HDPE Properties Evaluation via Instrumented Indentation: Experimental and Computer Simulation Approach

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Part

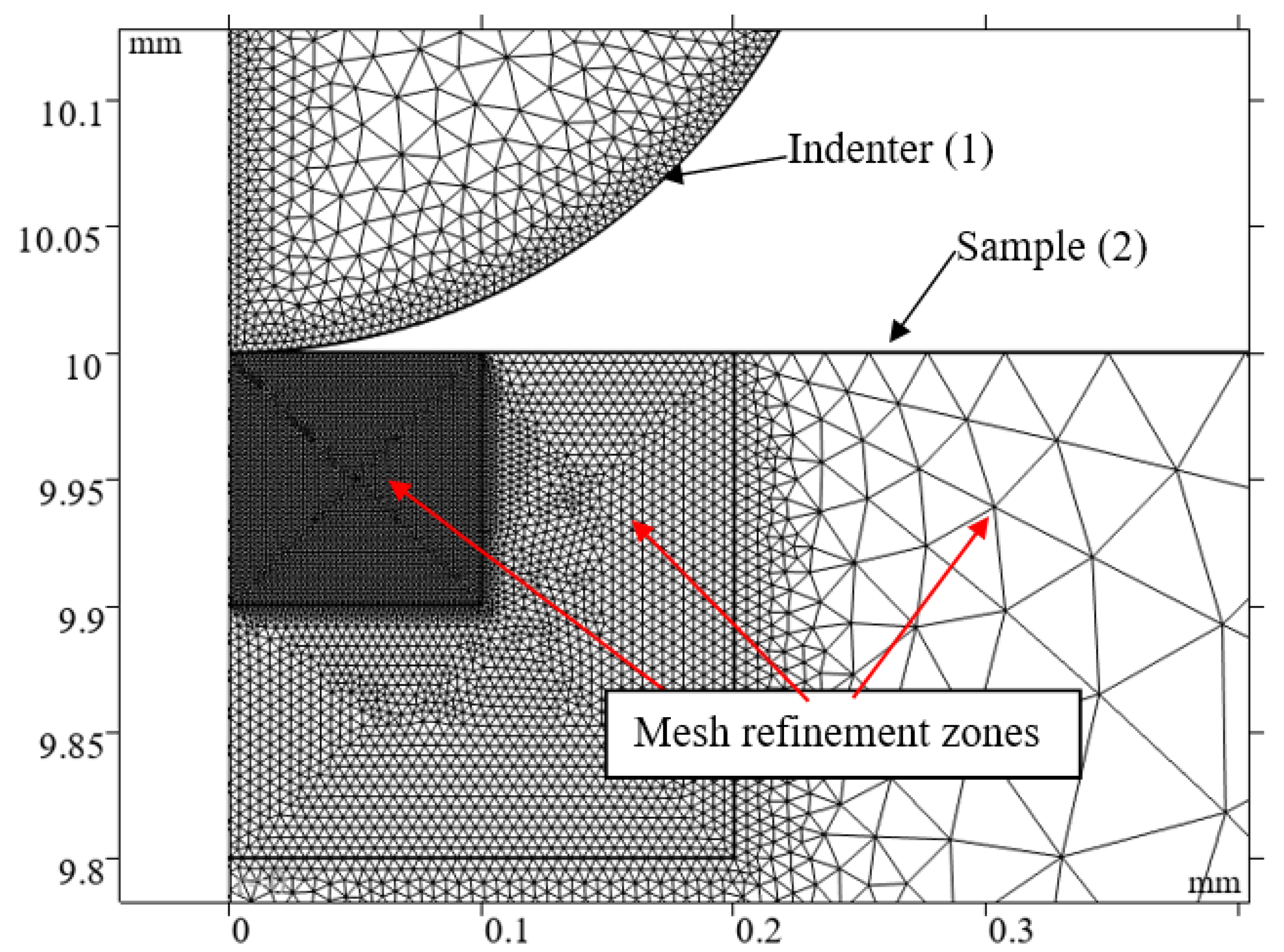

2.2. Simulation

