Impact of Pyrolysis Oil Addition to Ethanol on Combustion in the Internal Combustion Spark Ignition Engine

Abstract

:1. Introduction

- Compression ignition (CI) engines,

- Spark ignition (SI) engines.

1.1. Compression Ignition Engines

1.2. Spark Ignition Engines

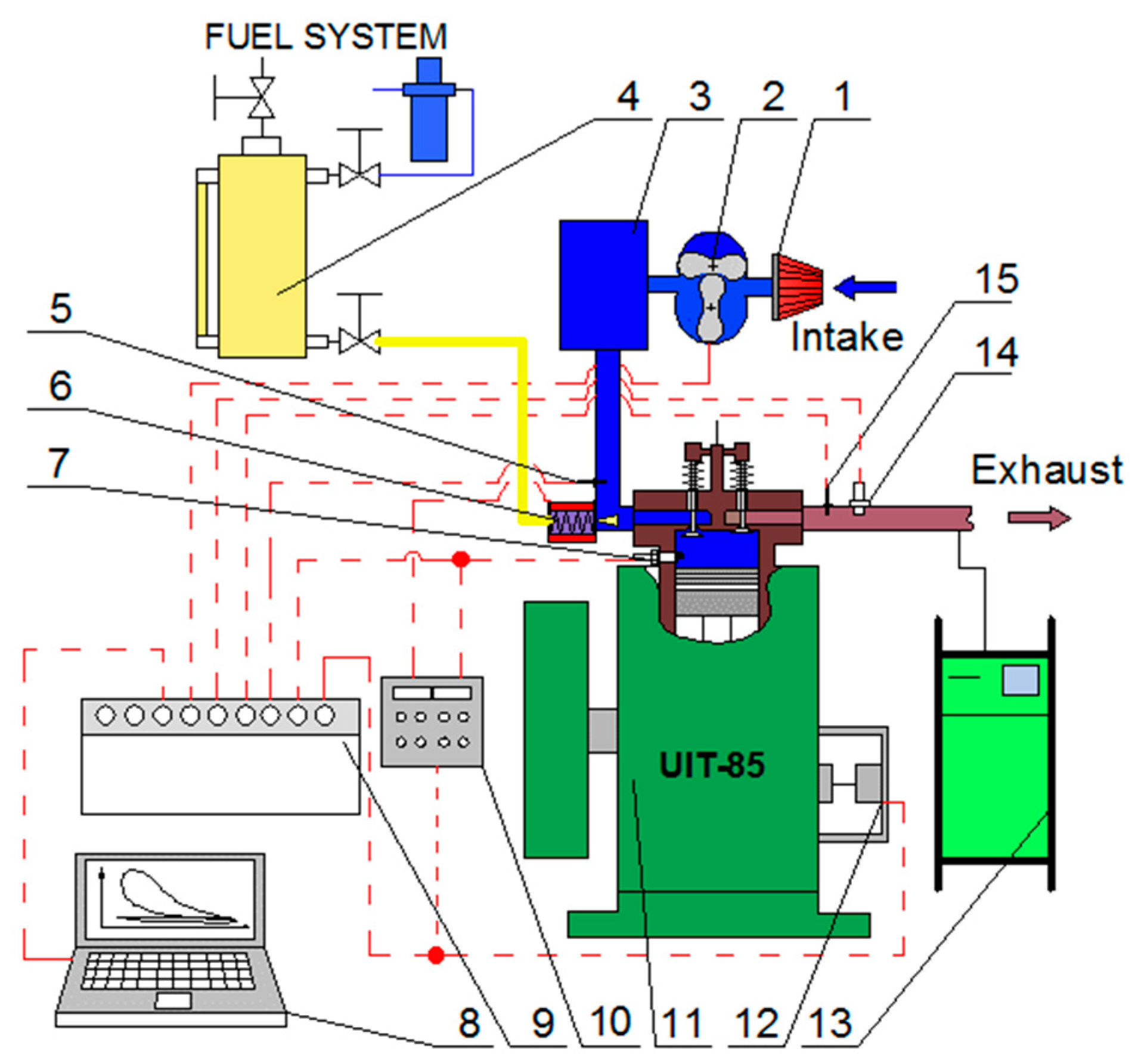

2. Methodology and Setup

Measurement Apparatus

3. Results and Discussion

- Preliminary research with changing spark timing to determine its optimal location vs. crank angle. Hence, optimal spark timing at maximum IMEP was determined. Additionally, maximum IMEP and coefficient of variance (COV) of IMEP were calculated;

