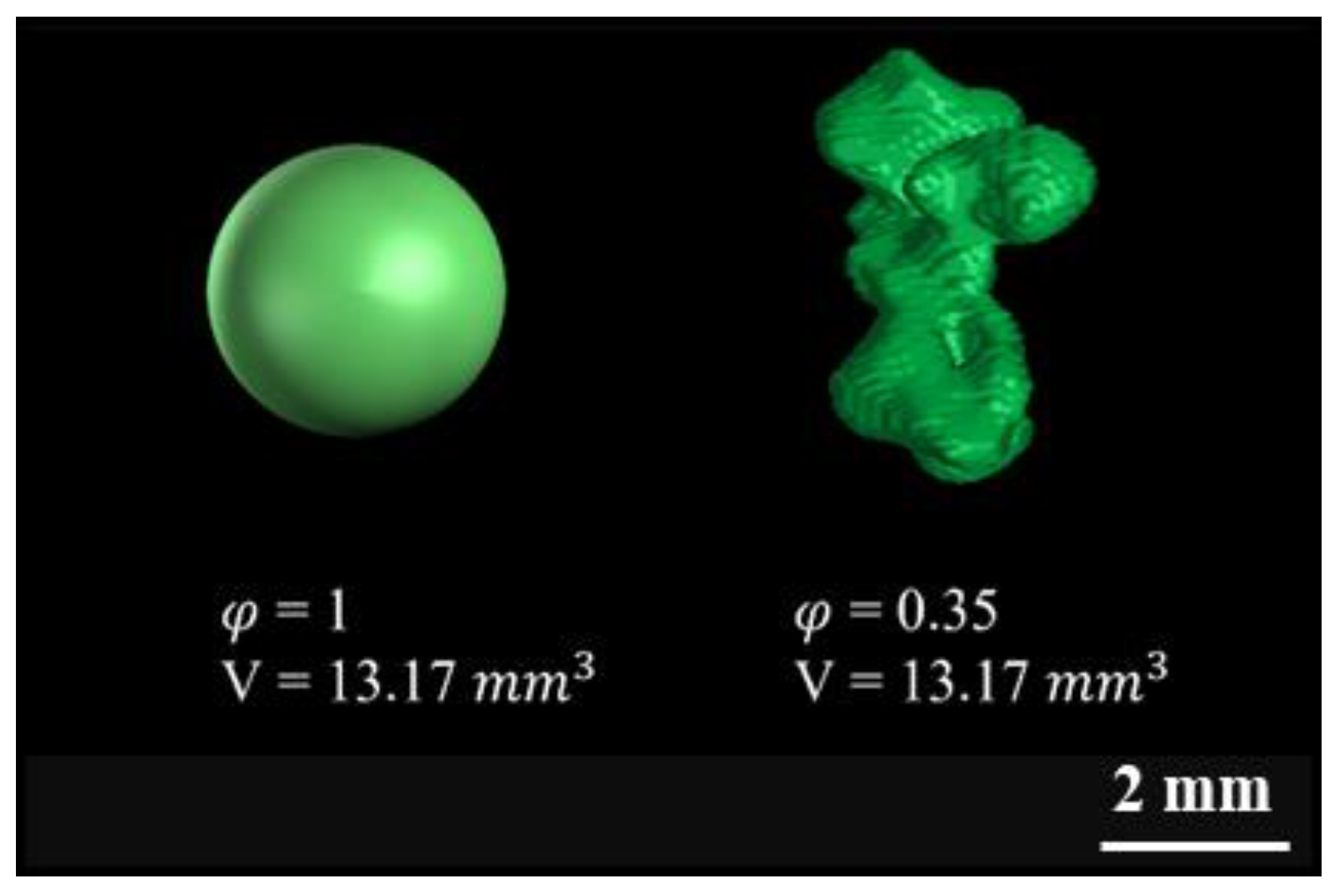

3.1.2. Void Sphericity

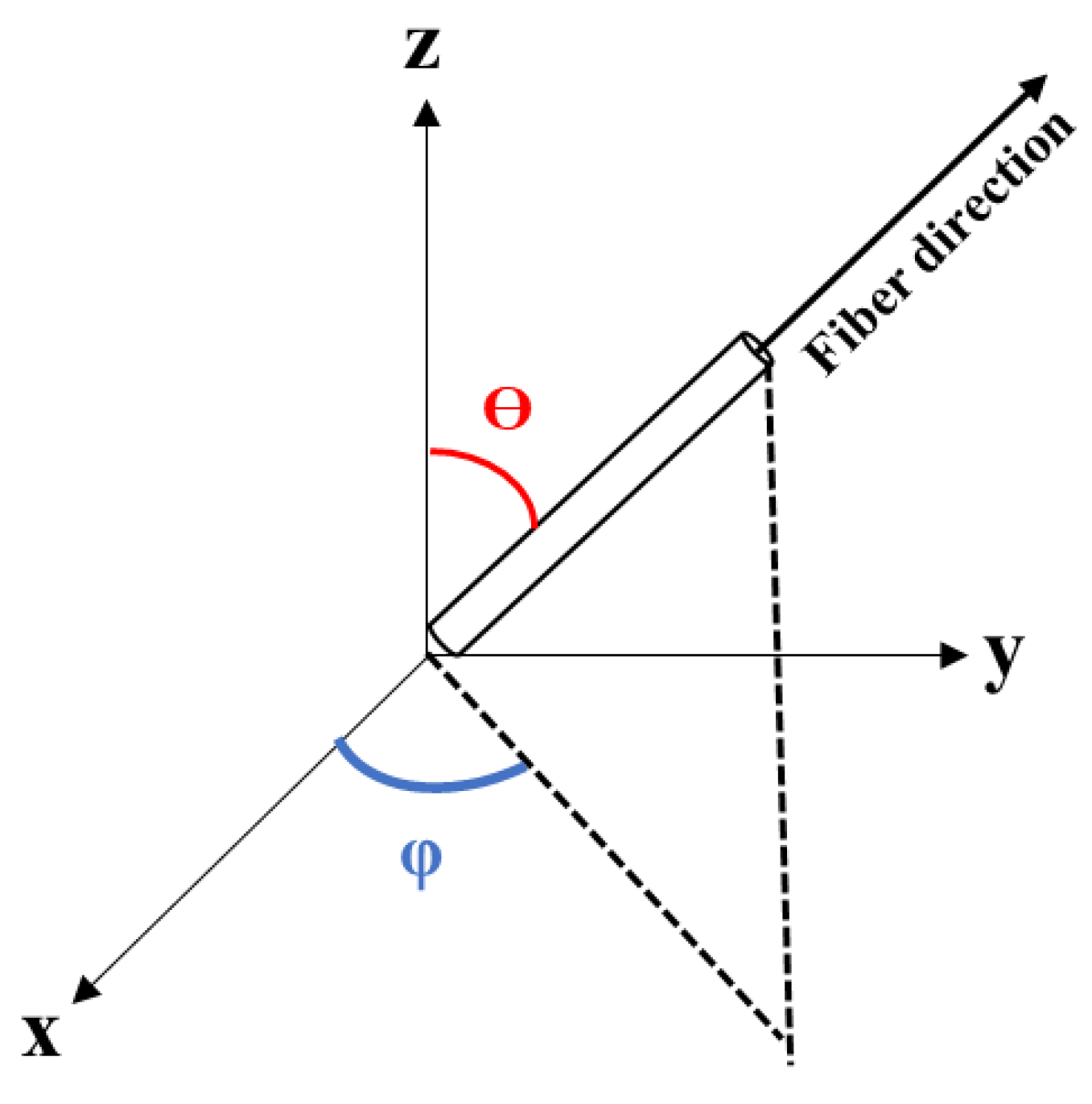

3.1.3. Fiber Orientation

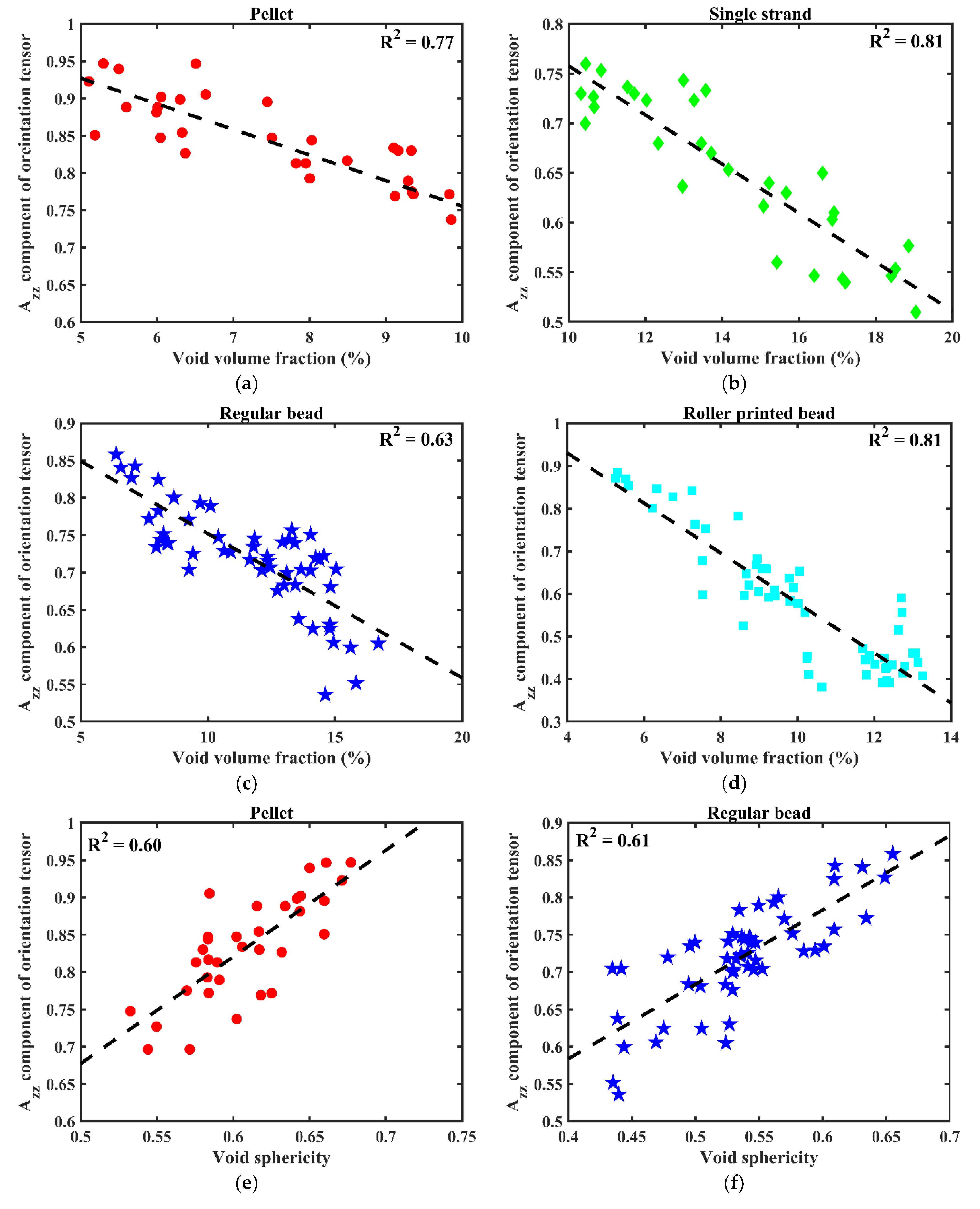

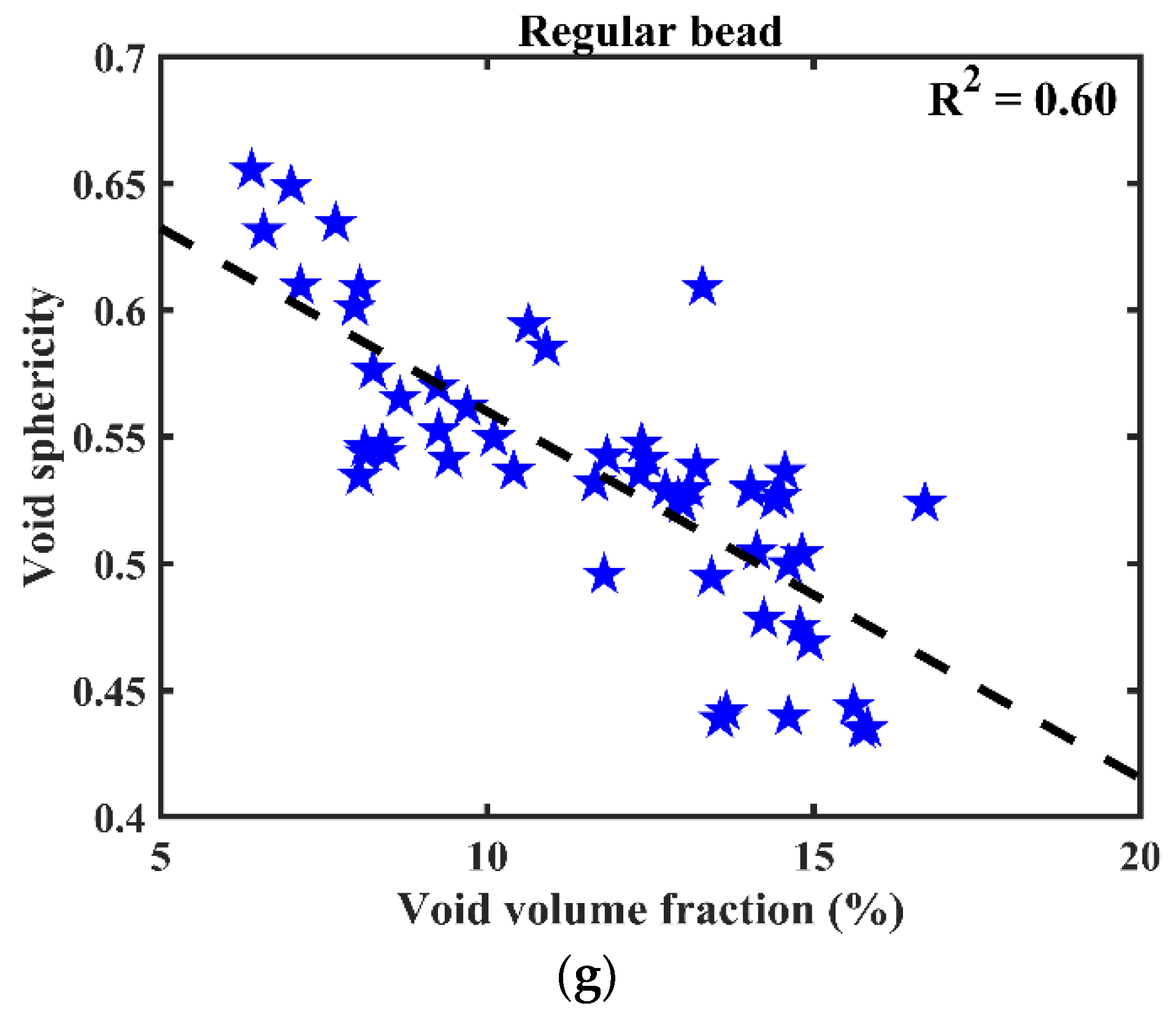

3.2. Microstructural Characteristics Correlation

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Sample | ) | ) |

|---|---|---|

| Pellet (i) | 0.63 | 8.98 |

| Single strand (ii) | 0.65 | 10.20 |

| Regular bead (iii) | 0.57 | 6.75 |

| Roller-printed bead (iv) | 0.56 | 5.35 |

Appendix B

References

- Billah, K.M.M.; Lorenzana, F.A.R.; Martinez, N.L.; Wicker, R.B.; Espalin, D. Thermomechanical characterization of short carbon fiber and short glass fiber-reinforced ABS used in large format additive manufacturing. Addit. Manuf. 2020, 35, 101299. [Google Scholar] [CrossRef]

- Mulholland, T.; Goris, S.; Boxleitner, J.; Osswald, T.; Rudolph, N. Process-Induced Fiber Orientation in Fused Filament Fabrication. J. Compos. Sci. 2018, 2, 45. [Google Scholar] [CrossRef]

