Empirical Model for the Retained Stability Index of Asphalt Mixtures Using Hybrid Machine Learning Approach

Abstract

:1. Introduction

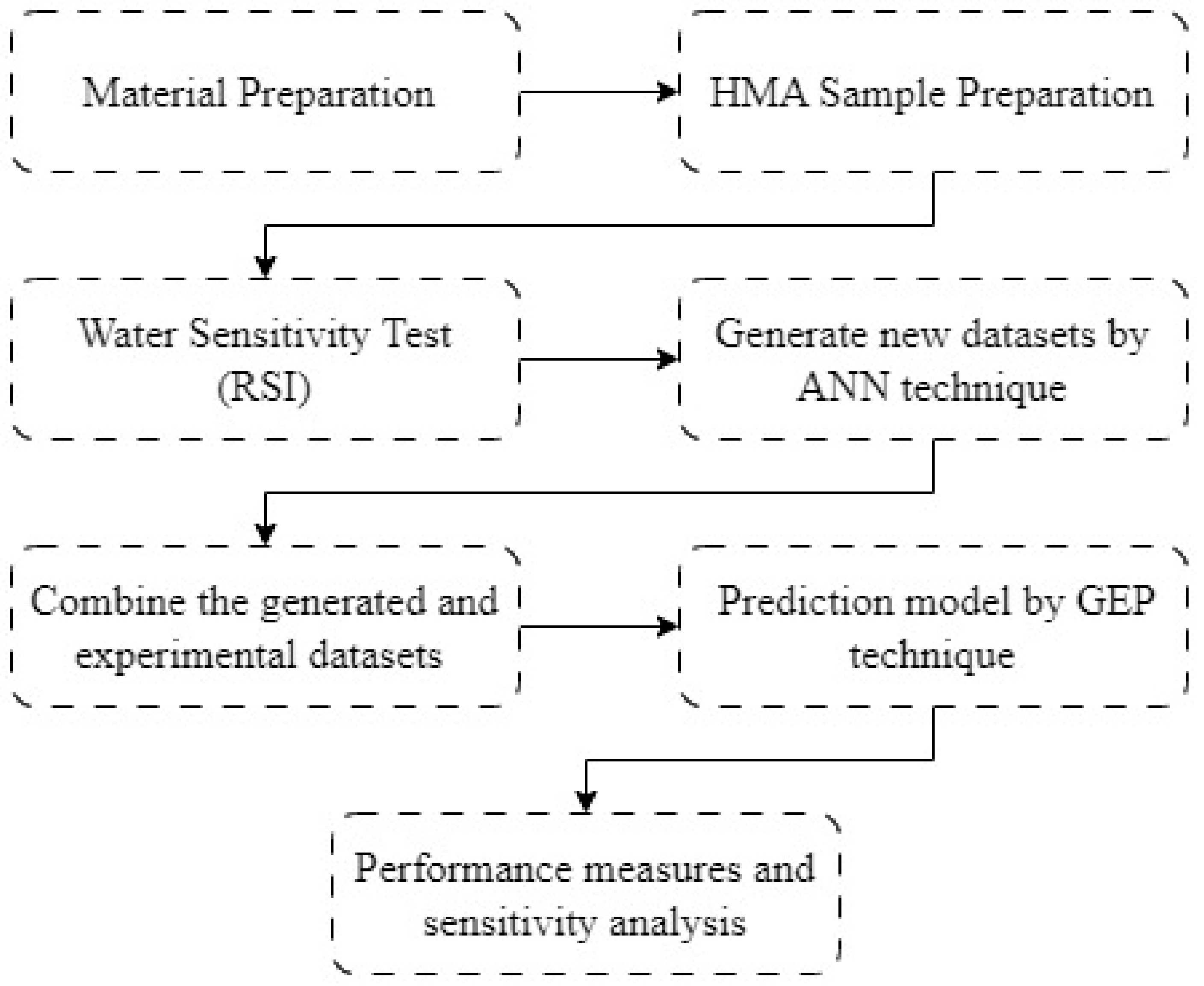

2. Objective and Methods

3. Materials and Testing

3.1. Raw Materials

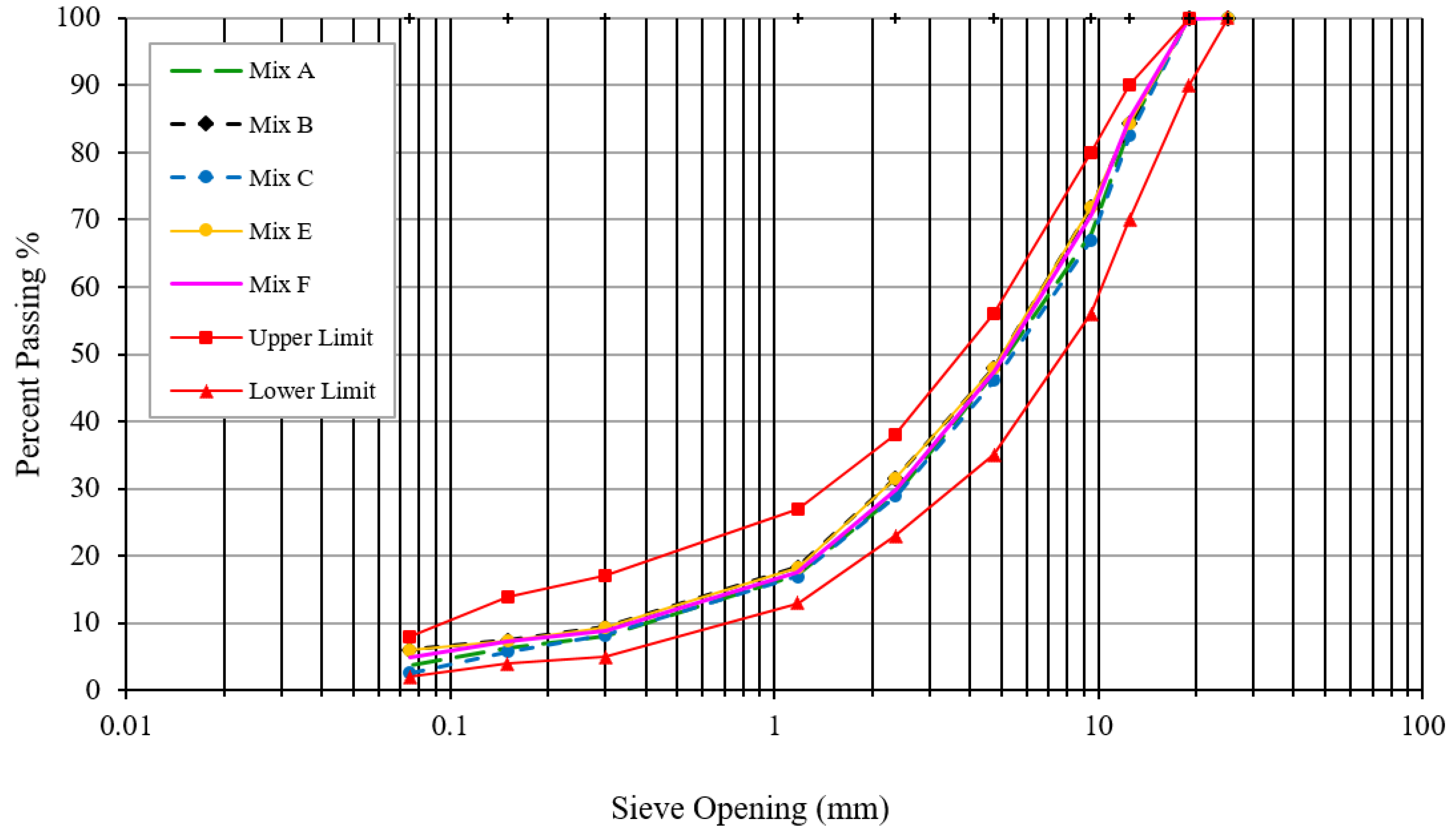

3.2. Sample Preparation and Testing Results

4. Model Development

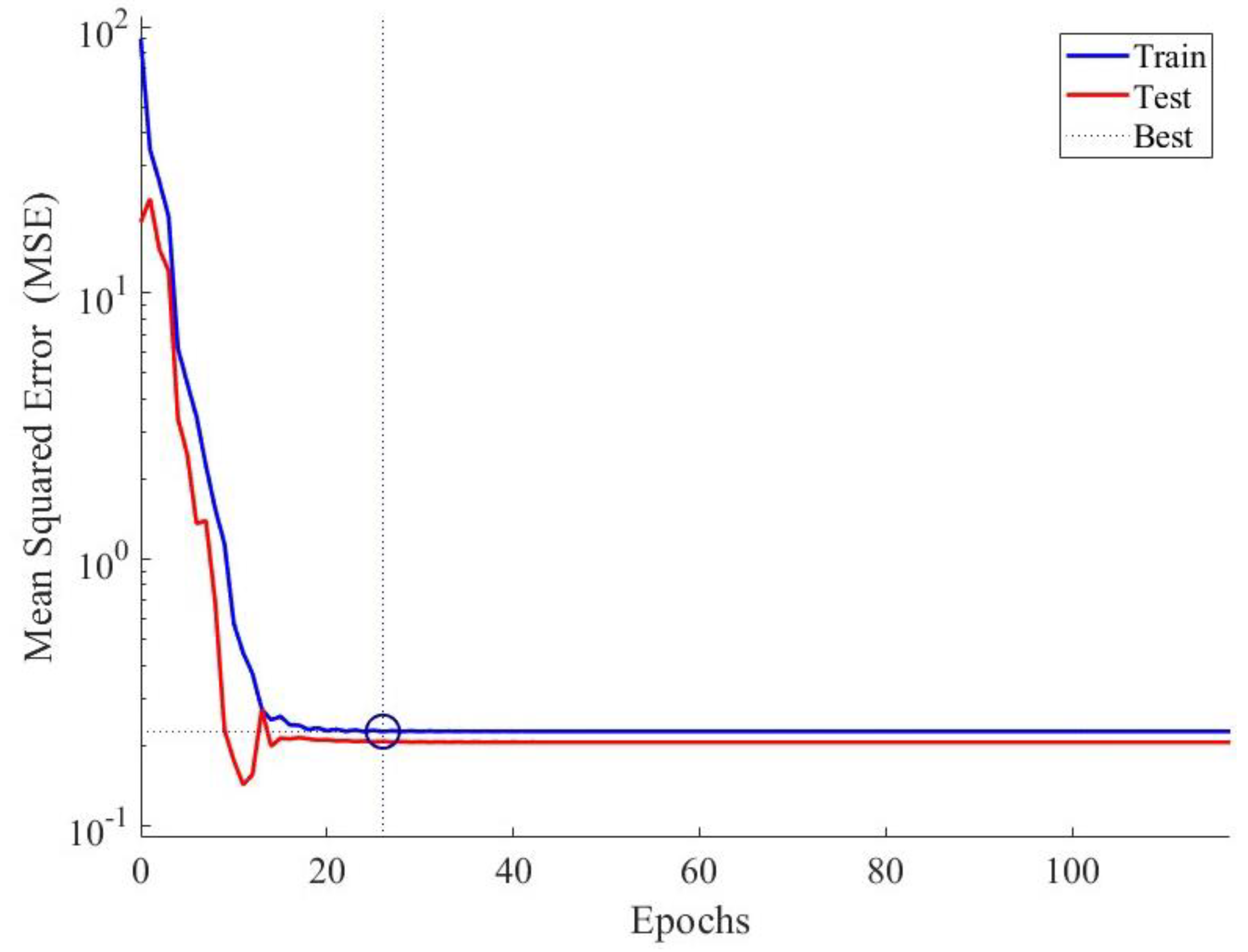

