Contribution to Controlled Method of Varnish Removal from Easel Paintings by ns Pulsed Nd:YAG Laser

Abstract

:1. Introduction

2. Materials and Methods

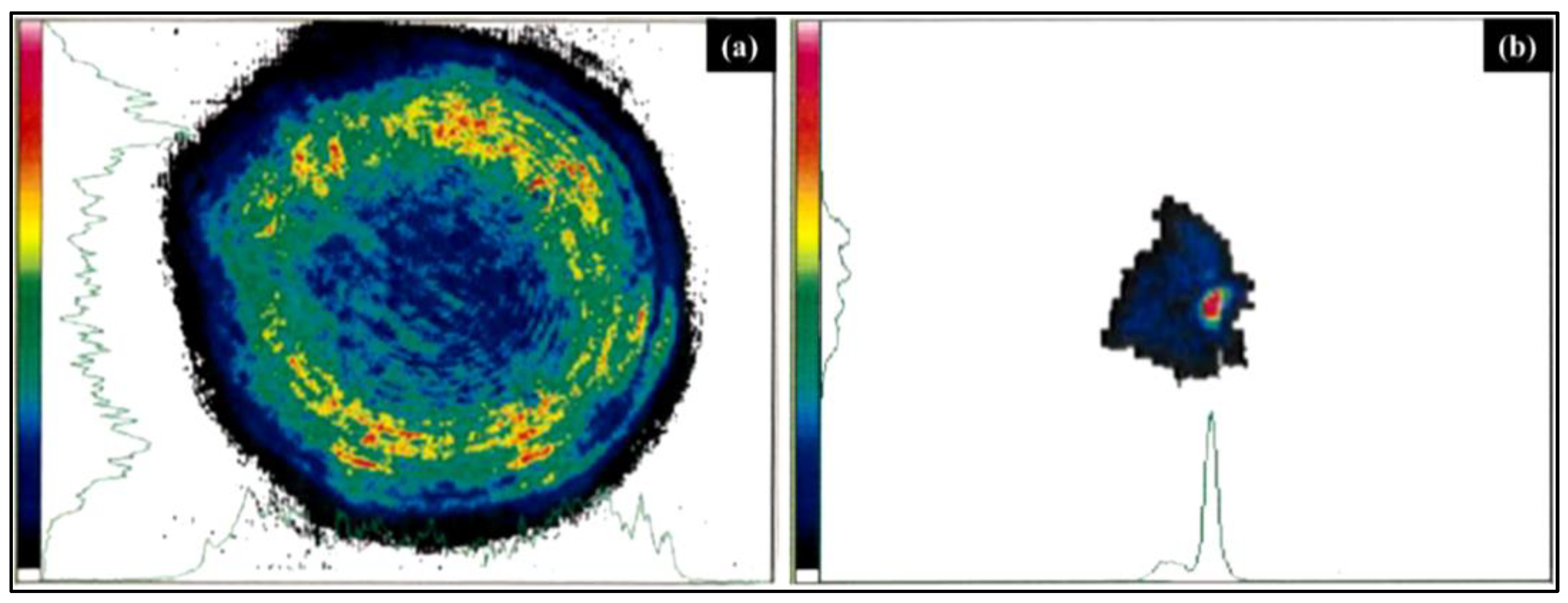

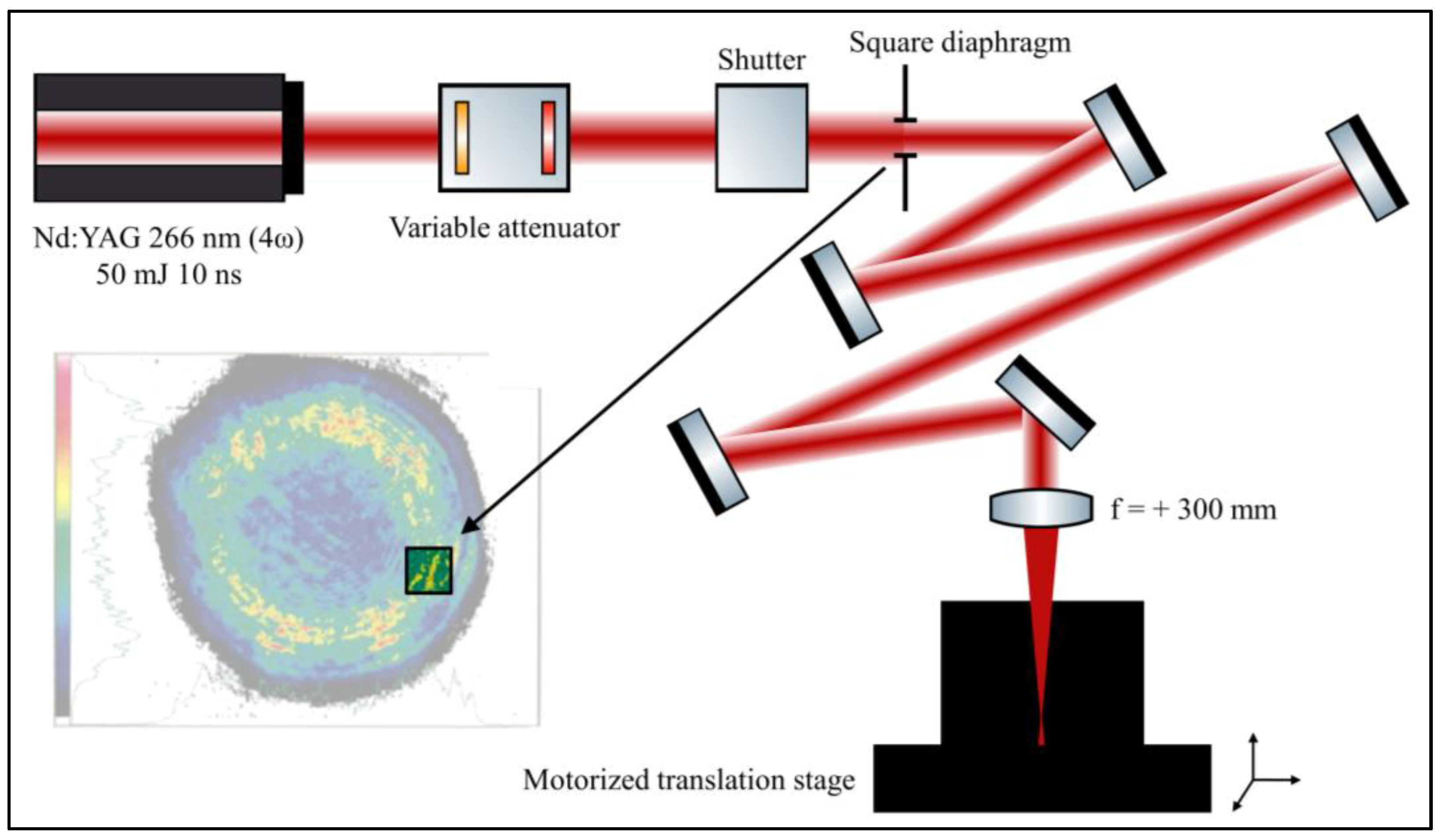

2.1. Optical Setups

2.2. Monitoring and Control

2.2.1. Optical Coherence Tomography

2.2.2. Laser-Induced Luminescence

2.3. Samples

- -

- A Philips Master TL-D 90 De Luxe 58W fluorescent tube (Amsterdam, the Netherlands), allowing the simulation of the daylight at noon (color T° = 6500 °K);

- -

- A Philips CLEO Performance 100 W fluorescent tube, emitting 99% of its radiation in the UVA range (between 310 and 400 nm) and 1% in the UVB range (between 280 and 315 nm) to simulate UV exposure in normal museum conditions.

