X-CT Reconstruction as a Tool for Monitoring the Conservation State and Decay Processes of Works of Art and in Support of Restoration and Conservation Strategies

Abstract

1. Introduction

2. Materials and Methods

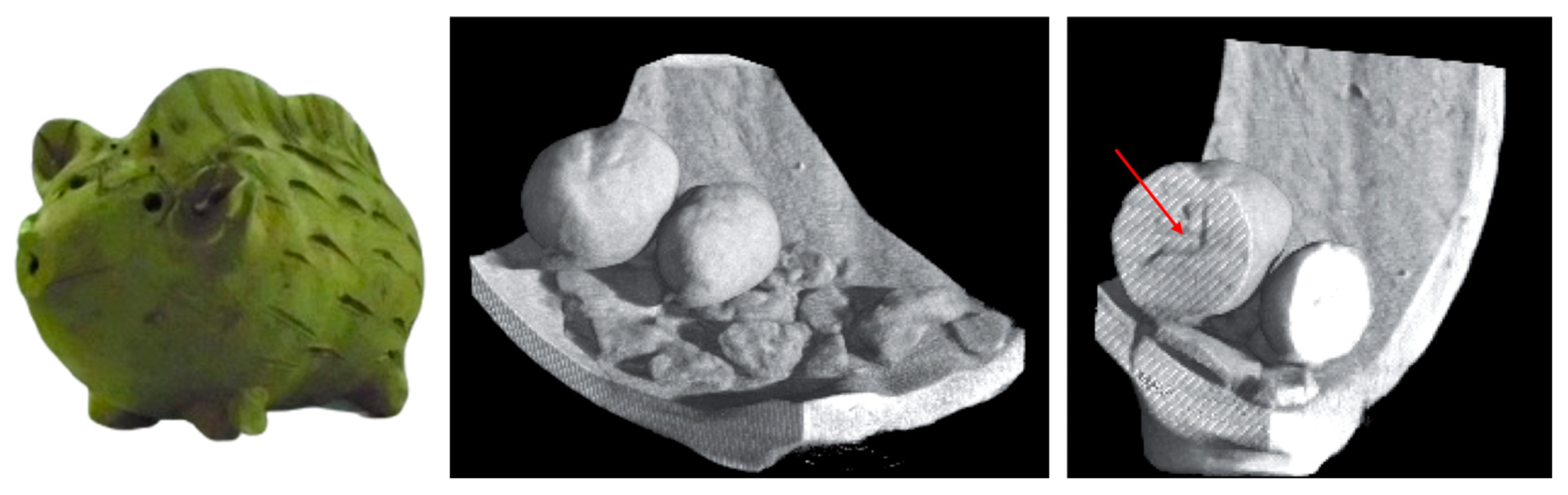

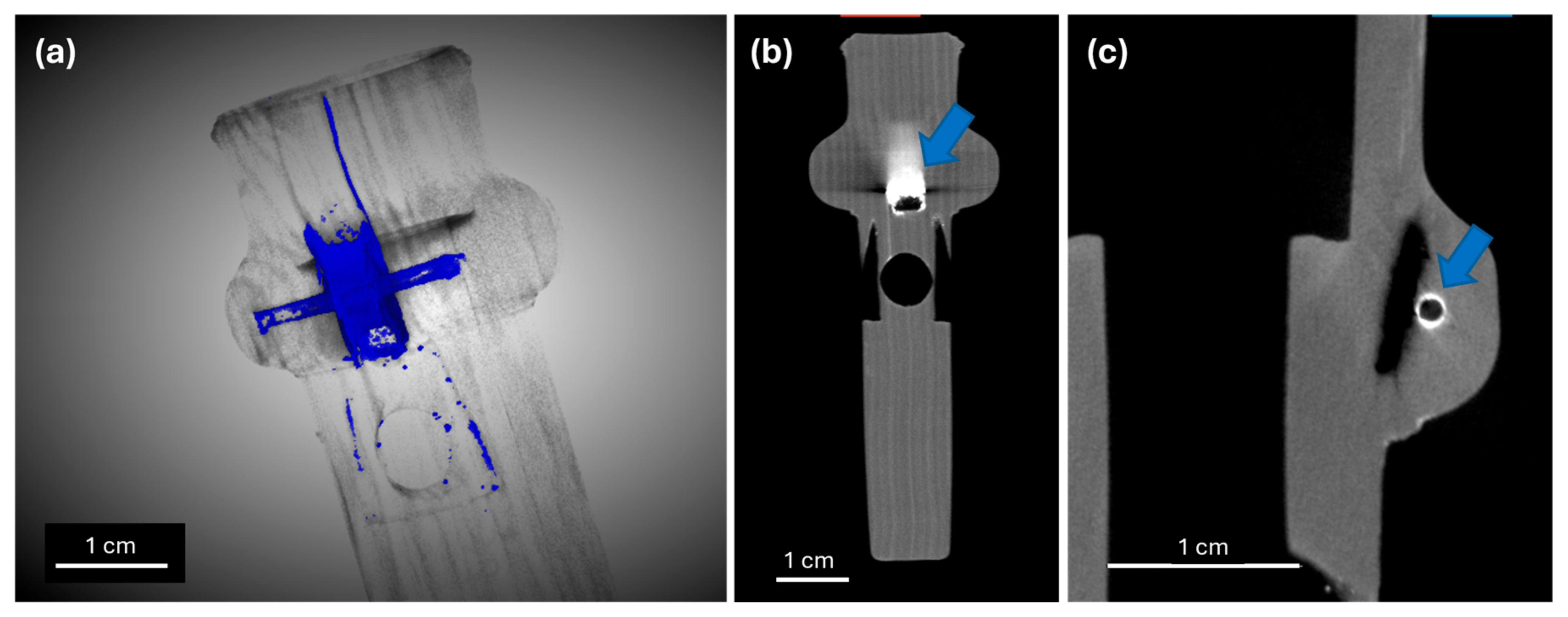

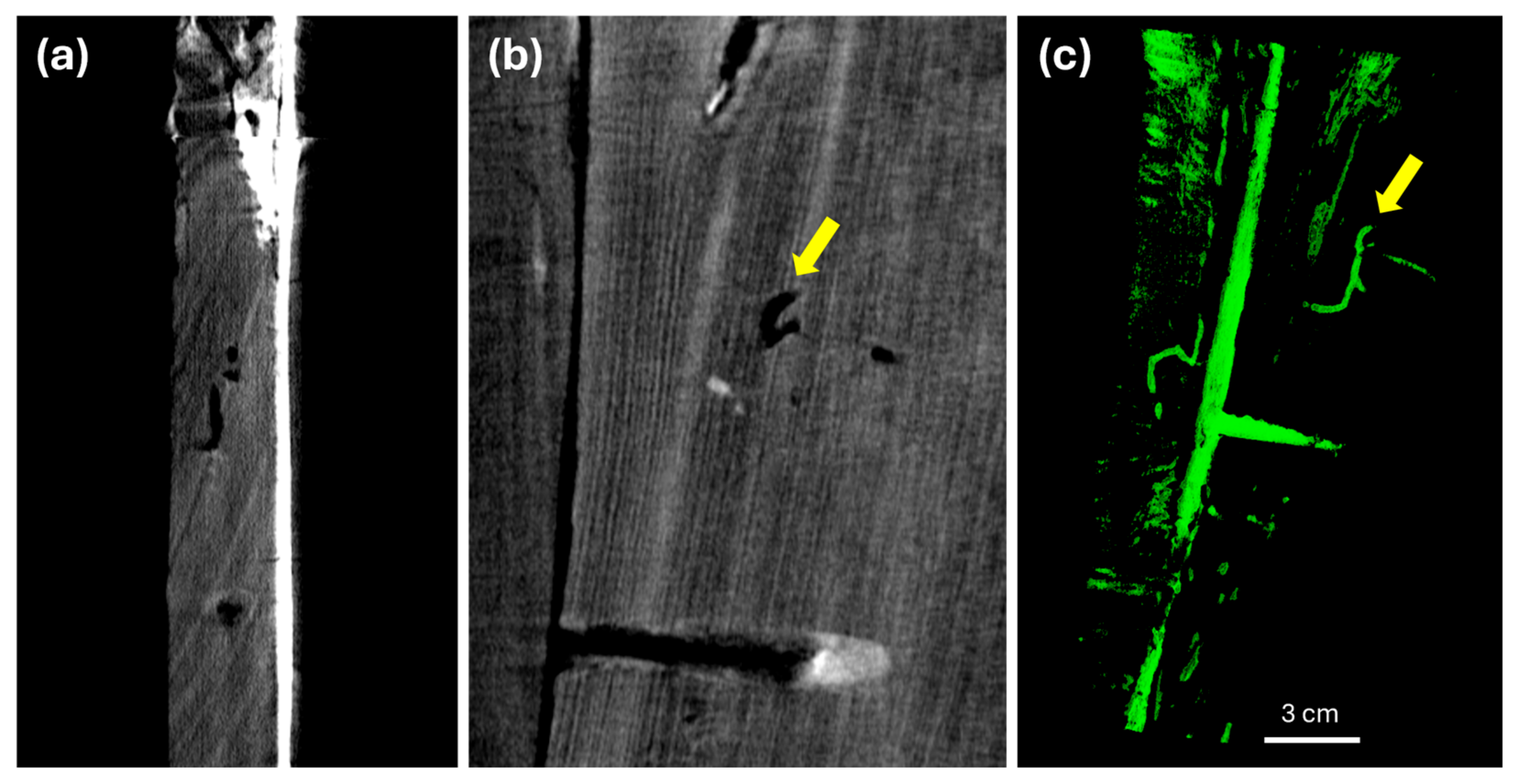

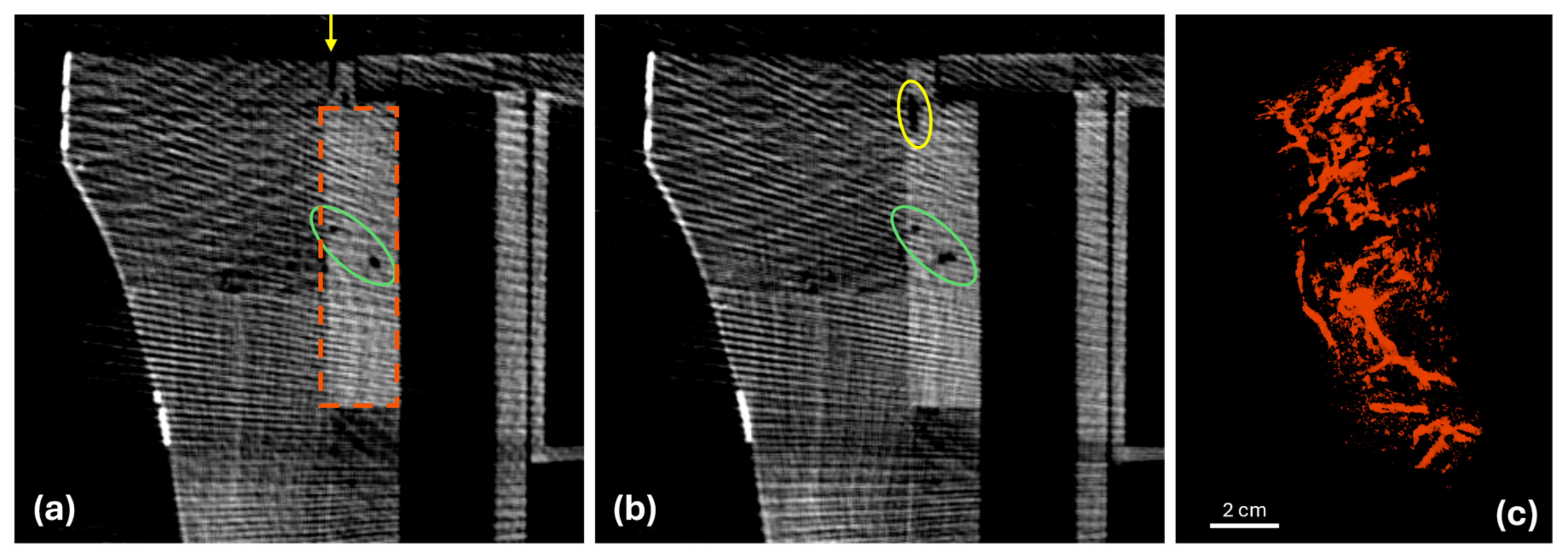

3. Results and Discussion

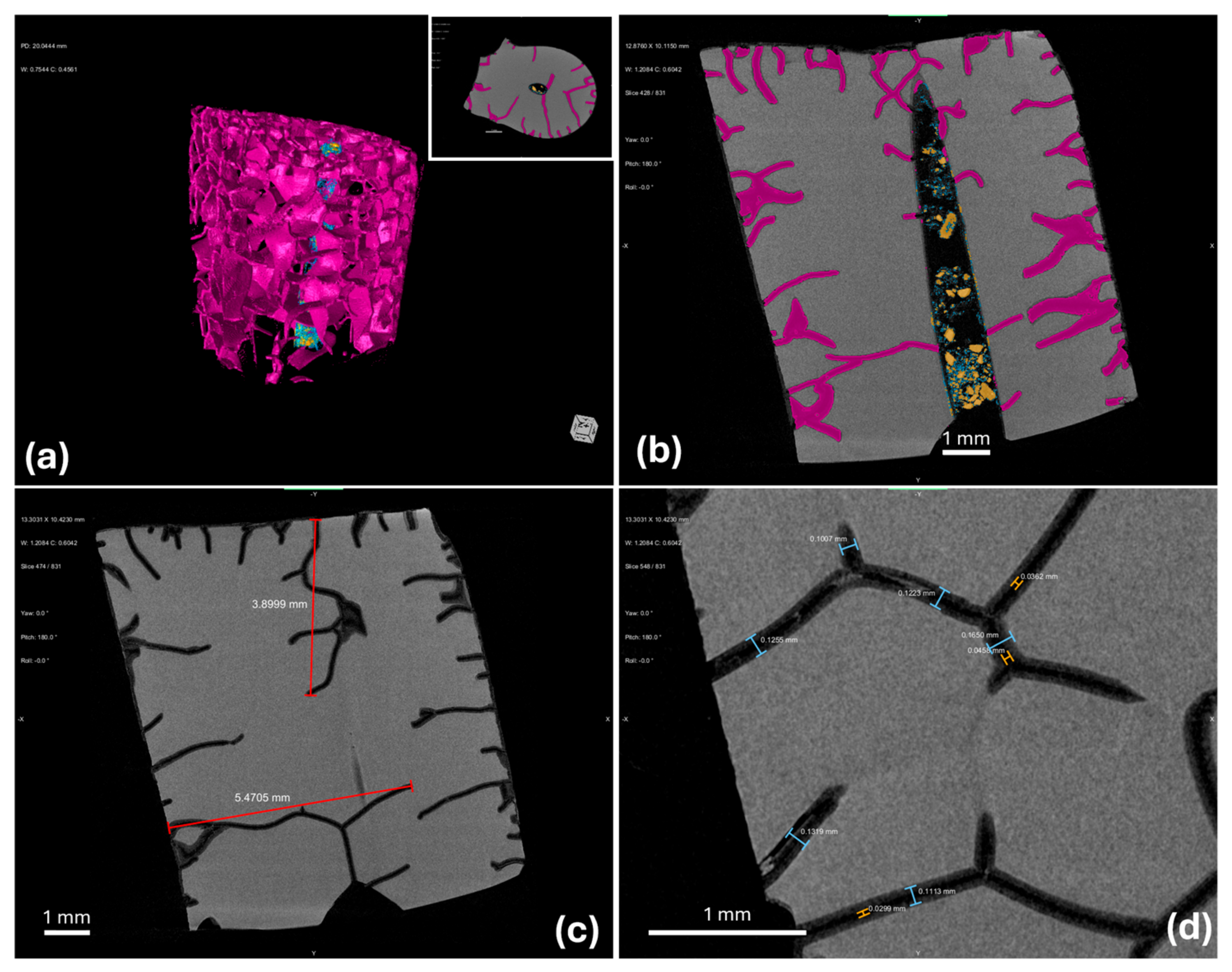

3.1. Breaking from Prolonged Use

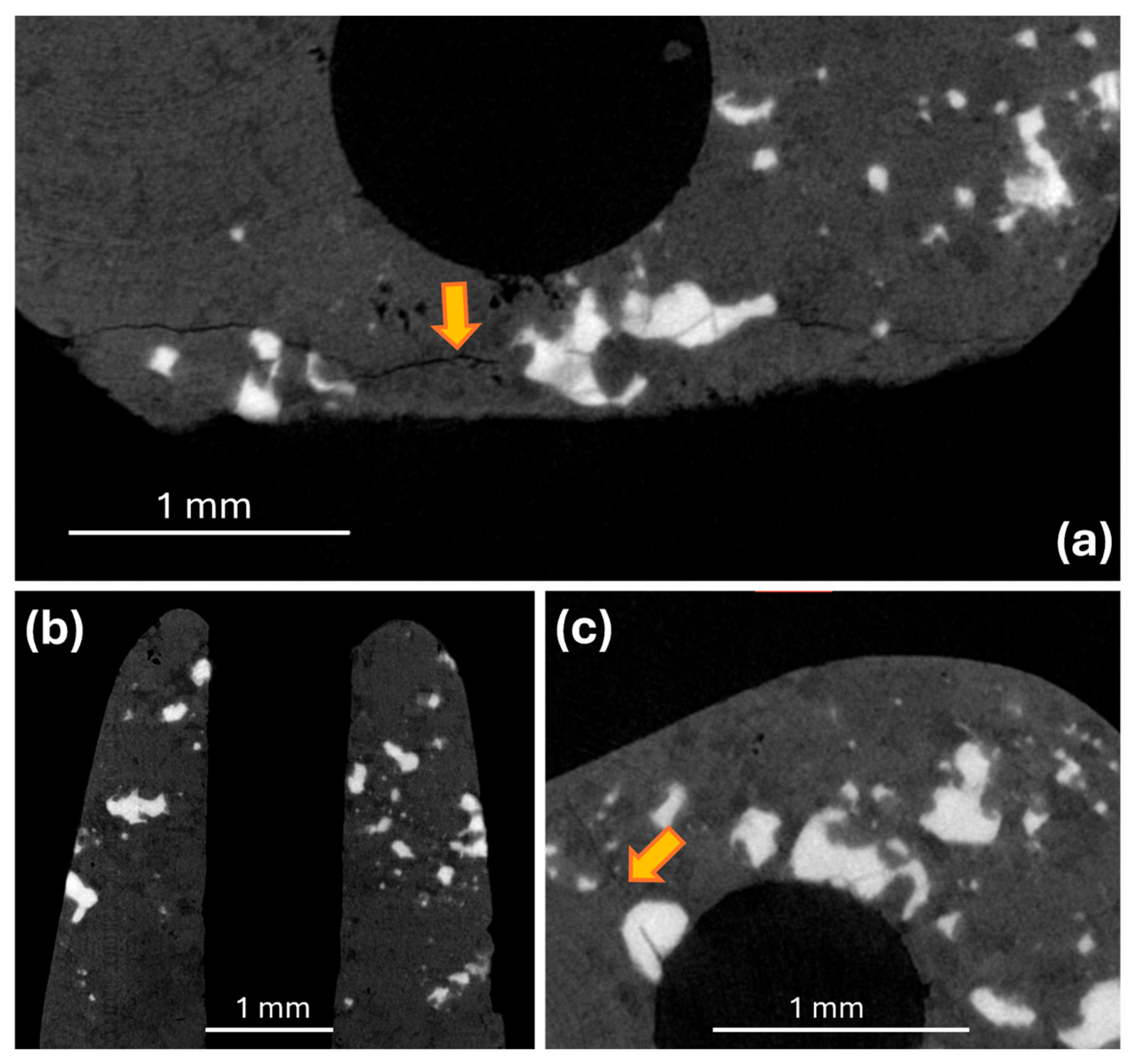