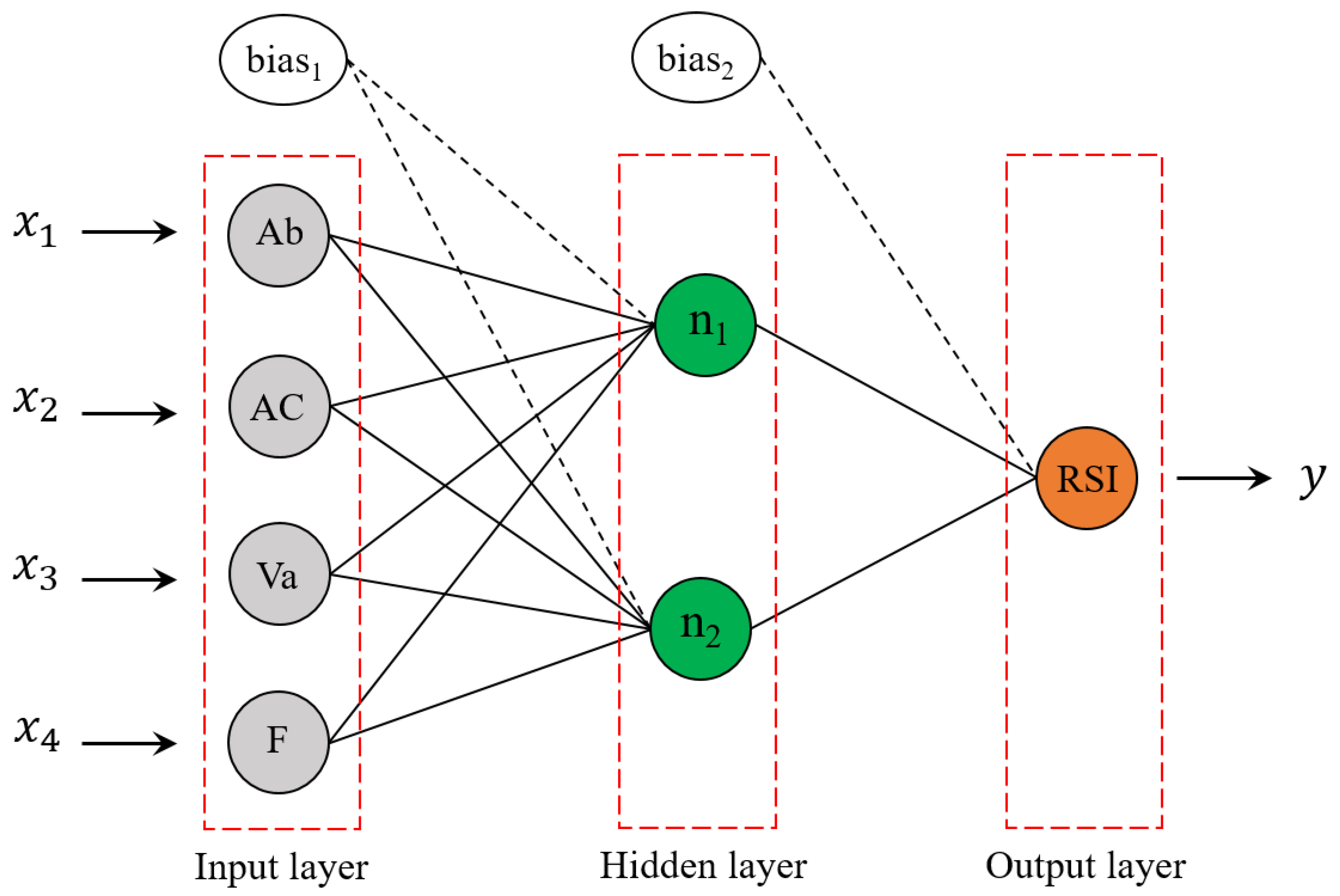

4.1. Developing ANN Model and Generating New Datasets

4.2. GEP Predictive Model

5. Evaluation and Sensitivity of the Proposed Model

6. Conclusions

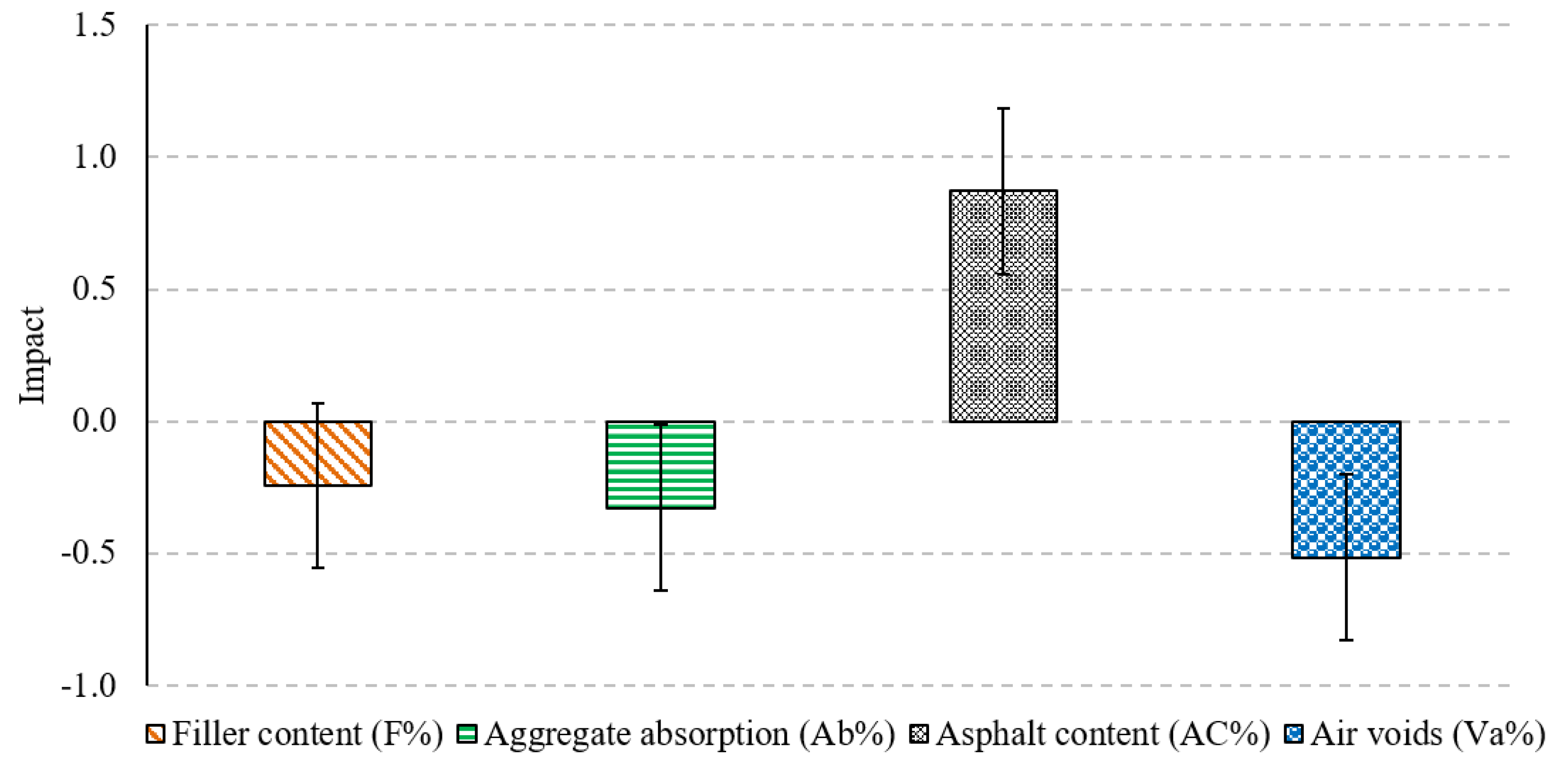

- The relative importance analysis of the network implied that AC% has the highest impact on the RSI value with a contribution