3. Results

3.1. Experiment

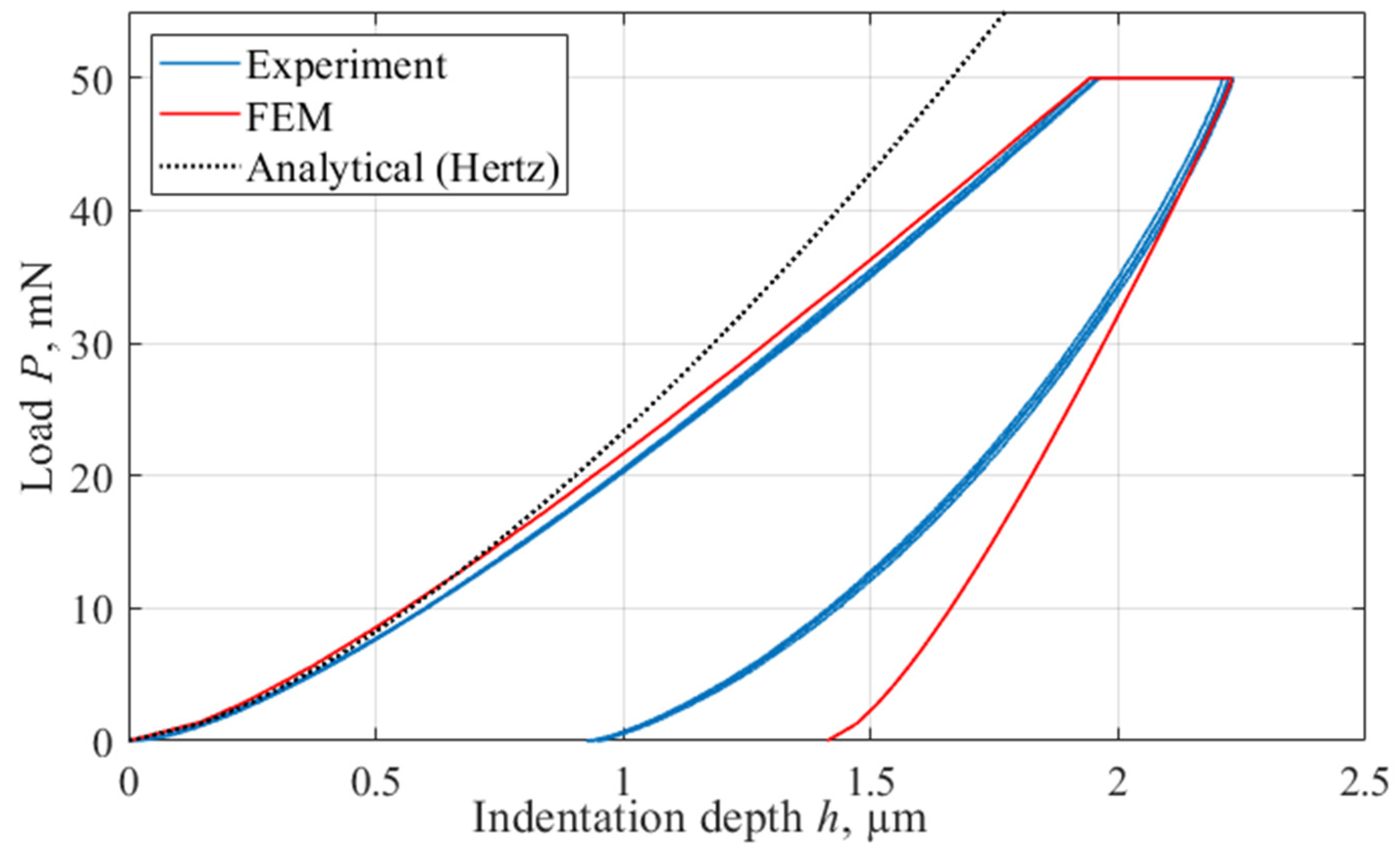

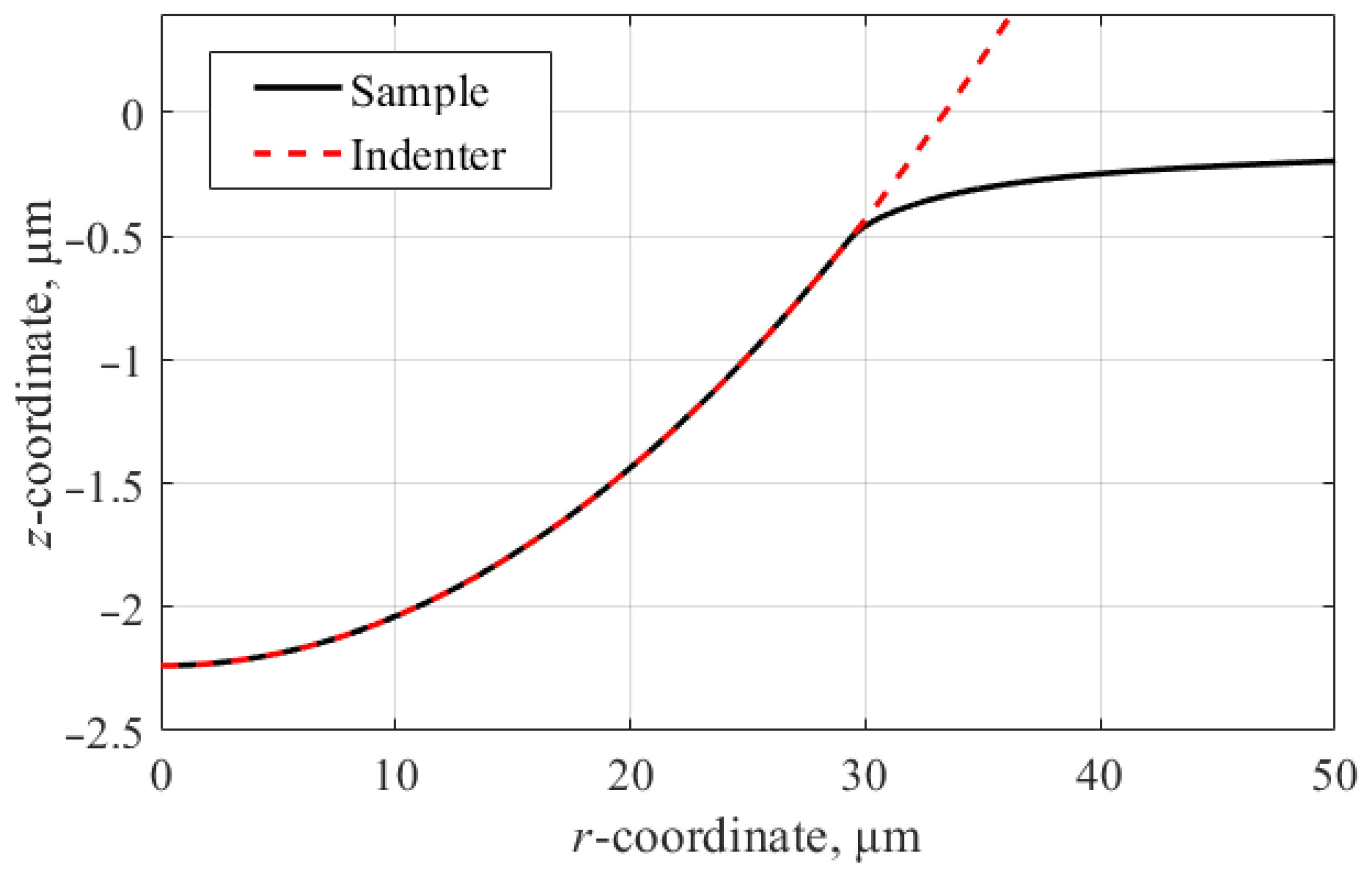

3.2. FEM Simulation

4. Discussion

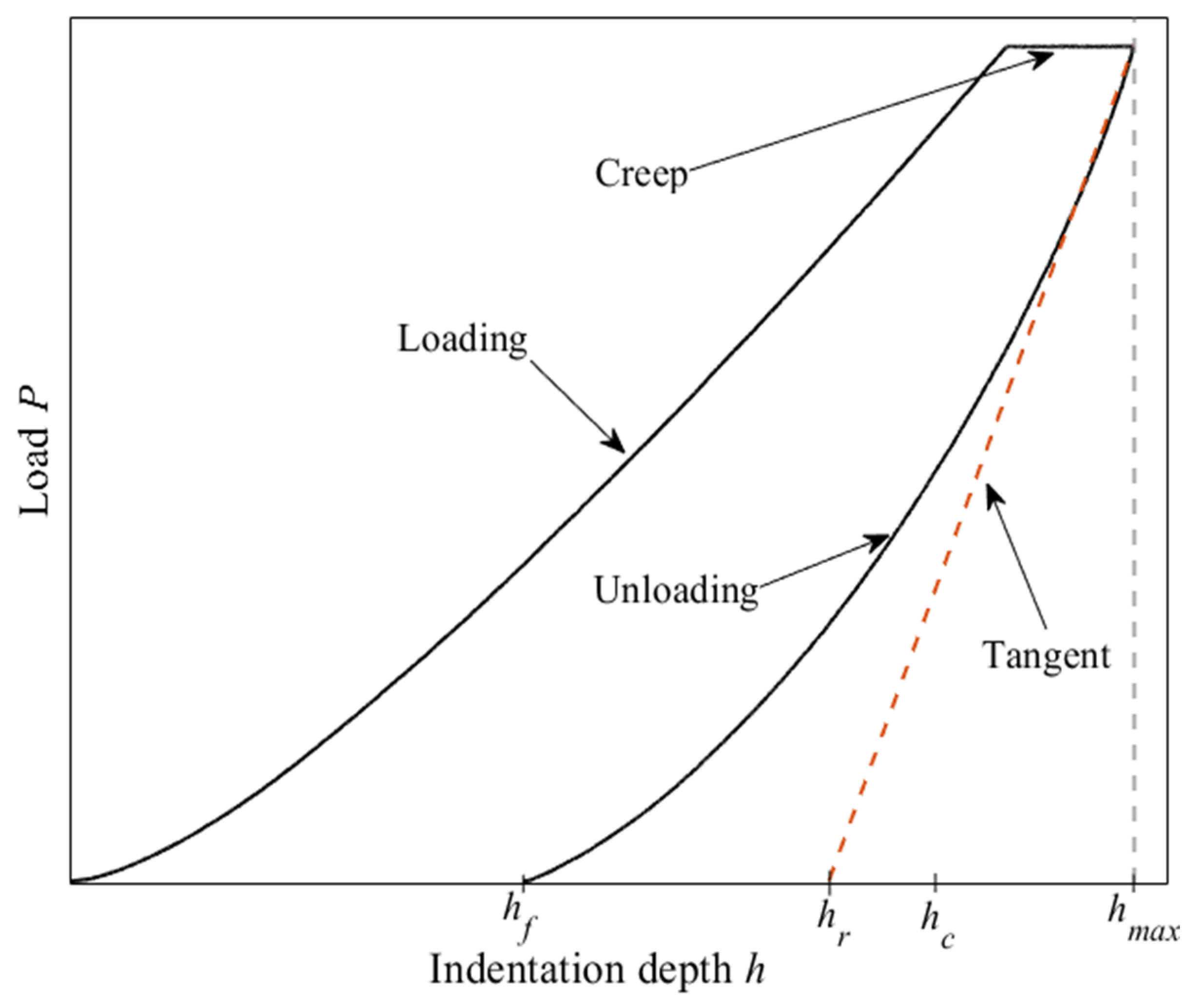

4.1. Estimation of Contact Indentation Depth

