Correlation Between the Anticorrosive Performance of Protective Coatings Under Neutral Salt Spray Testing and Outdoor Atmospheric and Immersion Exposure

Abstract

1. Introduction

| Reference | Coating on Steel Substrate 1 | Conditions | ISO 9223 Category (Steel) | Duration [Years] |

|---|---|---|---|---|

| Chico et al. [8] | Silane pre-treatment, alkyd/polyester aminoplast base paint | atmospheric, inland | C2 | 1/3 |

| Takeshita et al. [9] | Polyethylene terephthalate and polyvinyl butyral resins | atmospheric, inland and coastal | not specified | 0.5/0.7 |

| Seré et al. [10] | Electrogalvanized steel pre-treated with a silane, mercaptopropyltrimethoxysilane or chromium(III)-based solution (Cr), painted with an alkyd system | atmospheric, inland | not specified | 5 |

| Fragata et al. [11] | Aluminum polyamine epoxy mastic | atmospheric, coastal, addition of NaCl solution | C3 | 0.9 |

| Fekete and Lengyel [12] | Styrene–acrylate waterborne paint systems | atmospheric, inland | not specified | 0.3–2.5 |

| De Florian et al. [13] | Galvanized steel with Zn and Zn-Al alloys and a urethane chromate primer, a polyester chromate primer, an epoxy chromate primer and a fluoropolymer top coating | atmospheric, inland and coastal | not specified | 0.1–1 |

| Li et al. [14] | Epoxy polysiloxane coating | atmospheric and tidal, coastal | not specified | 0.77 |

| Almeida et al. [15] | Acrylic, acrylic enamel, epoxy and epoxy polyamide waterborne coatings | atmospheric, inland and coastal | C3, CX | 2, 3 |

| Zhang et al. [16] | Epoxy anticorrosion paint, polyurethane paint or fluorocarbon top paint | atmospheric, coastal | not specified | 2 |

| Davalos-Monteiro et al. [17] | Polyester, polyester–epoxy and epoxy powder coatings | atmospheric, coastal | C5 | 1–4 |

| LeBozec et al. [18] | Marine paint systems | atmospheric, coastal, atmospheric and splash zone, on a ship | C5, CX | 3, 4 |

| Pélissier et al. [19] | Ethyl silicate, epoxy, aliphatic acrylic polyurethane, polyamine epoxy, silicone alkyd, waterborne epoxy and acrylic, aliphatic polyurethane, vinylic epoxy, acrylic, polyamide epoxy, aliphatic acrylic polyurethane | atmospheric, coastal, atmospheric, on a ship | C5, CX | 1–6 |

| Momber et al. [20] | Epoxy, polyaspartate, epoxy/siloxane repair coatings | atmospheric, coastal | not specified | 0.5–5.75 |

| Perrin et al. [21] | Modified epoxy, alkyd silicon/TC | atmospheric, coastal | C3, C5 | 4 |

| Knudsen et al. [22] | Epoxy, epoxy mastic and polyurethane top coat | atmospheric, coastal | C5 | 1, 2 |

| Binder [23,24] | Epoxy and polyurethane | atmospheric, splash and immersion zone, inland and coastal | C2, C3, C4 | 5 |

2. Materials and Methods

2.1. Samples

2.2. Laboratory Testing Methods

2.2.1. NSS Testing

2.2.2. Pull-Off Adhesion

2.2.3. Abrasion Testing

2.3. Outdoor Exposure

2.4. Evaluation of the Results

3. Results

3.1. NSS Testing and Outdoor Exposure

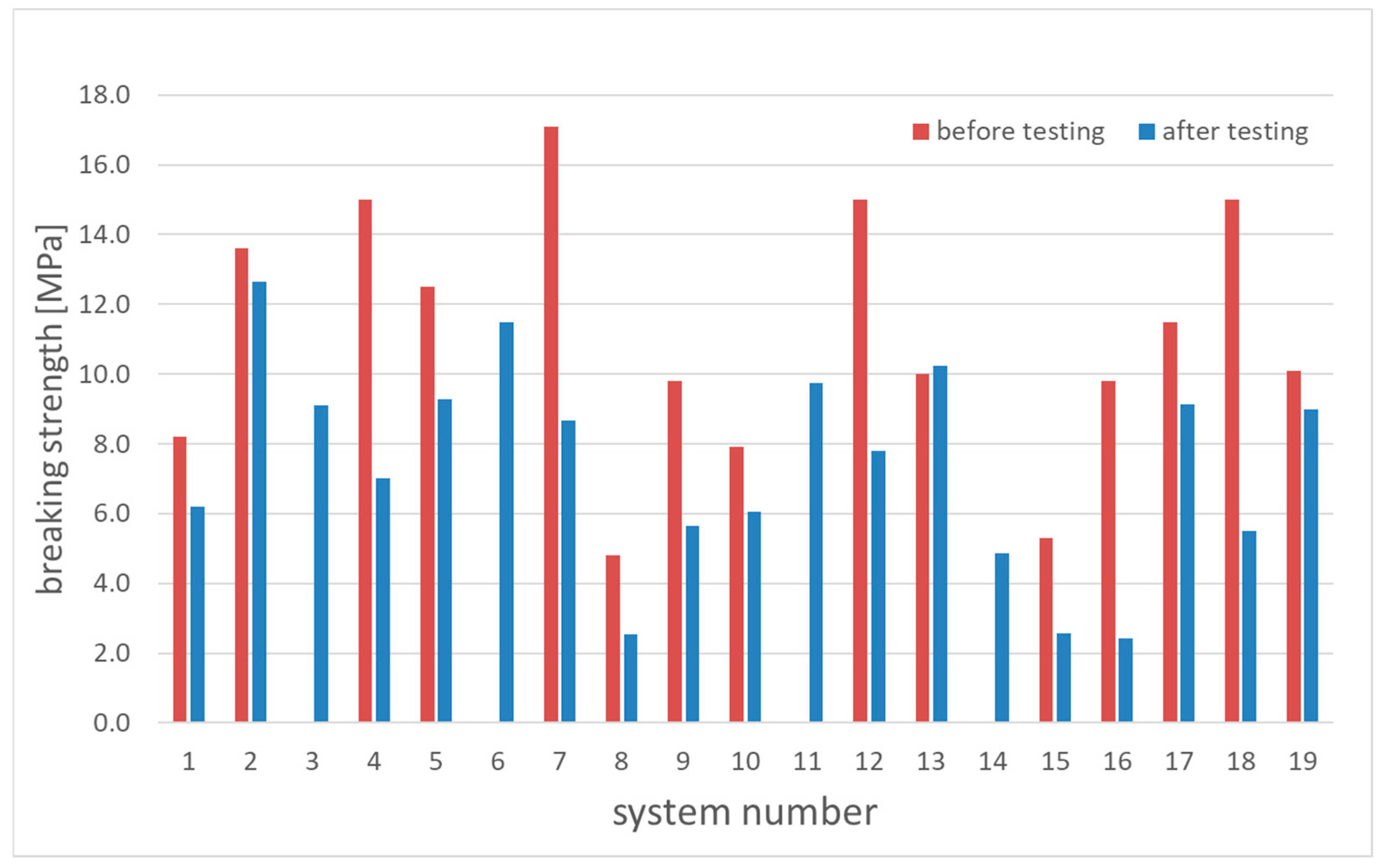

3.2. Pull-Off Adhesion

3.3. Abrasion Testing

4. Discussion

5. Summary and Conclusions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Pearson Correlation of NSS Testing and Outdoor Exposure Divided by Subgroups

