Interdisciplinary Analysis and the Role of Experiments in Raw Materials and Technology Identification for Prehistoric Pottery in the Bistrița River Basin (Romania)

Abstract

:1. Introduction

2. Materials and Methods

2.1. The Archaeological Context and Discoveries from the Siliştea-Pe Cetățuie Settlement

2.2. Materials and Sample Preparation Methodology

2.3. Analytical Methods

3. Results and Discussions

3.1. Results and Discussions Regarding the Costișa and Monteoru Ceramic Fragments

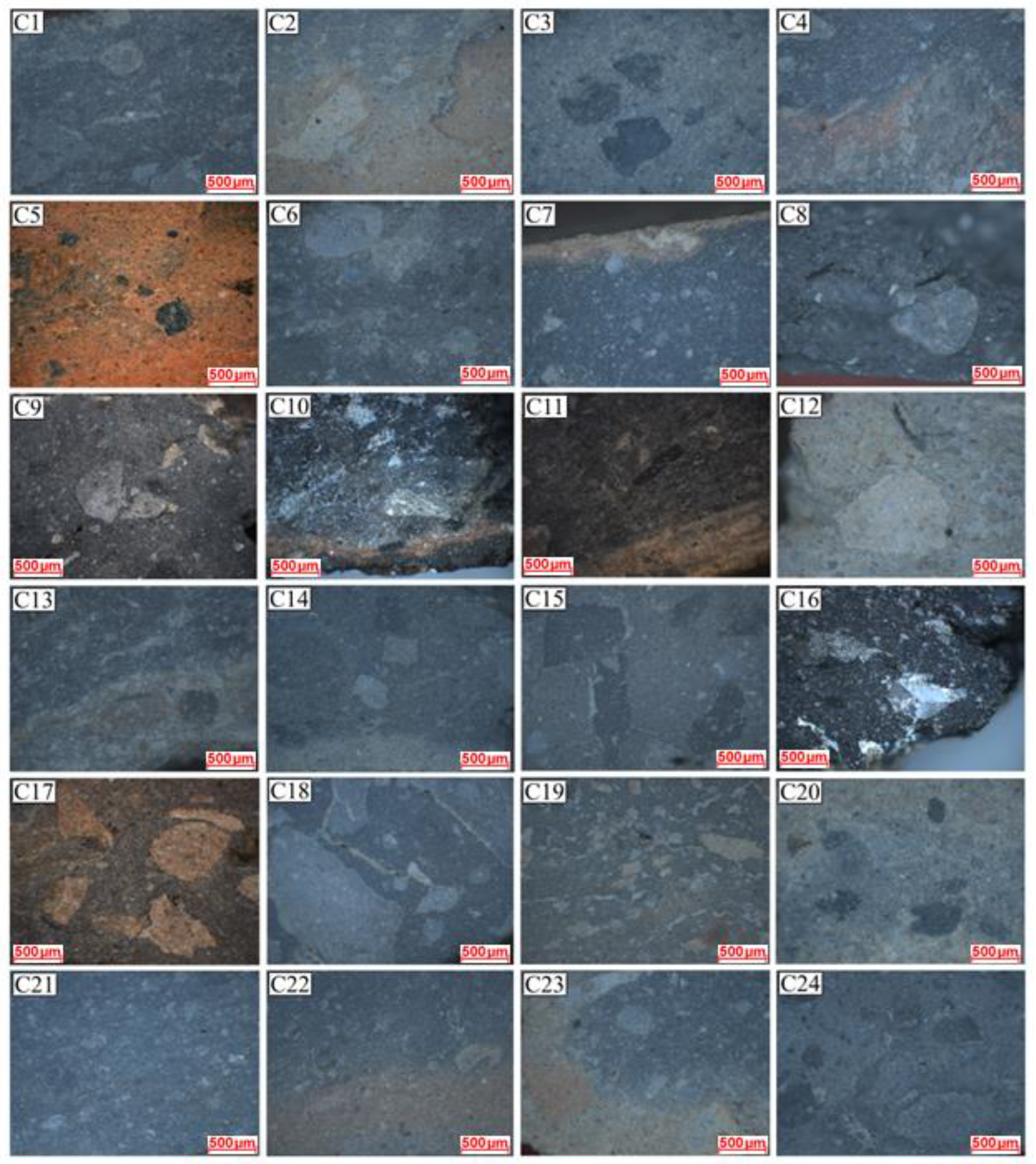

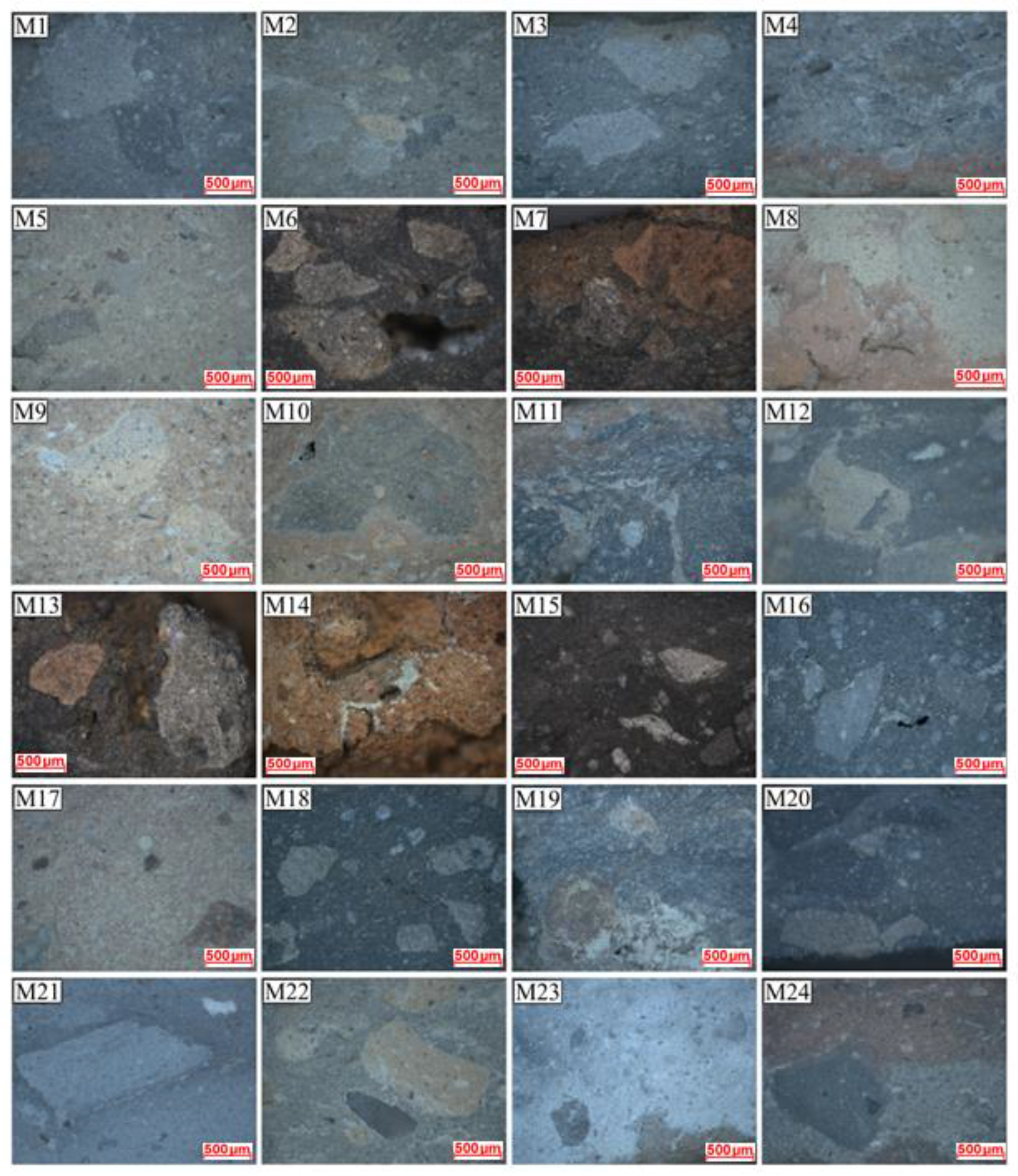

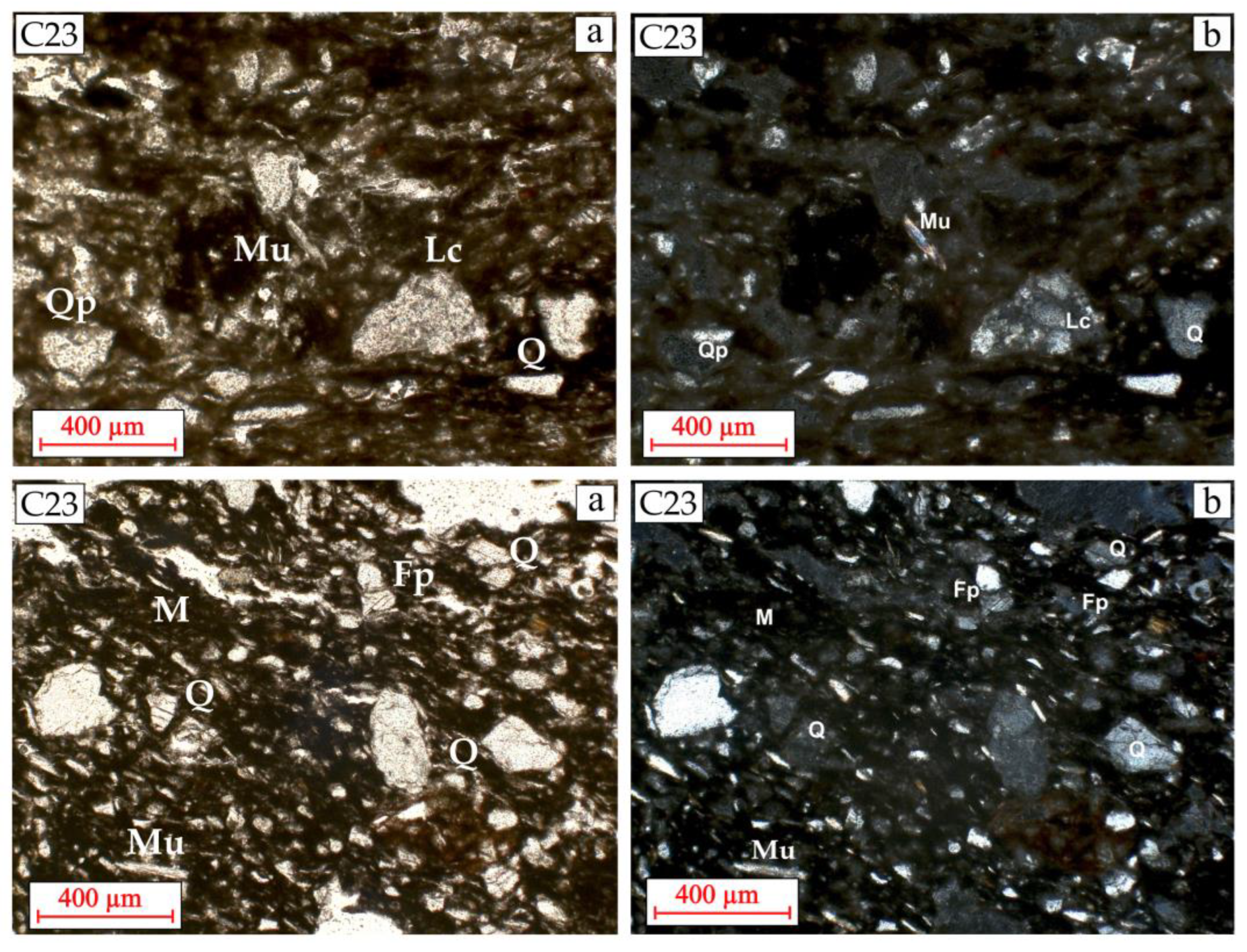

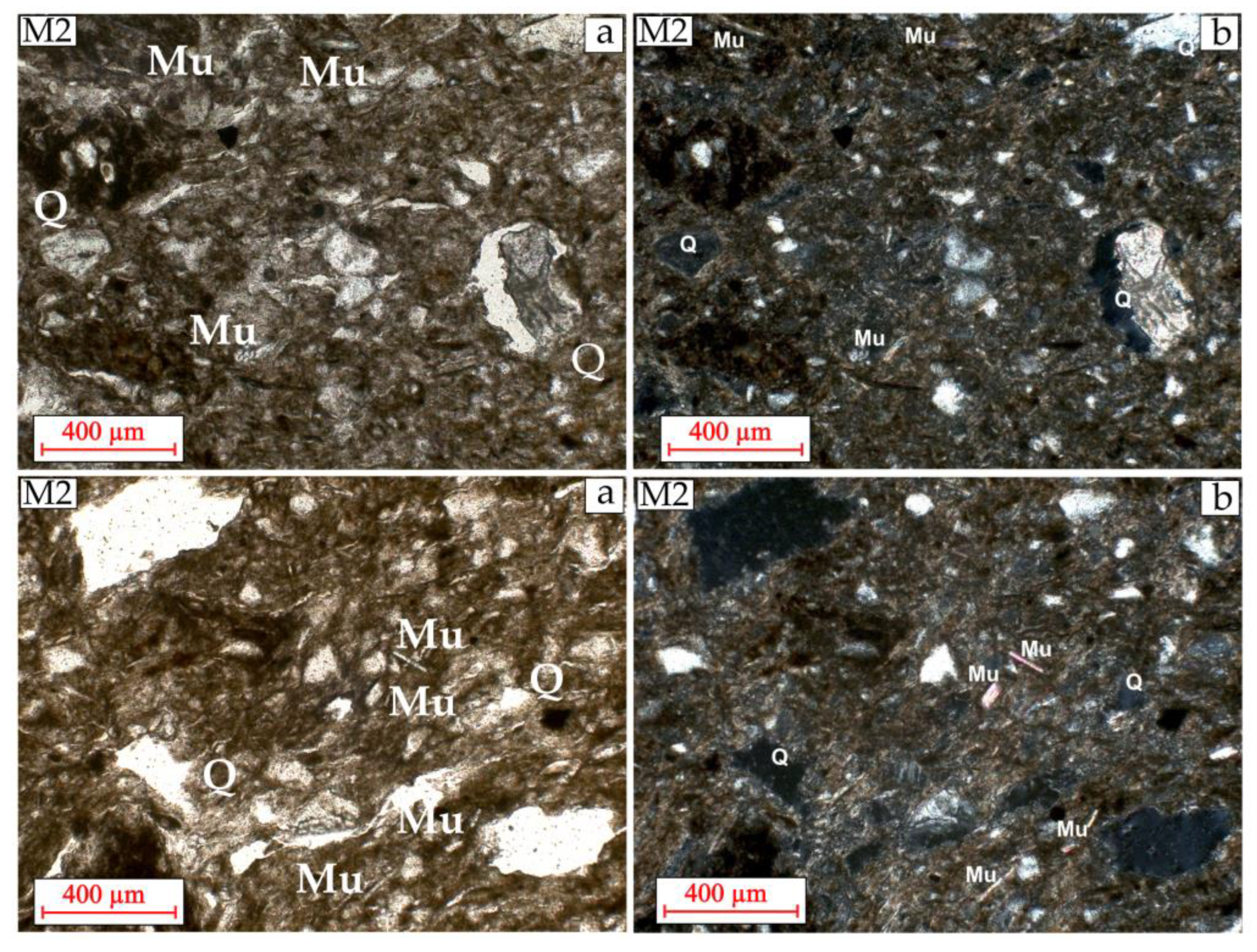