rate of 35.6%, followed by Va%, F%, and Ab% with contributions of 33.5%, 22.4%, and 8.5%, respectively.

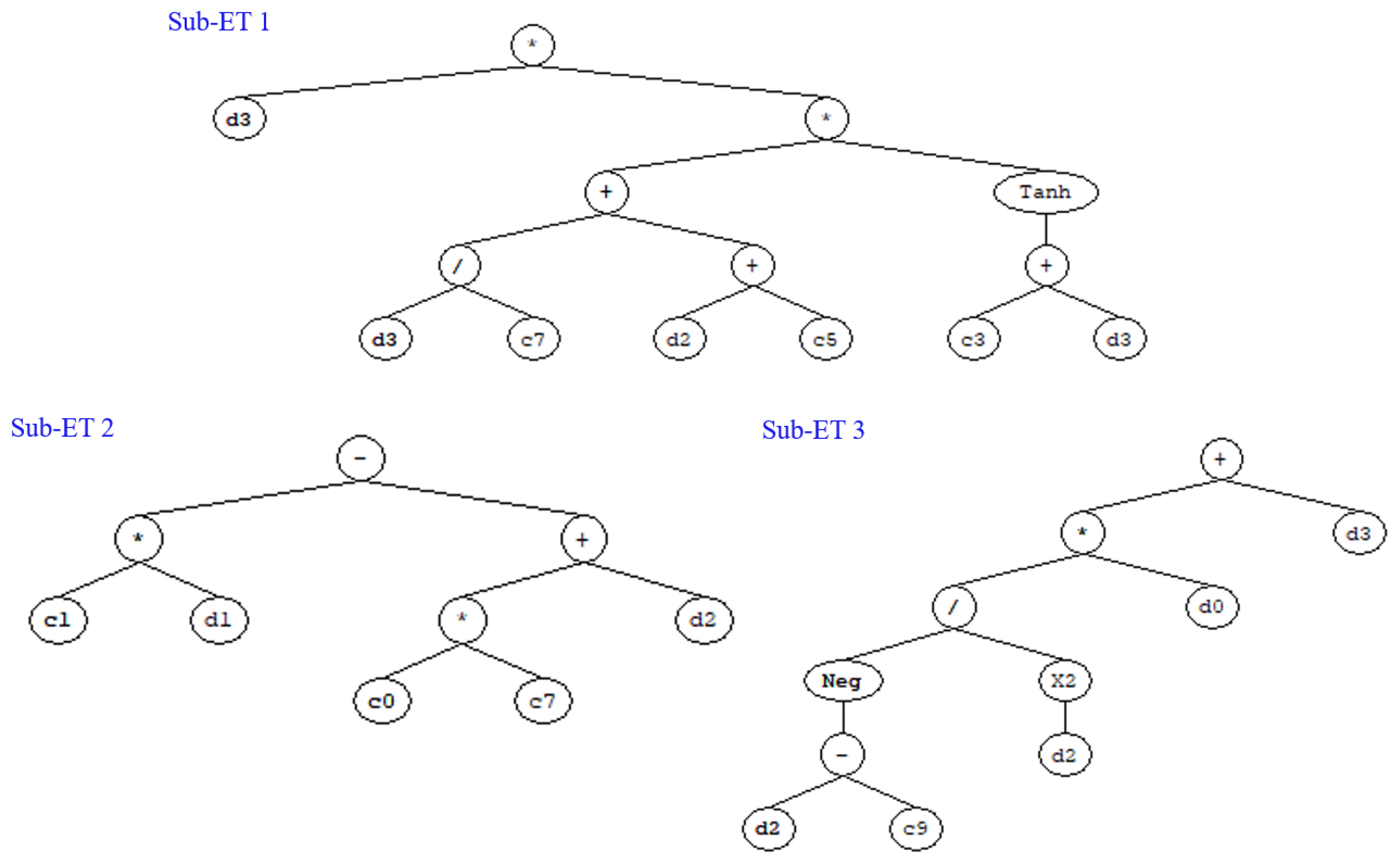

- The datasets generated by the ANN were combined with the experimental dataset and fed into the GEP tool to develop the final prediction model in terms of a simple mathematical function.

- The proposed GEP model proved its high accuracy and sensitivity in predicting the RSI of asphalt mixes, considering the impact of the input variables. The overall performance measures of the model result in a very high (R2) value of 96.6% and very low error values of 0.530 and 0.659 for MAE and RMSE. The experimental-to-predicted RSI values of the model have an average of 1.00 and a low coefficient of variation of 0.841.