| Location | Zone | r (Pearson) | p (Pearson) |

|---|---|---|---|

| Trier | Atmospheric | 0.64 | 0.12 |

| Splash | 0.21 | 0.65 | |

| Immersion | 0.81 | 0.03 | |

| Windheim | Atmospheric | 0.63 | 0.13 |

| Splash | 0.16 | 0.72 | |

| Immersion | 0.52 | 0.23 | |

| Kiel | Atmospheric | 0.17 | 0.72 |

| Splash | 0.56 | 0.20 | |

| Immersion | 0.28 | 0.52 | |

| Büsum | Atmospheric | 0.19 | 0.68 |

| Splash | 0.50 | 0.25 | |

| Immersion | 0.58 | 0.17 |

| Location | Zone | r (Pearson) | p (Pearson) |

|---|---|---|---|

| Trier | Atmospheric | 0.29 | 0.36 |

| Splash | <0.01 | >0.99 | |

| Immersion | −0.11 | 0.73 | |

| Windheim | Atmospheric | 0.57 | 0.05 |

| Splash | −0.16 | 0.64 | |

| Immersion | 0.72 | 0.01 | |

| Kiel | Atmospheric | 0.31 | 0.31 |

| Splash | 0.46 | 0.13 | |

| Immersion | −0.16 | 0.61 | |

| Büsum | Atmospheric | 0.15 | 0.64 |

| Splash | 0.30 | 0.35 | |

| Immersion | −0.20 | 0.54 |

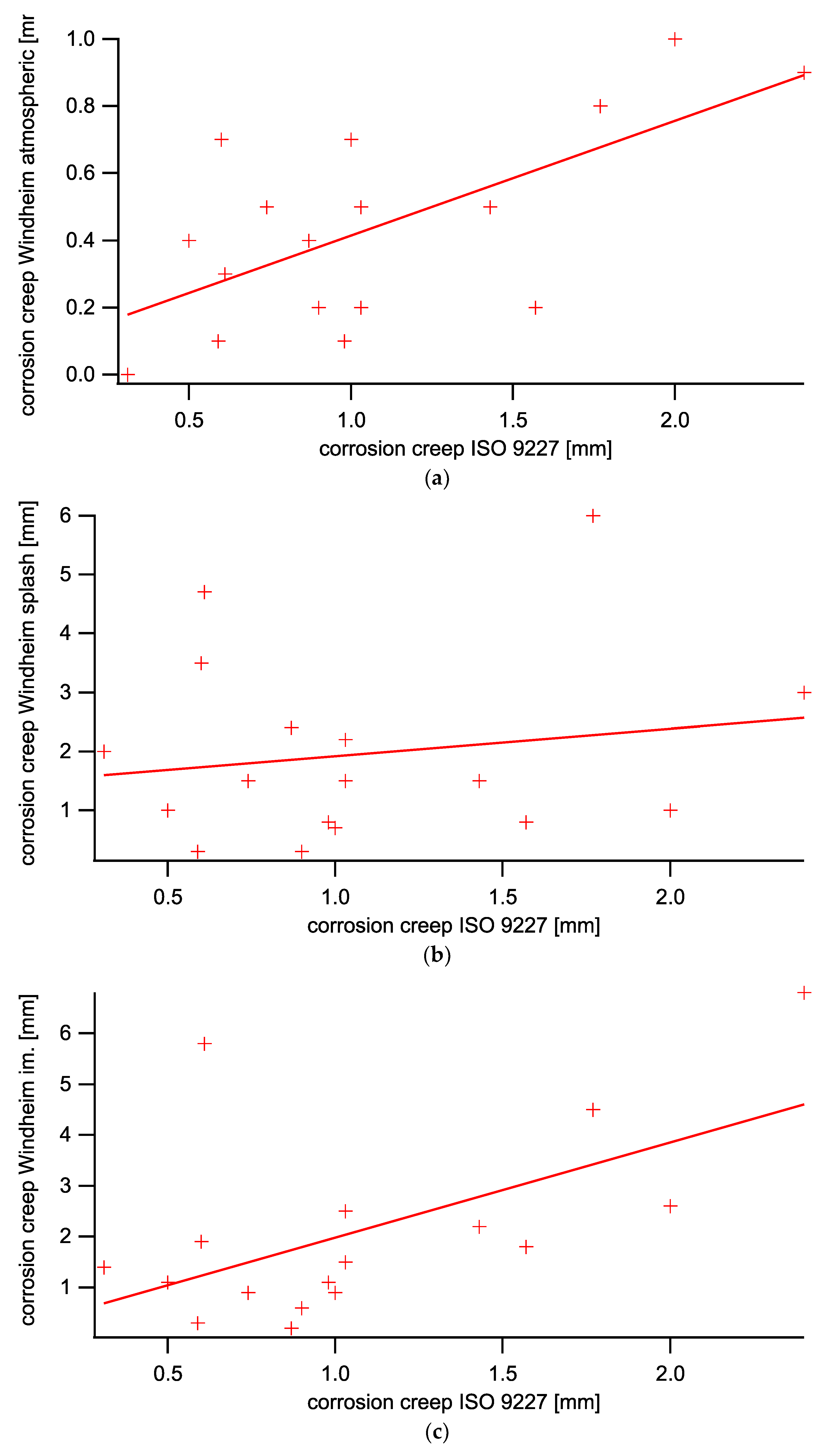

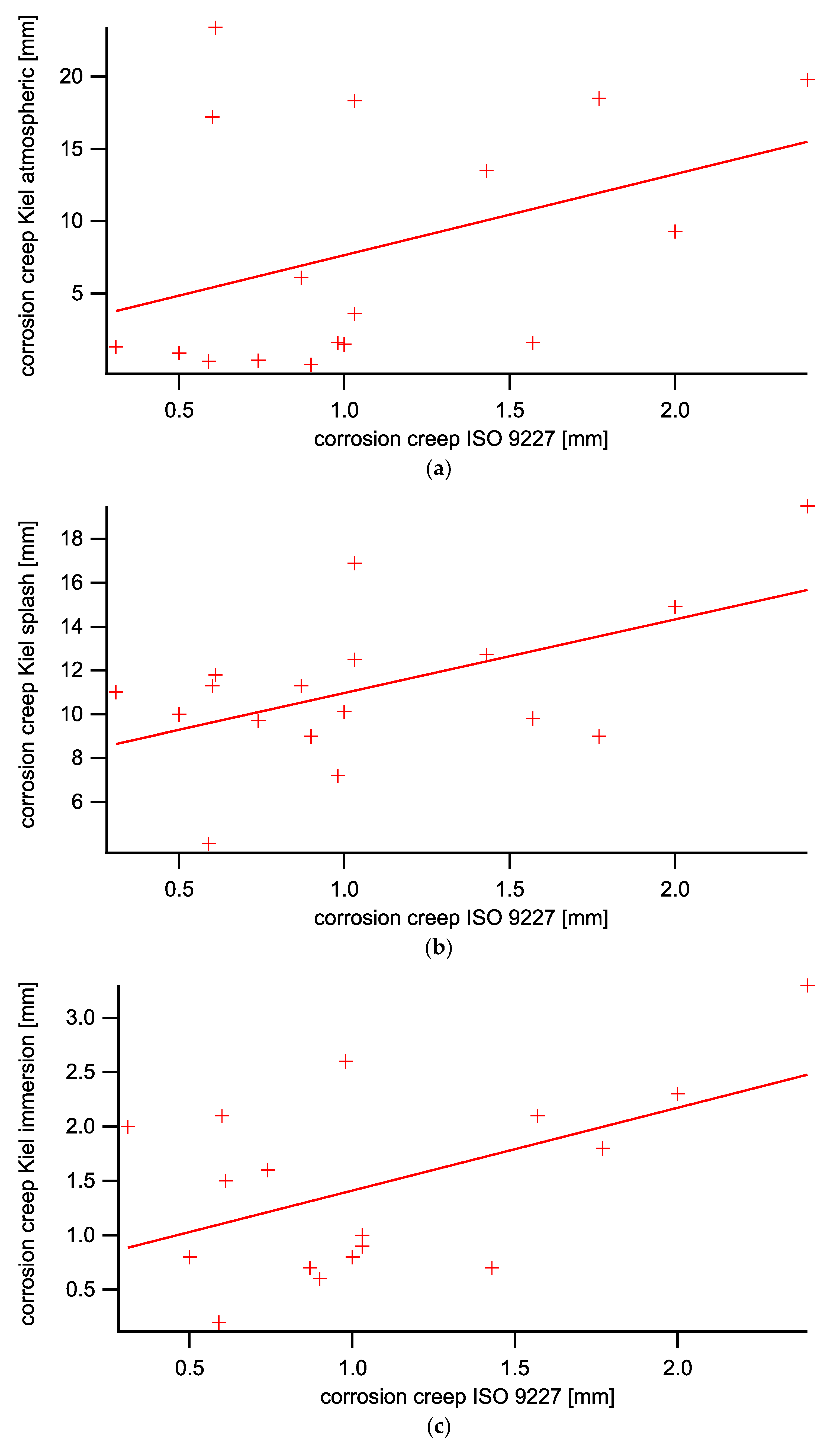

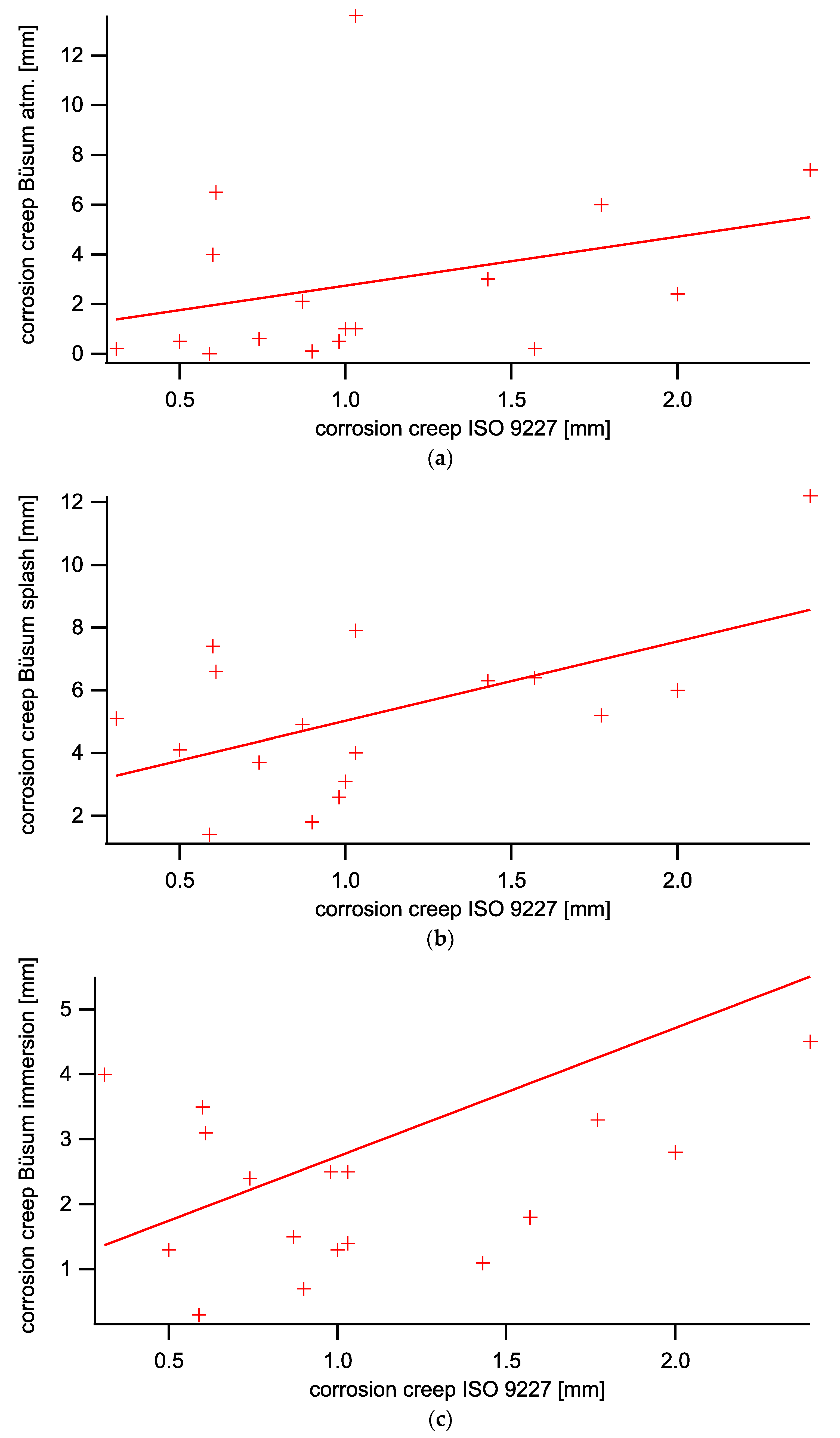

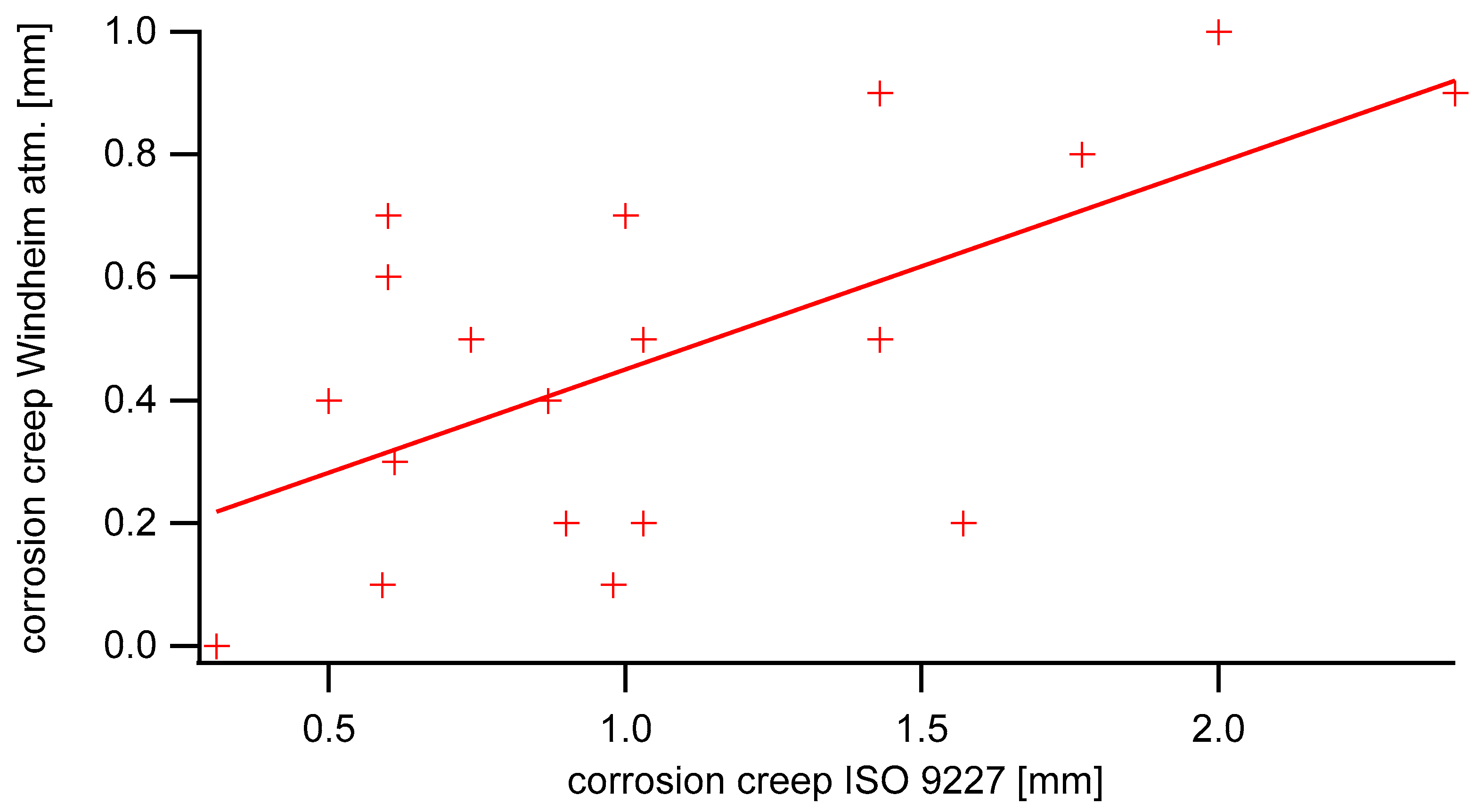

Appendix B. Plots of the Corrosion Creep After NSS Testing and Outdoor Exposure

References

- ISO 12944-1:2017; Paints and Varnishes—Corrosion Protection of Steel Structures by Protective Paint Systems Part 1: General Introduction. ISO: Geneva, Switzerland, 2017.

- ISO 12944-6:2018; Paints and Varnishes—Corrosion Protection of Steel Structures by Protective Paint Systems Part 6: Laboratory Performance Test Methods. ISO: Geneva, Switzerland, 2018.

- ISO 2812-2:2018; Paints and Varnishes—Determination of Resistance to Liquids Part 2: Water Immersion Method. ISO: Geneva, Switzerland, 2018.

- ISO 6270-1:2017; Paints and Varnishes—Determination of Resistance to Humidity Part 1: Condensation (Single-Sided Exposure). ISO: Geneva, Switzerland, 2017.

- ISO 9227:2022; Corrosion Tests in Artificial Atmospheres—Salt Spray Tests. ISO: Geneva, Switzerland, 2022.

- ISO 9223:2012; Corrosion of Metals and Alloys—Corrosivity of Atmospheres—Classification, Determination and Estimation. ISO: Geneva, Switzerland, 2012.

