Study on a Battery Thermal Management System Based on a Thermoelectric Effect

Abstract

:1. Introduction

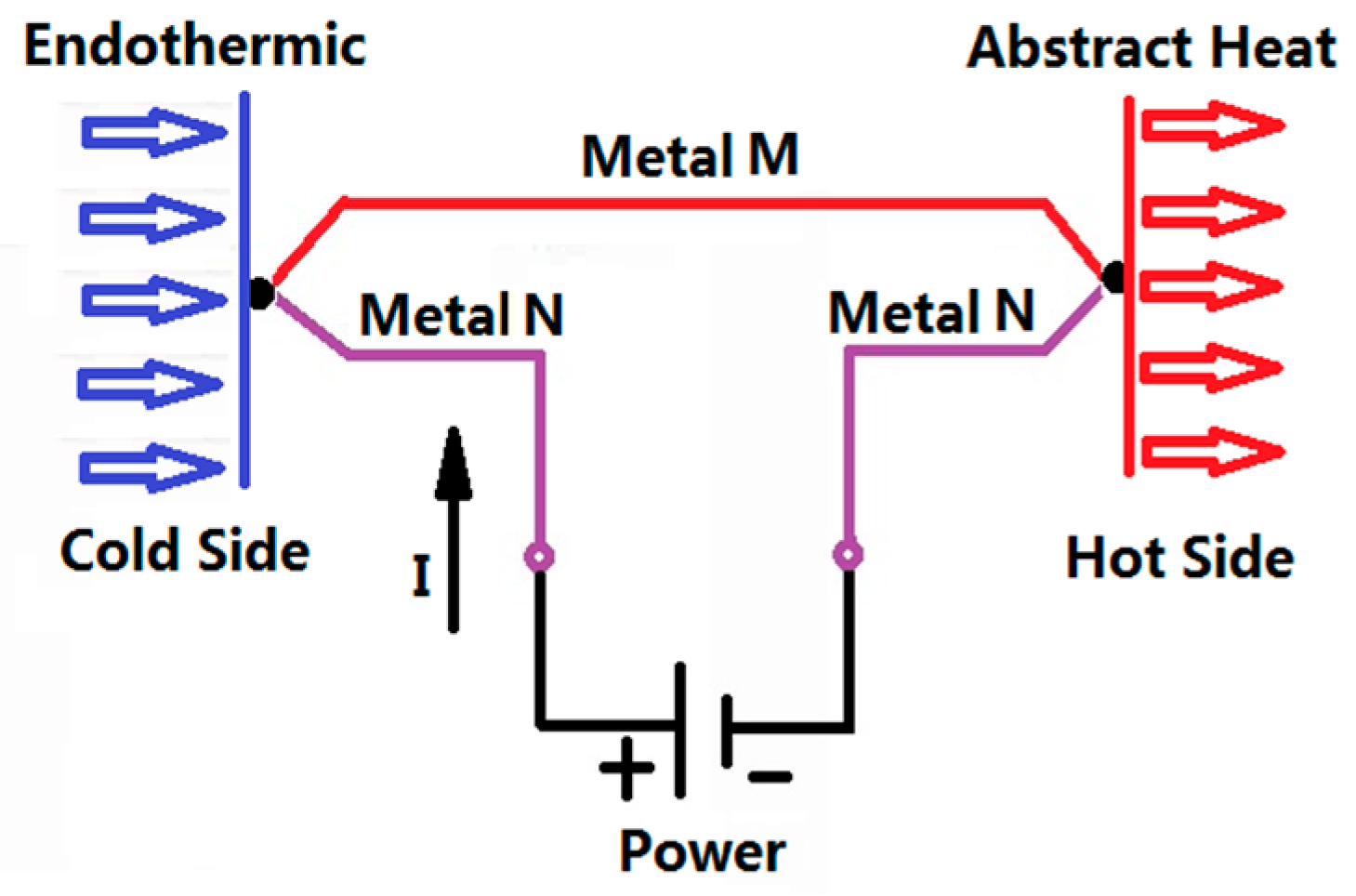

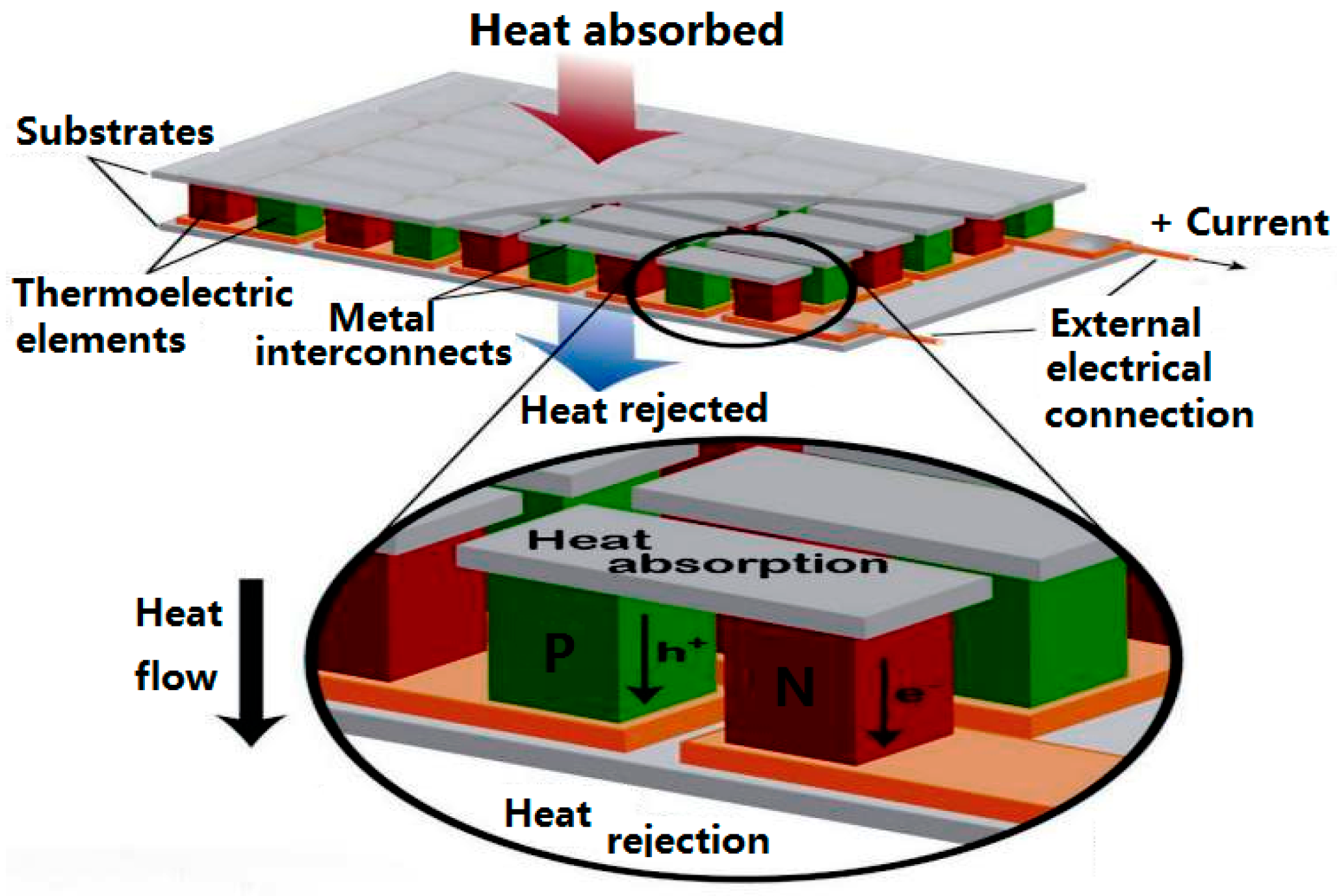

2. The Second Thermoelectric Effect

3. Model Analysis and Structure Optimization

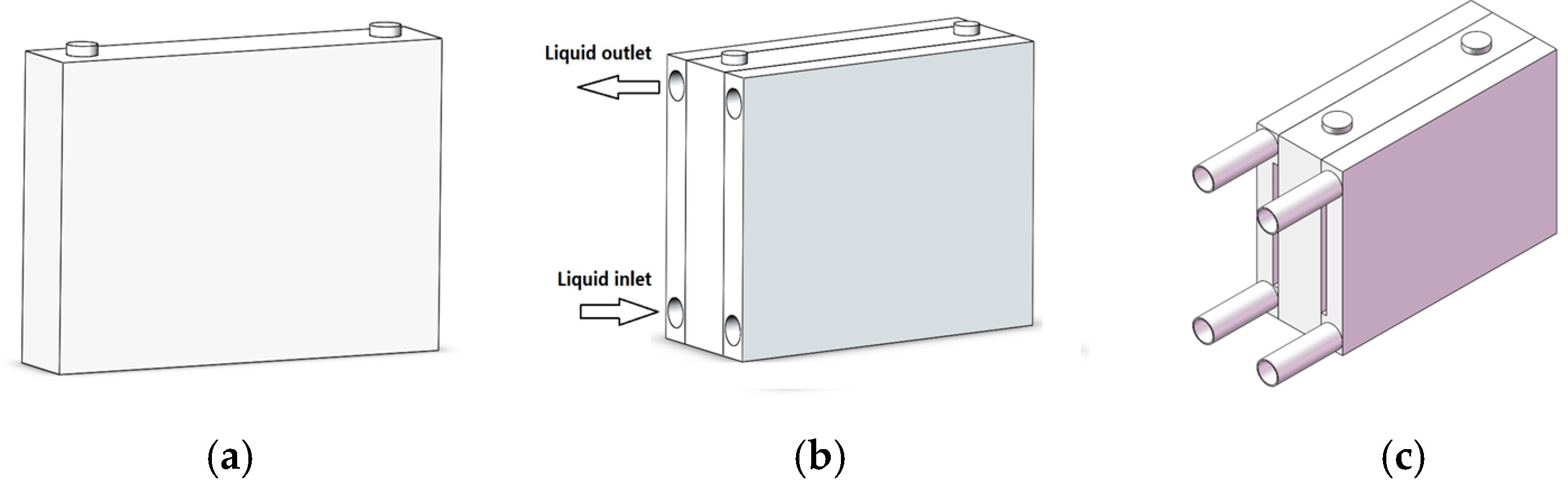

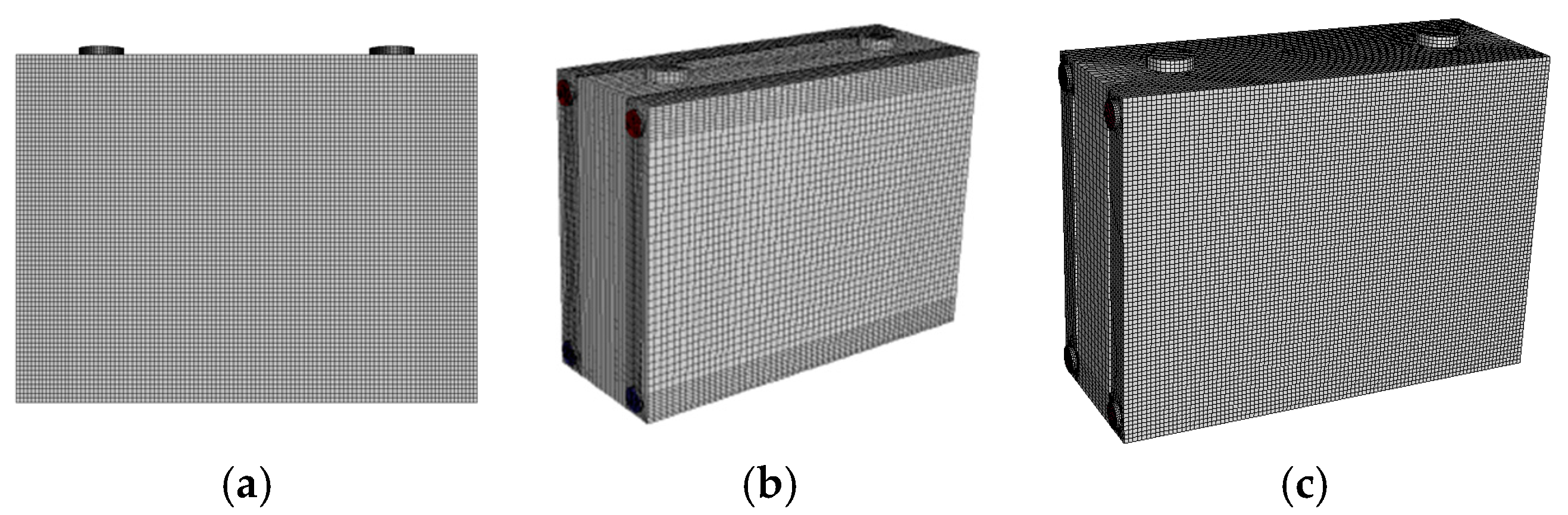