- Ning, F.; Cong, W.; Hu, Z.; Huang, K. Additive manufacturing of thermoplastic matrix composites using fused deposition modeling: A comparison of two reinforcements. J. Compos. Mater. 2017, 51, 3733–3742. [Google Scholar] [CrossRef]

- Pierce, J.B.; Smith, D.E. Modeling Carbon Fiber Suspension Dynamics for Additive Manufacturing Polymer Melt Flows; University of Texas at Austin: Austin, TX, USA, 2023. [Google Scholar] [CrossRef]

- Wang, Z.; Fang, Z.; Xie, Z.; Smith, D.E. A Review on Microstructural Formations of Discontinuous Fiber-Reinforced Polymer Composites Prepared via Material Extrusion Additive Manufacturing: Fiber Orientation, Fiber Attrition, and Micro-Voids Distribution. Polymers 2022, 14, 4941. [Google Scholar] [CrossRef]

- Pibulchinda, P.; Barocio, E.; Favaloro, A.J.; Pipes, R.B. Influence of printing conditions on the extrudate shape and fiber orientation in extrusion deposition additive manufacturing. Compos. Part B Eng. 2023, 261, 110793. [Google Scholar] [CrossRef]

- Blok, L.G.; Longana, M.L.; Yu, H.; Woods, B.K.S. An investigation into 3D printing of fibre reinforced thermoplastic composites. Addit. Manuf. 2018, 22, 176–186. [Google Scholar] [CrossRef]

