Mechanical Properties and Leak-Tightness of Polymeric Pipe Adhesive Joints

Abstract

:1. Introduction

2. Materials and Methods

2.1. Adherends

2.2. Adhesives

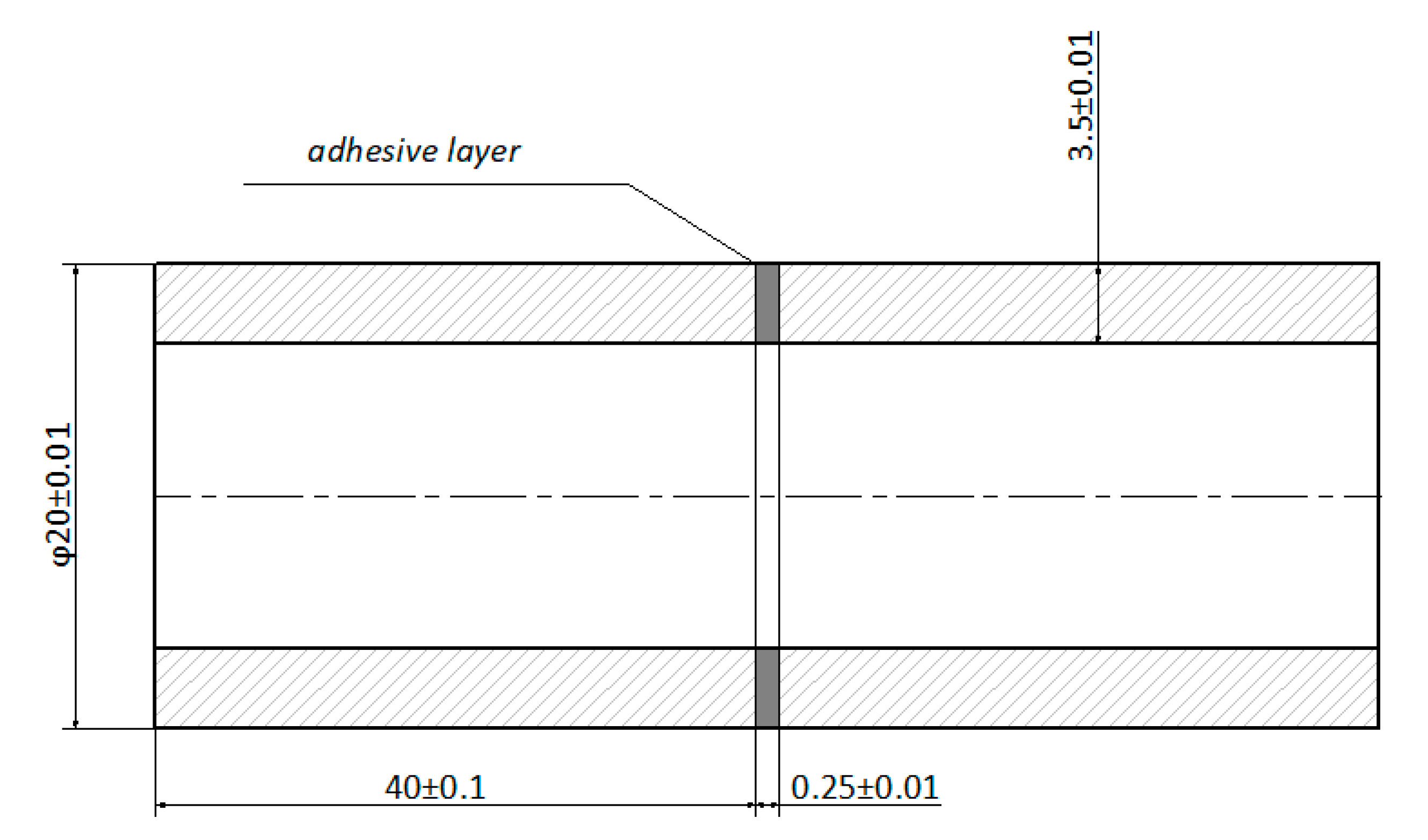

