Archaeometric Investigation of Artificial Stone Materials from the Theatrum Marcelli (Rome, Italy)

Abstract

1. Introduction

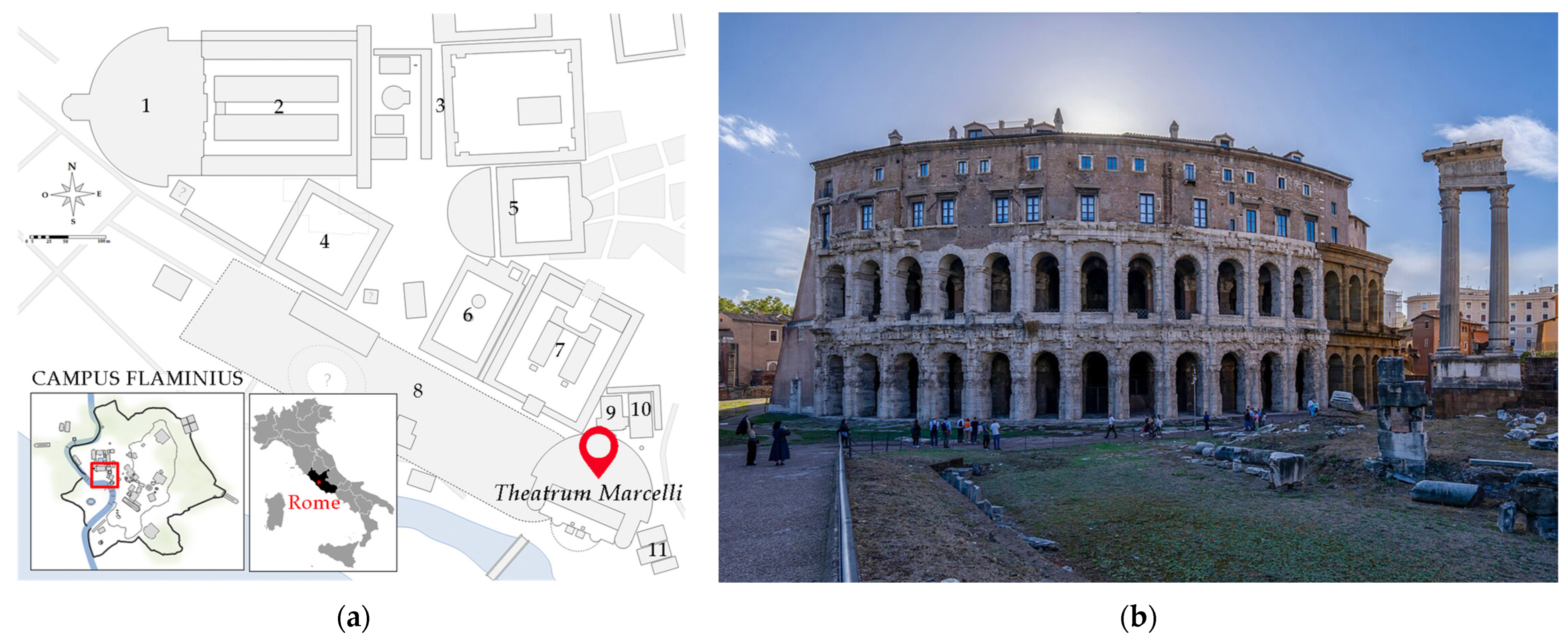

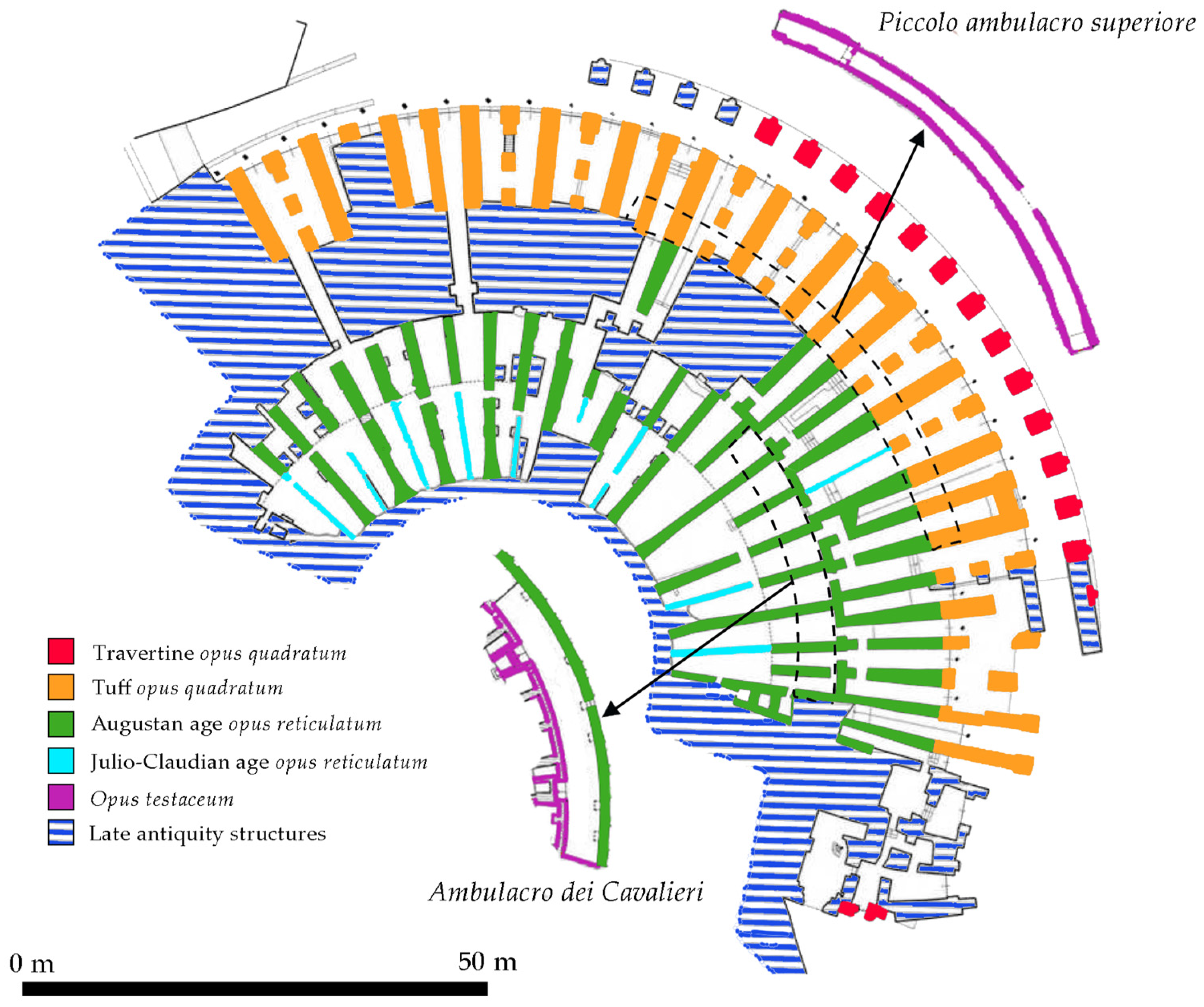

2. Historical Background and Building Materials of the Theatrum Marcelli