3.1. Three-Dimensional (3D) Model Design and Grid Partition

3.2. Heat Generation Model of Battery

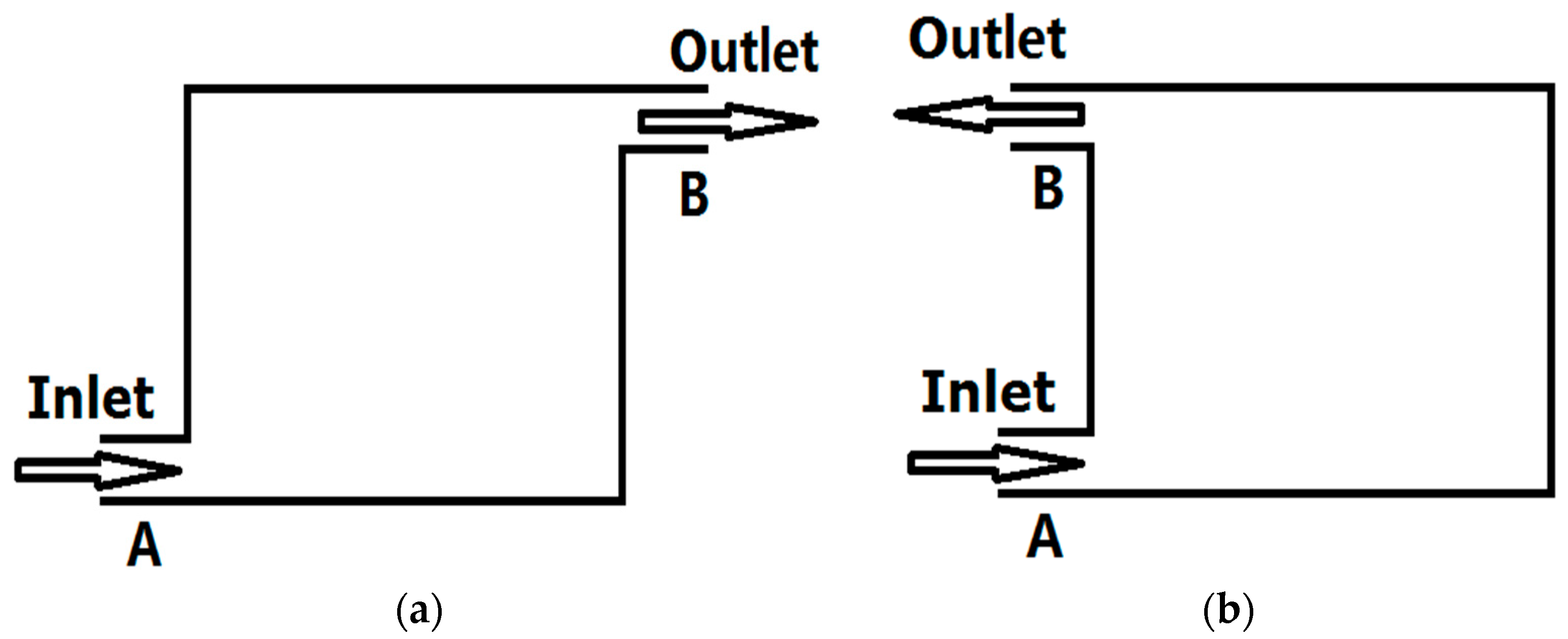

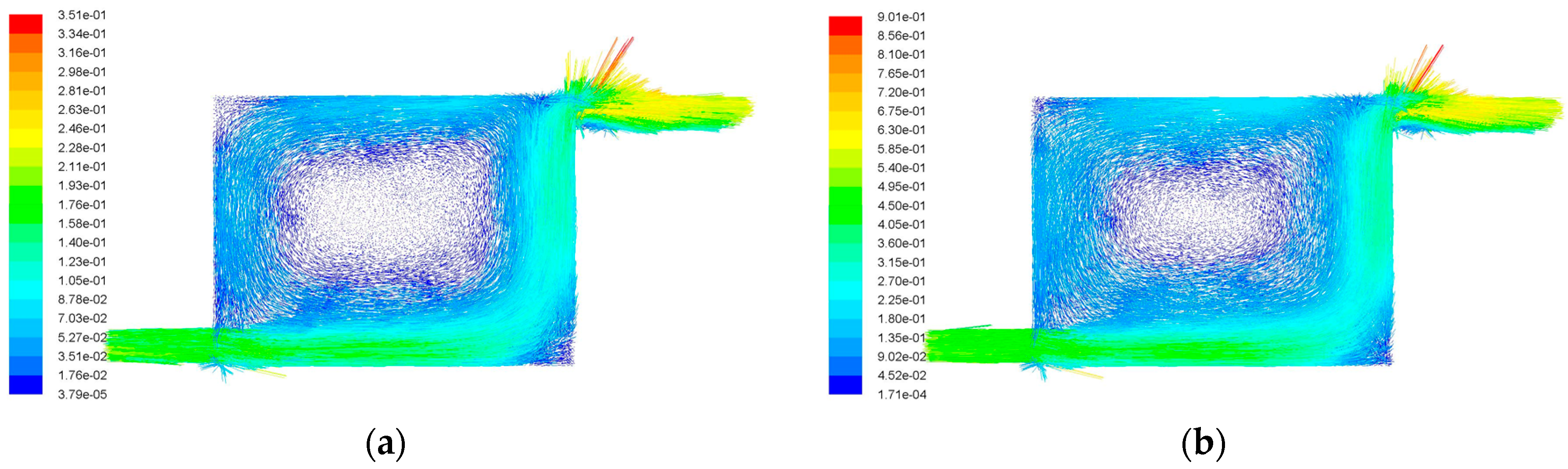

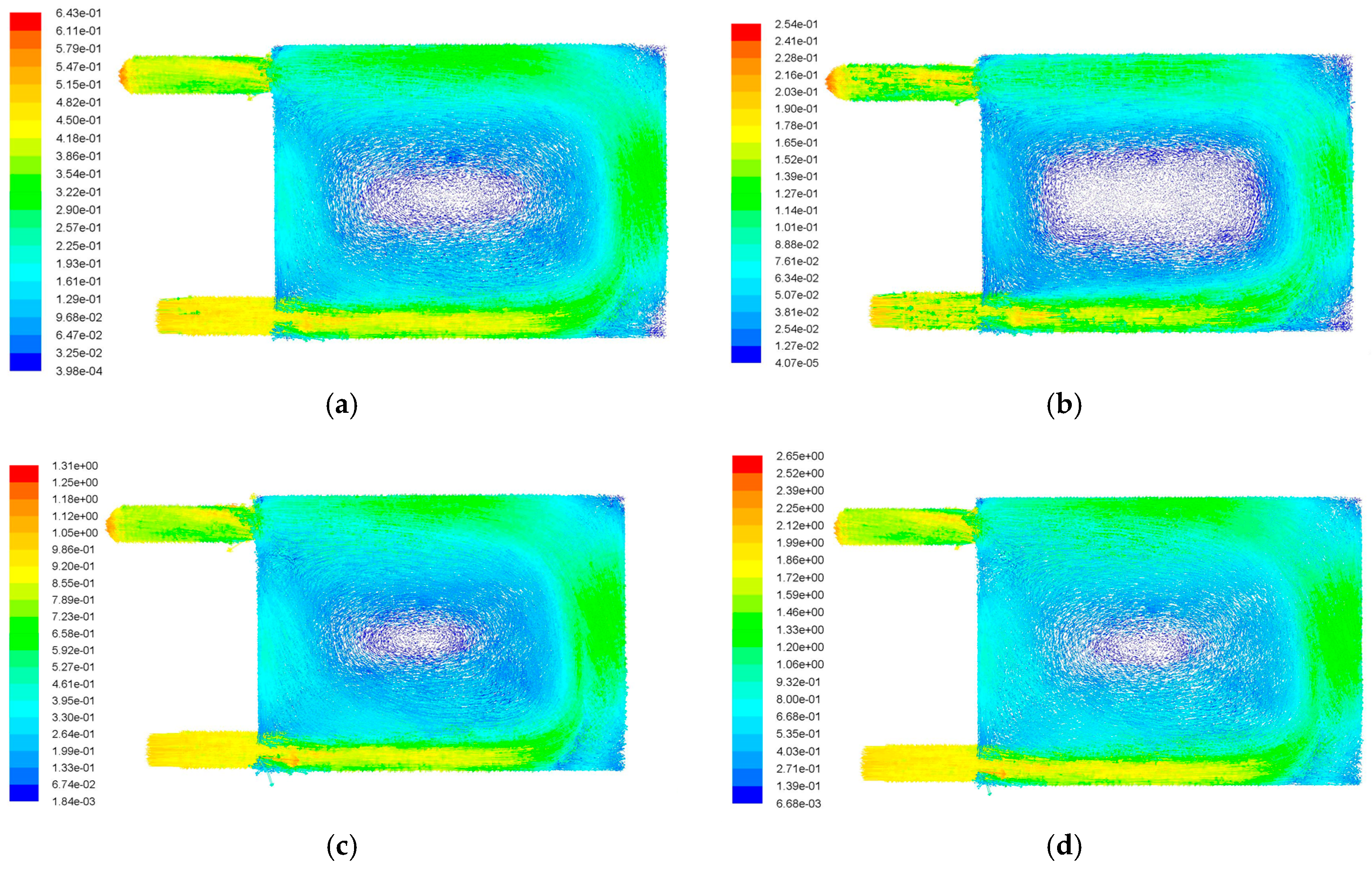

3.3. Structure Design and Optimization of Heat Exchanger

3.4. Cooling Effect of the Modified Cooling Structure

3.5. Pack Model Design

4. Control System Design

- The temperature sensor collects the temperature of each cell and feeds it back to the MCU (main control chip);

- The main control chip is used to determine whether there is a need to adjust the temperature according to the data in the comparison program. If necessary, break over the relative single cell battery switch array module and the H commutation circuit module;

- The flow rate on the thermoelectric chip is controlled through the intelligent module of flow control so as to control the temperature of the cold end and the hot end of thermoelectric chip, to achieve the purpose of regulating the surface temperature of the battery.