- Van De Werken, N.; Tekinalp, H.; Khanbolouki, P.; Ozcan, S.; Williams, A.; Tehrani, M. Additively manufactured carbon fiber-reinforced composites: State of the art and perspective. Addit. Manuf. 2020, 31, 100962. [Google Scholar] [CrossRef]

- Goh, G.D.; Dikshit, V.; Nagalingam, A.P.; Goh, G.L.; Agarwala, S.; Sing, S.L.; Wei, J.; Yeong, W.Y. Characterization of mechanical properties and fracture mode of additively manufactured carbon fiber and glass fiber reinforced thermoplastics. Mater. Des. 2018, 137, 79–89. [Google Scholar] [CrossRef]

- Love, L.J.; Kunc, V.; Rios, O.; Duty, C.E.; Elliott, A.M.; Post, B.K.; Smith, R.J.; Blue, C.A. The importance of carbon fiber to polymer additive manufacturing. J. Mater. Res. 2014, 29, 1893–1898. [Google Scholar] [CrossRef]

- Advani, S.G.; Tucker, C.L., III. The use of tensors to describe and predict fiber orientation in short fiber composites. J. Rheol. 1987, 31, 751–784. [Google Scholar] [CrossRef]

- Lewicki, J.P.; Rodriques, J.N.; Zhu, C.; Worsley, M.A.; Wu, A.S.; Kanarska, Y.; Horn, J.D.; Duoss, E.B.; Ortega, J.M.; Elmer, W.; et al. 3D-Printing of Meso-structurally Ordered Carbon Fiber/Polymer Composites with Unprecedented Orthotropic Physical Properties. Sci. Rep. 2017, 7, 43401. [Google Scholar] [CrossRef]

- Hmeidat, N.S.; Elkins, D.S.; Peter, H.R.; Kumar, V.; Compton, B.G. Processing and mechanical characterization of short carbon fiber-reinforced epoxy composites for material extrusion additive manufacturing. Compos. Part B Eng. 2021, 223, 109122. [Google Scholar] [CrossRef]

- Yu, S.; Bale, H.; Park, S.; Hwang, J.Y.; Hong, S.H. Anisotropic microstructure dependent mechanical behavior of 3D-printed basalt fiber-reinforced thermoplastic composites. Compos. Part B Eng. 2021, 224, 109184. [Google Scholar] [CrossRef]

- Wright, W.J.; Koerner, H.; Rapking, D.; Abbott, A.; Celik, E. Rapid fiber alignment quantification in direct write printing of short fiber reinforced composites. Compos. Part B Eng. 2022, 236, 109814. [Google Scholar] [CrossRef]