- In addition to the performance measures, a parametric analysis was conducted to evaluate the model sensitivity concerning every input variable. The result trends were confirmed with the ANN connection weight analysis and previous results found in the literature. It was found that increasing F%, Ab%, and Va% in asphalt mixes can reduce the RSI value, whereas increasing AC% can enhance the moisture susceptibility of the mixes by increasing the RSI value.

- Overall, the proposed model is accurate and provides a straightforward mathematical equation for predicting the RSI value of asphalt mixes. It can be recommended to assess the moisture sensitivity of asphalt mixes without performing destructive testing, which would save natural resources and experimental effort. It can also help to improve the moisture damage performance of the mixes prior to the design phase.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Caro, S.; Masad, E.; Bhasin, A.; Little, D.N. Moisture susceptibility of asphalt mixtures, Part 1: Mechanisms. Int. J. Pavement Eng. 2008, 9, 81–98. [Google Scholar] [CrossRef]

- Lu, Q.; Harvey, J.T. Field investigation of factors associated with moisture damage in asphalt pavements. In Proceedings of the 10th International Conference on Asphalt Pavements (ISAP), Quebec, QC, Canada, 12–17 August 2006; pp. 691–700. [Google Scholar]

- Masad, E.; Arambula, E.; Ketcham, R.; Abbas, A.; Martin, A.E. Nondestructive measurements of moisture transport in asphalt mixtures. Asph. Paving Technol.-Proc. 2007, 76, 919. [Google Scholar]

- Airey, G.D.; Collop, A.C.; Zoorob, S.E.; Elliott, R.C. The influence of aggregate, filler and bitumen on asphalt mixture moisture damage. Constr. Build. Mater. 2008, 22, 2015–2024. [Google Scholar] [CrossRef]

- Grenfell, J.; Ahmad, N.; Liu, Y.; Apeagyei, A.; Large, D.; Airey, G. Assessing asphalt mixture moisture susceptibility through intrinsic adhesion, bitumen stripping and mechanical damage. Road Mater. Pavement Des. 2014, 15, 131–152. [Google Scholar] [CrossRef]

- El Hussein, H.M.; Abd El Halim, A.O.; Kennepohl, G.J. Assessment of the influence of compaction method on asphalt concrete resistance to moisture damage. Constr. Build. Mater. 1993, 7, 149–156. [Google Scholar]

- Chen, J.S.; Lin, K.Y.; Young, S.Y. Effects of crack width and permeability on moisture-induced damage of pavements. J. Mater. Civ. Eng. 2004, 16, 276–282. [Google Scholar] [CrossRef]

- Bhasin, A.; Masad, E.; Little, D.; Lytton, R. Limits on adhesive bond energy for improved resistance of hot-mix asphalt to moisture damage. Transp. Res. Rec. 2006, 1970, 2–13. [Google Scholar] [CrossRef]

- Akentuna, M.; Mohammad, L.N.; Sachdeva, S.; Cooper, S.B., III; Cooper, S.B., Jr. Effectiveness of Loaded Wheel Tracking Test to Ascertain Moisture Susceptibility of Asphalt Mixtures. Transp. Res. Rec. 2022, 2676, 421–434. [Google Scholar] [CrossRef]

- Kim, Y.R.; Zhang, J.; Ban, H. Moisture damage characterization of warm-mix asphalt mixtures based on laboratory-field evaluation. Constr. Build. Mater. 2012, 31, 204–211. [Google Scholar] [CrossRef]

- Hamzah, M.O.; Kakar, M.R.; Hainin, M.R. An overview of moisture damage in asphalt mixtures. J. Teknol. 2015, 73, 125–131. [Google Scholar] [CrossRef]

- Behiry, A.E.A.E.M. Laboratory evaluation of resistance to moisture damage in asphalt mixtures. Ain Shams Eng. J. 2013, 4, 351–363. [Google Scholar] [CrossRef]

- Jweihan, Y.S. Performance of aged asphalt mixes containing waste oil shale filler. Int. J. Pavement Res. Technol. 2023, 1–15. [Google Scholar] [CrossRef]

- Al-Kheetan, M.J. Waste Not, Want Not: Sustainable Use of Anti-Stripping-Treated Waste Ceramic in Superpave Asphalt Mixtures. Sustainability 2023, 15, 7579. [Google Scholar] [CrossRef]

- Huang, B.; Shu, X.; Dong, Q.; Shen, J. Laboratory evaluation of moisture susceptibility of hot-mix asphalt containing cementitious fillers. J. Mater. Civ. Eng. 2010, 22, 667–673. [Google Scholar] [CrossRef]

- Jweihan, Y.S. Predictive model of asphalt mixes’ theoretical maximum specific gravity using gene expression programming. Results Eng. 2023, 19, 101242. [Google Scholar] [CrossRef]

- Jweihan, Y.S.; Alawadi, R.J.; Momani, Y.S.; Tarawneh, A.N. Prediction of Marshall Test Results for Dense Glasphalt Mixtures Using Artificial Neural Networks. Front. Built Environ. 2022, 8, 949167. [Google Scholar] [CrossRef]

- Maabreh, M.; Almasabha, G. Machine Learning Regression Algorithms for Shear Strength Prediction of SFRC-DBs: Performance Evaluation and Comparisons. Arab. J. Sci. Eng. 2023, 1–17. [Google Scholar] [CrossRef]

- Ghasemi, P.; Aslani, M.; Rollins, D.K.; Williams, R.C. Principal component neural networks for modeling, prediction, and optimization of hot mix asphalt dynamics modulus. Infrastructures 2019, 4, 53. [Google Scholar] [CrossRef]

- Majidifard, H.; Jahangiri, B.; Buttlar, W.G.; Alavi, A.H. New machine learning-based prediction models for fracture energy of asphalt mixtures. Measurement 2019, 135, 438–451. [Google Scholar] [CrossRef]

- Khan, K.; Jalal, F.E.; Khan, M.A.; Salami, B.A.; Amin, M.N.; Alabdullah, A.A.; Samiullah, Q.; Arab, A.M.A.; Faraz, M.I.; Iqbal, M. Prediction Models for Evaluating Resilient Modulus of Stabilized Aggregate Bases in Wet and Dry Alternating Environments: ANN and GEP Approaches. Materials 2022, 15, 4386. [Google Scholar] [CrossRef]

