Physical and Mechanical Characterization of Lime Pastes and Mortars for Use in Restoration

Abstract

:1. Introduction

Slaked Lime and Its Traditional Use in the Architectural Heritage and Restoration Works in Mexico

2. Materials and Methods

2.1. Materials and Preparation of the Specimens

2.2. Surface Area

2.3. Flowability Test

2.4. Ultrasonic Pulse Velocity Test

2.5. Electrical Resistivity Test

2.6. Colorimetry

2.7. Compressive Strength

3. Results

3.1. Surface Area

3.2. Flowability

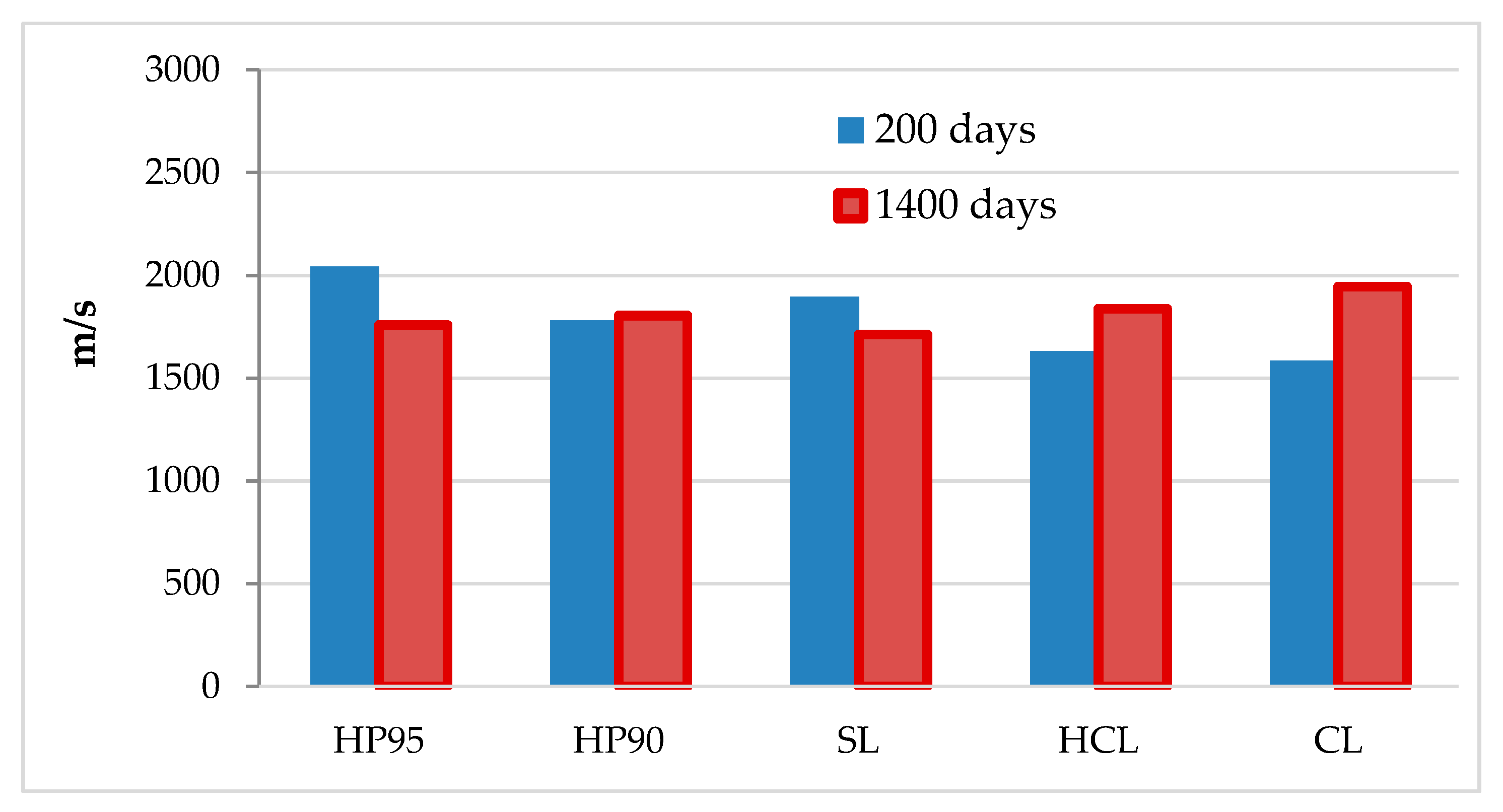

3.3. Ultrasonic Velocity Pulse

3.4. Electrical Resistivity

3.5. Colorimetry

3.6. Compressive Strength

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Elsen, J. Microscopy of historic mortars—A review. Cem. Concr. Res. 2006, 36, 1416–1424. [Google Scholar] [CrossRef]

- do Rosário Veiga, M.; Fragata, A.; Velosa, A.L.; Magalhães, A.C.; Margalha, G. Lime-Based Mortars: Viability for Use as Substitution Renders in Historical Buildings. Int. J. Archit. Herit. 2010, 4, 177–195. [Google Scholar] [CrossRef]

- Alonso, I.V.; Pingarrón, L.B. Los orígenes tecnológicos de la cal. Cuicuilco 2012, 55, 11–41. [Google Scholar]

- Aggelakopoulou, E.; Bakolas, A.; Moropoulou, A. Lime putty versus hydrated lime powder: Physicochemical and mechanical characteristics of lime based mortars. Constr. Build. Mater. 2019, 225, 633–641. [Google Scholar] [CrossRef]

- Liu, X.; Ma, X.; Zhang, B. Analytical Investigations of Traditional Masonry Mortars from Ancient City Walls Built during Ming and Qing Dynasties in China. Int. J. Archit. Herit. 2016, 10, 663–673. [Google Scholar] [CrossRef]