- Yan, J.; Demirci, E.; Ganesan, A.; Gleadall, A. Extrusion width critically affects fibre orientation in short fibre reinforced material extrusion additive manufacturing. Addit. Manuf. 2022, 49, 102496. [Google Scholar] [CrossRef]

- Tekinalp, H.L.; Kunc, V.; Velez-Garcia, G.M.; Duty, C.E.; Love, L.J.; Naskar, A.K.; Blue, C.A.; Ozcan, S. Highly oriented carbon fiber–polymer composites via additive manufacturing. Compos. Sci. Technol. 2014, 105, 144–150. [Google Scholar] [CrossRef]

- Wang, Z.; Smith, D.E. Screw Swirling Effects on Fiber Orientation Distribution in Large-Scale Polymer Composite Additive Manufacturing; University of Texas at Austin: Austin, TX, USA, 2018. [Google Scholar] [CrossRef]

- Sayah, N.; Smith, D.E. Fiber and Void Property Correlation within Bead Microstructure of Large Area Additive Manufacturing Polymer Composites. Composites 2023, 13, 16. [Google Scholar]

- Wang, J.; Geng, C.; Luo, F.; Liu, Y.; Wang, K.; Fu, Q.; He, B. Shear induced fiber orientation, fiber breakage and matrix molecular orientation in long glass fiber reinforced polypropylene composites. Mater. Sci. Eng. A 2011, 528, 3169–3176. [Google Scholar] [CrossRef]

- Sosa-Rey, F.; Abderrafai, Y.; Lewis, A.D.; Therriault, D.; Piccirelli, N.; Lévesque, M. OpenFiberSeg: Open-source segmentation of individual fibers and porosity in tomographic scans of additively manufactured short fiber reinforced composites. Compos. Sci. Technol. 2022, 226, 109497. [Google Scholar] [CrossRef]

- Sun, X.; Mazur, M.; Cheng, C.-T. A review of void reduction strategies in material extrusion-based additive manufacturing. Addit. Manuf. 2023, 67, 103463. [Google Scholar] [CrossRef]

- Mehdikhani, M.; Gorbatikh, L.; Verpoest, I.; Lomov, S.V. Voids in fiber-reinforced polymer composites: A review on their formation, characteristics, and effects on mechanical performance. J. Compos. Mater. 2019, 53, 1579–1669. [Google Scholar] [CrossRef]

- Sayah, N.; Smith, D.E. Effect of the Print Bed Temperature on Void Distribution within the Microstructure of Short Carbon Fiber Reinforced/ABS Manufactured via Large Area Additive Manufacturing; University of Texas at Austin: Austin, TX, USA, 2023. [Google Scholar] [CrossRef]

- Sayah, N.; Smith, D.E. Effect of Process Parameters on Void Distribution, Volume Fraction, and Sphericity within the Bead Microstructure of Large-Area Additive Manufacturing Polymer Composites. Polymers 2022, 14, 5107. [Google Scholar] [CrossRef]

- Vaxman, A.; Narkis, M.; Siegmann, A.; Kenig, S. Void formation in short-fiber thermoplastic composites. Polym. Compos. 1989, 10, 449–453. [Google Scholar] [CrossRef]

- Awenlimobor, A.; Smith, D.E.; Wang, Z. Simulation of fiber-induced melt pressure fluctuations within large scale polymer composite deposition beads. Addit. Manuf. 2024, 80, 103980. [Google Scholar] [CrossRef]

- Sang, L.; Han, S.; Li, Z.; Yang, X.; Hou, W. Development of short basalt fiber reinforced polylactide composites and their feasible evaluation for 3D printing applications. Compos. Part B Eng. 2019, 164, 629–639. [Google Scholar] [CrossRef]

- Lin, L.; Ecke, N.; Huang, M.; Pei, X.-Q.; Schlarb, A.K. Impact of nanosilica on the friction and wear of a PEEK/CF composite coating manufactured by fused deposition modeling (FDM). Compos. Part B Eng. 2019, 177, 107428. [Google Scholar] [CrossRef]

- Kendall, K.; Howard, A.J.; Birchall, J.D.; Pratt, P.L.; Proctor, B.A.; Jefferis, S.A. The relation between porosity, microstructure and strength, and the approach to advanced cement-based materials. Philos. Trans. R. Soc. Lond. Ser. Math. Phys. Sci. 1997, 310, 139–153. [Google Scholar] [CrossRef]

- Hakim, I.A.; Donaldson, S.L.; Meyendorf, N.G.; Browning, C.E. Porosity Effects on Interlaminar Fracture Behavior in Carbon Fiber-Reinforced Polymer Composites. Mater. Sci. Appl. 2017, 8, 170–187. [Google Scholar] [CrossRef]

- Mattingly, F.L.; Franc, A.; Kunc, V.; Duty, C. Characterizing Internal Porosity of 3D-Printed Fiber Reinforced Materials; University of Texas at Austin: Austin, TX, USA, 2021. [Google Scholar] [CrossRef]