3.2. Ion Migration

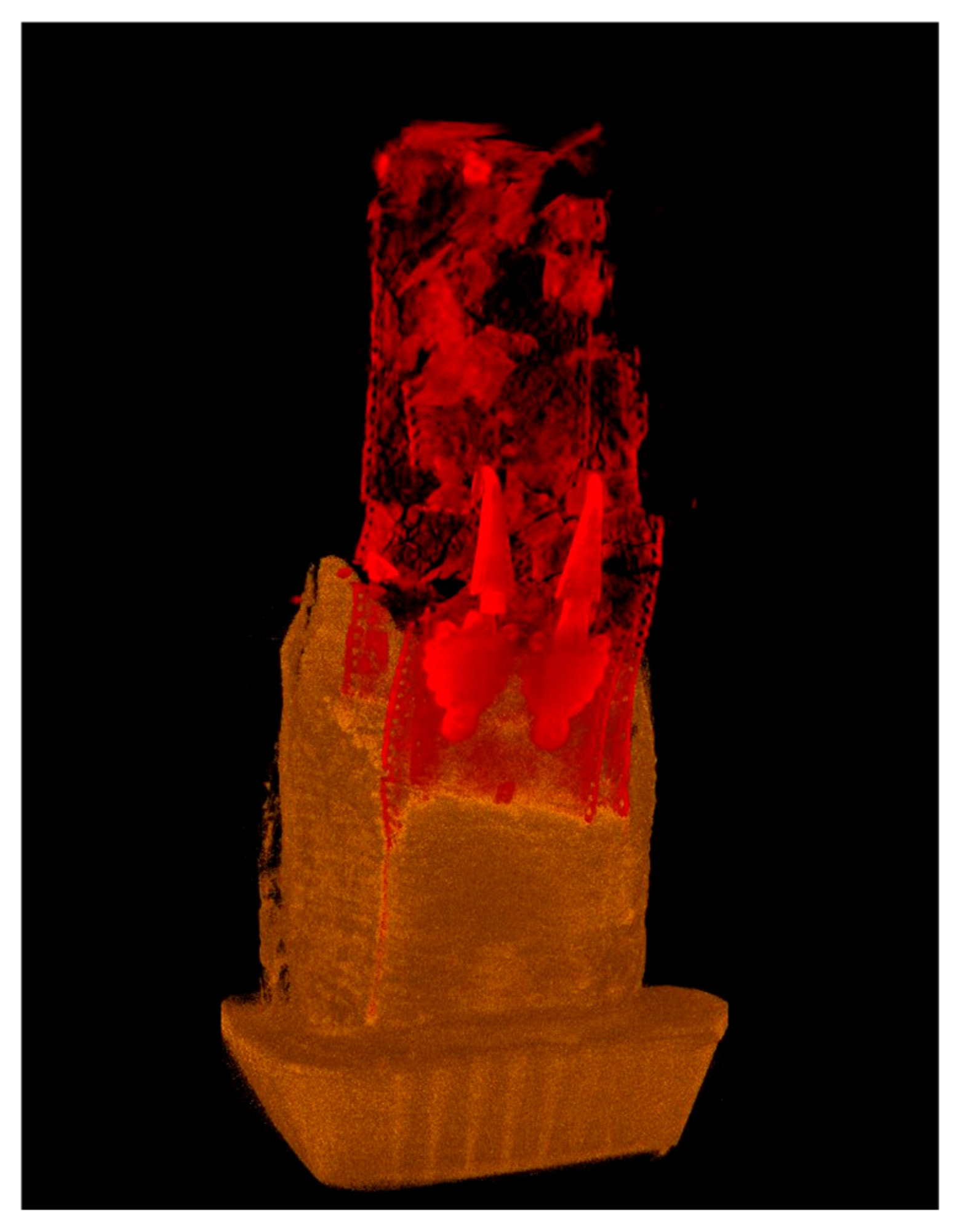

3.3. Biological Activity

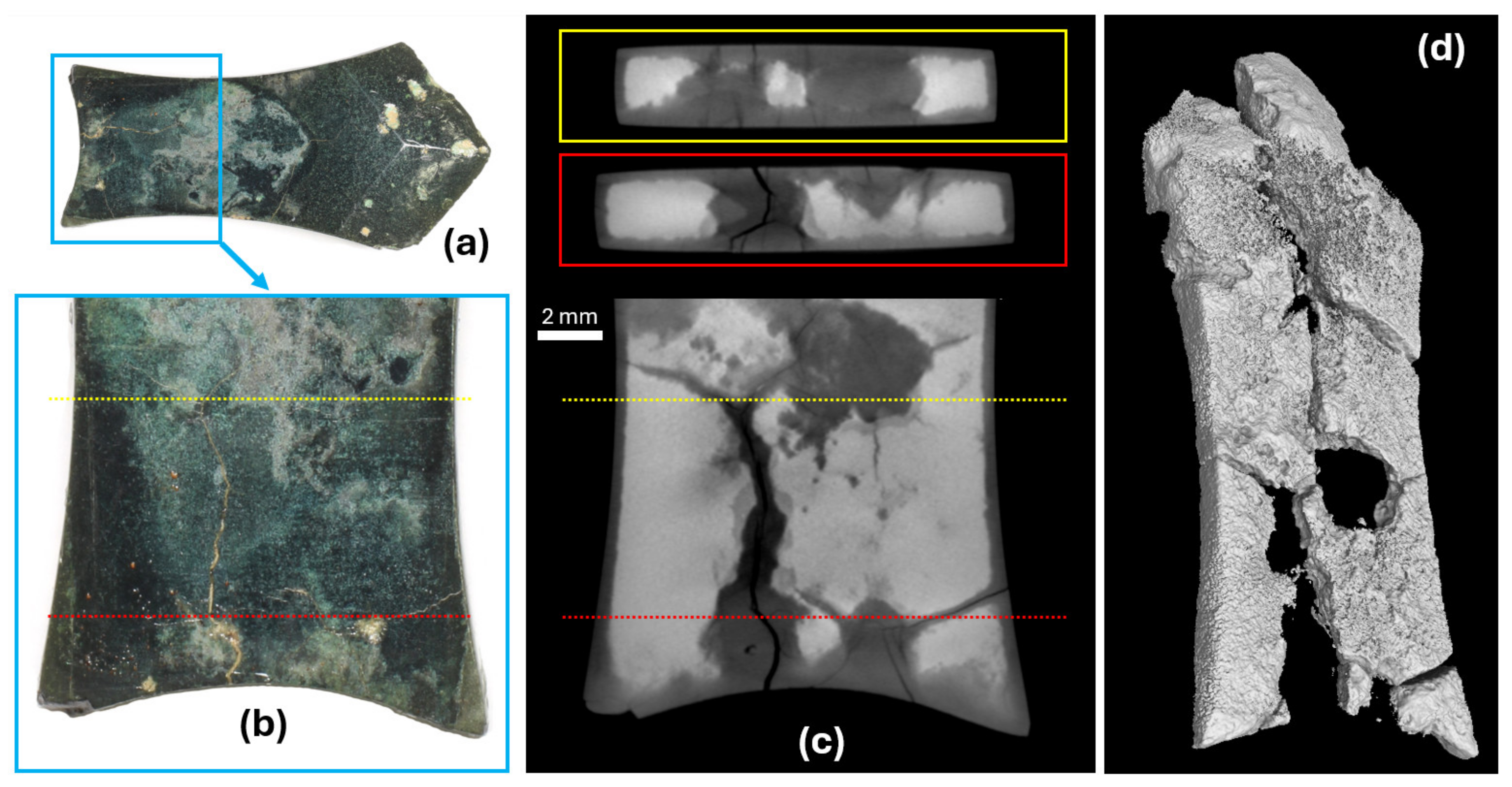

3.4. Environmental Effects

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hughes, S. CT Scanning in Archaeology. In Computed Tomography—Special Applications; Saba, L., Ed.; InTech: London, UK, 2011; pp. 57–70. [Google Scholar] [CrossRef]

- Albertin, F.; Bettuzzi, M.; Brancaccio, R.; Morigi, M.P.; Casali, F. X-Ray Computed Tomography In Situ: An Opportunity for Museums and Restoration Laboratories. Heritage 2019, 2, 2028–2038. [Google Scholar] [CrossRef]