- Csokán, P. Korrosionsschutzprobleme von hydrotechnischen Stahlbaukonstruktionen. Richtlinien zur Anlegung von Wasserexpositions-Korrosionsprüfstationen. Mater. Corros. 1972, 23, 675–680. [Google Scholar] [CrossRef]

- Chico, B.; de la Fuente, D.; Pérez, M.L.; Morcillo, M. Corrosion resistance of steel treated with different silane/paint systems. J. Coat. Technol. Res. 2012, 9, 3–13. [Google Scholar] [CrossRef]

- Takeshita, Y.; Kamisho, T.; Sakata, S.; Sawada, T.; Watanuki, Y.; Nishio, R.; Ueda, T. Dual layer structural thermoplastic polyester powder coating film and its weathering resistance. J. Appl. Polym. Sci. 2012, 128, 1732–1739. [Google Scholar] [CrossRef]

- Seré, P.R.; Schvezov, C.; Di Sarli, A.R.; Deyá, C. Triplex systems: Accelerated and outdoor tests. Mater. Corros. 2019, 70, 470–480. [Google Scholar] [CrossRef]

- Fragata, F.L.; Amorim, C.C.; Ordine, A.P.; Marroig, M.C.; Mota, R.O.; Margarit-Mattos, I.C.P. Influence of surface cleaning by tools made of copper alloys on the painting performance. J. Coat. Technol. Res. 2009, 6, 229–235. [Google Scholar] [CrossRef]

- Fekete, É.; Lengyel, B. Accelerated testing of waterborne coatings. Prog. Org. Coat. 2005, 54, 211–215. [Google Scholar] [CrossRef]

- Deflorian, F.; Rossi, S.; Fedel, M. Organic coatings degradation: Comparison between natural and artificial weathering. Corros. Sci. 2008, 50, 2360–2366. [Google Scholar] [CrossRef]

- Li, Y.; Xu, H.; He, Y.; Xu, Q.; Fan, X.; Liu, C. Study on the correlation between indoor accelerated corrosion testing of concrete epoxy polysiloxane coating and real-sea environmental testing in the East China Sea. Case Stud. Constr. Mater. 2024, 20, e02905. [Google Scholar] [CrossRef]

- Almeida, E.; Santos, D.; Uruchurtu, J. Corrosion performance of waterborne coatings for structural steel. Prog. Org. Coatings 1999, 37, 131–140. [Google Scholar] [CrossRef]

- Zhang, H.; Dun, Y.; Tang, Y.; Zuo, Y.; Zhao, X. Correlation between natural exposure and artificial ageing test for typical marine coating systems. J. Appl. Polym. Sci. 2016, 133, 43893. [Google Scholar] [CrossRef]