- Carran, D.; Hughes, J.; Leslie, A.; Kennedy, C. A Short History of the Use of Lime as a Building Material beyond Europe and North America. Int. J. Archit. Herit. 2012, 6, 117–146. [Google Scholar] [CrossRef]

- Jaime-Ledesma, P.J. La técnica constructiva en la arquitectura. Legado Arquit. Y Diseño 2014, 9, 21–30. [Google Scholar]

- Fernandez, F.; Germinario, S.; Basile, R.; Montagno, R.; Kapetanaki, K.; Gobakis, K.; Kolokotsa, D.; Lagou, A.M.; Dania, P.; Enna, M.T.; et al. Development of Eco-Friendly and Self-Cleaning Lime-Pozzolan Plasters for Bio-Construction and Cultural Heritage. Buildings 2020, 10, 172. [Google Scholar] [CrossRef]

- Speziale, A.; González-Sánchez, J.F.; Taşcı, B.; Pastor, A.; Sánchez, L.; Fernández-Acevedo, C.; Oroz-Mateo, T.; Salazar, C.; Navarro-Blasco, I.; Fernández, J.M.; et al. Development of Multifunctional Coatings for Protecting Stones and Lime Mortars of the Architectural Heritage. Int. J. Archit. Herit. 2020, 14, 1008–1029. [Google Scholar] [CrossRef] [Green Version]

- Loganina, V.; Sergeeva, K.; Fediuk, R.; Klyuev, S.; Vatin, N.; Vasilev, Y. Modified Lime Binders for Restoration Work. Buildings 2021, 11, 98. [Google Scholar] [CrossRef]

- Vitruvius, The Ten Books on Architecture; Alianza Forma: Madrid, Spain, 2000.

- Kotlyar, V.; Pishchulina, V.; Beskopylny, A.; Meskhi, B.; Popov, Y.; Efremenko, I. Estimation of the Age of Architectural Heritage Objects by Microstructural Changes of Calcite in Lime Mortars of Ancient Brickwork and Masonry. Buildings 2021, 11, 240. [Google Scholar] [CrossRef]

- NMX-C-486-ONNCCE-2014; Industria de la Construcción-Mampostería–Mortero Para Uso Estructural–Especificaciones y Métodos de Ensayo. Organismo Nocional de Normalización y Certificación de la Construcción y la Edificación (ONNCCE): Ciudad de Mexico, Mexico, 2014.

