Energy Consumption Prediction for Fused Deposition Modelling 3D Printing Using Machine Learning

Abstract

:1. Introduction

2. Literature Review

- Predict the energy use of FDM printed parts;

- Assess the impact of printing parameters on energy consumption;

- Optimize energy consumption based on the orientation of the part to be printed.

3. Design of Experiment Data

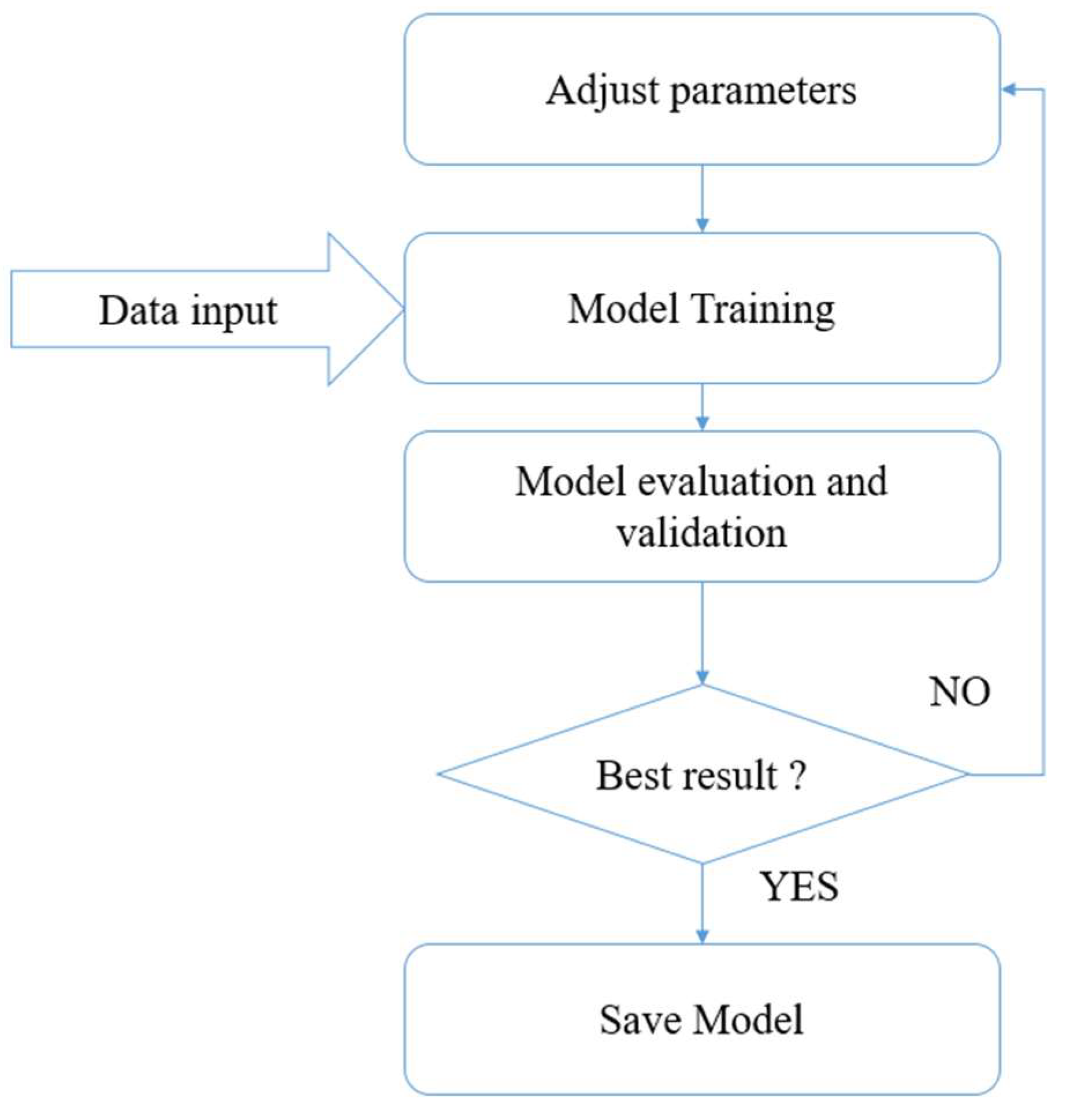

4. Methodology

- -

- The first step is data cleaning, in which we eliminate the useless information to keep only the input and output parameters used in our study, which are shown in Table 2.

