Current and Future Trends in Textiles for Concrete Construction Applications

Abstract

:1. Introduction

2. Improving the Mechanical Performance of TRC

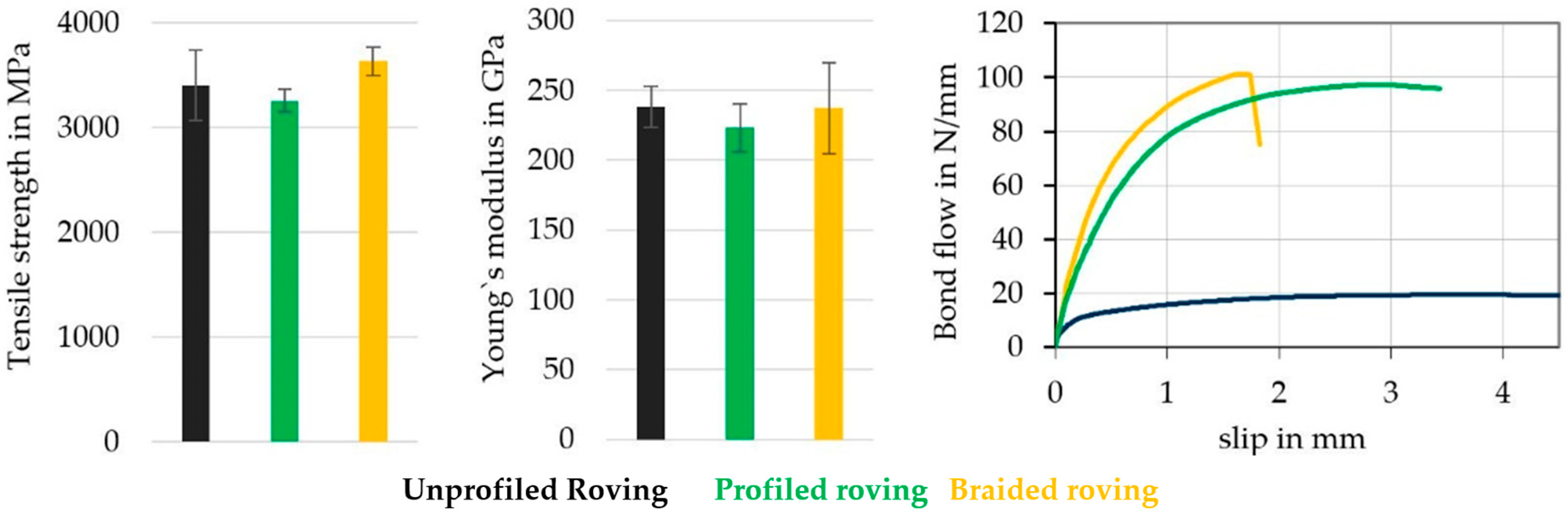

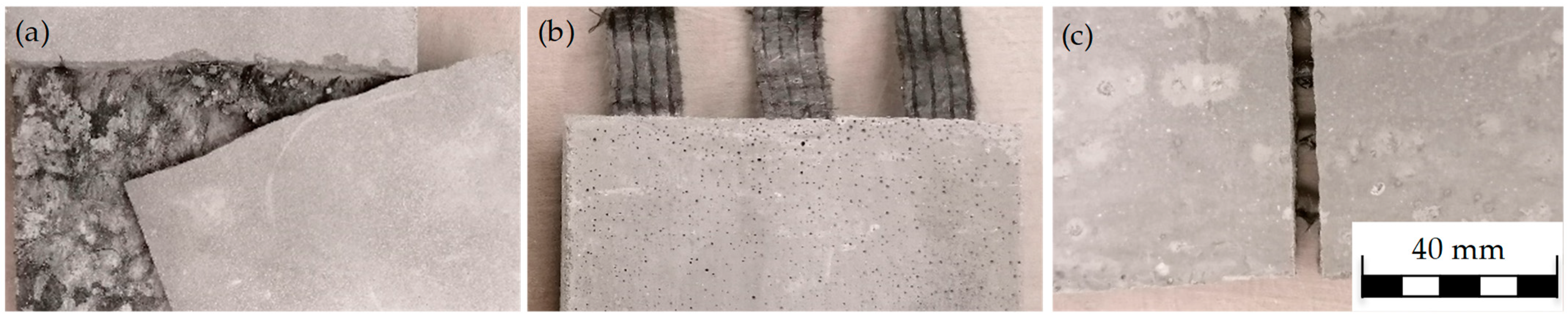

2.1. Surface Profiling of Textile Reinforcements

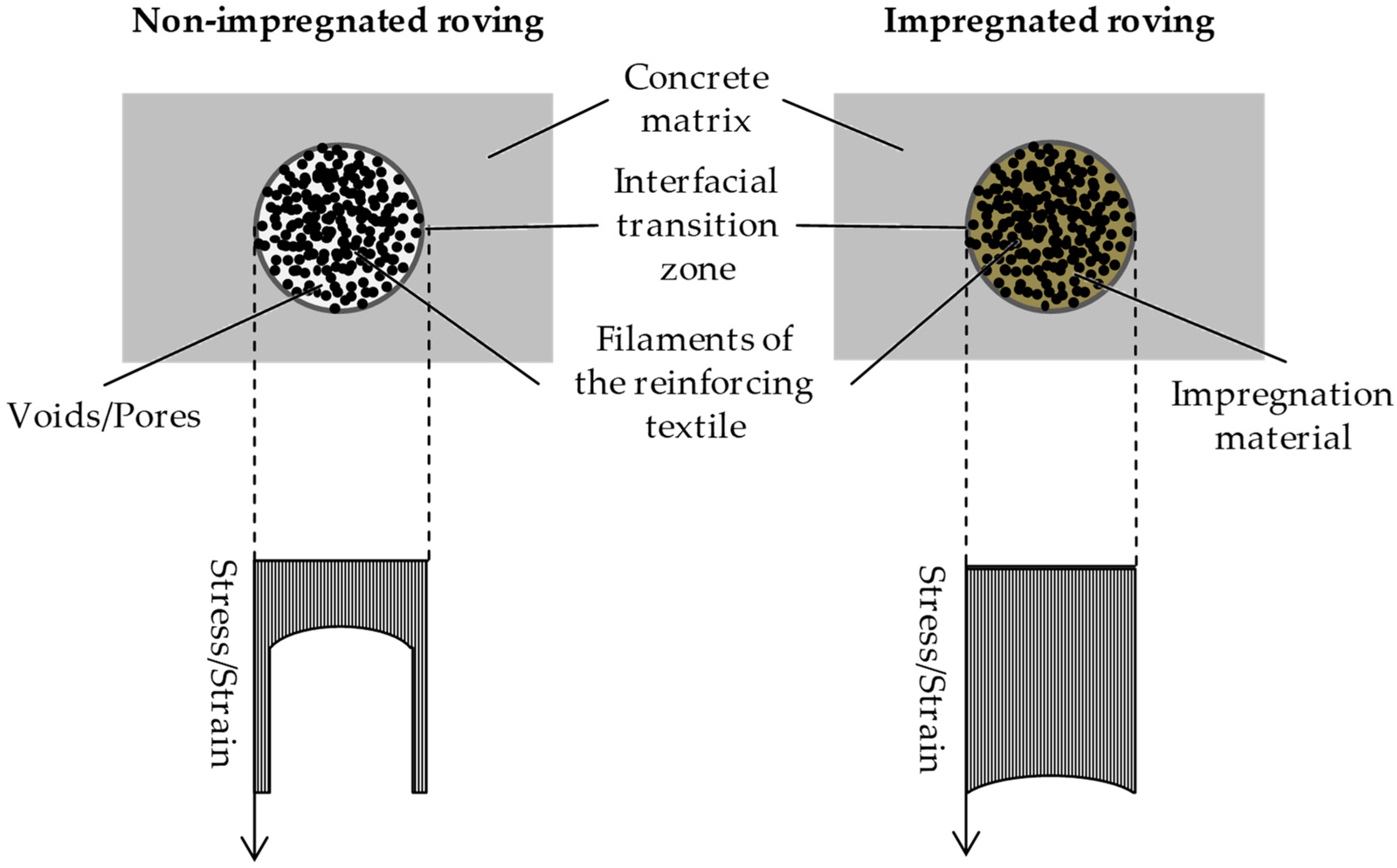

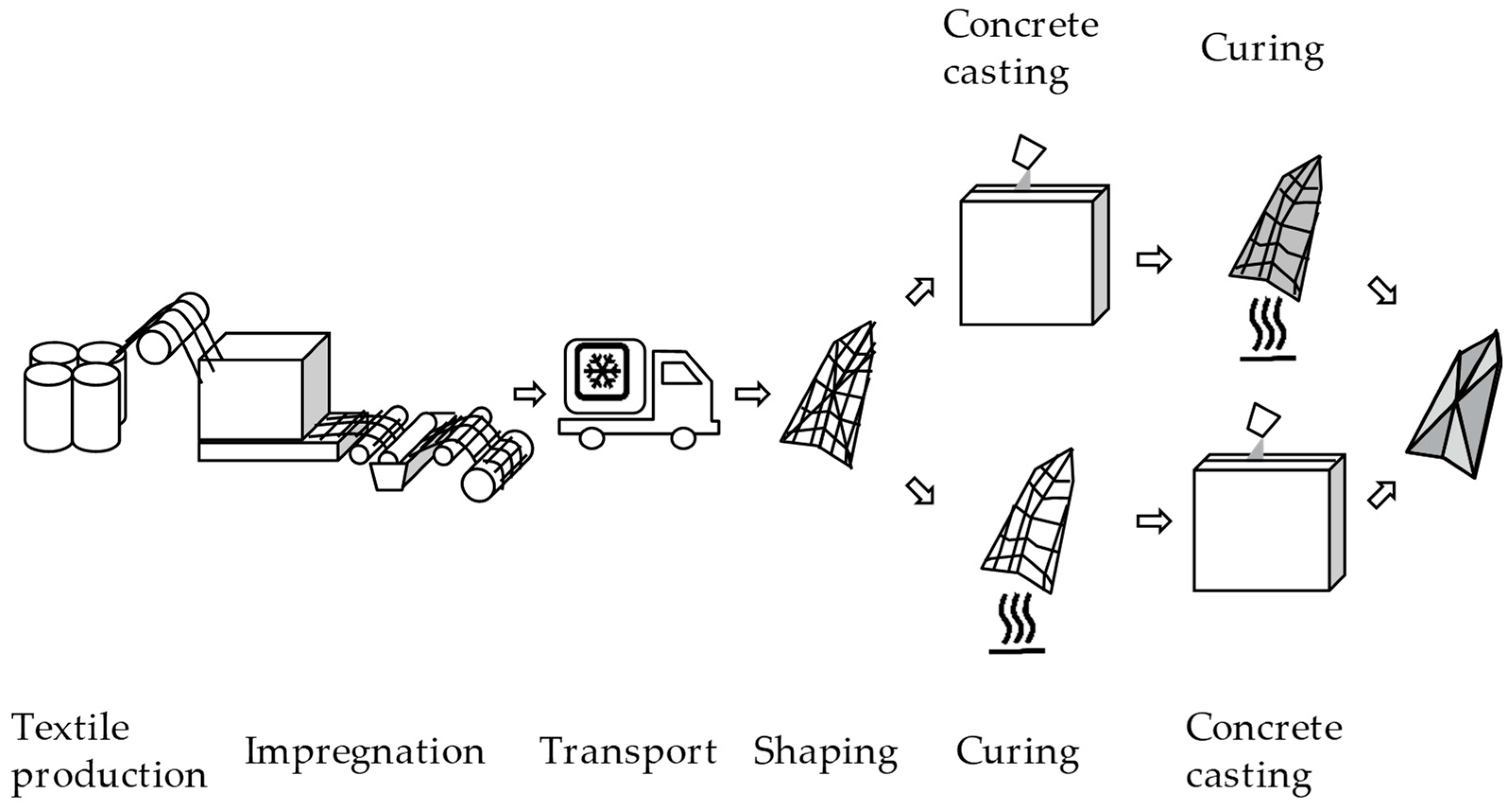

2.2. Preimpregnated Textile Reinforcement Cured in Concrete