3. Results

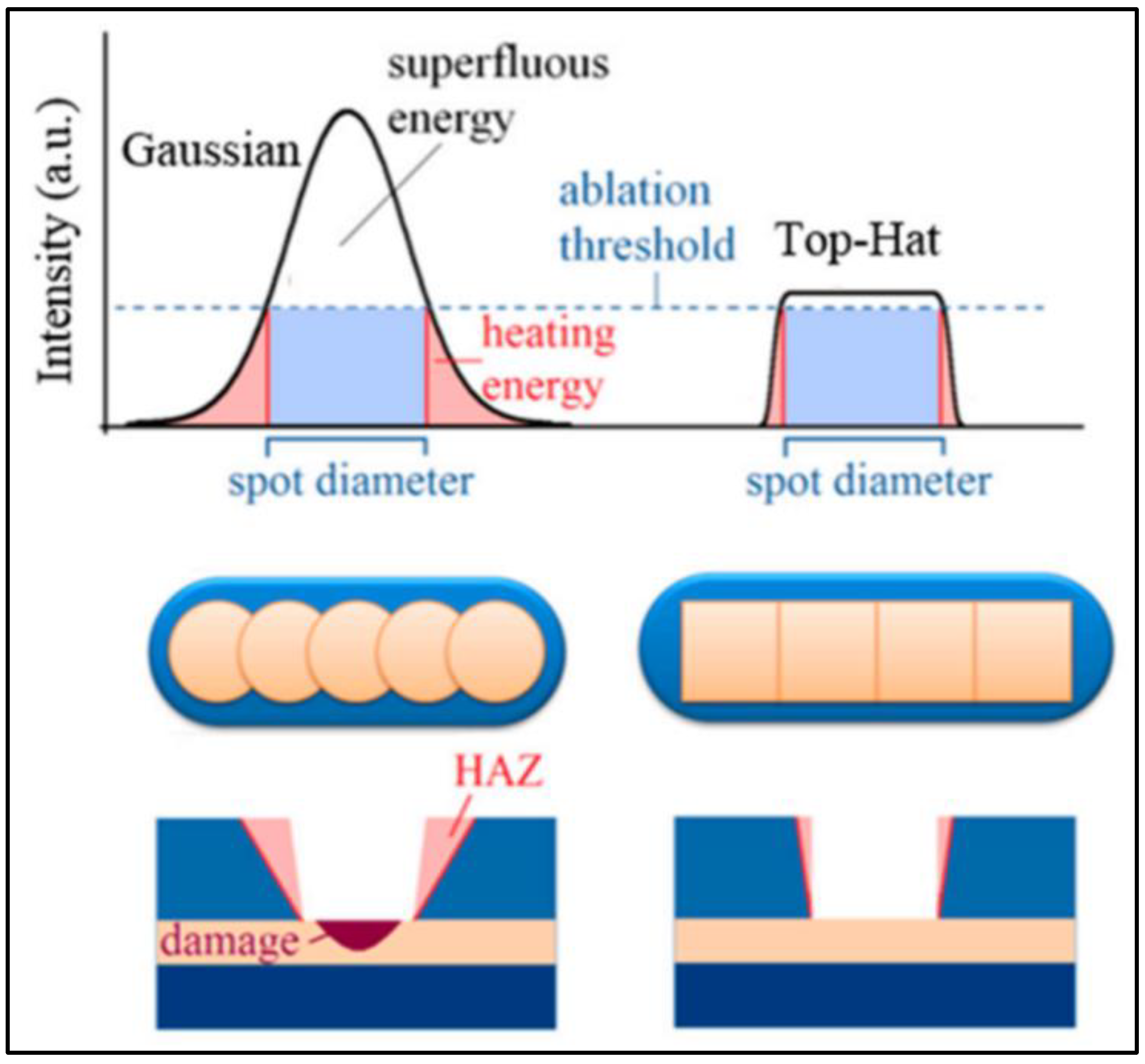

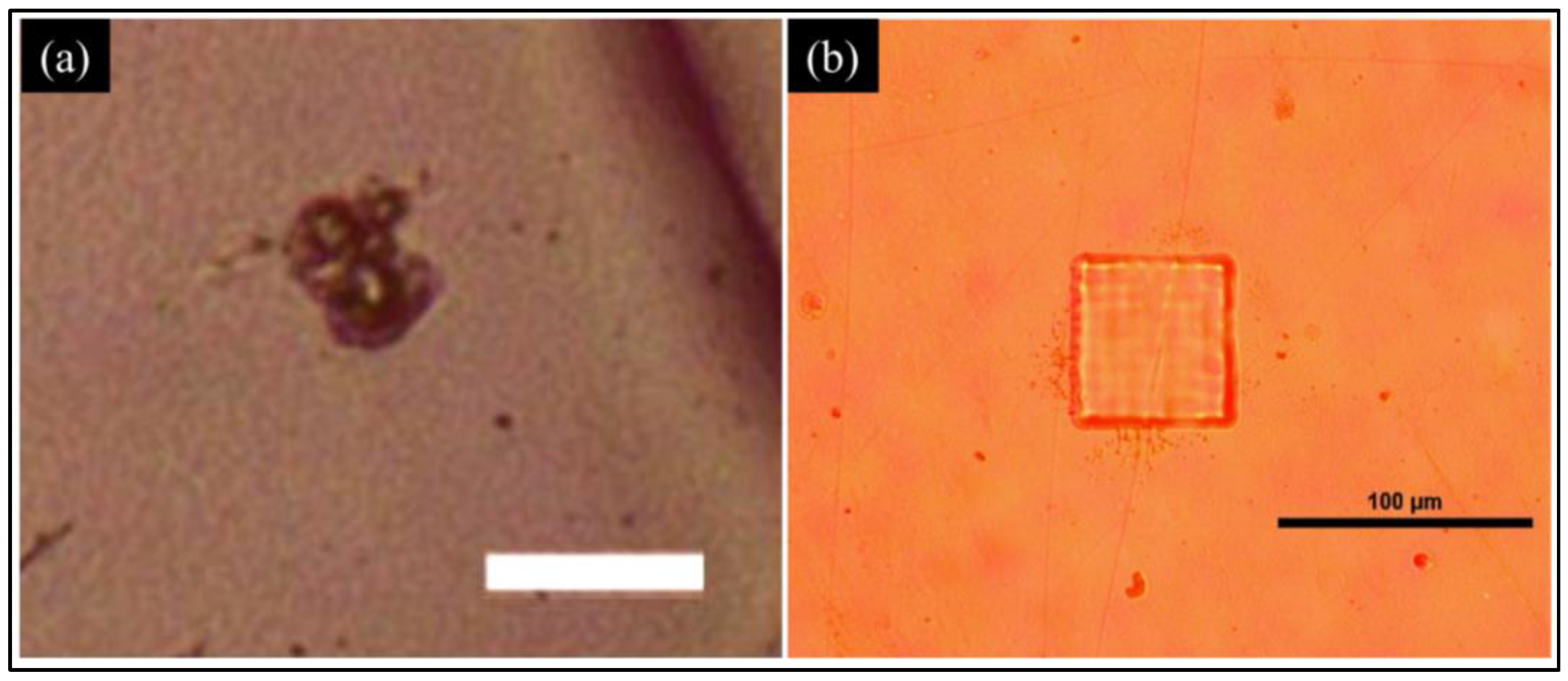

3.1. Optimization of Laser Ablation

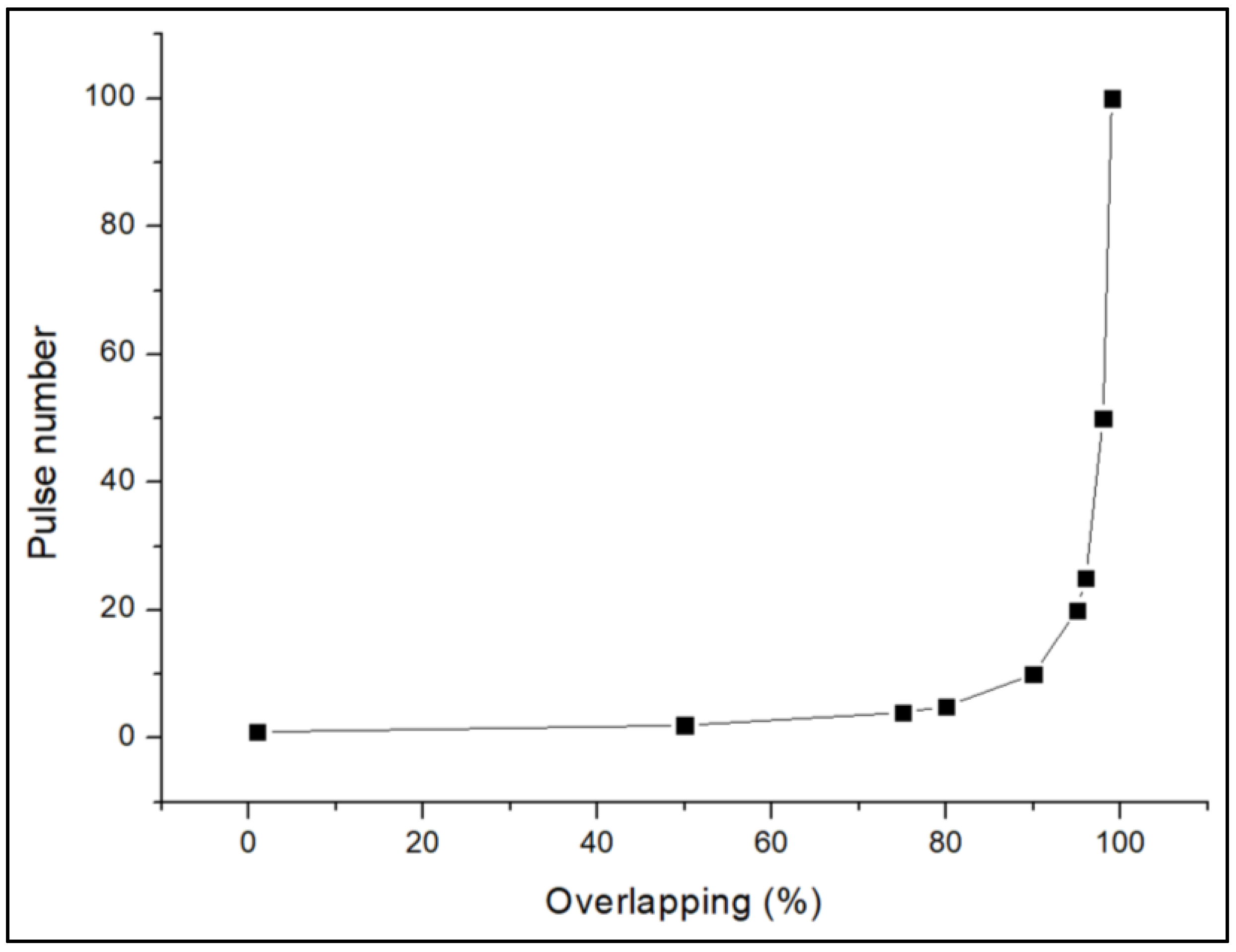

3.2. Overlapping Rate