4.1. Hardware Design

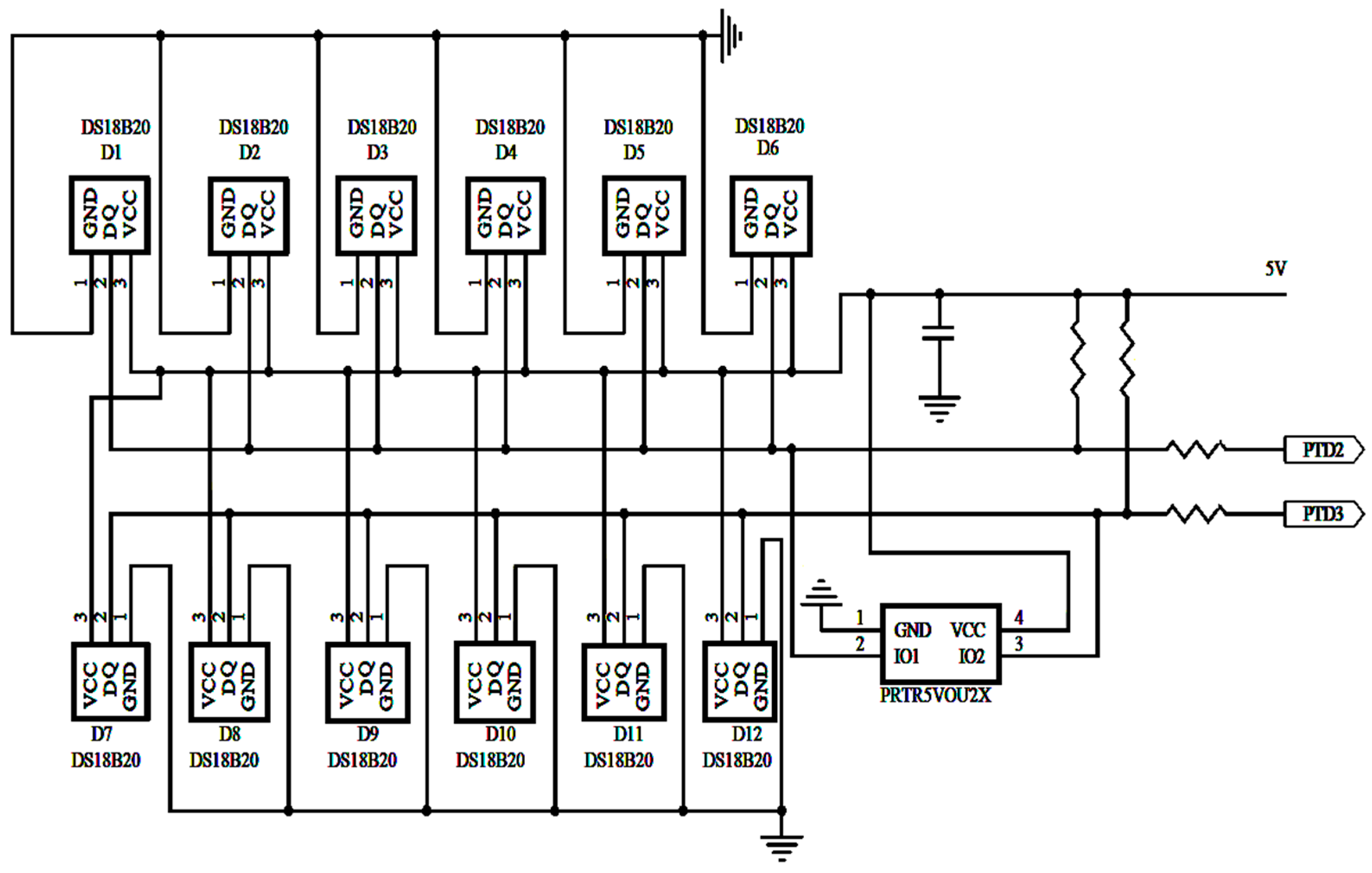

4.1.1 Temperature Acquisition Circuit

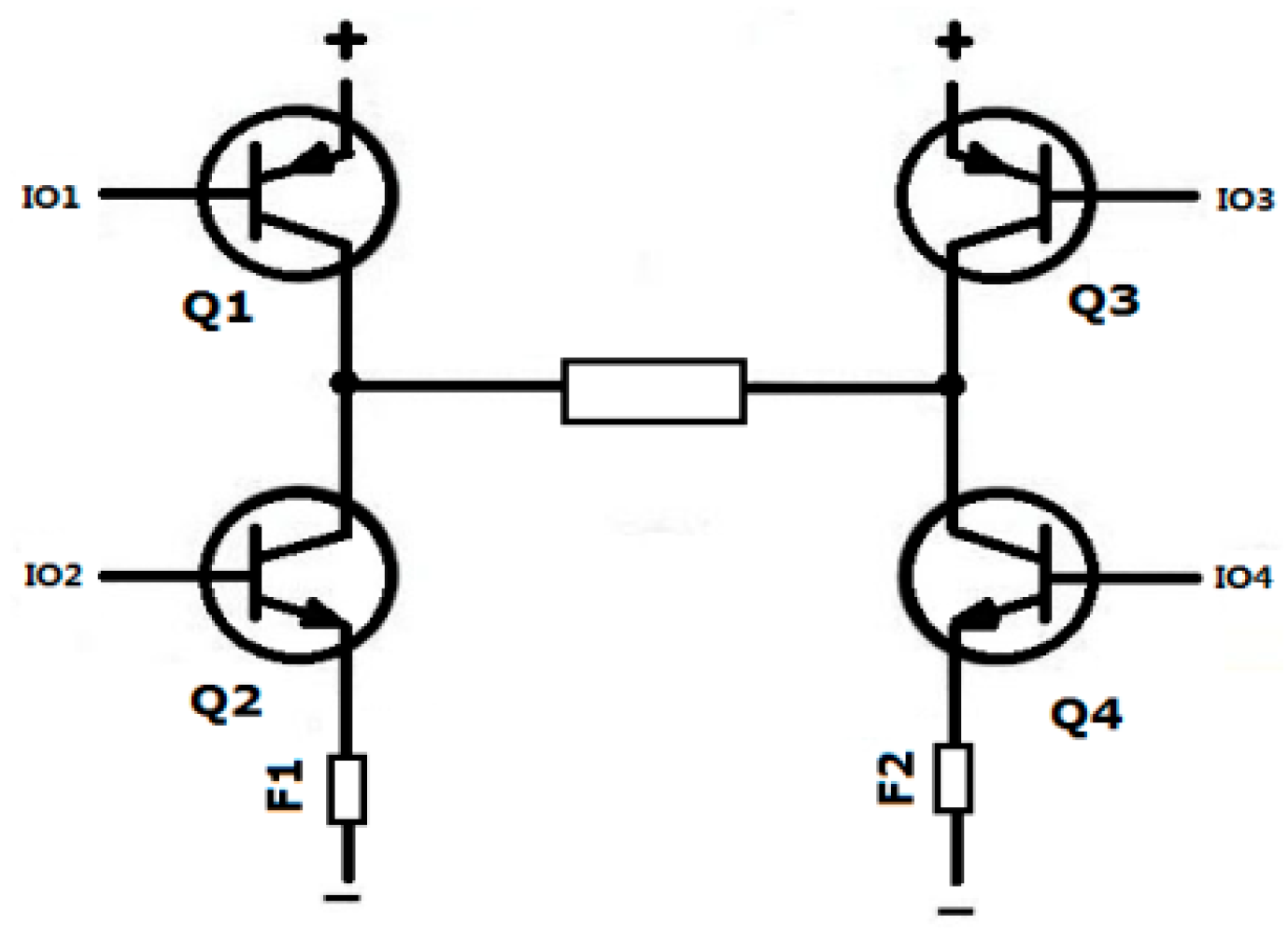

4.1.2. H Commutation Circuit Module

4.1.3. Matrix Switch Circuit Module

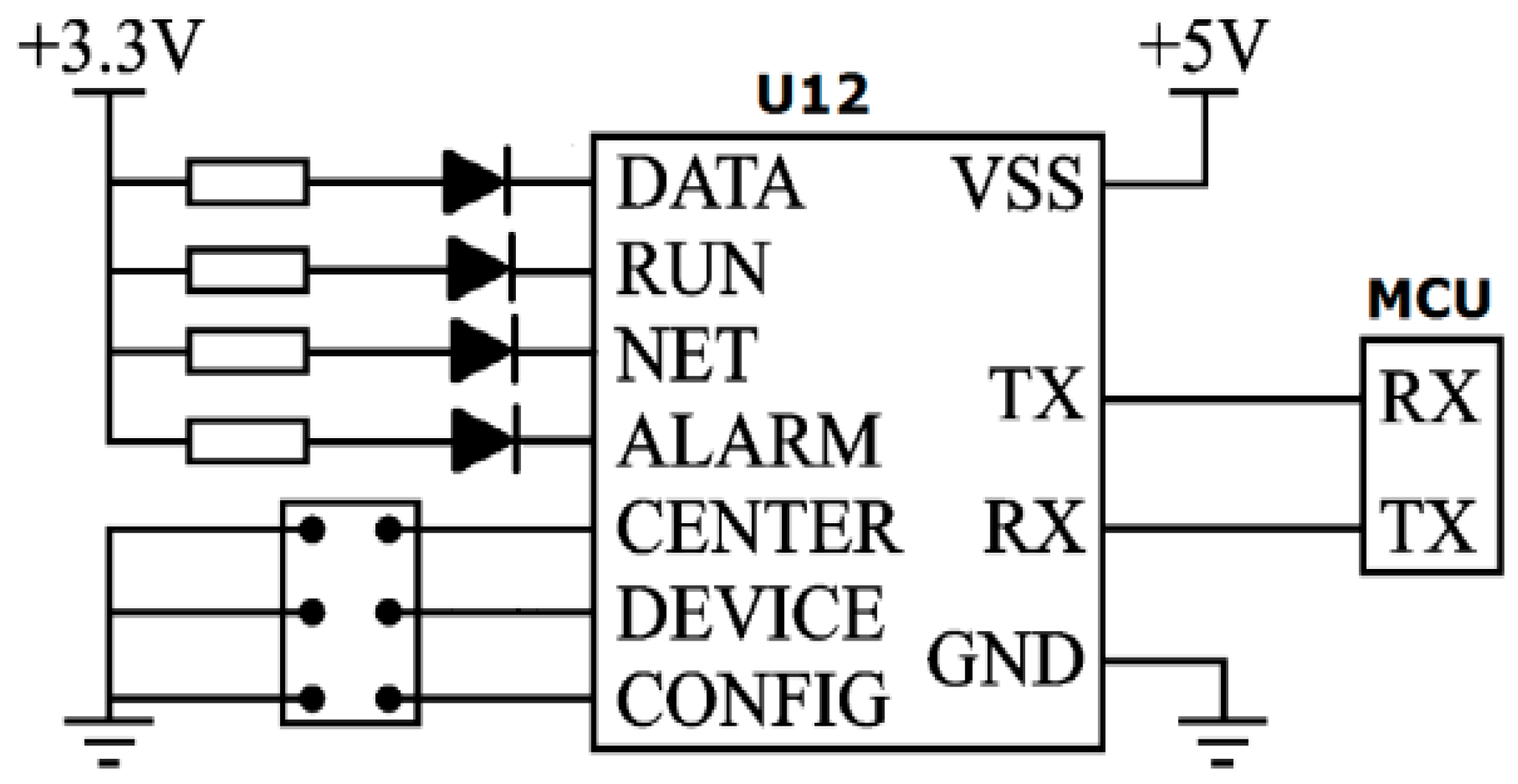

4.1.4. Wireless Communication Module

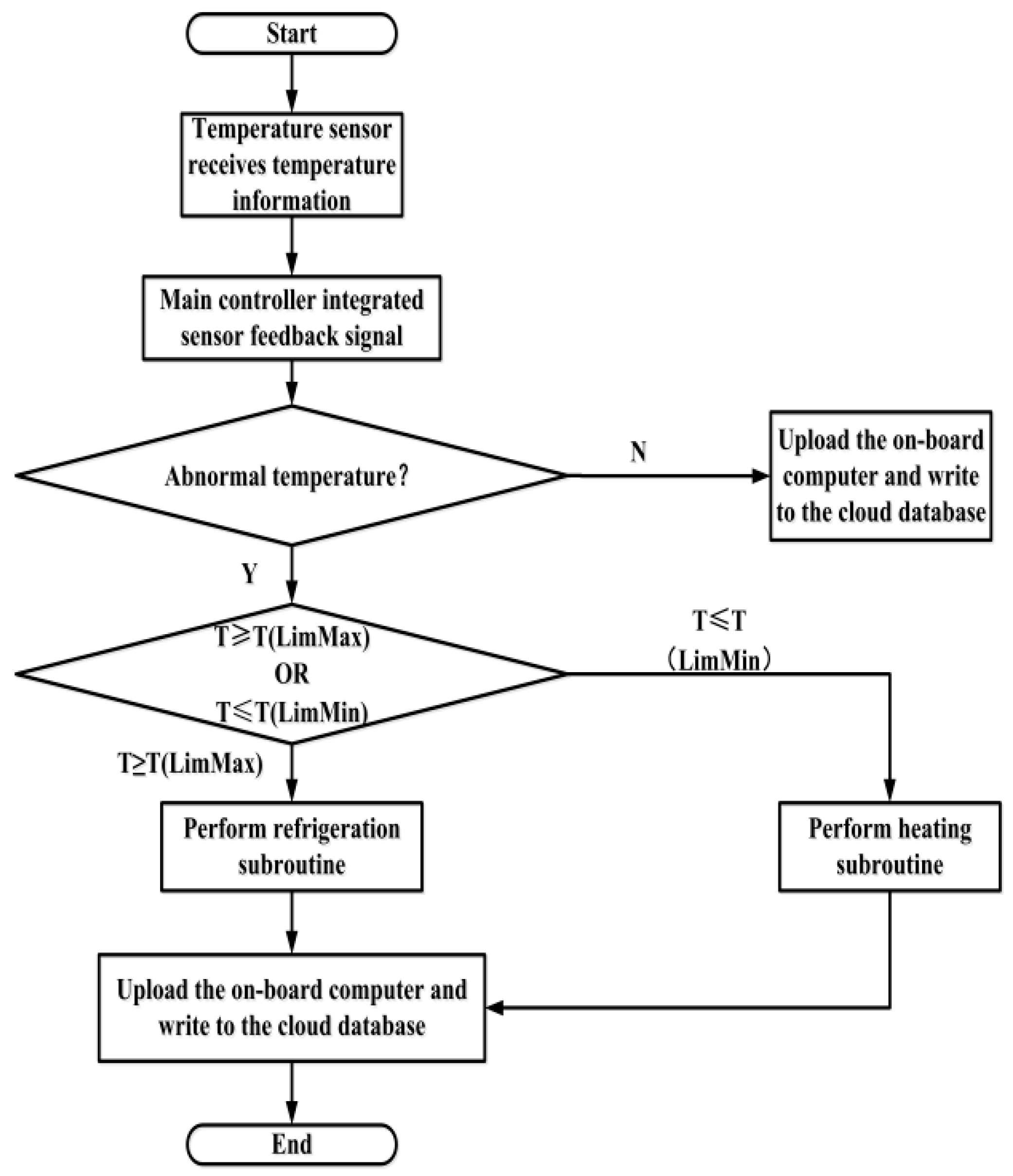

4.2. Design of Software

- (1)

- Capture the coordinates of the battery and display them on the battery simulator according to the temperature level;

- (2)

- The battery voltage Uij0, current I, and the estimated value of SOC are collected by the battery management system. The heating rate is determined to match the cloud database by the feedback information of the electronic label;

- (3)

- According to the corresponding relationship between the SOC and the open circuit voltage, the open circuit voltage of the battery is predicted;

- (4)

- The heating efficiency of battery’s surface is calculated according to the collected battery information from the following formula:where I is the charge and discharge current of the battery, VB is the volume of the battery, UOpen is the open circuit voltage of the battery, ΔU is the difference between the open circuit voltage and the terminal voltage of the battery, Tij0 is the surface temperature of the battery, and is the temperature coefficient.

- (5)

- The required cooling efficiency is determined according to the heating rate of the battery. Using the fuzzy control strategy, the cold end heat absorption rate Qm is equal to KTij0 multiplied by QB. Then, wait until the temperature sensor detects the battery surface temperature in the best operating temperature range (Tm, Tn), and make QB equal to