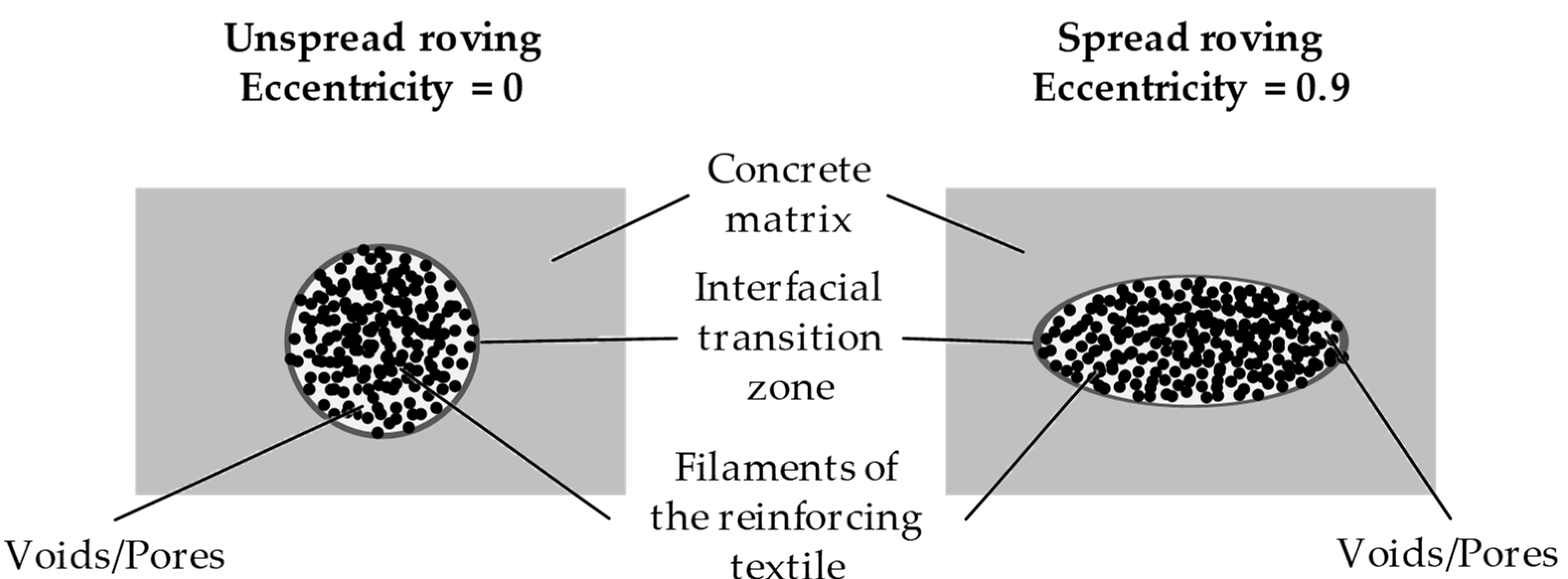

2.3. Textile Reinforcements Based on Spread Rovings

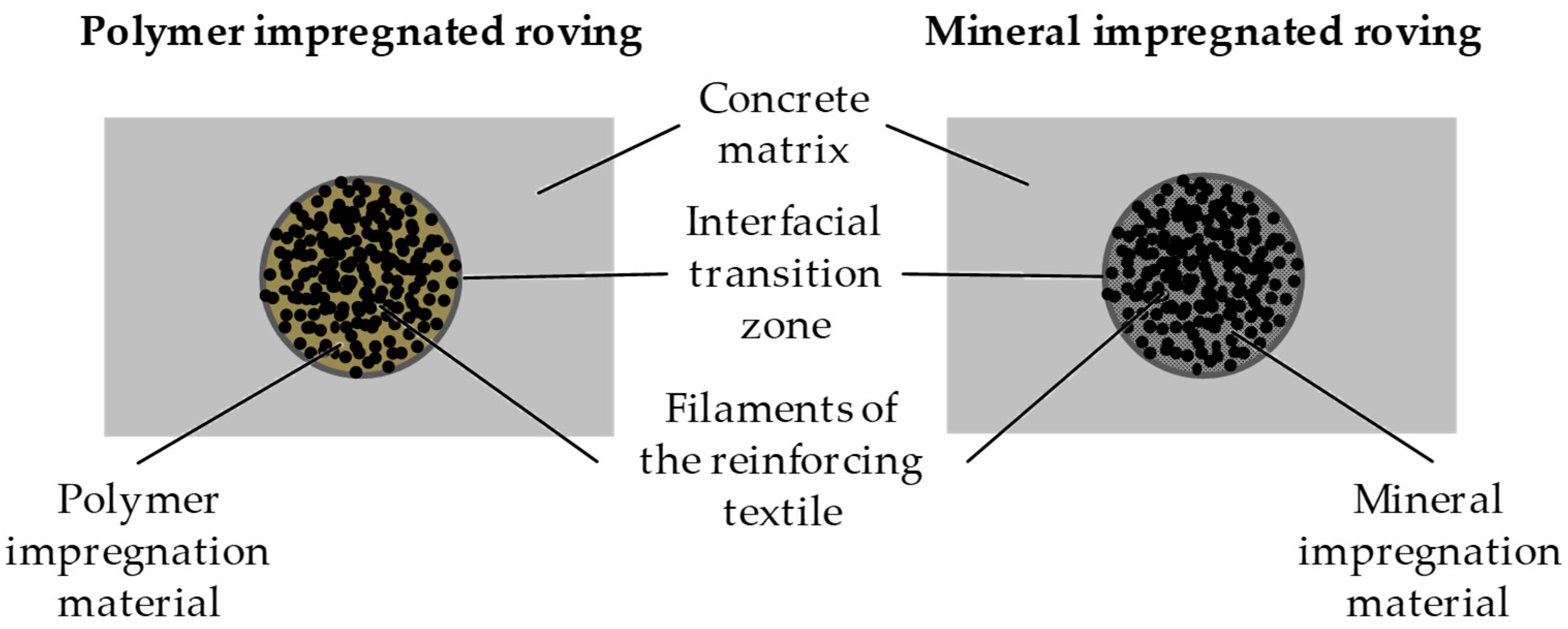

2.4. Mineral-Impregnated Textile Reinforcements

3. Improving Drapability of Reinforcement Textiles

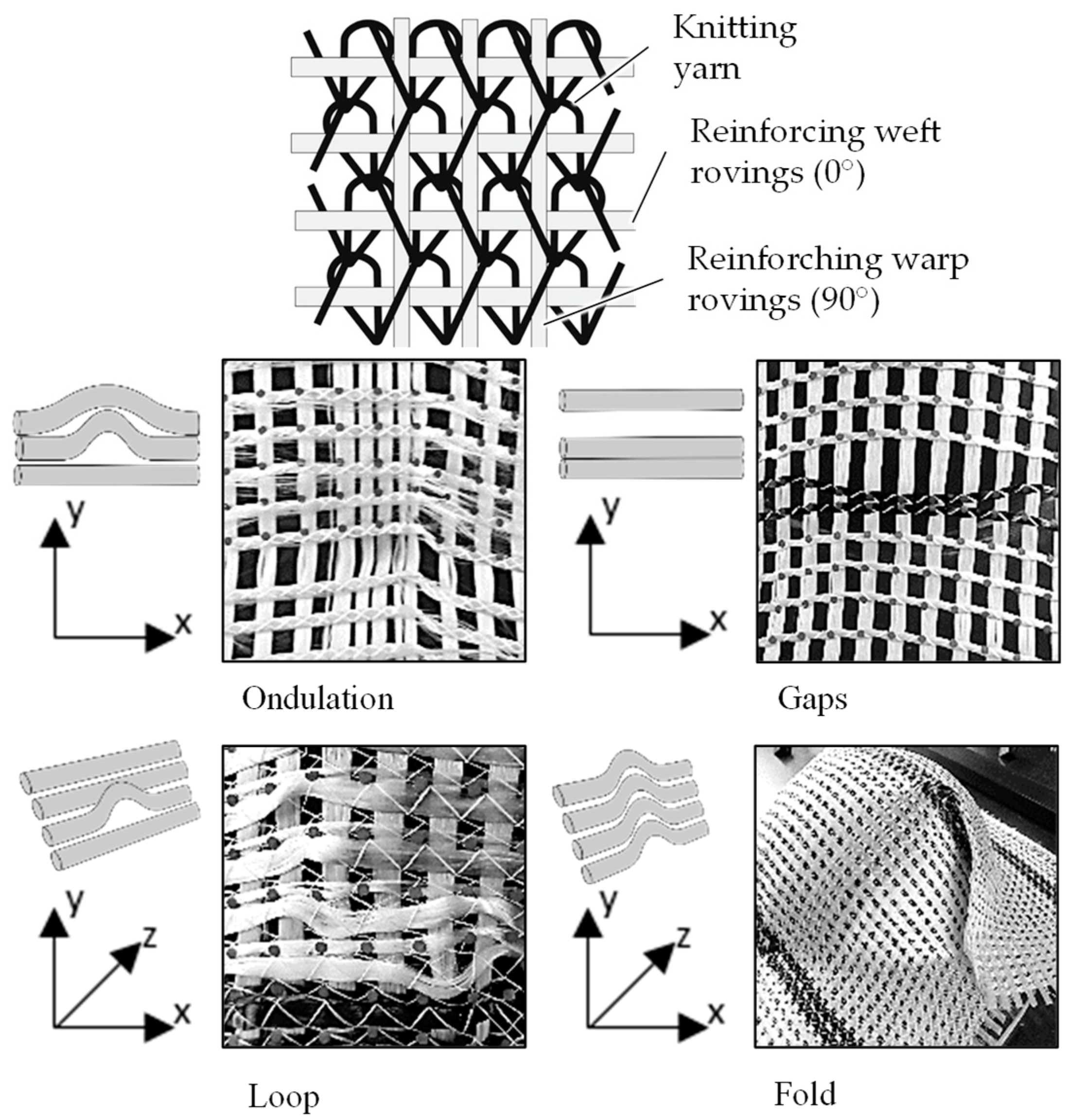

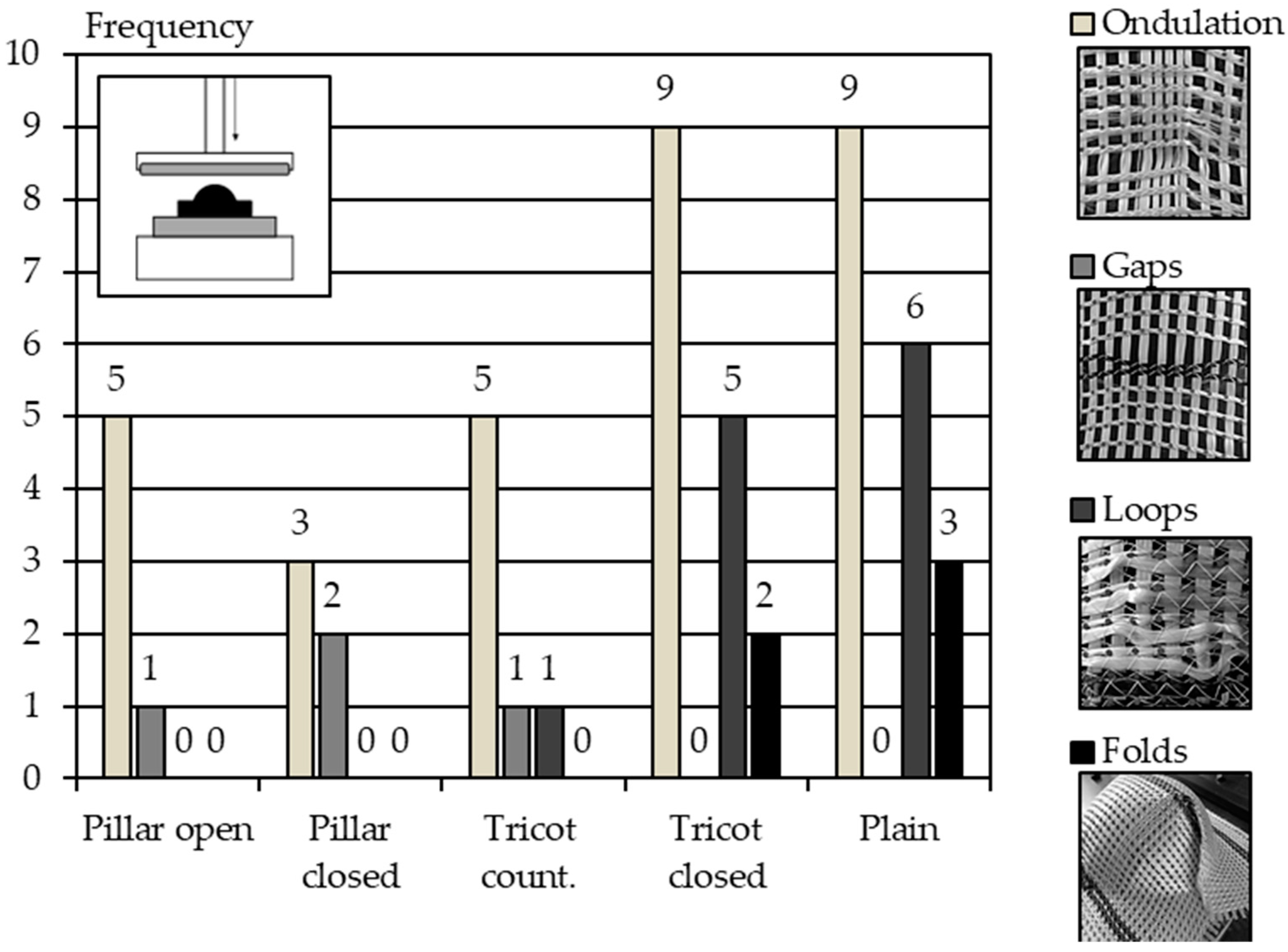

3.1. Adapting the Textile Structure of the Reinforcement Textile

- -

- The binding type significantly influences the formation of the various draping effects.

- -

- The tricot closed and plain binding types show more or less pronounced wrinkling, which reduces the drape quality.

- -

- Cross-connections of the rovings in the tricot closed and plain binding types prevent roving displacement parallel to the warp direction.

- -

- Both pillar binding types can be draped almost faultlessly.

