Comparison of the Use of Traditional Solvents and Nanosecond 213 nm Nd:YAG Laser in Thinning Naturally Aged Varnish on a Contemporary Oil Easel Painting

Abstract

:1. Introduction

2. Materials and Methods

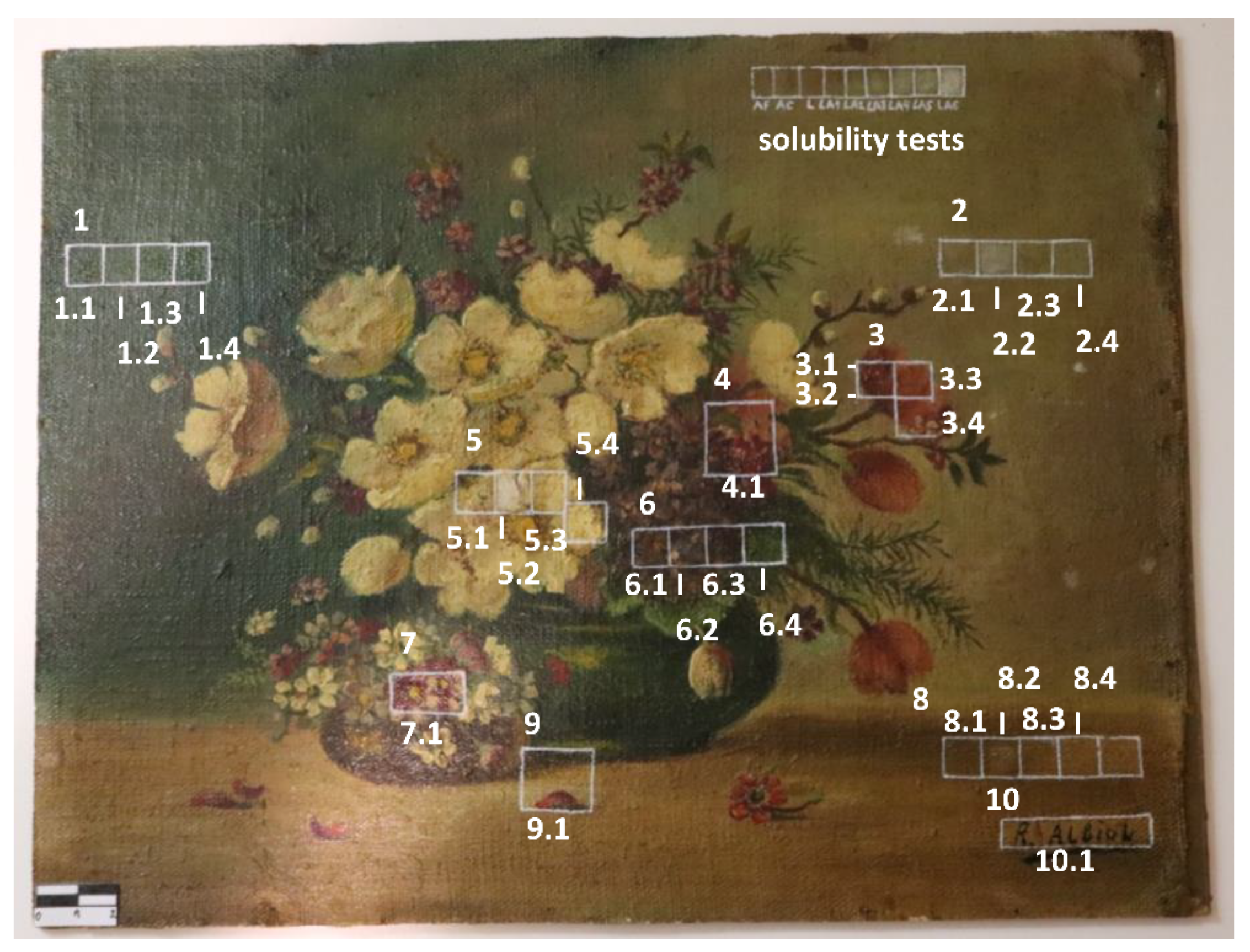

2.1. Description of the Artwork and the State of the Varnish Coating

2.2. Varnish Removal Tests

2.3. Experimental Methods to Assess Cleaning Tests