- -

- In the second step, we will transform the data into a format or structure that would be more appropriate for model development and also data exploration in general. In our case, we have used standard scaler.

4.1. Overview of Machine Learning Algorithms

4.1.1. Linear Regression

4.1.2. RANSACRegressor (Random Sample Consensus)

4.1.3. Ridge Regression

4.1.4. Lasso Regression

4.1.5. Gaussian Process Regressor (GPR)

4.1.6. Elastic Net Regressor

4.1.7. Random Forest Regressor

- Step 1: From the dataset, we choose N records at random.

- Step 2: For each N records, we create a regression tree.

- Step 3: For each tree, we repeat steps 1 and 2.

- Step 4: For a problem of a record E, we take the average of the other predictions of the other trees to estimate the Y value of the output.

4.1.8. SVM

4.1.9. Multi-Output Regression—SVR

4.1.10. Regression Chain

4.1.11. KNeighbors Regressor

4.1.12. DecisionTreeRegressor

4.2. Evaluation Metrics

- Mean absolute error (MAE) is the mean of the absolute value of the errors; this indicator represents the average of the absolute difference between the actual and predicted values in the database. It measures the average of the residuals in the data set (29).

- Root mean squared error (RMSE); this measure represents the root mean square error of the squared difference between the original and predicted values of the model (30).

- R-Squared expresses the ratio of the variance of the variable explained by the model with the original value (31).

5. Results

6. Discussion

- o For part number one, if we print it following orientation 180 instead of printing it following 0, we will lose about 70 Wh of energy.

- o For part number two, if we print it following orientation 90 instead of printing it following 0, we will lose about 50 Wh of energy.

- o For part number three, if we print it following orientation 90 instead of printing it following 0, we will lose about 7 Wh of energy.

- o For part number four, if we print it following orientation 90 instead of printing it following 0, we will lose about 90 Wh of energy.

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- ASTM-F2792-12a; Terminology for Additive Manufacturing Technologies. F42 Committee. ASTM International: West Conshohocken, PA, USA, 2012. [CrossRef]

- Yang, Y.; Li, L.; Pan, Y.; Sun, Z. Energy Consumption Modeling of Stereolithography-Based Additive Manufacturing Toward Environmental Sustainability. J. Ind. Ecol. 2017, 21, S168–S178. [Google Scholar] [CrossRef] [Green Version]

- Huang, R.; Riddle, M.; Graziano, D.; Warren, J.; Das, S.; Nimbalkar, S.; Cresko, J.; Masanet, E. Energy and emissions saving potential of additive manufacturing: The case of lightweight aircraft components. J. Clean. Prod. 2016, 135, 1559–1570. [Google Scholar] [CrossRef] [Green Version]

- Kellens, K.; Baumers, M.; Gutowski, T.G.; Flanagan, W.; Lifset, R.; Duflou, J. Environmental Dimensions of Additive Manufacturing: Mapping Application Domains and Their Environmental Implications. J. Ind. Ecol. 2017, 21, S49–S68. [Google Scholar] [CrossRef] [Green Version]

- Giannatsis, J.; Dedoussis, V. Additive fabrication technologies applied to medicine and health care: A review. Int. J. Adv. Manuf. Technol. 2007, 40, 116–127. [Google Scholar] [CrossRef]

- Salmi, M.; Akmal, J.S.; Pei, E.; Wolff, J.; Jaribion, A.; Khajavi, S.H. 3D Printing in COVID-19: Productivity Estimation of the Most Promising Open Source Solutions in Emergency Situations. Appl. Sci. 2020, 10, 4004. [Google Scholar] [CrossRef]

- Verhoef, L.A.; Budde, B.W.; Chockalingam, C.; Nodar, B.G.; van Wijk, A.J. The effect of additive manufacturing on global energy demand: An assessment using a bottom-up approach. Energy Policy 2018, 112, 349–360. [Google Scholar] [CrossRef]

- Gibson, I. Additive Manufacturing Technologies, 3rd ed.Springer: New York, NY, USA, 2021. [Google Scholar]