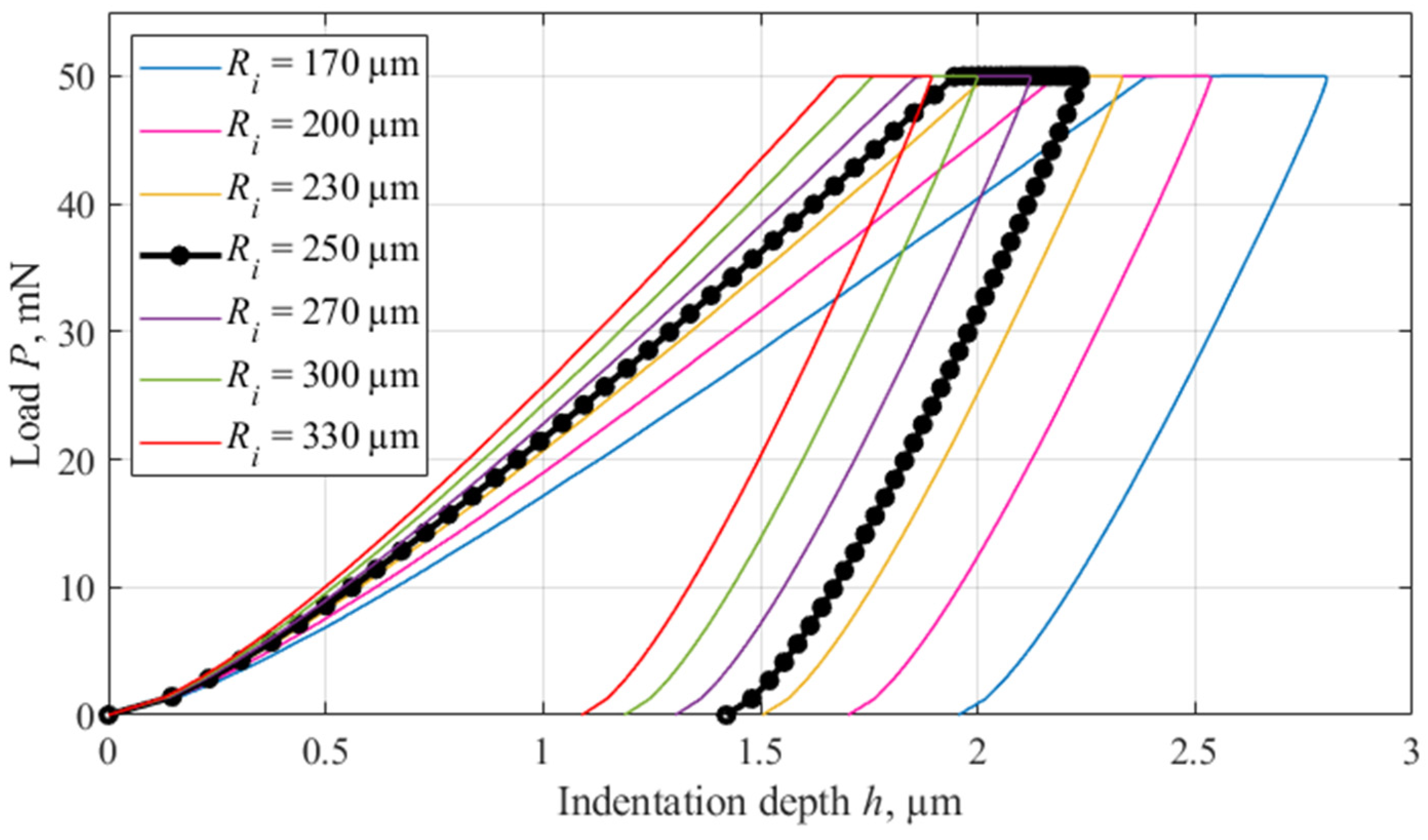

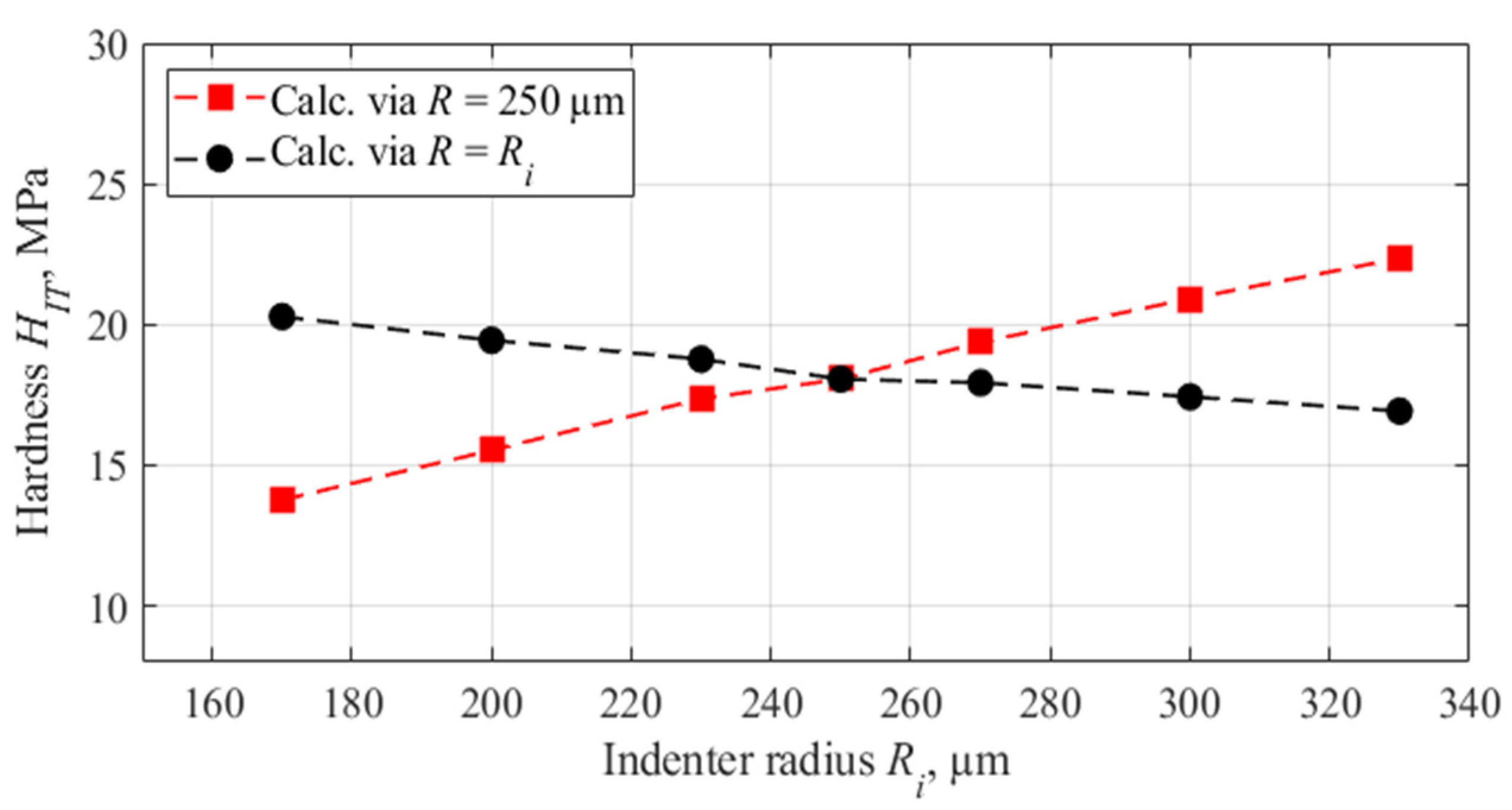

4.2. Indenter Radius Influence

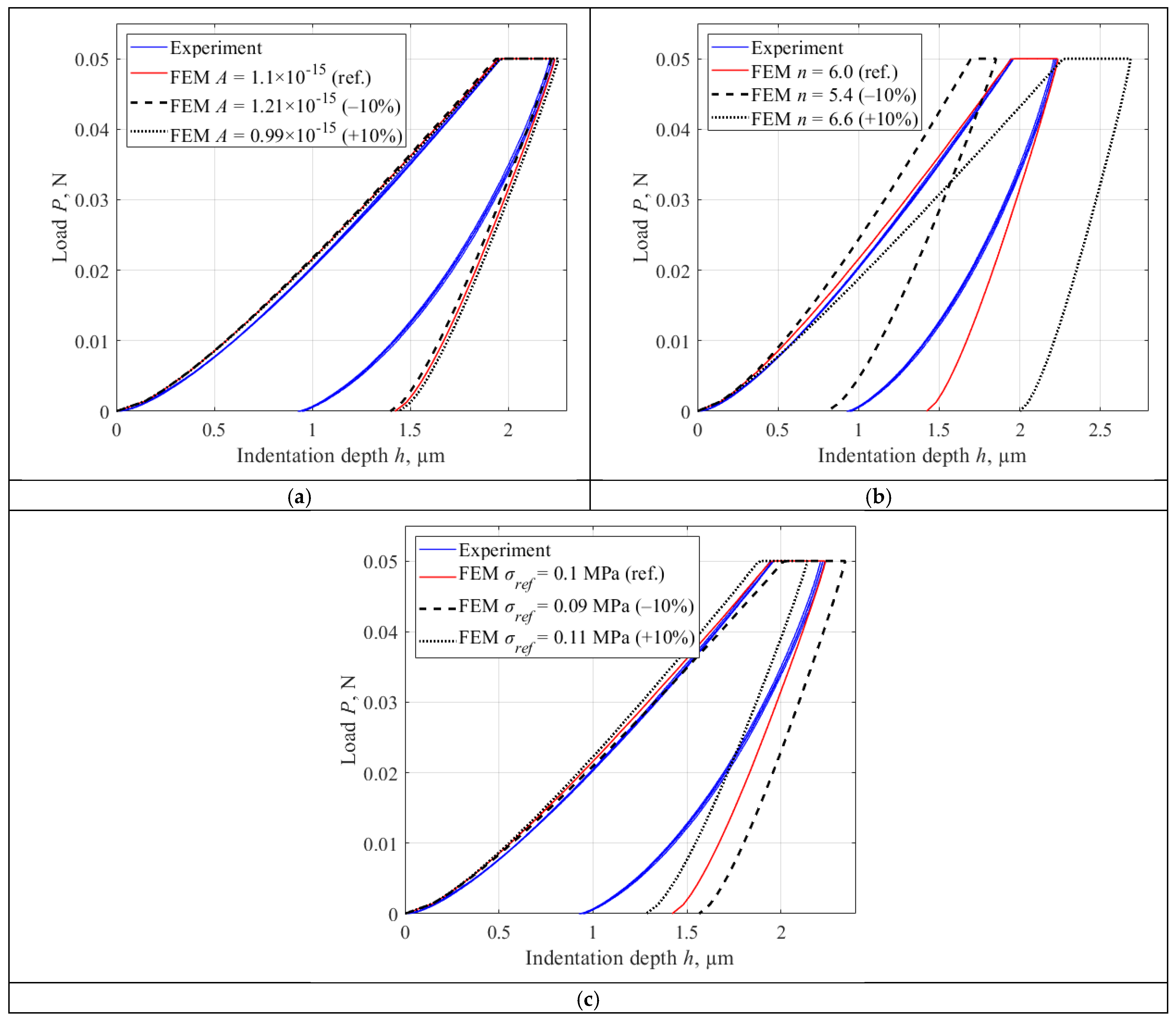

4.3. Norton Creep Material Model Parameters Influence

5. Conclusions

- (1)

- The obtained by II test values of hardness and elastic modulus, equal to 14 MPa and 1083 MPa, are consistent with reference data, the results of other studies and the results of measurements carried out using classical methods, which allows us to conclude that the II method is applicable as an alternative to tensile testing.

- (2)

- The simulation of the indentation process by FEM carried out in the work using the Norton model and determining the parameters of the material deformation function taking into account creep (A = 1.1 × 10−15, n = 6, σref = 0.1 MPa), allows to describe the process of contact interaction and successfully demonstrates convergence with experimental data (Figure 4 and Table 4). We can conclude that it is possible to use FEM in studying the mechanical properties of HDPE and describing the behavior of the material under load.

