Prediction of Time Domain Vibro-Acoustic Response of Conical Shells Using Jacobi–Ritz Boundary Element Method

Abstract

1. Introduction

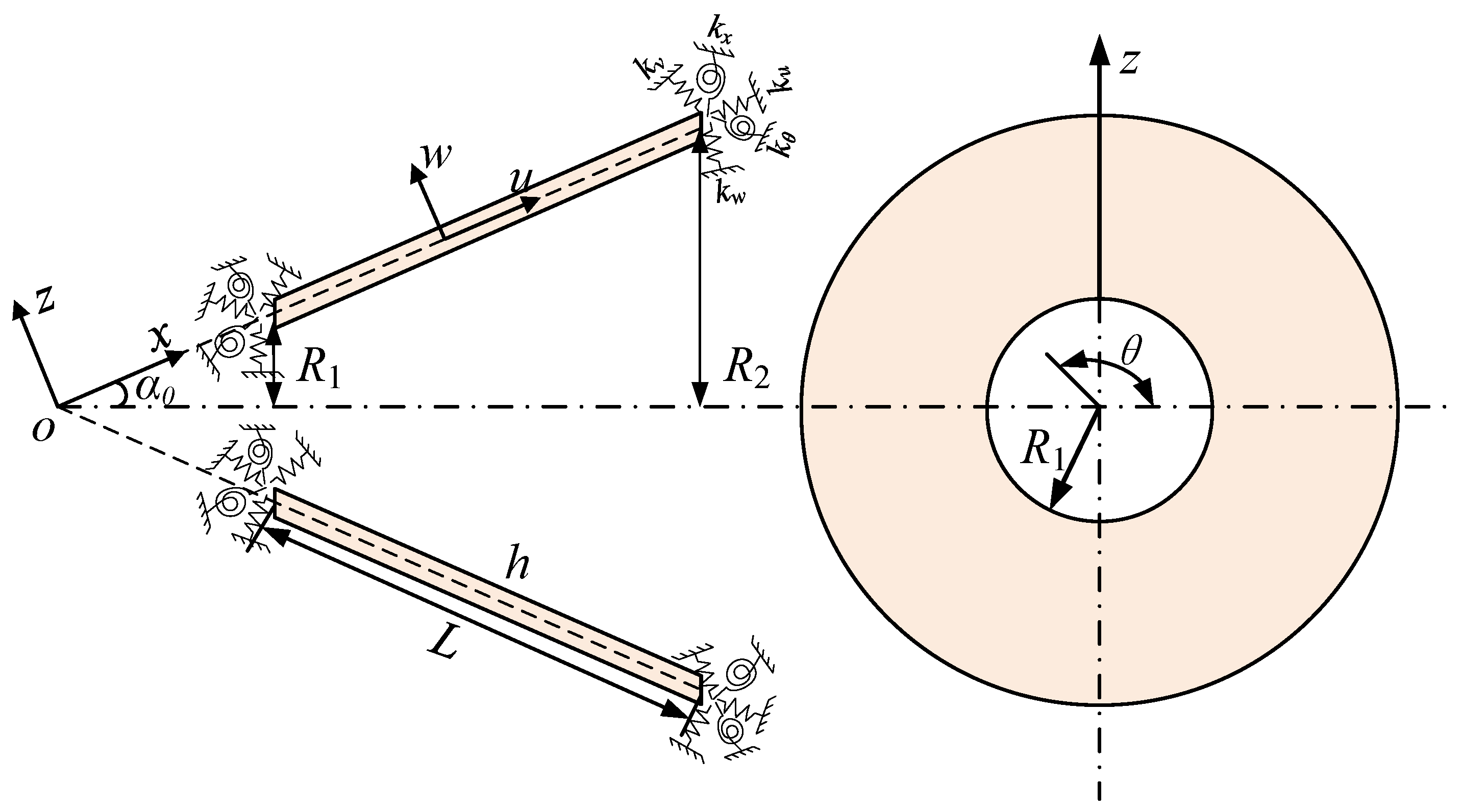

2. Theoretical Formulations of the Structure

2.1. Theoretical Model of the Structure

2.2. Vibration Response Solution of the Rayleigh–Ritz Method