- Yudhanto, A.; Aldhirgham, A.; Feron, E.; Lubineau, G. Post-consolidation process for modifying microscale and mesoscale parameters of 3D printed composite materials. Front. Mater. 2023, 10, 1286840. [Google Scholar] [CrossRef]

- Nargis, R.A.; Jack, D.A. Fiber Orientation Quantification for Large Area Additively Manufactured Parts Using SEM Imaging. Polymers 2023, 15, 2871. [Google Scholar] [CrossRef]

- Sommacal, S.; Matschinski, A.; Drechsler, K.; Compston, P. Characterisation of void and fiber distribution in 3D printed carbon-fiber/PEEK using X-ray computed tomography. Compos. Part Appl. Sci. Manuf. 2021, 149, 106487. [Google Scholar] [CrossRef]

- Garcea, S.C.; Wang, Y.; Withers, P.J. X-ray computed tomography of polymer composites. Compos. Sci. Technol. 2018, 156, 305–319. [Google Scholar] [CrossRef]

- Dana, H.R.; Barbe, F.; Delbreilh, L.; Azzouna, M.B.; Guillet, A.; Breteau, T. Polymer additive manufacturing of ABS structure: Influence of printing direction on mechanical properties. J. Manuf. Process. 2019, 44, 288–298. [Google Scholar] [CrossRef]

- Mehdikhani, M.; Straumit, I.; Gorbatikh, L.; Lomov, S.V. Detailed characterization of voids in multidirectional carbon fiber/epoxy composite laminates using X-ray micro-computed tomography. Compos. Part Appl. Sci. Manuf. 2019, 125, 105532. [Google Scholar] [CrossRef]

- Diouf-Lewis, A.; Farahani, R.D.; Iervolino, F.; Pierre, J.; Abderrefaie, Y.; Lévesque, M.; Piccirelli, N.; Therriault, D. Design and characterization of carbon fiber-reinforced PEEK/PEI blends for Fused Filament Fabrication additive manufacturing. Mater. Today Commun. 2022, 31, 103445. [Google Scholar] [CrossRef]

- Yudhanto, A.; Lubineau, G.; Ventura, I.A.; Watanabe, N.; Iwahori, Y.; Hoshi, H. Damage characteristics in 3D stitched composites with various stitch parameters under in-plane tension. Compos. Part Appl. Sci. Manuf. 2015, 71, 17–31. [Google Scholar] [CrossRef]

- Stano, G.; Pavone, A.; Jafor, M.A.; Matalgah, K.; Percoco, G.; Fleck, T.J. Enhancing the sensitivity of 3D printed sensors via ironing and void reduction. Virtual Phys. Prototyp. 2024, 19, e2331153. [Google Scholar] [CrossRef]

- Russell, T.D. The Effects of Fiber Orientation on Stiffness and Thermal Expansion of Large Volume, Anisotropic, Short-Fiber, Composite Material Fabricated by Fused Filament Fabrication. Ph.D. Thesis, Baylor University, Waco, TX, USA, 2017. [Google Scholar]

- Available online: https://www.volumegraphics.com/_Resources/Persistent/9/5/2/f/952ffc933187f783dd8ba7beaac35c48191fcdbf/Brochure_VGSTUDIO_MAX_33_en.pdf (accessed on 26 June 2024).

- Shen, H.; Nutt, S.; Hull, D. Direct observation and measurement of fiber architecture in short fiber-polymer composite foam through micro-CT imaging. Compos. Sci. Technol. 2004, 64, 2113–2120. [Google Scholar] [CrossRef]

- Stano, G.; Sayah, N.; Smith, D.E.; Fleck, T.J. Effect of Process Parameters in Additively Manufactured Sensors prepared via Material Extrusion Processes: Correlation among Electrical, Mechanical and Microstructure Properties. Addit. Manuf. Lett. 2024, 9, 100194. [Google Scholar] [CrossRef]

- Available online: https://www.volumegraphics.com/en/products/vgsm/fiber-composite-material-analysis (accessed on 26 June 2024).

- Yang, D.; Zhang, H.; Wu, J.; McCarthy, E.D. Fibre flow and void formation in 3D printing of short-fibre reinforced thermoplastic composites: An experimental benchmark exercise. Addit. Manuf. 2021, 37, 101686. [Google Scholar] [CrossRef]

- Lopes, B.J.; d’Almeida, J.R.M. Initial development and characterization of carbon fiber reinforced ABS for future Additive Manufacturing applications. Mater. Today Proc. 2019, 8, 719–730. [Google Scholar] [CrossRef]

- Denos, B.R.; Sommer, D.E.; Favaloro, A.J.; Pipes, R.B.; Avery, W.B. Fiber orientation measurement from mesoscale CT scans of prepreg platelet molded composites. Compos. Part Appl. Sci. Manuf. 2018, 114, 241–249. [Google Scholar] [CrossRef]

- Wang, Z.; Smith, D.E. Numerical analysis of screw swirling effects on fiber orientation in large area additive manufacturing polymer composite deposition. Compos. Part B Eng. 2019, 177, 107284. [Google Scholar] [CrossRef]

- Heller, B.P.; Smith, D.E.; Jack, D.A. Planar deposition flow modeling of fiber filled composites in large area additive manufacturing. Addit. Manuf. 2019, 25, 227–238. [Google Scholar] [CrossRef]