- Wohlers, T.T.; Associates, W.; Campbell, I.; Huff, R.; Diegel, O.; Kowen, J. 3D Printing and Additive Manufacturing State of the Industry. In Wohlers Report 2019; Wohlers Associates Inc.: Fort Collins, CO, USA, 2019. [Google Scholar]

- Hopkins, N.; Jiang, L.; Brooks, H. Energy consumption of common desktop additive manufacturing technologies. Clean. Eng. Technol. 2021, 2, 100068. [Google Scholar] [CrossRef]

- Ajay, J.; Song, C.; Rathore, A.S.; Zhou, C.; Xu, W. 3DGates: An Instruction-Level Energy Analysis and Optimization of 3D Printers. In Proceedings of the Twenty-Second International Conference on Architectural Support for Programming Languages and Operating Systems, Xi’an, China, 8–12 April 2017; pp. 419–433. [Google Scholar] [CrossRef] [Green Version]

- Weissman, A.; Gupta, S.K. Selecting a Design-Stage Energy Estimation Approach for Manufacturing Processes. In Proceedings of the ASME 2011 International Design Engineering Technical Conference & Computers and Information in Engineering Conference IDETC/CIE 2011, Washington, DC, USA, 28–31 August 2011; pp. 1075–1086. [Google Scholar] [CrossRef] [Green Version]

- Song, R.; Telenko, C. Material and energy loss due to human and machine error in commercial FDM printers. J. Clean. Prod. 2017, 148, 895–904. [Google Scholar] [CrossRef]

- Sood, A.K.; Ohdar, R.K.; Mahapatra, S.S. Experimental investigation and empirical modelling of FDM process for compressive strength improvement. J. Adv. Res. 2012, 3, 81–90. [Google Scholar] [CrossRef] [Green Version]

- Singh, S.; Singh, G.; Prakash, C.; Ramakrishna, S. Current status and future directions of fused filament fabrication. J. Manuf. Process. 2020, 55, 288–306. [Google Scholar] [CrossRef]

- Szemeti, G.; Ramanujan, D. An Empirical Benchmark for Resource Use in Fused Deposition Modelling 3D Printing of Isovolumetric Mechanical Components. Procedia CIRP 2022, 105, 183–191. [Google Scholar] [CrossRef]

- Yan, Z.; Huang, J.; Lv, J.; Hui, J.; Liu, Y.; Zhang, H.; Yin, E.; Liu, Q. A New Method of Predicting the Energy Consumption of Additive Manufacturing considering the Component Working State. Sustainability 2022, 14, 3757. [Google Scholar] [CrossRef]

- Hu, F.; Qin, J.; Li, Y.; Liu, Y.; Sun, X. Deep Fusion for Energy Consumption Prediction in Additive Manufacturing. Procedia CIRP 2021, 104, 1878–1883. [Google Scholar] [CrossRef]

- Qin, J.; Liu, Y.; Grosvenor, R. Multi-source data analytics for AM energy consumption prediction. Adv. Eng. Inform. 2018, 38, 840–850. [Google Scholar] [CrossRef]

- Baumers, M.; Tuck, C.; Wildman, R.; Ashcroft, I.; Rosamond, E.; Hague, R. Transparency Built-In. J. Ind. Ecol. 2012, 17, 418–431. [Google Scholar] [CrossRef]

- Meteyer, S.; Xu, X.; Perry, N.; Zhao, Y.F. Energy and Material Flow Analysis of Binder-jetting Additive Manufacturing Processes. Procedia CIRP 2014, 15, 19–25. [Google Scholar] [CrossRef] [Green Version]

- Yoon, H.-S.; Lee, J.-Y.; Kim, H.-S.; Kim, M.-S.; Kim, E.-S.; Shin, Y.-J.; Chu, W.-S.; Ahn, S.-H. A comparison of energy consumption in bulk forming, subtractive, and additive processes: Review and case study. Int. J. Precis. Eng. Manuf. Technol. 2014, 1, 261–279. [Google Scholar] [CrossRef]

- Yang, J.; Liu, Y. Energy, time and material consumption modelling for fused deposition modelling process. Procedia CIRP 2020, 90, 510–515. [Google Scholar] [CrossRef]

