Toward Eco-Friendly Rubber: Utilizing Paper Waste-Derived Calcium Carbonate to Replace Carbon Black in Natural Rubber Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Compounding and Mixing

2.3. Filler Characterization

2.3.1. Brunauer–Emmett–Teller (BET) Surface Area Measurement

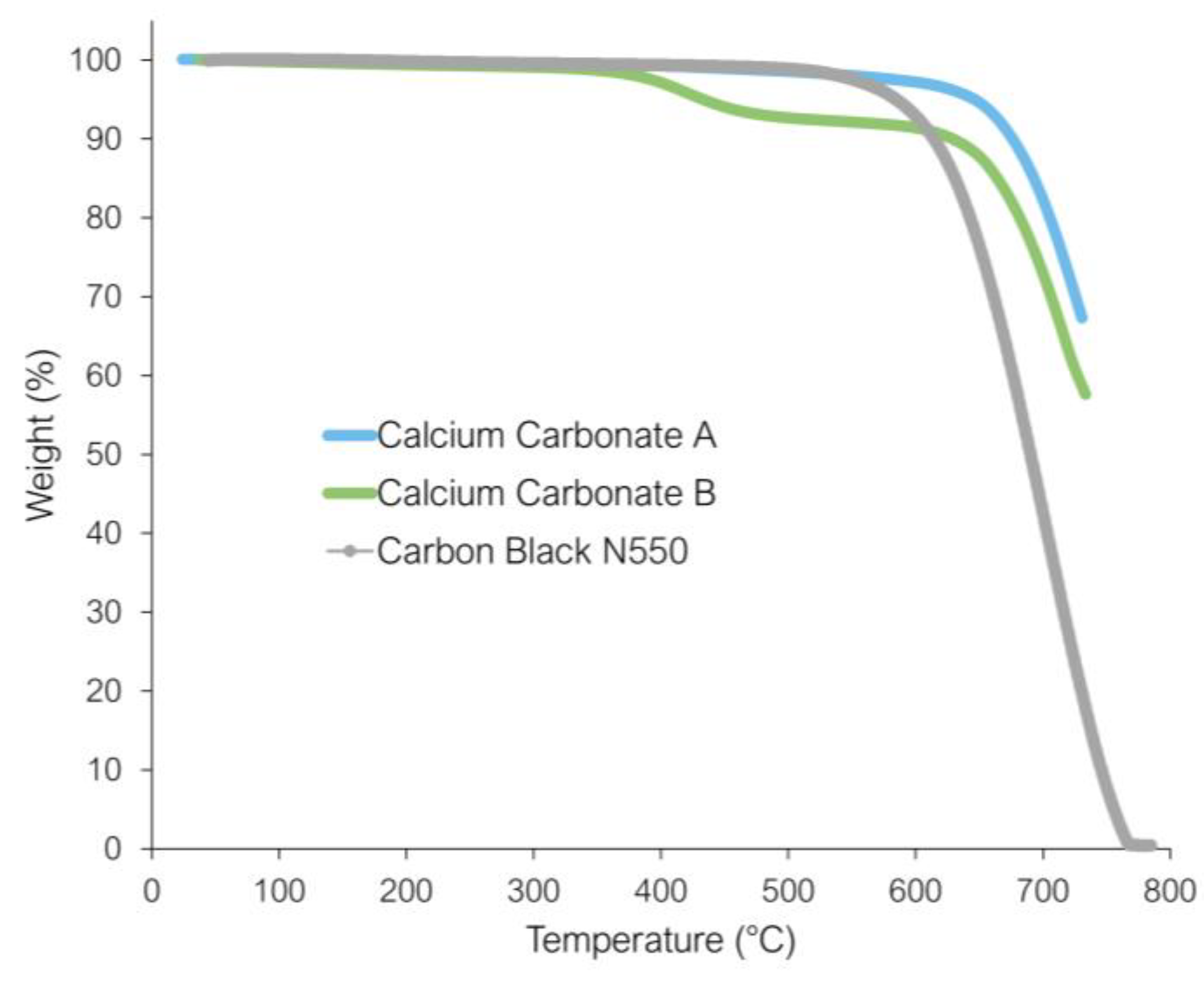

2.3.2. Thermogravimetric Analysis (TGA)

2.4. In-Rubber Tests

2.4.1. Mooney Viscosity

2.4.2. Cure Behavior

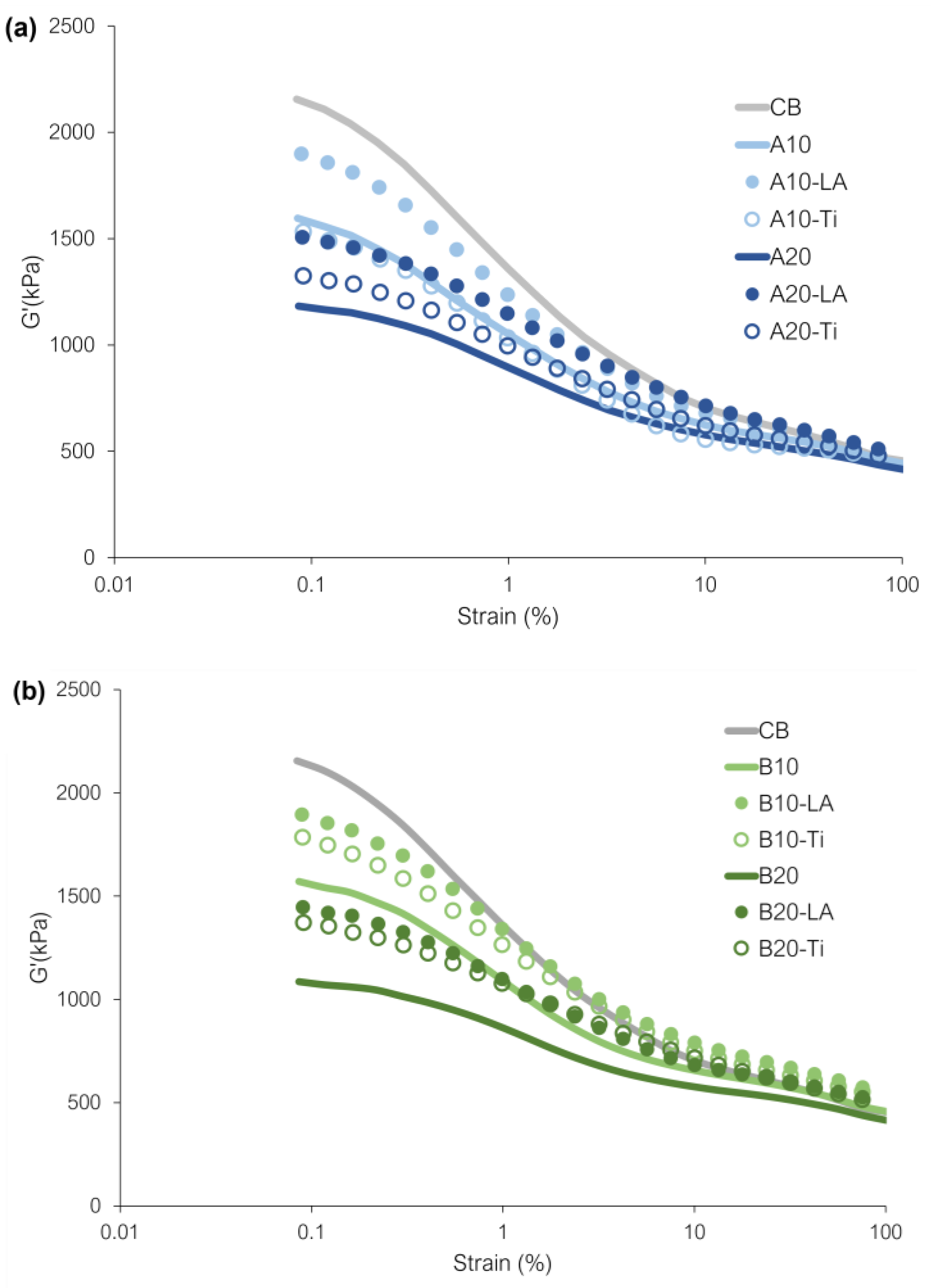

2.4.3. Payne Effect

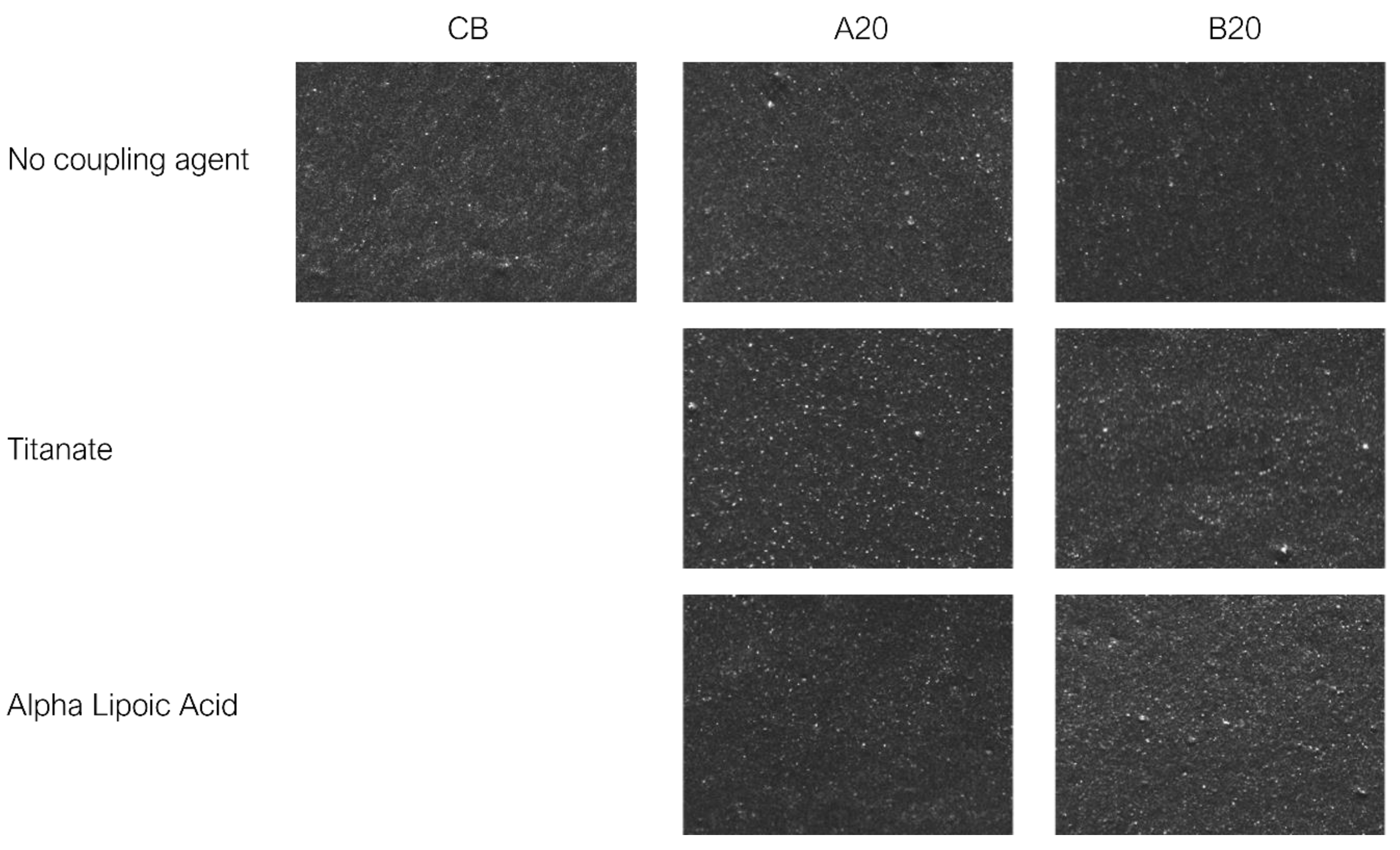

2.4.4. Macro-Dispersion

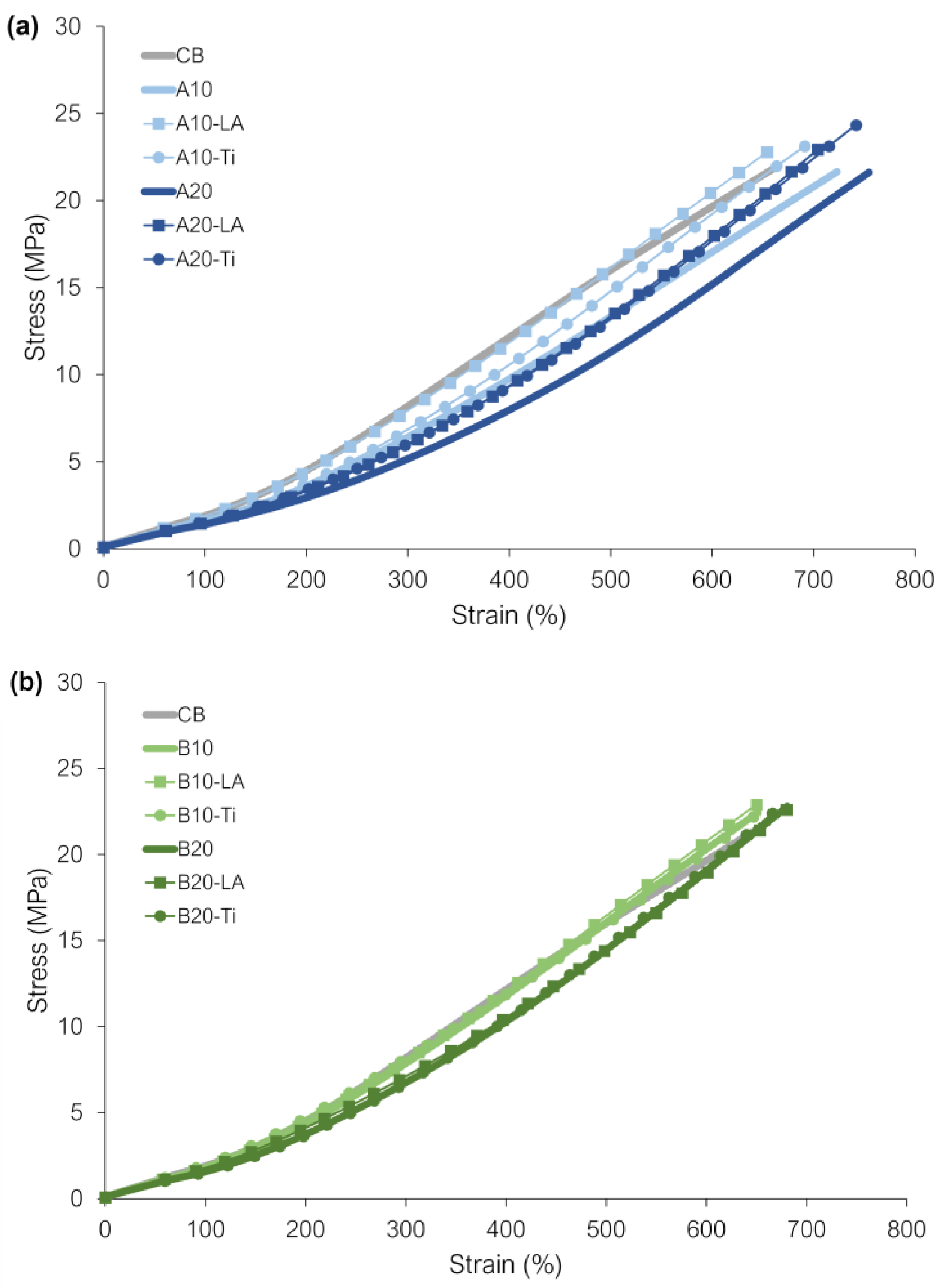

2.4.5. Tensile Behavior

3. Results and Discussion

3.1. BET Analysis

3.2. Thermogravimetric Analysis (TGA)