3. Materials and Methods

4. Results and Discussion

4.1. Bricks

4.2. Mortars and Plasters

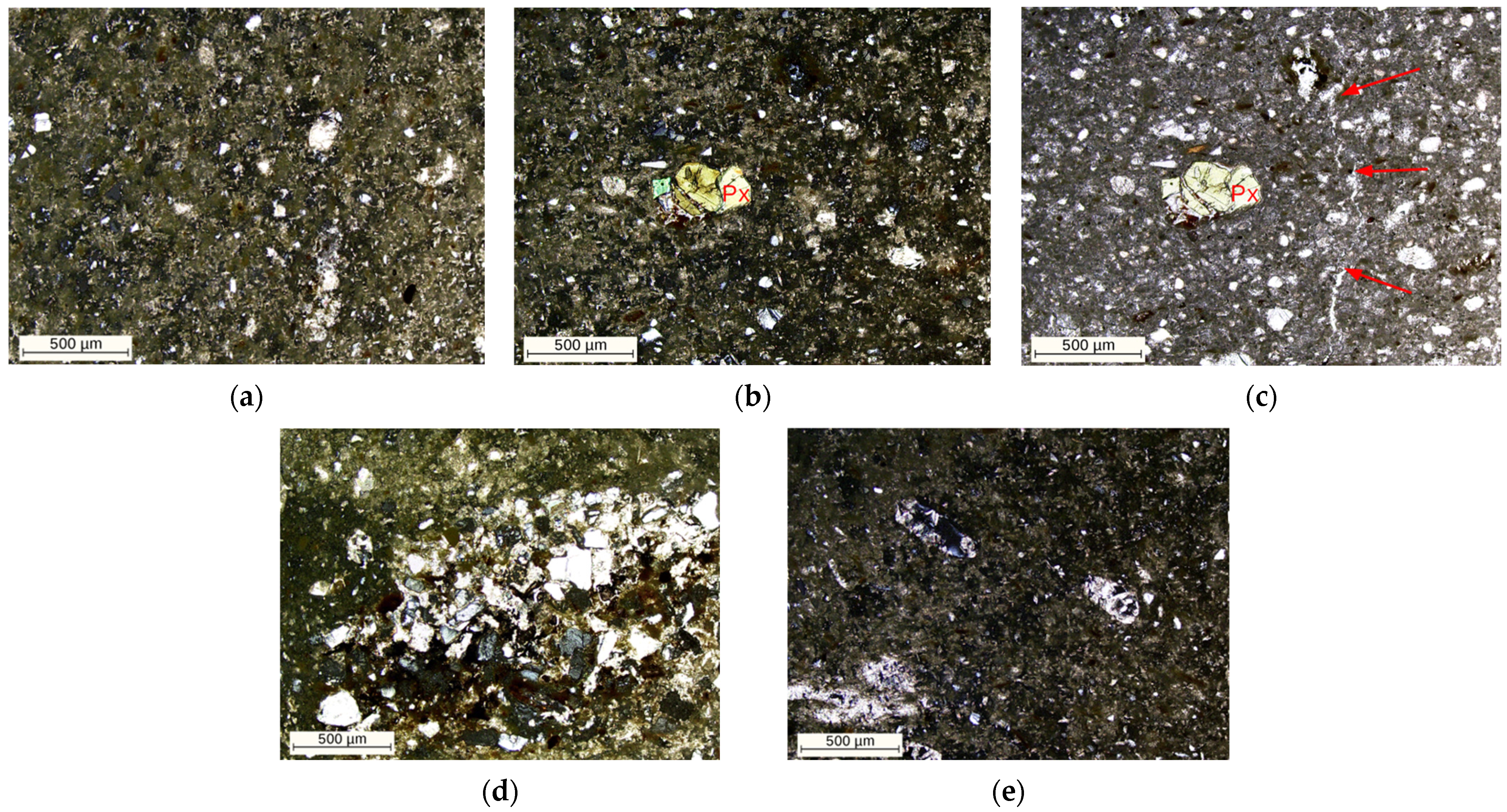

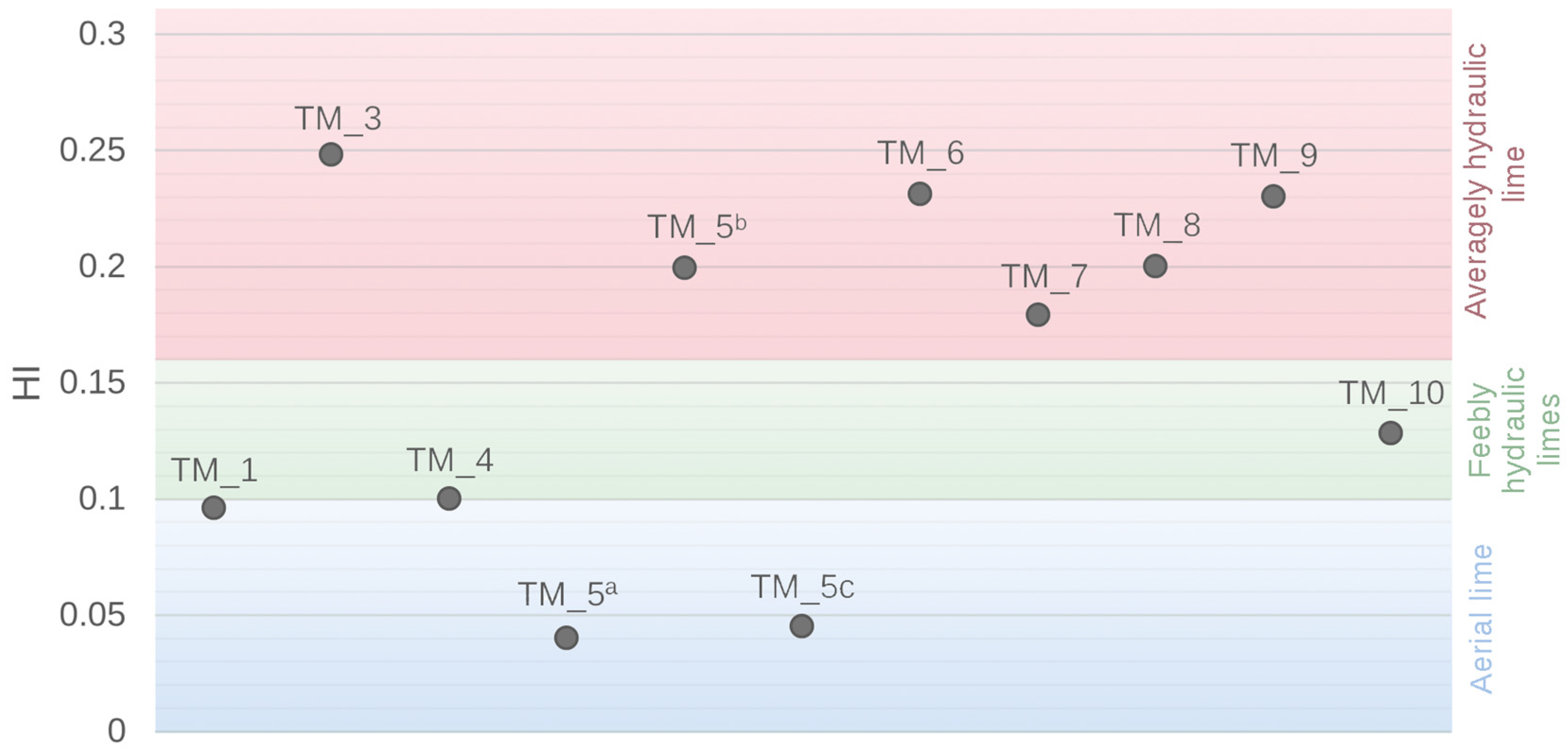

4.2.1. Minero-Petrographic Analysis

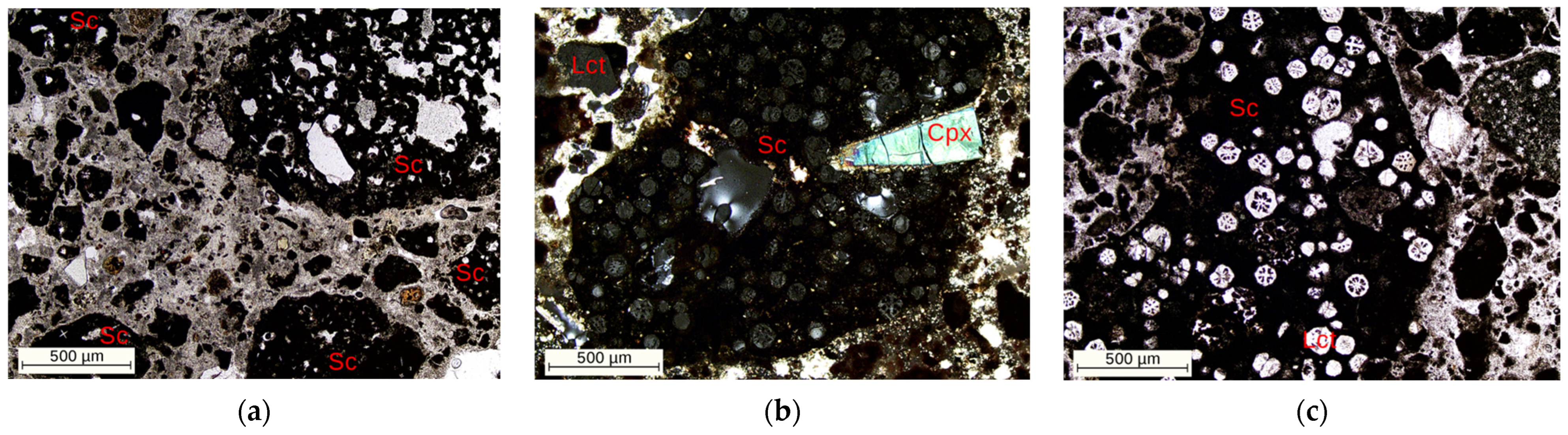

- Mortars

- 2.