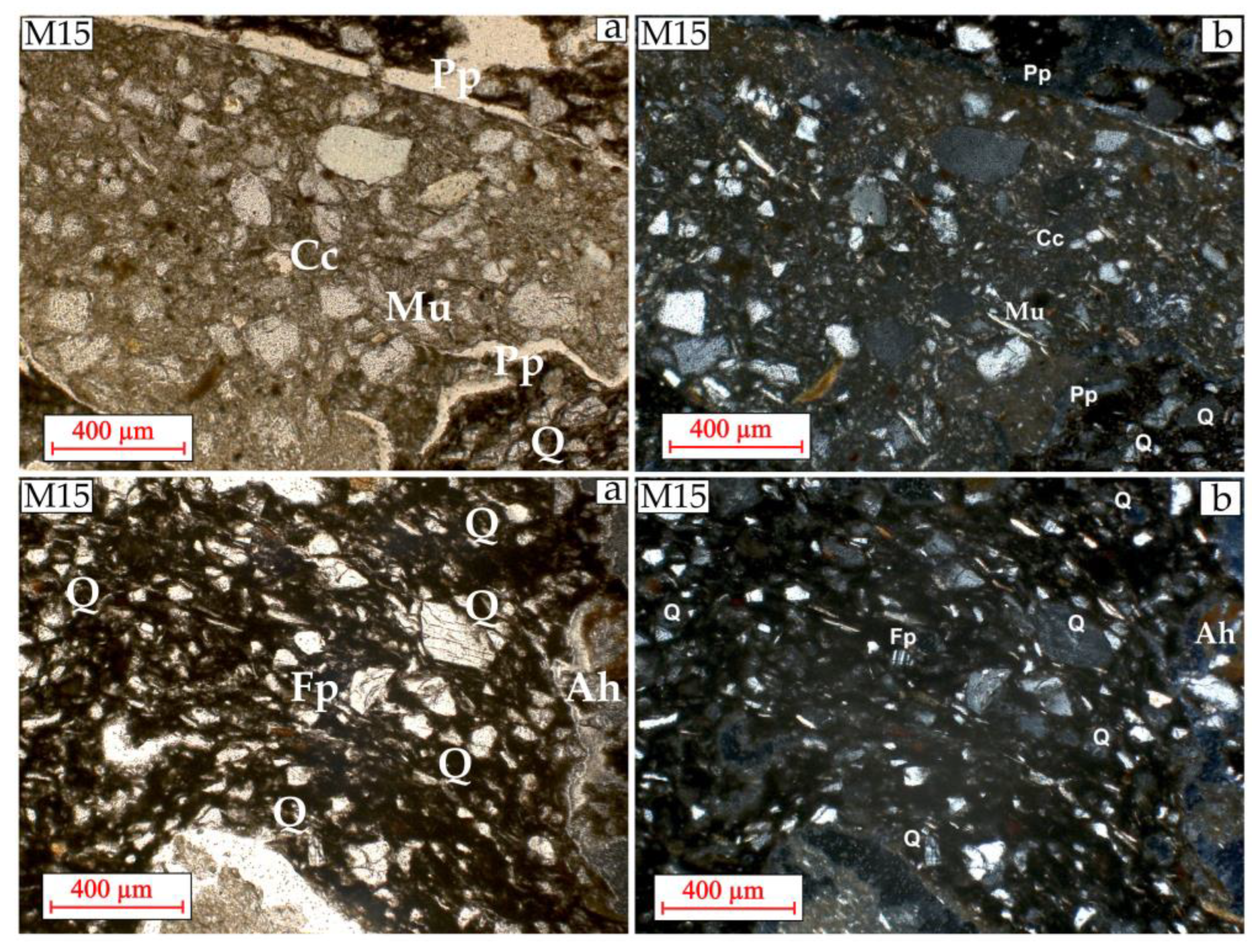

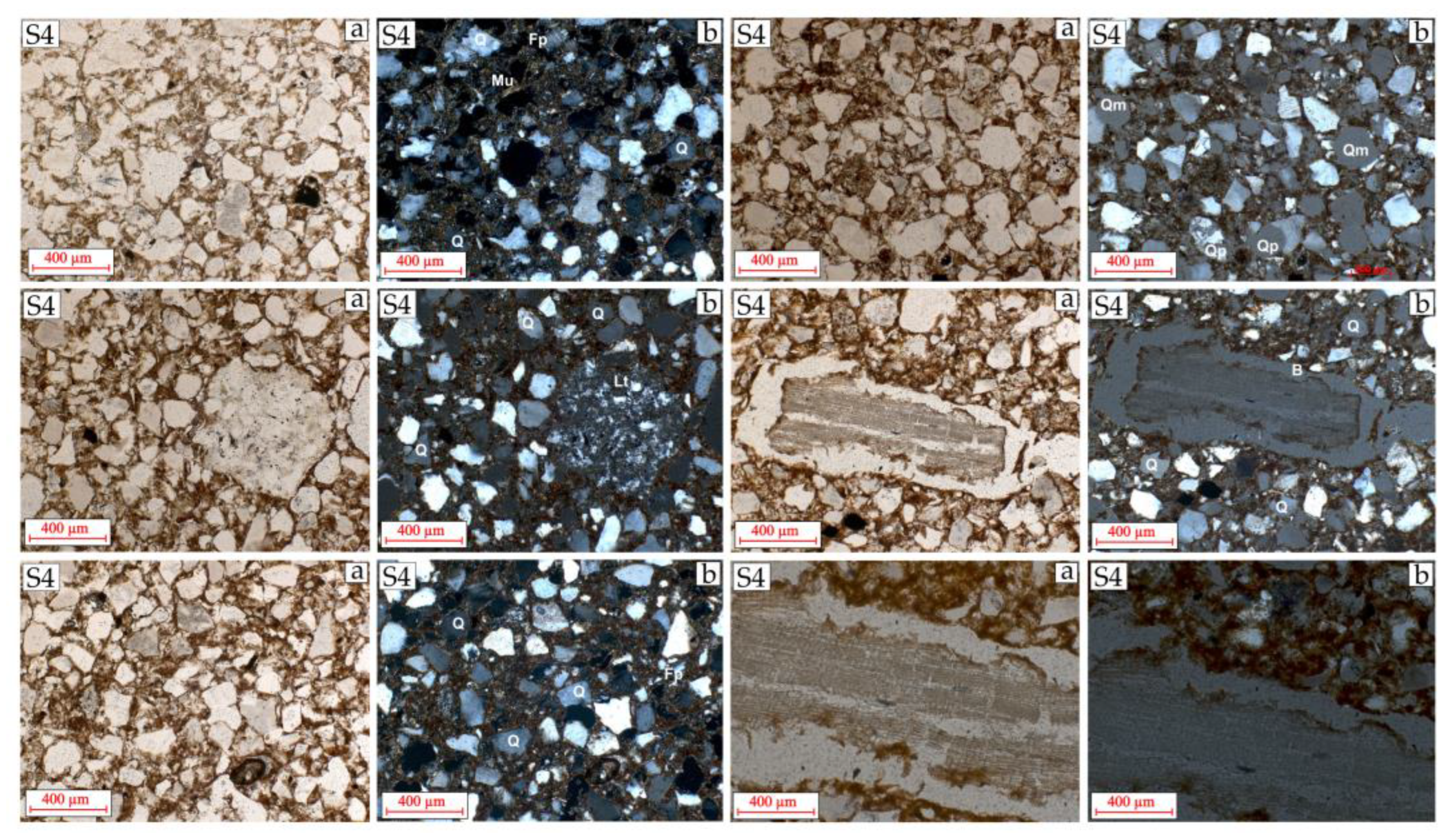

3.1.1. Microscopic Analysis

3.1.2. Mineralogical Analysis

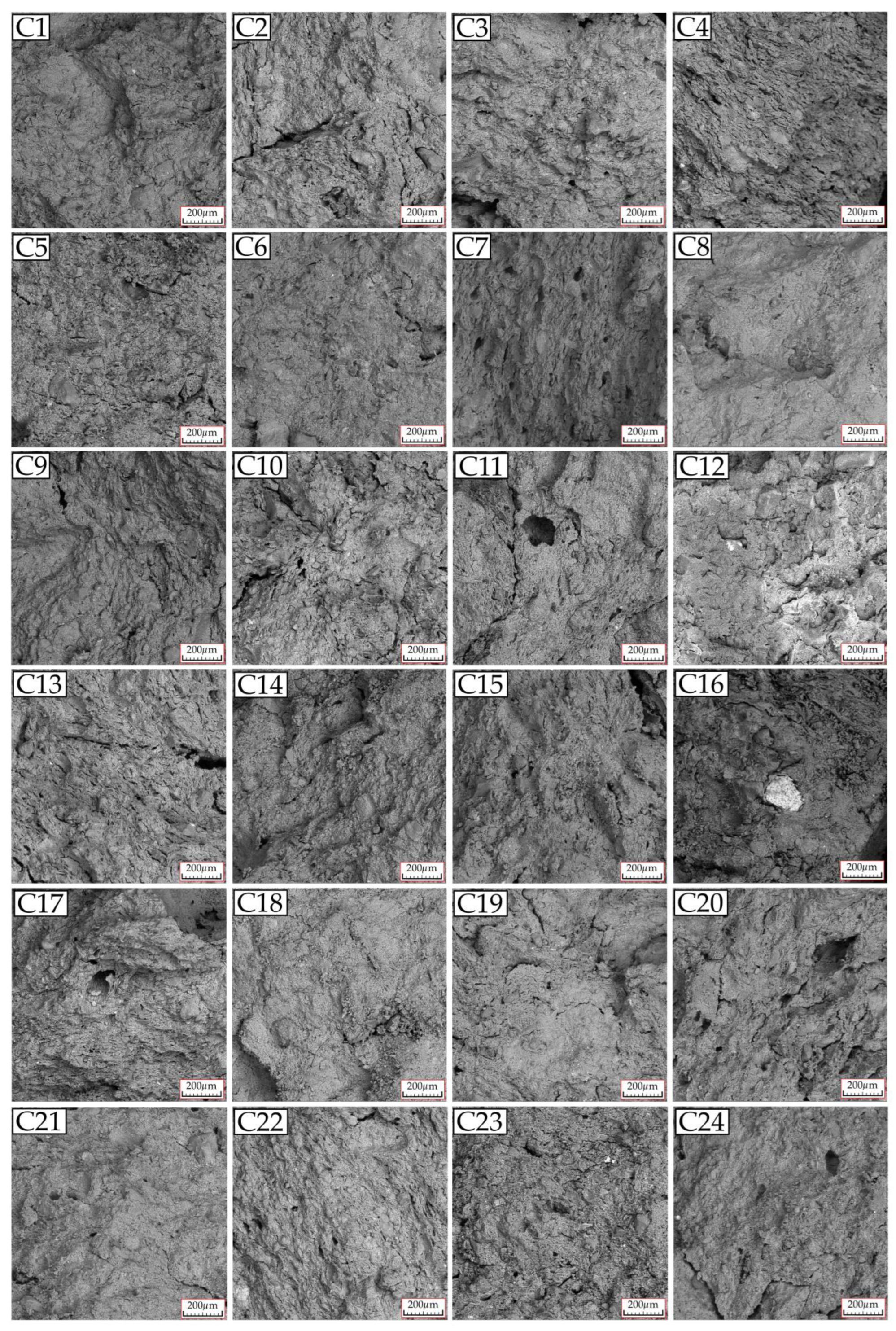

3.1.3. SEM-EDX Analysis

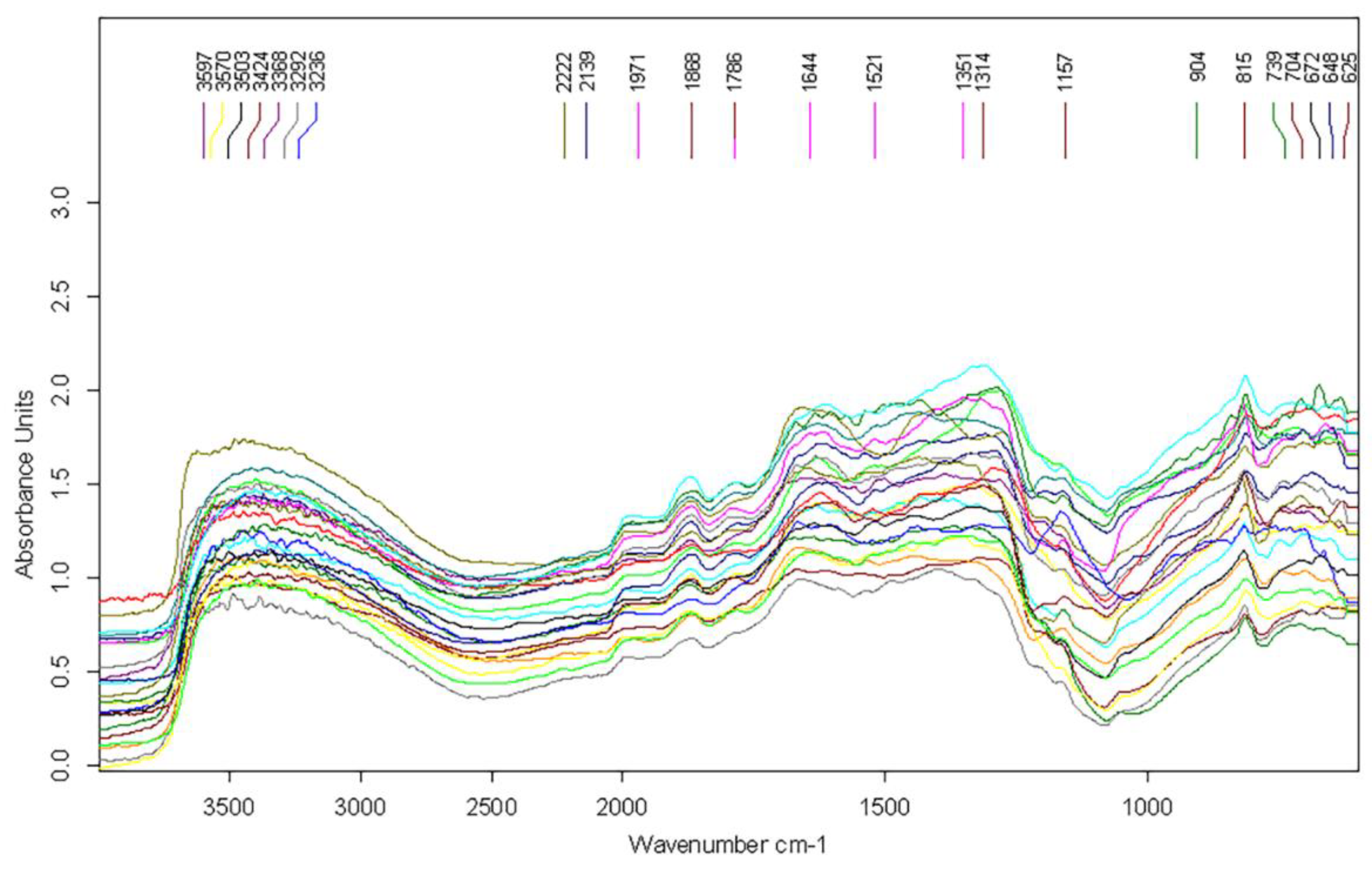

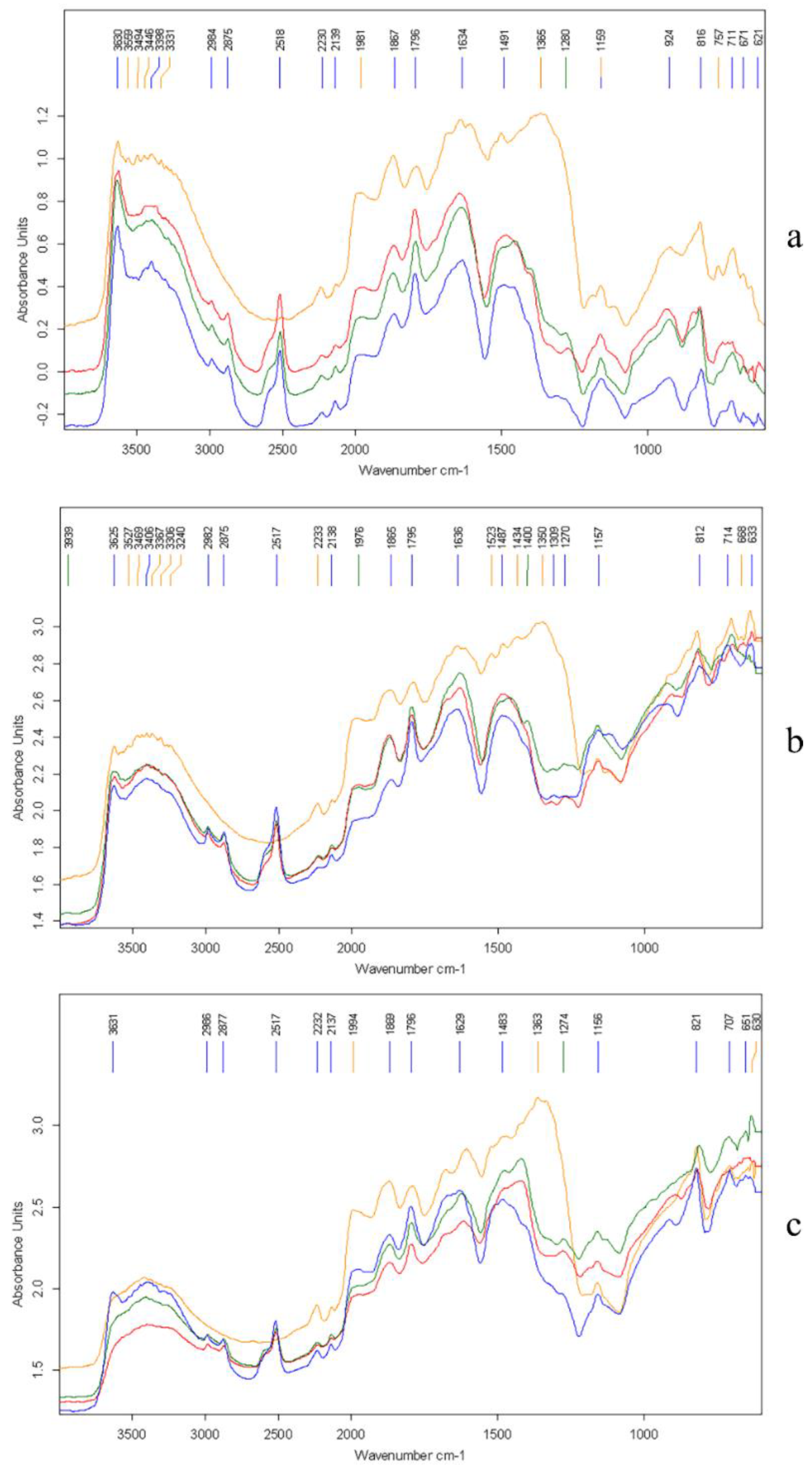

3.1.4. μ-FTIR Analysis

3.2. The Experiment’s Results and Discussion

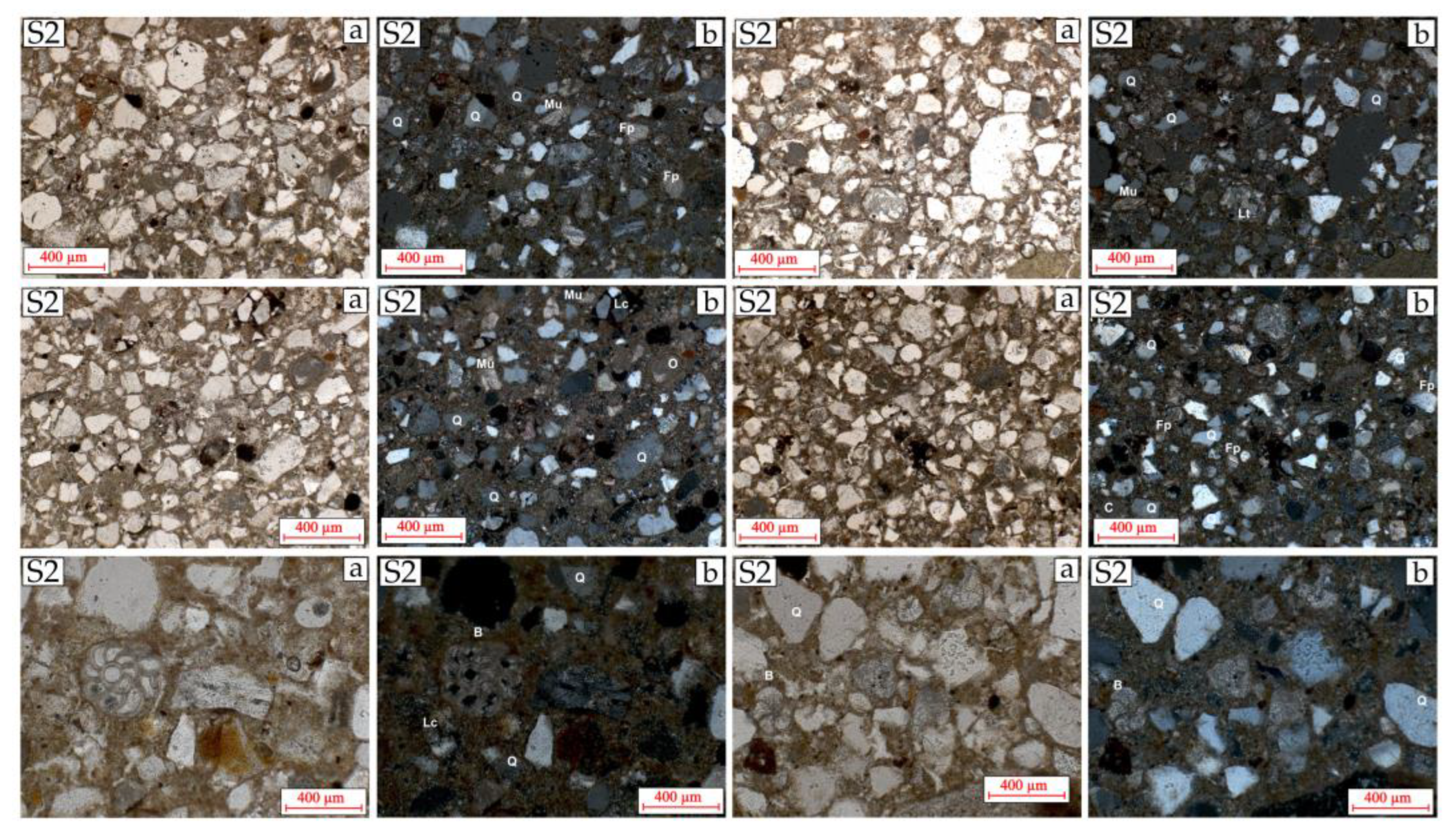

3.2.1. Optical Microscopy and Mineralogy Analysis

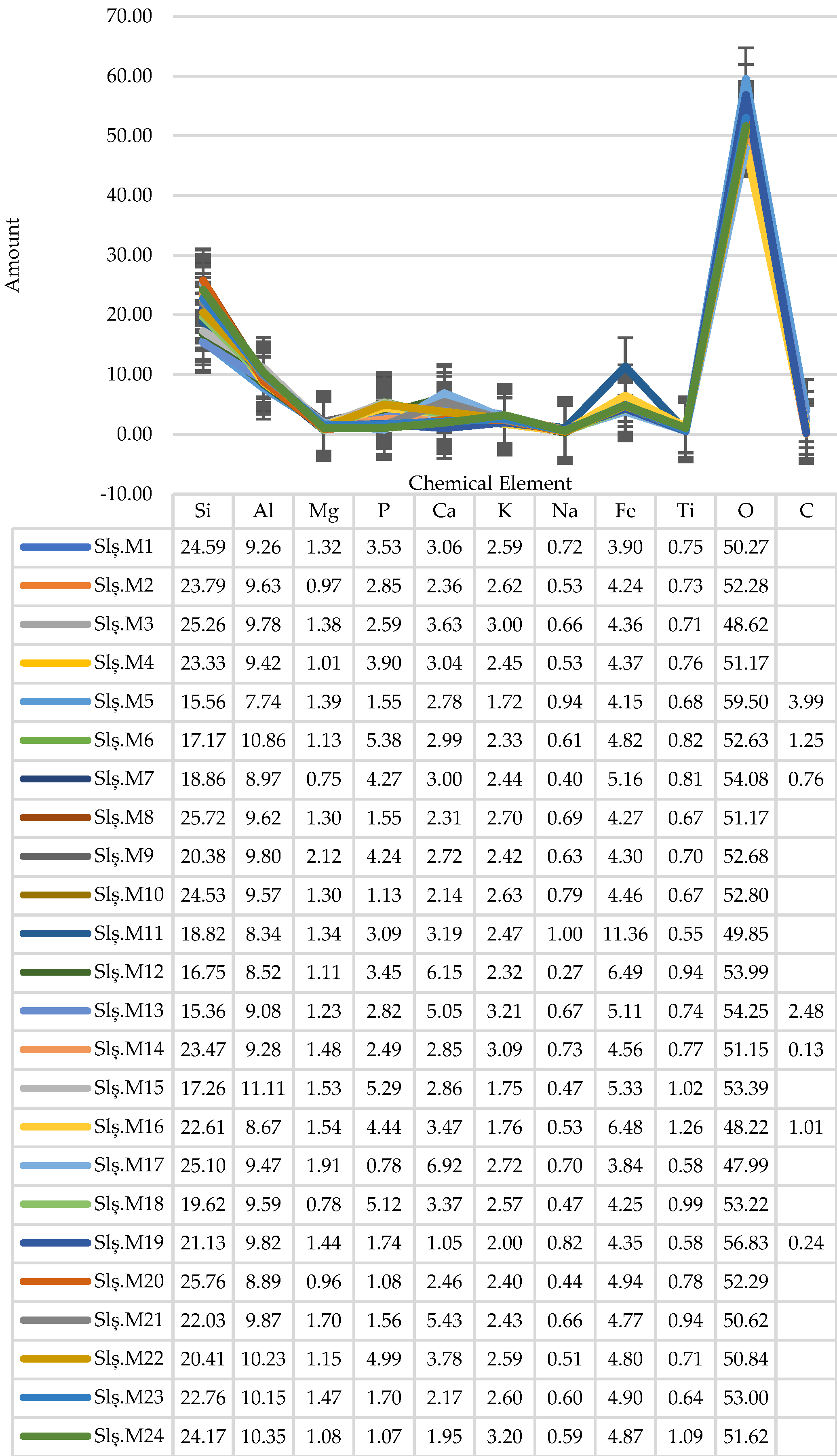

3.2.2. EDX Analysis

3.2.3. μ-FTIR Analysis

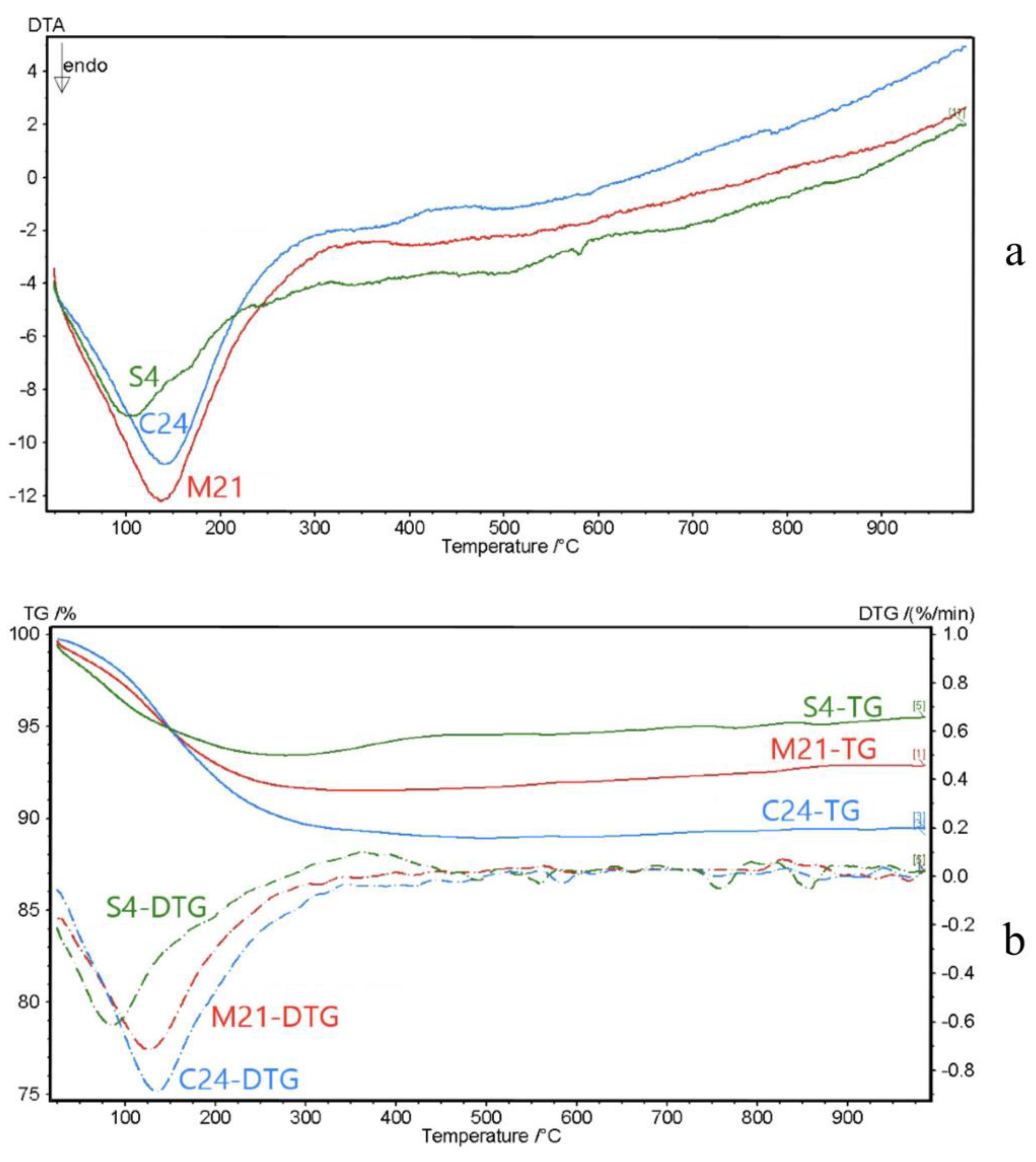

3.2.4. Thermal Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gliozzo, E. Ceramics investigation: Research questions and sampling criteria. Archaeol. Anthropol. Sci. 2020, 12, 202. [Google Scholar] [CrossRef]