3. Results and Discussion

3.1. Varnish Condition and Identification

3.2. Varnish Removal Tests

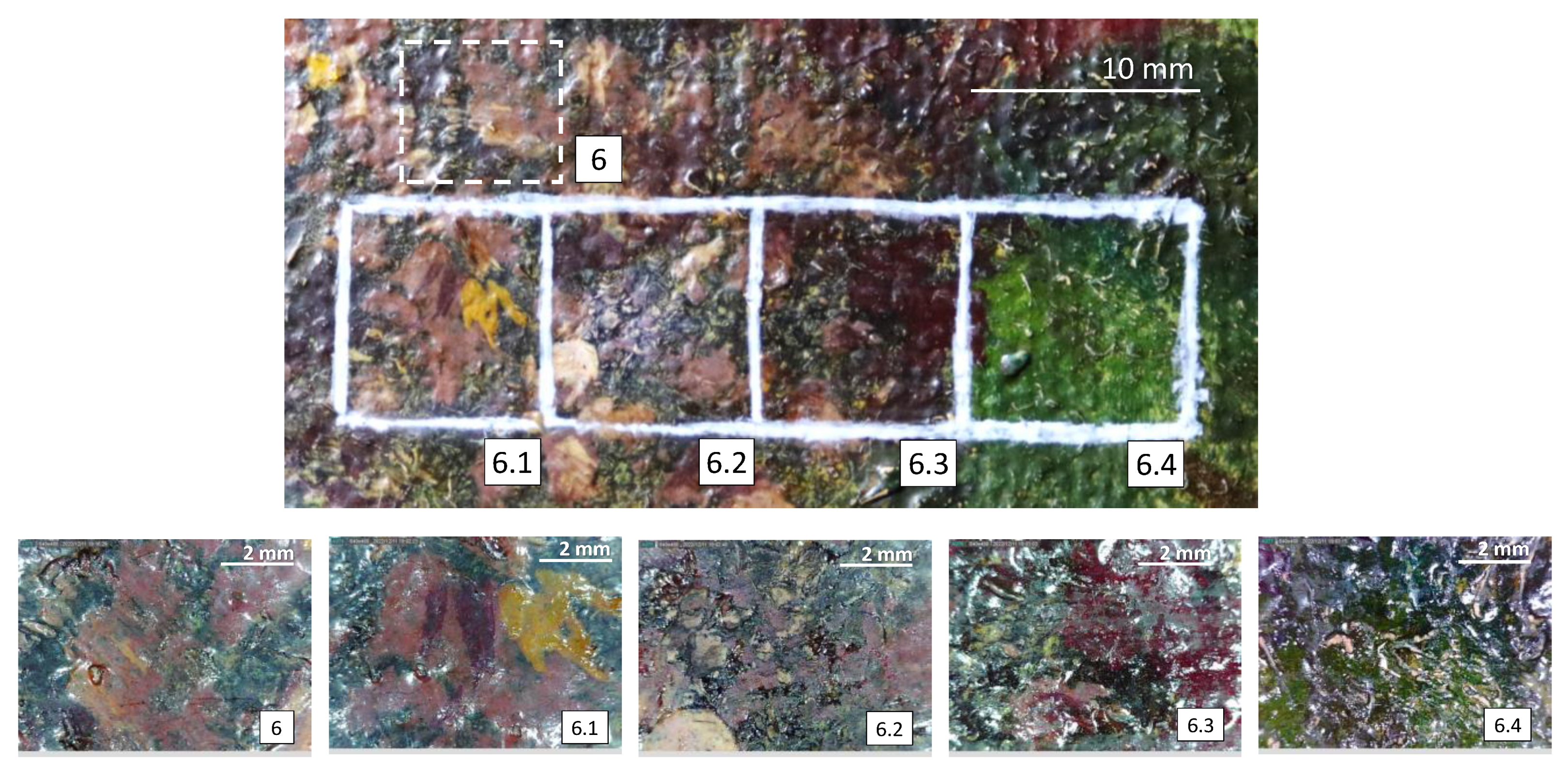

3.2.1. Low-Power Microscopy

3.2.2. UV Lamp Illumination

3.2.3. Laser-Induced Fluorescence (LIF)

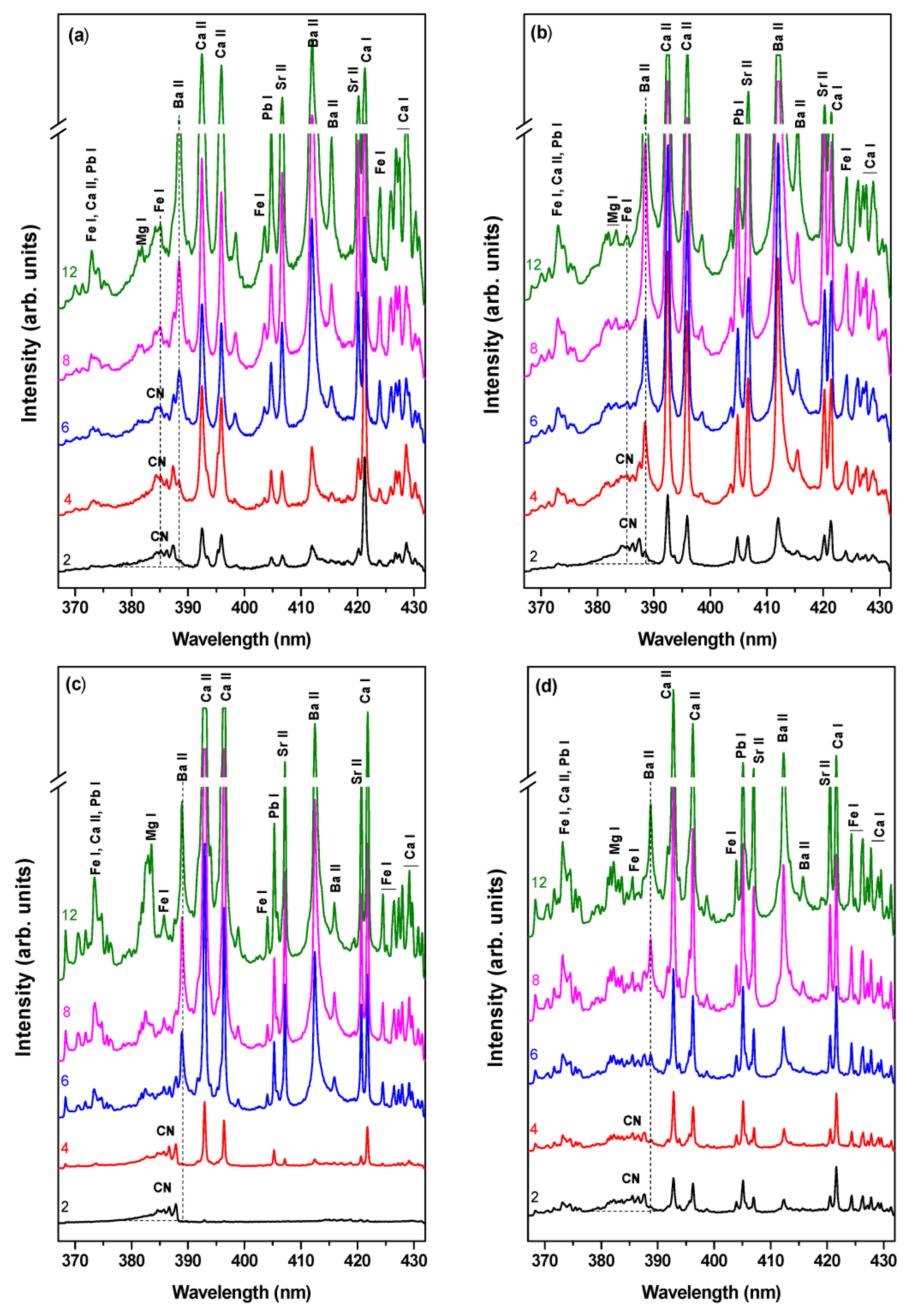

3.2.4. Laser-Induced Breakdown Spectroscopy (LIBS)

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zanini, A.; Trafeli, V.; Bartoli, L. The Laser as a Tool for the Cleaning of Cultural Heritage. IOP Conf. Ser. Mater. Sci. Eng. 2018, 364, 012078. [Google Scholar] [CrossRef]

- Baij, L.; Hermans, J.; Ormsby, B.; Noble, P.; Iedema, P.; Keune, K. A Review of Solvent Action on Oil Paint. Herit. Sci. 2020, 8, 43. [Google Scholar] [CrossRef]