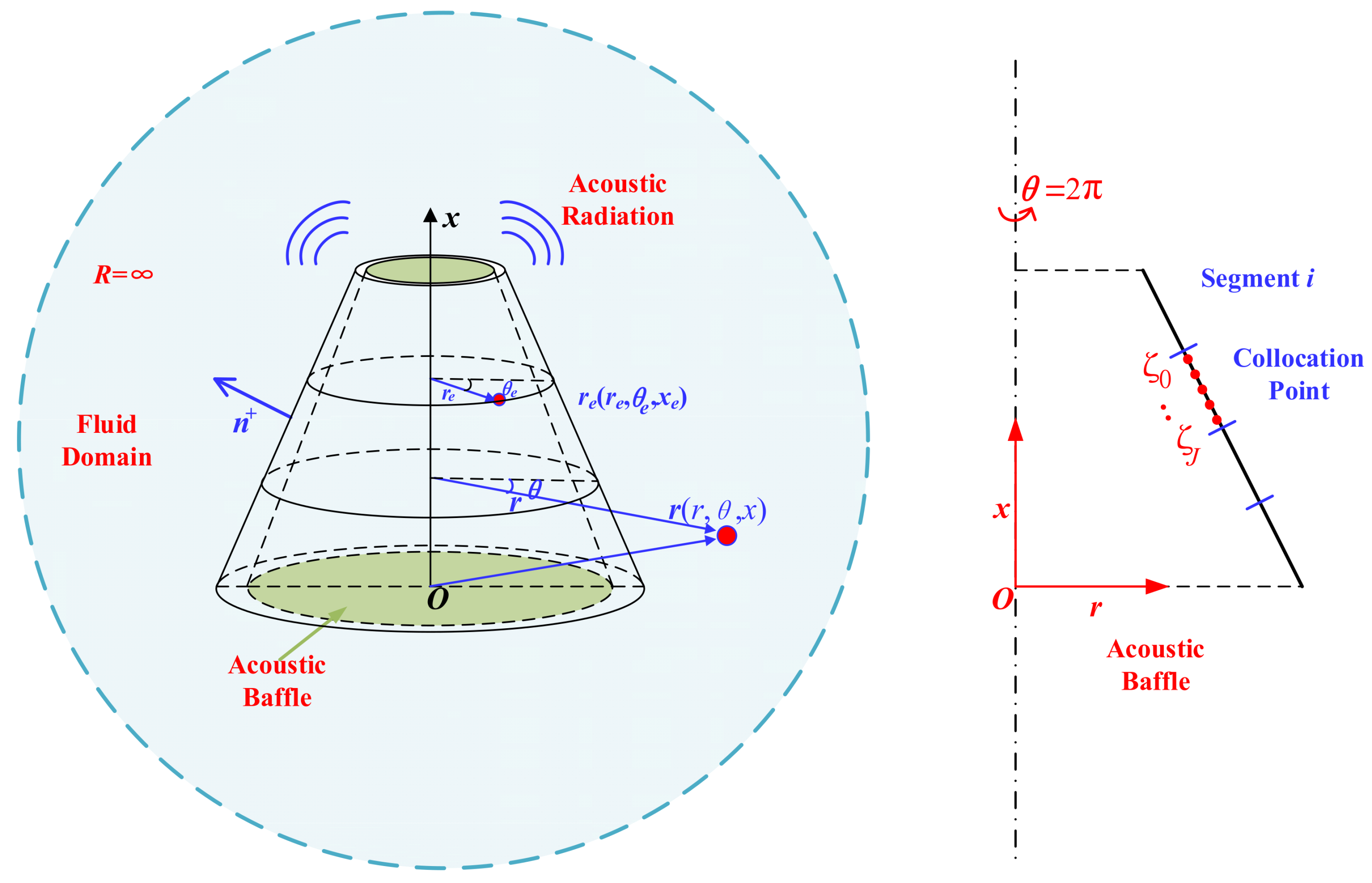

2.3. Acoustic Response Solution Based on the Boundary Element Method

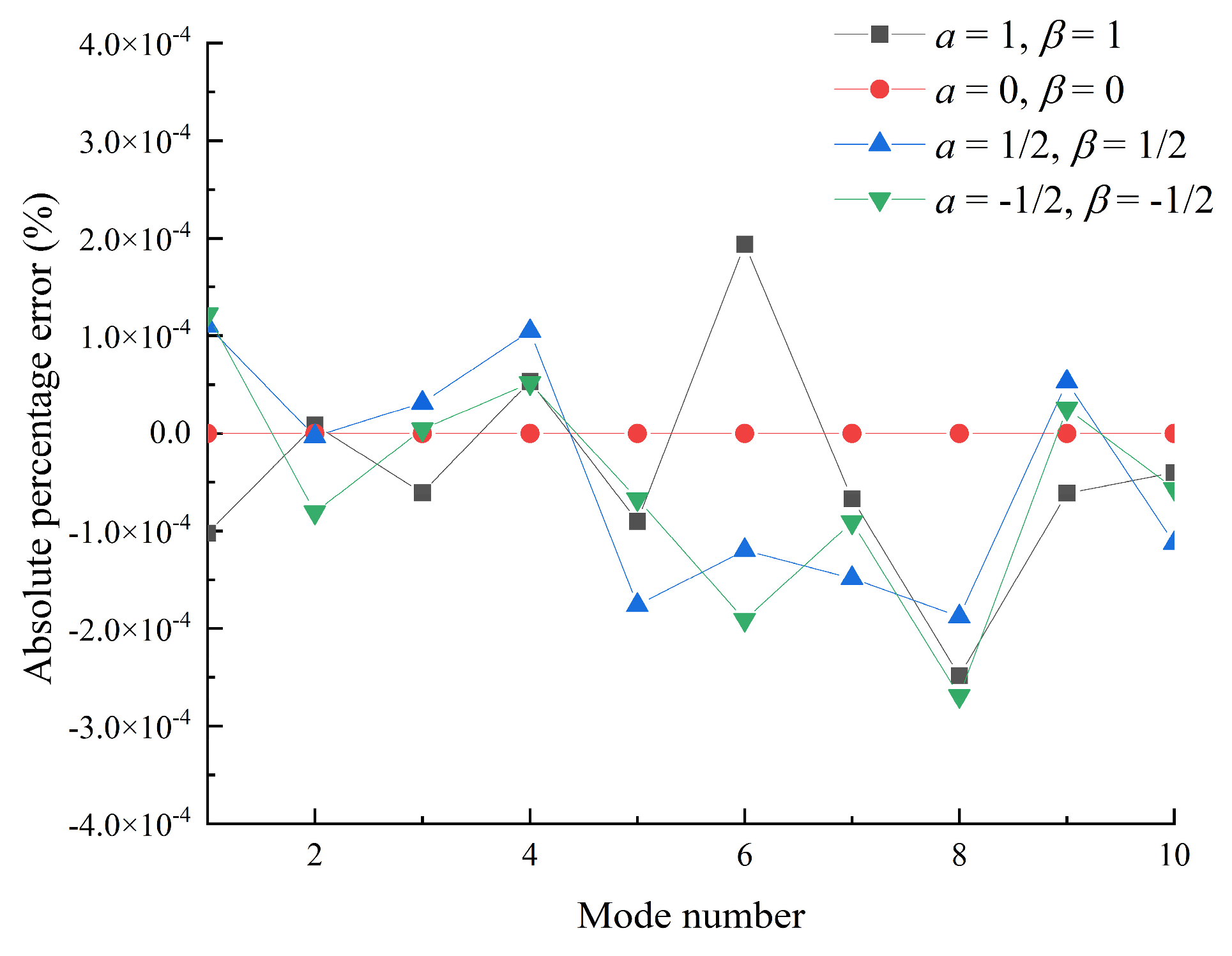

3. Convergence Discussion and Validity Verification

3.1. Computational Model

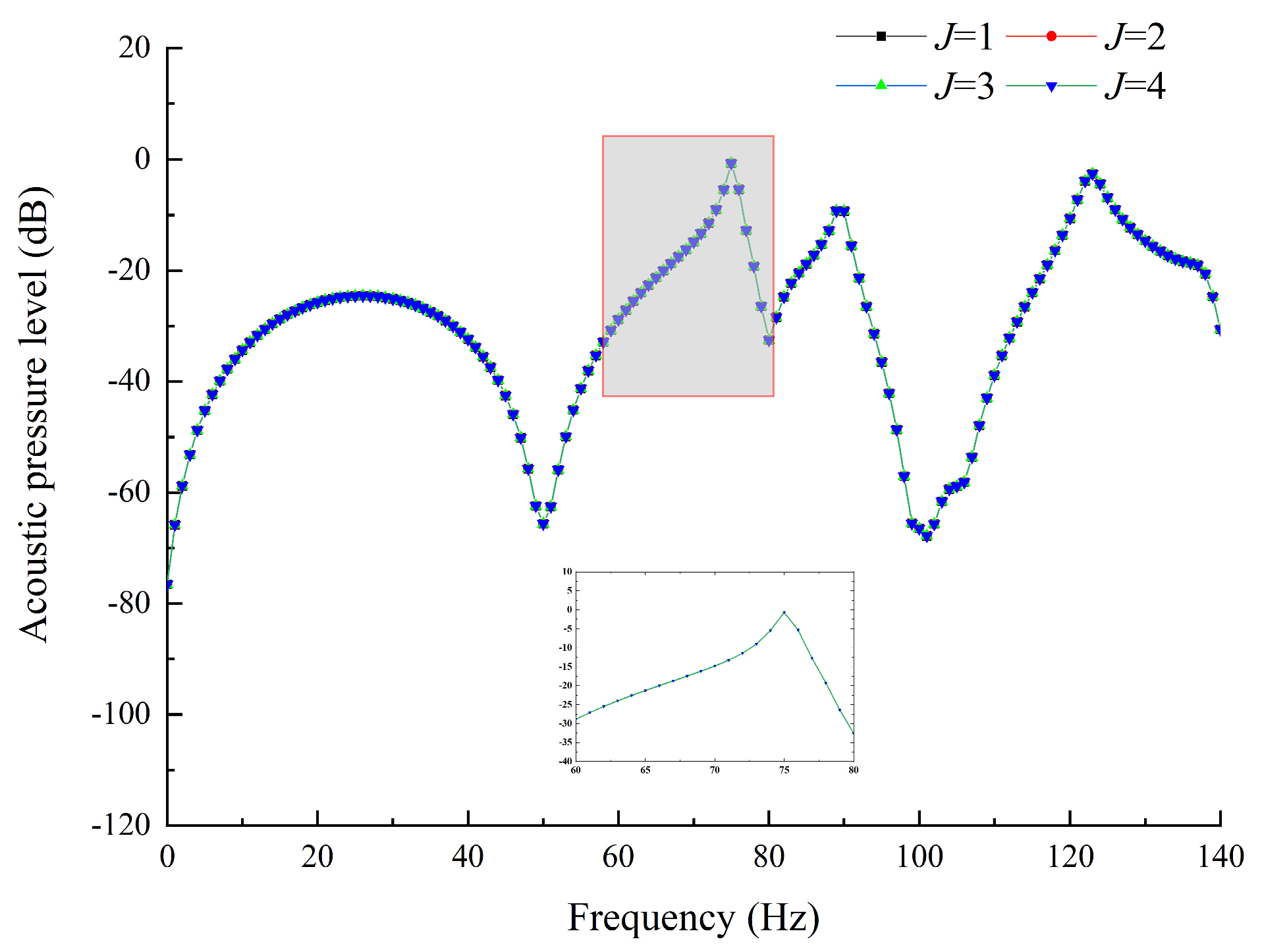

3.2. Convergence Discussion

