Tribological Study of Multi-Walled Carbon Nanotube-Reinforced Aluminum 7075 Using Response Surface Methodology and Multi-Objective Genetic Algorithm

Abstract

:1. Introduction

2. Materials and Methods

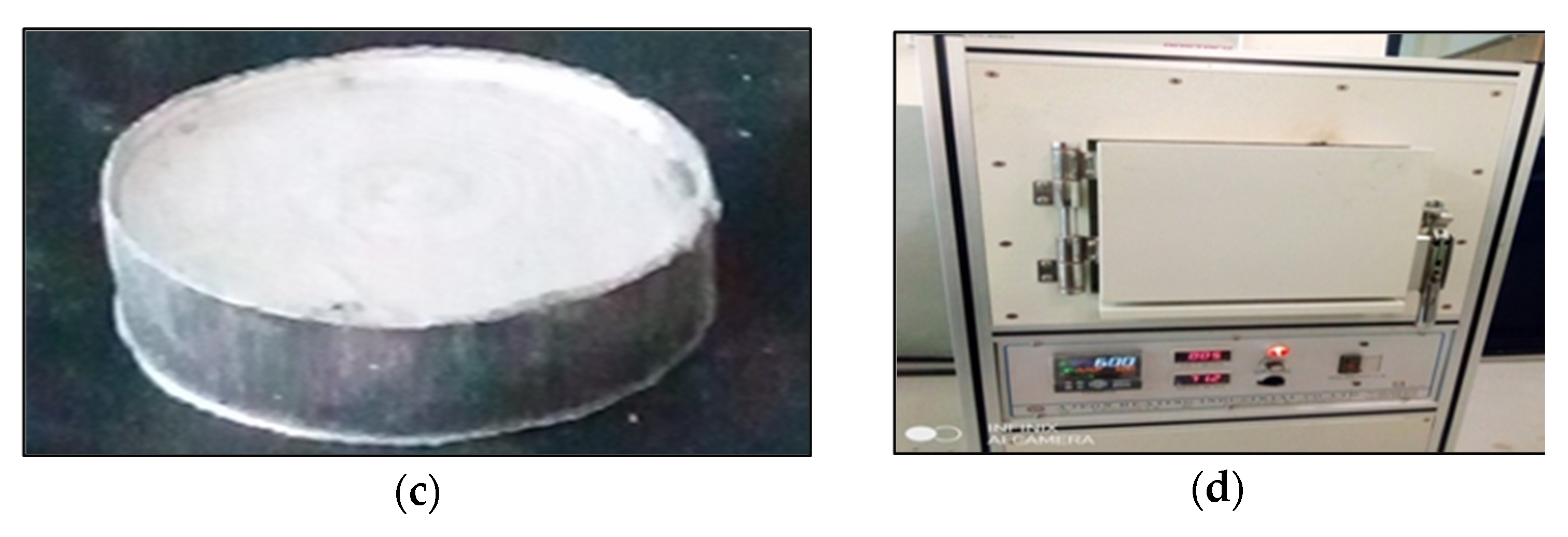

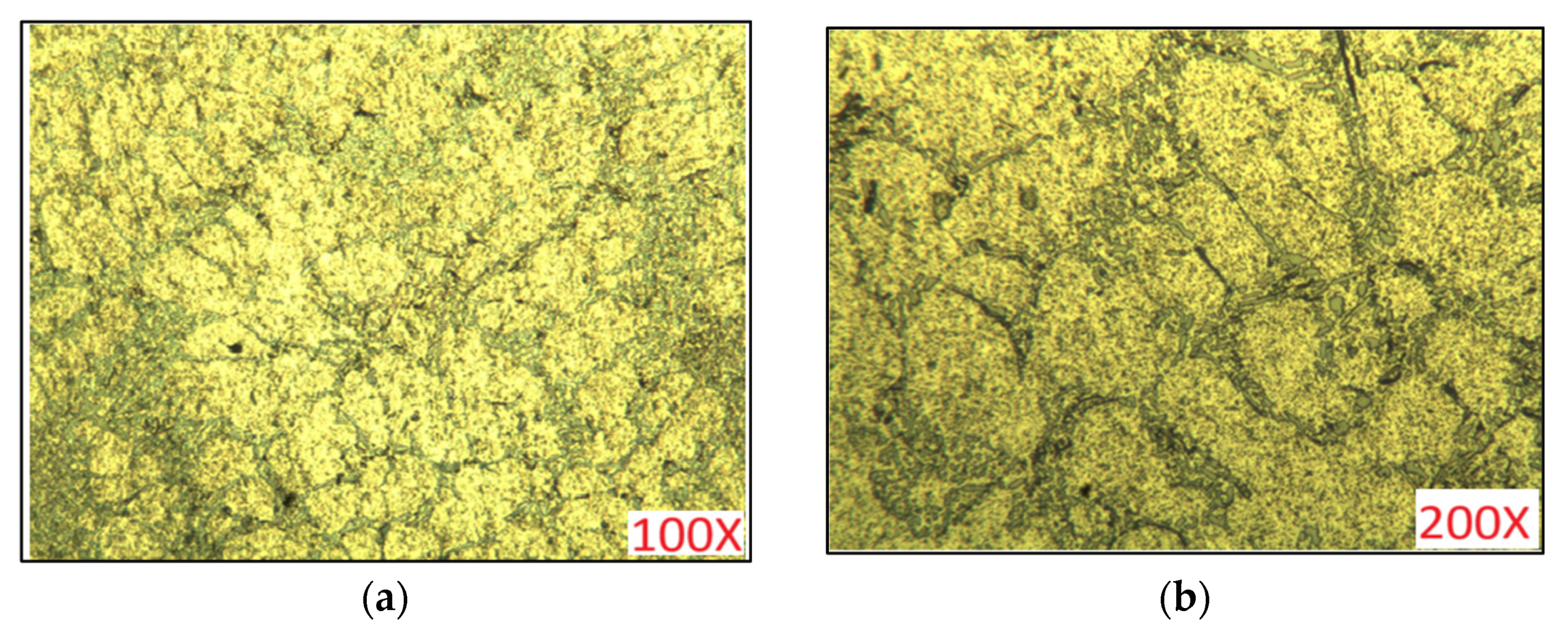

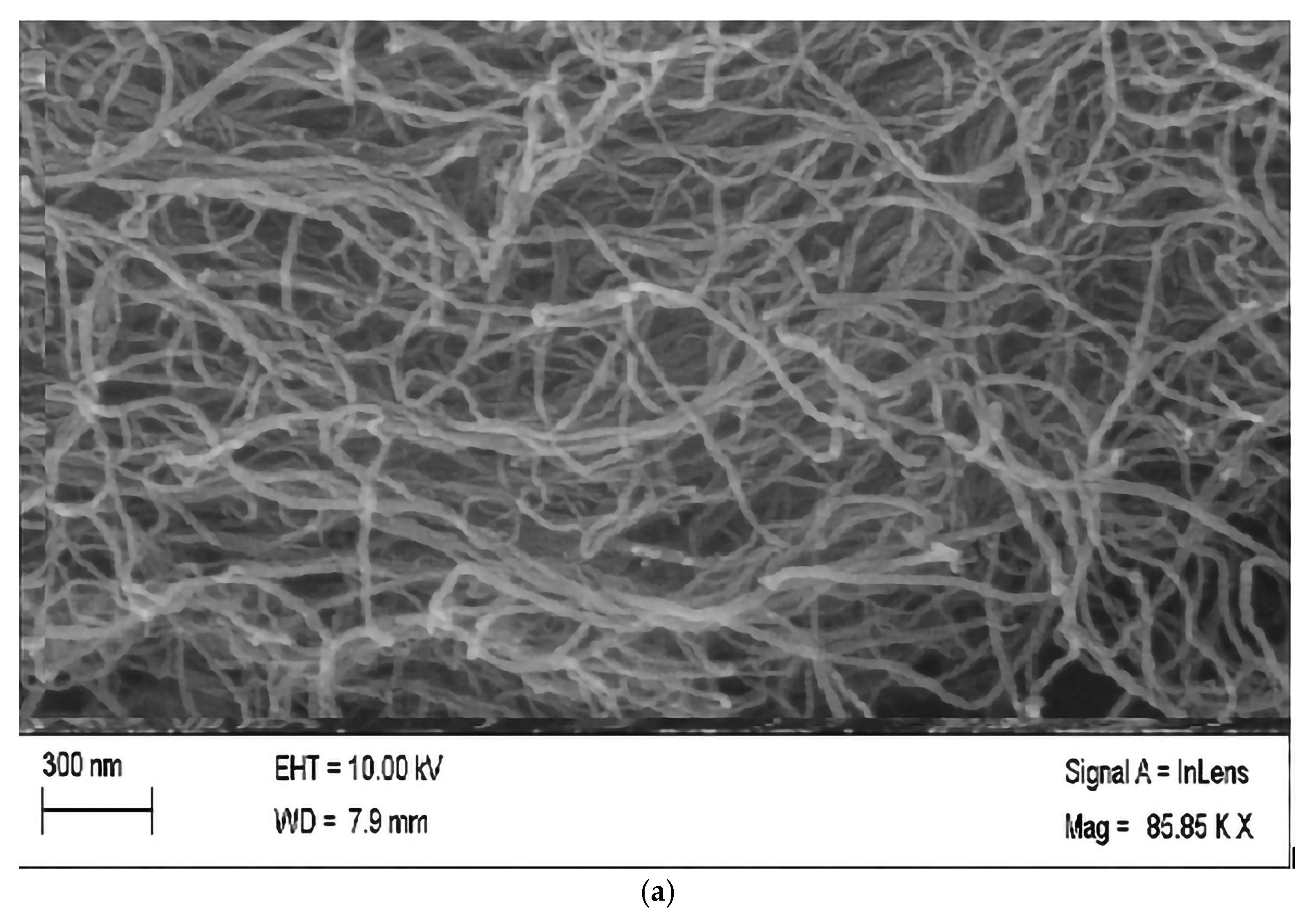

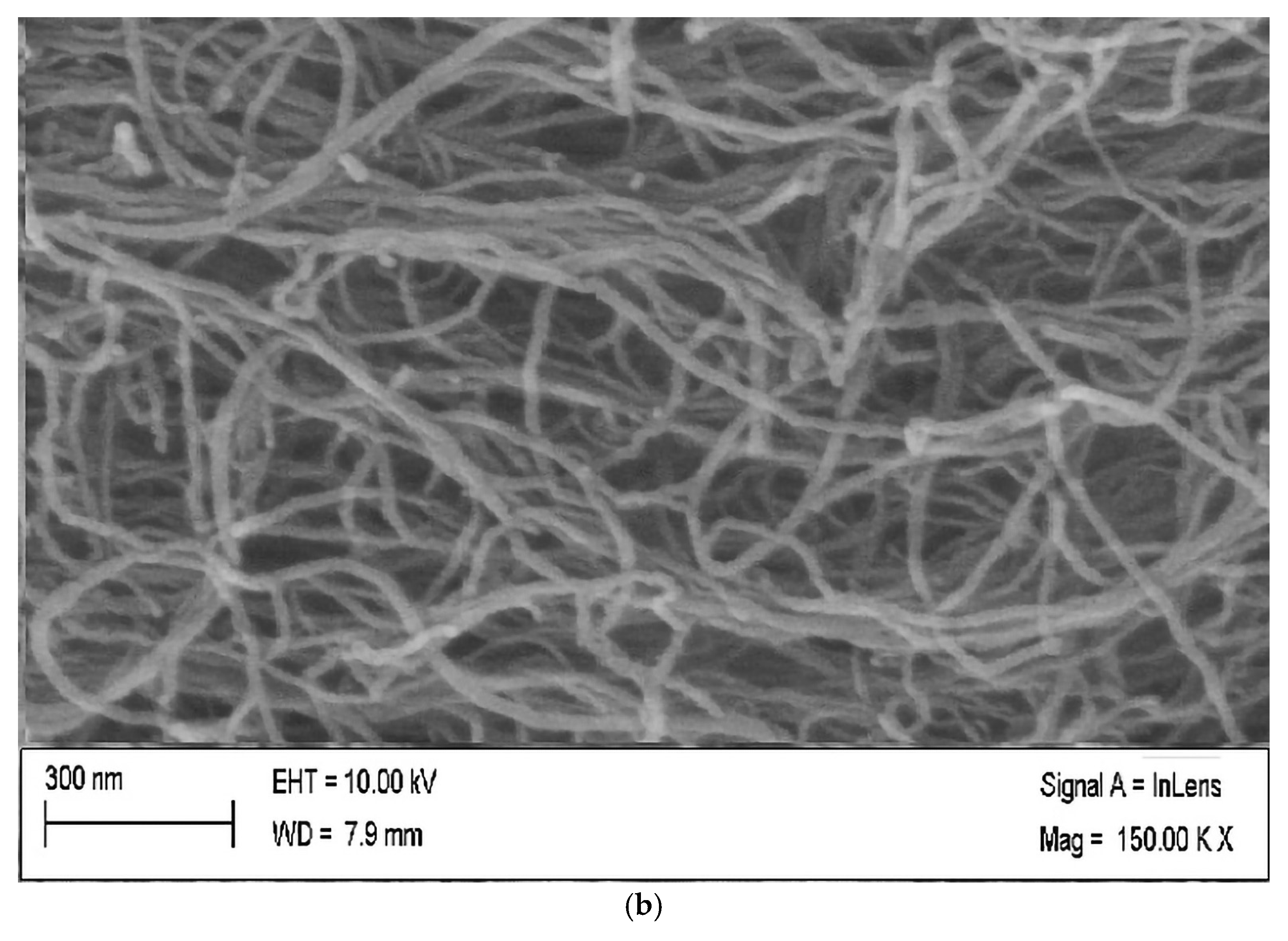

2.1. Fabrication of Al7075-MWCNT Composite

2.2. Measurement of Mechanical Properties

2.2.1. Hardness Measurement

2.2.2. Specific Wear Rate

3. Results and Discussion

3.1. Analysis of Variance

3.1.1. ANOVA Analysis to Predict Hardness

3.1.2. ANOVA Analysis of Specific Wear Rate

3.2. Interaction Effect

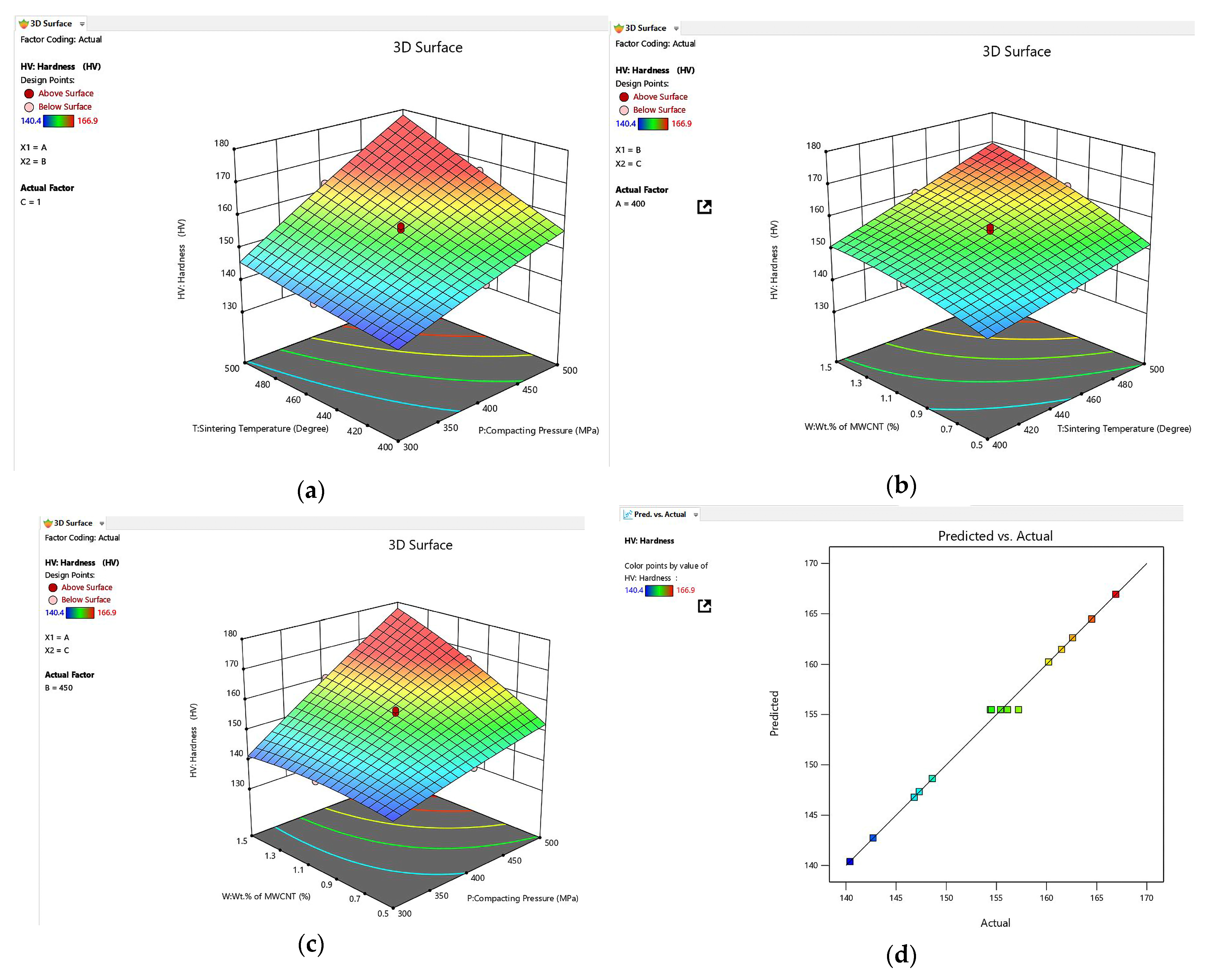