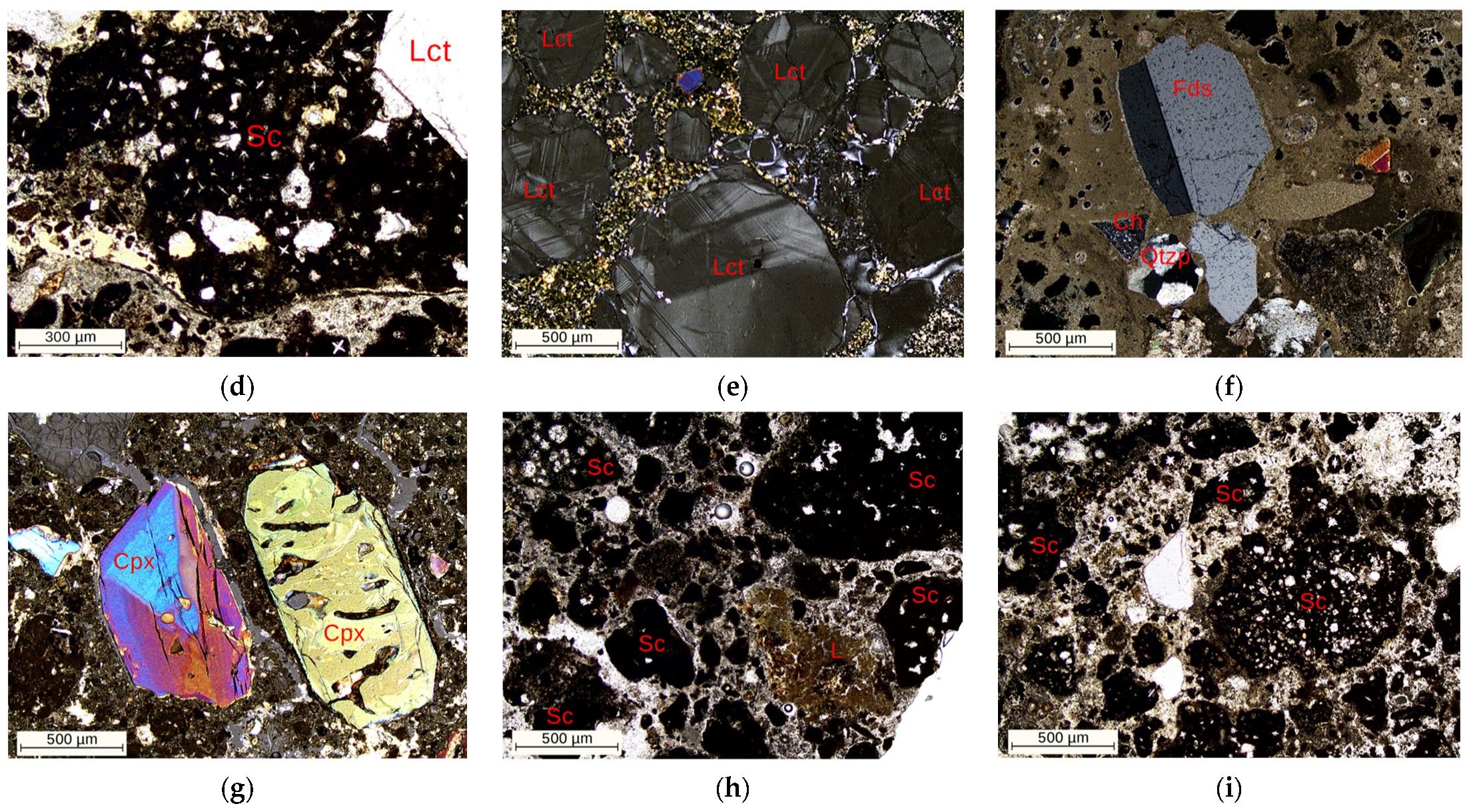

- Plasters

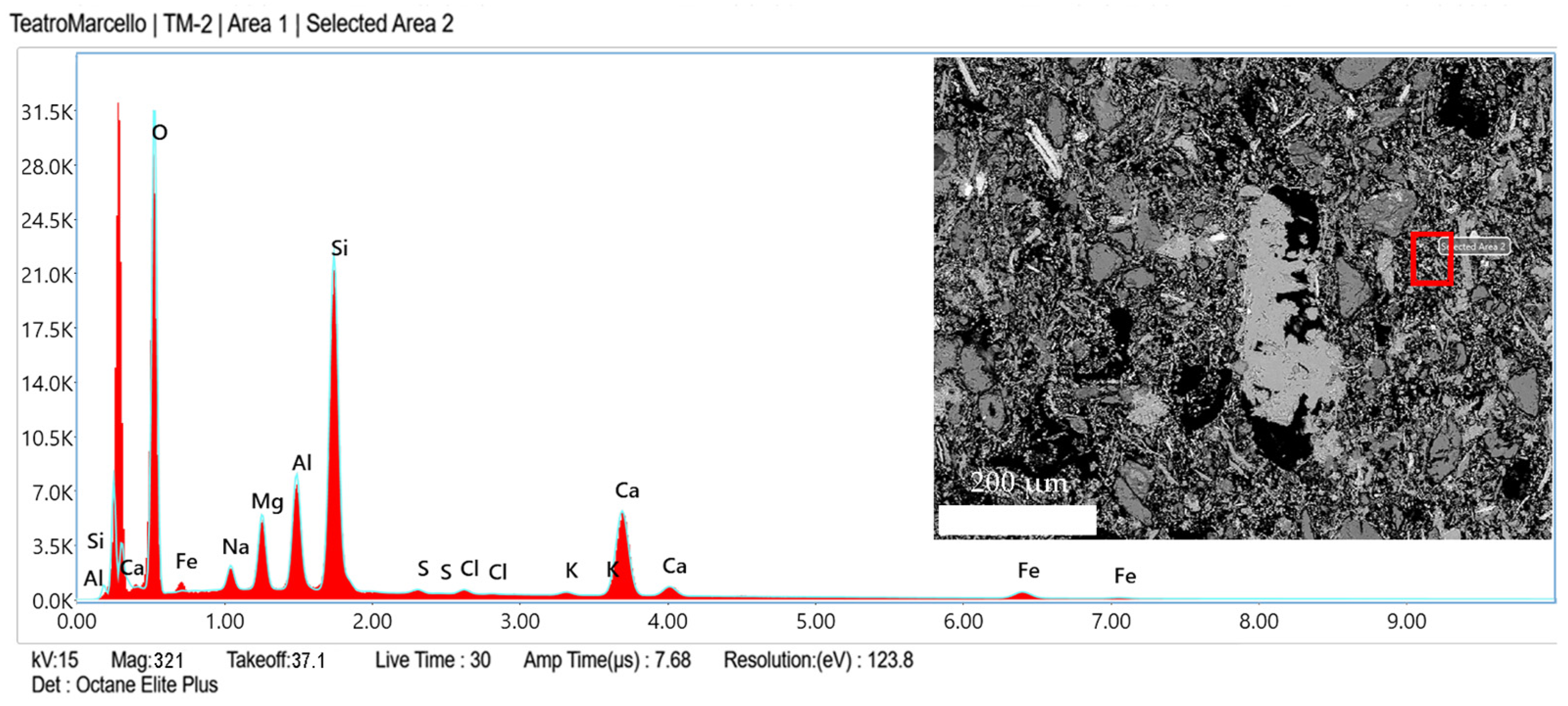

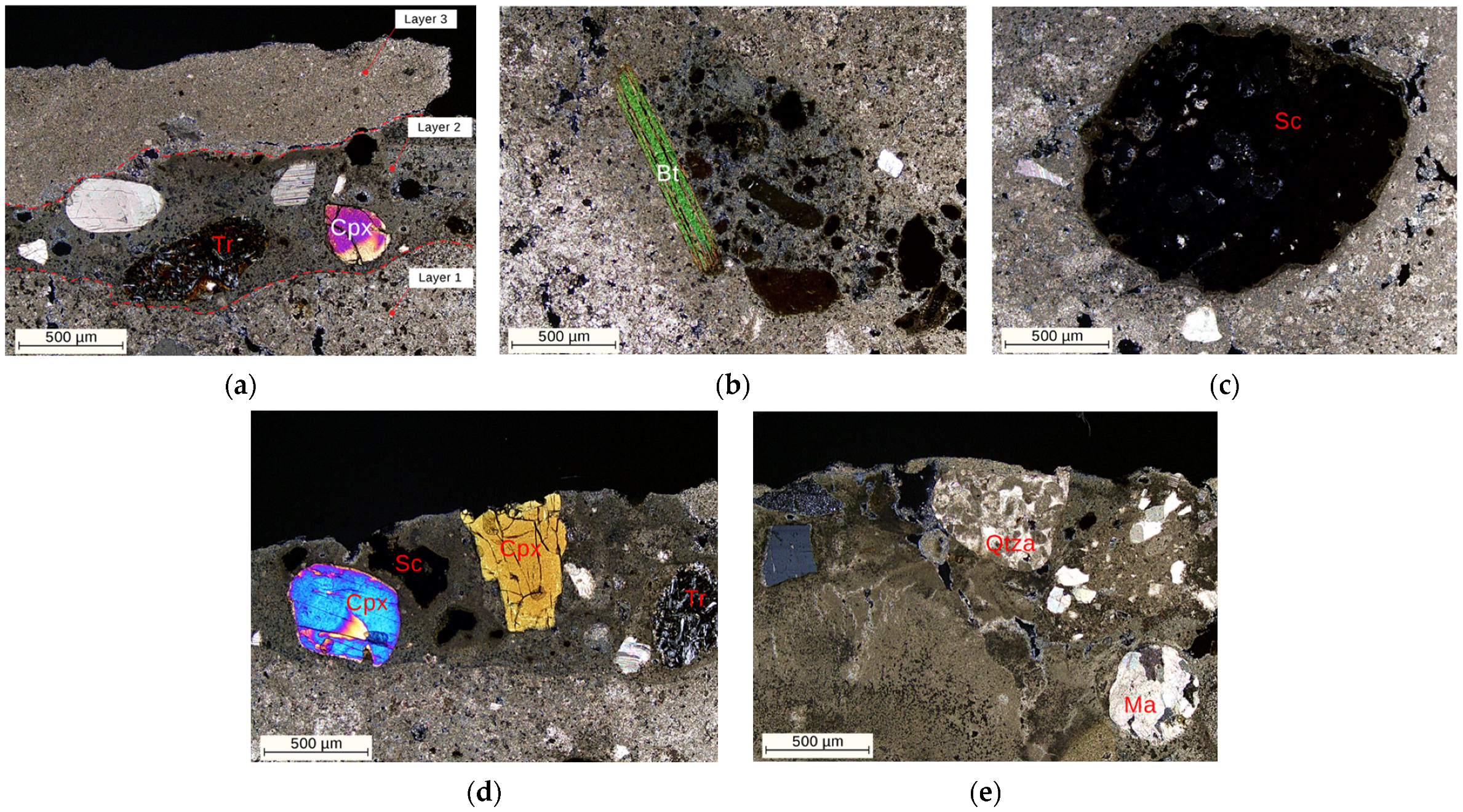

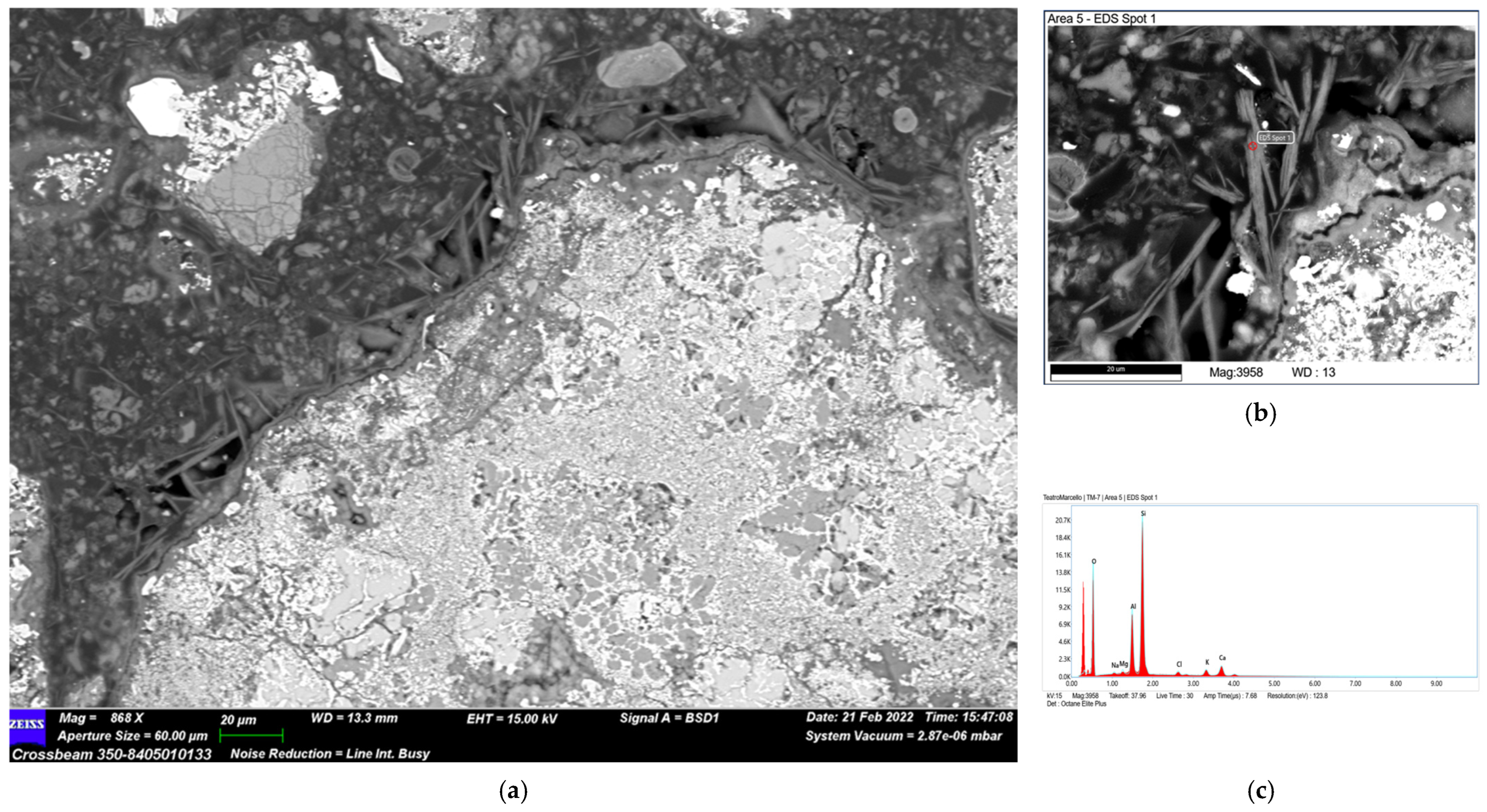

4.2.2. SEM-EDS Investigation and HI Index

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Rispoli, C.; De Bonis, A.; Guarino, V.; Graziano, S.F.; di Benedetto, C.; Esposito, R.; Morra, V.; Cappelletti, P. The Ancient Pozzolanic Mortars of the Thermal Complex of Baia (Campi Flegrei, Italy). J. Cult. Herit. 2019, 40, 143–154. [Google Scholar] [CrossRef]

- Jackson, M.D.; Kosso, C.K. Scientia in Republican Era stone and concrete masonry. In A Companion to the Archaeology of the Roman Republican Period; Evans, J.D., Ed.; Wiley Blackwell: London, UK, 2013; pp. 268–284. [Google Scholar] [CrossRef]