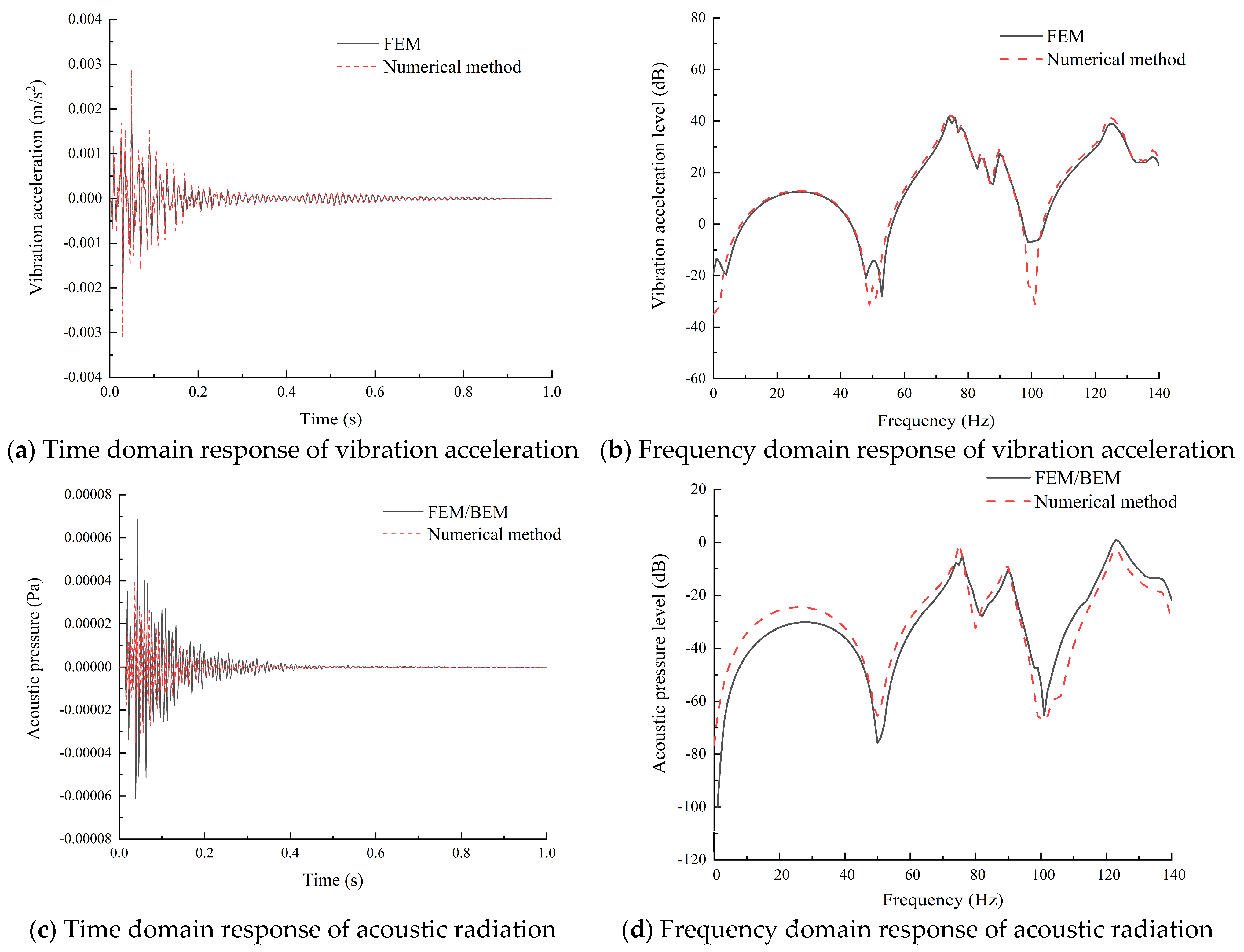

3.3. Validity Verification

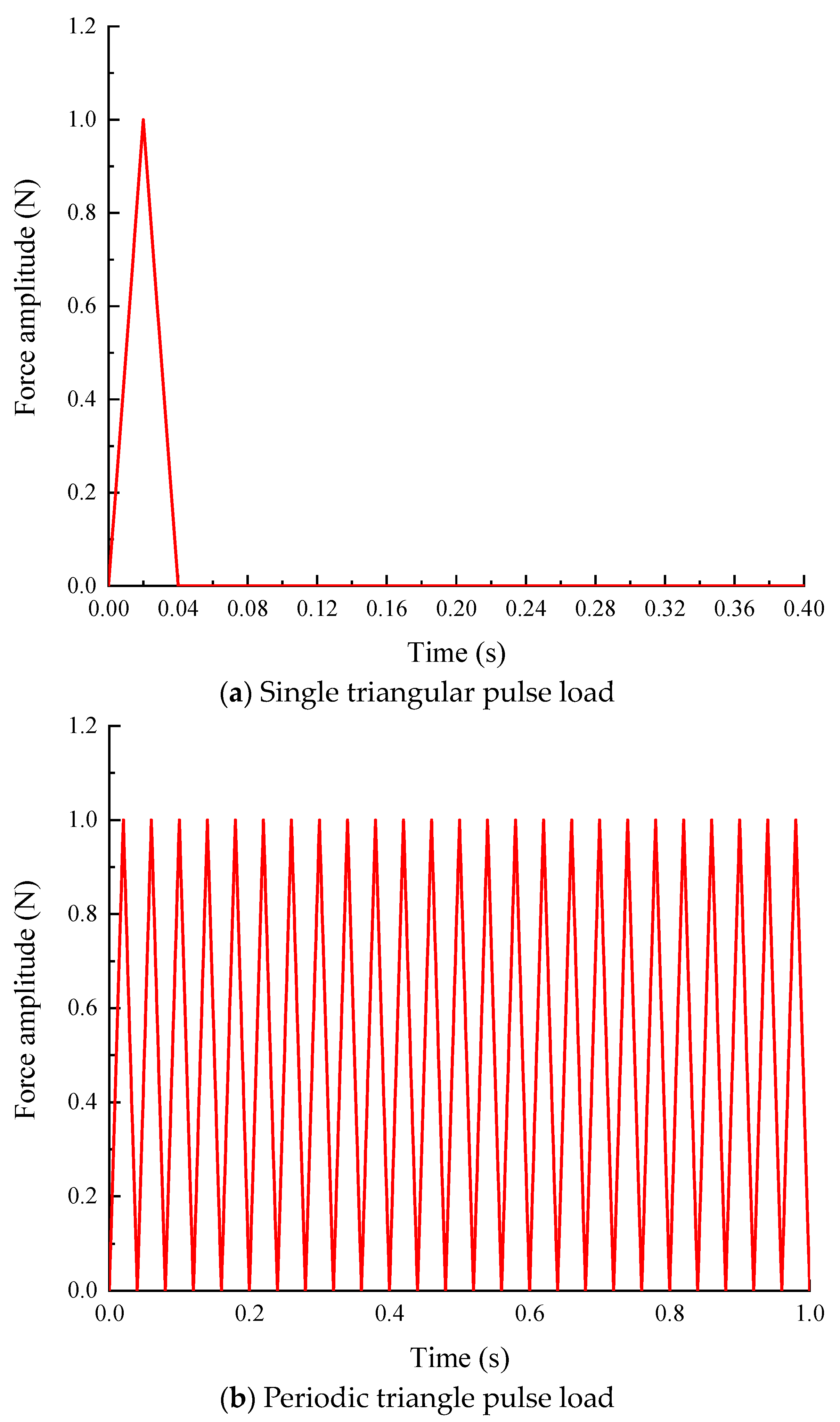

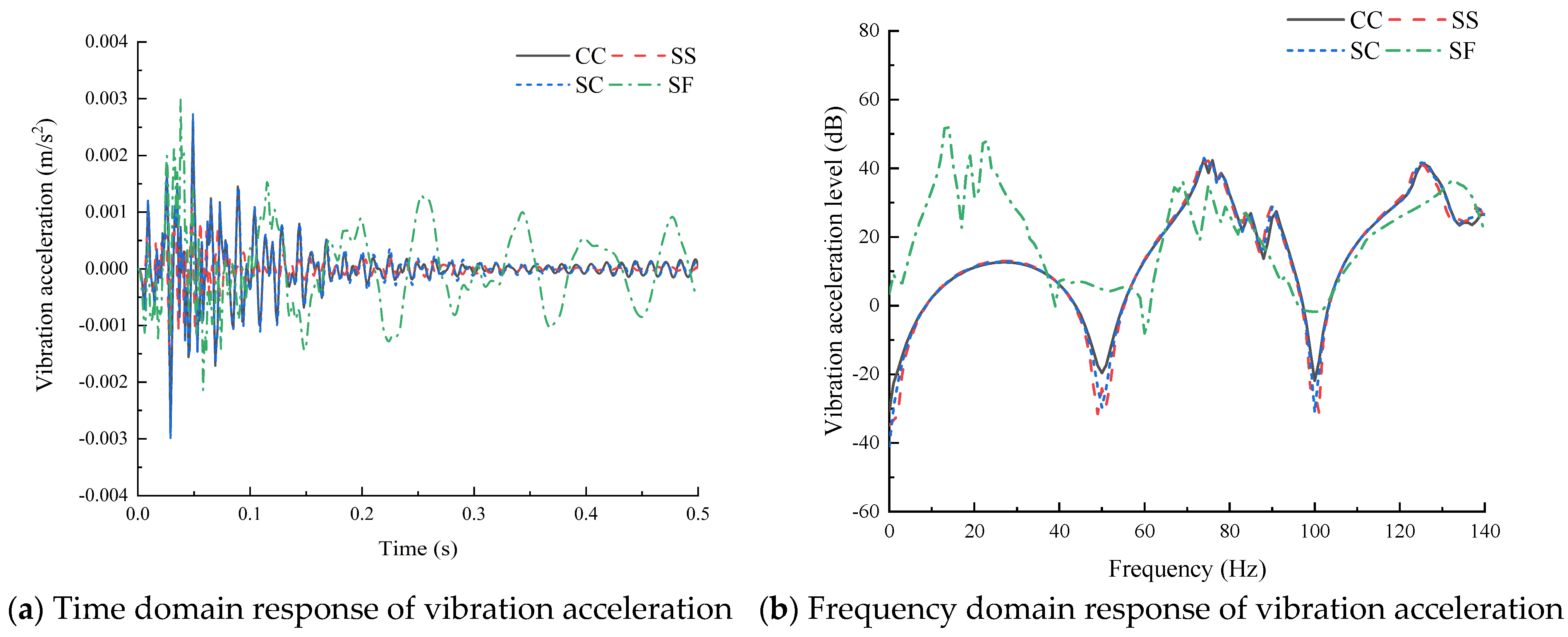

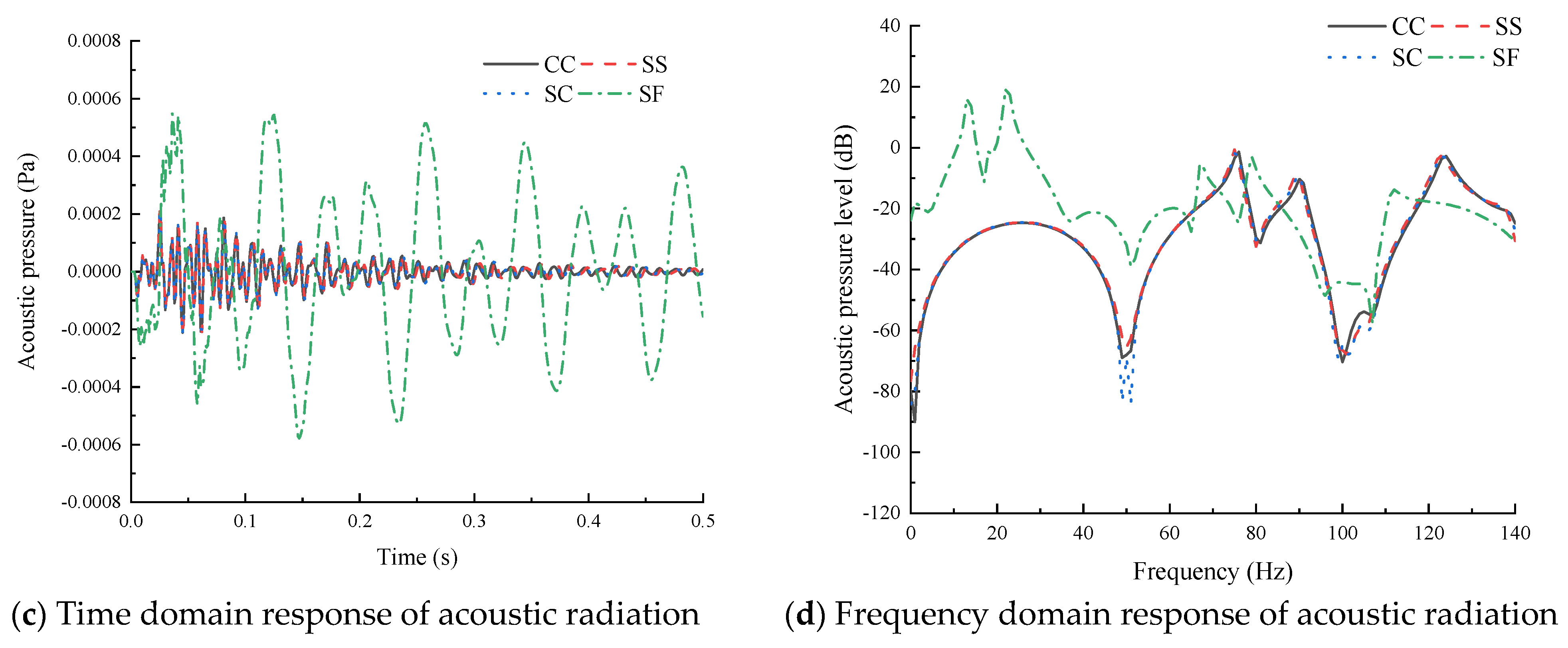

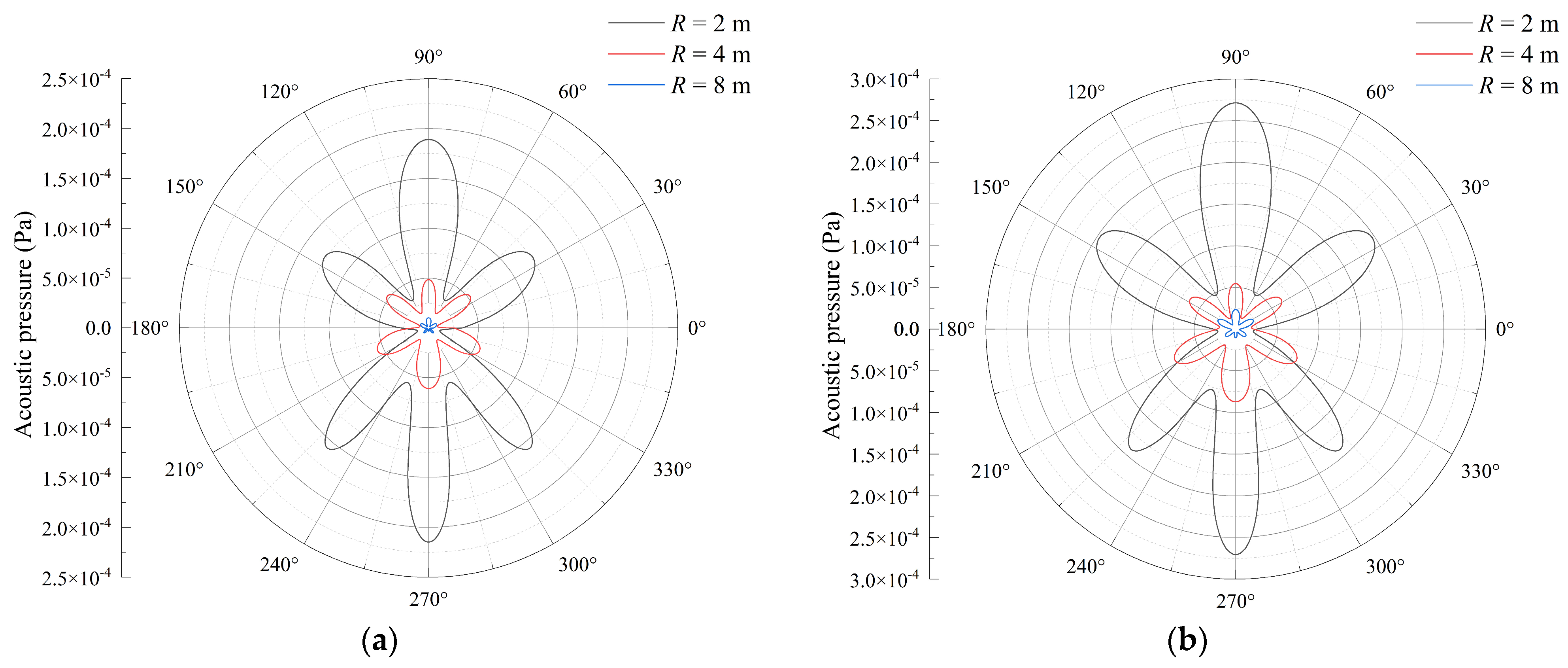

4. Results and Discussion

5. Conclusions

- Under simply supported boundary conditions, the results of the Jacobi–Ritz boundary element method were in agreement with the coupled FEM/BEM, which has advantages such as fast calculation efficiency and high accuracy and can be used to calculate the acoustic radiation characteristics of the forced vibration of conical shells.