- Oliveira, R.; de Paula, A.; Gonçalves, F.; Bueno, R.; Calgam, T.; Azeredo, S.; Araújo, O.; Machado, A.; Anjos, M.; Lopes, R.; et al. Development and characterization of a portable CT system for wooden sculptures analysis. Radiat. Phys. Chem. 2022, 200, 110409. [Google Scholar] [CrossRef]

- Björngrim, N.; Myronycheva, O.; Fjellström, P. The use of large-scale X-ray computed tomography for the evaluation of damaged structural elements from an old timber bridge. Wood Mater. Sci. Eng. 2022, 17, 1028–1029. [Google Scholar] [CrossRef]

- Friml, J.; Procházková, K.; Melnykc, G.; Zikmundb, T.; Kaiser, J. Investigation of Cheb relief intarsia and the study of the technological process of its production by micro computed tomography. J. Cult. Herit. 2014, 15, 609–613. [Google Scholar] [CrossRef]

- Vigorelli, L.; Re, A.; Buscaglia, P.; Manfredda, N.; Nervo, M.; Cavaleri, T.; Del Vesco, P.; Borla, M.; Grassini, S.; Guidorzi, L.; et al. Comparison of two ancient Egyptian Middle Kingdom statuettes from the Museo Egizio of Torino through computed tomographic measurements. J. Archaeol. Sci. Rep. 2022, 44, 103518. [Google Scholar] [CrossRef]

- Stelzner, J.; Stelzner, I.; Martinez-Garcia, J.; Gwerder, D.; Wittköpper, M.; Muskalla, W.; Cramer, A.; Heinz, G.; Egg, M.; Schuetz, P. Stabilisation of waterlogged archaeological wood: The application of structured-light 3D scanning and micro computed tomography for analysing dimensional changes. Herit. Sci. 2022, 10, 60. [Google Scholar] [CrossRef]

