Impermeability, Strength and Microstructure of Concrete Modified by Nano-Silica and Expansive Agent

Abstract

:1. Introduction

2. Experimental Program

2.1. Raw Materials

2.2. Experimental Design

2.3. Testing Methods

3. Experimental Results and Analysis

3.1. Workability

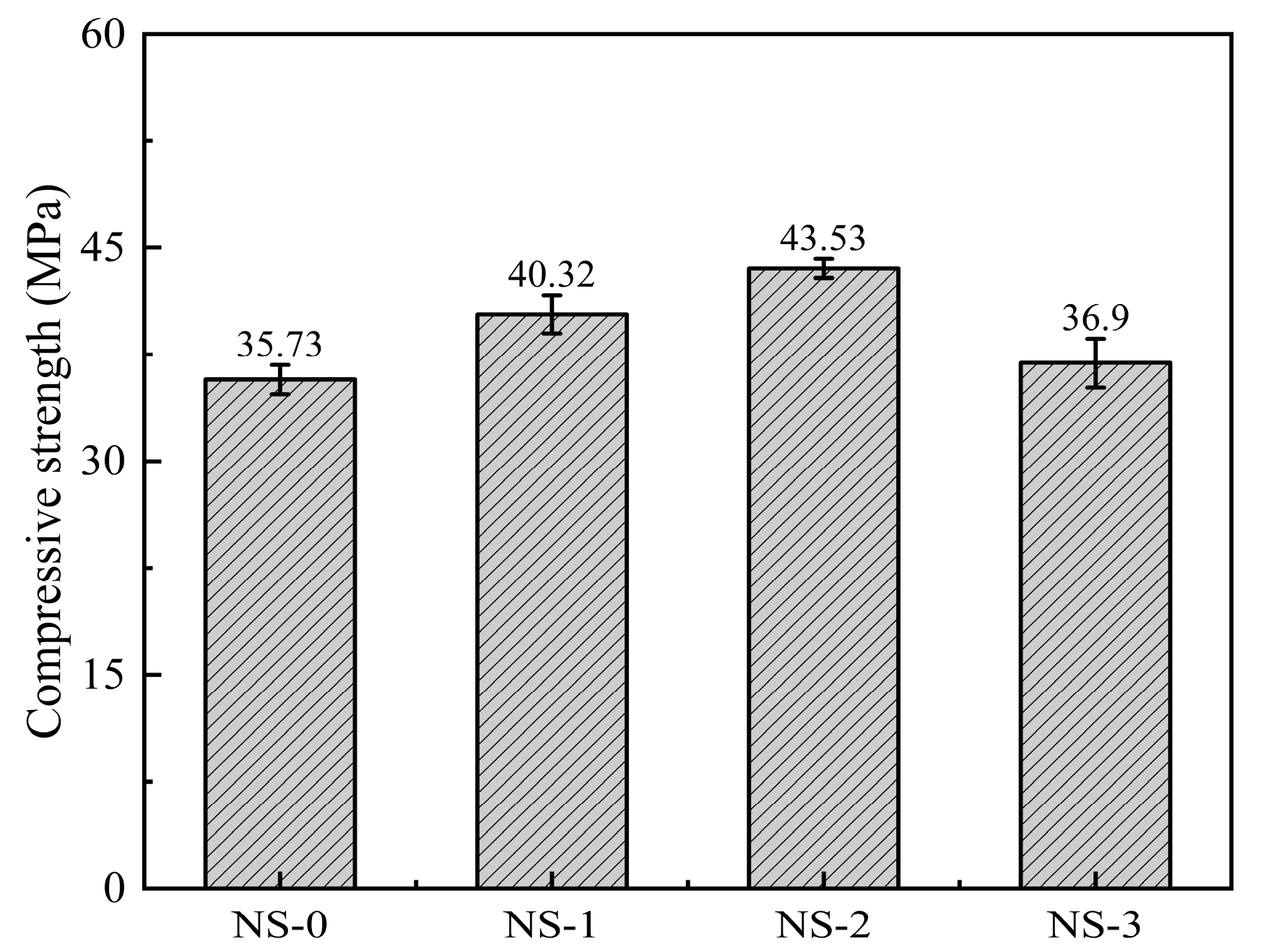

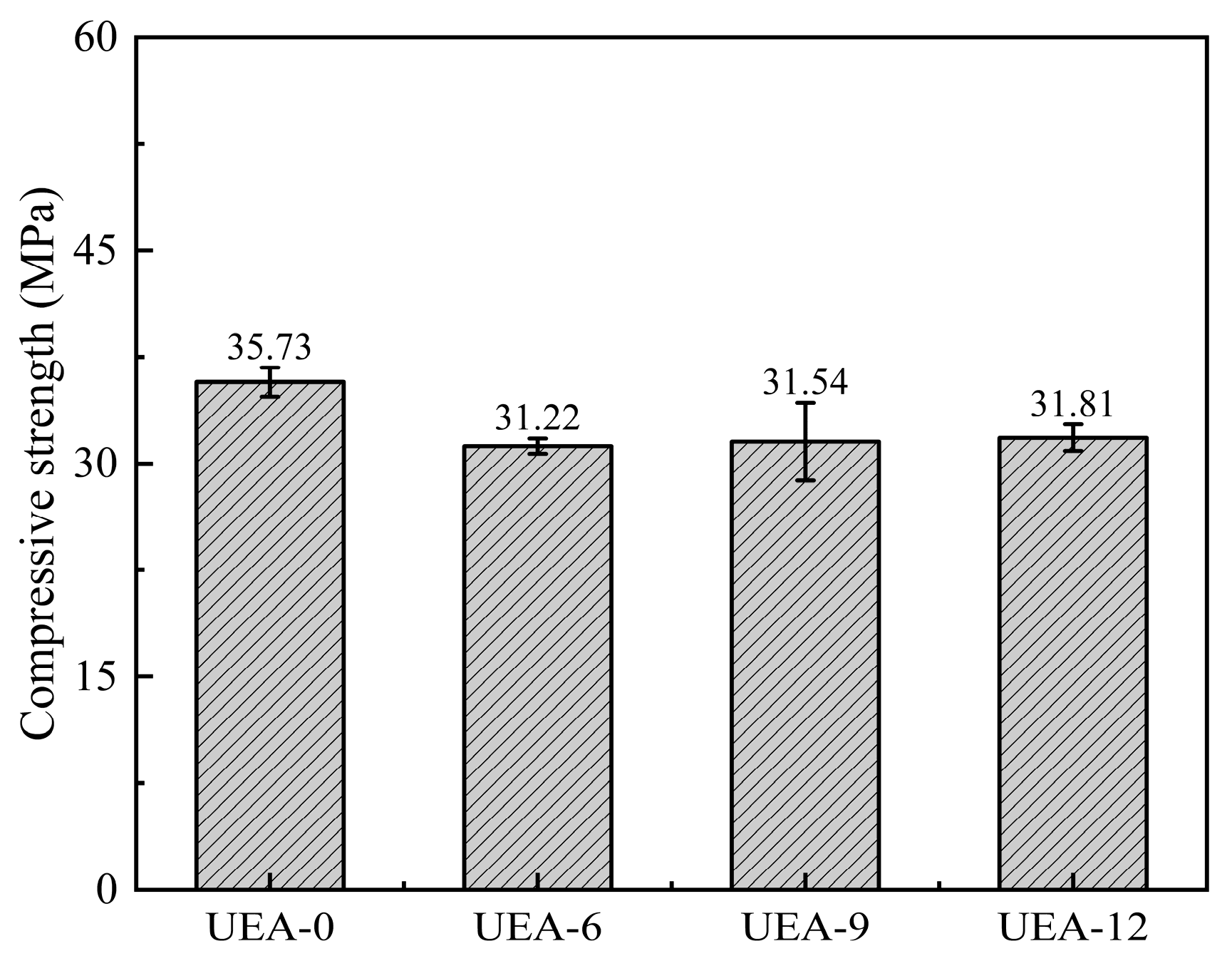

3.2. Compressive Strength

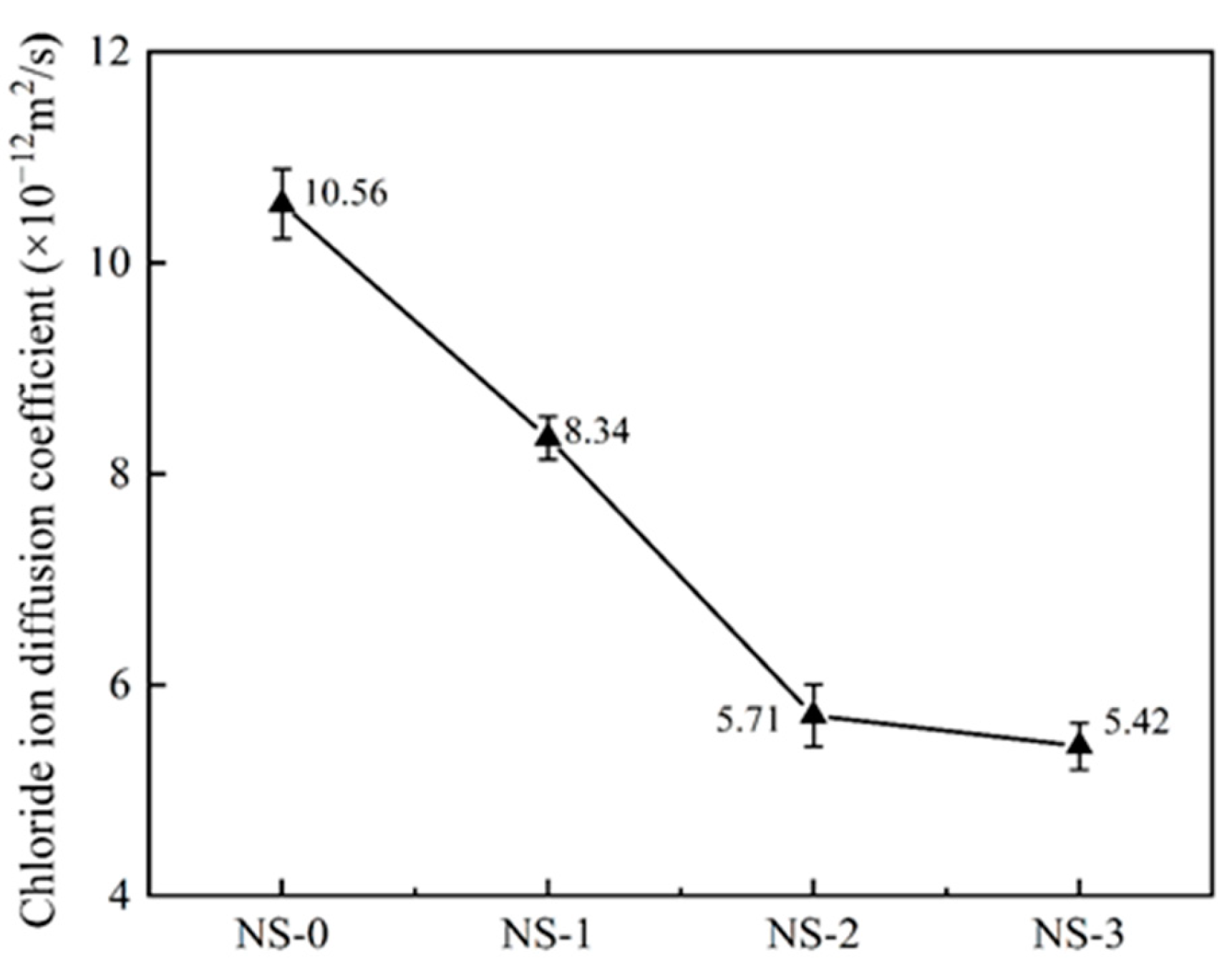

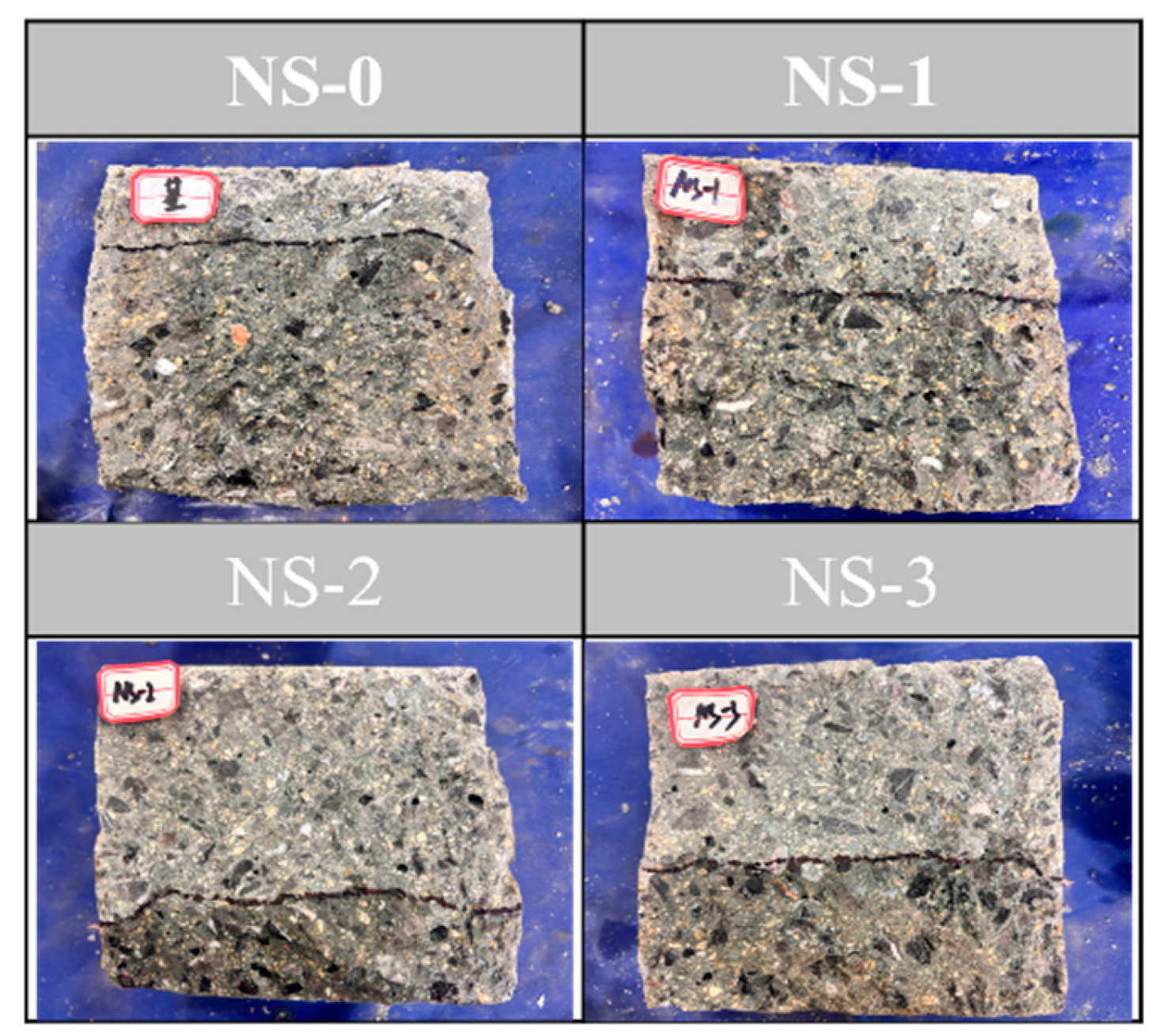

3.3. Chloride Ion Penetration Resistance

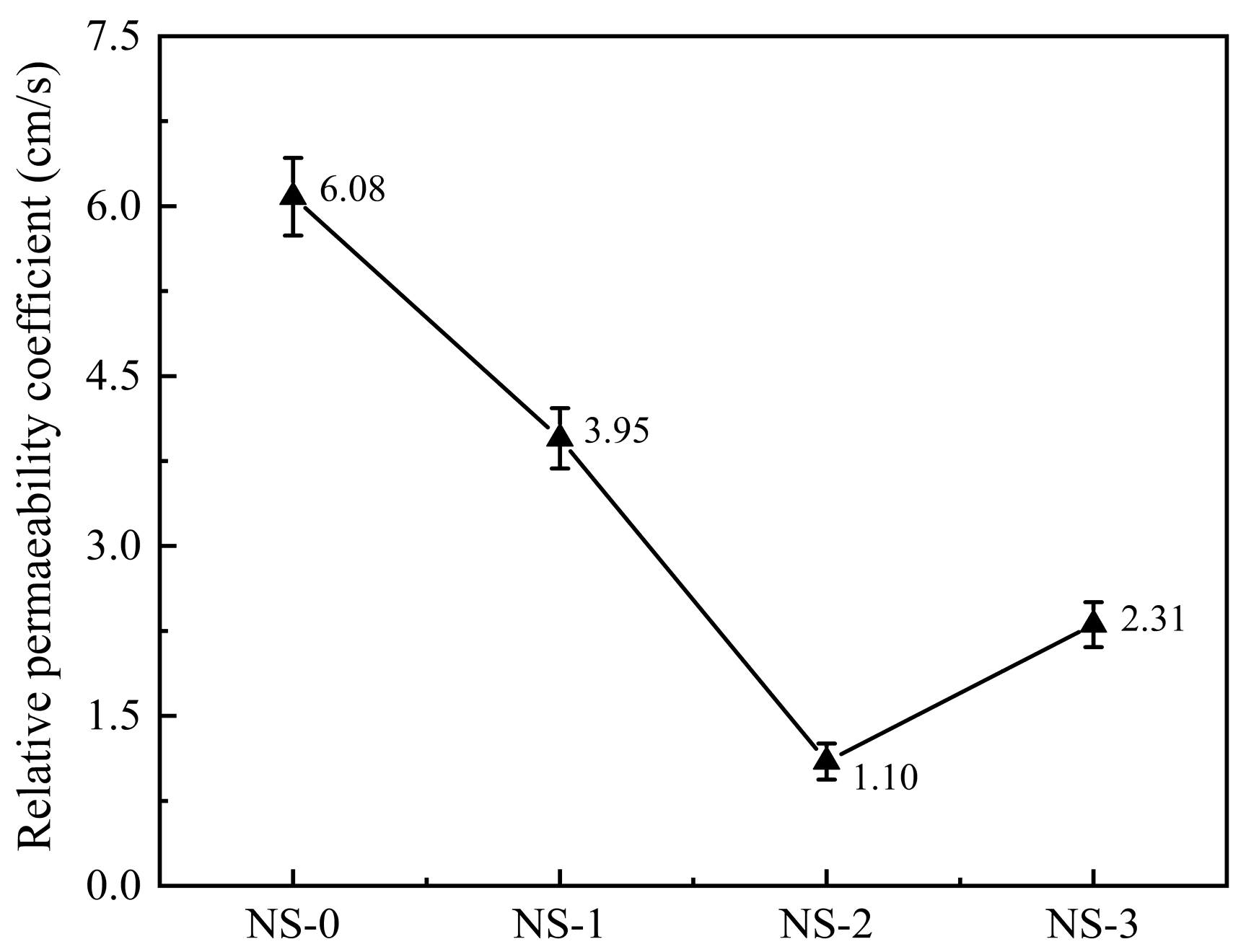

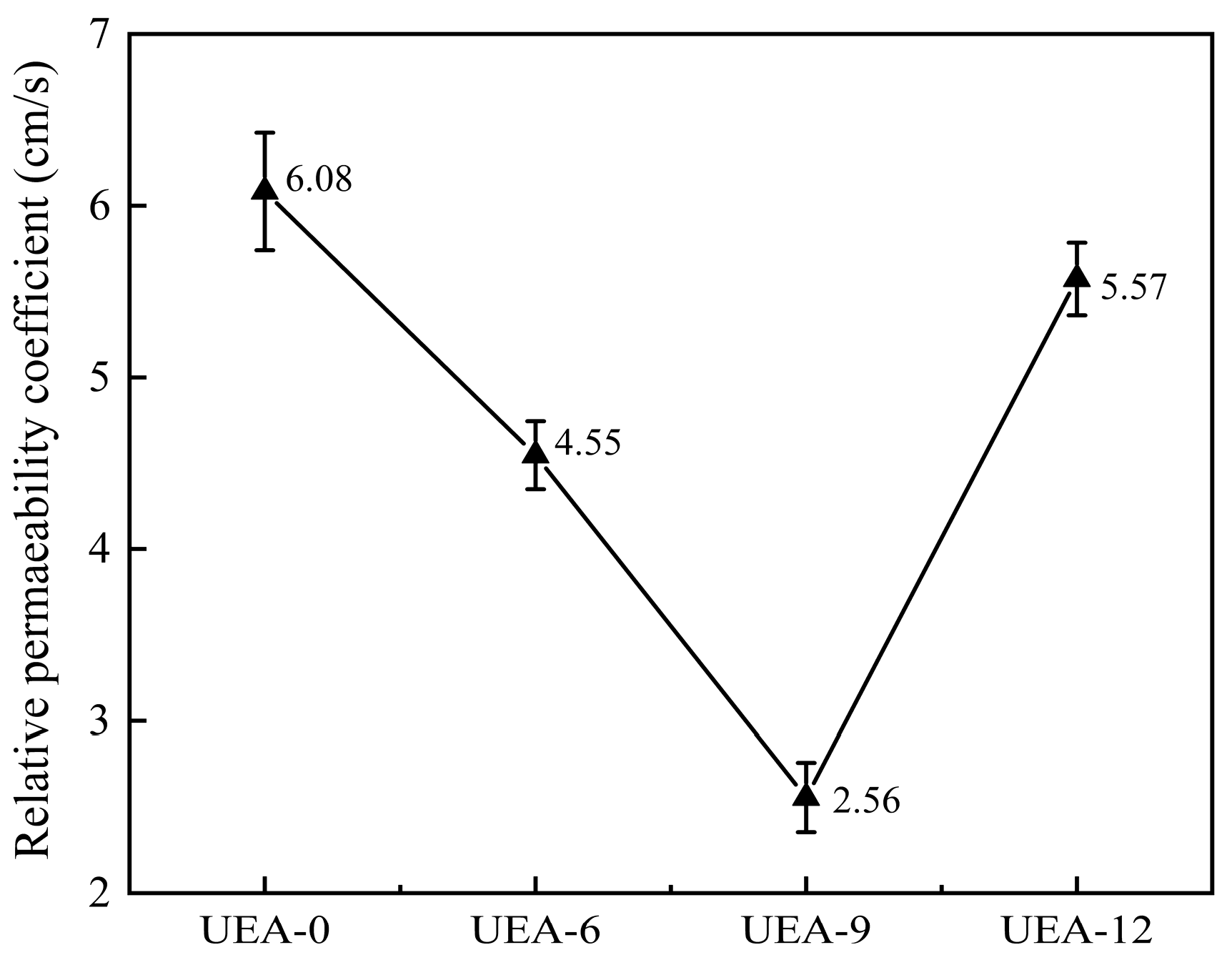

3.4. Water Permeability Resistance

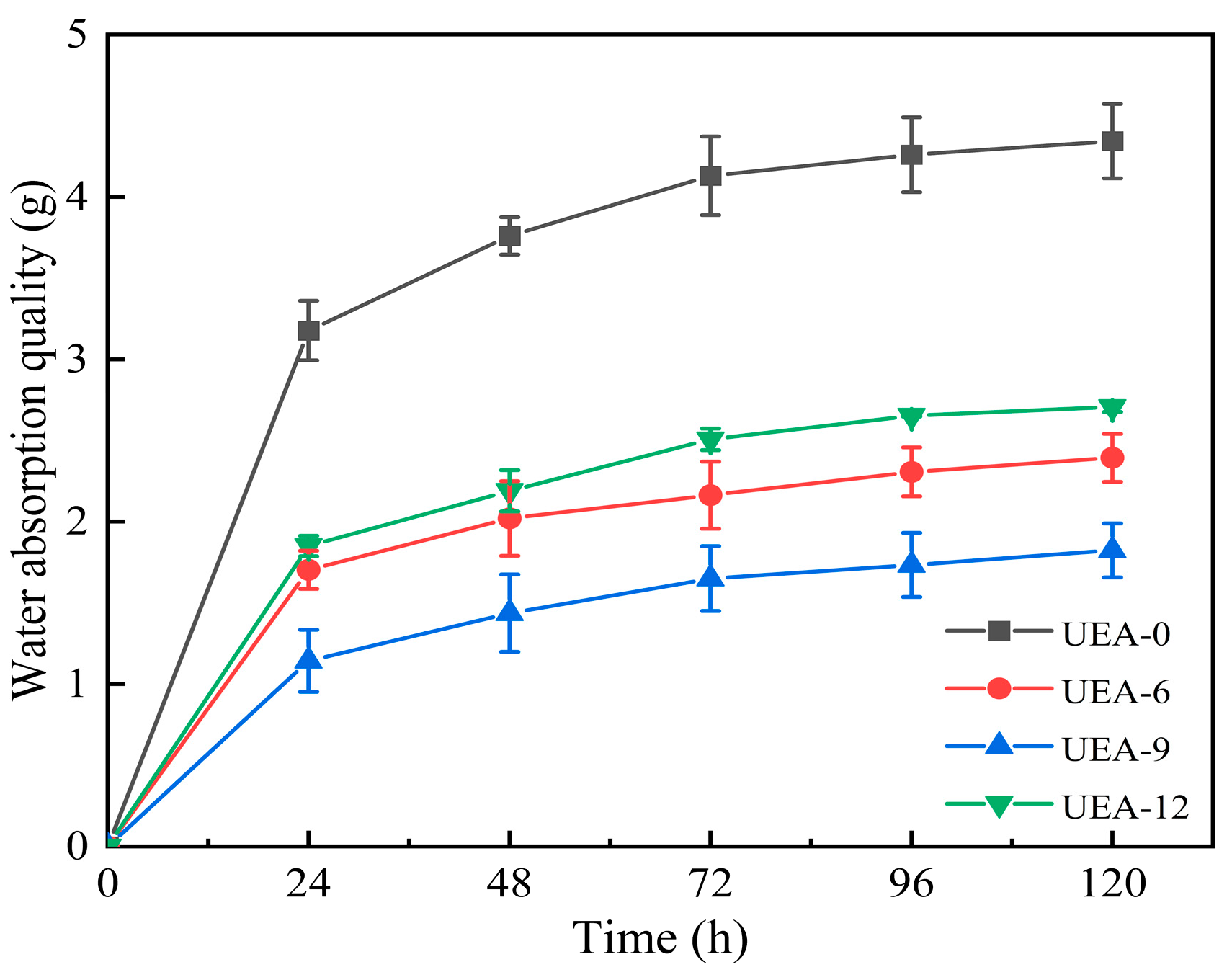

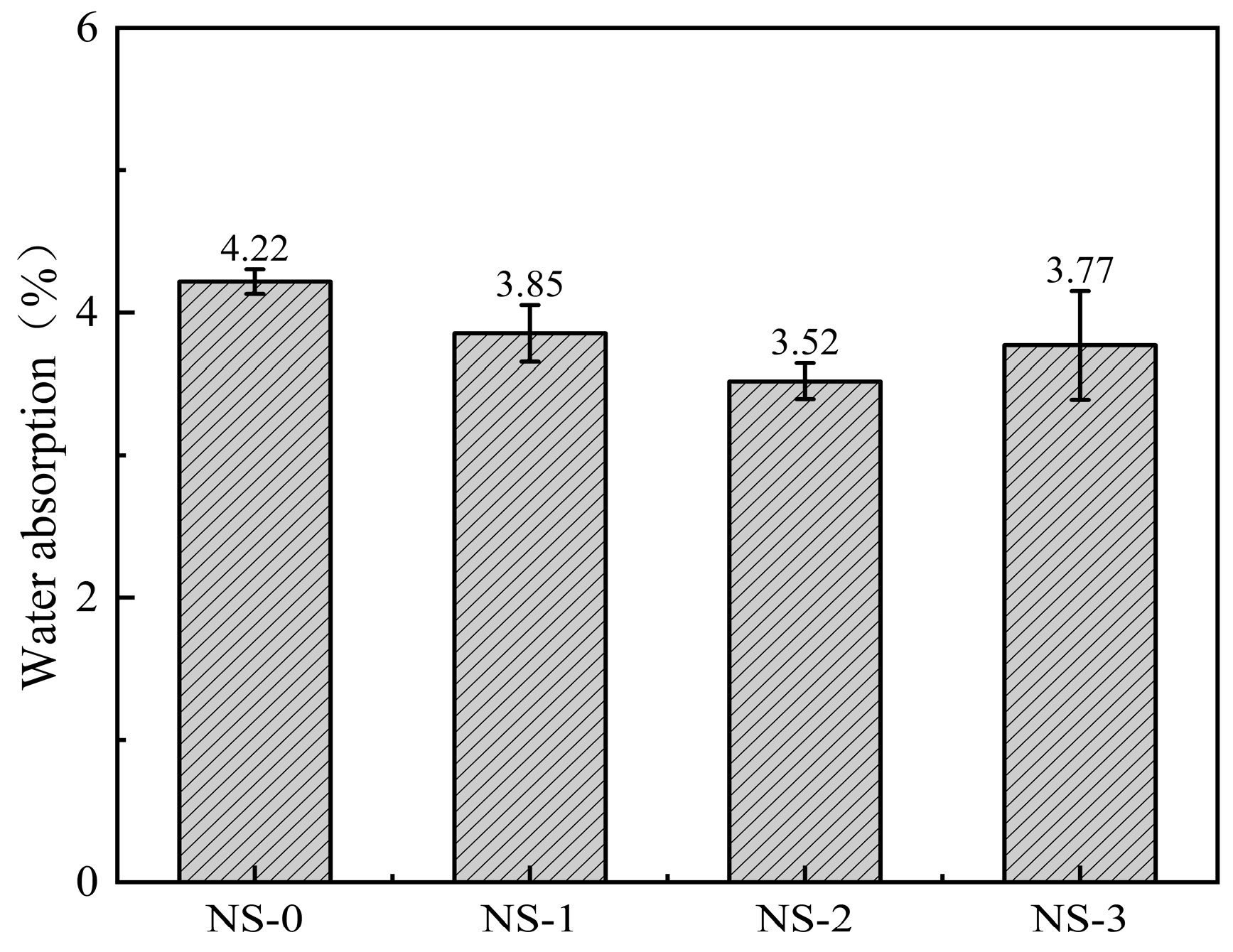

3.5. Water Absorption Performance

3.6. XRD Analysis

3.7. Microstructure Analysis

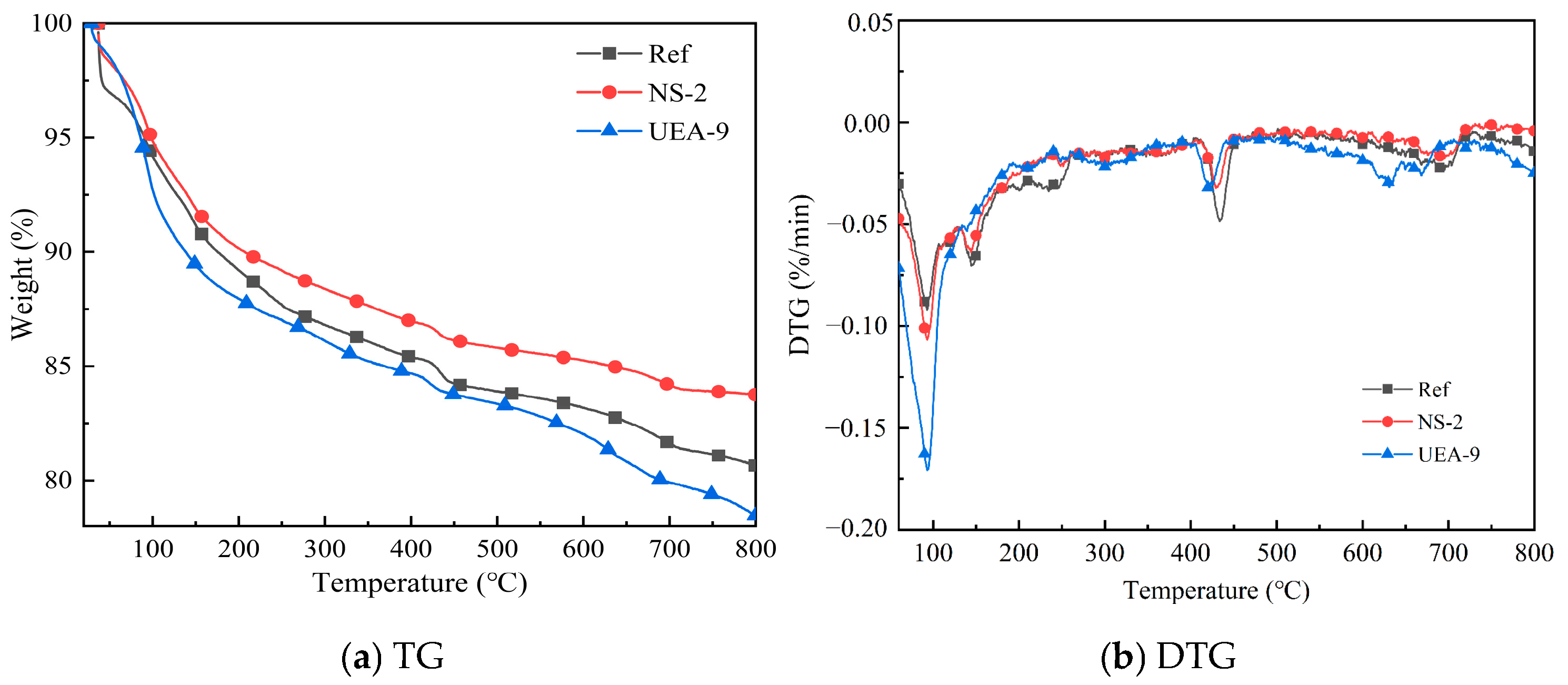

