Optimal Fuel Consumption Modelling, Simulation, and Analysis for Hybrid Electric Vehicles

Abstract

:1. Introduction

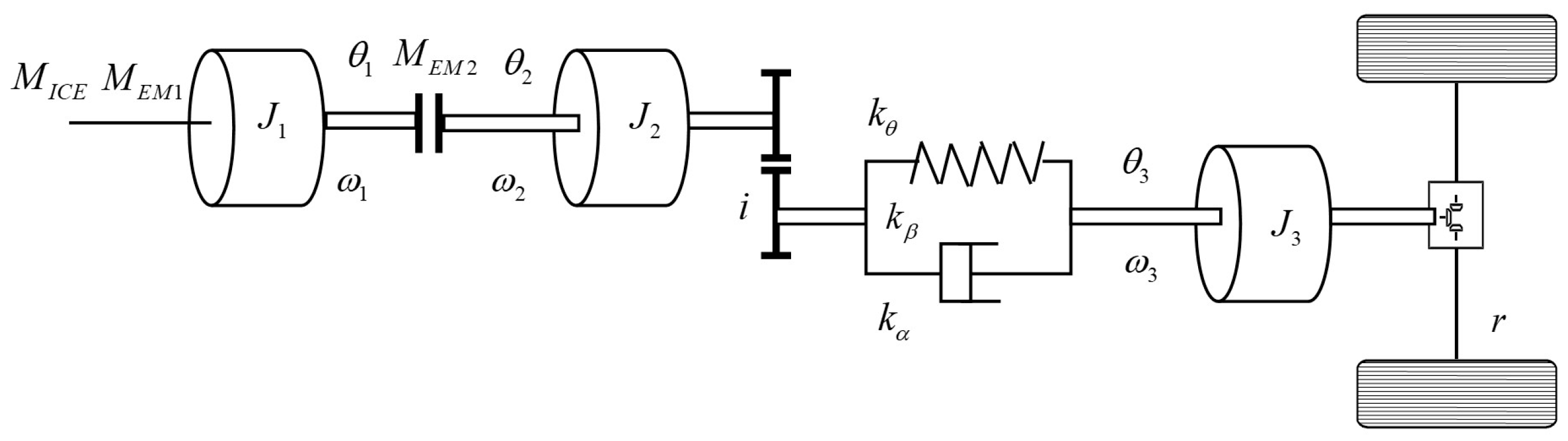

2. HEV Powertrain Modelling

3. HEV Scheme Simulations

3.1. Battery Modelling

3.2. DC–DC Converter

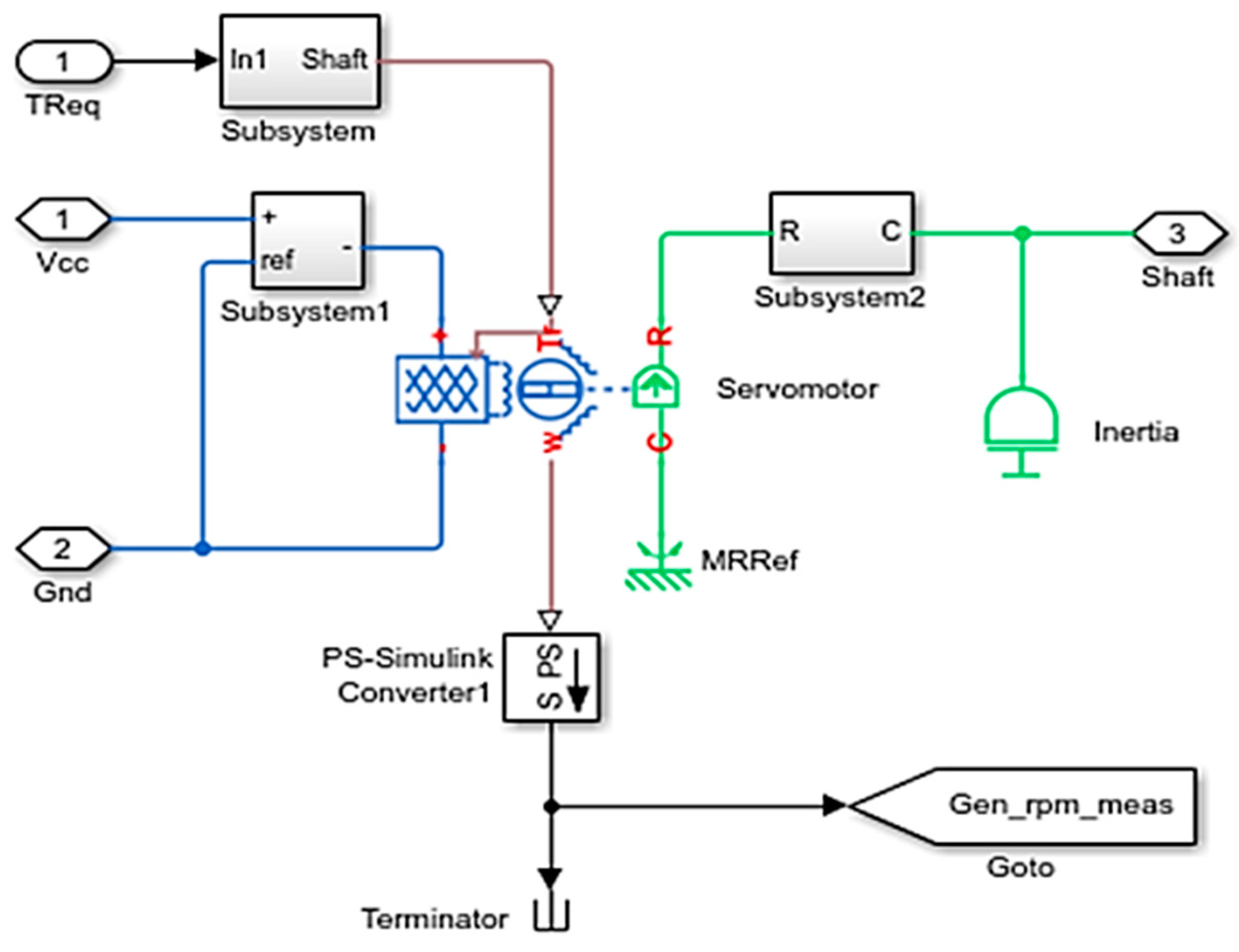

3.3. Model of the Starter/Generator

3.4. Model of the Planetary Gear

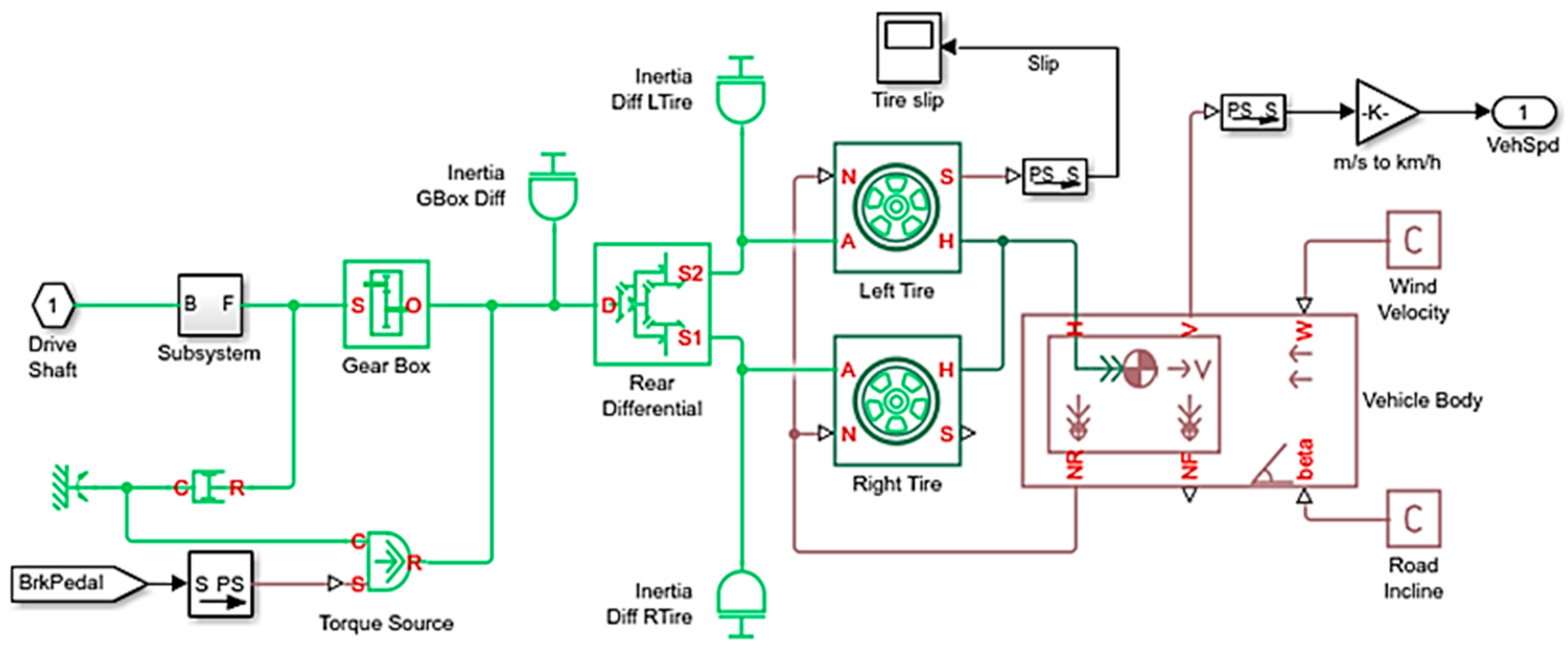

3.5. Model of the Vehicle Dynamics

3.6. Model of the ICE

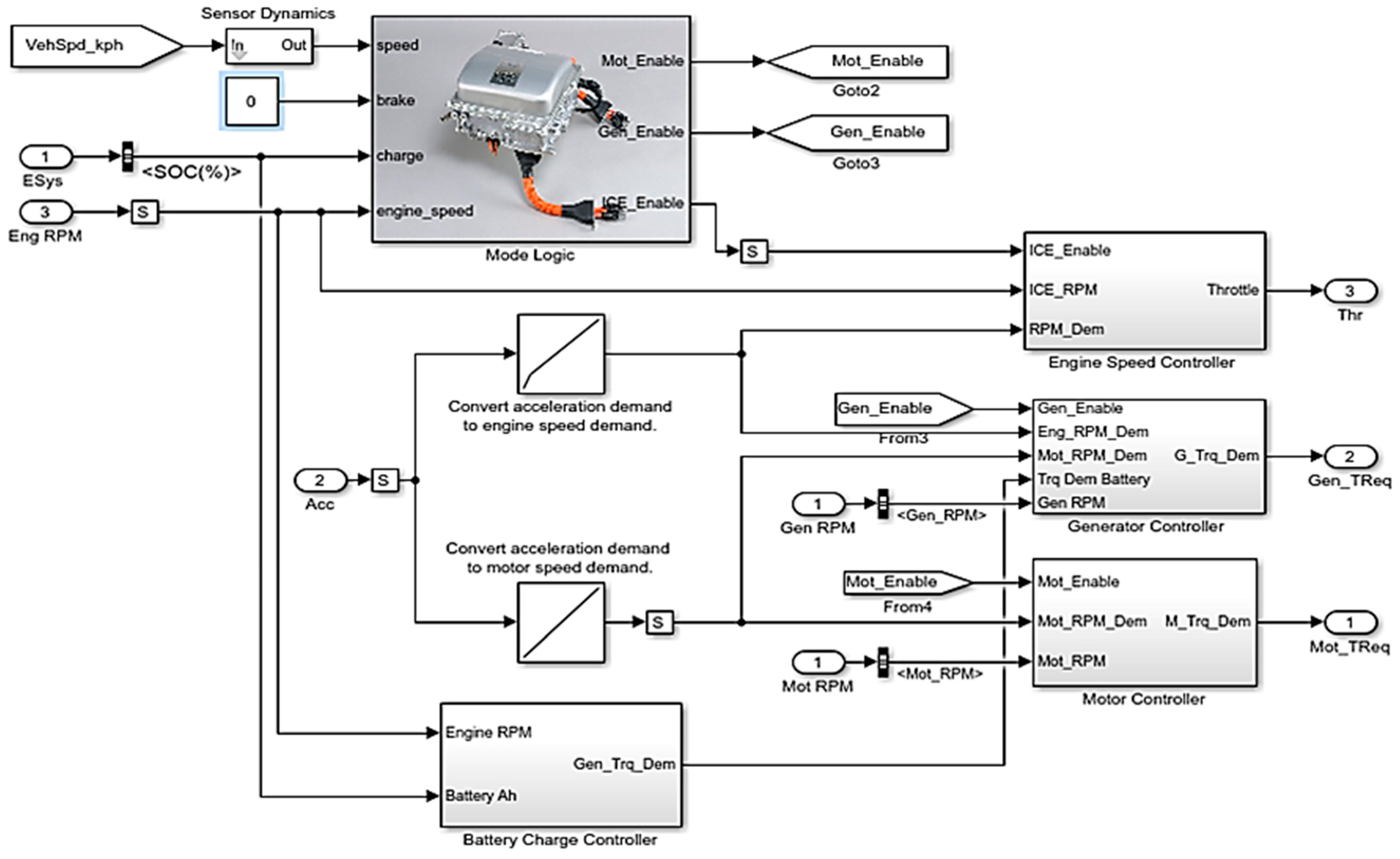

3.7. Model of the Control System

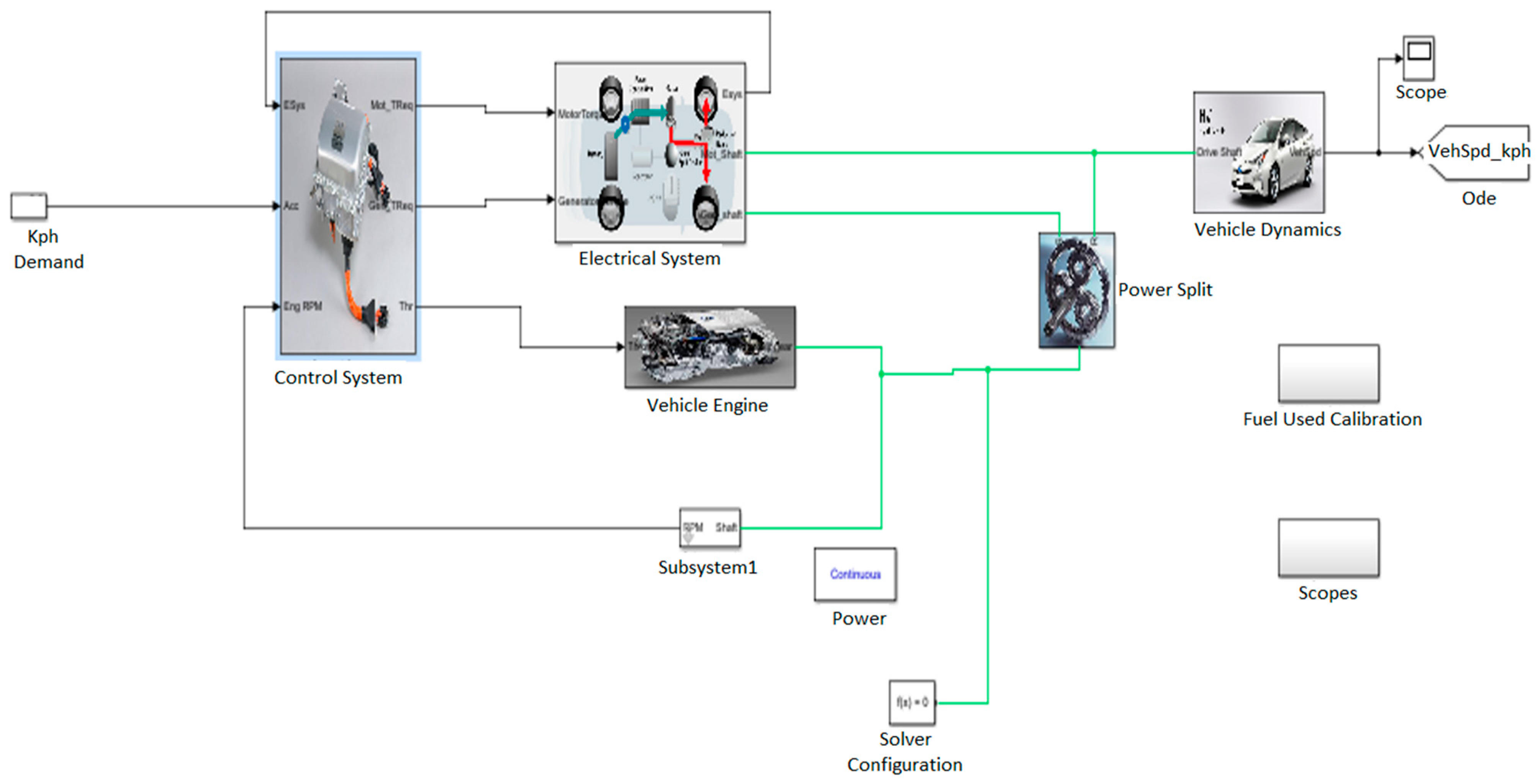