- Haneca, K.; Deforce, K.; Boone, M.N.; Van Loo, D.; Dierick, M.; Van Acker, J.; Van Den Bulcke, J. X-ray sub-micron tomography as a tool for the study of archaeological wood preserved through the corrosion of metal objects. Archaeometry 2012, 54, 893–905. [Google Scholar] [CrossRef]

- Waltenberger, L.; Bosch, M.D.; Fritzl, M.; Gahleitner, A.; Kurzmann, C.; Piniel, M.; Salisbury, R.B.; Strnad, L.; Skerjanz, H.; Verdianu, D.; et al. More than urns: A multi-method pipeline for analyzing cremation burials. PLoS ONE 2023, 18, e0289140. [Google Scholar] [CrossRef]

- Stelzner, I.; Stelzner, J.; Fischer, B.; Hamann, E.; Zuber, M.; Schuetz, P. A multi-technique and multiscale comparative study on the efficiency of conservation methods for the stabilisation of waterlogged archaeological pine. Sci. Rep. 2024, 14, 8681. [Google Scholar] [CrossRef]

- Allington-Jones, L.; Clark, B.; Fernandez, V. Fool’s gold, fool’s paradise? Utilising X-ray micro-Computed Tomography to evaluate the effect of environmental conditions on the deterioration of pyritic fossils. J. Inst. Conserv. 2020, 43, 213–224. [Google Scholar] [CrossRef]

- Bratasz, Ł.; Akoglu, K.G.; Kékicheff, P. Fracture saturation in paintings makes them less vulnerable to environmental variations in museums. Herit. Sci. 2020, 8, 11. [Google Scholar] [CrossRef]

- Nicolas, T.; Gaugne, R.; Tavernier, C.; Millet, E.; Bernadet, R.; Gouranton, V. Lift the veil of the block samples from the Warcq chariot burial with 3D digital technologies. In Proceedings of the Digital Heritage 2018—3rd International Congress & Expo, San Francisco, CA, USA, 26–30 October 2018; pp. 1–8, hal-01875702. [Google Scholar]

- Stromer, D.; Christlein, V.; Huang, X.; Zippert, P.; Hausotte, T.; Maier, A. Virtual cleaning and unwrapping of non-invasively digitized soiled bamboo scrolls. Sci. Rep. 2019, 9, 2311. [Google Scholar] [CrossRef] [PubMed]

- Kimball, J.J.L.; With, J.; Rødsrud, C.L. A new and ‘riveting’ method: Micro-CT scanning for the documentation, conservation, and reconstruction of the Gjellestad ship. J. Cult. Herit. 2024, 66, 76–85. [Google Scholar] [CrossRef]

- Buscaglia, P.; Baldi, A.; Grassini, S.; Croci, S.; Croveri, P.; Cervini, L.; Cremonini, C.; Re, A.; Lo Giudice, A. Assessment of consolidation treatments: Micro-CT as a potential tool for material’s penetration detection. In Proceedings of the 2022 IMEKO TC-4 International Conference on Metrology for Archaeology and Cultural Heritage, University of Calabria, Arcavacata, Italy, 19–21 October 2022. [Google Scholar]

- Sanches, F.A.C.R.A.; Nardes, R.C.; Santos, R.S.; Gama Filho, H.S.; Machado, A.S.; Leitao, R.G.; Leitao, C.C.G.; Calgam, T.E.; Bueno, R.; Assis, J.T.; et al. Characterization an wooden Pietà sculpture from the XVIII century using XRF and microct techniques. Radiat. Phys. Chem. 2023, 202, 110556. [Google Scholar] [CrossRef]

- Ševčík, R.; Adámková, I.; Vopálenský, M.; Viani, A. The visualization of microcracks in aged cement mortar using tomography. AIP Conf. Proc. 2024, 3094, 500007. [Google Scholar] [CrossRef]

- Johnson, D.; Tyldesley, J.; Lowe, T.; Withers, P.J.; Grady, M.M. Analysis of a prehistoric Egyptian iron bead with implications for the use and perception of meteorite iron in ancient Egypt. Meteorit. Planet. Sci. 2013, 48, 997–1006. [Google Scholar] [CrossRef]

- Simon, H.J.; Cibin, G.; Reinhard, C.; Liu, Y.; Schofield, E.; Freestone, I.C. Influence of microstructure on the corrosion of archaeological iron observed using 3D synchrotron micro-tomography. Corros. Sci. 2019, 159, 108132. [Google Scholar] [CrossRef]

- Nguyen, H.-Y.; Keating, S.; Bevan, G.; Gabov, A.; Daymond, M.; Schillinger, B.; Murray, A. Seeing through Corrosion: Using Micro-focus X-ray Computed Tomography and Neutron Computed Tomography to Digitally “Clean” Ancient Bronze Coins. Mater. Res. Soc. Symp. Proc. 2011, 1319, 305. [Google Scholar] [CrossRef]

- Bude, R.O.; Bigelow, E.M.R. Nano-CT evaluation of totally corroded coins: A demonstration study to determine if detail might still be discernible despite the lack of internal, non-corroded, metal. Archaeometry 2020, 62, 1195–1201. [Google Scholar] [CrossRef]

- Pagano, S.; Balassone, G.; Germinario, C.; Grifa, C.; Izzo, F.; Mercurio, M.; Munzi, P.; Pappalardo, L.; Spagnoli, E.; Verde, M.; et al. Archaeometric Characterisation and Assessment of Conservation State of Coins: The Case-Study of a Selection of Antoniniani from the Hoard of Cumae (Campania Region, Southern Italy). Heritage 2023, 6, 2038–2055. [Google Scholar] [CrossRef]

- Abate, F.; De Bernardin, M.; Stratigaki, M.; Franceschin, G.; Albertin, F.; Bettuzzi, M.; Brancaccio, R.; Bressan, A.; Morigi, M.P.; Daniele, S.; et al. X-ray computed microtomography: A non-invasive and time-efficient method for identifying and screening Roman copper-based coins. J. Cult. Herit. 2024, 66, 436–443. [Google Scholar] [CrossRef]

- Haubner, R.; Strobl, S. Examination of archaeological bronze parts using micro-computed tomography and metallography. Pract. Metallogr. 2024, 61, 4. [Google Scholar] [CrossRef]