- Jackson, M.D.; Marra, F.; Hay, R.L.; Cawood, C.; Winkler, E.M. The judicious selection and preservation of tuff and travertine building stone in Ancient Rome. Archaeometry 2005, 47, 485–510. [Google Scholar] [CrossRef]

- Jackson, M.D.; Kosso, C.; Marra, F.; Hay, R. Geological Basis of Vitruvius’ Empirical Observations of Materials Characteristics of Rock Utilized in Roman Masonry. In Proceedings of the Second International Congress of Construction History, Queens’ College, Cambridge University, UK, 29 March–2 April 2006; Dunkeld, M., Campbell, J., Louw, H., Tutton, M., Addis, B., Thorne, R., Eds.; The Construction History Society: London, UK, 2006; Volume 2, pp. 1685–1702. [Google Scholar]

- Collepardi, M. La lezione dei romani: Durabilità e sostenibilità delle opere architettoniche e strutturali. In Proceedings of the III Convegno AIMAT “Restauro E Conservazione Dei Beni Culturali: Materiali E Tecniche”, Cassino, Italy, 3–4 October 2003. [Google Scholar]

- Lancaster, L. Concrete Vaulted Construction in Imperial Rome: Innovations in Context; Cambridge University Press: Cambridge, UK, 2005. [Google Scholar]

- Pavia, S. A petrographic study of mortar hydraulicity. In Proceedings of the HMC 08—1st Historical Mortar Conference, Lisboa, Portugal, 24–28 September 2008. [Google Scholar]

- Rispoli, C.; Montesano, G.; Verde, M.; Balassone, G.; Columbu, S.; De Bonis, A.; Di Benedetto, C.; D’Uva, F.; Esposito, R.; Graziano, S.F.; et al. The key to ancient Roman mortars hydraulicity: Ceramic fragments or volcanic materials? A lesson from the Phlegrean archaeological area (southern Italy). Constr. Build. Mater. 2024, 411, 134408. [Google Scholar] [CrossRef]