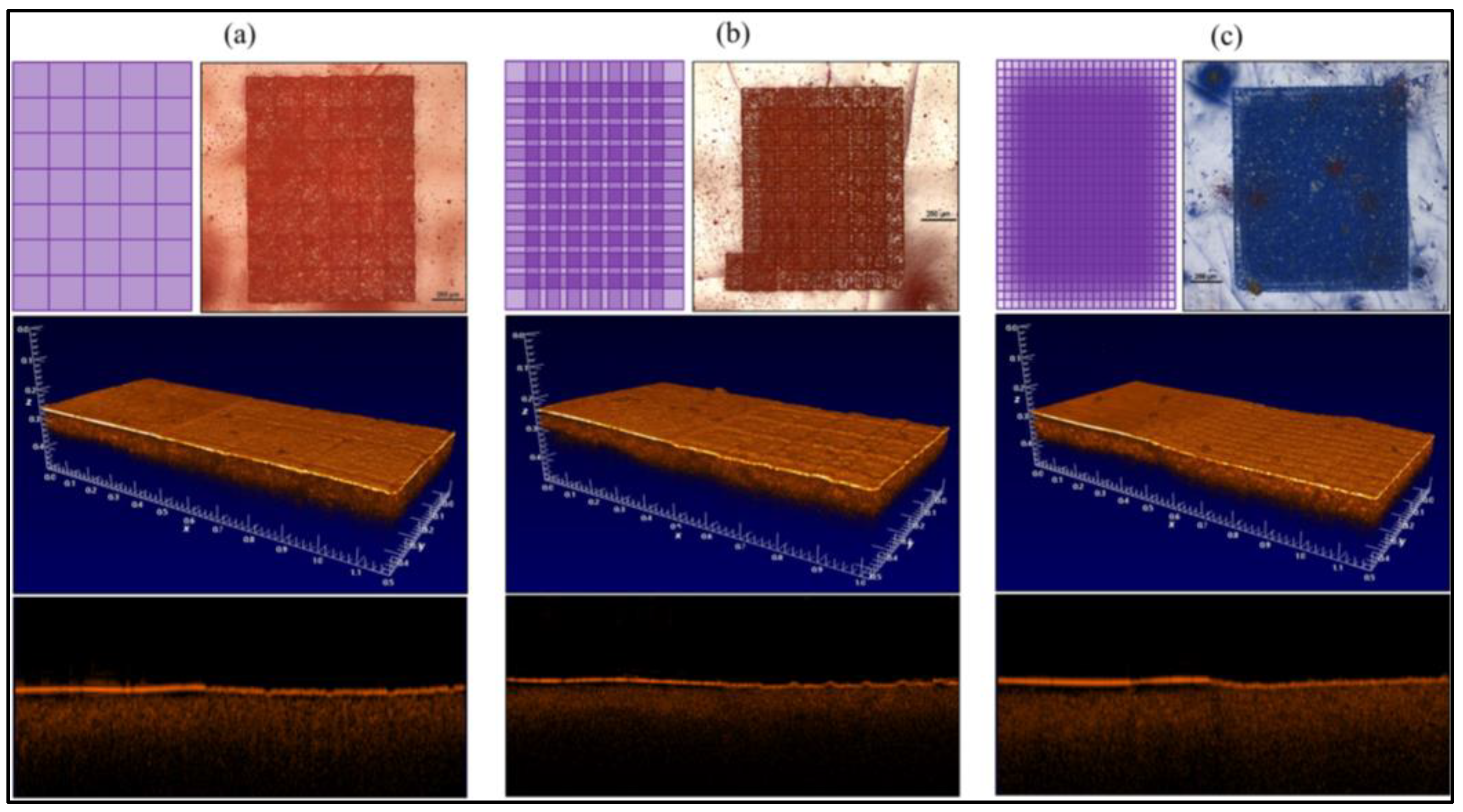

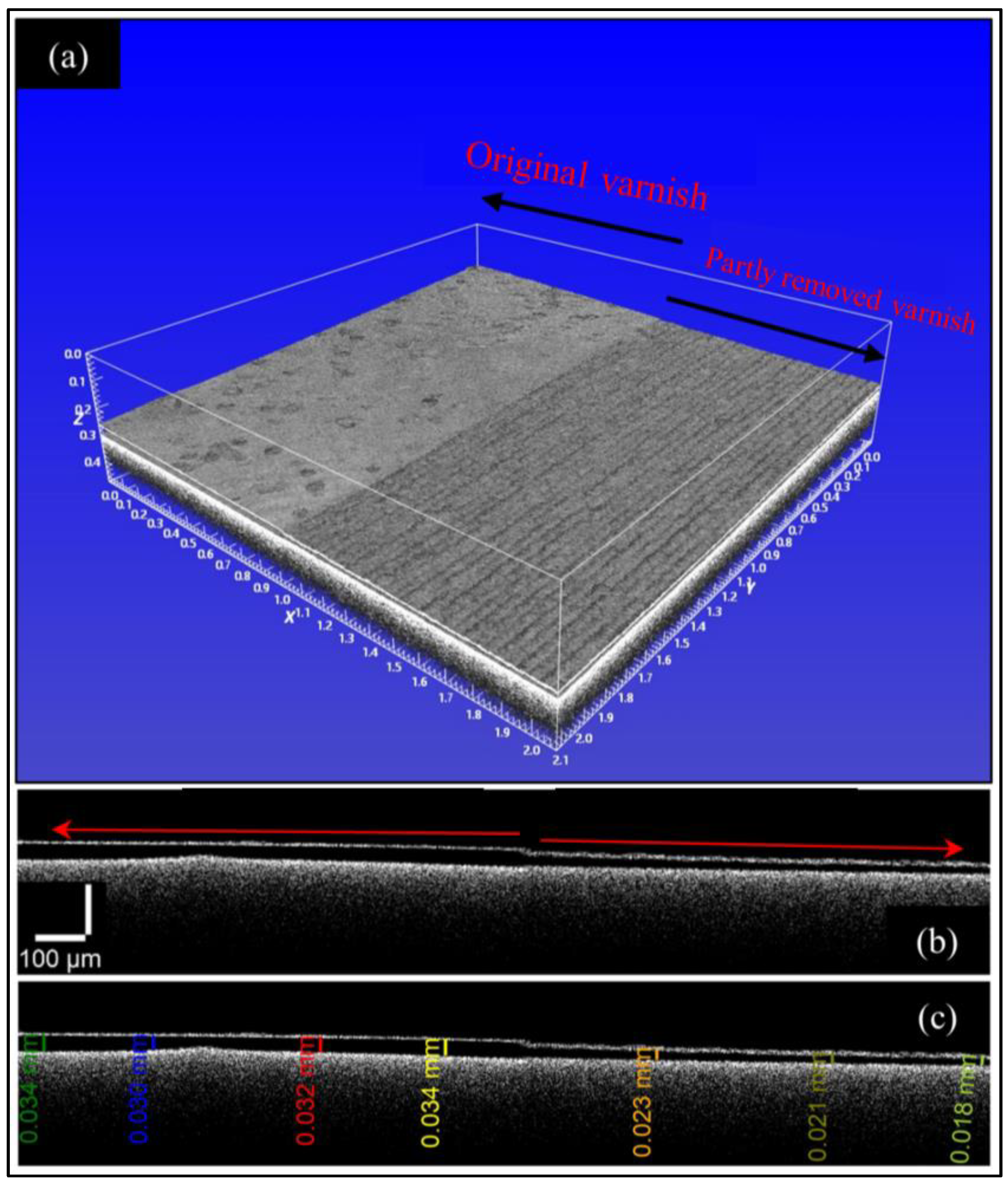

3.3. Calibration of Laser Ablation of Varnish

3.4. Controlled Laser Removal of Dammar Varnish

3.5. Spectroscopic Assessment of Remaining Material

3.6. Opacification of Varnish after Laser Ablation

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hontzopoulos, E.I.; Fotakis, C.; Doulgeridis, M. Excimer laser in art restoration. In 9th International Symposium on Gas Flow and Chemical Lasers; SPIE: Bellingham, WA, USA, 1993; Volume 1810. [Google Scholar] [CrossRef]