3.8. Model of the Integrated HEV

4. Fuel Economy Modelling and Regressions

5. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ehsani, M.; Singh, K.V.; Bansal, H.O.; Tafazzoli, R. State of the Art and Trends in Electric and Hybrid Electric Vehicles Proc. IEEE 2021, 109, 967–984. [Google Scholar] [CrossRef]

- Puma-Benavides, D.S.; Izquierdo-Reyes, J.; Calderon-Najera, J.d.D.; Ramirez-Mendoza, R.A. A Systematic Review of Technologies, Control Methods, and Optimization for Extended-Range Electric Vehicles. Appl. Sci. 2021, 11, 7095. [Google Scholar] [CrossRef]

- Faris, W.F.; Rakha, H.A.; Kafafy, R.I.; Idres, M.; Elmoselhy, S. Vehicle fuel consumption and emission modelling: An in-depth literature review. Int. J. Veh. Syst. Model. Test. 2011, 6, 318–395. [Google Scholar] [CrossRef]

- Tamada, S.; Bhattacharjee, D.; Dan, P.K. Review on automatic transmission control in electric and non-electric automotive powertrain. Int. J. Veh. Perform. 2020, 6, 98–128. [Google Scholar] [CrossRef]

- Singh, K.V.; Bansal, H.O.; Singh, D. A comprehensive review on hybrid electric vehicles: Architectures and components. J. Mod. Transp. 2019, 27, 77–107. [Google Scholar] [CrossRef] [Green Version]