- Gambino, F.; Glarey, A.; Cossio, R.; Appolonia, L.; d’Atri, A.; Borghi, A. SEM-EDS Characterization of Historic Mortar as a Tool in Archaeometric Study: An Updated Analytical Protocol Tested on the Roman Theatre of Aosta (NW Italy). Archaeol. Anthropol. Sci. 2022, 14, 179. [Google Scholar] [CrossRef]

- Marra, F.; D’Ambrosio, E.; Gaeta, M.; Mattei, M. Petrochemical identification and insights on chronological employment of the volcanic aggregates used in ancient Roman mortars. Archaeometry 2016, 58, 177–200. [Google Scholar] [CrossRef]

- Marra, F.; Danti, A.; Gaeta, M. The volcanic aggregate of ancient Roman mortars from the Capitoline Hill: Petrographic criteria for identification of Rome’s “pozzolans” and historical implications. J. Volcanol. Geotherm. Res. 2015, 308, 113–126. [Google Scholar] [CrossRef]

- Jackson, M.; Deocampo, D.; Marra, F.; Scheetz, B. Mid-Pleistocene pozzolanic volcanic ash in ancient Roman concretes. Geoarchaeol. Int. J. 2010, 25, 36–74. [Google Scholar] [CrossRef]

- Jackson, M.; Marra, F.; Deocampo, D.; Vella, A.; Kosso, C.; Hay, R. Geological Observations of Excavated Sand (Harenae Fossiciae) Used as Fine Aggregate in Roman Pozzolanic Mortars. J. Rom. Archaeol. 2007, 20, 25–53. [Google Scholar] [CrossRef]

- Pollio, M.V. De Architectura. The Architecture of Marcus Vitruvius Pollio; Gwilt, J., Ed.; Lockwood & CO.: London, UK, 1874; Available online: https://warburg.sas.ac.uk/pdf/kfh125b2128022.pdf (accessed on 28 November 2024).

- Bencivenga, M.; Di Loreto, E.; Liperi, L. Il regime idrologico del Tevere, con particolare riguardo alle piene della città di Roma. In Memorie Descrittive Della Carta Geologica D’Italia: La Geologia Di Roma; Anonymous, Ed.; Istituto Poligrafico E Zecca Dello Stato: Rome, Italy, 1995; pp. 125–172. [Google Scholar]

- Del Monte, M. La geomorfologia di Roma. In La Geomorfologia Di Roma; Sapienza Università Editrice: Rome, Italy, 2018; pp. 1–194. [Google Scholar]

- Pantaloni, M.; Guerra, M.; Console, F.; Primerano, P. Rome before Rome: A River among two volcanoes. Discovering the relationship between the history of the city and the territory. Geol. Field Trips Maps 2023, 15, 1–66. [Google Scholar] [CrossRef]

- Augustus, G.I.C.O. Monumentum Ancyranum (Res Gestae Divi Augusti). Velleius Paterculus. Compendium of Roman History. Res Gestae Divi Augusti; Shipley, F.W., Ed.; Harvard University Press: Cambridge, MA, USA, 1924; Available online: https://penelope.uchicago.edu/Thayer/E/Roman/Texts/Augustus/Res_Gestae/home.html (accessed on 28 November 2024).

- Tranquillus, C.S. De vita duodecim Caesarium. In Lives of the Caesars; Rolfe, J.C., Ed.; Harvard University Press: Cambridge, MA, USA, 1914; Available online: https://penelope.uchicago.edu/Thayer/E/Roman/Texts/Suetonius/12Caesars/Julius*.html#44 (accessed on 28 November 2024).

- Rossetto, P.C.; Buonfiglio, M. Teatro di Marcello: Analisi e riflessioni sugli aspetti progettuali e costruttivi. In Arqueología De La Construcción II, Los Procesos Constructivos En El Mundo Romano: Italia Y Provincias Orientales (Atti Convegno Siena 2008); Camporeale, S., Dessales, H., Pizzo, A., Eds.; Consejo Superior de Investigaciones Científicas (CSIC): Madrid, Spain, 2010; pp. 51–70. [Google Scholar]

- Dio, L.C.C. Historia Romana. Dio Cassius. In Roman History, Volume VI: Books 51–55; Cary, E., Foster, H.B., Eds.; Harvard University Press: Cambridge, MA, USA, 1917; Available online: https://penelope.uchicago.edu/Thayer/E/Roman/Texts/Cassius_Dio/53*.html#30.6 (accessed on 28 November 2024).

- Anonymous. Historia Augusta. In Historia Augusta, Volume II: Caracalla. Geta. Opellius Macrinus. Diadumenianus. Elagabalus. Severus Alexander. The Two Maximini. The Three Gordians. Maximus and Balbinus; Magie, D., Ed.; Harvard University Press: Cambridge, MA, USA, 1924; Available online: https://penelope.uchicago.edu/Thayer/E/Roman/Texts/Historia_Augusta/Severus_Alexander/2*.html#44.7 (accessed on 28 November 2024).

- Pensabene, P. Marmo ed evergetismo negli edifici teatrali d’Italia. Gallia e Hispania. Malnake 2007, 29, 7–52. [Google Scholar]

- Gigli, F.; Pergola, S. Teatro di Marcello. Nuova campagna di rilievi, indagini e ricerche. Bull. Comm. Arch. Rom. 2023, 124, 330–341. [Google Scholar]

- Hulsen, C. Il posto degli Arvali nel Colosseo e la capacità dei teatri di Roma antica. Bachelor Commer. 1894, 22, 312–324. [Google Scholar]

- Buonfiglio, M. L’utilizzo dei laterizi nella costruzione augustea del Teatro di Marcello. In Archeologia Dell’architettura, XX, 2015–Il Laterizio Nei Cantieri Imperiali. Roma E Il Mediterraneo. Atti Del I Workshop “Laterizio”(Roma, 27–28 Novembre 2014); Bukowiecki, E., Volpe, R., Wulf-Rheidt, U., Eds.; All’Insegna del Giglio: Florence, Italy, 2015; pp. 13–19. [Google Scholar]

- Montana, G. Ceramic raw materials: How to recognize them and locate the supply basins—Mineralogy, petrography. Archaeol. Anthropol. Sci. 2020, 12, 175. [Google Scholar] [CrossRef]

- Matthew, A.; Woods, A.; Oliver, C. Spots before the Eyes: New Comparison Charts for Visual Percentage Estimation in Archaeological Material. In Recent Developments in Ceramic Petrology; Middleton, A., Freestone, I., Eds.; British Museum Occasional Paper; British Museum: London, UK, 1991; pp. 221–263. [Google Scholar]

- Janssens, K.; Van Grieken, R. Non-Destructive Microanalysis of Cultural Heritage Materials; Elsevier: Amsterdam, The Netherlands, 2005; pp. 80–82. ISBN 9780444559883. [Google Scholar]

- Barba, L.; Blancas, J.; Manzanilla, L.R.; Ortiz, A.; Barca, D.; Crisci, G.; Miriello, D.; Pecci, A. Provenance of the limestone used in Teotihuacan (Mexico): A methodological approach. Archaeometry 2009, 51, 525–545. [Google Scholar] [CrossRef]