- Gandhi, T.; Xiao, F.; Amirkhanian, S.N. Estimating indirect tensile strength of mixtures containing anti-stripping agents using an artificial neural network approach. Int. J. Pavement Res. Technol. 2009, 2, 1. [Google Scholar]

- Goel, G.; Sachdeva, S.N.; Pal, M. Modelling of tensile strength ratio of bituminous concrete mixes using support vector machines and M5 model tree. Int. J. Pavement Res. Technol. 2022, 15, 86–97. [Google Scholar] [CrossRef]

- Kumar, A.J.B.; Parihar, M.S.; Murshida, P.; Sunitha, V.; Mathew, S. Moisture Damage Prediction of Hot Mix Asphalt Using Artificial Neural Network. In Proceedings of the Sixth International Conference of Transportation Research Group of India: CTRG 2021 Volume 1; Springer Nature: Berlin/Heidelberg, Germany, 2022; Volume 271, p. 123. [Google Scholar]

- Dalhat, M.A.; Osman, S.A. Studying the impact of aggregates and mix volumetric properties on the moisture resistance of asphalt concrete using a feed-Forward artificial neural network. Road Mater. Pavement Des. 2023, 24, 2737–2758. [Google Scholar] [CrossRef]

- Kringos, N.; Scarpas, A. Raveling of asphaltic mixes due to water damage: Computational identification of controlling parameters. Transp. Res. Rec. 2005, 1929, 79–87. [Google Scholar] [CrossRef]

- Apeagyei, A.K.; Grenfell, J.R.; Airey, G.D. Influence of aggregate absorption and diffusion properties on moisture damage in asphalt mixtures. Road Mater. Pavement Des. 2015, 16 (Suppl. S1), 404–422. [Google Scholar] [CrossRef]

- Little, D.N.; Jones, D.R. Chemical and mechanical processes of moisture damage in hot-mix asphalt pavements. In National Seminar on Moisture Sensitivity of Asphalt Pavements; Transportation Research Board: Washington, DC, USA, 2003; pp. 37–70. [Google Scholar]

- Zhang, J.; Apeagyei, A.K.; Airey, G.D.; Grenfell, J.R. Influence of aggregate mineralogical composition on water resistance of aggregate–bitumen adhesion. Int. J. Adhes. Adhes. 2015, 62, 45–54. [Google Scholar] [CrossRef]

- Zhang, J.; Airey, G.D.; Grenfell, J.; Apeagyei, A.K. Moisture damage evaluation of aggregate–bitumen bonds with the respect of moisture absorption, tensile strength and failure surface. Road Mater. Pavement Des. 2017, 18, 833–848. [Google Scholar] [CrossRef]

- Sengoz, B.; Agar, E. Effect of asphalt film thickness on the moisture sensitivity characteristics of hot-mix asphalt. Build. Environ. 2007, 42, 3621–3628. [Google Scholar] [CrossRef]

- Ahmad, N.; Haroon, W.; Abid, M.M. Effect of air voids on permeability and durability of hot mix asphalt. J. Natl. Sci. Found. Sri Lanka 2020, 48, 463–474. [Google Scholar] [CrossRef]

- Arambula, E.; Masad, E.; Martin, A.E. Influence of air void distribution on the moisture susceptibility of asphalt mixes. J. Mater. Civ. Eng. 2007, 19, 655–664. [Google Scholar] [CrossRef]

- Baldi-Sevilla, A.; Aguiar-Moya, J.P.; Vargas-Nordcbeck, A.; Loria-Salazar, L. Effect of aggregate–bitumen compatibility on moisture susceptibility of asphalt mixtures. Road Mater. Pavement Des. 2017, 18 (Suppl. 2), 318–328. [Google Scholar] [CrossRef]

- Aljassar, A.H.; Metwali, S.; Ali, M.A. Effect of filler types on Marshall stability and retained strength of asphalt concrete. Int. J. Pavement Eng. 2004, 5, 47–51. [Google Scholar] [CrossRef]

- Huang, B.; Shu, X.; Chen, X. Effects of mineral fillers on hot-mix asphalt laboratory-measured properties. Int. J. Pavement Eng. 2007, 8, 1–9. [Google Scholar] [CrossRef]

- Singh, B.; Jain, S. Effect of lime and cement fillers on moisture susceptibility of cold mix asphalt. Road Mater. Pavement Des. 2022, 23, 2433–2449. [Google Scholar] [CrossRef]

- Akbulut, H.; Gürer, C.; Çetin, S.; Elmacı, A. Investigation of using granite sludge as filler in bituminous hot mixtures. Constr. Build. Mater. 2012, 36, 430–436. [Google Scholar] [CrossRef]

- Sakanlou, F.; Shirmohammadi, H.; Hamedi, G.H. Investigating the effect of filler types on thermodynamic parameters and their relationship with moisture sensitivity of asphalt mixes. Mater. Struct. 2018, 51, 39. [Google Scholar] [CrossRef]

- ASTM D 946; Standard Specification for Penetration-Graded Asphalt Cement for Use in Pavement Construction. American Society for Testing and Materials: West Conshohocken, PA, USA, 2009.

- Ministry of Public Works and Housing, Director of Planning and Development. Specifications for Highway and Bridge Construction; Ministry of Public Works and Housing, Director of Planning and Development: Amman, Jordan, 2008; Volume II. [Google Scholar]

- ASTM D6927-15; Standard Test Method for Marshall Stability and Flow of Asphalt Mixtures. ASTM International: West Conshohocken, PA, USA, 2015.