3.2.1. Interaction Effect on Hardness

3.2.2. Interaction Effect on Specific Wear Rate (SWR)

4. Multi-Objective Optimization

5. Conclusions

- An increase in compacting pressure has a significant effect of increasing hardness and decreasing the specific wear rate.

- Increasing sintering temperature has the least impact on hardness and specific wear rate.

- An increase in the weight percentage of MWCNTs reduces the hardness, but increases the specific wear rate. A lower SWR was observed for the MWCNTs in the range of 0.9 to 1.3 weight percentages.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AlMMCs | Aluminum Metal Matrix Composites |

| ANOVA | Analysis of Variance |

| CNT | Carbon Nanotube |

| CCD | Central Composite Design |

| CRITIC | Criteria Importance through Intercriteria Correlation |

| FSP | Friction Stir Processing |

| GRA | Grey Relational Analysis |

| GNP | Graphene Nanoplatelet |

| HR-TEM | High-Resolution Transmission Electron Microscopy |

| MMC | Metal Matrix Composite |

| MWCNTs | Multi-Walled Carbon Nanotubes |

| MOGA | Multi-objective Genetic Algorithm |

| MOORA | Multi-Objective Optimization by Ratio Analysis |

| OM | Optical Microscope |

| RSM | Response Surface Methodology |

| SCM | Scanning Electron Microscope |

| XRD | X-ray Diffraction |

References

- Yildirim, M.; Özyürek, D.; Gürü, M. Investigation of microstructure and wear behaviors of al matrix composites reinforced by carbon nanotube. Fuller. Nanotub. Carbon Nanostruct. 2016, 24, 467–473. [Google Scholar] [CrossRef]

- Carreño-Gallardo, C.; Uriza-Vega, E.; Estrada-Guel, I.; Herrera-Ramírez, M.; Martínez-Sánchez, R.; Lopez-Meléndez, C.; Martínez-Franco, E. Effect of Multiwall Carbon Nanotubes (MWCNs) Reinforcement on the Mechanical Behavior of Synthesis 7075 Aluminum Alloy Composites by Mechanical Milling. Microsc. Microanal. 2017, 23 (Suppl. S1), 1930–1931. [Google Scholar] [CrossRef]

- Pasha, S.A.; Reddy, R.; Laxmi Narayana, P. Wear Behavior and Microstructural Characterization of AA7075/MWCNT Surface Composites Fabricated Through Friction Stir Processing. IOSR J. Mech. Civ. Eng. 2017, 14, 140–146. [Google Scholar] [CrossRef]