- Montana, G. Ceramic raw materials: How to recognize them and locate the supply basins—Mineralogy, petrography. Archaeol. Anthropol. Sci. 2020, 12, 175. [Google Scholar] [CrossRef]

- Drob, A. Analiza Interdisciplinară a Olăriei Bronzului Mijlociu din Bazinul Bistriței. Ph.D. Thesis, Alexandru Ioan Cuza University, Iași, Romania, 2024. [Google Scholar]

- Koutouvaki, E.; Amicone, S.; Kristew, A.; Ștefan, C.E.; Berthold, C. Shared traditions and shard conservatism: Pottery making at the Chalcolithic site of Radovanu (Romania). Archaeol. Anthropol. Sci. 2021, 13, 206. [Google Scholar] [CrossRef]

- Gualtieri, S. Ceramic raw materials: How to establish the technological suitability of a raw material. Archaeol. Anthropol. Sci. 2020, 12, 183. [Google Scholar] [CrossRef]

- Hein, A.; Kilikoglou, V. Ceramic raw materials: How to recognize them and locate the supply basins: Chemistry. Archaeol. Anthropol. Sci. 2020, 12, 180. [Google Scholar] [CrossRef]

- Ménager, M.; Esquivel, P.F.; Conejo, P.S. The use of FT-IR spectroscopy and SEM/EDS characterization of slips and pigments to determine the provenances of archaeological ceramics: The case of Guanacaste ceramics (Costa Rica). Microchem. J. 2021, 162, 105838. [Google Scholar] [CrossRef]