- Pereira-Pardo, L.; Melita, L.N.; Korenberg, C. Tackling Conservation Challenges Using Erbium Lasers: Case Studies at the British Museum. J. Inst. Conserv. 2020, 43, 25–43. [Google Scholar] [CrossRef]

- Pouli, P.; Oujja, M.; Castillejo, M. Practical Issues in Laser Cleaning of Stone and Painted Artefacts: Optimisation Procedures and Side Effects. Appl. Phys. A Mater. Sci. Process. 2012, 106, 447–464. [Google Scholar] [CrossRef]

- Andreotti, A.; Brown, W.P.; Camaiti, M.; Colombini, M.P.; DeCruz, A. Diagnosis of Materials and Effectiveness of Er:YAG Laser Cleaning as Complementary Treatment in a Panel Painting Attributed to Lluís Borrassà (Fifteenth Century). Appl. Phys. A 2016, 122, 572. [Google Scholar] [CrossRef]

- Bracco, P.; Lanterna, G.; Matteini, M.; Nakahara, K.; Sartiani, O.; de Cruz, A.; Wolbarsht, M.L.; Adamkiewicz, E.; Colombini, M.P. Er:YAG Laser: An Innovative Tool for Controlled Cleaning of Old Paintings: Testing and Evaluation. J. Cult. Herit. 2003, 4, 202–208. [Google Scholar] [CrossRef]

- Brunetto, A.; Bono, G.; Frezzato, F. Er:YAG Laser Cleaning of ‘San Marziale in Gloria’ by Jacopo Tintoretto in the Church of San Marziale, Venice. J. Inst. Conserv. 2020, 43, 44–58. [Google Scholar] [CrossRef]

- Castillejo, M.; Martín, M.; Oujja, M.; Silva, D.; Torres, R.; Manousaki, A.; Zafiropulos, V.; van den Brink, O.F.; Heeren, R.M.A.; Teule, R.; et al. Analytical Study of the Chemical and Physical Changes Induced by KrF Laser Cleaning of Tempera Paints. Anal. Chem. 2002, 74, 4662–4671. [Google Scholar] [CrossRef]

- Kokkinaki, O.; Dimitroulaki, E.; Melessanaki, K.; Anglos, D.; Pouli, P. Laser-Induced Fluorescence as a Non-Invasive Tool to Monitor Laser-Assisted Thinning of Aged Varnish Layers on Paintings: Fundamental Issues and Critical Thresholds. Eur. Phys. J. Plus 2021, 136, 938. [Google Scholar] [CrossRef]

- Moretti, P.; Iwanicka, M.; Melessanaki, K.; Dimitroulaki, E.; Kokkinaki, O.; Daugherty, M.; Sylwestrzak, M.; Pouli, P.; Targowski, P.; van den Berg, K.J.; et al. Laser Cleaning of Paintings: In Situ Optimization of Operative Parameters through Non-Invasive Assessment by Optical Coherence Tomography (OCT), Reflection FT-IR Spectroscopy and Laser Induced Fluorescence Spectroscopy (LIF). Herit. Sci. 2019, 7, 44. [Google Scholar] [CrossRef]

- Lopez, M.; Bai, X.; Koch-Dandolo, C.; Serfaty, S.; Wilkie-Chancellier, N.; Detalle, V. Nd:YAG vs Er:YAG: A Comparative Study of Laser Varnish Removal on Easel Paintings. In Proceedings of the Optics for Arts, Architecture, and Archaeology VII, Munich, Germany, 8 August 2019; Targowski, P., Groves, R., Liang, H., Eds.; SPIE: Bellingham, WA, USA, 2019; p. 3. [Google Scholar]

- Wang, C.; Cao, Y.; Tie, F.; Camaiti, M. Er:YAG Laser Cleaning of Painted Surfaces: Functional Considerations to Improve Efficacy and Reduce Side Effects. Coatings 2021, 11, 1315. [Google Scholar] [CrossRef]

- Striova, J.; Fontana, R.; Barbetti, I.; Pezzati, L.; Fedele, A.; Riminesi, C. Multisensorial Assessment of Laser Effects on Shellac Applied on Wall Paintings. Sensors 2021, 21, 3354. [Google Scholar] [CrossRef] [PubMed]