- Villaseñor, I.; Schneider, R. Principios generales para la elaboración de argamasas. In La Cal: Historia, Propiedades y Uso; Barba Pingarrón, L., Villaseñor Alonso, I., Eds.; UNAM, Instituto de Investigaciones Antropológicas, Asociación Nacional de Fabricantes de Cal: Ciudad de Mexico, Mexico, 2013; pp. 97–114. [Google Scholar]

- Curulli, A.; Montesperelli, G.; Ronca, S.; Cavalagli, N.; Ubertini, F.; Padeletti, G.; Ciprioti, S.V. A multidisciplinary approach to the mortars characterization from the Town Walls of Gubbio (Perugia, Italy). J. Anal. Calorim. 2020, 142, 1721–1737. [Google Scholar] [CrossRef]

- Caroselli, M.; Ruffolo, S.A.; Piqué, F. Mortars and plasters—How to manage mortars and plasters conservation. Archaeol. Anthr. Sci. 2021, 13, 188. [Google Scholar] [CrossRef]

- Biçer-şimşir, B.; Griffin, I.; Palazzo-Bertholon, B.; Rainer, L. Lime-based injection grouts for the conservation of architectural surfaces. Stud. Conserv. 2009, 54, 3–17. [Google Scholar] [CrossRef]

- Sepulcre Aguilar, A.; Hernández-Olivares, F. Interfacial Transition Zone (ITZ) Analysis in Hydraulic Lime Restoration Mortars for Grouting of Historical Masonries. Int. J. Archit. Herit. 2012, 6, 396–414. [Google Scholar] [CrossRef]

- Silva, B.A.; Ferreira Pinto, A.P.; Gomes, A. Natural hydraulic lime versus cement for blended lime mortars for restoration works. Constr. Build. Mater. 2015, 94, 346–360. [Google Scholar] [CrossRef]

- Pachta, V.; Papayianni, I.; Spyriliotis, T. Assessment of Laboratory and Field Testing Methods in Lime-based Grouts for the Consolidation of Architectural Surfaces. Int. J. Archit. Herit. 2020, 14, 1098–1105. [Google Scholar] [CrossRef]

- López Martínez, T.; García, M.d.R.B.; García Bueno, A. Metodología para el estudio de morteros arqueológicos de revestimiento. Ge-Conservacion 2021, 19, 31–44. [Google Scholar] [CrossRef]

- Tavares, M.; Magalhaes, A.C.; Veiga, M.D.R.; Aguiar, J. Métodos de diagnóstico para revestimientos de edificios antiguos. Importancia y aplicabilidad de los ensayos in situ. Rev. PH 2005, 53, 11–17. [Google Scholar] [CrossRef]

- RILEM TC 203-RHM: Repair mortars for historic masonry. Mater. Struct. 2012, 45, 1277–1285. [CrossRef]

- Lara Calderón, M.L.; Sanz-Arauz, D.; López-Andrés, S.; del Pino, I. Characterization and Analysis of the Mortars of the Church of Santo Domingo in Quito (Ecuador). Heritage 2022, 5, 4024–4036. [Google Scholar] [CrossRef]

- Alonso, E.; Martı, L.; Martı, W.; Villaseñor, L. Mechanical properties of concrete elaborated with igneous aggregates. Cem. Concr. Res. 2002, 32, 317–321. [Google Scholar] [CrossRef]

- Martínez, W.; Alonso, E.M.; Rubio, J.C.; Bedolla, J.A.; Velasco, F.A.; Torres, A.A. Comportamiento mecánico de morteros de cal apagada artesanalmente adicionados con mucílago de cactácea y ceniza volcánica, para su uso en restauración y conservación de monumentos coloniales. Rev. Constr. 2008, 7, 93–101. [Google Scholar]

- Molina, W.M.; Guzman, E.A.; Garcia, H.C.; Gomez, C.L.; Valdez, F.G.; Lica, O.F.; Acosta, A.T.; Alonso, W.M.; Arroyo, J.B.; Barrios, H.H. Mechanical Response of Portland Cement Mortars with added Expanded Polystyrene Spheres (EPS) under Accelerated Attack. In Proceedings of the 2015 International Conference on Structural, Mechanical and Material Engineering, Dalian, China, 6–8 November 2015. [Google Scholar] [CrossRef] [Green Version]