- Sarsam, S.; Azawee, E. Assessment of asphalt binder stripping using surface free energy. Res. Appl. Mater. 2013, 1, 27–30. [Google Scholar] [CrossRef]

- Mirzababaei, P.; Moghadas Nejad, F.; Naderi, K. Effect of liquid silane-based anti-stripping additives on rheological properties of asphalt binder and hot mix asphalt moisture sensitivity. Road Mater. Pavement Des. 2020, 21, 570–585. [Google Scholar] [CrossRef]

- Tarawneh, A.; Saleh, E.; Almasabha, G.; Alghossoon, A. Hybrid Data-Driven Machine Learning Framework for Determining Prestressed Concrete Losses. Arab. J. Sci. Eng. 2023, 48, 13179–13193. [Google Scholar] [CrossRef]

- Alghossoon, A.; Tarawneh, A.; Almasabha, G.; Murad, Y.; Saleh, E.; Sahawneh, H. Shear strength of circular concrete-filled tube (CCFT) members using human-guided artificial intelligence approach. Eng. Struct. 2023, 282, 115820. [Google Scholar] [CrossRef]

- Momani, Y.; Alawadi, R.; Majdalaweyh, S.; Tarawneh, A.; Jweihan, Y.S. Data-driven machine learning prediction models for the tensile capacity of anchors in thin concrete. Innov. Infrastruct. Solut. 2022, 7, 294. [Google Scholar] [CrossRef]

- Naderpour, H.; Sharei, M.; Fakharian, P.; Heravi, M.A. Shear strength prediction of reinforced concrete shear wall using ANN, GMDH-NN and GEP. J. Soft Comput. Civ. Eng. 2022, 6, 66–87. [Google Scholar]

- MATLAB and Statistics Toolbox Release 2022b; The MathWorks, Inc.: Natick, MA, USA, 2022.

- Burden, F.; Winkler, D. Bayesian regularization of neural networks. In Artificial Neural Networks: Methods and Applications; Springer: Berlin/Heidelberg, Germany, 2009; pp. 23–42. [Google Scholar]

- Đorđević, F.; Kostić, S.M. Practical ANN prediction models for the axial capacity of square CFST columns. J. Big Data 2023, 10, 67. [Google Scholar] [CrossRef]

- Garson, G.D. Interpreting neural-network connection weights. AI Expert 1991, 6, 46–51. [Google Scholar]

- Ibrahim, O.M. A comparison of methods for assessing the relative importance of input variables in artificial neural networks. J. Appl. Sci. Res. 2013, 9, 5692–5700. [Google Scholar]

- Rabi, M.; Ferreira, F.P.V.; Abarkan, I.; Limbachiya, V.; Shamass, R. Prediction of the cross-sectional capacity of cold-formed CHS using numerical modelling and machine learning. Results Eng. 2023, 17, 100902. [Google Scholar] [CrossRef]

- Rabi, M. Bond prediction of stainless-steel reinforcement using artificial neural networks. Proc. Inst. Civ. Eng.-Constr. Mater. 2023, 1–11. [Google Scholar] [CrossRef]

- Rabi, M.; Abarkan, I.; Shamass, R. Buckling resistance of hot-finished CHS beam-columns using FE modelling and machine learning. Steel Constr. 2023. [Google Scholar] [CrossRef]

- Isleem, H.F.; Peng, F.; Tayeh, B.A. Confinement model for LRS FRP-confined concrete using conventional regression and artificial neural network techniques. Compos. Struct. 2022, 279, 114779. [Google Scholar] [CrossRef]

- Ozgan, E. Artificial neural network based modelling of the Marshall Stability of asphalt concrete. Expert Syst. Appl. 2011, 38, 6025–6030. [Google Scholar] [CrossRef]

- Sharifi, Y.; Moghbeli, A. Shear capacity assessment of steel fiber reinforced concrete beams using artificial neural network. Innov. Infrastruct. Solut. 2021, 6, 89. [Google Scholar] [CrossRef]

- Olden, J.D.; Jackson, D.A. Illuminating the “black box”: A randomization approach for understanding variable contributions in artificial neural networks. Ecol. Model. 2002, 154, 135–150. [Google Scholar] [CrossRef]

- Ferreira, C. Gene expression programming: A new adaptive algorithm for solving problems. arXiv 2001, arXiv:cs/0102027. [Google Scholar]

- Almasabha, G. Gene expression model to estimate the overstrength ratio of short links. In Structures; Elsevier: Amsterdam, The Netherlands, 2022; Volume 37, pp. 528–535. [Google Scholar]

- Ferreira, C. Gene expression programming in problem solving. In Soft Computing and Industry: Recent Applications; Springer: Berlin/Heidelberg, Germany, 2002; pp. 635–653. [Google Scholar]

- Amin, M.N.; Iqbal, M.; Jamal, A.; Ullah, S.; Khan, K.; Abu-Arab, A.M.; Al-Ahmad, Q.M.; Khan, S. Gep tree-based prediction model for interfacial bond strength of externally bonded frp laminates on grooves with concrete prism. Polymers 2022, 14, 2016. [Google Scholar] [CrossRef] [PubMed]

- Asghar, R.; Javed, M.F.; Alrowais, R.; Khalil, A.; Mohamed, A.M.; Mohamed, A.; Vatin, N.I. Predicting the Lateral Load Carrying Capacity of Reinforced Concrete Rectangular Columns: Gene Expression Programming. Materials 2022, 15, 2673. [Google Scholar] [CrossRef] [PubMed]

| Test | Result | ASTM D946 Criteria | |

|---|---|---|---|

| Min. | Max. | ||

| Specific gravity at 25 °C | 1.02 | na | na |

| Ductility at 25 °C, cm | 127 | 100 | na |

| Flash Point (°C) | 306 | 230 | na |

| Softening Point (°C) | 51.8 | 46 | na |

| Penetration (0.1 mm) | 67.3 | 60 | 70 |

| Loss on heating (%) | 0.26 | na | 0.8 |

| Penetration of residue, % of original | 63.1 | 54 | na |

| Rotational viscosity at 135 °C, Pa·s | 0.458 | na | na |

| Rotational viscosity at 165 °C, Pa·s | 0.158 | na | na |

| Property | Aggregate Blends | Criteria (Jordan’s MPWH) | ||||

|---|---|---|---|---|---|---|

| Mix A | Mix B | Mix C | Mix D | Mix E | ||

| Bulk specific gravity of combined aggregate (dry) | 2.531 | 2.557 | 2.613 | 2.601 | 2.545 | na |