3.2. Thermoset Preimpregnated Textile Reinforcements

3.3. Thermoplastic-Impregnated Textile Reinforcements

4. Novel Manufacturing Methods

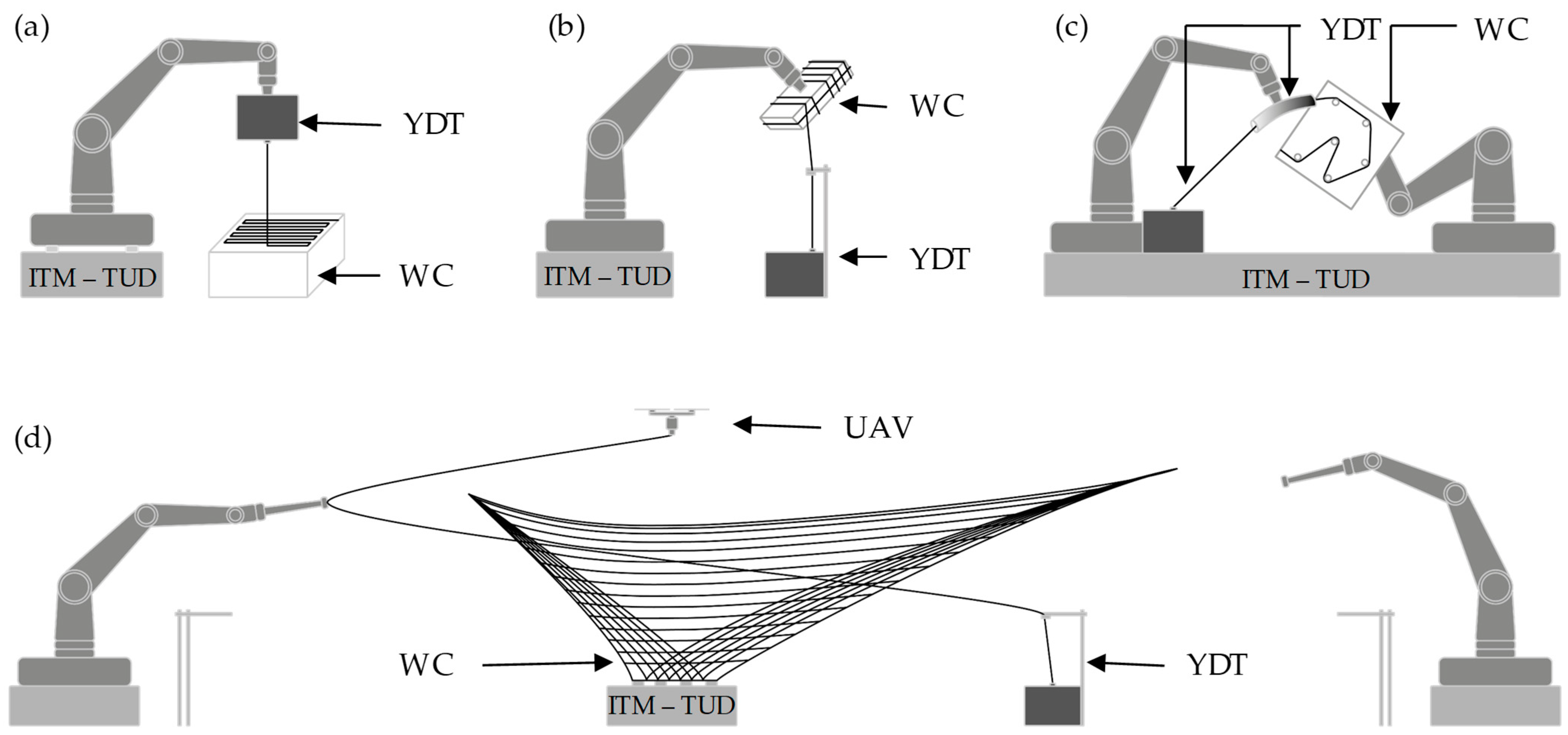

4.1. Robot-Based Manufacturing Methods for Reinforcement Textiles

4.1.1. Process Principle A

4.1.2. Process Principle B

4.1.3. Process Principle C

4.1.4. Process Principle D

4.1.5. Future Process Principle E

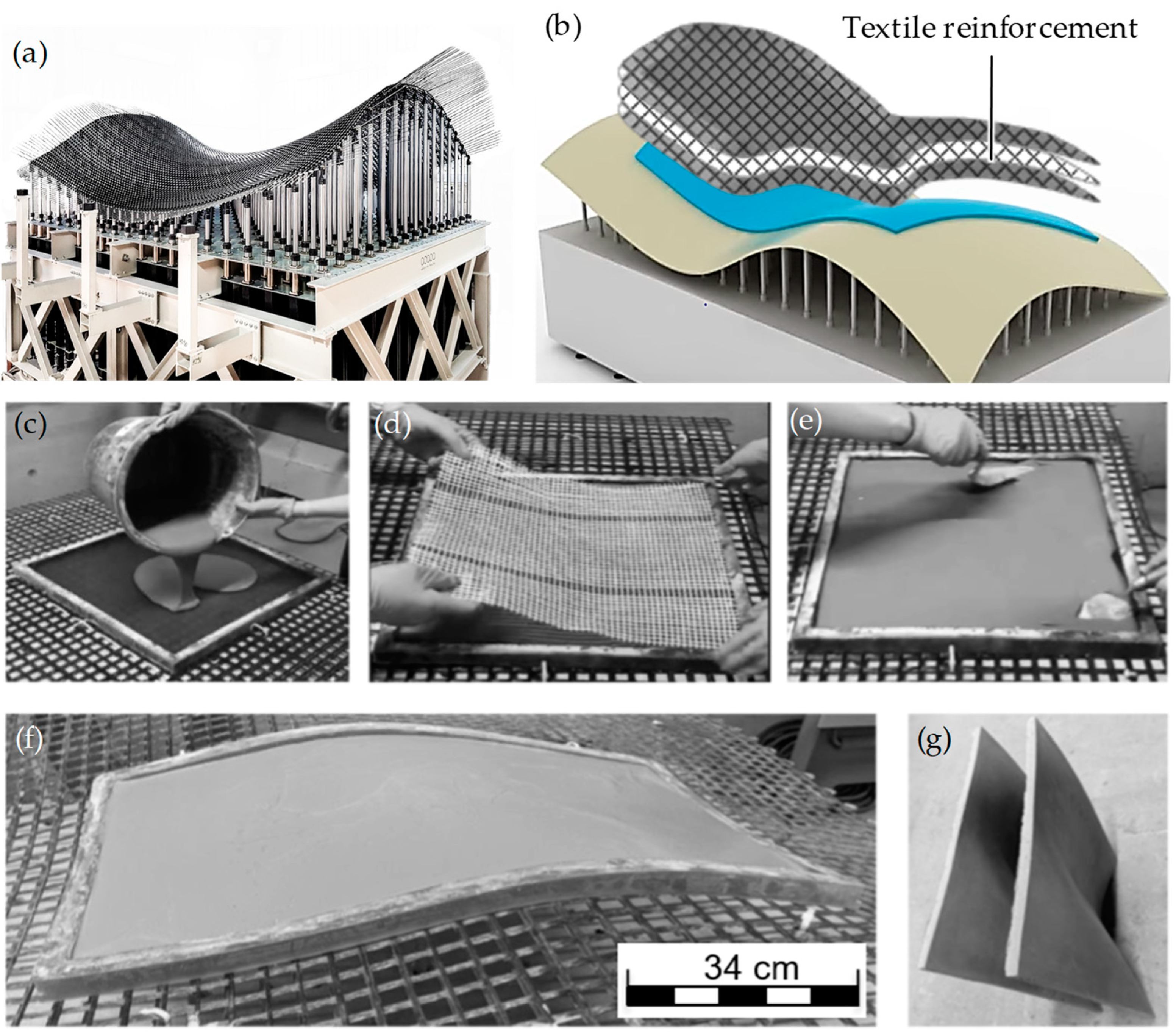

4.2. Production of Shaped TRC Elements Based on Adpative Molds

- -

- Definition of design potentials and aesthetic trends in construction for TRC elements.

- -

- Classification of building components with regard to form specifications and derivation of ideal textile architectures for the classified component groups.

- -

- Fabrication of component-specific textile reinforcements.

- -

- Shaping of TRC in the fresh state.

- -

- In situ integration of insulating materials on the TRC panels in the precast plant.

- -

- Integration of anchoring elements into the textile reinforcement.

- -

- Design of a process chain for series production of functionally integrated curved TRC panels.

- -

- Preparation of the implementation of a complete process chain for the form-flexible production of TRC components.

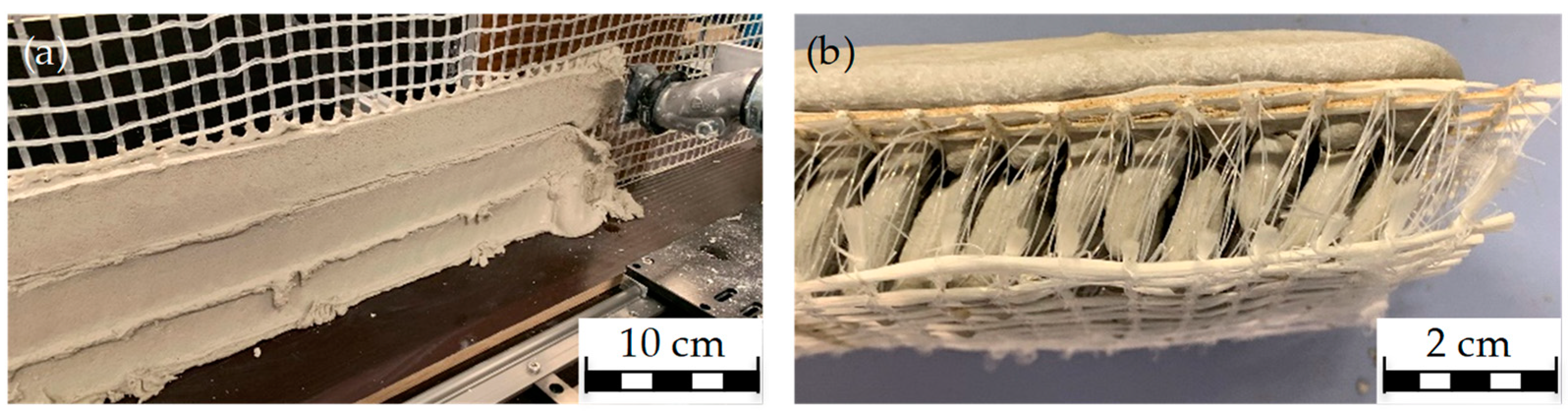

4.3. Textile Reinforcement for Additive Manufacturing of Concrete

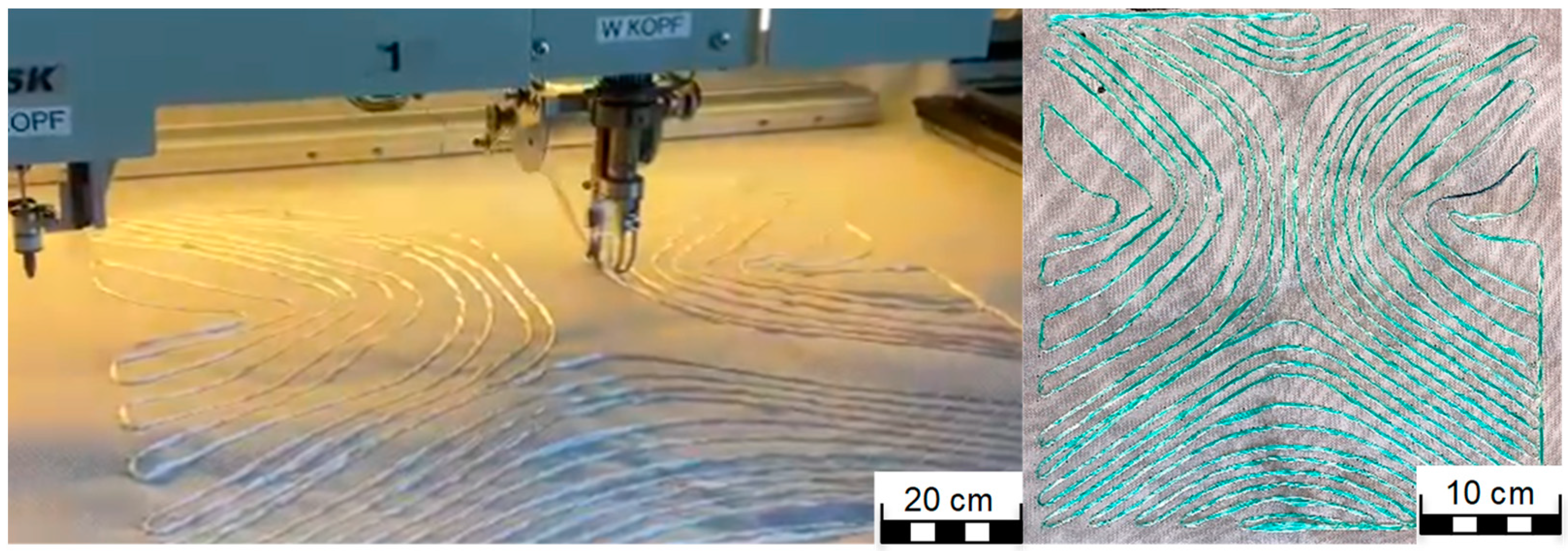

4.4. Load-Path-Oriented Textile Reinforcement Using Tailored Fiber Placement

5. Integration of Additional Functions in Reinforcement Textiles

5.1. Structural Health Monitoring

5.2. Energy Harvesting

6. Increasing the Sustainability of TRC

7. Summary and Outlook

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Barbosa, F.; Woetzel, J.; Mischke, J.; Ribeirinho, M.J.; Sridhar, M.; Parsons, M.; Bertram, N.; Brown, S. Reinventing Construction: A Route to Higher Productivity. 2017. Available online: https://www.mckinsey.com/~/media/mckinsey/business%20functions/operations/our%20insights/reinventing%20construction%20through%20a%20productivity%20revolution/mgi-reinventing-construction-a-route-to-higher-productivity-full-report.pdf (accessed on 31 July 2023).

- United Nations Environment Programme. 2021 Global Status Report for Buildings and Construction: Towards a Zero-Emission, Efficient and Resilient Buildings and Construction Sector, Nairobi. 2021. Available online: https://globalabc.org/sites/default/files/2021-10/GABC_Buildings-GSR-2021_BOOK.pdf (accessed on 31 July 2023).

- Backes, J.G.; Traverso, M. Application of Life Cycle Sustainability Assessment in the Construction Sector: A Systematic Literature Review. Processes 2021, 9, 1248. [Google Scholar] [CrossRef]

- Choi, J. Strategy for reducing carbon dioxide emissions from maintenance and rehabilitation of highway pavement. J. Clean. Prod. 2019, 209, 88–100. [Google Scholar] [CrossRef]

- World Economic Forum. Shaping the Future of Construction: A Breakthrough in Mindset and Technology. 2016. Available online: https://www3.weforum.org/docs/WEF_Shaping_the_Future_of_Construction_full_report__.pdf (accessed on 31 July 2023).

- Sameer, H.; Bringezu, S. Life cycle input indicators of material resource use for enhancing sustainability assessment schemes of buildings. J. Build. Eng. 2019, 21, 230–242. [Google Scholar] [CrossRef]

- UNEP. Resource Efficiency: Potential and Economic Implications. A Report of the International Resource Panel. 2017. Available online: https://wedocs.unep.org/bitstream/handle/20.500.11822/21230/resource_efficiency_potential_economic_implications.pdf?sequence=1&%3BisAllowed= (accessed on 31 July 2023).