3.8. TG-DTG Analysis

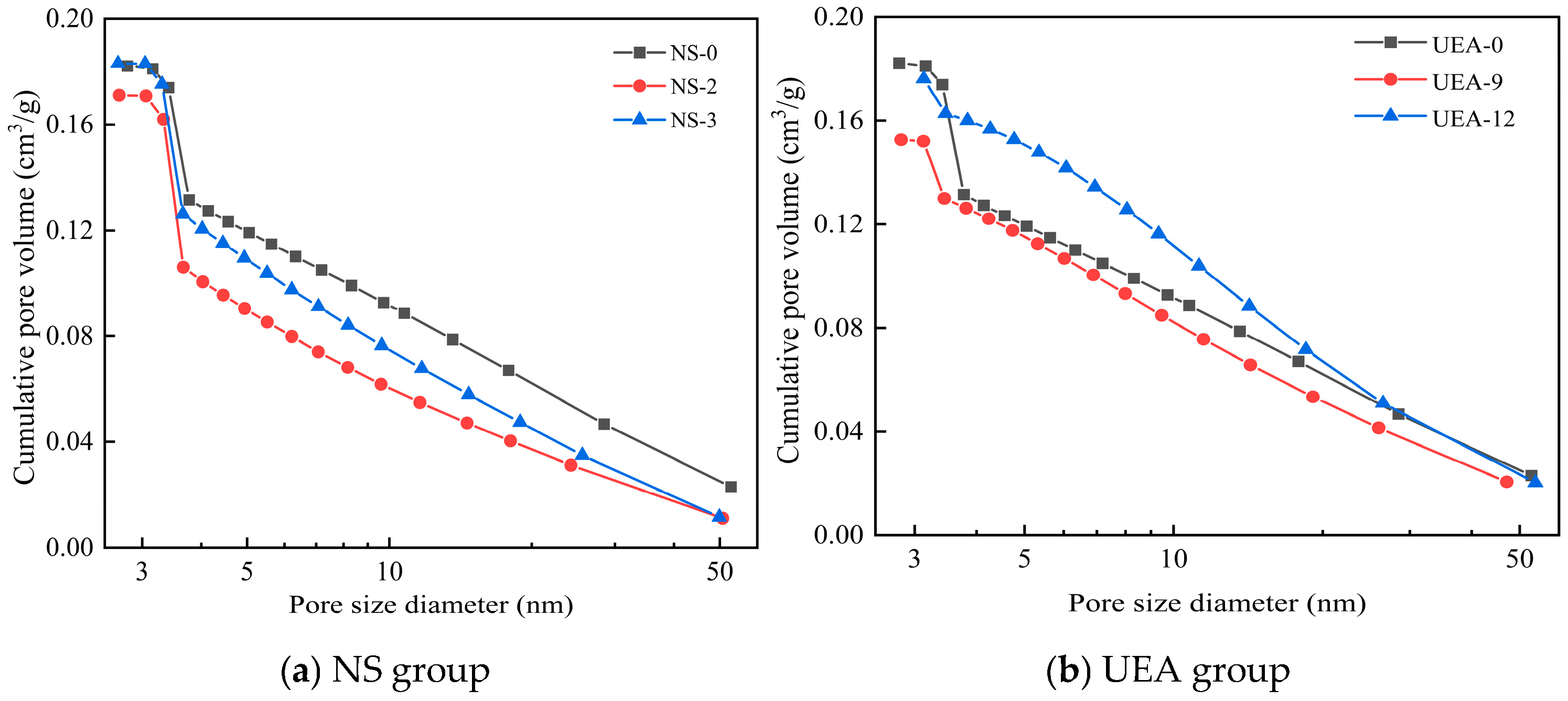

3.9. Pore Structure Analysis

4. Conclusions

- (1)

- The addition of NS can improve the 28 d compressive strength, water permeability, water absorption, and chloride ion permeability of concrete. The strength of concrete specimens with 2% NS shows a 21.9% increase in strength, a 21.0% reduction in the chloride ion permeability coefficient, a 35.0% decrease in the relative permeability coefficient, and an 8.8% uction in water absorption. A higher dosage of NS can lead to agglomeration, resulting in degraded performance. Considering both mechanical properties and impermeability, it is recommended that the suitable dosage of NS is 2%.

- (2)

- NS exhibits excellent pozzolanic activity, reacting with the primary hydration product Ca(OH)2 to form C-S-H gel. The physical filling effect and