- McComb, C.; Meisel, N.; Simpson, T.W.; Murphy, C. Predicting Part Mass, Required Support Material, and Build Time via Autoencoded Voxel Patterns. In Proceedings of the 2018 Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 13–15 August 2018. [Google Scholar] [CrossRef] [Green Version]

- Jackson, M.A.; Van Asten, A.; Morrow, J.D.; Min, S.; Pfefferkorn, F.E. A Comparison of Energy Consumption in Wire-based and Powder-based Additive-subtractive Manufacturing. Procedia Manuf. 2016, 5, 989–1005. [Google Scholar] [CrossRef] [Green Version]

- Rejeski, D.; Zhao, F.; Huang, Y. Research needs and recommendations on environmental implications of additive manufacturing. Addit. Manuf. 2018, 19, 21–28. [Google Scholar] [CrossRef] [Green Version]

- Simon, T.R.; Lee, W.J.; Spurgeon, B.E.; Boor, B.E.; Zhao, F. An Experimental Study on the Energy Consumption and Emission Profile of Fused Deposition Modeling Process. Procedia Manuf. 2018, 26, 920–928. [Google Scholar] [CrossRef]

- r3DiM Benchmark. Available online: https://www.kaggle.com/dataset/c22f9996866156344599fd5baf48aaa8ac8ccce9a849b050ceeea36ba4e9c8f9 (accessed on 22 June 2022).

- Weisberg, S. Applied Linear Regression, 3rd ed.Wiley: Hoboken, NJ, USA, 2005. [Google Scholar]

- Maulud, D.; AbdulAzeez, A.M. A Review on Linear Regression Comprehensive in Machine Learning. J. Appl. Sci. Technol. Trends 2020, 1, 140–147. [Google Scholar] [CrossRef]

- Fischler, M.A.; Bolles, R.C. Random sample consensus: A Paradigm for Model Fitting with Applications to Image Analysis and Automated Cartography. Commun. ACM 1981, 24, 381–395. [Google Scholar] [CrossRef]

- Hoerl, A.E.; Kennard, R.W. Ridge Regression: Biased Estimation for Nonorthogonal Problems. Technometrics 1970, 12, 55. [Google Scholar] [CrossRef]

- Van de Geer, S.A. High-dimensional generalized linear models and the lasso. Ann. Stat. 2008, 36. [Google Scholar] [CrossRef]

- Zou, H.; Hastie, T. Regularization and Variable Selection via the Elastic Net. J. R. Stat. Soc. Ser. B Stat. Methodol. 2005, 67, 301–320. [Google Scholar] [CrossRef] [Green Version]

- The Nature of Statistical Learning Theory. Available online: https://link.springer.com/book/10.1007/978-1-4757-3264-1 (accessed on 22 June 2022).

- Kernel Methods for Pattern Analysis. Available online: https://www.cambridge.org/core/books/kernel-methods-for-pattern-analysis/811462F4D6CD6A536A05127319A8935A (accessed on 22 June 2022).

- Pérez-Cruz, F.; Camps-Valls, G.; Soria-Olivas, E.; Pérez-Ruixo, J.J.; Figueiras-Vidal, A.R.; Artés-Rodríguez, A. Multi-dimensional Function Approximation and Regression Estimation. In Proceedings of the International Conference on Artificial Neural Networks, ICANN ’02, Lecture Notes in Computer Science. Madrid, Spain, 28–30 August 2002; Dorronsoro, J.R., Ed.; Springer: Berlin/Heidelberg, Germany, 2002; Volume 2415, pp. 757–762. [Google Scholar] [CrossRef]

| AM Process Type | Brief Description | Material Used | Technologies |

|---|---|---|---|

| Vat photopolymerization | photopolymers are exposed to repeated forms of radiation corresponding to cross sections of the part under construction. | Photopolymers | Stereolithography, digital light processing (DLP) |

| Powder bed fusion | Thermal energy selectively merges the regions of a powder bed. | Metals, polymers | Electron beam melting (EBM), selective laser sintering (SLS),selective heat sintering (SHS), direct metal laser sintering(DMLS) |

| Material extrusion | The melted material is selected through a nozzle. | Polymers | Fused deposition modelling (FDM) |

| Material jetting | Droplets of build material are placed selectively. | Polymers, waxes | Multi-jet modelling (MJM) |