- Striova, J.; Salvadori, B.; Fontana, R.; Sansonetti, A.; Barucci, M.; Pampaloni, E.; Marconi, E.; Pezzati, L.; Colombini, M.P. Optical and Spectroscopic Tools for Evaluating Er: YAG Laser Removal of Shellac Varnish. Stud. Conserv. 2015, 60, S91–S96. [Google Scholar] [CrossRef] [Green Version]

- Chillè, C.; Papadakis, V.M.; Theodorakopoulos, C. An Analytical Evaluation of Er:YAG Laser Cleaning Tests on a Nineteenth Century Varnished Painting. Microchem. J. 2020, 158, 105086. [Google Scholar] [CrossRef]

- Hellen, R. Preliminary Study into the Reduction and Removal of Naturally Aged Varnishes from Painted Surfaces Using an Er:YAG Laser in a Two-Step Cleaning Process with Solvents. J. Inst. Conserv. 2020, 43, 79–93. [Google Scholar] [CrossRef]

- Siano, S.; Osticioli, I.; Pavia, A.; Ciofini, D. Overpaint Removal from Easel Paintings Using an LQS Nd:YAG Laser: The First Validation Study. Stud. Conserv. 2015, 60, S49–S57. [Google Scholar] [CrossRef]

- Antonopoulou-Athera, N.; Chatzitheodoridis, E.; Doulgerides, M.; Evangelatos, C.; Serafetinides, A.A.; Terlixi, A. Laser Cleaning Treatment of Burnt Paintings. In Proceedings of the 18th International School on Quantum Electronics: Laser Physics and Applications, Sozopol, Bulgaria, 8 January 2015; Dreischuh, T., Gateva, S., Serafetinides, A., Eds.; Proccedings of SPIE Vol. 9447. SPIE: Bellingham, WA, USA, 2015; p. 944712. [Google Scholar]

- Ciofini, D.; Oujja, M.; Cañamares, M.V.; Siano, S.; Castillejo, M. Detecting Molecular Changes in UV Laser-Ablated Oil/Diterpenoid Resin Coatings Using Micro-Raman Spectroscopy and Laser Induced Fluorescence. Microchem. J. 2018, 141, 12–24. [Google Scholar] [CrossRef] [Green Version]

- Oujja, M.; Psilodimitrakopoulos, S.; Carrasco, E.; Sanz, M.; Philippidis, A.; Selimis, A.; Pouli, P.; Filippidis, G.; Castillejo, M. Nonlinear Imaging Microscopy for Assessing Structural and Photochemical Modifications upon Laser Removal of Dammar Varnish on Photosensitive Substrates. Phys. Chem. Chem. Phys. 2017, 19, 22836–22843. [Google Scholar] [CrossRef] [Green Version]

- Oujja, M.; García, A.; Romero, C.; Vázquez de Aldana, J.R.; Moreno, P.; Castillejo, M. UV Laser Removal of Varnish on Tempera Paints with Nanosecond and Femtosecond Pulses. Phys. Chem. Chem. Phys. 2011, 13, 4625. [Google Scholar] [CrossRef] [Green Version]

- Ciofini, D.; Oujja, M.; Cañamares, M.V.; Siano, S.; Castillejo, M. Spectroscopic Assessment of the UV Laser Removal of Varnishes from Painted Surfaces. Microchem. J. 2016, 124, 792–803. [Google Scholar] [CrossRef]

- Cremonesi, P. L’uso dei Solventi Organici Nella Pulitura di Opere Policrome, 2nd ed.; Il Prato: Padova, Italia, 2004; ISBN 978-88-87243-85-7. [Google Scholar]

- Derrick, M.R.; Stulik, D.C.; Landry, J.M. (Eds.) Scientific tools for conservation. In Infrared Spectroscopy in Conservation Science; Getty Conservation Institute: Los Angeles, CA, USA, 1999; ISBN 978-0-89236-469-5. [Google Scholar]

- Issa, Y.M.; Abdel-Maksoud, G.; Magdy, M. Analytical Study of Saint Gregory Nazianzen Icon, Old Cairo, Egypt. J. Mol. Struct. 2015, 1100, 70–79. [Google Scholar] [CrossRef]

- Zuena, M.; Buemi, L.P.; Stringari, L.; Legnaioli, S.; Lorenzetti, G.; Palleschi, V.; Nodari, L.; Tomasin, P. An Integrated Diagnostic Approach to Max Ernst’s Painting Materials in His Attirement of the Bride. J. Cult. Herit. 2020, 43, 329–337. [Google Scholar] [CrossRef]