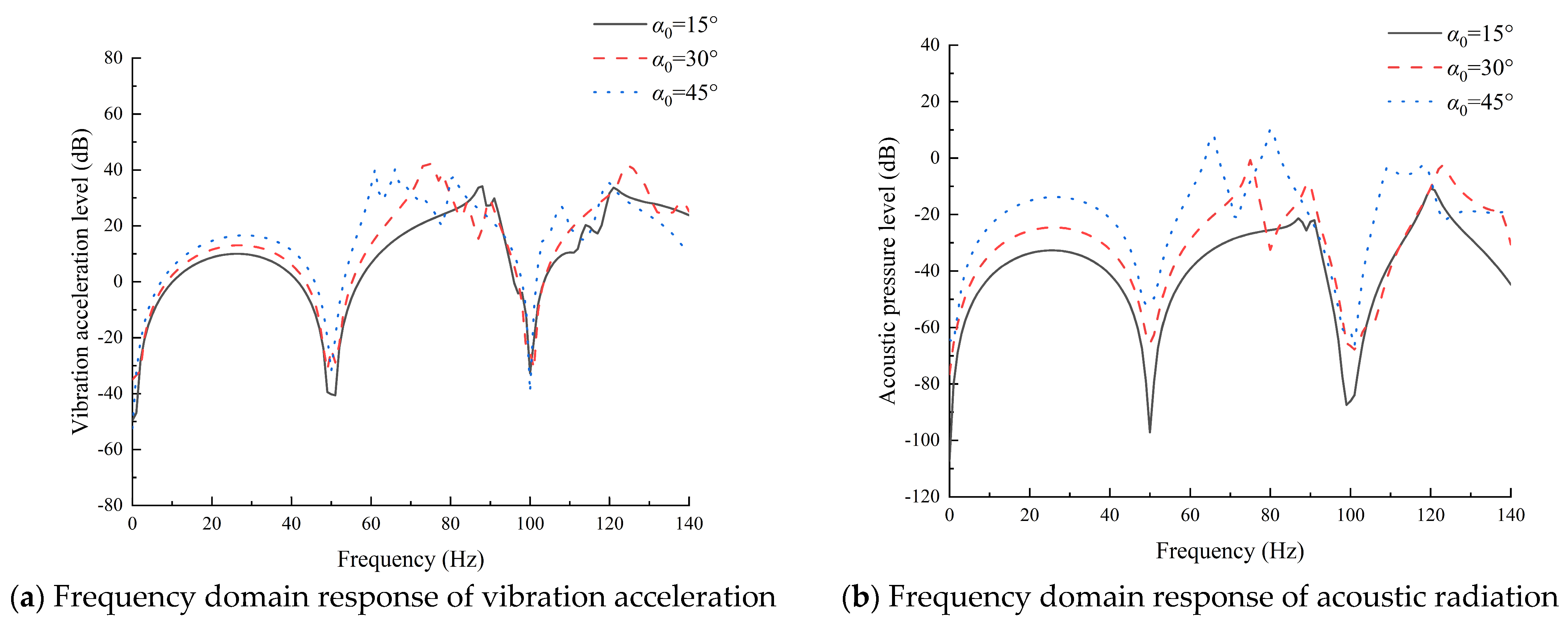

- Changes in structural parameters such as boundary conditions and semi-vertex angle had a great effect on the vibro-acoustic response. As the stiffness of the boundary conditions decreased, the natural frequency moved to the left. When the length and thickness were fixed, the natural frequency of the structure decreased with an increase in the semi-vertex angle; the amplitude of the vibro-acoustic response increased, and the peak frequency of the forced vibration response moved to the left.