- Bolohan, N.; Munteanu, R.; Dumitroaia, G. Siliștea, com. Români, jud. Neamț, CCA (Campania 2000), 2001, București, 229. Available online: https://cronica.cimec.ro/detaliu.asp?k=1127 (accessed on 1 June 2024).

- Bolohan, N. “All in one”. Issues of Methodology, Paradigms and radiocarbon Datings Concerning the Outer Eastern Carpathian Area. In Signa Praehistorica. Studia in Honorem Magistri Attila László Septuagesimo Anno. Honoraria, 9th ed.; Bolohan, N., Mățău, F., Tencariu, A.-F., Eds.; Alexandru Ioan Cuza University: Iași, Romania, 2010; pp. 229–244. [Google Scholar]

- Bolohan, N. Settlement system during Middle Bronze Age in the south-western area of the Cracău-Bistrița basin, eastern Romania. In Prehistroic Settlements: Social, Economic and Cultural Aspects. Seven Studies in the Charpathian Area; Gogâltan, F., Cordoș, C., Eds.; Editura Mega: Cluj-Napoca, Romania, 2016; pp. 73–86. [Google Scholar]

- Bolohan, N.; Gafincu, A. Raport de cercetare arheologică sistematică. Șantierul arheologic Siliștea-Pe Cetățuie, jud, Ne-amț. Campania 5–19 iulie 2018, Manuscris.

- Bolohan, N.; Gafincu, A.; Drob, A. Raport de Cercetare Arheologică Sistematică. Șantierul Arheologic Siliștea-Pe Cetățuie, jud, Neamț. Campania 13–27 Iulie 2019, Manuscris. Available online: https://cronica.cimec.ro/detaliu.asp?k=6430&d=Silistea-Romani-Neamt-Pe-Cetatuie-2019 (accessed on 1 June 2024).