secondary hydration reaction of NS significantly refine the pore structure of the concrete, improving both its mechanical and impermeability properties. According to the TG test results, the addition of NS enhances the thermal stability of concrete.

- (3)

- The addition of an expansive agent reduces the 28-day compressive strength of concrete; however, an appropriate amount of expansive agent can improve the concrete’s resistance to water and chloride ion penetration as well as reduce its water absorption. When the UEA expansive agent content is 9%, the concrete’s relative permeability coefficient, chloride ion permeability coefficient, and water absorption improve by 58%, 11%, and 20%, respectively.

- (4)

- The UEA expansive agent reacts with Ca(OH)2 to form AFt, which reduces the porosity of the concrete matrix. However, when the dosage of the expansive agent is too high, excessive volume expansion results in numerous microcracks, increasing the porosity and deteriorating the concrete’s performance. To ensure that concrete retains excellent properties after the addition of UEA expansive agent, the dosage should not exceed 9%.

- (5)

- The addition of appropriate contents of NS and UEA in concrete could improve the impermeability, strength, and microstructure. NS at 2% or UEA at 9% is suggested for an impermeability-enhanced concrete application.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Monticelli, C.; Frignani, A.; Trabanelli, G. A study on corrosion inhibitors for concrete application. Cem. Concr. Compos. 2000, 30, 635–642. [Google Scholar] [CrossRef]

- Chica, L.; Alzate, A. Cellular concrete review: New trends for application in construction. Constr. Build. Mater. 2019, 200, 637–647. [Google Scholar] [CrossRef]