- Davalos-Monteiro, R.; D’ambrosio, G.; Zhou, X.; Gibbon, S.; Curioni, M. Relationship between natural exposure testing and cyclic corrosion testing ISO 20340 for the assessment of the durability of powder-coated steel. Corros. Eng. Sci. Technol. 2021, 56, 742–752. [Google Scholar] [CrossRef]

- LeBozec, N.; Thierry, D.; Le Calvé, P.; Favennec, C.; Pautasso, J.; Hubert, C. Performance of marine and offshore paint systems: Correlation of accelerated corrosion tests and field exposure on operating ships. Mater. Corros. 2015, 66, 215–225. [Google Scholar] [CrossRef]

- Pélissier, K.; Le Bozec, N.; Thierry, D.; Larché, N. Evaluation of the Long-Term Performance of Marine and Offshore Coatings System Exposed on a Traditional Stationary Site and an Operating Ship and Its Correlation to Accelerated Test. Coatings 2022, 12, 1758. [Google Scholar] [CrossRef]

- Momber, A.W.; Marquardt, T.; Buchbach, S.; Plagemann, P. The corrosion protection performance of repair coatings for offshore wind power constructions after long-term splash zone site exposure. Mater. Corros. 2022, 73, 526–539. [Google Scholar] [CrossRef]

- Perrin, F.; Merlatti, C.; Aragon, E.; Margaillan, A. Degradation study of polymer coating: Improvement in coating weatherability testing and coating failure prediction. Prog. Org. Coatings 2009, 64, 466–473. [Google Scholar] [CrossRef]

- Knudsen, O.; Skilbred, A.; Løken, A.; Daneshian, B.; Höche, D. Correlations between standard accelerated tests for protective organic coatings and field performance. Mater. Today Commun. 2022, 31, 103729. [Google Scholar] [CrossRef]

- Binder, G. Research on protective coating systems for immersed steel structures. Mater. Corros. 2001, 52, 261–267. [Google Scholar] [CrossRef]

- Binder, G. Corrosion Protection in Maritime Environments: Assessing Systems for Offshore Structures. J. Prot. Coat. Linings 2016, 33, 34–36, 38–41. [Google Scholar]

- ISO 12944-9:2018; Paints and Varnishes—Corrosion Protection of Steel Structures by Protective Paint Systems Part 9: Protective Paint Systems and Laboratory Performance Test Methods for Offshore and Related Structures. ISO: Geneva, Switzerland, 2018.