- Yang, C.; Zha, M.; Wang, W.; Liu, K.; Xiang, C. Efficient energy management strategy for hybrid electric vehicles/plug-in hybrid electric vehicles: Review and recent advances under intelligent transportation system. IET Intell. Transp. Syst. 2020, 14, 702–711. [Google Scholar] [CrossRef]

- Tung, S.C.; Woydt, M.; Shah, R. Global Insights on Future Trends of Hybrid/EV Driveline Lubrication and Thermal Management. Front. Mech. Eng. 2020, 6, 571786. [Google Scholar] [CrossRef]

- Jiang, J.; Jiang, Q.; Chen, J.; Zhou, X.; Zhu, S.; Chen, T. Advanced Power Management and Control for Hybrid Electric Vehicles: A Survey. Wirel. Commun. Mob. Comput. 2021, 2021, 6652038. [Google Scholar] [CrossRef]

- Meng, Z.; Tang, G.; Zhou, Q.; Liu, B. A Review of Hybrid Electric Vehicle Energy Management Strategy Based on Road Condition Information. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Surakarta, Indonesia, 24–25 August 2021. [Google Scholar]

- Zhang, F.; Hu, X.; Langari, R.; Cao, D. Energy management strategies of connected HEVs and PHEVs: Recent progress and outlook. Prog. Energy Combust. Sci. 2019, 73, 235–256. [Google Scholar] [CrossRef]