- Teppo, E. Introduction: Er:YAG Lasers in the Conservation of Artworks. J. Inst. Conserv. 2020, 43, 2–11. [Google Scholar] [CrossRef]

- Gómez-Morón, A.; Ortiz, R.; Colao, F.; Fantoni, R.; Ortiz, P. Laser-Induced Fluorescence Mapping of Pigments in a Secco Painted Murals. Ge Conserv. 2020, 17, 233–250. [Google Scholar] [CrossRef]

- Anglos, D. Laser-Induced Breakdown Spectroscopy in Art and Archaeology. Appl. Spectrosc. 2001, 55, 186A–205A. [Google Scholar] [CrossRef]

- NIST Database. Available online: https://physics.nist.gov/PhysRefData/ASD/lines_form.html (accessed on 19 October 2022).

| Band (cm−1) | Functional Group | Band (cm−1) | Functional Group |

|---|---|---|---|

| 3435 | ν(O-H) | 1384 | δ(C-H) |

| 2955 | ν(CH3) | 1314 | Not assigned |

| 2925 | ν(CH3) | 1257 | ν(C-O) |

| 2853 | ν(CH2) | 1163 | ν(C-O) |

| 1735 | ν(C=O) | 1116 | ν(SO4), δ(C-H) |

| 1708 | ν(C=O) | 1078 | ν(SO4), δ(C-H) |

| 1638 | δ(O-H), ν(C=C) | 983 | ν(SO4) |

| 1547 | Not assigned | 878 | Not assigned |

| 1456 | δ(C-H) | 635 | δ(SO4) |

| 1417 | δ(C-H) | 610 | δ(SO4) |

| Area 1 | λ1 (nm) | I1 | λmax (nm) | Imax | Δλmax (nm) | Imax/I1 |

|---|---|---|---|---|---|---|

| ref | 373 | 22,175 | 469 | 30,990 | - | 1.4 |

| H2O | 374 | 20,868 | 474 | 33,631 | 5 | 1.6 |

| Ligroin:acetone | 376 | 37,389 | 474 | 78,858 | 5 | 2.1 |

| 213 nm, 0.10 J/cm2 | 372 | 42,289 | 475 | 75,940 | 6 | 1.8 |

| 213 nm, 0.14 J/cm2 | 371 | 49,480 | 477 | 104,494 | 8 | 2.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martínez-Weinbaum, M.; Lozano-Carbó, M.; Maestro-Guijarro, L.; Carmona-Quiroga, P.M.; Oujja, M.; Castillejo, M. Comparison of the Use of Traditional Solvents and Nanosecond 213 nm Nd:YAG Laser in Thinning Naturally Aged Varnish on a Contemporary Oil Easel Painting. Heritage 2023, 6, 957-967. https://doi.org/10.3390/heritage6020053

Martínez-Weinbaum M, Lozano-Carbó M, Maestro-Guijarro L, Carmona-Quiroga PM, Oujja M, Castillejo M. Comparison of the Use of Traditional Solvents and Nanosecond 213 nm Nd:YAG Laser in Thinning Naturally Aged Varnish on a Contemporary Oil Easel Painting. Heritage. 2023; 6(2):957-967. https://doi.org/10.3390/heritage6020053

Chicago/Turabian StyleMartínez-Weinbaum, Marina, Míriam Lozano-Carbó, Laura Maestro-Guijarro, Paula María Carmona-Quiroga, Mohamed Oujja, and Marta Castillejo. 2023. "Comparison of the Use of Traditional Solvents and Nanosecond 213 nm Nd:YAG Laser in Thinning Naturally Aged Varnish on a Contemporary Oil Easel Painting" Heritage 6, no. 2: 957-967. https://doi.org/10.3390/heritage6020053

APA StyleMartínez-Weinbaum, M., Lozano-Carbó, M., Maestro-Guijarro, L., Carmona-Quiroga, P. M., Oujja, M., & Castillejo, M. (2023). Comparison of the Use of Traditional Solvents and Nanosecond 213 nm Nd:YAG Laser in Thinning Naturally Aged Varnish on a Contemporary Oil Easel Painting. Heritage, 6(2), 957-967. https://doi.org/10.3390/heritage6020053