3.3. Mooney Viscosity

3.4. Cure Behavior

3.5. Payne Effect

3.6. Macro-Dispersion

3.7. Tensile Test

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Du, J.; Xu, Y.; Wang, Y. How to improve sustainability for industrial sectors: Optimizing production scales based on performance-oriented resource reallocation. Energy Econ. 2023, 119, 106525. [Google Scholar] [CrossRef]

- Fan, Y.; Fowler, G.D.; Zhao, M. The Past, Present and Future of Carbon Black as A Rubber Reinforcing Filler—A Review. J. Clean. Prod. 2019, 247, 119115. [Google Scholar] [CrossRef]

- Chang, B.P.P.; Gupta, A.; Muthuraj, R.; Mekonnen, T.H. Bioresourced fillers for rubber composite sustainability: Current development and future opportunities. Green Chem. 2021, 23, 5337–5378. [Google Scholar] [CrossRef]

- Mohamed, N.R.; Othman, N.; Shuib, R.K.; Hayeemasae, N. Perspective on opportunities of bio-based processing oil to rubber industry: A short review. Iran. Polym. J. 2023, 32, 1455–1475. [Google Scholar] [CrossRef]

- Azhar, N.N.H.; Ang, D.T.-C.; Abdullah, R.; Harikrishna, J.A.; Cheng, A. Bio-Based Materials Riding the Wave of Sustainability: Common Misconceptions, Opportunities, Challenges and the Way Forward. Sustainability 2022, 14, 5032. [Google Scholar] [CrossRef]

- Sae-Oui, P.; Sirisinha, C.; Thaptong, P. Utilization of limestone dust waste as filler in natural rubber. J. Mater. Cycles Waste Manag. 2009, 11, 166–171. [Google Scholar] [CrossRef]