- Bundesanstalt für Wasserbau. BAW Richtlinie Prüfung von Beschichtungssystemen für den Korrosionsschutz im Stahlwasserbau (RPB); Bundesanstalt für Wasserbau: Karlsruhe, Germany, 2011. [Google Scholar]

- EN 10025:2019; Hot Rolled Products of Structural Steels-Part 2: Technical Delivery Conditions for Non-Alloy Structural Steels. British Standards Institution: London, UK, 2019.

- ISO 8501-1:2007; Preparation of Steel Substrates before Application of Paints and Related Products—Visual Assessment of Surface Cleanliness-Part 1: Rust Grades and Preparation Grades of Uncoated Steel Substrates and of Steel Substrates after Overall Removal of Previous Coatings. ISO: Geneva, Switzerland, 2007.

- ISO 8503-1:2012; Preparation of Steel Substrates before Application of Paints and Related Products—Surface Roughness Characteristics of Blast-Cleaned Steel Substrates—Part 1: Specifications and Definitions for ISO Surface Profile Comparators for the Assessment of Abrasive Blast-Cleaned Surfaces. ISO: Geneva, Switzerland, 2012.

- ISO 4624:2023; Paints and Varnishes—Pull-Off Test for Adhesion. ISO: Geneva, Switzerland, 2023.

- ISO 12944-2:2017; Paints and Varnishes—Corrosion Protection of Steel Structures by Protective Paint Systems Part 2: Classification of Environments. ISO: Geneva, Switzerland, 2017.

- DIN 50929-3:2018-03; Korrosion der Metalle—Korrosionswahrscheinlichkeit Metallener Werkstoffe bei äußerer Korrosionsbelastung—Teil 3: Rohrleitungen und Bauteile in Böden und Wässern. Beuth Verlag GmbH: Berlin, Germany, 2018.

- ISO 4628-2:2016; Paints and Varnishes—Evaluation of Degradation of Coatings—Designation of Quantity and Size of Defects, and of Intensity of Uniform Changes in Appearance Part 2: Assessment of Degree of Blistering. ISO: Geneva, Switzerland, 2016.

- ISO 4628-3:2016; Paints and Varnishes—Evaluation of Degradation of Coatings—Designation of Quantity and Size of Defects, and of Intensity of Uniform Changes in Appearance Part 3: Assessment of Degree of Rusting. ISO: Geneva, Switzerland, 2016.

- ISO 4628-4:2016; Paints and Varnishes—Evaluation of Degradation Of Coatings—Designation of Quantity and Size of Defects, and of Intensity of Uniform Changes in Appearance Part 4: Assessment of Degree of Cracking. ISO: Geneva, Switzerland, 2016.

- ISO 4628-5:2022; Paints and Varnishes—Evaluation of Quantity and Size of Defects, and of Intensity of Uniform Changes in Appearance Part 5: Assessment of Degree of Flaking. ISO: Geneva, Switzerland, 2022.

- Wetzel, K.S.; Wanner, M.; Schmid, M.J. Weathering tests to investigate the durability of anti-corrosion coatings and on-site repair materials. Transp. Eng. 2024, 17, 100265. [Google Scholar] [CrossRef]

- Skerry, B.S.; Simpson, C.H. Corrosion and Weathering of Paints for Atmospheric Corrosion Control. Corrosion 1993, 49, 663–674. [Google Scholar] [CrossRef]

- LeBozec, N.; Blandin, N.; Thierry, D. Accelerated corrosion tests in the automotive industry: A comparison of the performance towards cosmetic corrosion. Mater. Corros. 2008, 59, 889–894. [Google Scholar] [CrossRef]

- ISO 16701:2015; Corrosion of Metals and Alloys—Corrosion in Artificial Atmosphere—Accelerated Corrosion Test Involving Exposure under Controlled Conditions of Humidity Cycling and Intermittent Spraying of a Salt Solution. ISO: Geneva, Switzerland, 2015.

- ASTM D5894-21; Standard Practice for Cyclic Salt Fog/UV Exposure of Painted Metal, (Alternating Exposures in a Fog/Dry Cabinet and a UV/Condensation Cabinet). ASTM: West Conshohocken, PA, USA, 2021.

- ASTM B 117-03; Standard Practice for Operating Salt Spray (Fog) Apparatus. ASTM: West Conshohocken, PA, USA, 2003.

| System Number | Number of Coats | Type of Coat 1 | Nominal Dry Film Thickness Per Layer [µm] 2 | Measured Total Dry Film Thickness [µm] 3 |

|---|---|---|---|---|

| 1 | 1 | Epoxy | 400 | 470 |

| 2 | 1 | Epoxy | 550 | 540 |

| 3 | 1 | Epoxy | 500 | 540 |

| 4 | 1 | Epoxy | 580 | 570 |

| 5 | 1 | Epoxy | 600 | 610 |

| 6 | 1 | Epoxy | 1100 | 1080 |

| 7 | 2 | Epoxy, Epoxy | 300/300 | 550 |

| 8 | 2 | Zn–Epoxy, Epoxy | 60/400 | 430 |

| 9 | 2 | Zn–Epoxy, Epoxy | 50/350 | 480 |

| 10 | 2 | Zn–Epoxy, Epoxy | 70/430 | 520 |

| 11 | 2 | Zn–Epoxy, Epoxy | 50/600 | 550 |

| 12 | 2 | Zn–Epoxy, Epoxy | 80/500 | 550 |

| 13 | 2 | Zn–Epoxy, Epoxy | 60/500 | 590 |

| 14 | 2 | Zn–Epoxy, Epoxy | 50/600 | 620 |

| 15 | 3 | Zn–Epoxy, Epoxy, Epoxy | 50/250/250 | 640 |

| 16 | 3 | Zn–Epoxy, Epoxy, Epoxy | 50/250/250 | 780 |

| 17 | 3 | Al–Epoxy, Epoxy, Epoxy | 170/170/160 | 500 |

| 18 | 1 | 2C-PUR | 1200–1500 | 1430 |

| 19 | 3 | 1C-PUR-Zn, 1C-PUR, 1C-PUR | 100/200/200 | 570 |

| Property | Trier (Moselle) | Windheim (Weser) | Kiel (Baltic Sea) | Büsum (North Sea) |

|---|---|---|---|---|

| Type of water | fresh water | fresh water, slightly increased salinity | sea water/brackish water | sea water |

| Conductivity [mS/cm] | 1.2 | 1.5 | 27.1 | 42.5 |

| Chloride [ppm] | 250 | 350 | 9000 | 16,500 |

| Sulfate [ppm] | 100 | 110 | 1900 | 1700 |

| Calcium [ppm] | 121 | 72 | 190 | 320 |

| Carbonate hardness [°dH] | 8 | 7 | 7 | 7 |

| pH | 7.8 | 7.7 | 7.8 | 7.7 |

| Salinity [g/kg] | 0.5 | 0.9 | 17 | 25 |

| Wo-value 1 | 2.2 | 1.2 | −6.4 | −7.6 |

| Fouling | algae, mussels | algae, mussels | algae, barnacles, oyster mussels | barnacles, oyster mussels |