2.3. Adhesive Joints

2.4. Adhesive Joints Preparation

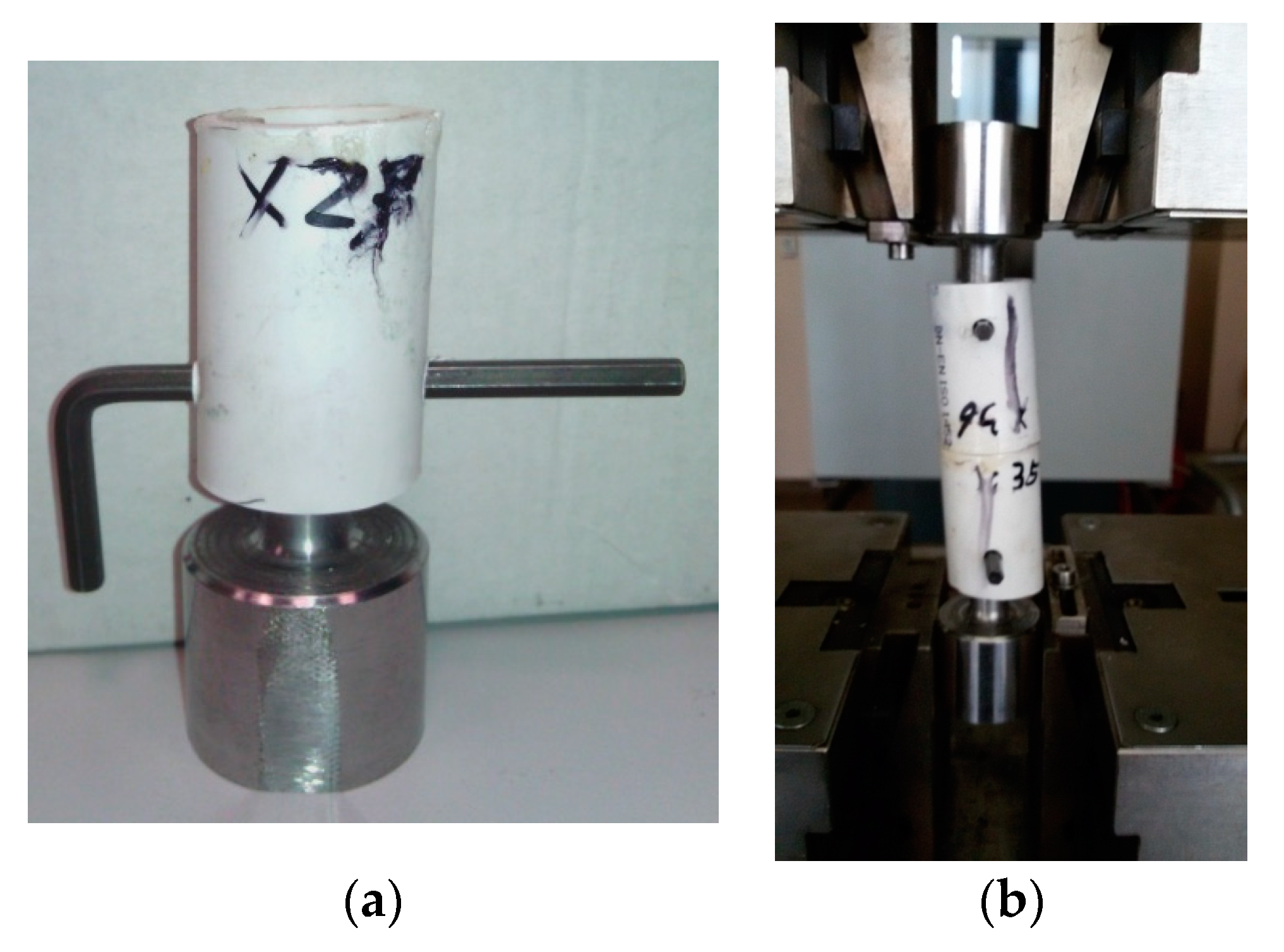

2.5. Leak-Tightness and Strength Tests

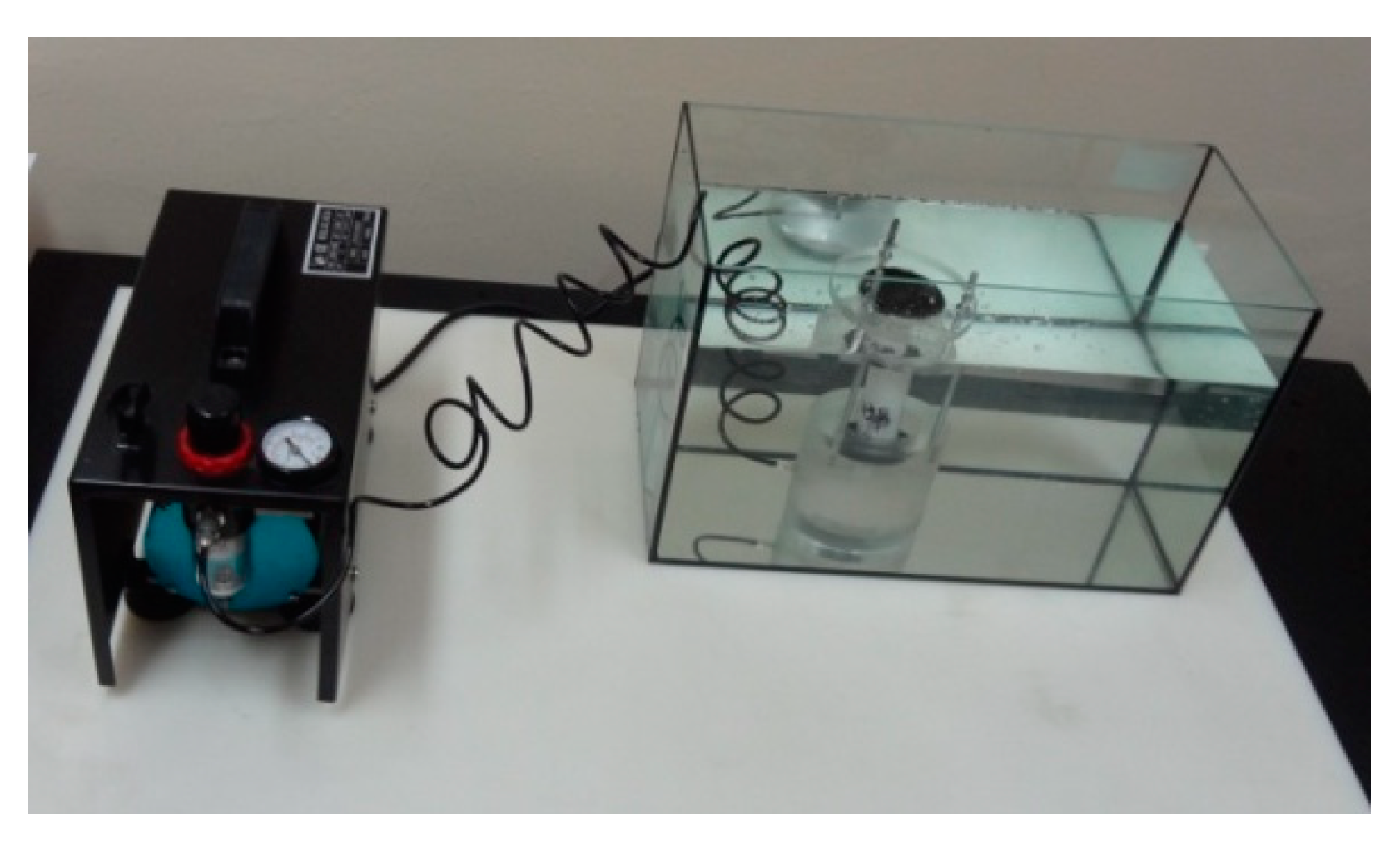