- Prochoń, M.; Sawicki, J.; Reda, M.; Sirek, P.; Suwalska, M.; Werstak, B. Shot blasting dust as a filler in elastomer composites. J. Elastomers Plast. 2021, 53, 1105–1127. [Google Scholar] [CrossRef]

- Hussain, A.I.; El-Sabbagh, S.H.; Abadir, I.F. Cement Dust as Filler in NBR Vulcanizates. J. Elastomers Plast. 2003, 35, 161–179. [Google Scholar] [CrossRef]

- Delgado, E.; Espitia, A.; Aperador, W. Comparative evaluation of Clusia multiflora wood flour, against mineral fillers, as reinforcement in SBR rubber composites. Iran. Polym. J. 2020, 29, 13–23. [Google Scholar] [CrossRef]

- Kaewpruk, C.; Boopasiri, S.; Poonsawat, C.; Sae-Oui, P.; Siriwong, C. Utilization of Sawdust and Wood Ash as a Filler in Natural Rubber Composites. ChemistrySelect 2021, 6, 264–272. [Google Scholar] [CrossRef]

- Hayeemasae, N.; Ismail, H. Utilization of Tea Waste as an Alternative Filler for Natural Rubber. J. Teknol. 2020, 82, 109–115. [Google Scholar] [CrossRef]

- Juszkiewicz, A.; Maciejewska, M. Tea Grounds as a Waste Biofiller for Natural Rubber. Materials 2024, 17, 1516. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, A.; Prayitno, A.; Satoto, R. Morphology and Mechanical Properties of Palm Based Fly Ash Reinforced Dynamically Vulcanized Natural Rubber/Polypropylene Blends. Procedia Chem. 2012, 4, 146–153. [Google Scholar] [CrossRef]