Qm. At the same time, the hot end of the thermoelectric chip is contacted with the heat transfer structure so as to use the flow of the heat transfer structure’s internal liquid to take away the excess heat. The flow rate of the cooling system is regulated by adjusting the regulating valve of the liquid heating/cooling structure so as to adjust the auxiliary cooling efficiency.

- (6)

- Check the temperature of the battery again. The cooling circuit of the battery is cut off when the temperature is OK, and then the data are recorded and uploaded to the on-board computer and cloud database.

5. Conclusions

- (1)

- A thermoelectric chip integrated into the liquid cooling unit is a better design for a battery’s thermal management system.

- (2)

- In the process of improving the heat exchanger structure, it is noted that the flow field distribution of the U-shape is more uniform than that of the Z-shape.

- (3)

- The vortex phenomenon at the center of the U-shape heat exchanger is initially weakened and then intensified as the inlet velocity of the pipe is increased. When the inlet velocity is 1 m/s, the distribution of the flow field is the most uniform.

- (4)

- The design process of this enhanced battery thermal management system can provide a wealth of guidelines for solving similar problems.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Li, J.H.; Barillas, J.K.; Guenther, C.; Danzer, M.A. Multicell state estimation using variation based sequential Monte Carlo filter for automotive battery packs. J. Power Sources 2015, 277, 95–103. [Google Scholar] [CrossRef]

- Rosario, M.; Fabio, V. Designing a Sustainable University Recharge Area for Electric Vehicles: Technical and Economic Analysis. Energies 2017, 10, 1604. [Google Scholar]