- Bong, W.S.K.; Matsumura, K.; Nakai, I. Firing Technologies and Raw Materials of Typical Early and Middle Bronze Age Pottery from Kaman-Kalehöyük: A Statistical and Chemical Analysis. Archaeol. Anthropol. Sci. 2008, XVII, 295–311. [Google Scholar]

- Amicone, S.; Radivojević, M.; Quinn, P.S.; Berthold, C.; Rehren, T. Pyrotechnological connections? Re-investigating the link between pottery firing technology and the origins of metallurgy in the Vinča Culture, Serbia. J. Archaeol. Sci. 2020, 118, 105123. [Google Scholar] [CrossRef]

- Maniatis, Y.; Simopoulos, A.; Kostakis, A.; Perdikatsis, V. Effect of reducing atmosphere on minerals and iron oxides developed in fired clays: The role of Ca. J. Am. Ceram. Soc. 1983, 66, 773–781. [Google Scholar] [CrossRef]

- Palanivel, R.; Meyvel, S. Microstructural and microanalytical study–(SEM) of archaeological pottery artifacts. Rom. J. Phys. 2010, 55, 333–341. [Google Scholar]

- Vasilache, V.; Sandu, I.; Enea, S.C.; Sandu, I.G. Determinări ceramografice pe loturi din siturile Costești și Giurgești. In Comunitățile Cucuteniene din Zona Târgului Frumos: Cercetări Interdisciplinare în Siturile de la Costești și Giurgești; Boghian, D., Enea, S.C., Ignătescu, S., Stanc, S.M., Eds.; Alexandru Ioan Cuza University: Iași, Romania, 2014; pp. 138–147. [Google Scholar]

- Sandu, I.; Vasilache, V.; Tencariu, F.-A.; Cotiugă, V. Conservarea Științifică a Artefactelor din Ceramic; Alexandru Ioan Cuza University: Iași, Romania, 2010. [Google Scholar]

- Sandu, I.; Cotiugă, V.; Sandu, A.V.; Ciocan, A.C.; Olteanu, G.I.; Vasilache, V. New archaeometric characteristics for ancient pottery identification. Int. J. Conserv. Sci. 2010, 1, 75–82. [Google Scholar]

- Bakkevig, S. Phosphate analysis in archaeology-problems and recent progress. Nor. Archaeol. Rev. 1980, 13, 73–100. [Google Scholar] [CrossRef]

- Keeley, H.C.M. Recent work using soil phosphorus analysis in archaeological prospection. ArchéoSci. Rev. D’Archéométrie 1981, 5, 89–95. [Google Scholar] [CrossRef]

- Kshirsagar, A. Soil Phosphorus Distribution Within Human Activity Areas at Kuntasi. Bull. Deccan Coll. Res. Inst. 1991, 51–52, 497–500. [Google Scholar]

- Golyeva, A.; Khokhlova, O.; Lebedeva, M.; Shcherbakov, N.; Shuteleva, I. Micromorphological and Chemical Features of Soils as Evidence of Bronze Age Ancient Anthropogenic Impact (Late Bronze Age Muradymovo Settlement, Ural Region, Russia). Geosciences 2018, 3, 313. [Google Scholar] [CrossRef]

- Salisbury, R.B. Advances in Archaeological Soil Chemistry in Central Europe. Interdiscip. Archaeol. Nat. Sci. Archaeol. 2020, XI, 199–211. [Google Scholar] [CrossRef]

- Maniatis, Y.; Tite, M.S. Technological Examination of Neolithic-Bronze Age Pottery from Central and Southeast Europe and from the Near East. J. Archaeol. Sci. 1981, 8, 59–76. [Google Scholar] [CrossRef]

- Nadeau, P.H.; Tite, J.M. Transmission electron microscopy. In A Handbook of Determinative Methods in Clay Minerals; Wilson, M.J., Ed.; Blackie & Son Ltd.: New York, NY, USA, 1987; pp. 209–247. [Google Scholar]

- Ravisankar, R.; Kiruba, S.; Shamira, C.; Naseerutheen, A.; Balaji, P.D.; Seran, M. Spectroscopic techniques applied to characterization of recently excavated ancient potteries from Thruverkadu Tamilandu, India. Microchem. J. 2011, 99, 370–375. [Google Scholar] [CrossRef]

- Papachristodoulou, C.; Oikonomou, A.; Ioannides, K.; Gravani, K. A study of ancient pottery by means of X-ray fluorescence spectroscopy multivariate statistics and mineralogical analysis. Anal. Chim. Acta 2006, 573–574, 347–353. [Google Scholar] [CrossRef]

- Nodari, L.; Marcuz, E.; Maritan, L.; Mazzoli, C.; Russo, U. Hematite nucleation and growth in the firing of carbonate-rich clay for pottery production. J. Eur. Ceram. Soc. 2007, 27, 4665–4673. [Google Scholar] [CrossRef]

- Ravisankar, R.; Kiruba, S.; Eswaran, P.; Senthilkumar, G.; Chandrasekaran, A. Mineralogical Characterization Studies of Ancient Potteries of Tamilnadu, India by FT-IR Spectroscopic Technique. J. Chem. 2010, 7, S185–S190. [Google Scholar] [CrossRef]

- Ravisankar, R.; Kiruba, S.; Chandrasekeran, A.; Senthilkumar, G.; Maheswaran, C. Analysis on ancient potteries of Tamilandu, India by spectroscopic techniques. Indian J. Sci. Technol. 2010, 3, 858–862. [Google Scholar] [CrossRef]

- Vasilache, V.; Kavruk, V.; Tencariu, F.A. OM, SEM-EDX, and micro-FTIR analysis of the Bronze Age pottery from the Băile Figa salt production site (Transylvania, Romania). Microsc. Res. Tech. 2020, 83, 604–617. [Google Scholar] [CrossRef]

- Duma, G. Phosphate Content of Ancient Pots as Indication of Use. Curr. Anthropol. 1972, 13, 127–130. [Google Scholar] [CrossRef]

- Béarat, H.; Dufournier, D. Quelques expériences sur la fixation du phosphore par les céramiques. ArchéoSci. Rev. D’Archéométrie 1994, 18, 65–73. [Google Scholar] [CrossRef]

- Freudiger-Bonzon, J. Archaeometrical Study (Petrography, Mineralogy and Chemistry) of Neolithic Ceramics from Ar-bon Blieche 3 (Canton of Thirgau, Switzerlnad). Ph.D. Thesis, Faculté des Sciences, Université de Freibourg, Freibourg, Switzerland, 2005. [Google Scholar]

- Santos Rodrigues, S.F.; Lima da Costa, M. Phosphorus in archaeological ceramics as evidence of the use of pots for cooking food. Appl. Clay Sci. 2016, 123, 224–231. [Google Scholar] [CrossRef]

- Karapukaitytė, A.; Pakutinskienė, I.; Tautkus, S.; Kareiva, A. SEM and EDX characterization of ancient pottery. Lith. J. Phys. 2006, 46, 383–388. [Google Scholar] [CrossRef]

- Aroke, U.O.; Abdulkarim, A.; Ogubunka, R.O. Fourier-transform Infrared Characterization of Kaolin, Granite, Bentonite and Barite. ATBU J. Environ. Technol. 2013, 6, 42–53. [Google Scholar]

- Forte, V.; Cesaro, S.N.; Medeghini, L. Cooking traces on Copper Age pottery from central Italy: An integrated approach comparising use wear analysis, spectroscopic analysis and experimental archaeology. J. Archeol. Sci. Rep. 2018, 18, 121–138. [Google Scholar] [CrossRef]

- Frost, R.L.; Vassallo, A.M. The dehydroxylation of the kaolinite clay minerals using infrared emission spectroscopy. Clays Clay Miner. 1996, 44, 635–651. [Google Scholar] [CrossRef]

- Damjanović, L.; Holclajtner-Antunović, I.; Mioć, U.B.; Bikić, V.; Milovanović, D.; Radosavlkević Evans, I. Archaeometric study of medieval pottery excavated at Stari (old) Ras, Serbia. J. Archaeol. Sci. 2011, 38, 818–828. [Google Scholar] [CrossRef]

- Manoharan, S.P.; Venkatachalapathy, R.; Vasanthi, S.; Dhanopandian, S.; Veeramuthu, K. Spectroscopic and rock magnetic studies on some ancient Indian pottery samples. Egypt. J. Basic Appl. Sci. 2015, 2, 39–49. [Google Scholar] [CrossRef]

- Oancea, A.V.; Bodi, G.; Nica, V.; Ursu, L.E.; Drobota, M.; Cotofana, C.; Vasiliu, A.L.; Simionescu, B.C.; Olaru, M. Multi-analytical characterization of Cucuteni pottery. J. Eur. Ceram. Soc. 2017, 37, 5079–5098. [Google Scholar] [CrossRef]