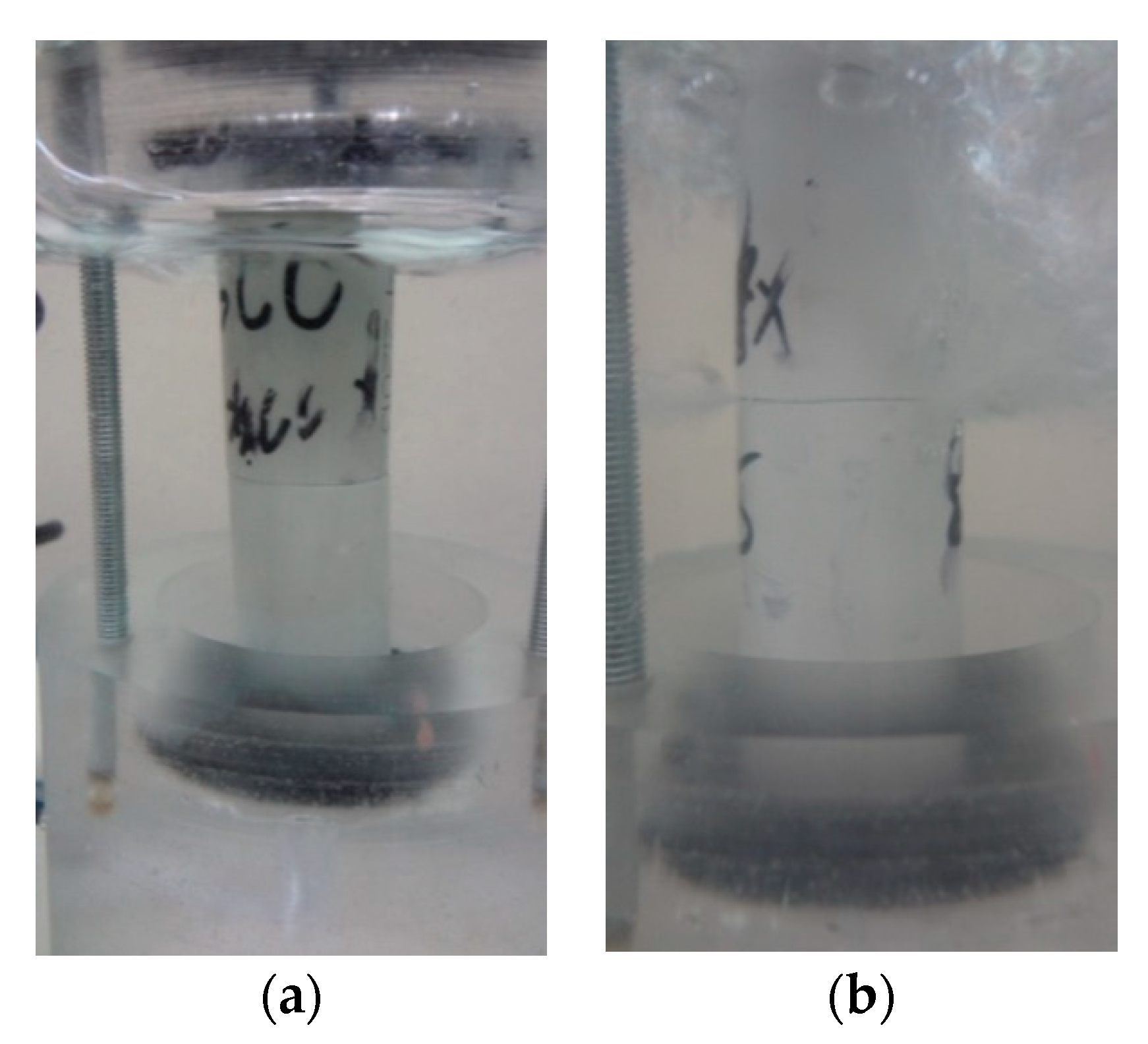

- A stand for testing the leak-tightness of the sample, using the appropriate test methodology [22],

- The Zwick/Roell Z150 testing machine with computer set and testXpert software, using DIN EN 1465 standard. The shear strength test was carried out in the ambient temperature. The test speed was 5 mm/min.