- Aranke, O.; Gandhi, C.; Dixit, N.; Kuppan, P. Influence of multiwall carbon nanotubes (MWCNT) on wear and coefficient of friction of aluminium (AL 7075) Metal matrix composite. Mater. Today Proc. 2018, 5, 7748–7757. [Google Scholar] [CrossRef]

- Uriza-Vega, E.; Carreño-Gallardo, C.; López-Meléndez, C.; Cuadros-Lugo, E.; Pérez-Bustamante, R.; Ledezma-Sillas, E.; Herrera-Ramirez, J.M. Mechanical behavior of multiwalled carbon nanotube reinforced 7075 aluminum alloy composites prepared by mechanical milling and hot extrusion. Mater. Res. 2019, 22, e20180652. [Google Scholar] [CrossRef]

- Topcu, İ. Determination of the mechanical properties of Al/MWCNT composites obtained with the reinforcement of Cu-coated multiwall carbon nanotubes (MWCNTs). Mater. Tehnol. 2020, 54, 689–695. [Google Scholar] [CrossRef]

- Suresh, S.; Sudhakara, D.; Vinod, B. Investigation on mechanical, wear, and machining characteristics of Al 7075/MWCNTs using the liquid state method. Adv. Compos. Hybrid Mater. 2020, 3, 243–254. [Google Scholar] [CrossRef]

- Suresh, S.; Sudhakara, D.; Vinod, B. Investigation on tribological and machining characteristics of AL 7075/MWCNTs nanocomposites. J. Bio Tribo-Corros. 2020, 6, 97. [Google Scholar] [CrossRef]

- Srinivas, P.N.S.; Babu, P.R.; Balakrishna, B. Material characterization and optimization of CNT-reinforced aluminum (AA7075) functionally graded material processed by ultrasonic cavitation. Funct. Compos. Struct. 2020, 2, 045002. [Google Scholar] [CrossRef]

- Kumaran Selvaraj, S.; Srinivasan, K.; Kumar, R.S.; Hu, Y.-C. Sensor-Assisted Assessment of the Tribological Behavior Patterns of AA7075 Hybrid MMC Reinforced with Multi-Wall Carbon Nanotubes and Pulverized Fuel Ash. Materials 2020, 13, 2583. [Google Scholar] [CrossRef]

- Tiwari, S.K.; Sharma, H.; Umamaheswararao, A.; Sharma, S. Synthesis and characterization of aluminum composite reinforced by multiwall carbon nanotubes. In Advances in Materials Science and Engineering: Select Proceedings of ICFMMP; Springer: Singapore, 2019; pp. 115–124. [Google Scholar] [CrossRef]

- Srinivas, V.; Jayaraj, A.; Venkataramana, V.S.N.; Avinash, T.; Dhanyakanth, P. Effect of ultrasonic stir casting technique on mechanical and tribological properties of Aluminium–Multi-walled Carbon nanotube nanocomposites. J. Bio Tribo-Corros. 2020, 6, 30. [Google Scholar] [CrossRef]

- Swamy, M.K.C.; Venkatagiriyappa, R.B. Experimental studies on mechanical properties of Carbon Nanotube reinforced Aluminum 7075 composite material. J. Eng. Technol. Sci. 2021, 53, 210611. [Google Scholar] [CrossRef]

- Parisa, F.D.; Pouyafar, V.; Meshkabadi, R. Fabrication of Al7075-MWCNT Composite Powder by Recycling Aluminum Alloy Chips Via High Energy Milling and Alloying. J. Adv. Mater. Process. 2021, 9, 55–66. [Google Scholar]

- Ajithkumar, J.P.; Xavior, M.A. Machinability studies on Al7075-based hybrid composites reinforced with SiC, graphene and CNT. Int. J. Mach. Mach. Mater. 2021, 23, 64. [Google Scholar] [CrossRef]

- Khanna, V.; Kumar, V.; Bansal, S.A. Mechanical properties of aluminium-graphene/carbon nanotubes (CNTs) metal matrix composites: Advancement, opportunities and perspective. Mater. Res. Bull. 2021, 138, 111224. [Google Scholar] [CrossRef]

- Feijoo, I.; Pena, G.; Cabeza, M.; Cristóbal, M.J.; Rey, P. MWCNT-Reinforced AA7075 Composites: Effect of reinforcement percentage on mechanical properties. Metals 2021, 11, 969. [Google Scholar] [CrossRef]

- Pasha, S.A.S.; Ahmed, M.N.; Tilak, S.R.; Kumar, B.N.A. Study on Properties of Multi-Walled Carbon Nanotube Reinforced Aluminum Matrix Composite Through Casting Technique. Mat. Sci. Res. 2021, 18, 97–101. [Google Scholar] [CrossRef]

- Barati, F.; Esfandiari, M. The effect of multi-walled carbon nanotubes, as the reinforcement phase, on the hardness and bending strength of aluminum alloy 7075. J. Stress Anal. 2021, 6, 61–66. [Google Scholar]

- Shan, L.; Tan, C.Y.; Shen, X.; Ramesh, S.; Kolahchi, R.; Hajmohammad, M.H.; Rajak, D.K. Creep Behavior of A356 Aluminum Alloy Reinforced with Multi-Walled Carbon Nanotubes by Stir Casting. Materials 2022, 15, 8959. [Google Scholar] [CrossRef]