- Cioica, N.; Coţa, C.; Nagy, M.; Ciutrilă, G. Thermoplastic Extrusion—A Method to Produce Starch-Based Loose Fill Packaging. Bull. Univ. Agric. Sci. Vet. Med. Cluj-Napoca Agric. 1970, 66, 2. [Google Scholar] [CrossRef]

- Wagner, A.; Yazici, R.; Kalyon, D.M. Extrudate swell behavior of glass fiber filled polyamide 6. Polym. Compos. 1996, 17, 840–849. [Google Scholar] [CrossRef]

- Lambert, J.; Chambers, A.R.; Sinclair, I.; Spearing, S.M. 3D damage characterisation and the role of voids in the fatigue of wind turbine blade materials. Compos. Sci. Technol. 2012, 72, 337–343. [Google Scholar] [CrossRef]

- Chambers, A.; Earl, J.; Squires, C.; Suhot, M. The effect of voids on the flexural fatigue performance of unidirectional carbon fibre composites developed for wind turbine applications. Int. J. Fatigue 2006, 28, 1389–1398. [Google Scholar] [CrossRef]

- Heller, B.P.; Smith, D.E.; Jack, D.A. Effects of extrudate swell and nozzle geometry on fiber orientation in Fused Filament Fabrication nozzle flow. Addit. Manuf. 2016, 12, 252–264. [Google Scholar] [CrossRef]

- Wang, Z.; Smith, D.E.; Jack, D.A. A statistical homogenization approach for incorporating fiber aspect ratio distribution in large area polymer composite deposition additive manufacturing property predictions. Addit. Manuf. 2021, 43, 102006. [Google Scholar] [CrossRef]

- Tagscherer, N.; Schromm, T.; Drechsler, K. Foundational Investigation on the Characterization of Porosity and Fiber Orientation Using XCT in Large-Scale Extrusion Additive Manufacturing. Materials 2022, 15, 2290. [Google Scholar] [CrossRef] [PubMed]

| Printing Process Parameters | Value |

|---|---|

| Temperature | 200 °C |

| Screw speed | 90 rpm |

| Nozzle translation speed | 240 cm/min |

| Mass flow rate | 1.04 g/s |

| Shear rate | |

| Nozzle diameter | 3.17 mm |

| Nozzle height | 1.2 mm |

| Roller height | 1.1 mm |

| Sample | x-Direction (mm) | y-Direction (mm) | z-Direction (mm) |

|---|---|---|---|

| Pellet | 3.98 | 3.40 | 1.50 |

| Single strand | 3.45 | 3.42 | 1.50 |

| Regular bead | 8.08 | 3.15 | 1.50 |

| Roller-printed bead | 8.26 | 2.36 | 1.50 |

| Stage | Sample | Void Volume Fraction (%) |

|---|---|---|

| (i) | Pellet | 7.8 |

| (ii) | Single strand | 14.0 |

| (iii) | Regular bead | 11.7 |

| (iv) | Roller-printed bead | 10.0 |

| Sample | Detected Void Shapes | |||

|---|---|---|---|---|

| Pellet |  = 0.35 |  = 0.35 |  = 0.55 |  = 0.79 |

| Single Strand |  = 0.16 |  = 0.35 |  = 0.55 |  = 0.75 |

| Regular Bead |  = 0.13 |  = 0.35 |  = 0.55 |  = 0.75 |

| Roller Printed Bead |  = 0.17 |  = 0.35 |  = 0.55 |  = 0.79 |

| ) | ||||

| ||||

| Decreasing void volume (V) | ||||

| Sample | |||

|---|---|---|---|

| Pellet (i) | 0.10 | 0.07 | 0.83 |

| Single strand (ii) | 0.17 | 0.17 | 0.66 |

| Regular bead (iii) | 0.18 | 0.10 | 0.72 |

| Roller-printed bead (iv) | 0.32 | 0.10 | 0.58 |

| Sample | x-Direction (mm) | y-Direction (mm) | z-Direction (mm) |

|---|---|---|---|

| Pellet | 0.66 | 0.57 | 1.50 |

| Single strand | 0.59 | 0.57 | 1.50 |

| Regular bead | 0.71 | 0.63 | 1.50 |

| Roller-printed bead | 0.68 | 0.50 | 1.50 |

| Sample | Microstructural Characteristic | Minimum | Maximum | Mean | Standard Deviation |