- Investigation on combustion duration phases—two combustion duration phases expressed in crank angle (CA) deg were determined on the basis of energy conservation law and in-cylinder combustion pressure traces as follows:

- -

- initial combustion phase CA0-10, which shows the first 10% heat released (considered as 10% fuel burnt) and it can correspond to ignition delay;

- -

- main combustion phase CA10-90 presenting next 80% heat released;

- -

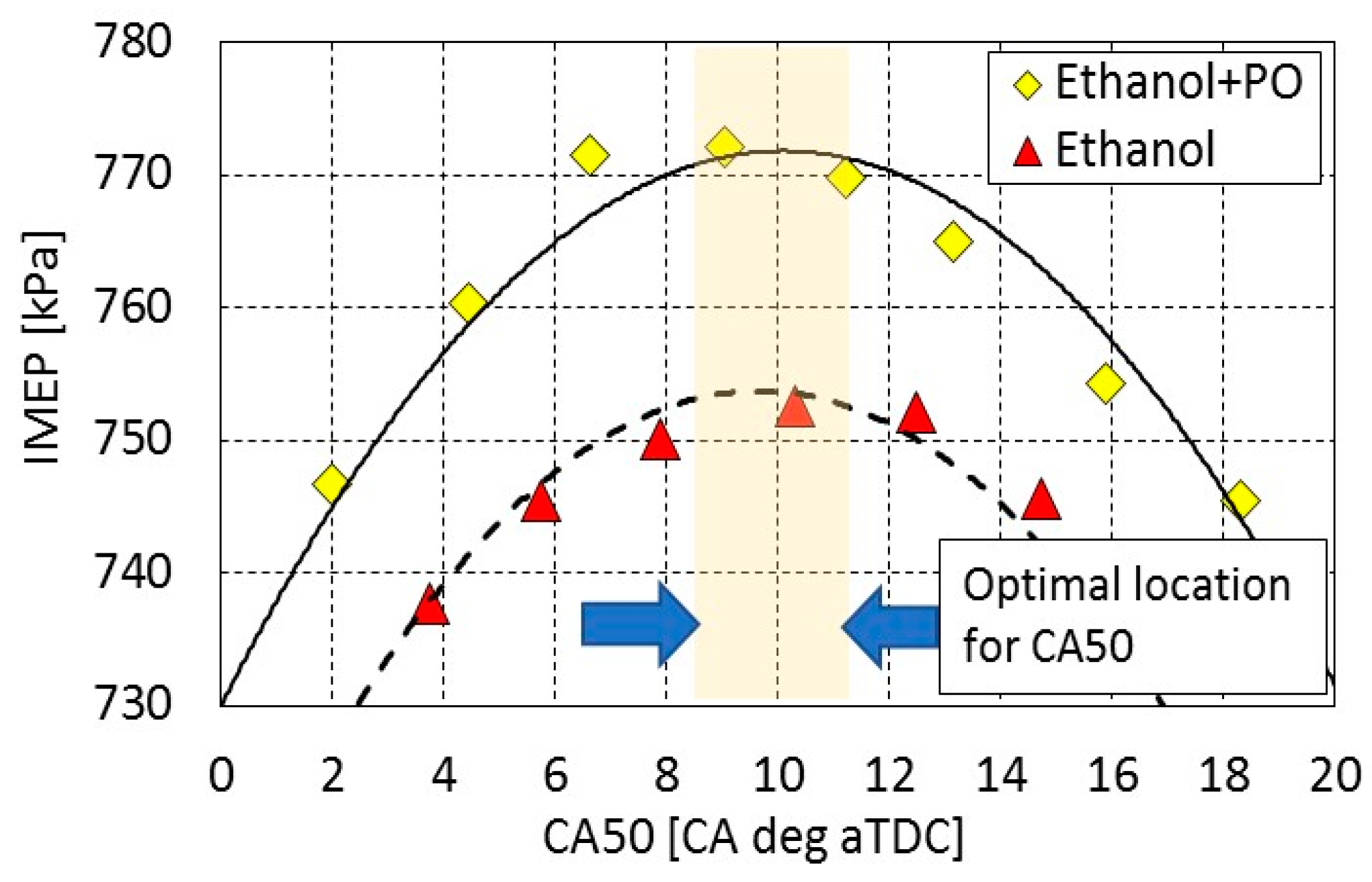

- middle location of combustion CA50;

- Investigation on knocking like conditions on the basis of pressure rise rate (defined as derivative dp/dCA).