| Zone | Trier (Moselle) | Windheim (Weser) | Kiel (Baltic Sea) | Büsum (North Sea) |

|---|---|---|---|---|

| Immersion | 1.5 | 1.5 | 2.5 | 2.5 |

| Splash zone | 2.0 | 2.0 | 10.0 | 5.0 |

| Atmospheric zone | 1.0 | 1.0 | 6.0 | 2.0 |

| System Number | Corrosion Creep [mm] | |||||||

| NSS | Trier (Im1) | Windheim (Im1) | ||||||

| Atm. Zone | Splash Zone | Immersion | Atm. Zone | Splash Zone | Immersion | |||

| 1 | 0.98 | 0.0 | 0.4 | 0.3 | 0.1 | 0.8 | 1.1 | |

| 2 | 1.03 | 0.0 | 3.1 | 0.3 | 0.2 | 2.2 | 2.5 | |

| 3 | 2.40 | 0.8 | 2.6 | 1.9 | 0.9 | 3.0 | 6.8 | |

| 4 | 0.61 | 0.1 | 0.6 | 0.2 | 0.3 | 4.7 | 5.8 | |

| 5 | 1.77 | 0.2 | 1.1 | 1.2 | 0.8 | 6.0 | 4.5 | |

| 6 | 0.60 | 0.4 | 1.0 | 1.0 | 0.7 | 3.5 | 1.9 | |

| 7 | 0.60 | 0.6 | 2.5 | 2.2 | 0.6 | * | * | |

| 8 | 1.00 | 0.8 | 0.8 | 0.7 | 0.7 | 0.7 | 0.9 | |

| 9 | 0.59 | 0.1 | 0.1 | 0.1 | 0.1 | 0.3 | 0.3 | |

| 10 | 0.74 | 0.2 | 0.5 | 0.6 | 0.5 | 1.5 | 0.9 | |

| 11 | 1.03 | 0.6 | 1.1 | 0.7 | 0.5 | 1.5 | 1.5 | |

| 12 | 0.31 | 0.1 | 0.3 | 0.6 | 0.0 | 2.0 | 1.4 | |

| 13 | 1.57 | 0.2 | 0.5 | 0.2 | 0.2 | 0.8 | 1.8 | |

| 14 | 0.50 | 0.4 | 0.5 | 0.7 | 0.4 | 1.0 | 1.1 | |

| 15 | 1.43 | 0.5 | 0.4 | 0.4 | 0.5 | 1.5 | 2.2 | |

| 16 | 0.87 | 0.3 | 0.6 | 0.7 | 0.4 | 2.4 | 0.2 | |

| 17 | 2.00 | 0.5 | 0.9 | 1.0 | 1.0 | 1.0 | 2.6 | |

| 18 | 1.43 | 0.6 | 13.7 | 0.7 | 0.9 | 13 | 8.4 | |

| 19 | 0.90 | 0.1 | 0.2 | 0.2 | 0.2 | 0.3 | 0.6 | |

| System Number | Corrosion Creep [mm] | |||||||

| NSS | Kiel (Im2) | Büsum (Im2) | ||||||

| Atm. Zone | Splash Zone | Immersion | Atm. Zone | Splash Zone | Immersion | |||