3. Results

3.1. Leak-Tightness Test

3.2. Strenght Test

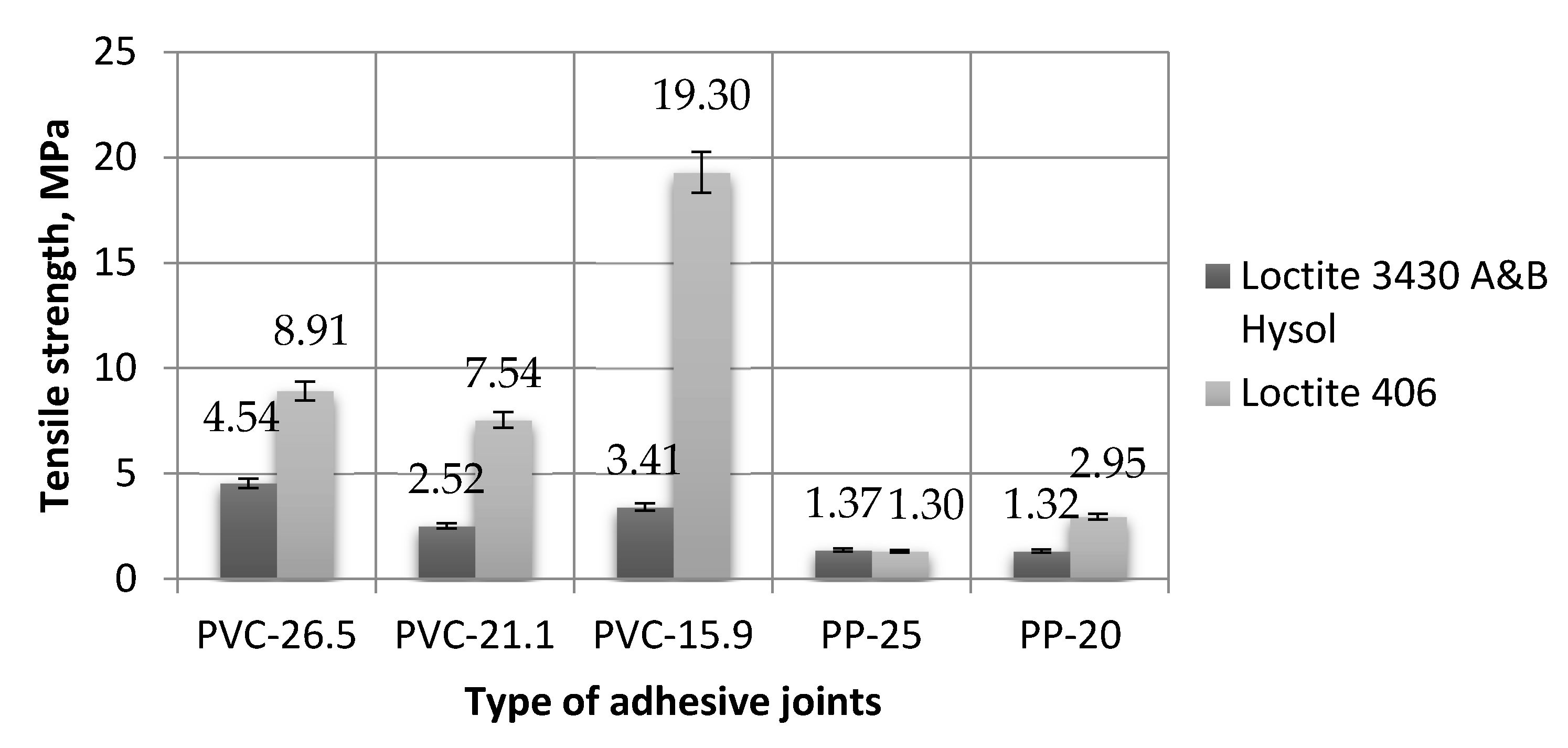

3.2.1. Tensile Strength

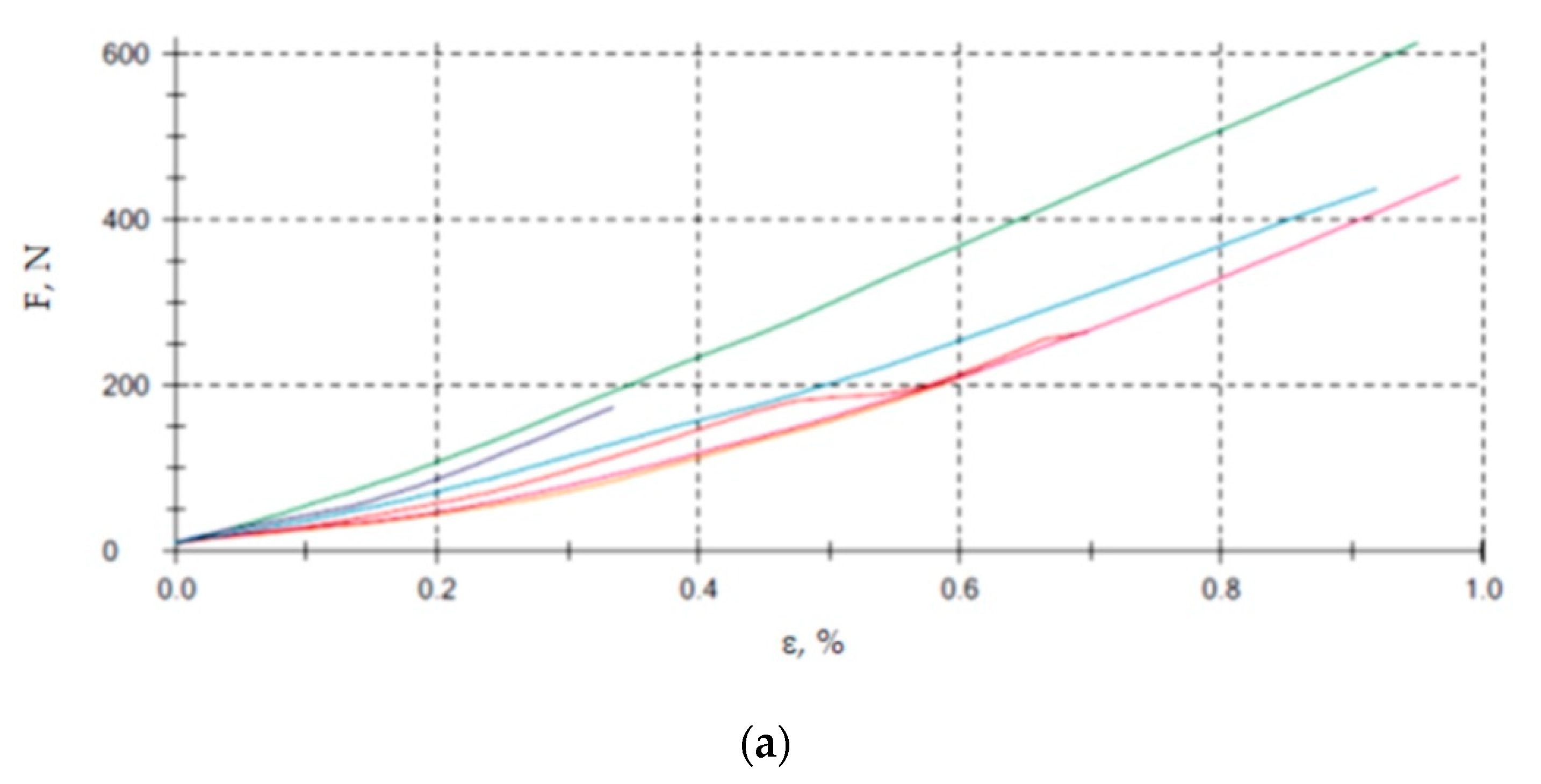

3.2.2. Elongation at Break

- The samples of the PVC pipes adhesive joints have higher elongation at break values than those of PP pipes adhesive joints;

- With the decrease in pipe diameter (and also with the decrease in the bonding area size—Table 3), the elongation at break value increases, and this relation applies to both types of the polymer pipe materials (both PVC pipes and PP pipes), which is the opposite relation observed in the case of the adhesive joints of these pipes but made with the Loctite 3430 A&B Hysol adhesive;

- In particular types of the polymer pipes adhesive joints, the elongation at break of the joints between maximum and minimum elongation values is twice as high (PP-25 and PP-20 as well as PVC-26.5 and PVC-15.9).

4. Discussion

4.1. Leak-Tightness Test Results

4.2. Strength Test Results

- In the case of adhesive joints made with Loctite 3430 A&B Hysol, both of PVC and PP pipes, a strong correlation was obtained between the size of the bonding area and the elongation at break value. In the case of PVC pipe adhesive joints, the correlation coefficient is 0.96, and in the case of the polypropylene pipe adhesive joints, the correlation coefficient is 1.00. The added sign of the coefficient means that as the bonding area increases, the elongation at break value increases, and this applies to the adhesive joints of both types of the polymer pipes;

- When considering the correlation between the size of the bonding area and the elongation at break of the adhesive joints of the polymer pipes made with Loctite 406, the correlation coefficient was −0.91 (the adhesive joints of PVC pipes) and −1 (the adhesive joints of PP pipes). This means that there is a strong correlation between the size of the bonding area and the elongation at break of the adhesive joints, with the elongation decreasing as the bonding area increases.