- Lu, L.G.; Li, J.Q.; Hua, J.F.; Ouyang, M.G. Key technology of electric vehicle lithium ion battery management system. Chin. J. Sci. Technol. Rev. 2016, 6, 39–48. [Google Scholar]

- Gao, Z.H.; Chin, C.S.; Chiew, J.H.K.; Jia, J.; Zhang, C.Z. Design and Implementation of Smart Lithium-ion Battery System with Real-time Fault Diagnosis Capability for Electric Vehicles. Energies 2017, 10, 1503. [Google Scholar] [CrossRef]

- Wu, X.G.; Lv, S.Y.; Chen, J.Z. Determination of the optimum heat transfer coefficient and temperature rise analysis for a Lithium-ion battery under the conditions of Harbin city bus driving cycles. Energies 2017, 10, 1723. [Google Scholar] [CrossRef]

- Amine, K.; Liu, J.; Belharouak, I. High-temperature storage and cycling of C-LiFePO4 graphite Li·ion cells. J. Electrochem. Commun. 2005, 7, 669–673. [Google Scholar] [CrossRef]

- Li, Z.; Han, X.B.; Lu, L.G.; Ouyang, M.G. Temperature characteristics of power LiFePO4 batteries. J. Mech. Eng. 2011, 18, 115–120. [Google Scholar] [CrossRef]

- Smith, K.; Wang, C.Y. Power and thermal characterization of a Li-ion battery pack for hybrid electric vehicles. J. Power Sources 2006, 160, 662–673. [Google Scholar] [CrossRef]

- Gao, Z.C.; Chin, C.S.; Woo, W.L.; Jia, J.B. Integrated Equivalent Circuit and Thermal Model for Simulation of Temperature-Dependent LiFePO4 Battery in Actual Embedded Application. Energies 2017, 10, 85. [Google Scholar] [CrossRef]

- Chiew, J.; Chin, C.S.; Jia, J.B.; Toh, W.D. Thermal Analysis of a Latent Heat Storage based Battery Thermal Cooling Wrap. In Proceedings of the COMSOL Conference 2017, Singapore, 22 November 2017. [Google Scholar]