| Binder jetting | A binder is printed onto a powder bed to form the part’s cross section. | Polymers, foundry sand, metals | Powder bed and inkjet head (PBIH), plaster-based 3D printing (PP) |

| Sheet lamination | Sheets of materials are cut, stacked, and bonded to form an object. | Paper, metals | Laminated object manufacturing (LOM), ultrasonic consolidation (UC) |

| Direct energy deposition | Thermal energy is used to merge materials by melting as the material is being deposited. | Metals | Laser metal deposition (LMD), electron beam metal deposition, wire arc additive manufacturing (WAAM) |

| Input Parameters | Intervals |

|---|---|

| Orientation | [0–180] |

| stl surface area | [1533.85–10,850.92] |

| Number of facets | [40–9368] |

| Sliced X | [3.23–153.87] |

| Sliced Y | [8.45–67.27] |

| Sliced Z | [3.23–153.87] |

| Sliced volume | [2142.39–5852.08] |

| Sliced volume including support | [2171.28–11,376.59] |

| Total Filament | [2.76–14.45] |

| Expected print time | [0.4166–4.033] |

| Number of layers | [21–1629] |

| Model | MAE | RMSE | R-Squared | Explained Variance | |

|---|---|---|---|---|---|

| 1 | Linear Regression | 5.251029 | 11.569446 | 0.965963 | 0.969285 |

| 2 | RANSACRegressor | 5.167925 | 10.929534 | 0.969624 | 0.973401 |

| 3 | Ridge Regression | 5.894558 | 13.867725 | 0.951097 | 0.956034 |

| 4 | GaussianProcessRegressor | 3.881234 | 5.793596 | 0.991465 | 0.991602 |

| 5 | Lasso Regression | 5.764058 | 13.284901 | 0.955121 | 0.960033 |

| 6 | Elastic Net Regression | 5.920195 | 14.095655 | 0.949476 | 0.954896 |

| 7 | Random Forest Regressor | 7.287192 | 19.347954 | 0.904808 | 0.904854 |

| 8 | SVM Regressor | 9.683700 | 23.169309 | 0.863493 | 0.877995 |

| 9 | Linear SVR Multi Output Regressor | 15.571200 | 22.334431 | 0.873154 | 0.893362 |

| 10 | Linear SVR Chain Regressor | 15.588542 | 22.311816 | 0.873410 | 0.893883 |

| 11 | KNeighborsRegressor | 13.197450 | 24.191009 | 0.851189 | 0.851421 |

| 12 | DecisionTreeRegressor | 9.929268 | 23.336388 | 0.861517 | 0.862568 |

| Part | Orientation | Predicted Energy by GPR | Actual Energy |

|---|---|---|---|

| 0 | 70.01837754 | 76.969 |

| 90 | 97.62380459 | 92.866 | |

| 180 | 196.11750589 | 143.278 | |

| 0 | 44.3041344 | 90.218 |

| 90 | 158.10571579 | 138.686 | |

| 180 | 166.36283187 | 133.051 | |

| 0 | 78.20556709 | 89.38 |

| 90 | 185.35942611 | 96.941 | |

| 180 | 98.38320959 | 90.133 | |

| 0 | 77.05352922 | 67.718 |

| 90 | 203.28819197 | 141.432 | |

| 180 | 86.72962282 | 75.973 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

El youbi El idrissi, M.A.; Laaouina, L.; Jeghal, A.; Tairi, H.; Zaki, M. Energy Consumption Prediction for Fused Deposition Modelling 3D Printing Using Machine Learning. Appl. Syst. Innov. 2022, 5, 86. https://doi.org/10.3390/asi5040086

El youbi El idrissi MA, Laaouina L, Jeghal A, Tairi H, Zaki M. Energy Consumption Prediction for Fused Deposition Modelling 3D Printing Using Machine Learning. Applied System Innovation. 2022; 5(4):86. https://doi.org/10.3390/asi5040086

Chicago/Turabian StyleEl youbi El idrissi, Mohamed Achraf, Loubna Laaouina, Adil Jeghal, Hamid Tairi, and Moncef Zaki. 2022. "Energy Consumption Prediction for Fused Deposition Modelling 3D Printing Using Machine Learning" Applied System Innovation 5, no. 4: 86. https://doi.org/10.3390/asi5040086