- Fotakis, C. Lasers for Art’s Sake! Opt. Photon-News 1995, 6, 30. [Google Scholar] [CrossRef]

- Castillejo, M.; Martín, M.; Oujja, M.; Silva, D.; Torres, R.; Manousaki, A.; Zafiropulos, V.; Brink, O.F.V.D.; Heeren, R.M.A.; Teule, R.; et al. Analytical Study of the Chemical and Physical Changes Induced by KrF Laser Cleaning of Tempera Paints. Anal. Chem. 2002, 74, 4662–4671. [Google Scholar] [CrossRef] [PubMed]

- Vounisiou, P.; Selimis, A.; Tserevelakis, G.J.; Melessanaki, K.; Pouli, P.; Filippidis, G.; Beltsios, C.; Georgiou, S.; Fotakis, C. The use of model probes for assessing in depth modifications induced during laser cleaning of modern paintings. Appl. Phys. A 2010, 100, 647–652. [Google Scholar] [CrossRef]

- Zergioti, I.; Petrakis, A.; Zafiropulos, V.; Fotakis, C.; Fostiridou, A.; Doulgeridis, M. Laser applications in painting conservation. In Proceedings of the Lacona I: Lasers in the Conservation of Artworks, Workshop, Heraklion, Greece, 4–6 October 1995; pp. 57–60. [Google Scholar]

- Fotakis, C.; Anglos, D.; Couris, S.; Georgiou, S.; Zafiropulos, V.; Zergioti, I. Laser technology in art conservation. AIP Conf. Proc. 1997, 388, 183–190. [Google Scholar] [CrossRef]

- Fotakis, C.; Zafiropulos, V.; Tornari, V.; Anglos, D.; Balas, C.J.; Georgiou, S.K.; Zergioti, I. Lasers in the conservation of painted artworks. In Second GR-I International Conference on New Laser Technologies and Applications; SPIE: Bellingham, WA, USA, 1998. [Google Scholar]

- Georgiou, S.; Zafiropulos, V.; Anglos, D.; Balas, C.; Tornari, V.; Fotakis, C. Excimer laser restoration of painted artworks: Procedures, mechanisms and effects. Appl. Surf. Sci. 1998, 127–129, 738–745. [Google Scholar] [CrossRef]

- Sansonetti, A.; Realini, M. Nd:YAG laser effects on inorganic pigments. J. Cult. Heritage 2000, 1, S189–S198. [Google Scholar] [CrossRef]

- Pouli, P.; Emmony, D. The effect of Nd:YAG laser radiation on medieval pigments. J. Cult. Heritage 2000, 1, S181–S188. [Google Scholar] [CrossRef]

- Pouli, P.; Emmony, D.; Madden, C.; Sutherland, I. Analysis of the laser-induced reduction mechanisms of medieval pigments. Appl. Surf. Sci. 2001, 173, 252–261. [Google Scholar] [CrossRef]

- Oujja, M.; García, A.; Romero, C.; de Aldana, J.R.V.; Moreno, P.; Castillejo, M. UV laser removal of varnish on tempera paints with nanosecond and femtosecond pulses. Phys. Chem. Chem. Phys. 2011, 13, 4625–4631. [Google Scholar] [CrossRef] [Green Version]

- Ciofini, D.; Oujja, M.; Cañamares, M.V.; Siano, S.; Castillejo, M. Spectroscopic assessment of the UV laser removal of varnishes from painted surfaces. Microchem. J. 2016, 124, 792–803. [Google Scholar] [CrossRef] [Green Version]

- Sutcliffe, E.; Srinivasan, R. Dynamics of UV laser ablation of organic polymer surfaces. J. Appl. Phys. 1986, 60, 3315–3322. [Google Scholar] [CrossRef]

- Srinivasan, R.; Braren, B. Ultraviolet laser ablation of organic polymers. Chem. Rev. 1989, 89, 1303–1316. [Google Scholar] [CrossRef]