- Doğan, K.; Özgün, M.İ.; Sübütay, H.; Salur, E.; Eker, Y.; Kuntoğlu, M.; Aslan, A.; Gupta, M.K.; Acarer, M. Dispersion mechanism-induced variations in microstructural and mechanical behavior of CNT-reinforced aluminum nanocomposites. Arch. Civ. Mech. Eng. 2022, 22, 55. [Google Scholar] [CrossRef]

- Shivalingaiah, K.; Nagarajaiah, V.; Selvan, C.; Kariappa, S.; Chandrashekarappa, N.; Lakshmikanthan, A.; Chandrashekarappa, M.; Linul, E. Stir casting process analysis and optimization for better properties in AL-MWCNT-GR-Based hybrid composites. Metals 2022, 12, 1297. [Google Scholar] [CrossRef]

- Feijoo, I.; Pena, G.; Cristóbal, M.J.; Cabeza, M.; Rey, P. Effect of carbon nanotube content and mechanical milling conditions on the manufacture of AA7075/MWCNT composites. Metals 2022, 12, 1020. [Google Scholar] [CrossRef]

- Swamy, A.; Shamitha, C.; Singh, M.K.; Rinawa, M.L.; Kumar, K.V.P.; Obaid, S.A.; Mahadik, M.A.; Alfarraj, S.; Markos, M. Experimental investigations on the wear behaviour of Eutectic AL-7075/CNT/Graphite composites manufactured by a combination of Two-Stage stir and squeeze casting techniques. J. Nanomater. 2022, 2022, 7995261. [Google Scholar] [CrossRef]

- Ramesh, B.; Kumar, D.; Chhabria, S.; Basavarajappa, V.; Krishnakumari, A.; Saravanan, M.; Sannakki, B.; Kumaravel, D.; Hassen, A.A. Investigation on the Properties of Multiwall Carbon Nanotube-, Graphene-, and Fullerene-Reinforced Hot-Extruded AA7075 Matrix Composites. J. Nanomater. 2022, 2022, 9419771. [Google Scholar] [CrossRef]

- Chaturvedi, R.; Sharma, A.; Sharma, K.; Saraswat, M. Tribological behaviour of multi-walled carbon nanotubes reinforced AA 7075 nano-composites. Adv. Mater. Process. Technol. 2022, 8, 4743–4755. [Google Scholar] [CrossRef]

- Kumar, P.S.S.R.; Mashinini, P.M.; Vignesh, R.V. Wear Behavior of Friction Stir Processed AA7075—Aluminosilicate/MWCNT Hybrid Composite Using Multi-Objective Optimization. Silicon 2022, 14, 12329–12347. [Google Scholar] [CrossRef]

- David, A.; Gopal, S.K.; Lakshmanan, P.; Chenbagam, A.S. Corrosion, mechanical and microstructural properties of aluminum 7075—Carbon nanotube nanocomposites for robots in corrosive environments. Int. J. Miner. Metall. Mater. 2023, 30, 1140–1151. [Google Scholar] [CrossRef]

- Ajithkumar, J.P.; Xavior, M.A. Machinability analysis on Al7075 matrix composites reinforced by nano-silicon carbide, boron carbide, graphene and MWCNT. J. Braz. Soc. Mech. Sci. Eng. 2023, 45, 534. [Google Scholar] [CrossRef]

- Kumar, A.; Kumar, V. Assessment of Mechanical and Tribological Properties of SIC- and Multi-Walled Carbon Nanotube-Reinforced Surface Composites of AA7075-T6 Fabricated via Friction Stir Processing. J. Mater. Eng. Perform. 2024. [Google Scholar] [CrossRef]

- Kadhim, M.M.; Naif, S.K.; Mohammed, D.F.; Hussein, A.W. The concentration influence of multi-walled carbon nanotubes coating on fatigue edge crack growth and other mechanical properties of Al 7075-T6 thin plates. Results Eng. 2024, 23, 102719. [Google Scholar] [CrossRef]

- Atta, M.; Megahed, M.; Saber, D. Using ANN and OA techniques to determine the specific wear rate effectors of A356 Al-Si/Al2O3 MMC. Neural Comput. Appl. 2022, 34, 14373–14386. [Google Scholar] [CrossRef]

- Gutema, E.M.; Gopal, M.; Lemu, H.G. Minimization of Surface Roughness and Temperature during Turning of Aluminum 6061 Using Response Surface Methodology and Desirability Function Analysis. Materials 2022, 15, 7638. [Google Scholar] [CrossRef] [PubMed]

- Salwan, G.K.; Subbarao, R.; Mondal, S. Investigation on compaction pressure and sintering temperature suitable for Nimonic 90 superalloy. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Zou, Q.; Wu, H.; Li, Y.; Wang, X.; Dai, L.; Luo, Y. Effects of carbon nanotubes and sintering parameters on microstructure and properties of PCD. Diam. Relat. Mater. 2022, 128, 109293. [Google Scholar] [CrossRef]