- Meng, X.; Feng, Q.; Zhang, Y.; Qiao, H.; Xie, X. Analysis of corrosion-induced deterioration behavior and competing failure of reinforced concrete in saline soil environment. Mater. Rep. 2023, 37, 40–49. [Google Scholar] [CrossRef]

- Rathore, P.; Verma, S.K. Carbonation based deterioration of concrete structures and effect of carbonation curing. Int. J. Struct. Eng. 2023, 13, 279–300. [Google Scholar] [CrossRef]

- Yamin, A.; Ahmet, R.; Oğuz, B.; Düzgün, A. Concrete deterioration effects on dynamic behavior of gravity dam-reservoir interaction problems. J. Vib. Eng. Technol. 2024, 12, 259–278. [Google Scholar] [CrossRef]

- Luo, D.; Li, F.; Niu, D. Study on the deterioration of concrete performance in saline soil area under the combined effect of high low temperatures, chloride and sulfate salts. Cem. Concr. Compos. 2024, 150, 105531. [Google Scholar] [CrossRef]

- Cao, Q.; Gao, Q.; Gao, R.; Jia, J. Chloride penetration resistance and frost resistance of fiber reinforced expansive self-consolidating concrete. Constr. Build. Mater. 2018, 158, 719–727. [Google Scholar] [CrossRef]

- Zhang, D.; Shao, Y. Effect of early carbonation curing on chloride penetration and weathering carbonation in concrete. Constr. Build. Mater. 2016, 123, 516–526. [Google Scholar] [CrossRef]

- Lu, S.; Wang, M.; He, P.; Sun, X.; Wang, X.; Tang, D. Effect of sodium methyl-silicate on the performance and structure of geopolymer. Mater. Lett. 2023, 350, 134893. [Google Scholar] [CrossRef]

- Kansotiya, M.; Chaturvedy, G.K.; Pandey, U.K. Influence of nano silica and crumb rubber on the physical and durability characteristics of concrete. Multiscale Multidiscip. Model. Exp. Des. 2024, 7, 2877–2892. [Google Scholar] [CrossRef]

- Ghafari, E.; Arezoumandi, M.; Costa, H.; Júlio, E. Influence of nano-silica addition on durability of UHPC. Constr. Build. Mater. 2015, 94, 181–188. [Google Scholar] [CrossRef]

- Wang, Q.; Ren, Z.; Zhang, Z. Study on the delayed ettringite formation in massive shrinkage compensating concrete with U-type expansive agent. Key Eng. Mater. 2011, 477, 340–347. [Google Scholar] [CrossRef]

- Jalal, M.; Pouladkhan, A.R.; Ramezanianpour, A.A.; Norouzi, H. Effects of silica nanopowder and silica fume on rheology and strength of high strength self compacting concrete. J. Am. Sci. 2012, 8, 270–277. [Google Scholar]

- Said, A.M.; Zeidan, M.S.; Bassuoni, M.T.; Tian, Y. Properties of concrete incorporating nano-silica. Constr. Build. Mater. 2012, 36, 838–844. [Google Scholar] [CrossRef]