| Apparent specific gravity of combined aggregate | 2.694 | 2.706 | 2.718 | 2.711 | 2.701 | na |

| Moisture absorption of combined aggregate (%) | 1.334 | 2.079 | 3.771 | 2.521 | 1.858 | na |

| Filler proportions (%) | 2.62 | 4.97 | 7.34 | 6.06 | 3.72 | 2–8% |

| Abrasion loss (500 revolutions) (%) | 25.2% | 28.3% | 26.5% | 27% | 25.8% | 35% max. |

| Ratio of wear loss (100/500) (%) | 20% | 22% | 19% | 23% | 22% | 25% max. |

| Sand equivalent (%) | 62.7% | 65.5% | 61.8% | 63.2% | 62.5% | 50% min. |

| Clay lumps (%) | 0.7% | 0.4% | 0.5% | 0.4% | 0.6% | 1% max. |

| Soundness by sodium sulfate (%) | 5.1% | 5.4% | 4.1% | 4.6% | 4.2% | 9% max. |

| Asphalt Mixtures | F% | Ab% | AC% | Average Values | |||

|---|---|---|---|---|---|---|---|

| Va% | S1 (kN) | S2 (kN) | RSI % | ||||

| Mix A | 2.62 | 1.334 | 3.5 | 8.8 | 10.934 | 7.900 | 72.25 |

| 2.62 | 1.334 | 4.0 | 7.5 | 11.425 | 8.752 | 76.61 | |

| 2.62 | 1.334 | 4.5 | 6.1 | 14.024 | 11.560 | 82.43 | |

| 2.62 | 1.334 | 5.0 | 4.5 | 14.151 | 12.286 | 86.82 | |

| 2.62 | 1.334 | 5.5 | 3.7 | 13.710 | 11.943 | 87.11 | |

| Mix B | 4.97 | 2.08 | 3.5 | 7.9 | 11.905 | 8.516 | 71.53 |

| 4.97 | 2.08 | 4.0 | 6.5 | 13.036 | 10.114 | 77.58 | |

| 4.97 | 2.08 | 4.5 | 5.1 | 14.386 | 11.850 | 82.37 | |

| 4.97 | 2.08 | 5.0 | 4.0 | 15.014 | 12.615 | 84.02 | |

| 4.97 | 2.08 | 5.5 | 3.0 | 15.377 | 12.957 | 84.26 | |

| Mix C | 7.34 | 3.77 | 3.5 | 7.0 | 12.062 | 8.494 | 70.42 |

| 7.34 | 3.77 | 4.0 | 5.4 | 14.926 | 10.912 | 73.11 | |

| 7.34 | 3.77 | 4.5 | 4.2 | 16.220 | 12.739 | 78.54 | |

| 7.34 | 3.77 | 5.0 | 3.3 | 15.759 | 12.661 | 80.34 | |

| 7.34 | 3.77 | 5.5 | 2.1 | 15.485 | 12.296 | 79.41 | |

| Mix D | 6.06 | 2.521 | 3.5 | 7.3 | 11.768 | 8.313 | 70.64 |

| 6.06 | 2.521 | 4.0 | 5.9 | 14.739 | 11.324 | 76.83 | |

| 6.06 | 2.521 | 4.5 | 4.4 | 15.563 | 12.724 | 81.76 | |

| 6.06 | 2.521 | 5.0 | 3.5 | 15.367 | 12.689 | 82.57 | |

| 6.06 | 2.521 | 5.5 | 2.4 | 14.582 | 11.940 | 81.88 | |

| Mix E | 3.72 | 1.86 | 3.5 | 8.4 | 10.768 | 7.734 | 71.83 |

| 3.72 | 1.86 | 4.0 | 6.9 | 11.797 | 9.150 | 77.56 | |

| 3.72 | 1.86 | 4.5 | 5.4 | 13.386 | 11.160 | 83.37 | |

| 3.72 | 1.86 | 5.0 | 4.2 | 14.092 | 11.959 | 84.86 | |

| 3.72 | 1.86 | 5.5 | 3.3 | 13.749 | 11.757 | 85.51 | |

| Neurons | Training Dataset | Testing Dataset | ||

|---|---|---|---|---|

| MSE | R2 | MSE | R2 | |

| 1 | 1.4394 | 0.9479 | 3.952 | 0.8207 |

| 2 | 0.2251 | 0.9924 | 0.2067 | 0.9928 |

| 3 | 0.2191 | 0.9922 | 1.0653 | 0.9700 |

| 4 | 0.1667 | 0.9940 | 0.7394 | 0.9702 |

| Linking Function | Addition |

|---|---|

| Number of genes | 3 |

| Function selections | |

| Head size | 8 |

| Number of chromosomes | 30 |

| Performance Measures | Training Dataset | Testing Dataset | All Datasets |

|---|---|---|---|

| MAE | 0.537 | 0.508 | 0.530 |

| RMSE | 0.662 | 0.648 | 0.659 |

| R2 | 0.962 | 0.973 | 0.966 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jweihan, Y.S.; Al-Kheetan, M.J.; Rabi, M. Empirical Model for the Retained Stability Index of Asphalt Mixtures Using Hybrid Machine Learning Approach. Appl. Syst. Innov. 2023, 6, 93. https://doi.org/10.3390/asi6050093

Jweihan YS, Al-Kheetan MJ, Rabi M. Empirical Model for the Retained Stability Index of Asphalt Mixtures Using Hybrid Machine Learning Approach. Applied System Innovation. 2023; 6(5):93. https://doi.org/10.3390/asi6050093

Chicago/Turabian StyleJweihan, Yazeed S., Mazen J. Al-Kheetan, and Musab Rabi. 2023. "Empirical Model for the Retained Stability Index of Asphalt Mixtures Using Hybrid Machine Learning Approach" Applied System Innovation 6, no. 5: 93. https://doi.org/10.3390/asi6050093

APA StyleJweihan, Y. S., Al-Kheetan, M. J., & Rabi, M. (2023). Empirical Model for the Retained Stability Index of Asphalt Mixtures Using Hybrid Machine Learning Approach. Applied System Innovation, 6(5), 93. https://doi.org/10.3390/asi6050093