- Seo, H.; Jiang, L.; Kang, C.; Jin, C. Effect of compression process of MWCNT-Reinforced AL6061 powder on densification characteristics and its mechanical properties. Metals 2017, 7, 437. [Google Scholar] [CrossRef]

- Matsagar, V.K.; Kushare, P.B. Influence of compacting pressure and sintering temperature effect on microstructure characteristics and tribological performance of NI-CR-MOS2 based composite. Surf. Rev. Lett. 2024, 2450137. [Google Scholar] [CrossRef]

- Capela, P.; Carvalho, S.F.; Guedes, A.; Pereira, M.; Carvalho, L.; Correia, J.; Soares, D.; Gomes, J.R. Effect of sintering temperature on mechanical and wear behaviour of a ceramic composite. Tribol. Int. 2017, 120, 502–509. [Google Scholar] [CrossRef]

- Gopal, M.; Gutema, E.M.; Lemu, H.G.; Sori, J. A hybrid Nondominant-Based Genetic Algorithm (NSGA-II) for Multiobjective Optimization to Minimize Vibration Amplitude in the End Milling Process. Adv. Mater. Sci. Eng. 2024, 2024, 6652973. [Google Scholar] [CrossRef]

| Al 6061 | Mg | Si | Fe | Mn | Cu | Cr | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|

| Weight | 2.1–2.9 | 0.4 | 0.50 | 0.30 | 1.2–2.0 | 0.18–0.28 | 5.1–6.1 | 0.20 | Remainder |

| Sl. No. | Parameters | Unit | Factorial Levels | ||

|---|---|---|---|---|---|

| −1 | 0 | +1 | |||

| 1 | Compacting pressure (P) | MPa | 300 | 400 | 500 |

| 2 | Sintering temperature (T) | °C | 400 | 450 | 500 |

| 3 | Wt.% of MWCNTs (W) | % | 0.5 | 1 | 1.5 |

| Sl. No. | Compacting Pressure | Sintering Temperature | Wt.% of MWCNTs | Hardness (HV) | SWR × 10−4 |

|---|---|---|---|---|---|

| MPa | °C | % | HV | mm3/Nm | |

| 1 | 500 | 500 | 0.5 | 161.5 | 1.4 |

| 2 | 300 | 400 | 0.5 | 140.4 | 2.4 |

| 3 | 400 | 400 | 1 | 148.6 | 2.1 |

| 4 | 500 | 400 | 1.5 | 164.5 | 1.2 |

| 5 | 300 | 450 | 1 | 142.7 | 2.3 |

| 6 | 400 | 500 | 1 | 162.6 | 1.3 |

| 7 | 400 | 450 | 1 | 154.5 | 1.8 |

| 8 | 500 | 450 | 1 | 166.9 | 1.1 |

| 9 | 400 | 450 | 1 | 154.4 | 1.7 |

| 10 | 400 | 450 | 1 | 156.1 | 1.7 |

| 11 | 300 | 500 | 1.5 | 146.8 | 2.2 |

| 12 | 400 | 450 | 1 | 157.2 | 1.6 |

| 13 | 400 | 450 | 0.5 | 147.3 | 2.1 |

| 14 | 400 | 450 | 1 | 155.4 | 1.8 |

| 15 | 400 | 450 | 1.5 | 160.2 | 1.6 |

| Sl. no | Compacting Pressure | Sintering Temperature | Wt.% of MWCNT | RSM Predicted Values | |