- Ren, X.; Sancaktar, E. Use of fly ash as eco-friendly filler in synthetic rubber for tire applications. J. Clean. Prod. 2018, 206, 374–382. [Google Scholar] [CrossRef]

- Barrera, C.S.; Cornish, K. Characterization of Agricultural and Food Processing Residues for Potential Rubber Filler Applications. J. Compos. Sci. 2019, 3, 102. [Google Scholar] [CrossRef]

- El Mogy, S.A.; Darwish, N.A.; Awad, A. Comparative Study of the Cure Characteristics and Mechanical Properties of Natural Rubber Filled with Different Calcium Carbonate Resources. J. Vinyl Addit. Technol. 2020, 26, 309–315. [Google Scholar] [CrossRef]

- Roy, K.; Debnath, S.C.; Raengthon, N.; Potiyaraj, P. Understanding the reinforcing efficiency of waste eggshell-derived nano calcium carbonate in natural rubber composites with maleated natural rubber as compatibilizer. Polym. Eng. Sci. 2019, 59, 1428–1436. [Google Scholar] [CrossRef]

- Zuiderduin, W.; Westzaan, C.; Huétink, J.; Gaymans, R. Toughening of polypropylene with calcium carbonate particles. Polymer 2003, 44, 261–275. [Google Scholar] [CrossRef]

- He, S.; Bijl, A.; Rohrbach, L.; Yuan, Q.; Santosa, D.S.; Wang, Z.; Heeres, H.J.; Brem, G. Catalytic upcycling paper sludge for the recovery of minerals and production of renewable high-grade biofuels and bio-based chemicals. Chem. Eng. J. 2021, 420, 129714. [Google Scholar] [CrossRef]

- Shi, X.; Rosa, R.; Lazzeri, A. On the Coating of Precipitated Calcium Carbonate with Stearic Acid in Aqueous Medium. Langmuir 2010, 26, 8474–8482. [Google Scholar] [CrossRef] [PubMed]

- Fairbanks, B.D.; Singh, S.P.; Bowman, C.N.; Anseth, K.S. Photodegradable, Photoadaptable Hydrogels via Radical-Mediated Disulfide Fragmentation Reaction. Macromolecules 2011, 44, 2444–2450. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Waymouth, R.M. 1,2-Dithiolane-Derived Dynamic, Covalent Materials: Cooperative Self-Assembly and Reversible Cross-Linking. J. Am. Chem. Soc. 2017, 139, 3822–3833. [Google Scholar] [CrossRef]

- Wiita, A.P.; Ainavarapu, S.R.K.; Huang, H.H.; Fernandez, J.M. Force-dependent chemical kinetics of disulfide bond reduction observed with single-molecule techniques. Proc. Natl. Acad. Sci. USA 2006, 103, 7222–7227. [Google Scholar] [CrossRef]

- Anyszka, R.; Jia, L.; Blume, A. Tires for Mars Rovers: Reinforcing BR and BR/Vinyl-Methyl Silicone Rubber Compounds with Carbon Black, Nano-CaCO3, or Silica for Good Low-Temperature Dynamic-Mechanical Performance. Tire Sci. Technol. 2024, 52, 225–254. [Google Scholar] [CrossRef]

- Sarazyn, J. Smart Electronic Pet Collar System for Training and Tracking Health, Location, and Accurate Activity Levels of Pets. US20140331942A1, 13 November 2014. Available online: https://patents.google.com/patent/US20140331942A1/en (accessed on 13 June 2023).

- Yanti, E.D.; Pratiwi, I. Correlation between thermal behavior of clays and their chemical and mineralogical composition: A review. IOP Conf. Ser. Earth Environ. Sci. 2018, 118, 012078. [Google Scholar] [CrossRef]

- Worrall, W.E. Clays: Their Nature, Origin and General Properties; Maclaren: London, UK, 1968; Available online: https://books.google.nl/books?id=OVQSAQAAIAAJ (accessed on 13 June 2023).