- Re, A.; Albertin, F.; Avataneo, C.; Brancaccio, R.; Corsi, J.; Cotto, G.; De Blasi, S.; Dughera, G.; Durisi, E.; Ferrrarese, W.; et al. X-ray tomography of large wooden artworks: The case study of “Doppio corpo” by Pietro Piffetti. Herit. Sci. 2014, 2, 19. [Google Scholar] [CrossRef]

- Re, A.; Lo Giudice, A.; Nervo, M.; Buscaglia, P.; Luciani, P.; Borla, M.; Greco, C. The importance of tomography studying wooden artefacts: A comparison with radiography in the case of a coffin lid from Ancient Egypt. Int. J. Conserv. Sci. 2016, 7, 935–944. [Google Scholar]

- Re, A.; Corsi, J.; Demmelbauer, M.; Martini, M.; Mila, G.; Ricci, C. X-ray tomography of a soil block: A useful tool for the restoration of archaeological finds. Herit. Sci. 2015, 3, 4. [Google Scholar] [CrossRef]

- Vigorelli, L.; Re, A.; Guidorzi, L.; Brancaccio, R.; Bortolin, C.; Grassi, N.; Mila, G.; Pastrone, N.; Sacchi, R.; Grassini, S.; et al. The study of ancient archaeological finds through X-ray tomography: The case of the “Tintinnabulum” from the Museum of Anthropology and Ethnography of Torino. J. Phys. Conf. Ser. 2022, 2204, 012034. [Google Scholar] [CrossRef]

- Magalini, M.; Guidorzi, L.; Re, A.; Tansella, F.; Picollo, F.; Sturari, S.; Aprà, P.; Herrmann, G.; Law, R.; Lemasson, Q.; et al. Micro-Computed Tomography and Micro-laser ablation on altered pyrite in lapis lazuli to enhance provenance investigation: A new methodology and its application to archaeological cases. Eur. Phys. J. Plus 2025, 140, 59. [Google Scholar] [CrossRef]

- Zanini, R.; Franceschin, G.; Vigorelli, L.; Iori, G.; Chiaberge, L.; Longo, E.; Guidorzi, L.; Re, A.; Lo Giudice, A.; Traviglia, A. Laboratory and synchrotron X-ray computed microtomography to shed light on degradation features of corroded Roman glass. J. Am. Ceram. Soc. 2024, 108, e20241. [Google Scholar] [CrossRef]

- Tansella, F.; Vigorelli, L.; Ricchiardi, G.; Re, A.; Bonizzoni, L.; Grassini, S.; Staropoli, M.; Lo Giudice, A. X-ray Computed Tomography Analysis of Historical Woodwind Instruments of the Late Eighteenth Century. J. Imaging 2022, 8, 260. [Google Scholar] [CrossRef]

- Kondō, Y.; Niiro, I. (Eds.) Urama-chausuyama Kofun [Urama-chausuyama Mounded Tomb]; Shin’yōsha: Kyoto, Japan, 1991. [Google Scholar]

- Meeks, M. Patination phenomena on Roman and Chinese high-tin bronze mirrors and other artefacts. In Metal Plating and Patination; La Niece, S., Craddock, P., Eds.; Butterworth-Heinemann: Oxford, UK, 1993. [Google Scholar]

- Chase, W.T. Chinese Bronzes: Casting, Finishing, Patination and Corrosion. In Ancient & Historic: Metals Conservation and Scientific Research; Scott, D.A., Podany, J., Considine, B.B., Eds.; Getty Conservation Institute and J. Paul Getty Museum: Malibu, USA, 1995. [Google Scholar]

- Li, B.; Jiang, X.; Tu, Y.; Fu, Q.; Pan, C. “Inward Growth” corrosion and its growth mechanism in ancient Chinese bronzes. MRS Adv. 2020, 5, 1457–1466. [Google Scholar] [CrossRef]

- Re, A.; Brancaccio, R.; Corsi, J.; Cotto, G.; Dughera, G.; Ferrarese, W.; Grassi, N.; Lo Giudice, A.; Lusso, S.; Mereu, P.; et al. L’apparato radio-tomografico/The radio-tomographic apparatus. In Il Progetto neu_ART. Studi e Applicazioni/Neutron and X-Ray Tomography and Imaging for Cultural Heritage, Cronache 4; Nervo, M., Ed.; Editris: Torino, Italy, 2013. [Google Scholar]

- Re, A.; Peruzzi, N.; Del Greco, F.; Nervo, M.; Pastrone, N.; Sacchi, R.; Lo Giudice, A. A procedure for the dynamic range characterization of X-ray imaging linear and TDI detectors. J. Instrum. 2024, 19, C10005. [Google Scholar] [CrossRef]

- Martz, H.E.; Shull, P.J.; Schneberk, D.J.; Logan, C.M. X-Ray Imaging; CRC Press Inc.: Boca Raton, FL, USA, 2009. [Google Scholar]

- Brancaccio, R.; Bettuzzi, M.; Casali, F.; Morigi, M.P.; Levi, G.; Gallo, A.; Marchetti, G.; Schneberk, D. Real-time reconstruction for 3-D CT applied to large objects of cultural heritage. IEEE Trans. Nucl. Sci. 2011, 58, 1864–1871. [Google Scholar] [CrossRef]

| Object | Piffetti’s “Doppio Corpo” | Coffin Lid | Soil Block | Tintinnabulum | Lapis Lazuli Bead | Roman Glass | Flute | Bronze Arrowhead |

|---|---|---|---|---|---|---|---|---|

| Object dimensions | 129 × 59 × 312 cm3 | 31 × 50 × 182 cm3 | 40 × 15 × 10 cm3 | 7.4 × 11.2 × 6.2 cm3 | (ca.) 8.4 × 3.5 × 3.5 mm3 | Dmax 2.5 cm | 42.7 × 3.4 × 3.4 cm3 | 3.5 × 2.0 × 0.5 cm3 |

| X-ray source | General Electric Eresco 42MF4 | General Electric Eresco 42MF4 | General Electric Eresco 42MF4 | General Electric Eresco 42MF4 | Hamamatsu Microfocus L8121-03 | Hamamatsu Microfocus L8121-03 | Hamamatsu Microfocus L8121-03 | SHIMADZU inspeXio SMX-225CT FPD HR Micro Focus X-Ray CT System |