|---|---|---|---|---|---|

| Pellet | Void volume fraction | 5.11 | 10.63 | 7.76 | 1.76 |

| Fiber volume fraction | 7.13 | 8.49 | 8.09 | 0.38 | |

| Void sphericity | 0.53 | 0.68 | 0.61 | 0.04 | |

| 0.70 | 0.95 | 0.83 | 0.07 | ||

| Single strand | Void volume fraction | 9.86 | 19.05 | 13.91 | 2.92 |

| Fiber volume fraction | 6.98 | 8.75 | 8.07 | 0.53 | |

| Void sphericity | 0.51 | 0.71 | 0.61 | 0.06 | |

| 0.51 | 0.76 | 0.66 | 0.08 | ||

| Regular bead | Void volume fraction | 6.39 | 16.70 | 11.69 | 2.83 |

| Fiber volume fraction | 6.39 | 8.85 | 8.08 | 0.48 | |

| Void sphericity | 0.43 | 0.66 | 0.54 | 0.05 | |

| 0.54 | 0.86 | 0.72 | 0.07 | ||

| Roller-printed bead | Void volume fraction | 5.26 | 13.26 | 10.02 | 2.32 |

| Fiber volume fraction | 6.78 | 8.98 | 8.07 | 0.60 | |

| Void sphericity | 0.46 | 0.67 | 0.52 | 0.05 | |

| 0.38 | 0.88 | 0.58 | 0.15 |

| Sample | X | Y | m | b | |

|---|---|---|---|---|---|

| Pellet | Void volume fraction | Fiber volume fraction | −0.08 | 8.66 | 0.12 |

| Fiber volume fraction | Void sphericity | 0.03 | 0.34 | 0.12 | |

| Void volume fraction | Void sphericity | −0.02 | 0.73 | 0.59 | |

| Fiber volume fraction | 0.09 | 0.11 | 0.24 | ||

| Void volume fraction | −0.03 | 1.10 | 0.77 | ||

| Void sphericity | 1.43 | −0.04 | 0.60 | ||

| Single strand | Void volume fraction | Fiber volume fraction | −0.12 | 9.74 | 0.45 |

| Fiber volume fraction | Void sphericity | 0.05 | 0.19 | 0.16 | |

| Void volume fraction | Void sphericity | −0.02 | 0.85 | 0.51 | |

| Fiber volume fraction | 0.12 | −0.28 | 0.54 | ||

| Void volume fraction | −0.03 | 1.00 | 0.81 | ||

| Void sphericity | 0.79 | 0.17 | 0.42 | ||

| Regular bead | Void volume fraction | Fiber volume fraction | −0.06 | 8.80 | 0.14 |

| Fiber volume fraction | Void sphericity | 0.04 | 0.20 | 0.14 | |

| Void volume fraction | Void sphericity | −0.01 | 0.71 | 0.60 | |

| Fiber volume fraction | 0.07 | 0.14 | 0.24 | ||

| Void volume fraction | −0.02 | 0.95 | 0.63 | ||

| Void sphericity | 1.00 | 0.19 | 0.61 | ||

| Roller-printed bead | Void volume fraction | Fiber volume fraction | −0.04 | 8.48 | 0.03 |

| Fiber volume fraction | Void sphericity | 0.01 | 0.45 | 0.01 | |

| Void volume fraction | Void sphericity | −0.02 | 0.69 | 0.56 | |

| Fiber volume fraction | 0.05 | 0.16 | 0.03 | ||

| Void volume fraction | −0.06 | 1.17 | 0.81 | ||

| Void sphericity | 2.04 | −0.49 | 0.50 |

| Sample | X | Y | m | b | |

|---|---|---|---|---|---|

| All samples | Void volume fraction | Fiber volume fraction | −0.04 | 8.51 | 0.07 |

| Fiber volume fraction | Void sphericity | 0.03 | 0.32 | 0.05 | |

| Void volume fraction | Void sphericity | −0.01 | 0.65 | 0.17 | |

| Fiber volume fraction | 0.07 | 0.09 | 0.06 | ||

| Void volume fraction | −0.03 | 0.96 | 0.37 | ||

| Void sphericity | 1.34 | −0.07 | 0.40 | ||

| Roller-printed bead data is excluded | Void volume fraction | Fiber volume fraction | −0.04 | 8.55 | 0.11 |

| Fiber volume fraction | Void sphericity | 0.04 | 0.22 | 0.01 | |

| Void volume fraction | Void sphericity | −0.01 | 0.68 | 0.24 | |

| Fiber volume fraction | 0.09 | 0.01 | 0.16 | ||

| Void volume fraction | −0.03 | 1.02 | 0.83 | ||

| Void sphericity | 0.74 | −0.31 | 0.23 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sayah, N.; Smith, D.E. Correlation of Microstructural Features within Short Carbon Fiber/ABS Manufactured via Large-Area Additive- Manufacturing Beads. J. Compos. Sci. 2024, 8, 246. https://doi.org/10.3390/jcs8070246

Sayah N, Smith DE. Correlation of Microstructural Features within Short Carbon Fiber/ABS Manufactured via Large-Area Additive- Manufacturing Beads. Journal of Composites Science. 2024; 8(7):246. https://doi.org/10.3390/jcs8070246

Chicago/Turabian StyleSayah, Neshat, and Douglas E. Smith. 2024. "Correlation of Microstructural Features within Short Carbon Fiber/ABS Manufactured via Large-Area Additive- Manufacturing Beads" Journal of Composites Science 8, no. 7: 246. https://doi.org/10.3390/jcs8070246

APA StyleSayah, N., & Smith, D. E. (2024). Correlation of Microstructural Features within Short Carbon Fiber/ABS Manufactured via Large-Area Additive- Manufacturing Beads. Journal of Composites Science, 8(7), 246. https://doi.org/10.3390/jcs8070246