- Pasanen, P.; Tikka, S.; Le Gouvello, L.; Koukoulopoulos, K.; Kalfountzos, V.; Bounds, L. Decarbonizing Construction: Guidance for Investors and Developers to Reduce Embodied Carbon; World Business Council for Sustainable Development: Geneva, Switzerland, 2021. [Google Scholar]

- Hatzfeld, T.; Schlüter, D.; Scope, C.; Krois, K.; Guenther, E.; Etzold, B.; Curbach, M. Rethinking residential energy storage: GHG minimization potential of a Carbon Reinforced Concrete facade with function integrated supercapacitors. Build. Environ. 2022, 224, 109520. [Google Scholar] [CrossRef]

- Gagg, C.R. Cement and concrete as an engineering material: An historic appraisal and case study analysis. Eng. Fail. Anal. 2014, 40, 114–140. [Google Scholar] [CrossRef]

- Wight, J.K. Reinforced Concrete: Mechanics and Design, 7th ed.; Pearson: Boston, MA, USA; Amsterdam, The Netherlands; London, UK, 2016; ISBN 978-1-292-10600-7. [Google Scholar]

- Bentur, A.; Diamond, S.; Berke, N.S. Steel Corrosion in Concrete: Fundamentals and Civil Engineering Practice, 1st ed.; E & FN Spon: London, UK, 1997; ISBN 0419225307. [Google Scholar]

- Hegger, J.; Voss, S. Investigations on the bearing behaviour and application potential of textile reinforced concrete. Eng. Struct. 2008, 30, 2050–2056. [Google Scholar] [CrossRef]

- Friese, D.; Scheurer, M.; Hahn, L.; Gries, T.; Cherif, C. Textile reinforcement structures for concrete construction applications—A review. J. Compos. Mater. 2022, 56, 4041–4064. [Google Scholar] [CrossRef]

- Rempel, S.; Kulas, C.; Will, N.; Bielak, J. Extremely Light and Slender Precast Pedestrian-Bridge Made Out of Textile-Reinforced Concrete (TRC). In High Tech Concrete: Where Technology and Engineering Meet; Hordijk, D.A., Luković, M., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 2530–2537. ISBN 978-3-319-59470-5. [Google Scholar]

- Kromoser, B.; Preinstorfer, P.; Kollegger, J. Building lightweight structures with carbon-fiber-reinforced polymer-reinforced ultra-high-performance concrete: Research approach, construction materials, and conceptual design of three building components. Struct. Concr. 2019, 20, 730–744. [Google Scholar] [CrossRef]

- May, S.; Steinbock, O.; Michler, H.; Curbach, M. Precast Slab Structures Made of Carbon Reinforced Concrete. Structures 2019, 18, 20–27. [Google Scholar] [CrossRef]

- Raupach, M.; Morales Cruz, C. Textile-Reinforced Concrete: Selected Case Studies. In Textile Fibre Composites in Civil Engineering; Elsevier: Amsterdam, The Netherlands, 2016; pp. 275–299. ISBN 9781782424468. [Google Scholar]

- O’Hegarty, R.; Kinnane, O. Review of precast concrete sandwich panels and their innovations. Constr. Build. Mater. 2020, 233, 117145. [Google Scholar] [CrossRef]

- Tomoscheit, S.; Gries, T.; Horstmann, M.; Hegger, J. Project Life INSUSHELL: Reducing the Carbon Footprint in Concrete Construction. Int. J. Sustain. Build. Technol. Urban Dev. 2011, 2, 162–169. [Google Scholar] [CrossRef]

- Shams, A.; Stark, A.; Hoogen, F.; Hegger, J.; Schneider, H. Innovative sandwich structures made of high performance concrete and foamed polyurethane. Compos. Struct. 2015, 121, 271–279. [Google Scholar] [CrossRef]

- Adam, V.; Bielak, J.; Dommes, C.; Will, N.; Hegger, J. Flexural and Shear Tests on Reinforced Concrete Bridge Deck Slab Segments with a Textile-Reinforced Concrete Strengthening Layer. Materials 2020, 13, 4210. [Google Scholar] [CrossRef] [PubMed]

- Koutas, L.N.; Tetta, Z.; Bournas, D.A.; Triantafillou, T.C. Strengthening of Concrete Structures with Textile Reinforced Mortars: State-of-the-Art Review. J. Compos. Constr. 2019, 23, 03118001. [Google Scholar] [CrossRef]

- Tietze, M.; Kirmse, S.; Kahnt, A.; Schladitz, F.; Curbach, M. The ecological and economic advantages of carbon reinforced concrete—Using the C 3 result house CUBE especially the BOX value chain as an example. Civ. Eng. Des. 2022, 4, 79–88. [Google Scholar] [CrossRef]

- Chudoba, R.; Sharei, E.; Scholzen, A. A strain-hardening microplane damage model for thin-walled textile-reinforced concrete shells, calibration procedure, and experimental validation. Compos. Struct. 2016, 152, 913–928. [Google Scholar] [CrossRef]

- Häußler-Combe, U.; Hartig, J. Bond and failure mechanisms of textile reinforced concrete (TRC) under uniaxial tensile loading. Cem. Concr. Compos. 2007, 29, 279–289. [Google Scholar] [CrossRef]

- Li, Y.; Bielak, J.; Hegger, J.; Chudoba, R. An incremental inverse analysis procedure for identification of bond-slip laws in composites applied to textile reinforced concrete. Compos. Part B Eng. 2018, 137, 111–122. [Google Scholar] [CrossRef]

- Fib Model Code for Concrete Structures 2010; International Federation for Structural Concrete: Lausanne, Switzerland; Ernst & Sohn: Berlin, Germany, 2013; ISBN 978-3-433-03061-5.

- Bentur, A.; Mindess, S. Fibre Reinforced Cementitious Composites, 2nd ed.; Taylor & Francis: London, UK, 2007; ISBN 0-203-08872-7. [Google Scholar]

- Hahn, L.; Rittner, S.; Nuss, D.; Ashir, M.; Cherif, C. Development of Methods to Improve the Mechanical Performance of Coated Grid-Like Non-Crimp Fabrics for Construction Applications. Fibres Text. East. Eur. 2019, 27, 51–58. [Google Scholar] [CrossRef]

- Cherif, C. (Ed.) Textile Materials for Lightweight Constructions; Springer: Berlin/Heidelberg, Germany, 2016; ISBN 978-3-662-46340-6. [Google Scholar]

- Betz, P.; Schumann, A.; Scheerer, S.; Curbach, M. Carbonstäbe im Bauwesen—Teil 5: Einflussfaktoren auf das Verbundverhalten. Beton Stahlbetonbau 2021, 116, 924–934. [Google Scholar] [CrossRef]

- Schumann, A.; May, M.; Schladitz, F.; Scheerer, S.; Curbach, M. Carbonstäbe im Bauwesen. Beton Stahlbetonbau 2020, 115, 962–971. [Google Scholar] [CrossRef]

- Esfandeh, M.; Sabet, A.R.; Rezadoust, A.M.; Alavi, M.B. Bond performance of FRP rebars with various surface deformations in reinforced concrete. Polym. Compos. 2009, 30, 576–582. [Google Scholar] [CrossRef]

- Preinstorfer, P.; Kromoser, B.; Kollegger, J. Einflussparameter auf die Spaltrissbildung in Textilbeton. Beton Stahlbetonbau 2018, 113, 877–885. [Google Scholar] [CrossRef]

- Kruppke, I.; Butler, M.; Schneider, K.; Hund, R.-D.; Mechtcherine, V.; Cherif, C. Carbon Fibre Reinforced Concrete: Dependency of Bond Strength on Tg of Yarn Impregnating Polymer. Mater. Sci. Appl. 2019, 10, 328–348. [Google Scholar] [CrossRef]

- Penzel, P.; Hahn, L.; Abdkader, A.; Cherif, C. Increased performance and sustainability through the use of profiled textile reinforcements for concrete applications. Available online: https://textination.de/system/files/2023-01/Verbundgerecht%20profilierte%20Textilbetonbewehrungen_en.pdf (accessed on 31 July 2023).

- Penzel, P.; May, M.; Hahn, L.; Cherif, C.; Curbach, M.; Mechtcherine, V. Tetrahedral Profiled Carbon Rovings for Concrete Reinforcements. Solid State Phenom. 2022, 333, 173–182. [Google Scholar] [CrossRef]

- Penzel, P.; May, M.; Hahn, L.; Scheerer, S.; Michler, H.; Butler, M.; Waldmann, M.; Curbach, M.; Cherif, C.; Mechtcherine, V. Bond Modification of Carbon Rovings through Profiling. Materials 2022, 15, 5581. [Google Scholar] [CrossRef]

- Abdkader, A.; Penzel, P.; Friese, D.; Overberg, M.; Hahn, L.; Butler, M.; Mechtcherine, V.; Cherif, C. Improved Tensile and Bond Properties through Novel Rod Constructions Based on the Braiding Technique for Non-Metallic Concrete Reinforcements. Materials 2023, 16, 2459. [Google Scholar] [CrossRef]

- Manfred, C.; Sebastian, M.; Müller, E.; Schumann, A.; Schütze, E.; Wagner, J. Verstärken mit Carbonbeton. In BetonKalender 2022; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2022; pp. 761–804. [Google Scholar]

- Cherif, C.; Diestel, O.; Engler, T.; Hufnagl, E.; Weiland, S. Textilbewehrter Beton. In Textile Materials for Lightweight Constructions: Technologies—Methods—Materials—Properties; Cherif, C., Ed.; Springer: Berlin/Heidelberg, Germany, 2016; pp. 666–687. [Google Scholar]

- Waldmann, M.; Rittner, S.; Cherif, C. Bewehrungsstab zum Einbringen in eine Betonmatrix sowie dessen Herstellungsverfahren, ein Bewehrungssystem aus Mehreren Bewehrungsstäben sowie ein Betonbauteil. Germany Patent DE 10 2017 107 948 A1, 12 April 2017. [Google Scholar]

- Lengsfeld, H.; Mainka, H.; Altstädt, V. Carbon Fibers; Carl Hanser GmbH & Co. KG: Munich, Germany, 2020; ISBN 978-1-56990-828-0. [Google Scholar]

- Glowania, M.; Gries, T.; Schoene, J.; Schleser, M.; Reisgen, U. Innovative Coating Technology for Textile Reinforcements of Concrete Applications. Key Eng. Mater. 2011, 466, 167–173. [Google Scholar] [CrossRef]

- Schoene, J.; Glowania, M.; Schleser, M.; Gries, T.; Reisgen, U. Betonteil und Verfahren zum Bewehren von Teilen aus Beton, patent DE 10 2010 022 396 A1, 1 December 2011. Available online: https://patentimages.storage.googleapis.com/1a/79/95/cd17234bb3a600/DE102010022396A1.pdf (accessed on 31 July 2023).