- It may result from both the cohesive properties of the adhesive and the adhesive properties at the interface between the surface of the joined elements and the adhesive. The adhesives used differ in both the chemical base and the viscosity. The abovementioned factors may result in obtaining various dependencies related to the elongation of the considered adhesive joints.

- For the adhesive joints of pipes made with two-component epoxy adhesive, there were the following two types of failure: a special cohesion failure (SCF)—34% of all evaluated pipe adhesive joints—and an adhesion failure (AF)—66% of all evaluated pipe adhesive joints;

- For the adhesive joints of pipes made with one-component cyanoacrylate adhesive, for almost all of the assessed adhesive joints, the adhesive failure type (AF) was noted.

5. Conclusions

- The sealing properties of Loctite 3430 A&B Hysol and Loctite 406 adhesives are similar, and the main factor in obtaining a leak-proof sample is the correct course of the bonding process, in particular the stages of pressing, fixing the joined elements and curing the adhesive;

- The geometrical accuracy of the adherends has a great influence on the tightness and the strength of the adhesive joints,

- The adhesive joints made with Loctite 406 cyanoacrylate adhesive have higher the strength than the adhesive joints made with Loctite 3430 A&B Hysol two-component epoxy adhesive;

- The type of the adhesive has a significant effect on the elongation at break of the adhesive joints.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Adams, R.D.; Comyn, J.; Wake, W.C. Structural Adhesive Joints in Engineering, 2nd ed.; Chapmann & Hall: London, UK, 1997; pp. 140–144. [Google Scholar]

