Study of Friction Force in Electrodynamic Rail Accelerator: Experiment and Interpretation Using FEM Modelling

Abstract

:1. Introduction

2. Problem Formulation

- Modelling the time-dependent equivalent circuit.

- Finding the time dependence of the field current.

- Modelling magnetic field in the system rails—projectile.

- Determining the accelerating and drag forces on the projectile (using our experimental data).

- Finding the time dependencies of its acceleration, velocity and trajectory, using the same data.

- Measuring the transient field current.

- Measuring the time-dependent trajectory of the projectile.

- Finding its velocity and acceleration.

- Finding the total force acting on the projectile.

- Separating the total force into the magnetic (accelerating) force and the friction force.

3. Modelling of Individual Parts of System

3.1. Equivalent Circuit

3.2. Magnetic Field in System Rails–Projectile

3.3. Motion of the Projectile

4. Measurements

4.1. Measurement of the Circuit Parameters and Field Current

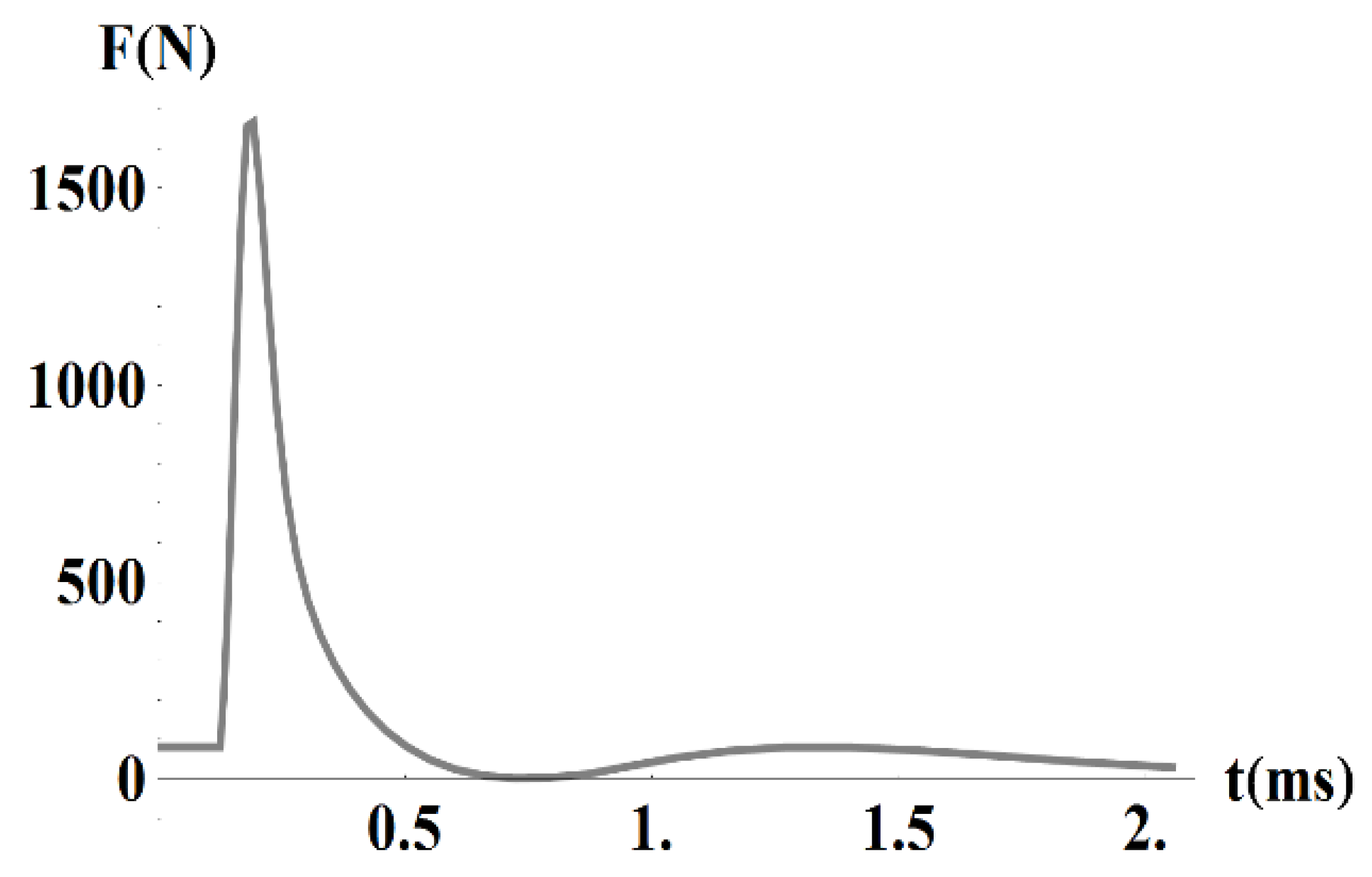

4.2. Measurement of the Magnetic Force

5. Conclusions

6. Patents

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- McNab, I.R. Launch to space with an electromagnetic railgun. IEEE Trans. Magn. 2003, 39, 295–304. [Google Scholar] [CrossRef] [Green Version]

- Siaenen, T.; Schneider, M.; Hogan, J. Block diagram model for the simulation of an electromagnetic rail accelerator. In Proceedings of the 17th International Symposium on Electromagnetic Launch Technology, La Jolla, CA, USA, 7–11 July 2014; pp. 1–5. [Google Scholar]

- Uryukov, B.A.; Lebedev, A.D.; Milyaev, C.C. Influence of materials properties on the dynamics of metal armature acceleration in a railgun. In Proceedings of the Fourth European Symposium on Electromagnetic Launch Technology, Gelle, Germany, 2–6 May 1993; pp. 153–158. [Google Scholar]

- Zhang, Y.; Ruan, J.; Liao, J.; Hu, Y.; Liu, K. Nonlinear scaling study of a railgun. In Proceedings of the 16th International Symposium on Electromagnetic Launch Technology, Beijing, China, 15–19 May 2012. [Google Scholar] [CrossRef]