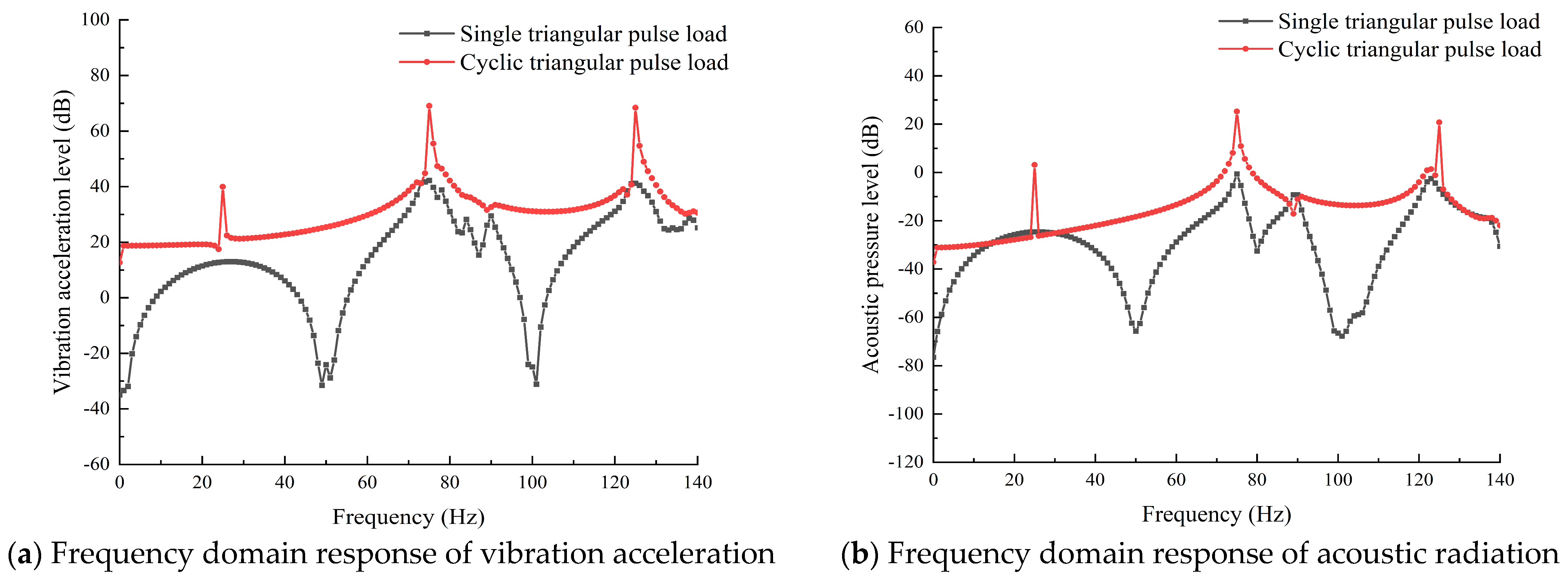

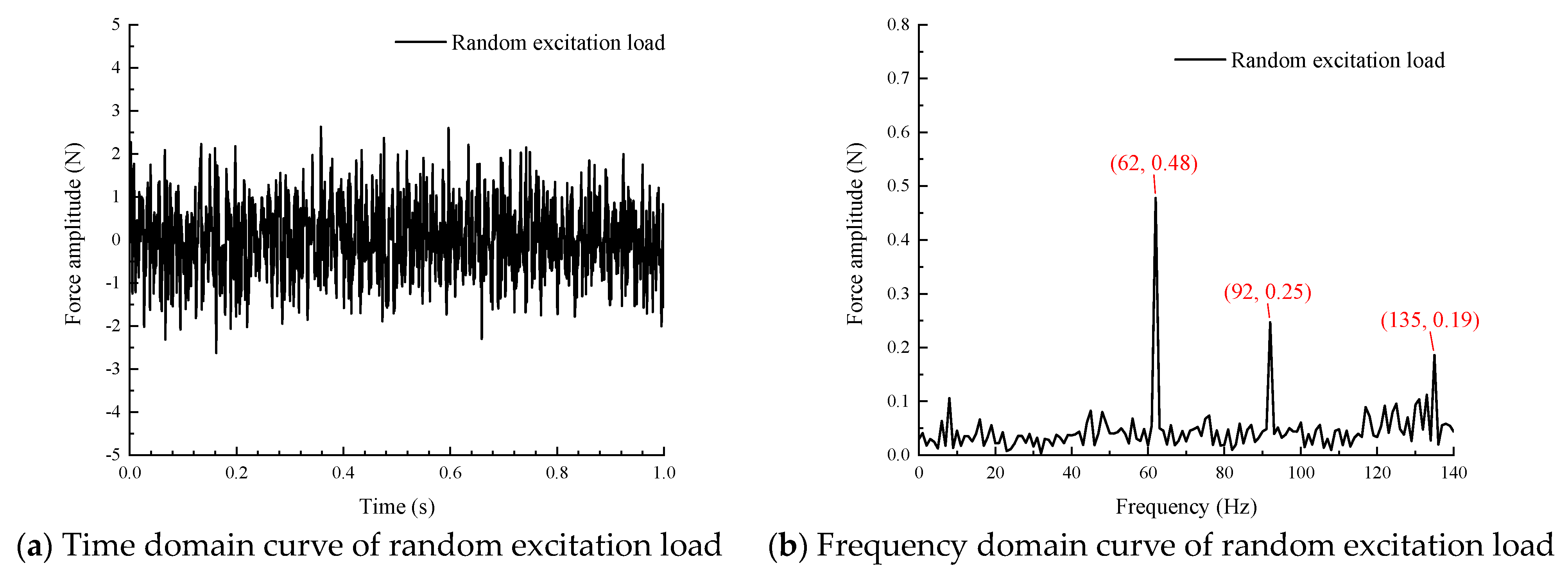

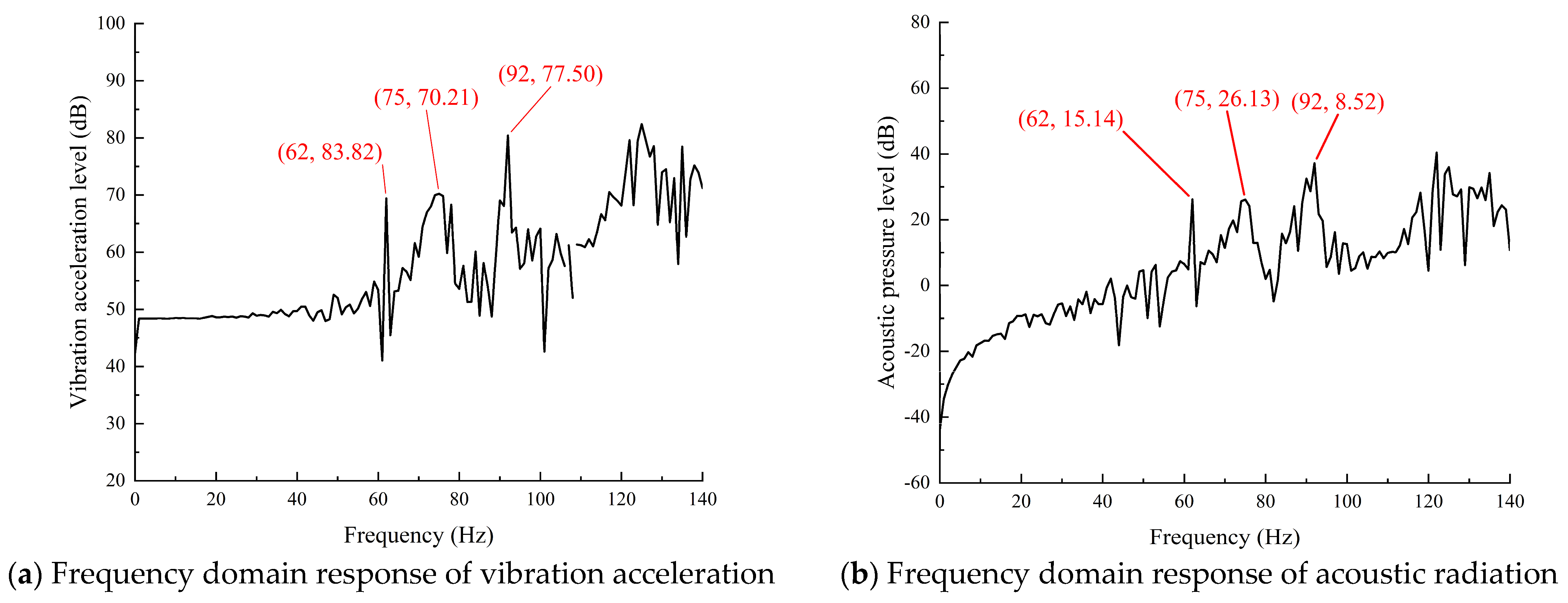

- The characteristic line spectrum of the forced vibration response and acoustic radiation of the conical shell under an impulse load and random load excitation was caused by the natural frequency of the structure and the peak value of the excitation load. At the natural frequency of the structure, the small excitation load may also cause a strong characteristic line spectrum.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Caresta, M.; Kessissoglou, N.; Tso, Y. Low frequency structural and acoustic responses of a submarine hull. Acoust. Aust. 2008, 36, 47–52. [Google Scholar]

- Caresta, M.; Kessissoglou, N.J. Acoustic signature of a submarine hull under harmonic excitation. Appl. Acoust. 2010, 71, 17–31. [Google Scholar] [CrossRef]

- Lam, K.; Li, H.; Ng, T.; Chua, C. Generalized differential quadrature method for the free vibration of truncated conical panels. J. Sound Vib. 2002, 251, 329–348. [Google Scholar] [CrossRef]

- Guo, C.; Liu, T.; Bin, Q.; Wang, Q.; Wang, A. Free vibration analysis of coupled structures of laminated composite conical, cylindrical and spherical shells based on the spectral-Tchebychev technique. Compos. Struct. 2022, 281, 114965. [Google Scholar] [CrossRef]

- Chen, M.; Xie, K.; Jia, W.; Xu, K. Free and forced vibration of ring-stiffened conical–cylindrical shells with arbitrary boundary conditions. Ocean Eng. 2015, 108, 241–256. [Google Scholar] [CrossRef]

- Xie, K.; Chen, M.; Dong, W.; Li, W. A unified semi-analytical method for vibration analysis of shells of revolution stiffened by rings with T cross-section. Thin-Walled Struct. 2019, 139, 412–431. [Google Scholar] [CrossRef]

- Caresta, M.; Kessissoglou, N.J. Free vibrational characteristics of isotropic coupled cylindrical–conical shells. J. Sound Vib. 2010, 329, 733–751. [Google Scholar] [CrossRef]