- Shi, T.; Zhao, F.; Hao, H.; Liu, Z. Development Trends of Transmissions for Hybrid Electric Vehicles Using an Optimized Energy Management Strategy. Automot. Innov. 2018, 1, 291–299. [Google Scholar] [CrossRef] [Green Version]

- Galvagno, E.; Guercioni, G.; Rizzoni, G.; Velardocchia, M.; Vigliani, A. Effect of Engine Start and Clutch Slip Losses on the Energy Management Problem of a Hybrid DCT Powertrain. Int. J. Automot. Technol. 2020, 21, 953–969. [Google Scholar] [CrossRef]

- Zou, Y.; Huang, R.; Wu, X.; Zhang, B.; Zhang, Q.; Wang, N.; Qin, T. Modeling and energy management strategy research of a power-split hybrid electric vehicle. Adv. Mech. Eng. 2020, 12, 12. [Google Scholar] [CrossRef]

- Heppeler, G.; Sonntag, M.; Sawodny, O. Fuel efficiency analysis for simultaneous optimization of the velocity trajectory and the energy management in hybrid electric vehicles. IFAC Proc. Vol. 2014, 47, 6612–6617. [Google Scholar] [CrossRef] [Green Version]

- Xu, Q.; Wang, F.; Zhang, X.; Cui, S. Research on the Efficiency Optimization Control of the Regenerative Braking System of Hybrid Electrical Vehicle Based on Electrical Variable Transmission. IEEE Access 2019, 7, 116823–116834. [Google Scholar] [CrossRef]

- Reksowardojo, I.K.; Arya, R.R.; Budiman, B.A.; Islameka, M.; Santosa, S.P.; Sambegoro, P.L.; Aziz, A.R.A.; Abidin, E.Z.Z. Energy management system design for good delivery electric trike equipped with different powertrain configurations. World Electr. Veh. J. 2020, 11, 76. [Google Scholar] [CrossRef]

- Yao, Z.; Yoon, H. Control Strategy for Hybrid Electric Vehicle Based on Online Driving Pattern Classification. SAE Int. J. Altern. Powertrains 2019, 8, 8. [Google Scholar] [CrossRef]

- Sim, K.; Oh, S.; Namkoong, C.; Lee, J.; Han, K.; Hwang, S. Control strategy for clutch engagement during mode change of plug-in hybrid electric vehicle. Int. J. Automot. Technol. 2017, 18, 901–909. [Google Scholar] [CrossRef]

- Wang, S.; Xia, B.; He, C.; Zhang, S.; Shi, D. Mode transition control for single-shaft parallel hybrid electric vehicle using model predictive control approach. Adv. Mech. Eng. 2018, 10, 10. [Google Scholar] [CrossRef] [Green Version]

- Robuschi, N.; Zeile, C.; Sager, S.; Braghin, F. Multiphase mixed-integer nonlinear optimal control of hybrid electric vehicles. Automatica 2021, 123, 109325. [Google Scholar] [CrossRef]

- Wróblewski, P.; Kupiec, J.; Drozdz, W.; Lewicki, W.; Jaworski, J. The Economic Aspect of Using Different Plug-In Hybrid Driving Techniques in Urban Conditions. Energies 2021, 14, 3543. [Google Scholar] [CrossRef]

- Mahroogi, F.O.; Narayan, S. A recent review of hybrid automotive systems in Gulf Corporation Council region. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2019, 233, 3579–3587. [Google Scholar] [CrossRef]

- Miri, I.; Fotouhi, A.; Ewin, N. Electric vehicle energy consumption modelling and estimation-A case study. Int. J. Energy Res. 2021, 45, 501–520. [Google Scholar] [CrossRef]

- Heni, H.; Arona Diop, S.; Renaud, J.; Coelho, L.C. Measuring fuel consumption in vehicle routing: New estimation models using supervised learning. Int. J. Prod. Res. 2021, 1–17. [Google Scholar] [CrossRef]

- Minh, V.T. Advanced Vehicle Dynamics; Universiti of Malaya Press: Kuala, Lumpur, 2012; Volume 265. [Google Scholar]