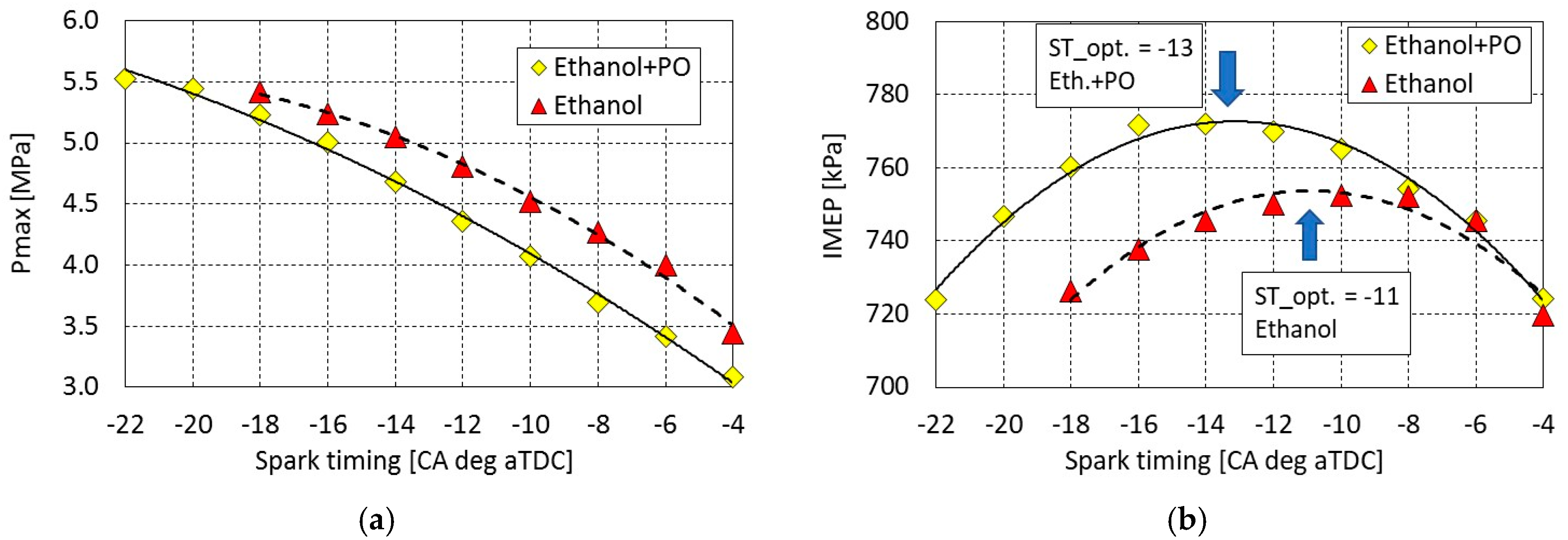

3.1. Optimal Spark Timing and Engine Performance

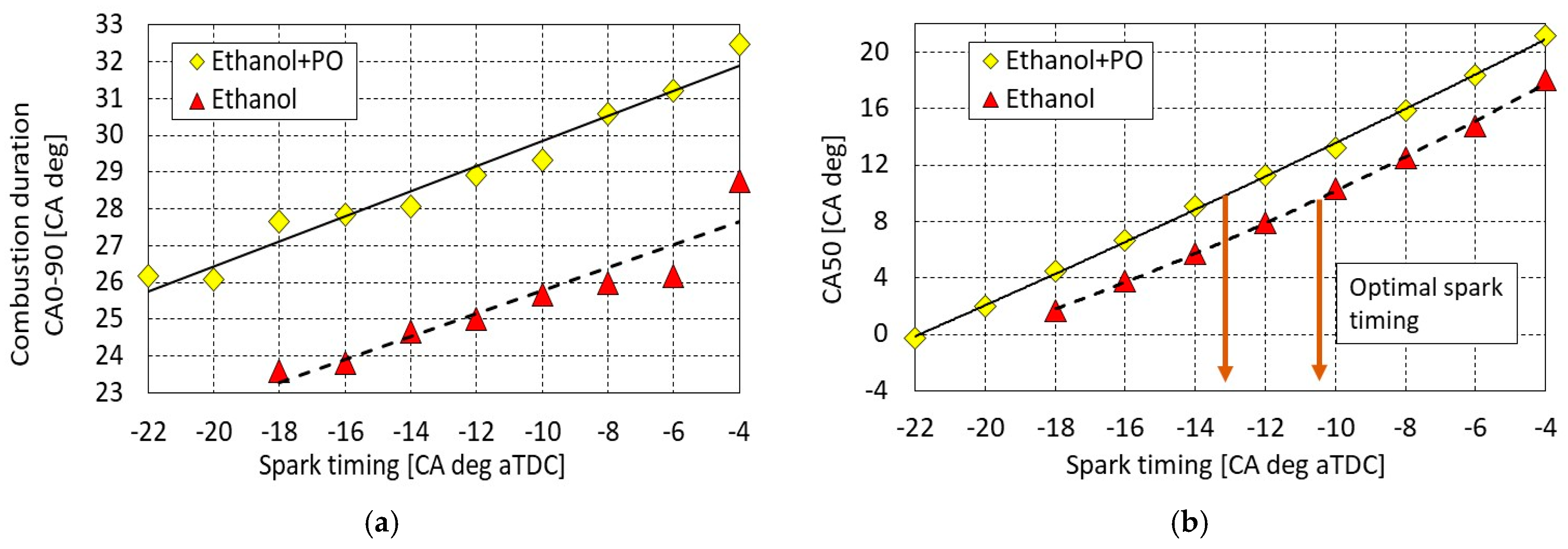

3.2. Combustion Duration Phases

3.3. Pressure Rise Rate

4. Conclusions

- Although pyrolysis oil can be applied as a single fuel in compression ignition engines due to its good self-ignition tendency, it can be also be used in spark-ignition engines. The proposed mixture which can be applied as the engine fuel is the mixture consisting of ethanol and pyrolysis oil at ratio of 3:1 by volume, respectively. At this proportion, the fuel can be burnt without any significant deterioration in the engine performance.

- Addition of pyrolysis oil to ethanol at ratio of 3:1 causes lengthening both the initial combustion phase CA0-10 and the main combustion phase CA10-90 as well as overall combustion denoted as CA0-90. Thus, optimal spark timing should be corrected to get maximum engine work when the fuel is changed from ethanol to ethanol + PO (3:1) in the modern engine installed in a flexible fuel type vehicle.

- Optimal spark timing for the ethanol-pyrolysis oil mixture is shifted to be more advanced in comparison to pure ethanol, therefore modifications in the control algorithm for ignition module in the engine control unit must be taken into consideration.