- Ye, T.; Jin, G.; Chen, Y.; Ma, X.; Su, Z. Free vibration analysis of laminated composite shallow shells with general elastic boundaries. Compos. Struct. 2013, 106, 470–490. [Google Scholar] [CrossRef]

- Qu, Y.; Hua, H.; Meng, G. A domain decomposition approach for vibration analysis of isotropic and composite cylindrical shells with arbitrary boundaries. Compos. Struct. 2013, 95, 307–321. [Google Scholar] [CrossRef]

- Su, Z.; Jin, G.; Shi, S.; Ye, T.; Jia, X. A unified solution for vibration analysis of functionally graded cylindrical, conical shells and annular plates with general boundary conditions. Int. J. Mech. Sci. 2014, 80, 62–80. [Google Scholar] [CrossRef]

- Tong, B.; Li, Y.; Zhu, X.; Zhang, Y. Three-dimensional vibration analysis of arbitrary angle-ply laminated cylindrical shells using differential quadrature method. Appl. Acoust. 2019, 146, 390–397. [Google Scholar] [CrossRef]

- Jafari, A.; Khalili, S.; Azarafza, R. Transient dynamic response of composite circular cylindrical shells under radial impulse load and axial compressive loads. Thin-Walled Struct. 2005, 43, 1763–1786. [Google Scholar] [CrossRef]

- Forouzesh, F.; Jafari, A.A. Nonlinear Forced vibration of pseudoelastic shape memory alloy cylindrical shell subjected to the time and space dependant internal pressure. Modares Mech. Eng. 2015, 15, 1–12. [Google Scholar]

- Li, H.; Pang, F.; Miao, X.; Du, Y.; Tian, H. A semi-analytical method for vibration analysis of stepped doubly-curved shells of revolution with arbitrary boundary conditions. Thin-Walled Struct. 2018, 129, 125–144. [Google Scholar] [CrossRef]

- Li, H.; Pang, F.; Miao, X.; Li, Y. Jacobi–Ritz method for free vibration analysis of uniform and stepped circular cylindrical shells with arbitrary boundary conditions: A unified formulation. Comput. Math. Appl. 2019, 77, 427–440. [Google Scholar] [CrossRef]

- Pang, F.; Li, H.; Wang, X.; Miao, X.; Li, S. A semi analytical method for the free vibration of doubly-curved shells of revolution. Comput. Math. Appl. 2018, 75, 3249–3268. [Google Scholar] [CrossRef]