- Wang, Z.H.; Wan, M.; Li, X.J. Numerical modeling of electromagnetic railgun rail temperature field. Int. J. Appl. Electromagn. Mech. 2016, 51, 173–183. [Google Scholar] [CrossRef]

- Yin, D.; Xiao, H.; Li, B. Dynamics response of filament-wound composite barrel for rail gun with acceleration load. IEEE Trans. Plasma Sci. 2018, 46, 1847–1854. [Google Scholar] [CrossRef]

- Khandryga, D.V.; Plekhanov, A.V.; Tereschenko, A.N. Numerical simulation and experimental results of the metal armature acceleration. IEEE Trans. Magn. 1995, 31, 193–197. [Google Scholar] [CrossRef]

- Rodger, D.; Lai, H.C. A comparison of formulation for 3D finite element modelling of electromagnetic launchers. IEEE Trans. Magn. 2001, 37, 135–138. [Google Scholar] [CrossRef]

- Hundertmark, S. Comparing a Dynamic railgun simulation with experiment. J. Electr. Eng. 2011, 11, 4. [Google Scholar]

- Hundertmark, S.; Roch, M. Transient 3-d simulation of an experimental railgun using finite element methods. In Proceedings of the 16th International Symposium on Electromagnetic Launch Technology, Beijing, China, 15–19 May 2012. [Google Scholar] [CrossRef]

- Bayati, M.S.; Keshtkar, A.; Gharib, L. Numerical analyzing the electromagnetic launcher using FEM-3D in time domain. In Proceedings of the 16th International Symposium on Electromagnetic Launch Technology, Beijing, China, 15–19 May 2012. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, J.; Li, S.; Liu, P.; Cao, R.; Cheng, L.; Yuan, W. Simulation and test study on different structure bore of electromagnetic launch. In Proceedings of the 17th International Symposium on Electromagnetic Launch Technology, San Diego, CA, USA, 7–11 July 2014. [Google Scholar] [CrossRef]

- Tumonis, L.; Kačianauskas, R.; Kačeniauskas, A. Evaluation of friction due to deformed behaviour of rail in the electromagnetic railgun: Numerical investigation. Mechanika 2007, 63, 58–63. Available online: https://mechanika.ktu.lt/index.php/Mech/article/view/14786 (accessed on 22 October 2020).