- ASTM D75/D75M-19; Standard Practice for Sampling Aggregates. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM C128-22; Standard Test Method for Relative Density (Specific Gravity) and Absorption of Fine Aggregate. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM C29/C29M 17a; Standard Test Method for Bulk Density (“Unit Weight”) and Voids in Aggregate. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM C136/C136M19; Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM C40/C40M-20; Standard Test Method for Organic Impurities in Fine Aggregates for Concrete. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM D2419-22; Standard Test Method for Sand Equivalent Value of Soils and Fine Aggregate. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM C117-17; Standard Test Method for Materials Finer than 75-μm (No. 200) Sieve in Mineral Aggregates by Washing. ASTM International: West Conshohocken, PA, USA, 2017.

- NMX-C-061-ONNCCE-2015; Building Industry–Hydraulic Cements–Determination of Compressive Strength of Hydraulic Cements. Organismo Nacional de Normalización y Certificación de la Construcción y Edificación (ONNCCE): Ciudad de Mexico, Mexico, 2015.

- Mendoza, E.G.N.; Bedolla-Arroyo, J.A.; Calvillo, A.S.; Guzmán, E.M.A.; Blancas-Herrera, V.H.; Molina, W.M.; García, H.L.C. High Purity Lime as an Ecologic Alternative for Construction Mortars and Pastes. Key Eng. Mater. 2020, 841, 188–192. [Google Scholar] [CrossRef]

- NMX-C-144-ONNCCE-2015; Building Industry–Hydraulic Cement–Specifications for the Aparatus used in the Flow Test for Mortars made of Hydraulic Cements. Organismo Nacional de Normalización y Certificación de la Construcción y Edificación (ONNCCE): Ciudad de Mexico, Mexico, 2015.

- NMX-C-275-ONNCCE-2020; Building Industry–Hydraulic Concrete–Determination of the Ultrasonic Pulse Velocity through Concrete–Test Method. Organismo Nacional de Normalización y Certificación de la Construcción y Edificación (ONNCCE): Ciudad de Mexico, Mexico, 2020.

- Ravi, R.; Selvaraj, T.; Sekar, S.K. Characterization of Hydraulic Lime Mortar Containing Opuntia ficus-indica as a Bio-Admixture for Restoration Applications. Int. J. Archit. Herit. 2016, 10, 714–725. [Google Scholar] [CrossRef]

- Barnaure, M.; Bonnet, S.; Poullain, P. Earth buildings with local materials: Assessing the variability of properties measured using non-destructive methods. Constr. Build. Mater. 2021, 281, 122613. [Google Scholar] [CrossRef]

- NMX-C-514-ONNCCE-2019; Building Industry–Electrical Resistivity of Hydraulic Concrete–Specifications and Testing Methods. Organismo Nacional de Normalización y Certificación de la Construcción y Edificación (ONNCCE): Ciudad de Mexico, Mexico, 2019.

- La Russa, M.F.; Ruffolo, S.A. Mortars and plasters—How to characterize mortar and plaster degradation. Archaeol. Anthr. Sci. 2021, 13, 165. [Google Scholar] [CrossRef]

- Sánchez-Calvillo, A.; Alonso-Guzmán, E.M.; Ruvalcaba-Sil, J.L.; Martínez-Molina, W.; Chavez-Garcia, H.L.; Bedolla-Arroyo, J.A.; Navarro-Mendoza, E.G.; Blancas-Herrera, V.H.; Perez, J.A.V. Colorimetry of clays as a tool to identify soil materials for earthen buildings restoration. Key Eng. Mater. 2020, 862, 56–60. [Google Scholar] [CrossRef]

- Berns, R.S. Billmeyer and Saltzman’s Principles of Color Technology; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2019. [Google Scholar]