- Scheurer, M.; Kalthoff, M.; Matschei, T.; Raupach, M.; Gries, T. Analysis of Curing and Mechanical Performance of Pre-Impregnated Carbon Fibers Cured within Concrete. Textiles 2022, 2, 657–672. [Google Scholar] [CrossRef]

- Scheurer, M.; Dittel, G.; Kalthoff, M.; Raupach, M.; Matschei, T.; Gries, T. Evaluation of Properties of Impregnated Reinforcement Textiles Cured within Concrete for Applications in Concrete Extrusion. In Building for the Future: Durable, Sustainable, Resilient; Ilki, A., Çavunt, D., Çavunt, Y.S., Eds.; Springer Nature: Cham, Switzerland, 2023; pp. 1293–1302. ISBN 978-3-031-32518-2. [Google Scholar]

- Dolatabadi, M.K.; Janetzko, S.; Gries, T.; Kang, B.-G.; Sander, A. Permeability of AR-glass fibers roving embedded in cementitious matrix. Mater. Struct. 2011, 44, 245–251. [Google Scholar] [CrossRef]

- Janetzko, S.; Kravaev, P.; Gries, T.; Kang, B.-G.; Brameshuber, W.; Schneider, M.; Hegger, J. Textile Reinforcements with Spread and Commingled Yarn Structures. In Proceedings of the Textile Reinforced Concrete: 2nd ICTRC, International Conference of Textile Reinforced Concrete, Aachen, Germany, 6–8 September 2010; Brameshuber, W., Ed.; RILEM Publications: Bagneux, France, 2010; pp. 37–44, ISBN 978-2-35158-107-0. [Google Scholar]

- Perry, G.; Dittel, G.; Gries, T.; Goldfeld, Y. Mutual Effect of Textile Binding and Coating on the Structural Performance of TRC Beams. J. Mater. Civ. Eng. 2020, 32, 04020232. [Google Scholar] [CrossRef]

- Quadflieg, T.; Stolyarov, O.; Gries, T. Influence of the fabric construction parameters and roving type on the tensile property retention of high-performance rovings in warp-knitted reinforced fabrics and cement-based composites. J. Ind. Text. 2017, 47, 453–471. [Google Scholar] [CrossRef]

- Scheurer, M.; Quenzel, P.; Nölke, P.; Reuter-Schniete, J.; Gries, T. Investigating the feasibility of using carbon fiber tapes as reinforcement for 3D concrete printing. Civ. Eng. Des. 2021, 3, 136–142. [Google Scholar] [CrossRef]

- Cohen, Z.; Peled, A. Effect of nanofillers and production methods to control the interfacial characteristics of glass bundles in textile fabric cement-based composites. Compos. Part A Appl. Sci. Manuf. 2012, 43, 962–972. [Google Scholar] [CrossRef]

- Dvorkin, D.; Peled, A. Effect of reinforcement with carbon fabrics impregnated with nanoparticles on the tensile behavior of cement-based composites. Cem. Concr. Res. 2016, 85, 28–38. [Google Scholar] [CrossRef]

- Nadiv, R.; Peled, A.; Mechtcherine, V.; Hempel, S.; Schroefl, C. Micro-and nanoparticle mineral coating for enhanced properties of carbon multifilament yarn cement-based composites. Compos. Part B Eng. 2017, 111, 179–189. [Google Scholar] [CrossRef]

- Nadiv, R.; Peled, A.; Mechtcherine, V.; Hempel, S.; Nicke, D.; Schroefl, C. Improved Bonding of Carbon Fiber Reinforced Cement Composites by Mineral Particle Coating. In Strain-Hardening Cement-Based Composites; Mechtcherine, V., Slowik, V., Kabele, P., Eds.; Springer: Dordrecht, The Netherlands, 2018; pp. 392–399. ISBN 978-94-024-1193-5. [Google Scholar]

- Signorini, C.; Nobili, A.; Cedillo González, E.I.; Siligardi, C. Silica coating for interphase bond enhancement of carbon and AR-glass Textile Reinforced Mortar (TRM). Compos. Part B Eng. 2018, 141, 191–202. [Google Scholar] [CrossRef]

- Schneider, K.; Lieboldt, M.; Liebscher, M.; Fröhlich, M.; Hempel, S.; Butler, M.; Schröfl, C.; Mechtcherine, V. Mineral-Based Coating of Plasma-Treated Carbon Fibre Rovings for Carbon Concrete Composites with Enhanced Mechanical Performance. Materials 2017, 10, 360. [Google Scholar] [CrossRef]

- Schneider, K.; Michel, A.; Liebscher, M.; Terreri, L.; Hempel, S.; Mechtcherine, V. Mineral-impregnated carbon fibre reinforcement for high temperature resistance of thin-walled concrete structures. Cem. Concr. Compos. 2019, 97, 68–77. [Google Scholar] [CrossRef]

- de Castro Silva, R.M.; Zhao, J.; Liebscher, M.; Curosu, I.; de Andrade Silva, F.; Mechtcherine, V. Bond behavior of polymer- and mineral-impregnated carbon fiber yarns towards concrete matrices at elevated temperature levels. Cem. Concr. Compos. 2022, 133, 104685. [Google Scholar] [CrossRef]

- Kämpfe, H. Bewehrungstechnik: Grundlagen—Praxis—Beispiele—Wirtschaftlichkeit, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2020; ISBN 978-3-8348-1455-5. [Google Scholar]

- Moro, J.L.; Schlaich, J. Baukonstruktion—Vom Prinzip zum Detail, 3rd ed.; Springer: Berlin/Heidelberg, Germany, 2021; ISBN 978-3-662-64154-5. [Google Scholar]

- Curbach, M.; Hegger, J.; Schladitz, F.; Tietze, M.; Lieboldt, M. (Eds.) Handbuch Carbonbeton: Einsatz Nichtmetallischer Bewehrung; Ernst & Sohn: Berlin, Germany, 2023; ISBN 978-3-433-03206-0. [Google Scholar]

- Hu, J.; Chan, Y.-F. Effect of Fabric Mechanical Properties on Drape. Text. Res. J. 1998, 68, 57–64. [Google Scholar] [CrossRef]

- Dittel, G.; Koch, A.; Gries, T. Innovative Manufacturing Methods of Drapable Textile Reinforcements for Folded/Double Curved Concrete Facade Elements. In Proceedings of the International Conference on Advances in Construction Materials and Systems, in Conjuction with 71st RILEM Annual Week, Chennai, India, 3–8 September 2017; Santhanam, M., Gettu, R., Radhakrishna, G.P., Sunitha, K.N., Eds.; RILEM Publications: Paris, France, 2017; pp. 252–257, ISBN 978-2-35158-194-0. [Google Scholar]

- Cherif, C. (Ed.) The Textile Process Chain and Classification of Textile Semi-finished Products. In Textile Materials for Lightweight Constructions; Springer: Berlin/Heidelberg, Germany, 2016; pp. 9–35. ISBN 978-3-662-46340-6. [Google Scholar]

- Krieger, H. Methode zur Auslegung von Gelegen mit Lokal Angepassten Fertigungsparametern für Hochleistungs-Faserverbundkunststoffe. Ph.D. Thesis, Rheinisch-Westfälische Technische Hochschule Aachen, Aachen, Germany, 2015. [Google Scholar]

- Krieger, H.; Gries, T.; Stapleton, S.E. Design of Tailored Non-Crimp Fabrics Based on Stitching Geometry. Appl. Compos. Mater. 2018, 25, 113–127. [Google Scholar] [CrossRef]

- Bhat, S.; Kalthoff, M.; Shroeder, P.; Gries, T.; Matschei, T. Textile Reinforced Concrete for free-form concrete elements: Influence of the binding type of textile reinforcements on the drapability for manufacturing double-curved concrete elements. MATEC Web Conf. 2022, 364, 5019. [Google Scholar] [CrossRef]

- Centea, T.; Grunenfelder, L.K.; Nutt, S.R. A review of out-of-autoclave prepregs—Material properties, process phenomena, and manufacturing considerations. Compos. Part A Appl. Sci. Manuf. 2015, 70, 132–154. [Google Scholar] [CrossRef]

- Mi, Z.; Hu, Y.; Li, Q.; Gao, X.; Yin, T. Maturity model for fracture properties of concrete considering coupling effect of curing temperature and humidity. Constr. Build. Mater. 2019, 196, 1–13. [Google Scholar] [CrossRef]

- Mi, Z.; Li, Q.; Hu, Y.; Liu, C.; Qiao, Y. Fracture Properties of Concrete in Dry Environments with Different Curing Temperatures. Appl. Sci. 2020, 10, 4734. [Google Scholar] [CrossRef]

- Beckmann, B.; Bielak, J.; Scheerer, S.; Schmidt, C.; Hegger, J.; Curbach, M. Standortübergreifende Forschung zu Carbonbetonstrukturen im SFB/TRR 280. Bautechnik 2021, 98, 232–242. [Google Scholar] [CrossRef]

- Heins, K.; Lesker, S.; Pütz, J.; Hüntemann, M.; Gries, T. Effect of thermoplastic impregnation on the mechanical behaviour of textile reinforcement for concrete. SN Appl. Sci. 2023, 5, 93. [Google Scholar] [CrossRef]

- Friese, D.; Hahn, L.; Cherif, C. Biologically Inspiried Load Adapted 3D Textile Reinforcement Structures. Mater. Sci. Forum 2022, 1063, 101–110. [Google Scholar] [CrossRef]

- Otto, J.; Kortmann, J.; Krause, M. Wirtschaftliche Perspektiven von Beton-3D-Druckverfahren. Beton Stahlbetonbau 2020, 115, 586–597. [Google Scholar] [CrossRef]

- Hahn, L.; Rittner, S.; Bauer, C.; Cherif, C. Development of alternative bondings for the production of stitch-free non-crimp fabrics made of multiple carbon fiber heavy tows for construction industry. J. Ind. Text. 2018, 48, 660–681. [Google Scholar] [CrossRef]

- Friese, D.; Mersch, J.; Hahn, L.; Cherif, C. (Eds.) Development of a Yarn Guiding and Impregnation Technology for Robot-Asissted Fiber Manufacturing of 3d Textile Reinforcement Structures; Zenodo: Honolulu, HI, USA, 2023. [Google Scholar]

- Michel, A.; Zernsdorf, K.; Mechtcherine, V. Mineral-bonded carbon fiber reinforcement for novel concrete construction technologies. In Proceedings of the International Textile Conference, Dresden, Germany, 28–29 November 2019; ADDITC 2019; Institute für Textilmaschinen und Textile Hochleistungswerkstofftechnik: Dresden, Germany, 2019; p. 84. [Google Scholar]