- Qu, Y.; Meng, G. Prediction of acoustic radiation from functionally graded shells of revolution in light and heavy fluids. J. Sound Vib. 2016, 376, 112–130. [Google Scholar] [CrossRef]

- Qu, Y.; Meng, G. Vibro-acoustic analysis of multilayered shells of revolution based on a general higher-order shear deformable zig-zag theory. Compos. Struct. 2015, 134, 689–707. [Google Scholar] [CrossRef]

- Zhong, R.; Hu, S.; Liu, X.; Qin, B.; Wang, Q.; Shuai, C. Vibro-acoustic analysis of a circumferentially coupled composite laminated annular plate backed by double cylindrical acoustic cavities. Ocean Eng. 2022, 257, 111584. [Google Scholar] [CrossRef]

- Zhong, R.; Guan, X.; Wang, Q.; Qin, B.; Shuai, C. Prediction of acoustic radiation from elliptical caps of revolution by using a semi-analytic method. J. Braz. Soc. Mech. Sci. Eng. 2021, 43, 383. [Google Scholar] [CrossRef]

- Sharma, N.; Mahapatra, T.R.; Panda, S.K. Numerical analysis of acoustic radiation properties of laminated composite flat panel in thermal environment: A higher-order finite-boundary element approach. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2018, 232, 3235–3249. [Google Scholar] [CrossRef]

- Kumar, B.R.; Ganesan, N.; Sethuraman, R. Vibro-acoustic analysis of functionally graded elliptic disc under thermal environ-ment. Mech. Adv. Mater. Struct. 2009, 16, 160–172. [Google Scholar] [CrossRef]

- Gao, C.; Zhang, H.; Li, H.; Pang, F.; Wang, H. Numerical and experimental investigation of vibro-acoustic characteristics of a submerged stiffened cylindrical shell excited by a mechanical force. Ocean Eng. 2022, 249, 110913. [Google Scholar] [CrossRef]

- Pang, F.; Tang, Y.; Qin, Y.; Zheng, J.; Hui, D.; Li, H. Analysis of acoustic radiation characteristic of laminated paraboloidal shell based on Jacobi-Ritz-spectral BEM. Ocean Eng. 2023, 280, 114686. [Google Scholar] [CrossRef]

- Xie, K.; Chen, M. A semi-analytic model for vibro-acoustic analysis of functionally graded shells of revolution. Thin-Walled Struct. 2022, 173, 108949. [Google Scholar] [CrossRef]

- Xie, K.; Chen, M.; Zhang, L.; Li, W.; Dong, W. A unified semi-analytic method for vibro-acoustic analysis of submerged shells of revolution. Ocean Eng. 2019, 189, 106345. [Google Scholar] [CrossRef]

- Li, Z.; Wang, Q.; Zhong, R.; Qin, B.; Shao, W. Vibro-acoustic analysis of laminated composite cylindrical and conical shells using meshfree method. Eng. Anal. Bound. Elements 2023, 152, 789–807. [Google Scholar] [CrossRef]

- Jin, G.; Ma, X.; Wang, W.; Liu, Z. An energy-based formulation for vibro-acoustic analysis of submerged submarine hull struc-tures. Ocean. Eng. 2018, 164, 402–413. [Google Scholar] [CrossRef]

- Chen, M.; Zhang, C.; Tao, X.; Deng, N. Structural and acoustic responses of a submerged stiffened conical shell. Shock Vib. 2014, 2014, 954253. [Google Scholar] [CrossRef]

- Wang, X.; Wu, W.; Yao, X. Structural and acoustic response of a finite stiffened conical shell. Acta Mech. Solida Sin. 2015, 28, 200–209. [Google Scholar] [CrossRef]

- Wang, X.-Z.; Jiang, Q.-Z.; Xiong, Y.-P.; Gu, X. Experimental studies on the vibro-acoustic behavior of a stiffened submerged conical-cylindrical shell subjected to force and acoustic excitation. J. Low Freq. Noise, Vib. Act. Control 2020, 39, 280–296. [Google Scholar] [CrossRef]

- Qu, Y.; Zhang, W.; Peng, Z.; Meng, G. Time-domain structural-acoustic analysis of composite plates subjected to moving dynamic loads. Compos. Struct. 2019, 208, 574–584. [Google Scholar] [CrossRef]

- Zuo, Y.; Yang, D.; Zhuang, Y. Broadband transient vibro-acoustic prediction and control for the underwater vehicle power cabin with metamaterial components. Ocean Eng. 2024, 298, 117121. [Google Scholar] [CrossRef]

- Gao, C.; Xu, J.; Pang, F.; Li, H.; Wang, K. Modeling and experiments on the vibro-acoustic analysis of ring stiffened cylindrical shells with internal bulkheads: A comparative study. Eng. Anal. Bound. Elements 2024, 162, 239–257. [Google Scholar] [CrossRef]

- Gao, C.; Pang, F.; Li, H.; Huang, X.; Liang, R. Prediction of vibro-acoustic response of ring stiffened cylindrical shells by using a semi-analytical method. Thin-Walled Struct. 2024, 200, 111930. [Google Scholar] [CrossRef]

- Wang, Q.; Shi, D.; Liang, Q.; Pang, F. Free vibrations of composite laminated doubly-curved shells and panels of revolution with general elastic restraints. Appl. Math. Model. 2017, 46, 227–262. [Google Scholar] [CrossRef]

- Gao, C.; Pang, F.; Cui, J.; Li, H.; Zhang, M.; Du, Y. Free and forced vibration analysis of uniform and stepped combined coni-cal-cylindrical-spherical shells: A unified formulation. Ocean. Eng. 2022, 260, 111842. [Google Scholar] [CrossRef]

| Type | Wire Spring Stiffness ku = kv = kw (N/m) | Rotating Spring Stiffness kx = kθ (N·m/rad) |

|---|---|---|

| Clamped—C | 1015 | 1015 |

| Simply Support—S | 1015 | 0 |

| Free—F | 0 | 0 |

| Elastic—E | 108 | 10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, C.; Zheng, J.; Pang, F.; Xu, J.; Li, H.; Yan, J. Prediction of Time Domain Vibro-Acoustic Response of Conical Shells Using Jacobi–Ritz Boundary Element Method. Acoustics 2024, 6, 523-540. https://doi.org/10.3390/acoustics6020028

Gao C, Zheng J, Pang F, Xu J, Li H, Yan J. Prediction of Time Domain Vibro-Acoustic Response of Conical Shells Using Jacobi–Ritz Boundary Element Method. Acoustics. 2024; 6(2):523-540. https://doi.org/10.3390/acoustics6020028

Chicago/Turabian StyleGao, Cong, Jiajun Zheng, Fuzhen Pang, Jiawei Xu, Haichao Li, and Jibing Yan. 2024. "Prediction of Time Domain Vibro-Acoustic Response of Conical Shells Using Jacobi–Ritz Boundary Element Method" Acoustics 6, no. 2: 523-540. https://doi.org/10.3390/acoustics6020028

APA StyleGao, C., Zheng, J., Pang, F., Xu, J., Li, H., & Yan, J. (2024). Prediction of Time Domain Vibro-Acoustic Response of Conical Shells Using Jacobi–Ritz Boundary Element Method. Acoustics, 6(2), 523-540. https://doi.org/10.3390/acoustics6020028