- Zafiropulos, V. Laser Ablation In Cleaning of Artworks. In Laser Cleaning; World Scientific: Singapore, 2022. [Google Scholar] [CrossRef]

- Rung, S.; Barth, J.; Hellmann, R. Characterization of Laser Beam Shaping Optics Based on Their Ablation Geometry of Thin Films. Micromachines 2014, 5, 943–953. [Google Scholar] [CrossRef]

- Dickey, F.M.; Weichman, L.S.; Shagam, R.N. Laser beam shaping techniques. In High-Power Laser Ablation III; SPIE: Bellingham, WA, USA, 2000; Volume 4065. [Google Scholar] [CrossRef]

- Popescu, D.P.; Choo-Smith, L.-P.; Flueraru, C.; Mao, Y.; Chang, S.; Disano, J.; Sherif, S.; Sowa, M. Optical coherence tomography: Fundamental principles, instrumental designs and biomedical applications. Biophys. Rev. 2011, 3, 155–169. [Google Scholar] [CrossRef] [PubMed]

- Targowski, P.; Iwanicka, M. Optical Coherence Tomography: Its role in the non-invasive structural examination and conservation of cultural heritage objects—A review. Appl. Phys. A 2011, 106, 265–277. [Google Scholar] [CrossRef] [Green Version]

- Targowski, P.; Kowalska, M.; Sylwestrzak, M.; Iwanicka, M. OCT for Examination of Cultural Heritage Objects. In Optical Coherence Tomography and Its Non-medical Applications; IntechOpen: London, UK, 2022. [Google Scholar] [CrossRef]

- Góra, M.; Targowski, P.; Rycyk, A.; Marczak, J. Varnish Ablation Control by Optical Coherence Tomography. Laser Chem. 2006, 2006, 010647. [Google Scholar] [CrossRef] [Green Version]

- Oujja, M.; Psilodimitrakopoulos, S.; Carrasco, E.; Sanz, M.; Philippidis, A.; Selimis, A.; Pouli, P.; Filippidis, G.; Castillejo, M. Nonlinear imaging microscopy for assessing structural and photochemical modifications upon laser removal of dammar varnish on photosensitive substrates. Phys. Chem. Chem. Phys. 2017, 19, 22836–22843. [Google Scholar] [CrossRef] [Green Version]

- Siano, S.; Salimbeni, R. Advances in Laser Cleaning of Artwork and Objects of Historical Interest: The Optimized Pulse Duration Approach. Accounts Chem. Res. 2010, 43, 739–750. [Google Scholar] [CrossRef]

- De La Rie, E.R. Photochemical and thermal degradation of films of dammar resin. Stud. Conserv. 1988, 33, 53–70. [Google Scholar] [CrossRef]

- Nevin, A.; Anglos, D. Assisted Interpretation of Laser-Induced Fluorescence Spectra of Egg-Based Binding Media Using Total Emission Fluorescence Spectroscopy. Laser Chem. 2006, 2006, 82823. [Google Scholar] [CrossRef] [Green Version]

- Arslanoglu, J.; Learner, T. The evaluation of Laropal A81: Paraloid B-72 polymer blend varnishes for painted and decorative surfaces-appearance and practical considerations. Conservator 2001, 25, 62–72. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lopez, M.; Bai, X.; Wilkie-Chancellier, N.; Detalle, V. Contribution to Controlled Method of Varnish Removal from Easel Paintings by ns Pulsed Nd:YAG Laser. Heritage 2023, 6, 3307-3323. https://doi.org/10.3390/heritage6030175

Lopez M, Bai X, Wilkie-Chancellier N, Detalle V. Contribution to Controlled Method of Varnish Removal from Easel Paintings by ns Pulsed Nd:YAG Laser. Heritage. 2023; 6(3):3307-3323. https://doi.org/10.3390/heritage6030175

Chicago/Turabian StyleLopez, Maxime, Xueshi Bai, Nicolas Wilkie-Chancellier, and Vincent Detalle. 2023. "Contribution to Controlled Method of Varnish Removal from Easel Paintings by ns Pulsed Nd:YAG Laser" Heritage 6, no. 3: 3307-3323. https://doi.org/10.3390/heritage6030175

APA StyleLopez, M., Bai, X., Wilkie-Chancellier, N., & Detalle, V. (2023). Contribution to Controlled Method of Varnish Removal from Easel Paintings by ns Pulsed Nd:YAG Laser. Heritage, 6(3), 3307-3323. https://doi.org/10.3390/heritage6030175