- Mechtcherine, V.; Michel, A.; Liebscher, M.; Schneider, K.; Großmann, C. Neue Carbonfaserbewehrung für digitalen automatisierten Betonbau. Beton Stahlbetonbau 2019, 114, 947–955. [Google Scholar] [CrossRef]

- Minsch, N. Process and Method Development for the Generative Manufacturing of Complex Lightweight Structures in Hybrid Design. Ph.D. Thesis, Technische Universität Dresden, Dresden, Germany, 2018. [Google Scholar]

- Solly, J.; Frueh, N.; Saffarian, S.; Prado, M. ICD/ITKE Research Pavilion 2016/2017: Integrative Design of a Composite Lattice Cantilever. In Proceedings of the IASS 2018 Creativity in Structural Design, Cambridge, MA, USA, 16–20 July 2018. [Google Scholar]

- Mindermann, P.; Gil Pérez, M.; Knippers, J.; Gresser, G.T. Investigation of the Fabrication Suitability, Structural Performance, and Sustainability of Natural Fibers in Coreless Filament Winding. Materials 2022, 15, 3260. [Google Scholar] [CrossRef] [PubMed]

- von Zuben, M.; Cherif, C. Robot based Technology for the Production Novel Resource-Saving and Cost-Efficient Textile Reinforcement Structures for Direct further Proceedings into Prefabricated Parts. In Proceedings of the 19th World Textile Conference on Textiles at the Crossroads, AUTEX2019, Ghent, Belgium, 11–15 June 2019. [Google Scholar]

- Mechtcherine, V.; Michel, A.; Liebscher, M.; Schneider, K.; Großmann, C. Mineral-impregnated carbon fiber composites as novel reinforcement for concrete construction: Material and automation perspectives. Autom. Constr. 2020, 110, 103002. [Google Scholar] [CrossRef]

- Minsch, N.; Müller, M.; Gereke, T.; Nocke, A.; Cherif, C. Novel fully automated 3D coreless filament winding technology. J. Compos. Mater. 2018, 52, 3001–3013. [Google Scholar] [CrossRef]

- Knippers, J. BUGA Faserpavillon: Bundesgartenschau Heilbronn. 2019. Available online: https://www.janknippers.com/de/archives/portfolio-type/faserpavillon-bundesgartenschau-heilbronn-2019 (accessed on 1 December 2021).

- Knippers, J.; Koslowski, V.; Solly, J.; Fildhuth, T. Modular coreless filament winding for lightweight systems in architecture. In Proceedings of the CICE 2016 8th International Conference on Fibre-Reinforced Polymer (FRP) Composites in Civil Engineering, Hong Kong, China, 14–16 December 2016; CICE: Hong Kong, China, 2016. [Google Scholar]

- Dörstelmann, M. FibR GmbH. Exhibition Architecture and Mobile Structures. Available online: https://www.fibr.tech/gallery (accessed on 23 November 2021).

- Gil Pérez, M.; Guo, Y.; Knippers, J. Integrative material and structural design methods for natural fibres filament-wound composite structures: The LivMatS pavilion. Mater. Des. 2022, 217, 110624. [Google Scholar] [CrossRef]

- Minsch, N.; Herrmann, F.H.; Gereke, T.; Nocke, A.; Cherif, C. Analysis of Filament Winding Processes and Potential Equipment Technologies. Procedia CIRP 2017, 66, 125–130. [Google Scholar] [CrossRef]

- Minsch, N.; Müller, M.; Gereke, T.; Nocke, A.; Cherif, C. 3D truss structures with coreless 3D filament winding technology. J. Compos. Mater. 2018, 53, 2077–2089. [Google Scholar] [CrossRef]

- Hawkins, W.J.; Herrmann, M.; Ibell, T.J.; Kromoser, B.; Michaelski, A.; Orr, J.J.; Pedreschi, R.; Pronk, A.; Schipper, H.R.; Shepherd, P.; et al. Flexible formwork technologies—A state of the art review. Struct. Concr. 2016, 17, 911–935. [Google Scholar] [CrossRef]

- Bhat, S.; Dittel, G.; Knobel, A.; Gries, T. Investigation of the drapeability of elastic adapted Textile Reinforced Concrete Elements for double curved concrete elements. In Proceedings of the SAMPE 2022 Technical Proceedings, Charlotte, NC, USA, 23–26 May 2022; SAMPE: Diamond Bar, CA, USA, 2022. [Google Scholar]

- Mechtcherine, V.; Buswell, R.; Kloft, H.; Bos, F.P.; Hack, N.; Wolfs, R.; Sanjayan, J.; Nematollahi, B.; Ivaniuk, E.; Neef, T. Integrating reinforcement in digital fabrication with concrete: A review and classification framework. Cem. Concr. Compos. 2021, 119, 103964. [Google Scholar] [CrossRef]

- Classen, M.; Ungermann, J.; Sharma, R. Additive Manufacturing of Reinforced Concrete—Development of a 3D Printing Technology for Cementitious Composites with Metallic Reinforcement. Appl. Sci. 2020, 10, 3791. [Google Scholar] [CrossRef]

- Asprone, D.; Auricchio, F.; Menna, C.; Mercuri, V. 3D printing of reinforced concrete elements: Technology and design approach. Constr. Build. Mater. 2018, 165, 218–231. [Google Scholar] [CrossRef]

- Marchment, T.; Sanjayan, J. Mesh reinforcing method for 3D Concrete Printing. Autom. Constr. 2020, 109, 102992. [Google Scholar] [CrossRef]

- Le, T.T.; Austin, S.A.; Lim, S.; Buswell, R.A.; Law, R.; Gibb, A.; Thorpe, T. Hardened properties of high-performance printing concrete. Cem. Concr. Res. 2012, 42, 558–566. [Google Scholar] [CrossRef]

- Panda, B.; Chandra Paul, S.; Jen Tan, M. Anisotropic mechanical performance of 3D printed fiber reinforced sustainable construction material. Mater. Lett. 2017, 209, 146–149. [Google Scholar] [CrossRef]

- Neef, T.; Müller, S.; Mechtcherine, V. Integration of Mineral Impregnated Carbon Fibre (MCF) into Fine 3D-Printed Concrete Filaments. In Proceedings of the Third RILEM International Conference on Concrete and Digital Fabrication, Loughborough, UK, 27–29 June 2022; Buswell, R., Blanco, A., Cavalaro, S., Kinnell, P., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 397–403, ISBN 978-3-031-06115-8. [Google Scholar]

- Willmann, J.; Block, P.; Hutter, M.; Byrne, K.; Schork, T. Robotic Fabrication in Architecture, Art and Design 2018; Springer International Publishing: Cham, Switzerland, 2019; ISBN 978-3-319-92293-5. [Google Scholar]

- Taha, N.; Walzer, A.N.; Ruangjun, J. Robotic AeroCrete A novel robotic spraying and surface treatment technology for the production of slender reinforced concrete elements. In Blucher Design Proceedings. 37 Education and Research in Computer Aided Architectural Design in Europe and XXIII Iberoamerican Society of Digital Graphics, Joint Conference (N. 1), Porto, Portugal, 11–13 September 2019; Editora Blucher: São Paulo, Brazil, 2019; pp. 245–256. [Google Scholar]

- Nikravan, A.; Aydogan, O.G.; Dittel, G.; Scheurer, M.; Bhat, S.; Ozyurt, N.; Gries, T. Implementation of Continuous Textile Fibers in 3D Printable Cementitious Composite. In Building for the Future: Durable, Sustainable, Resilient; Ilki, A., Çavunt, D., Çavunt, Y.S., Eds.; Springer Nature: Cham, Switzerland, 2023; pp. 1243–1252. ISBN 978-3-031-32518-2. [Google Scholar]

- Lindemann, H.; Gerbers, R.; Ibrahim, S.; Dietrich, F.; Herrmann, E.; Dröder, K.; Raatz, A.; Kloft, H. Development of a Shotcrete 3D-Printing (SC3DP) Technology for Additive Manufacturing of Reinforced Freeform Concrete Structures. In Proceedings of the First RILEM International Conference on Concrete and Digital Fabrication—Digital Concrete 2018, Zurich, Switzerland, 10–12 September 2018; Wangler, T., Flatt, R.J., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 287–298, ISBN 978-3-319-99518-2. [Google Scholar]

- Mechtcherine, V.; Nerella, V.N.; Will, F.; Näther, M.; Otto, J. On-site, large-scale, monolithic 3D concrete printing. Constr Print Technol. 2020, 2, 14–22. [Google Scholar]

- Scheurer, M.; Dittel, G.; Gries, T. Potential for the Integration of Continuous Fiber-Based Reinforcements in Digital Concrete Production. In Proceedings of the Second RILEM International Conference on Concrete and Digital Fabrication, Online, 6–9 July 2020; Bos, F.P., Lucas, S.S., Wolfs, R.J., Salet, T.A., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 701–711, ISBN 978-3-030-49915-0. [Google Scholar]

- Dittel, G.; Scheurer, M.; Dringenberg, S.; Jitton, J.V.; Gries, T. Digital Concrete Production with Vertical Textile Reinforcement. Open Conf. Proc. 2022, 1, 35–43. [Google Scholar] [CrossRef]

- Dittel, G.; Dringenberg, S.; Gries, T. Through Textile to Reinforced 3D Concrete Printing. In Building for the Future: Durable, Sustainable, Resilient; Ilki, A., Çavunt, D., Çavunt, Y.S., Eds.; Springer Nature: Cham, Switzerland, 2023; pp. 1094–1103. ISBN 978-3-031-32518-2. [Google Scholar]

- Lüling, C.; Biehl, S.; Tennert, R.; Dittel, G.; Chernyshova, M.; Gries, T. 6dTEX: Lightweight building components made of 3D textiles in combination with 3D printing. In Proceedings of the Powerskin Conference, Aachen, Germany, 8 December 2022; Auer, T., Knaack, U., Schneider, J., Hildebrand, L., Santucci, D., Eds.; Druckzentrum: Neumünster, Germany, 2022; pp. 119–134. [Google Scholar]

- Lüling, C.; Carl, T. Fuzzy 3D Fabrics & Precise 3D Printing: Combining Research with Design-Build Investigations. In Proceedings of the International Conference on Education and Research in Computer Aided Architectural Design in Europe 2022, Ghent, Belgium, 13–16 September 2022; eCAADe: Liverpool, UK, 2022. [Google Scholar]

- Neef, T.; Dittel, G.; Scheurer, M.; Gries, T.; Mechtcherine, V. Utilizing Textiles as Integrated Formwork for Additive Manufacturing with Concrete. In Building for the Future: Durable, Sustainable, Resilient; Ilki, A., Çavunt, D., Çavunt, Y.S., Eds.; Springer Nature: Cham, Switzerland, 2023; pp. 1285–1292. ISBN 978-3-031-32518-2. [Google Scholar]