- Hughes, J.J.; Leslie, A.B.; Callebaut, K. The Petrography of Lime Inclusions in Historic Lime-Based Mortars. Ann. Géol. Pays Hellén. 2001, 39, 359–364. [Google Scholar]

- Boynton, R.S. Chemistry and Technology of Lime and Limestone; John Wiley & Sons, Inc.: New York, NY, USA, 1966. [Google Scholar]

- Elsen, J.; Van Balen, K.; Mertens, G. Hydraulicity in Historic Lime Mortars: A Review. In Historic Mortars; Válek, J., Hughes, J.J., Groot, C.J.W.P., Eds.; RILEM Bookseries; Springer: Dordrecht, The Netherlands, 2012; pp. 125–139. [Google Scholar] [CrossRef]

- Blair, T.C.; Mcpherson, J.G. Grain-size and textural classification of coarse sedimentary particles. J. Sed. Res. 1999, 69, 6–19. [Google Scholar] [CrossRef]

- Scatigno, C.; Prieto-Taboada, N.; Martinez, M.P.; Conte, A.M.; Madariaga, J.M. A non-invasive spectroscopic study to evaluate both technological features and conservation state of two types of ancient Roman coloured bricks. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2018, 204, 55–63. [Google Scholar] [CrossRef]

- Fragnoli, P.; Boccalon, E.; Liberotti, G. Designing a ‘yellow brick road’ for the archaeometric analyses of fired and unfired bricks. J. Cult. Herit. 2023, 59, 231–246. [Google Scholar] [CrossRef]

- Powers, M.C. A new roundness scale for sedimentary particles. J. Sediment. Res. 1953, 23, 117–119. [Google Scholar] [CrossRef]

- Wentworth, C.K. A scale of grade and class terms for clastic sediments. J. Geol. 1922, 30, 377–392. [Google Scholar] [CrossRef]

- Peccerillo, A. Plio-Quaternary Volcanism in Italy; Springer: Berlin/Heidelberg, Germany, 2005; ISBN 3-540-25885-X. [Google Scholar]

- Trigila, R.; Agosta, E.; Currado, C.; De Benedetti, A.A.; Freda, C.; Gaeta, M.; Palladino, D.M.; Rosa, C. Petrology. In The Volcano of the Alban Hills; Trigila, R., Ed.; Università degli Studi di Roma “La Sapienza”: Rome, Italy, 1995; pp. 95–165. [Google Scholar]

- Conticelli, S.; Boari, E.; Benedetti, A.A.; Giordano, G.; Mattei, M.; Melluso, L.; Morra, V. Geochemistry, isotopes and mineral chemistry of the Colli Albani volcanic Rocks: Constraints on magma genesis and evolution. In The Colli Albani Volcano; Geological Society of London: London, UK, 2010; pp. 107–139. [Google Scholar] [CrossRef]

- Marra, F.; Deocampo, D.; Jackson, M.D.; Ventura, G. The Alban Hills and Monti Sabatini volcanic products used in ancient Roman masonry (Italy): An integrated stratigraphic, archaeological, environmental and geochemical approach. Earth-Sci. Rev. 2011, 108, 115–136. [Google Scholar] [CrossRef]

- Belfiore, C.M.; Fichera, G.V.; La Russa, M.F.; Pezzino, A.; Ruffolo, S.A.; Galli, G.D. A Multidisciplinary Approach for the Archaeometric Study of Pozzolanic Aggregate in Roman Mortars: The Case of Villa dei Quintili (Rome, Italy). Archeometry 2015, 57, 269–296. [Google Scholar] [CrossRef]

- Freda, C.; Gaeta, M.; Giaccio, B.; Marra, F.; Palladino, D.M.; Scarlato, P.; Sottili, G. CO2-driven large mafic explosive eruptions: The Pozzolane Rosse case study from the Colli Albani Volcanic District (Italy). Bull. Volcanol. 2011, 73, 241–256. [Google Scholar] [CrossRef]

- Elsen, J.; Brutsaert, A.; Deckers, M.; Brulet, R. Microscopical study of ancient mortars from Tournai (Belgium). Mater. Charact. 2004, 53, 289–294. [Google Scholar] [CrossRef]

- Elsen, J. Microscopy of historic mortars—A review. Cem. Concr. Res. 2006, 36, 1416–1424. [Google Scholar] [CrossRef]

- Columbu, S.; Lisci, C.; Sitzia, F.; Lorenzetti, G.; Lezzerini, M.; Pagnotta, S.; Raneri, S.; Legnaioli, S.; Palleschi, V.; Gallello, G.; et al. Mineralogical, Petrographic and Physical-Mechanical Study of Roman Construction Materials from the Maritime Theatre of Hadrian’s Villa (Rome, Italy). Measurement 2018, 127, 264–276. [Google Scholar] [CrossRef]

- Miriello, D.; Bloise, A.; Crisci, G.M.; de Luca, R.; de Nigris, B.; Martellone, A.; Osanna, M.; Pace, R.; Pecci, A.; Ruggieri, N. New compositional data on ancient mortars and plasters from Pompeii (Campania–Southern Italy): Archaeometric results and considerations about their time evolution. Mater. Charact. 2018, 146, 189–203. [Google Scholar] [CrossRef]

- Jackson, M.D.; Logan, J.M.; Scheetz, B.E.; Deocampo, D.M.; Cawood, C.G.; Marra, F.; Vitti, M.; Ungaro, L. Assessment of material characteristics of ancient concretes, Grande Aula, Markets of Trajan, Rome. J. Archaeol. Sci. 2009, 36, 2481–2492. [Google Scholar] [CrossRef]

- Morimoto, N.; Fabries, J.; Ferguson, A.K.; Ginzburg, I.V.; Ross, M.; Seifert, F.A.; Zussman, J. Nomenclature of pyroxenes. Mineral. Mag. 1988, 52, 535–550. [Google Scholar] [CrossRef]

- Hughes, J.J.; Cuthbert, S.; Bartos, P.J.M. Alteration textures in historic Scottish lime mortars and implications for practical mortar analysis. In Proceedings of the 7th Euroseminar on Microscopy Applied to Building Materials, Delft, The Netherlands, 29 June–2 July 1999; pp. 417–426, ISBN 9076554021. [Google Scholar]

- Callebaut, K.; Van Balen, K. Dry-Slaked Lime: An alternative binder for restoration mortars. In Proceedings of the International Workshop on Urban Heritage and Building Maintenance VII, Zürich, Switzerland, 1 September 2000; pp. 65–72. [Google Scholar]

- Bakolas, A.; Biscontin, G.; Moropoulou, A.; Zendri, E. Characterization of the lumps in the mortars of historic masonry. Thermochim. Acta 1995, 269–270, 809–816. [Google Scholar] [CrossRef]

- Bruni, S.; Cariati, F.; Fermo, P.; Cairati, P.; Alessandrini, G.; Toniolo, L. White lumps in fifth- to seventeenth-century A.D. mortars from Northern Italy. Archaeometry 1997, 39, 1–7. [Google Scholar] [CrossRef]