- Habenicht, G. Applied Adhesive Bonding; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2006; pp. 139–143. [Google Scholar]

- Taib, A.A.; Boukhili, R.; Achiou, S.; Gordon, S.; Boukehili, H. Bonded joints with composite adherends. Part I. Effect of specimen configuration, adhesive thickness, spew fillet and adherend stiffness on fracture. Int. J. Adhes. Adhes. 2006, 26, 226–236. [Google Scholar] [CrossRef]

- Liao, L.; Huang, C.; Sawa, T. Effect of adhesive thickness, adhesive type and scarf angle on the mechanical properties of scarf adhesive joints. Int. J. Solids Struct. 2013, 50, 4333–4340. [Google Scholar] [CrossRef] [Green Version]

- Da Silva, L.F.; Carbas, R.; Critchlow, G.W.; Figueiredo, M.; Brown, K. Effect of material, geometry, surface treatment and environment on the shear strength of single lap joints. Int. J. Adhes. Adhes. 2009, 29, 621–632. [Google Scholar] [CrossRef] [Green Version]

- Wong, L.; Deo, R.; Rathnayaka, S.; Shannon, B.; Zhang, C.; Chiu, W.K.; Kodikara, J.; Widyastuti, H. Leak detection in water pipes using submersible optical optic-based pressure sensor. Sensors 2018, 18, 4192. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jensen, R.A.; Agnone, A.M. A new method to leak test piping joints. J. Manuf. Sci. Eng. 1996, 118, 604–609. [Google Scholar] [CrossRef]

- Rudawska, A.; Wahab, M.A.; Müller, M. Effect of ageing process on mechanical properties of adhesive tubular butt joints in aqueous environment. Int. J. Adhes. Adhes. 2020, 96, 102466. [Google Scholar] [CrossRef]

- Van Zyl, J.E.; Malde, R. Evaluating the pressure-leakage behaviour of leaks in water pipes. J. Wat. Supp. Res. Technol. AQUA 2017, 66, 287–299. [Google Scholar] [CrossRef]

- Makris, K.F.; Langeveld, J.; Clemens, F.H.L.R. A review on the durability of PVC sewer pipes: Research vs. practice. Struct. Infrastruct. Eng. 2020, 16, 880–897. [Google Scholar] [CrossRef]

- Marmarokopos, K.; Doukakis, D.; Frantziskonis, G.; Avlonitis, M. Leak detection in plastic water supply pipes with a high signal-to-noise ratio accelerometer. Measur. Contr. 2018, 51, 27–31. [Google Scholar] [CrossRef]

- Sadr-Al-Sadati, S.A.; Jalili Ghazizadeh, M. Experimental study of crack behavior in pressurized high-density polyethylene water pipes. MethodsX 2019, 6, 1009–1020. [Google Scholar] [CrossRef] [PubMed]

- Yalçin, B.C.; Torun, Z.; Balcilar, M.; Koyun, A. Design and servo control of a leak tightness working based on hydrostatic pressure aging method. Proc. Inst. Mech. Eng. Part I J. Sys. Cont. Eng. 2016, 230, 932–942. [Google Scholar] [CrossRef]

- Liu, J.; Liu, G.; Wang, J.; Liu, S. Research on pipeline leakage identification method based on Lyapunov exponent spectrum. Vibroeng. Procedia 2019, 23, 61–65. [Google Scholar] [CrossRef]

- ASTM F2164-21. Standard Practice for Filed Leak Testing of Polyethylene (PE) and Crosslinked Polyethylene (PEX) Pressure Piping Systems Using Hydrostatic Pressure. Available online: https://www.astm.org/f2164-21.html (accessed on 28 September 2021).

- Wang, X.J.; Simpson, A.R.; Lambert, M.F.; Vítkovský, J.P. Leak detection in pipeline systems using hydraulic methods: A review. In Proceedings of the Conference on Hydraulics in Civil Engineering, the Institution of Engineers, Hobart, Australia, 23–30 November 2001; pp. 391–400. [Google Scholar]

- Polyvinyl Chloride. Available online: https://www.sigmaaldrich.com/PL/pl/product/aldrich/346764 (accessed on 28 September 2021).

- Polypropylene. Available online: https://en.wikipedia.org/wiki/Polypropylene (accessed on 28 September 2021).

- Mechanical Properties of Polymer Pipes. Available online: http://www.instsani.pl/614/rury-z-polichlorku-winylu-pvc (accessed on 28 September 2021).