- Spickenheuer, A.; Scheffler, C.; Bittrich, L.; Haase, R.; Weise, D.; Garray, D.; Heinrich, G. Tailored Fiber Placement in Thermoplastic Composites. TLS 2018, 1, 114–127. [Google Scholar] [CrossRef]

- Lotte, S.-B.; Georgia, M.; Axel, K.; Suzuki, S. Tailoring Self-Formation fabrication and simulation of membrane-actuated stiffness gradient composites. In Proceedings of the IASS Symposium 2018—Creativity in Structural Design, Cambridge, MA, USA, 16–20 July 2018. [Google Scholar]

- Costalonga Martins, V.; Cutajar, S.; van der Hoven, C.; Baszyński, P.; Dahy, H. FlexFlax Stool: Validation of Moldless Fabrication of Complex Spatial Forms of Natural Fiber-Reinforced Polymer (NFRP) Structures through an Integrative Approach of Tailored Fiber Placement and Coreless Filament Winding Techniques. Appl. Sci. 2020, 10, 3278. [Google Scholar] [CrossRef]

- Rihaczek, G.; Klammer, M.; Başnak, O.; Petrš, J.; Grisin, B.; Dahy, H.; Carosella, S.; Middendorf, P. Curved Foldable Tailored Fiber Reinforcements for Moldless Customized Bio-Composite Structures. Proof of Concept: Biomimetic NFRP Stools. Polymers 2020, 12, 2000. [Google Scholar] [CrossRef]

- Goldfeld, Y.; Quadflieg, T.; Gries, T. Pre- and Post- Damage Structural Health Monitoring in Carbon Fiber Textile Reinforced Concrete (TRC) Structures. In Proceedings of the 8th European Workshop on Structural Health Monitoring, Bilbao, Spain, 5–8 January 2016. [Google Scholar]

- Goldfeld, Y.; Perry, G. Electrical characterization of smart sensory system using carbon based textile reinforced concrete for leakage detection. Mater. Struct. 2018, 51, 170. [Google Scholar] [CrossRef]

- Newell, S.; Goggins, J. Real-time monitoring of concrete–lattice-girder slabs during construction. Proc. Inst. Civ. Eng. Struct. Build. 2017, 170, 885–900. [Google Scholar] [CrossRef]

- Goldfeld, Y.; Perry, G. AR-glass/carbon-based textile-reinforced concrete elements for detecting water infiltration within cracked zones. Struct. Health Monit. 2019, 18, 1383–1400. [Google Scholar] [CrossRef]

- Goldfeld, Y.; Quadflieg, T.; Gries, T. Sensing capabilities of carbon based TRC beam from slack to pull-out mechanism. Compos. Struct. 2017, 181, 294–305. [Google Scholar] [CrossRef]

- Goldfeld, Y.; Ben-Aarosh, S.; Rabinovitch, O.; Quadflieg, T.; Gries, T. Integrated self-monitoring of carbon based textile reinforced concrete beams under repeated loading in the un-cracked region. Carbon 2016, 98, 238–249. [Google Scholar] [CrossRef]

- Goldfeld, Y.; Rabinovitch, O.; Fishbain, B.; Quadflieg, T.; Gries, T. Sensory carbon fiber based textile-reinforced concrete for smart structures. J. Intell. Mater. Syst. Struct. 2016, 27, 469–489. [Google Scholar] [CrossRef]

- Goldfeld, Y.; Quadflieg, T.; Ben-Aarosh, S.; Gries, T. Micro and macro crack sensing in TRC beam under cyclic loading. J. Mech. Mater. Struct. 2017, 12, 579–601. [Google Scholar] [CrossRef]

- Goldfeld, Y.; Yosef, L. Sensing accumulated cracking with smart coated and uncoated carbon based TRC. Measurement 2019, 141, 137–151. [Google Scholar] [CrossRef]

- Valeri, P.; Fernàndez Ruiz, M.; Muttoni, A. Tensile response of textile reinforced concrete. Constr. Build. Mater. 2020, 258, 119517. [Google Scholar] [CrossRef]

- Quadflieg, T.; Stolyarov, O.; Gries, T. Carbon rovings as strain sensors for structural health monitoring of engineering materials and structures. J. Strain Anal. Eng. Des. 2016, 51, 482–492. [Google Scholar] [CrossRef]

- Quadflieg, T.; Stolyarov, O.; Gries, T. Carbonfaserbewehrung als Sensor für Bauwerke. Beton Stahlbetonbau 2017, 112, 541–544. [Google Scholar] [CrossRef]

- Quadflieg, T. Gewirkte Verstärkungstextilien mit Kohlenstofffaserbasierter Sensorik im Verbundwerkstoff mit Mineralischer Matrix. Ph.D. Thesis, Institut für Textiltechnik of RWTH Aachen University, Aachen, Germany, 2017. [Google Scholar]

- Dittel, G.; Cicek, I.E.; Bredol, M.; Gries, T. Carbon Rovings as Strain Sensor in TRC Structures: Effect of Roving Cross-Sectional Shape and Coating Material on the Electrical Response under Bending Stress. Sensors 2023, 23, 4601. [Google Scholar] [CrossRef] [PubMed]

- Gaben, M.; Goldfeld, Y. Self-sensory carbon-based textile reinforced concrete beams—Characterization of the structural-electrical response by AC measurements. Sens. Actuators A Phys. 2022, 334, 113322. [Google Scholar] [CrossRef]

- Perry, G.; Dittel, G.; Gries, T.; Goldfeld, Y. Monitoring capabilities of various smart self sensory carbon-based textiles to detect water infiltration. J. Intell. Mater. Syst. Struct. 2021, 32, 2566–2581. [Google Scholar] [CrossRef]

- Quadflieg, T.; Goldfeld, Y.; Dittel, G.; Gries, T. New Age Advanced Smart Water Pipe Systems Using Textile Reinforced Concrete. Procedia Manuf. 2018, 21, 376–383. [Google Scholar] [CrossRef]

- Koch, A. Multifunktionale Textilbetonsysteme für die Gebäudehülle. Ph.D. Thesis, Rheinisch-Westfälische Technische Hochschule Aachen, Aachen, Germany, 2018. [Google Scholar]

- Monteiro, P.J.M.; Miller, S.A.; Horvath, A. Towards sustainable concrete. Nat. Mater. 2017, 16, 698–699. [Google Scholar] [CrossRef]

- Ellis, L.D.; Badel, A.F.; Chiang, M.L.; Park, R.J.-Y.; Chiang, Y.-M. Toward electrochemical synthesis of cement-An electrolyzer-based process for decarbonating CaCO3 while producing useful gas streams. Proc. Natl. Acad. Sci. USA 2020, 117, 12584–12591. [Google Scholar] [CrossRef]

- IPCC. Global Warming of 1.5 °C; Cambridge University Press: Cambridge, UK, 2022; ISBN 9781009157940. [Google Scholar]

- Alsheyab, M.A.T. Recycling of construction and demolition waste and its impact on climate change and sustainable development. Int. J. Environ. Sci. Technol. 2022, 19, 2129–2138. [Google Scholar] [CrossRef]

- European Commission. Waste Prevention and Management. Available online: https://ec.europa.eu/environment/green-growth/waste-prevention-and-management/index_en.htm (accessed on 12 April 2023).

- Zhang, J.; Chevali, V.S.; Wang, H.; Wang, C.-H. Current status of carbon fibre and carbon fibre composites recycling. Compos. Part B Eng. 2020, 193, 108053. [Google Scholar] [CrossRef]

- Kimm, M.K. Ressourceneffizientes und recyclinggerechtes Design von Faserverbundwerkstoffen im Bauwesen. Ph.D. Thesis, Rheinisch-Westfälische Technische Hochschule Aachen, Aachen, Germany, 2020. [Google Scholar]

- Bayram, B.; Overhage, V.; Raulf, K.; Greiff, K.; Gries, T. Recycling potential of recycled carbon fibers used in textile concrete from a technical and environmental point of view. In Proceedings of the Recy & DepoTech, Leoben, Austria, 9–11 November 2022. [Google Scholar]

- Kimm, M.; Gerstein, N.; Schmitz, P.; Simons, M.; Gries, T. On the separation and recycling behaviour of textile reinforced concrete: An experimental study. Mater. Struct. 2018, 51, 122. [Google Scholar] [CrossRef]

- Kortmann, J. Verfahrenstechnische Untersuchungen zur Recyclingfähigkeit von Carbonbeton. Ph.D. Thesis, Technische Universität Dresden, Dresden, Germany, 2020. [Google Scholar]

| Yarn Type | Illustration | Scheme |

|---|---|---|

| Unprofiled roving |  |  |

| Profiled roving |  |  |

| Braided roving |  |  |

| PO | PC | TG | TC | P | |

|---|---|---|---|---|---|

| Handling |  |  |  |  |  |

| Shape deviation |  |  |  |  |  |

| Mesh opening |  |  |  |  |  |

| Drape quality |  |  |  |  |  |

| Fulfillment (%) | 75 | 88 | 75 | 38 | 50 |

Unsuitable Unsuitable  Rather suitable Rather suitable | |||||

Rather unsuitable Rather unsuitable  Suitable Suitable | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Scheurer, M.; Friese, D.; Penzel, P.; Dittel, G.; Bhat, S.; Overhage, V.; Hahn, L.; Heins, K.; Cherif, C.; Gries, T. Current and Future Trends in Textiles for Concrete Construction Applications. Textiles 2023, 3, 408-437. https://doi.org/10.3390/textiles3040025

Scheurer M, Friese D, Penzel P, Dittel G, Bhat S, Overhage V, Hahn L, Heins K, Cherif C, Gries T. Current and Future Trends in Textiles for Concrete Construction Applications. Textiles. 2023; 3(4):408-437. https://doi.org/10.3390/textiles3040025

Chicago/Turabian StyleScheurer, Martin, Danny Friese, Paul Penzel, Gözdem Dittel, Shantanu Bhat, Vanessa Overhage, Lars Hahn, Kira Heins, Chokri Cherif, and Thomas Gries. 2023. "Current and Future Trends in Textiles for Concrete Construction Applications" Textiles 3, no. 4: 408-437. https://doi.org/10.3390/textiles3040025

APA StyleScheurer, M., Friese, D., Penzel, P., Dittel, G., Bhat, S., Overhage, V., Hahn, L., Heins, K., Cherif, C., & Gries, T. (2023). Current and Future Trends in Textiles for Concrete Construction Applications. Textiles, 3(4), 408-437. https://doi.org/10.3390/textiles3040025