| X-ray detector | Hamamatsu X-ray Line Sensor Camera C9750-20TCN | Hamamatsu X-ray Line Sensor Camera C9750-20TCN | Hamamatsu X-ray Line Sensor Camera C9750-20TCN | Hamamatsu X-ray TDI Camera C10650-321 | Shad-O-Box 6K HS Flat Panel | Shad-O-Box 6K HS Flat Panel | Shad-O-Box 6K HS Flat Panel | |

| Rotary stage | Newport RV350PE | Newport RV350PE | Newport RV350PE | custom | Newport URS150BPP | Newport URS150BPP | Newport URS150BPP | |

| Tube voltage | 180 kV | 180 kV | 200 kV | 80 kV | 150 kV | 90 kV | 90 kV | 200 kV |

| Tube current | 5 mA | 5 mA | 4.5 mA | 10 mA | 66 µA | 111 µA | 500 µA | 120 µA |

| Focal spot size | 3 mm | 3 mm | 3 mm | 3 mm | 7 µm | 7 µm | 50 µm | ca. 4 µm |

| Filter | Al (2 mm) | Al (2 mm) | Al (2 mm) | Al (2 mm) | Al (2 mm) | Al (2 mm) | Al (2 mm) | Cu (1 mm) |

| Detector pixel size | 200 µm | 200 µm | 200 µm | 48 µm | 49.5 µm | 49.5 µm | 49.5 µm | 130 µm |

| Detector pixels number | 2560 × 1 | 2560 × 1 | 2560 × 1 | 4608 × 128 | 2304 × 2940 | 2304 × 2940 | 2304 × 2940 | 3000 × 3000 |

| Detector active area | 51.2 × 0.2 cm2 | 51.2 × 0.2 cm2 | 51.2 × 0.2 cm2 | 22.1 × 0.6 cm2 | 11.4 × 14.6 cm2 | 11.4 × 14.6 cm2 | 11.4 × 14.6 cm2 | 40.6 × 40.6 cm2 |

| A/D converter | 12 bit | 12 bit | 12 bit | 12 bit | 14 bit | 14 bit | 14 bit | 16 bit |

| Detector scan speed (m/min) or integration time (s) | 5 m/min | 2.2 m/min | 2 m/min | 4 m/min | 1.9 s | 3 s | 4 s | 1 s |

| Rotation | 360° | 270° | 270° | 360° | 360° | 360° | 360° | 360° |

| Angular step | 0.5° | 0.25° | 0.5° | 0.5° | 0.15° | 0.15° | 0.25° | 0.3° |

| Number of projections | 720 (×13 sections) | 1080 (×6 sections) | 540 | 720 | 2400 | 2400 | 1440 (×3 sections) | 1200 |

| Total time for CT scan | 5.6 days | 90 h | 220 min | 105 min | 120 min | 120 min | 426 min | 20 min |

| Source-Detector Distance (SDD) | 2950 mm | 3690 mm | 2940 mm | 1465 mm | 650 mm | 650 mm | 1400 mm | 800 mm |

| Source-Object Distance (SOD) | 2140 mm | 3180 mm | 2640 mm | 1368 mm | 90 mm | 100 mm | 1300 mm | 90 mm |

| Object-Detector Distance (ODD) | 810 mm | 510 mm | 300 mm | 97 mm | 560 mm | 550 mm | 100 mm | 710 mm |

| Magnification | 1.38× | 1.16× | 1.11× | 1.07× | 7.22× | 6.50× | 1.08× | 8.89× |

| Binning | 4 × 4 | 2 × 2 | none | 2 × 2 | none | none | none | 3 × 3 |

| Voxel size | 580 µm | 340 µm | 180 µm | 90 µm | 7 µm | 8 µm | 46 µm | 45 µm |

| Penumbra | 1.1 mm | 480 µm | 340 µm | 210 µm | 44 µm | 39 µm | 4 µm | 32 µm |

| Reconstruction | LLNL 1 | LLNL | LLNL | ParRec 2 + LLNL | ParRec | ParRec | ParRec | Instrumentation proprietary software |

| Visualization | VGStudio MAX 2.2 | VGStudio MAX 2.2 | VGStudio MAX 2.2 | VGStudio MAX 2.2 | ORS Dragonfly | ORS Dragonfly | ORS Dragonfly | MyVGL |

| Reference | [26] | [27] | [28] | [29] | [30] | [31] | [32] | unpublished |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guidorzi, L.; Re, A.; Tansella, F.; Vigorelli, L.; Ricci, C.; Ryan, J.; Lo Giudice, A. X-CT Reconstruction as a Tool for Monitoring the Conservation State and Decay Processes of Works of Art and in Support of Restoration and Conservation Strategies. Heritage 2025, 8, 52. https://doi.org/10.3390/heritage8020052

Guidorzi L, Re A, Tansella F, Vigorelli L, Ricci C, Ryan J, Lo Giudice A. X-CT Reconstruction as a Tool for Monitoring the Conservation State and Decay Processes of Works of Art and in Support of Restoration and Conservation Strategies. Heritage. 2025; 8(2):52. https://doi.org/10.3390/heritage8020052

Chicago/Turabian StyleGuidorzi, Laura, Alessandro Re, Francesca Tansella, Luisa Vigorelli, Chiara Ricci, Joseph Ryan, and Alessandro Lo Giudice. 2025. "X-CT Reconstruction as a Tool for Monitoring the Conservation State and Decay Processes of Works of Art and in Support of Restoration and Conservation Strategies" Heritage 8, no. 2: 52. https://doi.org/10.3390/heritage8020052

APA StyleGuidorzi, L., Re, A., Tansella, F., Vigorelli, L., Ricci, C., Ryan, J., & Lo Giudice, A. (2025). X-CT Reconstruction as a Tool for Monitoring the Conservation State and Decay Processes of Works of Art and in Support of Restoration and Conservation Strategies. Heritage, 8(2), 52. https://doi.org/10.3390/heritage8020052