- An, S.; Lee, B.; Bae, Y.; Lee, Y.H.; Kim, S.H. Numerical analysis of the transient inductance gradient of electromagnetic launcher using 2-D and 3-D finite-element methods. IEEE Trans. Plasma Sci. 2017, 45, 1635–1638. [Google Scholar] [CrossRef]

- Go, B.S.; Le, D.V.; Song, M.G.; Park, M.; Yu, I.K. Design and electromagnetic analysis of an induction-type coilgun system with a pulse power module. IEEE Trans. Plasma Sci. 2019, 47, 971–976. [Google Scholar] [CrossRef]

- Meger, R.A.; Huhman, B.; Neri, J.; Brintlinger, T.; Jones, H.; Michopoulos, J.; Cairns, R.; Douglas, S. Electromagnetic railgun barrel damage experiments. NRL Rev. 2012, 85–92. Available online: https://www.nrl.navy.mil/content_images/2012Review/12_FA2.pdf (accessed on 22 October 2020).

- Marshall, A. Railgun overview. In Proceedings of the Impact Fusion Workshop, Los Alamos, NM, USA, 10–13 July 1979. [Google Scholar]

- Taher, S.A.; Jafari, M.; Pakdel, M. A new approach for modeling electromagnetic railguns. IEEE Trans. Plasma Sci. 2015, 43, 1733–1741. [Google Scholar] [CrossRef]

- COMSOL Multiphysics® version 5.3a. Available online: www.comsol.com (accessed on 22 October 2020).

- NATO—STANAG 4367, Thermodynamic interior ballistic model with global parameters, 2012–05. Available online: https://standards.globalspec.com/std/1686991/STANAG%204367 (accessed on 22 October 2020).

| Inductance of capacitor bank, circuit conductors and resistors | |

| Inductance of rails | |

| Resistance of conductors in capacitor bank and feeding cables | |

| Resistance of barrel and projectile | |

| Voltage of capacitor bank |

| Element | Value (Unit) |

|---|---|

| 5.18 × 10−3 (F) | |

| 0.069 (Ω) | |

| 1.525 × 10−6 (H) | |

| 0.053 × 10−6 + 0.344 × 10−6x (H) | |

| 7.512 × 10−3 + 182 × 10−6x (Ω) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tichý, T.; Zemen, J.; Dražan, L.; Racek, F.; Papež, V.; Doležel, I. Study of Friction Force in Electrodynamic Rail Accelerator: Experiment and Interpretation Using FEM Modelling. Physics 2020, 2, 596-607. https://doi.org/10.3390/physics2040034

Tichý T, Zemen J, Dražan L, Racek F, Papež V, Doležel I. Study of Friction Force in Electrodynamic Rail Accelerator: Experiment and Interpretation Using FEM Modelling. Physics. 2020; 2(4):596-607. https://doi.org/10.3390/physics2040034

Chicago/Turabian StyleTichý, Tomáš, Jan Zemen, Libor Dražan, František Racek, Václav Papež, and Ivo Doležel. 2020. "Study of Friction Force in Electrodynamic Rail Accelerator: Experiment and Interpretation Using FEM Modelling" Physics 2, no. 4: 596-607. https://doi.org/10.3390/physics2040034

APA StyleTichý, T., Zemen, J., Dražan, L., Racek, F., Papež, V., & Doležel, I. (2020). Study of Friction Force in Electrodynamic Rail Accelerator: Experiment and Interpretation Using FEM Modelling. Physics, 2(4), 596-607. https://doi.org/10.3390/physics2040034