|---|---|---|---|---|---|

| Hardness (HVPred) | SWR × 10−4 (Ws Pred) | ||||

| MPa | °C | % | HV | mm3/Nm | |

| 1 | 500 | 500 | 0.5 | 161.48 | 1.40 |

| 2 | 300 | 400 | 0.5 | 140.38 | 2.40 |

| 3 | 400 | 400 | 1 | 148.64 | 2.10 |

| 4 | 500 | 400 | 1.5 | 164.48 | 1.20 |

| 5 | 300 | 450 | 1 | 142.74 | 2.30 |

| 6 | 400 | 500 | 1 | 162.64 | 1.30 |

| 7 | 400 | 450 | 1 | 155.49 | 1.72 |

| 8 | 500 | 450 | 1 | 166.94 | 1.10 |

| 9 | 400 | 450 | 1 | 155.49 | 1.72 |

| 10 | 400 | 450 | 1 | 155.49 | 1.72 |

| 11 | 300 | 500 | 1.5 | 146.78 | 2.20 |

| 12 | 400 | 450 | 1 | 155.49 | 1.72 |

| 13 | 400 | 450 | 0.5 | 147.34 | 2.10 |

| 14 | 400 | 450 | 1 | 155.49 | 1.72 |

| 15 | 400 | 450 | 1.5 | 160.24 | 1.60 |

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value | |

|---|---|---|---|---|---|---|

| Model | 889.87 | 9 | 98.87 | 90.18 | <0.0001 | significant |

| P: Compacting pressure | 292.82 | 1 | 292.82 | 267.07 | <0.0001 | |

| T: Sintering temperature | 98.00 | 1 | 98.00 | 89.38 | 0.0002 | |

| W: Wt.% of MWCNT | 83.20 | 1 | 83.20 | 75.89 | 0.0003 | |

| PT | 22.41 | 1 | 22.41 | 20.44 | 0.0063 | |

| PW | 50.43 | 1 | 50.43 | 45.99 | 0.0011 | |

| TW | 7.68 | 1 | 7.68 | 7.00 | 0.0456 | |

| P2 | 1.12 | 1 | 1.12 | 1.02 | 0.3595 | |

| T2 | 0.0566 | 1 | 0.0566 | 0.0516 | 0.8293 | |

| W2 | 7.58 | 1 | 7.58 | 6.92 | 0.0465 | |

| Residual | 5.48 | 5 | 1.10 | |||

| Lack of Fit | 0.0142 | 1 | 0.0142 | 0.0104 | 0.9238 | not significant |

| Pure Error | 5.47 | 4 | 1.37 | |||

| Cor Total | 895.35 | 14 |

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value | |

|---|---|---|---|---|---|---|

| Model | 2.25 | 9 | 0.2499 | 44.57 | 0.0003 | significant |

| P: Compacting pressure | 0.7200 | 1 | 0.7200 | 128.39 | < 0.0001 | |

| T: Sintering temperature | 0.3200 | 1 | 0.3200 | 57.06 | 0.0006 | |

| W: Wt.% of MWCNT | 0.1250 | 1 | 0.1250 | 22.29 | 0.0052 | |

| PT | 0.0300 | 1 | 0.0300 | 5.35 | 0.0687 | |

| PW | 0.2133 | 1 | 0.2133 | 38.04 | 0.0016 | |

| TW | 0.0133 | 1 | 0.0133 | 2.38 | 0.1837 | |

| P2 | 0.0014 | 1 | 0.0014 | 0.2582 | 0.6330 | |

| T2 | 0.0014 | 1 | 0.0014 | 0.2582 | 0.6330 | |

| W2 | 0.0418 | 1 | 0.0418 | 7.46 | 0.0412 | |

| Residual | 0.0280 | 5 | 0.0056 | |||

| Lack of Fit | 0.0000 | 1 | 0.0000 | 0.0056 | 0.9439 | not significant |

| Pure Error | 0.0280 | 4 | 0.0070 | |||

| Cor Total | 2.28 | 14 |

| Sl. No | Compacting Pressure (P) | Sintering Temperature (T) | Wt.% of MWCNTs (W) | MOGA Results | |

|---|---|---|---|---|---|

| Hardness (HVPred) | SWR × 10−4 (WsPred) | ||||

| 1 | 498.09 | 442.93 | 1.35 | 172.94 | 2.99 |

| 2 | 300.00 | 400.00 | 0.86 | 140.49 | 4.01 |

| 3 | 498.09 | 400.00 | 1.5 | 164.33 | 3.09 |

| 4 | 498.09 | 473.82 | 1.49 | 183.97 | 2.71 |

| 5 | 378.31 | 400.04 | 0.86 | 146.09 | 3.88 |

| 6 | 499.99 | 400.04 | 0.86 | 153.16 | 3.67 |

| 7 | 499.99 | 400.04 | 1.49 | 164.59 | 3.09 |

| 8 | 499.99 | 400.04 | 0.98 | 155.88 | 3.52 |

| 9 | 498.09 | 400.00 | 1.17 | 159.22 | 3.34 |

| 10 | 300 | 400.00 | 1.34 | 137.74 | 4.31 |

| 11 | 499.99 | 473.83 | 1.34 | 181.15 | 2.84 |

| 12 | 378.31 | 400.04 | 1.17 | 147.68 | 3.85 |

| 13 | 498.09 | 442.93 | 1.49 | 175.66 | 2.88 |

| 14 | 499.99 | 473.83 | 1.49 | 184.42 | 2.69 |

| 15 | 300 | 400.00 | 1.49 | 136.24 | 4.45 |

| 16 | 499.99 | 400.04 | 1.17 | 159.49 | 3.33 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gutema, E.M.; Gopal, M.; Lemu, H.G. Tribological Study of Multi-Walled Carbon Nanotube-Reinforced Aluminum 7075 Using Response Surface Methodology and Multi-Objective Genetic Algorithm. J. Compos. Sci. 2025, 9, 137. https://doi.org/10.3390/jcs9030137

Gutema EM, Gopal M, Lemu HG. Tribological Study of Multi-Walled Carbon Nanotube-Reinforced Aluminum 7075 Using Response Surface Methodology and Multi-Objective Genetic Algorithm. Journal of Composites Science. 2025; 9(3):137. https://doi.org/10.3390/jcs9030137

Chicago/Turabian StyleGutema, Endalkachew Mosisa, Mahesh Gopal, and Hirpa G. Lemu. 2025. "Tribological Study of Multi-Walled Carbon Nanotube-Reinforced Aluminum 7075 Using Response Surface Methodology and Multi-Objective Genetic Algorithm" Journal of Composites Science 9, no. 3: 137. https://doi.org/10.3390/jcs9030137

APA StyleGutema, E. M., Gopal, M., & Lemu, H. G. (2025). Tribological Study of Multi-Walled Carbon Nanotube-Reinforced Aluminum 7075 Using Response Surface Methodology and Multi-Objective Genetic Algorithm. Journal of Composites Science, 9(3), 137. https://doi.org/10.3390/jcs9030137