- Li, B.; Chang, G.F.; Lin, C.J.; Xu, S.C. Research on heat generate mechanism of Li-ion batteries for electric vehicles. Chin. J. Power Sources 2017, 2, 378–381. [Google Scholar]

- Chen, K.; Li, Z.Y.; Chen, Y.M.; Long, S.M.; Hou, J.S.; Song, M.X.; Wang, S.F. Design of parallel air-cooled battery thermal management system through numerical study. Energies 2017, 10, 1677. [Google Scholar] [CrossRef]

- Chen, K.; Wang, S.F.; Song, M.X. Structure optimization of parallel air-cooled battery thermal management system. Int. J. Heat Mass Transf. 2017, 4, 943–952. [Google Scholar] [CrossRef]

- Yu, K.; Yang, Y.; Li, C.C. Thermal analysis and two-directional air flow thermal management for lithium-ion battery pack. J. Power Sources 2014, 270, 193–200. [Google Scholar] [CrossRef]

- Saw, L.H.; Ye, Y.; Tay, A.A.O.; Chong, W.T.; Kuan, S.H.; Yew, M.C. Computational fluid dynamic and thermal analysis of Lithium-ion battery pack with air cooling. Appl. Energy 2016, 177, 783–792. [Google Scholar] [CrossRef]

- Yuan, H.; Wang, L.F.; Wang, L.Y. Battery thermal management system with liquid cooling and heating in electric vehicles. J. Automot. Saf. Energy 2012, 4, 371–380. [Google Scholar]

- Huo, Y.T.; Rao, Z.H.; Liu, X.J.; Zhao, J.P. Research development of battery thermal management system based on liquid medium. Adv. New Renew. Energy 2014, 2, 135–140. [Google Scholar]

- Lin, C.J.; Xu, S.C.; Chang, G.F. Thermal uniformity and enhanced thermal transfer of rectangular Lithium-ion power batteries. J. Automot. Technol. 2014, 10, 55–58. [Google Scholar]

- Ramandi, M.Y.; Dincer, I.; Naterer, G.F. Heat transfer and thermal management of electric vehicle batteries with phase change materials. Heat Mass Transf. 2011, 7, 777–788. [Google Scholar] [CrossRef]

- Wei, Z.H.; Xu, S.C.; Li, Z.; Lin, C.J. Study on thermal management package LiFePO4 battery based on phase change material and liquid cooling. Chin. J. Power Sources 2016, 1, 44–46. [Google Scholar]

- Ma, X.F.; Zhou, D.Q.; Liu, X.S.; Li, L.Y. Research progress of phase change materials for thermal management of power batteries. New Chem. Mater. 2017, 9, 23–25. [Google Scholar]

- Florin, S.; Venetia, S.; Stefan, N.; Adrian, I.D. Data acquisition and virtual instrumentation system for the study of Peltier and Seebeck effects. In Proceedings of the International Conference on Optimization of Electrical and Electronic Equipment, Brasov, Romania, 20–22 May 2016. [Google Scholar]

- Manoj, S.R. Thermoelectric air cooling for cars. Int. J. Eng. Sci. Technol. 2012, 5, 2381–2394. [Google Scholar]

- Kaushik, S.; Manikandan, S. The influence of Thomson effect in the performance optimization of a two stage thermoelectric cooler. Cryogenics 2015, 72, 57–64. [Google Scholar] [CrossRef]

- Meng, F.; Chen, L.; Sun, F. Effects of thermocouples’ physical size on the performance of the TEG–TEH system. Int. J. Low-Carbon Technol. 2016, 3, 375–382. [Google Scholar] [CrossRef]

- Meghali, G.; Dhanashri, S.; Abhijit, K.; Bhandwalkar, S. Review on thermoelectric refrigeration: Materials and technology. Int. J. Curr. Eng. Technol. 2017, 4, 67–71. [Google Scholar]

- Liu, Z.J. Multi point temperature measurement system based on DS18B20. Adv. Mater. Res. 2013, 9, 756–759. [Google Scholar] [CrossRef]

| Characteristic | Parameter | Characteristic | Parameter |

|---|---|---|---|

| Type | TEC-12708 | Size | 40 mm × 40 mm × 3.2 mm |

| Voltage | 12 V | Maximum current | 8 A |

| Maximum temperature difference | 70 K | maximum refrigeration power | 76 W |

| Length (mm) | Width (mm) | Height (mm) | |

|---|---|---|---|

| Single battery | 200 | 40 | 150 |

| Heat exchanger | 200 | 20 | 150 |

| Simplified Thermoelectric | 200 | 6 | 106 |

| Item | Features | Item | Features |

|---|---|---|---|

| Viscous | k-epsilon | Solid | Aluminum |

| Fluid | Water-liquid | Heating rate | 100 W |

| Velocity-inlet | 1 m/s | Solution method | Pressure–velocity coupling/SIMPLE |

| Temperature | 298.15 K | Criteria for convergence | Energy/1e-06 |

| IO1 | IO2 | IO3 | IO4 | Result |

|---|---|---|---|---|

| 1 | 0 | 0 | 1 | Forward current |

| 0 | 1 | 1 | 0 | Reverse current |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.-W.; Xu, K.-J.; Li, L.-Y.; Yang, M.-Z.; Gao, H.-B.; Chen, S.-R. Study on a Battery Thermal Management System Based on a Thermoelectric Effect. Energies 2018, 11, 279. https://doi.org/10.3390/en11020279

Zhang C-W, Xu K-J, Li L-Y, Yang M-Z, Gao H-B, Chen S-R. Study on a Battery Thermal Management System Based on a Thermoelectric Effect. Energies. 2018; 11(2):279. https://doi.org/10.3390/en11020279

Chicago/Turabian StyleZhang, Chuan-Wei, Ke-Jun Xu, Lin-Yang Li, Man-Zhi Yang, Huai-Bin Gao, and Shang-Rui Chen. 2018. "Study on a Battery Thermal Management System Based on a Thermoelectric Effect" Energies 11, no. 2: 279. https://doi.org/10.3390/en11020279

APA StyleZhang, C.-W., Xu, K.-J., Li, L.-Y., Yang, M.-Z., Gao, H.-B., & Chen, S.-R. (2018). Study on a Battery Thermal Management System Based on a Thermoelectric Effect. Energies, 11(2), 279. https://doi.org/10.3390/en11020279