- Borinaga-Treviño, R.; Orbe, A.; Canales, J.; Norambuena-Contreras, J. Experimental evaluation of cement mortars with recycled brass fibres from the electrical discharge machining process. Constr. Build. Mater. 2020, 246, 118522. [Google Scholar] [CrossRef]

| Lime | pH | Calcium Hydroxide (%) | Silica (%) | Molecular Weight (g/mol) | Relative Density (kg/L) | Water Solubility (mg/L) |

|---|---|---|---|---|---|---|

| HP95 | 12.45 | 95–96 | 0.1–0.5 | 74.10 | 0.4–0.6 | 1650 |

| HP90 | 12.45 | 90–94 | 0.1–2.0 | 74.10 | 0.6–0.7 | 1650 |

| SL | 12.45 | 75–85 | 0.1–2.0 | 74.10 | 0.5–0.7 | 1650 |

| CL | 12.45 | 80–95 | 0.1–2.0 | 56.10 | 0.7–1.3 | 1650 |

| HCL | 12.45 | 80–95 | 0.1–2.0 | 56.10 | 0.7–1.3 | 1650 |

| ID | Description | Format | Origin Quarry |

|---|---|---|---|

| HP95 | High-purity lime with 95% calcium hydroxide | Powder | Acajete, Puebla, Mexico |

| HP90 | High-purity lime with 90% calcium hydroxide | Powder | Piedras de Lumbre, Michoacán, Mexico |

| SL | Traditional slaked lime matured for more than 900 days | Paste | Piedras de Lumbre, Michoacán, Mexico |

| HCL | Construction industry lime hydrated for more than 900 days | Paste | Piedras de Lumbre, Michoacán, Mexico |

| CL | Construction industry lime | Powder | Piedras de Lumbre, Michoacán, Mexico |

| FRX (%) | SiO2 | TiO2 | Al2O3 | Fe2O3 | MnO | MgO | CaO | Na2O | K2O | P2O5 | LC | Total |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 59.74 | 0.782 | 17.024 | 5.909 | 0.089 | 3.426 | 5.264 | 3.636 | 1.648 | 0.217 | 0.55 | 98.285 |

| ppm | Rb | Sr | Ba | Y | Zr | Nb | V | Cr | Co | Ni | Cu | Zn | Th | Pb |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 50 | 591 | 567 | 31 | 177 | 56 | 96 | 76 | 75 | 64 | 148 | 107 | <3 | 9 |

| Standard | 2002 [25] | 2008 [26] | 2015 [27] |

|---|---|---|---|

| ASTM D75/D75M-19. Standard Practice for Sampling Aggregates, (kg) [28] | 500 | 500 | 500 |

| ASTM C128-22. Standard Test Method for Relative Density (Specific Gravity) and Absorption of Fine Aggregate, (%) [29] | 2.41 | 2.33 | 2.3 |

| ASTM C29/C29M 17a. Standard Test Method for Bulk Density (“Unit Weight”) and Voids in Aggregate, (Ton/m3) [30] | 1.305 | 1.14 | 1.23 |

| ASTM C136/C136M19. Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates, (FM) [31] | 3.58 | 3.03 | 2.19 |

| ASTM C40/C40M-20. Standard Test Method for Organic Impurities in Fine Aggregates for Concrete, (Level) [32] | 1 | 1 | 3 |

| ASTM D2419-22. Standard Test Method for Sand Equivalent Value of Soils and Fine Aggregate, (%) [33] | 96.98 | 98.19 | 97.5 |

| ASTM C117-17. Standard Test Method for Materials Finer than 75-μm (No. 200) Sieve in Mineral Aggregates by Washing, (%) [34] | 3.01 | 5.3 | 1.98 |