- Minh, V.T.; Mohd Hashim, F. Adaptive teleoperation system with neural network-based multiple model control. Math. Probl. Eng. 2010, 2010, 592054. [Google Scholar] [CrossRef] [Green Version]

- Minh, V.T.; Afzulpurkar, N. Robustness of model predictive control for Ill-conditioned distillation process. Dev. Chem. Eng. Min. Process. 2005, 13, 311–316. [Google Scholar] [CrossRef]

- Hybrid Toyota Prius. 2021. Available online: https://www.toyota.com/prius (accessed on 4 October 2021).

- Hybrid Honda Insight. 2021. Available online: https://automobiles.honda.com/insight (accessed on 4 October 2021).

- Hybrid Kia Niro. 2021. Available online: https://www.kia.com/cz/modely/niro/objevte (accessed on 4 October 2021).

- Hyundai Sonata. 2021. Available online: https://www.hyundaiusa.com/us/en/vehicles/sonata-hybrid (accessed on 4 October 2021).

- Hybrid Kia Optima. 2021. Available online: https://www.kia.ca/vehicles/optimahybrid/overview (accessed on 4 October 2021).

- Hybrid Hyundai Avante LPi. 2021. Available online: https://www.hyundai.com/worldwide/en/ (accessed on 4 October 2021).

- Hybrid Toyota Camry. 2021. Available online: https://www.toyota.com/camryhybrid/ (accessed on 4 October 2021).

- Hybrid Honda Civic. 2021. Available online: https://automobiles.honda.com/civic (accessed on 4 October 2021).

- Minh, V.T.; Moezzi, R.; Cyrus, J.; Dhoska, K. Smart Mechatronic Elbow Brace using EMG Sensors. Int. J. Innov. Technol. Interdiscip. Sci. 2022, 5, 865–873. [Google Scholar]

- Minh, V.T.; Katushin, N.; Moezzi, R.; Dhoska, K.; Pumwa, J. Smart Glove for Augmented and Virtual Reality. Int. J. Innov. Technol. Interdiscip. Sci. 2021, 4, 663–671. [Google Scholar] [CrossRef]

- Minh, V.T.; Moezzi, R.; Dhoska, K.; Pumwa, J. Model Predictive Control for Autonomous Vehicle Tracking. Int. J. Innov. Technol. Interdiscip. Sci. 2021, 4, 560–603. [Google Scholar]

- Minh, V.T.; Tamre, M.; Musalimov, V.; Kovalenko, P.; Rubinshtein, I.; Ovchinnikov, I.; Moezzi, R. Simulation of Human Gait Movements. Int. J. Innov. Technol. Interdiscip. Sci. 2020, 3, 326–345. [Google Scholar]

| No. | HEV Models | HEV Weights in Kg |

|---|---|---|

| 1. | Hybrid Toyota Prius 2021 | 1335 [28] |

| 2. | Hybrid Honda Insight 2021 | 1247 [29] |

| 3. | Hybrid Kia Niro 2021 | 1419 [30] |

| 4. | Hyundai Sonata 2021 | 1578 [31] |

| 5. | Hybrid Kia Optima 2021 | 1595 [32] |

| 6. | Hybrid Hyundai Avante LPi 2021 | 1287 [33] |

| 7. | Hybrid Toyota Camry 2021 | 1639 [34] |

| 8. | Hybrid Honda Civic 2021 | 1270 [35] |

| No. | Parameters | Rolling Radius in Meters | Rim Width in Inch |

|---|---|---|---|

| 1. | 154/65/R13 | 0.242 | 4.5 |

| 2. | 154/80/R13 | 0.262 | 4.5 |

| 3. | 164/60/R14 | 0.252 | 5.0 |

| 4. | 164/65/R13 | 0.246 | 5.0 |

| 5. | 164/65/R14 | 0.257 | 5.0 |

| 6. | 164/70/R14 | 0.267 | 5.0 |

| 7. | 164/80/R13 | 0.268 | 4.5 |

| 8. | 174/65/R14 | 0.265 | 5.0 |

| 9. | 174/65/R15 | 0.275 | 5.0 |

| 10. | 204/50/R15 | 0.276 | 6.5 |

| 1335 | 1247 | 1419 | 1578 | 1595 | 1287 | 1639 | 1270 | |

|---|---|---|---|---|---|---|---|---|

| 0.242 | 0.01983 | 0.01983 | 0.01984 | 0.01992 | 0.01994 | 0.01983 | 0.02008 | 0.01983 |