| 1 | 0.98 | 1.6 | 7.2 | 2.6 | 0.5 | 2.6 | 2.5 | |

| 2 | 1.03 | 18.3 | 12.5 | 0.9 | 13.6 | 7.9 | 2.5 | |

| 3 | 2.40 | 19.8 | 19.5 | 3.3 | 7.4 | 12.2 | 4.5 | |

| 4 | 0.61 | 23.4 | 11.8 | 1.5 | 6.5 | 6.6 | 3.1 | |

| 5 | 1.77 | 18.5 | 9.0 | 1.8 | 6.0 | 5.2 | 3.3 | |

| 6 | 0.60 | 17.2 | 11.3 | 2.1 | 4.0 | 7.4 | 3.5 | |

| 7 | 0.60 | 16.1 | 11.3 | 15.0 | 5.7 | 8.5 | 7.3 | |

| 8 | 1.00 | 1.5 | 10.1 | 0.8 | 1.0 | 3.1 | 1.3 | |

| 9 | 0.59 | 0.3 | 4.1 | 0.2 | 0.0 | 1.4 | 0.3 | |

| 10 | 0.74 | 0.4 | 9.7 | 1.6 | 0.6 | 3.7 | 2.4 | |

| 11 | 1.03 | 3.6 | 16.9 | 1.0 | 1.0 | 4.0 | 1.4 | |

| 12 | 0.31 | 1.3 | 11.0 | 2.0 | 0.2 | 5.1 | 4.0 | |

| 13 | 1.57 | 1.6 | 9.8 | 2.1 | 0.2 | 6.4 | 1.8 | |

| 14 | 0.50 | 0.9 | 10.0 | 0.8 | 0.5 | 4.1 | 1.3 | |

| 15 | 1.43 | 13.5 | 12.7 | 0.7 | 3.0 | 6.3 | 1.1 | |

| 16 | 0.87 | 6.1 | 11.3 | 0.7 | 2.1 | 4.9 | 1.5 | |

| 17 | 2.00 | 9.3 | 14.9 | 2.3 | 2.4 | 6.0 | 2.8 | |

| 18 | 1.43 | 26.5 | 18.2 | 8.5 | 12 | 12.3 | 2.6 | |

| 19 | 0.90 | 0.1 | 9.0 | 0.6 | 0.1 | 1.8 | 0.7 | |

| Location | Zone | a | b | r (Pearson) | p (Pearson) |

|---|---|---|---|---|---|

| Im1 Trier | Atmospheric | 0.1390 | 0.1895 | 0.40 | 0.08 |

| Splash | 0.2363 | 1.2971 | 0.24 | 0.33 | |

| Immersion | 0.3804 | 0.3179 | 0.32 | 0.19 | |

| Im1 Windheim | Atmospheric | 0.1135 | 0.3361 | 0.62 | <0.01 |

| Splash | 1.3174 | 1.138 | 0.21 | 0.40 | |

| Immersion | 0.0363 | 2.219 | 0.53 | 0.02 | |

| Im2 Kiel | Atmospheric | 3.3086 | 5.7533 | 0.35 | 0.14 |

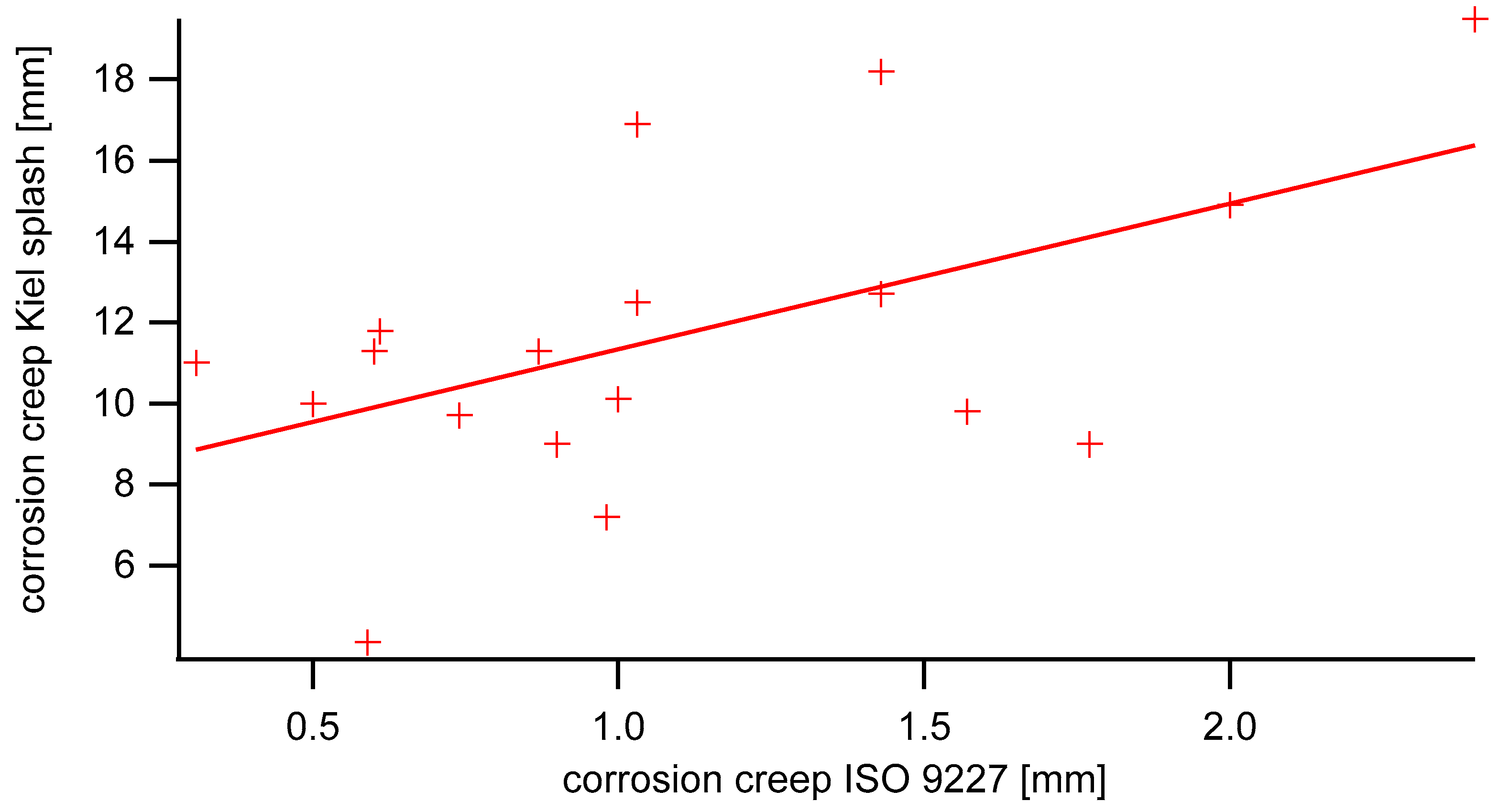

| Splash | 7.7446 | 3.593 | 0.54 | 0.02 | |

| Immersion | 2.5262 | 0.0247 | <0.01 | 0.99 | |

| Im2 Büsum | Atmospheric | 1.1584 | 2.1999 | 0.30 | 0.21 |

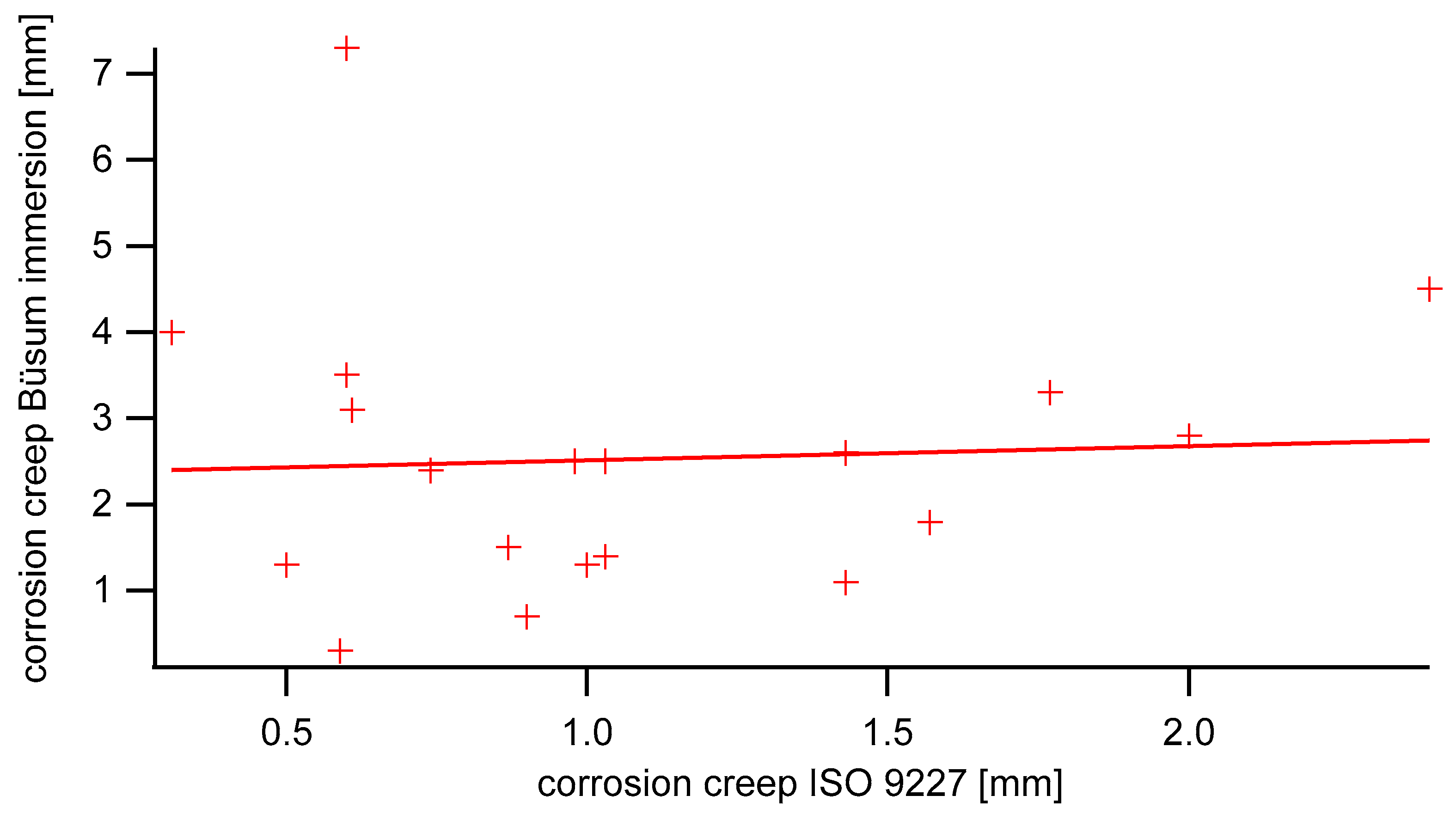

| Splash | 3.0254 | 2.5549 | 0.47 | 0.04 | |

| Immersion | 2.3406 | 0.1684 | 0.06 | 0.81 |

| System Number | Sample 1 | Sample 2 | Sample 3 | Average | Reference Sample | ||||

|---|---|---|---|---|---|---|---|---|---|

| σ | Type of Fracture | σ | Type of Fracture | σ | Type of Fracture | σ | σi | Type of Fracture | |