- Even though pyrolysis oil characterizes with relatively low octane rating, its addition to ethanol at amounts of 25% does not lead to any knock symptoms.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| A/F stoic. | Air to fuel stoichiometric ratio |

| BDC | Bottom Dead Center |

| aTDC | after Top Dead Center |

| bTDC | before Top Dead Center |

| CA | Crank Angle |

| CFR | Cooperative Fuel Research |

| CI | Compression Ignition |

| CO | Carbon Monoxide |

| COV | Coefficient of Variation |

| CR | Compression Ratio |

| HC | Hydrocarbons |

| IC | Internal Combustion |

| IMEP | Indicated Mean Effective Pressure |

| LHV | Lower Heating Value |

| PAH | Polycyclic Aromatic HC |

| PO | Pyrolysis Oil |

| SI | Spark Ignition |

| ST | Spark Timing |

| TDC | Top Dead Center |

| UEGO | Universal Exhaust gas Oxygen |

| WOT | Widely Open Throttle |

References

- Klinger, J.; Bar-Ziv, E.; Shonnard, D. Unified Kinetic Model for Torrefaction-Pyrolysis. Fuel Process. Technol. 2015, 138, 175–183. [Google Scholar] [CrossRef] [Green Version]

- Kumaravel, S.T.; Murugesan, A.; Kumaravel, A. Tyre Pyrolysis Oil as an Alternative Fuel for Diesel Engines—A Review. Renew. Sustain. Energy Rev. 2016, 60, 1678–1685. [Google Scholar] [CrossRef]