- Elshereksi, N.W.; Ghazali, M.; Muchtar, A.; Azhari, C.H. Review of titanate coupling agents and their application for dental composite fabrication. Dent. Mater. J. 2017, 36, 539–552. [Google Scholar] [CrossRef] [PubMed]

| Ingredient | CB | A/B-10 | A/B-LA10 | A/B-Ti10 | A/B-20 | A/B-LA20 | A/B-Ti20 |

|---|---|---|---|---|---|---|---|

| NR—TSR10 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| TDAE 1 | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| Zinc oxide | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| Stearic acid | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| 6PPD 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| Paraffin wax | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| Sulfur | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| TBBS 3 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| TBzTD 4 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| Carbon Black N550 | 60 | 50 | 50 | 50 | 40 | 40 | 40 |

| Calcium Carbonate A/B | - | 10 | 10 | 10 | 20 | 20 | 20 |

| Alpha-Lipoic Acid | - | - | 0.7 | - | - | 1.4 | - |

| Titanate | - | - | - | 0.5 | - | - | 0.5 |

| Time (min) | Action |

|---|---|

| Step 1 pre-heating 70 °C—70 rpm | |

| 0.00 | Addition of rubber |

| 1.00 | Addition of 1/2 filler, processing oil |

| 2.30 | Addition of 1/2 filler, anti-degradants, and activators |

| 4.00 | Ram up, sweep for 15 s |

| 6.00 | Stop mixing |

| Step 2 pre-heating 50 °C—50 rpm | |

| 0.00 | Addition elastomer batch stage 1 |

| 1.00 | Addition curing system |

| 3.00 | Stop mixing |

| Filler Name | Code | BET SA [m2g−1] |

|---|---|---|

| Carbon Black N550 | CB | 42 |

| Calcium Carbonate A | CCA | 11.0 |

| Calcium Carbonate B | CCB | 14.9 |

| ΔG’(kPa) | G’100%(kPa) | |

|---|---|---|

| CB | 1700 | 455 |

| A10 | 1154 | 442 |

| A10-LA | 1430 | 470 |

| A10-Ti | 1070 | 462 |

| A20 | 766 | 416 |

| A20-LA | 1020 | 486 |

| A20-Ti | 867 | 458 |

| B10 | 1114 | 457 |

| B10-LA | 1350 | 544 |

| B10-Ti | 1255 | 530 |

| B20 | 671 | 414 |

| B20-LA | 944 | 503 |

| B20-Ti | 880 | 492 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schouw, C.; Bernal-Ortega, P.; Anyszka, R.; Bijl, A.; Gucho, E.; Blume, A. Toward Eco-Friendly Rubber: Utilizing Paper Waste-Derived Calcium Carbonate to Replace Carbon Black in Natural Rubber Composites. J. Compos. Sci. 2025, 9, 115. https://doi.org/10.3390/jcs9030115

Schouw C, Bernal-Ortega P, Anyszka R, Bijl A, Gucho E, Blume A. Toward Eco-Friendly Rubber: Utilizing Paper Waste-Derived Calcium Carbonate to Replace Carbon Black in Natural Rubber Composites. Journal of Composites Science. 2025; 9(3):115. https://doi.org/10.3390/jcs9030115

Chicago/Turabian StyleSchouw, Colin, Pilar Bernal-Ortega, Rafal Anyszka, Anton Bijl, Eyerusalem Gucho, and Anke Blume. 2025. "Toward Eco-Friendly Rubber: Utilizing Paper Waste-Derived Calcium Carbonate to Replace Carbon Black in Natural Rubber Composites" Journal of Composites Science 9, no. 3: 115. https://doi.org/10.3390/jcs9030115

APA StyleSchouw, C., Bernal-Ortega, P., Anyszka, R., Bijl, A., Gucho, E., & Blume, A. (2025). Toward Eco-Friendly Rubber: Utilizing Paper Waste-Derived Calcium Carbonate to Replace Carbon Black in Natural Rubber Composites. Journal of Composites Science, 9(3), 115. https://doi.org/10.3390/jcs9030115