| 1 | 5.3 | 100% B | 6.7 | 100% B | 6.6 | 100% B | 6.2 | 8.2 | 100% B |

| 2 | 10.2 | 100% B | 15.2 | 100% B | 12.5 | 100% B | 12.6 | 13.6 | 100% B |

| 3 | 10.2 | 100% B | 6.1 | 100% B | 11.0 | 100% B | 9.1 | * | * |

| 4 | 4.5 | 100% B | 9.3 | 100% B | 7.2 | 100% B | 7.0 | 15.0 | 100% B |

| 5 | 5.8 | 100% B | 10.0 | 100% B | 12.0 | 100% B | 9.3 | 12.5 | 100% C |

| 6 | 10.9 | 95% A/B 5% B | 11.7 | 80% A/B 20% B | 11.9 | 80% A/B 20% B | 11.5 | * | * |

| 7 | 8.8 | 40% B 60% C | 8.8 | 80% B 20% C | 8.4 | 80% B 20% C | 8.7 | 17.1 | 30% B 70% C |

| 8 | 2.3 | 100% B | 2.1 | 100% B | 3.2 | 100% B | 2.5 | 4.8 | 100% B |

| 9 | 5.3 | 100% C | 6 | 100% C | 5.6 | 100% C | 5.6 | 9.8 | 100% C |

| 10 | 5.7 | 100% C | 5.7 | 100% C | 6.8 | 100% C | 6.1 | 7.9 | 100% C |

| 11 | 10.3 | 100% C | 9.7 | 100% C | 9.2 | 100% C | 9.7 | * | * |

| 12 | 5.4 | 100% B | 8.7 | 100% B | 9.3 | 100% B | 7.8 | 15 | 100% B |

| 13 | 9.3 | 40% B 60% C | 11.0 | 10% B 90% C | 10.4 | 70% B 30% C | 10.2 | 10 | 100% C |

| 14 | 5.9 | 100% C | 4.6 | 100% C | 4.1 | 100% C | 4.9 | * | * |

| 15 | 2.7 | 100% B | 2.8 | 100% B | 2.2 | 100% B | 2.6 | 5.3 | 100% B |

| 16 | 1.6 | 100% B | 2.8 | 100% B | 2.9 | 100% B | 2.4 | 9.8 | 100% B |

| 17 | 9.4 | 90% B 10% D | 8.2 | 80% B 20% D | 9.8 | 90% B 10% D | 9.1 | 11.5 | 100% C |

| 18 | 5.6 | 100% B | 5 | 100% B | 5.9 | 100% B | 5.5 | 15 | 100% B |

| 19 | 9.5 | 100% C | 9.1 | 100% C | 8.4 | 100% C | 9.0 | 10.1 | 100% C |

| System Number | aw |

|---|---|

| 1 | 58 |

| 2 | 30 |

| 3 | 35 |

| 4 | 32 |

| 5 | 34 |

| 6 | 29 |

| 7 | 29 |

| 8 | 31 |

| 9 | 50 |

| 10 | 58 |

| 11 | 34 |

| 12 | 32 |

| 13 | 30 |

| 14 | 29 |

| 15 | 50 |

| 16 | 30 |

| 17 | 58 |

| 18 | 25 |

| 19 | 46 |

| System Number | Lab Approval Im1 | Lab Approval Im2 | Outdoor Approval Im1 | Outdoor Approval Im2 |

|---|---|---|---|---|

| 1 | Yes | Yes | Yes | Yes |

| 2 | Yes | Yes | No | No |

| 3 | Yes | No | No | No |

| 4 | Yes | Yes | No | No |

| 5 | Yes | No | No | No |

| 6 | Yes | Yes | Yes | No |

| 7 | Yes | Yes | Yes | No |

| 8 | Yes | Yes | Yes | Yes |

| 9 | Yes | Yes | Yes | Yes |

| 10 | Yes | Yes | Yes | Yes |

| 11 | Yes | Yes | Yes | Yes |

| 12 | Yes | Yes | Yes | Yes |

| 13 | Yes | No | Yes | Yes |

| 14 | Yes | Yes | Yes | Yes |

| 15 | Yes | No | Yes | No |

| 16 | Yes | Yes | Yes | Yes |

| 17 | Yes | No | Yes | No |

| 18 | Yes | No | No | No |

| 19 | Yes | Yes | Yes | Yes |

| Results | Number of Systems |

|---|---|

| Match | 11 |

| Approval in Im1 and Im2 | 9 |

| Approval in Im1, rejection in Im2 | 2 |

| Difference | 8 |

| Lab: Approval in Im1 and Im2 Outdoor: Rejection in Im1 and Im2 | 2 |

| Lab: Approval in Im1 and Im2 Outdoor: Approval only in Im1, rejection in Im2 | 2 |

| Lab: Approval in Im1, rejection in Im2 Outdoor: Rejection in Im1 and Im2 | 3 |

| Lab: Approval only in Im1, rejection in Im2 Outdoors: Approval in Im1 and Im2 outdoors | 1 |

| Location | Zone | ρ (Spearman) | p (Spearman) |

|---|---|---|---|

| Trier | Atmospheric | 0.3405 | 0.1542 |

| Splash | 0.4599 | 0.0476 | |

| Immersion | 0.232 | 0.3392 | |

| Windheim | Atmospheric | 0.5395 | 0.0171 |

| Splash | 0.1649 | 0.5133 | |

| Immersion | 0.5791 | 0.0118 | |

| Kiel | Atmospheric | 0.4605 | 0.0473 |

| Splash | 0.4155 | 0.0769 | |

| Immersion | 0.2779 | 0.2493 | |

| Büsum | Atmospheric | 0.4244 | 0.0702 |

| Splash | 0.3294 | 0.1685 | |

| Immersion | 0.0787 | 0.7488 |

| Location | Zone | r (Pearson) | p (Pearson) |

|---|---|---|---|

| Trier | Atmospheric | 0.46 | 0.06 |

| Splash | 0.47 | 0.06 | |

| Immersion | 0.60 | 0.01 | |

| Windheim | Atmospheric | 0.66 | <0.01 |

| Splash | 0.17 | 0.52 | |

| Immersion | 0.57 | 0.02 | |

| Kiel | Atmospheric | 0.38 | 0.13 |

| Splash | 0.54 | 0.02 | |

| Immersion | 0.51 | 0.03 | |

| Büsum | Atmospheric | 0.31 | 0.22 |

| Splash | 0.56 | 0.02 | |

| Immersion | 0.29 | 0.25 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schmid, M.J. Correlation Between the Anticorrosive Performance of Protective Coatings Under Neutral Salt Spray Testing and Outdoor Atmospheric and Immersion Exposure. Corros. Mater. Degrad. 2024, 5, 490-512. https://doi.org/10.3390/cmd5040023

Schmid MJ. Correlation Between the Anticorrosive Performance of Protective Coatings Under Neutral Salt Spray Testing and Outdoor Atmospheric and Immersion Exposure. Corrosion and Materials Degradation. 2024; 5(4):490-512. https://doi.org/10.3390/cmd5040023

Chicago/Turabian StyleSchmid, Matthias J. 2024. "Correlation Between the Anticorrosive Performance of Protective Coatings Under Neutral Salt Spray Testing and Outdoor Atmospheric and Immersion Exposure" Corrosion and Materials Degradation 5, no. 4: 490-512. https://doi.org/10.3390/cmd5040023

APA StyleSchmid, M. J. (2024). Correlation Between the Anticorrosive Performance of Protective Coatings Under Neutral Salt Spray Testing and Outdoor Atmospheric and Immersion Exposure. Corrosion and Materials Degradation, 5(4), 490-512. https://doi.org/10.3390/cmd5040023