- Fichera, G.V.; Belfiore, C.M.; La Russa, M.F.; Ruffolo, S.A.; Barca, D.; Frontoni, R.; Galli, G.; Pezzino, A. Limestone provenance in Roman lime-volcanic ash mortars from the villa dei quintili, Rome. Geoarchaeology 2015, 30, 79–99. [Google Scholar] [CrossRef]

- Pavia, S.; Caro, S. An investigation of Roman mortar technology through the petrographic analysis of archaeological material. Constr. Build. Mater. 2008, 22, 1807–1811. [Google Scholar] [CrossRef]

- Belfiore, C.M.; Fichera, G.V.; Ortolano, G.; Pezzino, A.; Visalli, R.; Zappalà, L. Image processing of the pozzolanic reactions in Roman mortars via X-ray Map Analyser. Microchem. J. 2016, 125, 242–253. [Google Scholar] [CrossRef]

- Randazzo, L.; Ricca, M.; Ruffolo, S.; Aquino, M.; Davidde Petriaggi, B.; Enei, F.; La Russa, M.F. An Integrated Analytical Approach to Define the Compositional and Textural Features of Mortars Used in the Underwater Archaeological Site of Castrum Novum (Santa Marinella, Rome, Italy). Minerals 2019, 9, 268. [Google Scholar] [CrossRef]

| Sample ID | Sampling Location | Description |

|---|---|---|

| TM_1 | Ambulacro dei Cavalieri (fornice 4) | Mortar (opus testaceum) |

| TM_2 | Ambulacro dei Cavalieri (fornice 4) | Yellow brick |

| TM_3 | Ambulacro dei Cavalieri (fornice 4) | Mortar (opus reticolatum) |

| TM_4 | Ambulacro dei Cavalieri (fornice 4) | Mortar |

| TM_5 | Ambulacro dei Cavalieri (fornice 4) | Three-layer plaster |

| TM_6 | Fornice 10 | Mortar (opus reticolatum), external coating |

| TM_7 | Fornice 10 | Mortar (opus reticolatum), internal wall |

| TM_8 | Fornice 12 | Mortar (opus reticolatum), central wall |

| TM_9 | Fornice 15 | Mortar (opus reticolatum), central wall, Augustan age |

| TM_10 | Fornice 15 | Mortar (opus reticolatum), central wall, Julio-Claudian age |

| Sample ID | Type | Na2O | MgO | Al2O3 | SiO2 | S | Cl | K2O | CaO | FeO | HI |

| TM_1 | Binder | 0.6 | 7.8 | 1.8 | 6.8 | 0.5 | 0.0 | 0.5 | 81.9 | 0.0 | 0.096 |

| TM_3 | Binder | 0.5 | 0.3 | 4.9 | 14.5 | 0.5 | 0.4 | 1.4 | 77.7 | 0.0 | 0.248 |

| TM_4 | Binder | 0.5 | 6.3 | 2.0 | 6.9 | 0.4 | 0.0 | 0.8 | 83.0 | 0.0 | 0.100 |

| TM_5a | Binder | 1.5 | 2.7 | 1.0 | 2.7 | 0.6 | 0.5 | 1.8 | 73.8 | 0.0 | 0.040 |

| TM_5b | Binder | 1.8 | 4.6 | 3.5 | 12.1 | 1.5 | 1.0 | 1.8 | 73.8 | 0.0 | 0.199 |

| TM_5c | Binder | 0.5 | 2.7 | 0.4 | 3.8 | 0.6 | 0.5 | 0.1 | 91.5 | 0.0 | 0.045 |

| TM_6 | Binder | 1.2 | 0.3 | 4.3 | 13.7 | 1.0 | 1.3 | 1.1 | 77.4 | 0.0 | 0.231 |

| TM_7 | Binder | 0.6 | 2.3 | 5.0 | 9.6 | 0.7 | 0.2 | 2.1 | 79.4 | 0.0 | 0.179 |

| TM_8 | Binder | 0.0 | 0.8 | 4.3 | 12.0 | 0.8 | 0.3 | 0.9 | 80.9 | 0.0 | 0.200 |

| TM_9 | Binder | 0.0 | 0.6 | 4.7 | 13.7 | 0.6 | 0.4 | 0.7 | 79.3 | 0.0 | 0.230 |

| TM_10 | Binder | 0.2 | 0.3 | 2.8 | 8.2 | 1.9 | 0.4 | 0.5 | 85.7 | 0.0 | 0.128 |

| Sample ID | Type | Na2O | MgO | Al2O3 | SiO2 | S | Cl | K2O | CaO | FeO | HI |

| TM_1 | Lump | 0.0 | 0.0 | 0.0 | 0.4 | 0.0 | 0.0 | 0.4 | 98.2 | 0.0 | 0.004 |

| TM_1 | Lump | 0.0 | 0.4 | 0.3 | 1.3 | 0.0 | 0.0 | 0.0 | 97.3 | 0.0 | 0.016 |

| TM_4 | Lump | 0.3 | 0.9 | 1.3 | 3.8 | 0.8 | 0.0 | 0.9 | 91.8 | 0.0 | 0.055 |

| TM_4 | Lump | 0.2 | 1.2 | 1.6 | 4.1 | 0.8 | 0.0 | 0.9 | 91.4 | 0.1 | 0.063 |

| TM_7 | Lump | 0.2 | 0.0 | 0.0 | 0.2 | 0.0 | 0.3 | 0.0 | 99.2 | 0.0 | 0.002 |

| TM_8 | Lump | 0.0 | 1.1 | 0.0 | 1.2 | 0.0 | 0.0 | 0.0 | 97.7 | 0.0 | 0.012 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zicarelli, M.A.; Ricca, M.; Alberghina, M.F.; Schiavone, S.; La Russa, M.F.; Randazzo, L. Archaeometric Investigation of Artificial Stone Materials from the Theatrum Marcelli (Rome, Italy). Heritage 2025, 8, 57. https://doi.org/10.3390/heritage8020057

Zicarelli MA, Ricca M, Alberghina MF, Schiavone S, La Russa MF, Randazzo L. Archaeometric Investigation of Artificial Stone Materials from the Theatrum Marcelli (Rome, Italy). Heritage. 2025; 8(2):57. https://doi.org/10.3390/heritage8020057

Chicago/Turabian StyleZicarelli, Maria Aantonietta, Michela Ricca, Maria Francesca Alberghina, Salvatore Schiavone, Mauro Francesco La Russa, and Luciana Randazzo. 2025. "Archaeometric Investigation of Artificial Stone Materials from the Theatrum Marcelli (Rome, Italy)" Heritage 8, no. 2: 57. https://doi.org/10.3390/heritage8020057

APA StyleZicarelli, M. A., Ricca, M., Alberghina, M. F., Schiavone, S., La Russa, M. F., & Randazzo, L. (2025). Archaeometric Investigation of Artificial Stone Materials from the Theatrum Marcelli (Rome, Italy). Heritage, 8(2), 57. https://doi.org/10.3390/heritage8020057