- Umeki, E.R.; de Oliveira, C.F.; Torres, R.B.; dos Santos, R.G. Physico-Chemistry Properties of Fuel Blends Composed of Diesel and Tire Pyrolysis Oil. Fuel 2016, 185, 236–242. [Google Scholar] [CrossRef]

- Wongkhorsub, C.; Chindaprasert, N. A Comparison of the Use of Pyrolysis Oils in Diesel Engine. Energy Power Eng. 2013, 5, 350–355. [Google Scholar] [CrossRef]

- Čížková, A.; Juchelková, D. Comparison of Yield of Tires Pyrolysis in Laboratory and Pilot Scales. Geosci. Eng. 2009, 4, 60–65. [Google Scholar]

- Kaminsky, W.; Mennerich, C. Pyrolysis of Synthetic Tire Rubber in a Fluidised-Bed Reactor to Yield 1,3-Butadiene, Styrene and Carbon Black. J. Anal. Appl. Pyrolysis 2001, 58–59, 803–811. [Google Scholar] [CrossRef]

- Barbooti, M.M.; Mohamed, T.J.; Hussain, A.A.; Abas, F.O. Optimization of Pyrolysis Conditions of Scrap Tires under Inert Gas Atmosphere. J. Anal. Appl. Pyrolysis 2004, 72, 165–170. [Google Scholar] [CrossRef]

- Boxiong, S.; Chunfei, W.; Cai, L.; Binbin, G.; Rui, W. Pyrolysis of Waste Tyres: The Influence of USY Catalyst/Tyre Ratio on Products. J. Anal. Appl. Pyrolysis 2007, 78, 243–249. [Google Scholar] [CrossRef]

- Vihar, R.; Žvar Baškovič, U.; Seljak, T.; Katrašnik, T. Combustion and Emission Formation Phenomena of Tire Pyrolysis Oil in a Common Rail Diesel Engine. Energy Convers. Manag. 2017, 149, 706–721. [Google Scholar] [CrossRef] [Green Version]

- Marinangelli, R.; Boldingh, E.; Cabanban, S.; Fei, S.; Ellis, G.; Bain, R.; Hsu, G.; Elliott, D.C. Pyrolysis Oil to Gasoline-Final Report; No. PNNL-19053; Pacific Northwest National Lab: Richland, WA, USA, 2009. [Google Scholar]

- Chwist, M.; Szwaja, S.; Grab-Rogalinski, K.; Pyrc, M. Bio-Oil Blended Butanol as a Fuel to the Spark Ignition Internal Combustion Reciprocating Engine. Combust. Engines 2017, 169, 93–96. [Google Scholar] [CrossRef]

- Mikulski, M.; Ambrosewicz-Walacik, M.; Hunicz, J.; Nitkiewicz, S. Combustion Engine Applications of Waste Tyre Pyrolytic Oil. Prog. Energy Combust. Sci. 2021, 85, 100915. [Google Scholar] [CrossRef]

- Zahir Hussain, A.; Santhoshkumar, A.; Ramanathan, A. Assessment of Pyrolysis Waste Engine Oil as an Alternative Fuel Source for Diesel Engine. J. Therm. Anal. Calorim. 2020, 141, 2277–2293. [Google Scholar] [CrossRef]

- Karagoz, M.; Uysal, C.; Agbulut, U.; Saridemir, S. Energy, Exergy, Economic and Sustainability Assessments of a Compression Ignition Diesel Engine Fueled with Tire Pyrolytic Oil−diesel Blends. J. Clean. Prod. 2020, 264, 121724. [Google Scholar] [CrossRef]

- Koc, A.B.; Abdullah, M. Performance of a 4-Cylinder Diesel Engine Running on Tire Oil–Biodiesel–Diesel Blend. Fuel Process. Technol. 2014, 118, 264–269. [Google Scholar] [CrossRef]

- Krutof, A.; Hawboldt, K. Blends of Pyrolysis Oil, Petroleum, and Other Bio-Based Fuels: A Review. Renew. Sustain. Energy Rev. 2016, 59, 406–419. [Google Scholar] [CrossRef]

- Hürdoğan, E.; Ozalp, C.; Kara, O.; Ozcanli, M. Experimental Investigation on Performance and Emission Characteristics of Waste Tire Pyrolysis Oil–Diesel Blends in a Diesel Engine. Int. J. Hydrog. Energy 2017, 42, 23373–23378. [Google Scholar] [CrossRef]