- Mohammed, B.S.; Adamu, M. Mechanical performance of roller compacted concrete pavement containing crumb rubber and nano silica. Constr. Build. Mater. 2018, 159, 234–251. [Google Scholar] [CrossRef]

- Guo, J.; Zhang, S.; Guo, T.; Zhang, P. Effects of UEA and MgO expansive agents on fracture properties of concrete. Constr. Build. Mater. 2020, 263, 120245. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, J.; Xiao, W.; Wang, Q.; Shao, F. Experimental study on the effect of expansive agent on the durability of concrete in civil air defense engineering. Adv. Mater. Sci. Eng. 2021, 2021, 1–7. [Google Scholar] [CrossRef]

- GB/T18046-2017; Granulated blast furnace slag powder for use in cement, mortar and concrete. Standards Press of China: Beijing, China, 2018. (In Chinese)

- GB/T50080-2016; Standard for Performance Test Method of Ordinary Concrete Mixture. China Architecture and Building Press: Beijing, China, 2017. (In Chinese)

- GB/T50081-2019; Standard for Test Method of Mechanical Properties on Ordinary Concrete. China Architecture and Building Press: Beijing, China, 2019. (In Chinese)

- GB/T50082-2009; Standard for Test Methods for Long-Term Performance and Durability of Ordinary Concrete. China Architecture and Building Press: Beijing, China, 2010. (In Chinese)

- Mahmood, A.; Kaish, A.B.M.A.; Raman, S.N.; Jamil, M.; Hamid, R. Effects of different expansive agents on the properties of expansive cementitious materials. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1200, 012002. [Google Scholar] [CrossRef]

- Khan, K.; Ahmad, W.; Amin, M.N.; Nazar, S. Nano-silica-modified concrete: A bibliographic analysis and comprehensive review of material properties. Nanomaterials 2022, 12, 1989. [Google Scholar] [CrossRef]

- Aggarwal, P.; Singh, R.P.; Aggarwal, Y. Use of nano-silica in cement-based materials—A review. Cogent Eng. 2015, 2, 1078018. [Google Scholar] [CrossRef]

- Materak, K.; Wieczorek, A.; Bednarska, D.; Cha, K.; Ma, M.; Buczkowski, A.; Koniorczyk, M. Novel application of potassium methylsiliconate in cement-based materials: Retarding of hydration process and improvement of compressive strength. Constr. Build. Mater. 2023, 406, 133400. [Google Scholar] [CrossRef]

- Gao, P.; Geng, F.; Lu, X. Hydration and expansion properties of novel concrete expansive agent. Key Eng. Mater. 2009, 406, 267–271. [Google Scholar] [CrossRef]

- Chen, X.; Chen, Y. Experimental study on damage identification of nano-SiO2 concrete filled GFRP tube column using piezo-ceramic transducers. Sensors 2020, 20, 2883. [Google Scholar] [CrossRef] [PubMed]

- Gao, J.; Li, S.C.; Zhang, W.F.; Geng, Y.J.; Xiao, Q.L.; Hou, D.S. Effect of isobutyltriethoxysilane composite latex on waterproofing properties of foam concrete. Paint Coat. Ind. 2020, 50, 2–7. [Google Scholar] [CrossRef]

- Li, P.P.; Brouwers, H.J.H.; Chen, W.; Yu, Q. Optimization and characterization of high-volume limestone powder in sustainable ultra-high performance concrete. Constr. Build. Mater. 2020, 242, 118112. [Google Scholar] [CrossRef]

| CaO | SiO2 | Al2O3 | Fe2O3 | MgO | R2O | SO3 | Loss |

|---|---|---|---|---|---|---|---|

| 57.74 | 24.56 | 6.35 | 3.97 | 3.52 | 0.34 | 2.15 | 1.37 |

| SiO2/% | Na2O/% | Specific Gravity | Viscosity | pH | Mean Diameter/(nm) |

|---|---|---|---|---|---|

| 29.70 | 0.12 | 1.192 | 3.39 | 7.45 | 14.7 |

| No. | Cement | Slag | Fly Ash | NS | UEA | Sand | Aggregate | Water | Superplasticizer |

|---|---|---|---|---|---|---|---|---|---|

| Ref (NS-0/UEA-0) | 190 | 80 | 70 | 0 | 0 | 800 | 1054 | 170 | 1.7 |

| NS-1 | 190 | 80 | 70 | 3.4 | 0 | 800 | 1054 | 170 | 1.7 |

| NS-2 | 190 | 80 | 70 | 6.8 | 0 | 800 | 1054 | 170 | 1.7 |

| NS-3 | 190 | 80 | 70 | 10.2 | 0 | 800 | 1054 | 170 | 1.7 |

| UEA-6 | 190 | 80 | 70 | 0 | 20.4 | 800 | 1054 | 170 | 1.7 |

| UEA-9 | 190 | 80 | 70 | 0 | 30.6 | 800 | 1054 | 170 | 1.7 |

| UEA-12 | 190 | 80 | 70 | 0 | 40.8 | 800 | 1054 | 170 | 1.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, P.; Abbas, M.A.A.M.; Ran, X.; Li, P. Impermeability, Strength and Microstructure of Concrete Modified by Nano-Silica and Expansive Agent. J. Compos. Sci. 2025, 9, 108. https://doi.org/10.3390/jcs9030108

Zeng P, Abbas MAAM, Ran X, Li P. Impermeability, Strength and Microstructure of Concrete Modified by Nano-Silica and Expansive Agent. Journal of Composites Science. 2025; 9(3):108. https://doi.org/10.3390/jcs9030108

Chicago/Turabian StyleZeng, Pinmo, Mohammed A. A. M. Abbas, Xinyi Ran, and Peipeng Li. 2025. "Impermeability, Strength and Microstructure of Concrete Modified by Nano-Silica and Expansive Agent" Journal of Composites Science 9, no. 3: 108. https://doi.org/10.3390/jcs9030108

APA StyleZeng, P., Abbas, M. A. A. M., Ran, X., & Li, P. (2025). Impermeability, Strength and Microstructure of Concrete Modified by Nano-Silica and Expansive Agent. Journal of Composites Science, 9(3), 108. https://doi.org/10.3390/jcs9030108