- Loctite 406. Data Sheet. Available online: https://www.henkel-adhesives.com/pl/pl/produkty/instant-adhesives/loctite_406.html (accessed on 20 March 2021).

- Loctite 3430 A&B Hysol. Data Sheet. Available online: https://www.henkel-adhesives.com/pl/pl/produkty/structural-adhesives/loctite_ea_3430.html (accessed on 20 March 2021).

- Miturska, I.; Rudawska, A. Leakproofness control station of glue joints in the assembly processes. In Advanced Technologies in Designing, Engineering and Manufacturing. Research Problems; Jachowicz, T., Kłonica, M., Eds.; Perfekto Info: Lublin, Poland, 2015; pp. 88–100. [Google Scholar]

- Davies, P.; Sohier, L.; Cognard, J.-Y.; Bourmaud, A.; Choqueuse, D.; Rinnert, E.; Créac’hcadec, R. Influence of adhesive bond line thickness on joint strength. Int. J. Adhes. Adhes. 2009, 29, 724–736. [Google Scholar] [CrossRef] [Green Version]

- Rudawska, A. Influence of the thickness of joined elements on lap length of alluminium alloy sheet bonded joints. Adv. Sci. Technol. Res. J. 2015, 9, 35–44. [Google Scholar] [CrossRef] [Green Version]

| Type of Material | Polyvinyl Chloride (PVC) | Polypropylene (PP) | |||

|---|---|---|---|---|---|

| Diameter, mm | 26.5 | 21.1 | 15.5 | 25.0 | 20.0 |

| Thickness of wall, mm | 2.2 | 1.8 | 1.8 | 4.5 | 3.5 |

| Designation | PVC-26.5 | PVC-21.1 | PVC-15.5 | PP-25 | PP-20 |

| Mechanical Properties | Type of Material | |

|---|---|---|

| Polyvinyl Chloride (PVC-U) | Polypropylene (PP-R) | |

| Young modulus 1 | 2758 MPa | 850–900 MPa |

| Tensile strength | 48.3 MPa | |

| Stress in plastic deformation 2 | 27 MPa | |

| Stress at break 2 | 32 MPa | |

| Elongation at break 2 | 10–14% | |

| Type of Material | Polyvinyl Chloride (PVC) | Polypropylene (PP) | |||

|---|---|---|---|---|---|

| Designation of pipes | PVC-26.5 | PVC-21.1 | PVC-15.9 | PP-25 | PP-20 |

| Bonding area, mm2 | 89.5 | 57.1 | 41.3 | 160.7 | 100.3 |

| Designation of Pipe | Loctite 3430 A&B Hysol | Loctite 406 | ||

|---|---|---|---|---|

| Number of Leaky Samples | Number of Leaks | Number of Leaky Samples | Number of Leaks | |

| Polyvinyl chloride (PVC) | ||||

| PVC-26.5 | 0 | 0 | 2 | 1/1 1; 2/2 1 |

| PVC-21.1 PVC-15.9 | 0 | 0 | 1 | 1/1 1 |

| 4 | 1/2 1; 2/2 1; 3/1 1; 4/1 1 | 0 | 0 | |

| Polypropylene (PP) | ||||

| PP-25 | 0 | 0 | 1 | 1/2 1 |

| PP-20 | 2 | 1/1 1; 2/1 1 | 0 | 0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rudawska, A.; Wahab, M.A.; Müller, M.; Stančeková, D. Mechanical Properties and Leak-Tightness of Polymeric Pipe Adhesive Joints. Appl. Mech. 2022, 3, 64-77. https://doi.org/10.3390/applmech3010004

Rudawska A, Wahab MA, Müller M, Stančeková D. Mechanical Properties and Leak-Tightness of Polymeric Pipe Adhesive Joints. Applied Mechanics. 2022; 3(1):64-77. https://doi.org/10.3390/applmech3010004

Chicago/Turabian StyleRudawska, Anna, Magd Abdel Wahab, Miroslav Müller, and Dana Stančeková. 2022. "Mechanical Properties and Leak-Tightness of Polymeric Pipe Adhesive Joints" Applied Mechanics 3, no. 1: 64-77. https://doi.org/10.3390/applmech3010004

APA StyleRudawska, A., Wahab, M. A., Müller, M., & Stančeková, D. (2022). Mechanical Properties and Leak-Tightness of Polymeric Pipe Adhesive Joints. Applied Mechanics, 3(1), 64-77. https://doi.org/10.3390/applmech3010004