| 0.262 | 0.01962 | 0.01962 | 0.01965 | 0.02033 | 0.02053 | 0.01962 | 0.02182 | 0.01962 |

| 0.252 | 0.01972 | 0.01972 | 0.01972 | 0.0198 | 0.01994 | 0.01972 | 0.02052 | 0.01972 |

| 0.246 | 0.01978 | 0.01978 | 0.01978 | 0.01992 | 0.01994 | 0.01998 | 0.02025 | 0.01978 |

| 0.257 | 0.01967 | 0.01965 | 0.01969 | 0.01996 | 0.02026 | 0.01965 | 0.02122 | 0.01965 |

| 0.267 | 0.01955 | 0.01956 | 0.01956 | 0.02056 | 0.02087 | 0.01956 | 0.02254 | 0.01956 |

| 0.268 | 0.01954 | 0.01955 | 0.01958 | 0.02092 | 0.02128 | 0.01952 | 0.02323 | 0.01955 |

| 0.265 | 0.01957 | 0.01958 | 0.01961 | 0.02044 | 0.02062 | 0.01957 | 0.02208 | 0.01957 |

| 0.275 | 0.01947 | 0.01947 | 0.01955 | 0.02187 | 0.02237 | 0.01946 | 0.02512 | 0.01946 |

| 0.276 | 0.01961 | 0.01961 | 0.01964 | 0.02024 | 0.02045 | 0.01961 | 0.0215 | 0.01961 |

| Rolling Tire Radius in Meters | 0.242 | 0.248 | 0.252 | 0.259 | 0.262 | 0.265 | 0.267 | 0.269 | 0.277 | 0.278 |

| Optimal HEV Weights in Kg | 1472 | 1429 | 1402 | 1354 | 1333 | 1312 | 1298 | 1277 | 1229 | 1222 |

| No | HEV Type | Driving Cycle | HEV Weight in Kg | Tire Radius in Meters | Fuel Consumption in Litres |

|---|---|---|---|---|---|

| 1. | Normal Optimal | FTP75 | 1200 1222 | 0.262 0.278 | 0.03667 0.03648 |

| 2. | Normal Optimal | NYCC | 1200 1222 | 0.262 0.278 | 0.03294 0.03262 |

| 3. | Normal Optimal | HWFET | 1200 1222 | 0.262 0.278 | 0.03968 0.03914 |

| 4. | Normal Optimal | EUDC | 1200 1222 | 0.262 0.278 | 0.03714 0.03654 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Minh, V.T.; Moezzi, R.; Cyrus, J.; Hlava, J. Optimal Fuel Consumption Modelling, Simulation, and Analysis for Hybrid Electric Vehicles. Appl. Syst. Innov. 2022, 5, 36. https://doi.org/10.3390/asi5020036

Minh VT, Moezzi R, Cyrus J, Hlava J. Optimal Fuel Consumption Modelling, Simulation, and Analysis for Hybrid Electric Vehicles. Applied System Innovation. 2022; 5(2):36. https://doi.org/10.3390/asi5020036

Chicago/Turabian StyleMinh, Vu Trieu, Reza Moezzi, Jindrich Cyrus, and Jaroslav Hlava. 2022. "Optimal Fuel Consumption Modelling, Simulation, and Analysis for Hybrid Electric Vehicles" Applied System Innovation 5, no. 2: 36. https://doi.org/10.3390/asi5020036

APA StyleMinh, V. T., Moezzi, R., Cyrus, J., & Hlava, J. (2022). Optimal Fuel Consumption Modelling, Simulation, and Analysis for Hybrid Electric Vehicles. Applied System Innovation, 5(2), 36. https://doi.org/10.3390/asi5020036