- Kumar, R.; Mishra, M.K.; Singh, S.K.; Kumar, A. Experimental Evaluation of Waste Plastic Oil and Its Blends on a Single Cylinder Diesel Engine. J. Mech. Sci. Technol. 2016, 30, 4781–4789. [Google Scholar] [CrossRef]

- Tomar, M.; Jain, A.; Pujari, P.C.; Dewal, H.; Kumar, N. Potentials of Waste Plastic Pyrolysis Oil as an Extender Fuel for Diesel Engine. Arab. J. Geosci. 2020, 13, 1–10. [Google Scholar] [CrossRef]

- Kim, T.Y.; Lee, S.H. Combustion and Emission Characteristics of Wood Pyrolysis Oil-Butanol Blended Fuels in a DI Diesel Engine. Int. J. Automot. Technol. 2015, 16, 903–912. [Google Scholar] [CrossRef]

- Hossain, A.K.; Davies, P.A. Pyrolysis Liquids and Gases as Alternative Fuels in Internal Combustion Engines—A Review. Renew. Sustain. Energy Rev. 2013, 21, 165–189. [Google Scholar] [CrossRef]

- Chwist, M.; Pyrc, M.; Gruca, M.; Szwaja, M. By-Products from Thermal Processing of Rubber Waste as Fuel for the Internal Combustion Piston Engine. Combust. Engines 2020, 181, 11–18. [Google Scholar] [CrossRef]

- Kalargaris, I.; Tian, G.; Gu, S. Combustion, Performance and Emission Analysis of a DI Diesel Engine Using Plastic Pyrolysis Oil. Fuel Process. Technol. 2017, 157, 108–115. [Google Scholar] [CrossRef] [Green Version]

- Fan, Y.; Cai, Y.; Li, X.; Jiao, L.; Xia, J.; Deng, X. Effects of the Cellulose, Xylan and Lignin Constituents on Biomass Pyrolysis Characteristics and Bio-Oil Composition Using the Simplex Lattice Mixture Design Method. Energy Convers. Manag. 2017, 138, 106–118. [Google Scholar] [CrossRef]

- Sunaryo, S.; Effendy, M.; Sarjito, S.; Kamarrudin, N.S. Pyrolysis of Plastic Waste as an Alternative Fuels in Spark Ignition Engine. Int. J. Emerg. Trends Eng. Res. 2019, 7, 454–459. [Google Scholar] [CrossRef]

- Kareddula, V.K.; Puli, R.K. Influence of Plastic Oil with Ethanol Gasoline Blending on Multi Cylinder Spark Ignition Engine. Alexandria Eng. J. 2018, 57, 2585–2589. [Google Scholar] [CrossRef]

- Szwaja, S. Dilution of Fresh Charge for Reducing Combustion Knock in the Internal Combustion Engine Fueled with Hydrogen Rich Gases. Int. J. Hydrog. Energy 2019, 44, 19017–19025. [Google Scholar] [CrossRef]

| Pyrolysis Plant | Process Temperature | Char | Oil | Gas |

|---|---|---|---|---|

| [C] | [%] | |||

| CSN ISO 647 [5] | 520 | 38.5 | 44.5 | 16.8 |

| Pilot plant [5] | 600 | 39.2 | 51.8 | 7.9 |

| Barbooti [7] | 460 | 34.1 | 53.0 | 12.9 |

| Kaminsky [6] | 600 | 40 | 51 | 9.1 |

| Boxioing [8] | 500 | 37.6 | 45.7 | 16.5 |

| Property | Unit | Ethanol | Pyrolysis Oil | Ethanol + PO |

|---|---|---|---|---|

| LHV | MJ/kg | 26.7 | 39.1 | 30.0 |

| A/F stoic. | - | 10.4 | 14.5 | 11.4 |

| Water content | % mass | <1 | <1 | <1 |

| Sulphur content | % mass | <0.0 | <0.5 | <0.13 |

| Carbon content | % mass | 52 | 85 | 60 |

| Hydrogen content | % mass | 13 | 10 | 12 |

| Chemical constituents | Ethanol 99% | straight alkanes, PAH alkanes | Ethanol 75% Pyro. oil 25% |