- Costa, T.G.; Correia, M.D.d.M.; Reis, L.B.; dos Santos, S.S.; Machado, J.S.; Bueno, L.; da Silva Müller, I. Spectroscopic characterization of recently excavated archaeological potsherds of Taquaea/Itararé tradition from Tobias Wagner site (Santa Catarina-Brazil). J. Archeol. Sci. Rep. 2017, 12, 561–568. [Google Scholar] [CrossRef]

- Tironi, A.; Trezza, M.A.; Irassar, E.F.; Scian, A.N. Thermal treatment of kaolin: Effect on the pozzolanic activity. Procedia Mater. Sci. 2012, 1, 343–350. [Google Scholar] [CrossRef]

- Chen, Y.; Zou, C.; Mastalerz, M.; Hu, S.; Gasaway, C.; Tao, X. Applications of Micro-Fourier Transform Infrared Spectroscopy (FTIR) in the Geological Sciences—A Review. Int. J. Mol. Sci. 2015, 16, 30223–30250. [Google Scholar] [CrossRef]

- Velraj, G.; Janaki, K.; Mustafa, A.M.; Palanivel, R. Estimation of firing temperatures of some archaeological pottery sherds excavated recently in Tamilandu, India. Spectrochim. Acta A 2009, 72, 730–733. [Google Scholar] [CrossRef]

- Palanivel, R.; Kumar, U.R. Thermal and spectroscopic analysis of ancient potteries. Rom. J. Phys. 2011, 56, 195–208. [Google Scholar]

- Velraj, G.; Tamilarasu, S.; Ramaya, R. FTIR, XRD and SEM-EDS studies of archaeological pottery samples from recently excavated site in Tamil Nadu, India. Mater. Today 2015, 2, 934–942. [Google Scholar] [CrossRef]

- Berzina-Cimdina, L.; Borodajenko, N. Research of Calcium Phosphates Using Fourier Transform Infrared Spectroscopy. In Infrared Spectroscopy: Materials Science, Engineering and Technology; Theopanides, T., Ed.; IntechOpen: London, UK, 2012; pp. 123–148. [Google Scholar]

- Miller, F.A.; Wilkins, C.H. Infrared Spectra and Characteristic Frequencies of Inorganic Ions. Their Use in Qualitative Analysis. Anal. Chem. 1952, 24, 1253–1294. [Google Scholar] [CrossRef]

- Kumar, R.S.; Rajkumar, P. Characterization of minerals in air dust particles in the state of Tamilandu, India through FTIR Spectroscopy. Infrared Phys. Technol. 2014, 67, 30–41. [Google Scholar] [CrossRef]

- Gasaway, C.; Mastalerz, M.; Krause, F.; Clarkson, C.; Debuhr, C. Applicability of Micro-FTIR in Detecting Shale Heterogenity. Microscopy 2017, 265, 60–72. [Google Scholar] [CrossRef] [PubMed]

- Niculae, M.D. Sistem Integrat Pentru Stabilirea Identității Probelor Ceramice. Ph.D. Thesis, “Dunarea de Jos” University, Galati, Romania, 2011. [Google Scholar]

- Barilaro, D.; Barone, G.; Crupi, V.; Majolino, D.; Mazzoleni, P.; Tigano, G.; Venuti, V. FT-IR absorbance spectroscopy to study Sicilian “proto-majolica” pottery. Vib. Spectrosc. 2008, 48, 269–275. [Google Scholar] [CrossRef]

- Akyuza, S.; Guliyev, F.; Celik, S.; Ozel, A.E.; Alakbarov, V. Investigations of the Neolithic potteries of 6th millennium BC from Goytepe-Azerbaijan by vibrational spectroscopy and chemometric techniques. Vib. Spectrosc. 2019, 105, 102980. [Google Scholar] [CrossRef]

- Stevenson, C.M.; Gurnick, M. Structural collapse in kaolinite, montmorillonite and illite clay and its role in the ceramic rehydroxylation dating of low-fired earthenware. J. Archaeol. Sci. 2016, 69, 54–63. [Google Scholar] [CrossRef]

- Hofmeister, A.M.; Bowey, J.E. Quantitative infrared spectra of hydrosilicates and related minerals. Mon. Not. R. Astron. Soc. 2006, 367, 577–591. [Google Scholar] [CrossRef]

| Si | Al | Mg | P | Ca | K | Na | Fe | Ti | O | C | |

| S1 unburned | 29.81 | 4.04 | 1.20 | 0.16 | 4.84 | 2.19 | 0.77 | 2.27 | 0.31 | 53.09 | 1.31 |

| S1 450 °C | 21.46 | 5.71 | 1.66 | 0.07 | 10.58 | 3.26 | 0.36 | 3.83 | 0.71 | 51.75 | 0.61 |

| S1 700 °C | 26.18 | 5.65 | 1.75 | 0.19 | 8.26 | 2.51 | 0.47 | 3.03 | 0.41 | 51.55 | 0.00 |

| S1 900 °C | 25.88 | 5.98 | 1.82 | 0.24 | 9.31 | 2.55 | 0.45 | 3.36 | 0.47 | 49.93 | 0.00 |

| Si | Al | Mg | P | Ca | K | Na | Fe | Ti | O | C | |

| S2 unburned | 14.78 | 5.61 | 2.26 | 0.15 | 14.78 | 3.55 | 0.48 | 2.44 | 0.49 | 52.23 | 3.23 |

| S2 450 °C | 23.76 | 6.85 | 2.18 | 0.24 | 8.77 | 2.58 | 0.38 | 3.65 | 0.53 | 50.46 | 0.60 |

| S2 700 °C | 24.36 | 6.72 | 2.08 | 0.18 | 9.08 | 2.70 | 0.52 | 3.43 | 0.56 | 50.36 | 0.00 |

| S2 900 °C | 24.02 | 6.67 | 2.30 | 0.19 | 11.28 | 2.98 | 0.47 | 3.70 | 0.69 | 47.71 | 0.00 |

| Si | Al | Mg | P | Ca | K | Na | Fe | Ti | O | C | |

| S3 unburned | 20.71 | 6.49 | 1.72 | 0.64 | 9.40 | 2.24 | 0.83 | 2.58 | 0.49 | 54.42 | 0.48 |

| S3 450 °C | 27.48 | 5.98 | 1.14 | 0.27 | 7.14 | 2.30 | 0.37 | 3.42 | 0.45 | 51.21 | 0.25 |

| S3 700 °C | 26.70 | 6.29 | 1.28 | 0.26 | 6.95 | 2.28 | 0.60 | 3.58 | 0.53 | 51.27 | 0.27 |

| S3 900 °C | 25.76 | 6.56 | 1.31 | 0.22 | 8.64 | 2.36 | 0.51 | 3.69 | 0.43 | 50.52 | 0.00 |

| Si | Al | Mg | P | Ca | K | Na | Fe | Ti | O | C | |

| S4 unburned | 25.12 | 7.03 | 1.30 | 0.19 | 0.99 | 2.49 | 0.58 | 4.22 | 0.76 | 54.49 | 2.83 |

| S4 450 °C | 30.16 | 7.54 | 1.26 | 0.23 | 0.84 | 2.14 | 0.75 | 3.97 | 0.65 | 52.27 | 0.19 |

| S4 700 °C | 31.06 | 7.14 | 1.27 | 0.28 | 0.96 | 2.10 | 0.49 | 4.07 | 0.80 | 51.71 | 0.10 |

| S4 900 °C | 32.66 | 7.08 | 1.21 | 0.22 | 0.73 | 1.69 | 0.53 | 4.24 | 0.40 | 51.25 | 0.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Drob, A.; Bolohan, N.; Vasilache, V.; Rățoi, B.-G.; Brebu, M. Interdisciplinary Analysis and the Role of Experiments in Raw Materials and Technology Identification for Prehistoric Pottery in the Bistrița River Basin (Romania). Heritage 2024, 7, 5120-5147. https://doi.org/10.3390/heritage7090242

Drob A, Bolohan N, Vasilache V, Rățoi B-G, Brebu M. Interdisciplinary Analysis and the Role of Experiments in Raw Materials and Technology Identification for Prehistoric Pottery in the Bistrița River Basin (Romania). Heritage. 2024; 7(9):5120-5147. https://doi.org/10.3390/heritage7090242

Chicago/Turabian StyleDrob, Ana, Neculai Bolohan, Viorica Vasilache, Bogdan-Gabriel Rățoi, and Mihai Brebu. 2024. "Interdisciplinary Analysis and the Role of Experiments in Raw Materials and Technology Identification for Prehistoric Pottery in the Bistrița River Basin (Romania)" Heritage 7, no. 9: 5120-5147. https://doi.org/10.3390/heritage7090242