| Type | Lime Paste kg | Water Content |

|---|---|---|

| SL | 10.89 * | 31% |

| HCL | 11.35 | 26% |

| Type | HP95 | HP90 | SL | HCL | CL |

|---|---|---|---|---|---|

| Surface area m2/gr | 13.45 | 11.67 | 23.80 | 18.81 | 3.07 |

| Type | HP95 | HP90 | SL | HCL | CL |

|---|---|---|---|---|---|

| Paste | 115% | 118% | 132% | 185% | 139% |

| Mortar | 125% | 145% | 132% | 115% | 112% |

| Pastes (m/s) | Mortars (m/s) | |||

|---|---|---|---|---|

| Type | 200 Days | 1400 Days | 200 Days | 1400 Days |

| HP95 | 2043.0 | 1757.67 | 1663.3 | 2096.09 |

| HP90 | 1781.7 | 1804.12 | 1772.7 | 2638.34 |

| SL | 1897.3 | 1712.29 | 1286.7 | 1304.51 |

| HCL | 1631.0 | 1836.97 | 1229.3 | 1867.00 |

| CL | 1584.0 | 1945.65 | 1925.0 | 2605.91 |

| Pastes (Ω·cm) | Mortars (Ω·cm) | |||

|---|---|---|---|---|

| Type | 200 Days | 1400 Days | 200 Days | 1400 Days |

| HP95 | 882.07 | 119.97 | 1546.35 | 1420.88 |

| HP90 | 765.8 | 285.74 | 2433.1 | 2656.91 |

| SL | 418.94 | 647.29 | 1061.06 | 1113.77 |

| HCL | 520.23 | 686.01 | 2579.69 | 3361.05 |

| CL | 513.36 | 464.05 | 1533.07 | 3151.43 |

| Pastes | a* | b* | L* | Color | Mortars | a* | b* | L* | Color |

|---|---|---|---|---|---|---|---|---|---|

| HP95 | 0.73 | 4.55 | 93.53 |  | HP95 | 0.25 | 2.55 | 87.42 |  |

| HP90 | 1.41 | 6.59 | 90.60 |  | HP90 | 0.93 | 4.98 | 85.53 |  |

| SL | 1.65 | 7.13 | 89.40 |  | SL | 0.93 | 5.10 | 83.33 |  |

| HCL | 2.00 | 7.60 | 90.29 |  | HCL | 0.85 | 5.31 | 86.96 |  |

| CL | 1.70 | 6.39 | 90.08 |  | CL | 1.10 | 4.75 | 87.45 |  |

| Pastes (MPa) | Mortars (MPa) | |||

|---|---|---|---|---|

| Type | 200 Days | 1400 Days | 200 Days | 1400 Days |

| HP95 | 0.84 | 2.58 | 1.34 | 2.47 |

| HP90 | 1.09 | 2.23 | 1.60 | 4.66 |

| SL | 1.90 | 4.42 | 1.11 | 1.77 |

| HCL | 1.57 | 2.97 | 0.91 | 1.10 |

| CL | 1.53 | 3.13 | 1.80 | 4.57 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Navarro-Mendoza, E.G.; Alonso-Guzman, E.M.; Sanchez-Calvillo, A.; Bedolla-Arroyo, J.A.; Becerra-Santacruz, H.; Navarro-Ezquerra, A.; Gonzalez-Sanchez, B.; Martinez-Molina, W. Physical and Mechanical Characterization of Lime Pastes and Mortars for Use in Restoration. Heritage 2023, 6, 2582-2600. https://doi.org/10.3390/heritage6030136

Navarro-Mendoza EG, Alonso-Guzman EM, Sanchez-Calvillo A, Bedolla-Arroyo JA, Becerra-Santacruz H, Navarro-Ezquerra A, Gonzalez-Sanchez B, Martinez-Molina W. Physical and Mechanical Characterization of Lime Pastes and Mortars for Use in Restoration. Heritage. 2023; 6(3):2582-2600. https://doi.org/10.3390/heritage6030136

Chicago/Turabian StyleNavarro-Mendoza, Elena G., Elia M. Alonso-Guzman, Adria Sanchez-Calvillo, Juan A. Bedolla-Arroyo, Habid Becerra-Santacruz, Antonia Navarro-Ezquerra, Belén Gonzalez-Sanchez, and Wilfrido Martinez-Molina. 2023. "Physical and Mechanical Characterization of Lime Pastes and Mortars for Use in Restoration" Heritage 6, no. 3: 2582-2600. https://doi.org/10.3390/heritage6030136

APA StyleNavarro-Mendoza, E. G., Alonso-Guzman, E. M., Sanchez-Calvillo, A., Bedolla-Arroyo, J. A., Becerra-Santacruz, H., Navarro-Ezquerra, A., Gonzalez-Sanchez, B., & Martinez-Molina, W. (2023). Physical and Mechanical Characterization of Lime Pastes and Mortars for Use in Restoration. Heritage, 6(3), 2582-2600. https://doi.org/10.3390/heritage6030136