| Fuels Applied for Tests | |||

| Fuel | Primary fuel | Reference fuel | |

| Ethanol + PO (3:1) | Ethanol | ||

| LHV (MJ/kg) | 30.0 | 26.9 | |

| Preliminary tests to determine optimal spark timing | |||

| Spark timing in CA deg aTDC | sweeping: −2...−20 | sweeping: −2...−16 | |

| Air excess ratio “lambda” | 1.00...1.07 | 1.00...1.09 | |

| Secondary tests to determine optimal combustion duration | |||

| Spark timing in CA deg aTDC | −10 (for Ethanol) and −14 (for Ethanol+PO) | ||

| Air excess ratio “lambda” | nearly stoichiometric 1.00...1.06 | ||

| Other parameters common for all tests | |||

| Engine speed (rpm) | 600 rpm | ||

| Engine compression ratio | 9.5 | ||

| Engine load | Full load at WOT, IMEP = 720...775 kPa | ||

| Ambient pressure | 1007 hPa | ||

| Air intake temperature | 21.3 °C | ||

| Type of Engine | Four-Stroke, Spark Ignited, Naturally Aspirated |

|---|---|

| Number of cylinders | 1 |

| Number of valves | 2 |

| Cylinder bore | 85 mm |

| Piston stroke | 115 mm |

| Connecting rod | 266 mm |

| Engine displacement | 652 cm3 |

| Compression ratio | 9.5 |

| Intake valve open | 10 CA deg aTDC |

| Intake valve closure | 145 CA deg bTDC |

| Exhaust valve open | 178 CA deg aTDC |

| Exhaust valve closure | 5 CA deg aTDC |

| Crank shaft speed | 600 rpm |

| Cooling | water cooling system |

| Instrument | Range | Resolution and/or Accuracy |

|---|---|---|

| Charge amplifier: Kistler 5018A | 2 ÷ 10 pC 10 ÷ 100 pC 100 ÷ 2,200,000 pC | resolution: 0.01 pC accuracy: <±2%, <±0.6%, <±0.3%, respectively to range |

| Pressure sensor: Kistler 6118C | 0 ÷ 200 bar | resolution: 10 pC/bar, accuracy: <±1% |

| MAP sensor | 0 ÷ 1.1 bar | accuracy: <2.5% |

| Data acquisition system: USB-1608HS | ±10 V | accuracy: 16 bits ±1 LSB, sampling rate: 50 kHz |

| Rotor flowmeter CGR-FX | 0.25 ÷ 25.00 m3/h | accuracy: 6.45∙10 × 10−5 m3/h |

| Temperature sensor: thermocouple NiCr-Ni (K) | −40 … 1000 °C | accuracy: ±1 °C |

| Crank angle encoder PR90 | max 6000 rpm | res.: 720 pulses per rev. |

| Fuel | ST_opt (CA deg aTDC) |

|---|---|

| Ethanol | −10 as the middle in the range: −12…−8 −11 from trend line |

| Ethanol + PO (3:1) | −14 as the middle in the range: −16…−12 −13 from trend line |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szwaja, M.; Chwist, M.; Szwaja, S.; Juknelevičius, R. Impact of Pyrolysis Oil Addition to Ethanol on Combustion in the Internal Combustion Spark Ignition Engine. Clean Technol. 2021, 3, 450-461. https://doi.org/10.3390/cleantechnol3020026

Szwaja M, Chwist M, Szwaja S, Juknelevičius R. Impact of Pyrolysis Oil Addition to Ethanol on Combustion in the Internal Combustion Spark Ignition Engine. Clean Technologies. 2021; 3(2):450-461. https://doi.org/10.3390/cleantechnol3020026

Chicago/Turabian StyleSzwaja, Magdalena, Mariusz Chwist, Stanislaw Szwaja, and Romualdas Juknelevičius. 2021. "Impact of Pyrolysis Oil Addition to Ethanol on Combustion in the Internal Combustion Spark Ignition Engine" Clean Technologies 3, no. 2: 450-461. https://doi.org/10.3390/cleantechnol3020026

APA StyleSzwaja, M., Chwist, M., Szwaja, S., & Juknelevičius, R. (2021). Impact of Pyrolysis Oil Addition to Ethanol on Combustion in the Internal Combustion Spark Ignition Engine. Clean Technologies, 3(2), 450-461. https://doi.org/10.3390/cleantechnol3020026