- (3)

- The paper presents the calculation of the contact depth and mechanical properties of the material based on the P(h) diagram using the Oliver–Pharr method. The error in determining the contact depth was 2.3%, which leads to an error in calculating the Young’s modulus of 1.3%. Thus, the applicability of the Oliver–Pharr method for the problem of measuring the mechanical properties of polymers using the II method is confirmed, and the adequacy of the proposed FEM in the context of the methodology for determining mechanical properties based on indentation is demonstrated.

- (4)

- The work studies the influence of the radius of a spherical indenter on the results of determining the mechanical properties of HDPE using the II method when the radius is varied from 170 to 330 μm. The result of determining the elastic modulus depends slightly (within 5%) on the indenter radius used in the experiment. At the same time, the obtained hardness values demonstrate a significant dependence (up to 20%), which indicates the need for strict standardization of experimental conditions to ensure reproducibility and comparability of the results.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| HDPE | high-density polyethylene |

| FEM | Finite element method |

| II | Instrumented indentation |

References

- Shen, J.; Liang, J.; Lin, X.; Lin, H.; Yu, J.; Yang, Z. Recent Progress in Polymer-Based Building Materials. Int. J. Polym. Sci. 2020, 2020, 8838160. [Google Scholar] [CrossRef]

- Chen, S.; Lai, H.S.; Lin, R.; Duan, X.H. Study on the creep properties of butt fusion–welded joints of HDPE pipes using the nanoindentation test. Weld. World 2022, 66, 135–144. [Google Scholar] [CrossRef]

- Arora, G.; Pathak, H. Nanoindentation characterization of polymer nanocomposites for elastic and viscoelastic properties: Experimental and mathematical approach. Compos. Part. C Open Access 2021, 4, 100103. [Google Scholar] [CrossRef]

- Torskaya, E.V.; Yakovenko, A.A.; Shkaley, I.V.; Svistkov, A.L. An indentation study of the temperature-dependent properties of modified polyurethanes. Fiz. Mezomekhanika 2023, 3, 505–513. [Google Scholar] [CrossRef]

- Hardiman, M.; Vaughan, T.J.; McCarthy, C.T. A review of key developments and pertinent issues in nanoindentation testing of fibre reinforced plastic microstructures. Compos. Struct. 2017, 180, 782–798. [Google Scholar] [CrossRef]

- Christöfl, P.; Czibula, C.; Seidlhofer, T.; Berer, M.; Macher, A.; Helfer, E.; Schrank, T.; Oreski, G.; Teichert, C.; Pinter, G. Morphological characterization of semi-crystalline POM using nanoindentation. Int. J. Polym. Anal. Charact. 2021, 26, 692–706. [Google Scholar] [CrossRef]

- Schieppati, J.; Gehling, T.; Azevedo, M.; Kerschbaumer, R.C.; Christöfl, P.; Oreski, G.; Fasching, M.A.; Schwarz, T.; Pinter, G. Investigation into the state of cure of elastomers through nanoindentation. Polym. Test. 2024, 133, 108417. [Google Scholar] [CrossRef]

- Christöfl, P.; Ottersböck, B.; Czibula, C.; Macher, A.; Teichert, C.; Pinter, G.; Oreski, G. Nanoindentation for Fast Investigation of PET Film Degradation. JOM 2022, 74, 2287–2294. [Google Scholar] [CrossRef]

- Christöfl, P.; Czibula, C.; Berer, M.; Oreski, G.; Teichert, C.; Pinter, G. Comprehensive investigation of the viscoelastic properties of PMMA by nanoindentation. Polym. Test. 2021, 93, 106978. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, H.; Zhang, Z.; Celli, J.; Percec, S.; Ren, F. Nanoindentation study of time-dependent mechanical properties of ultra-high-molecular-weight polyethylene (UHMWPE) at different temperatures. Polym. Test. 2020, 91, 106787. [Google Scholar] [CrossRef]

- Poulose, A.M.; Elnour, A.Y.; Samad, U.A.; Alam, M.A.; George, J.; Sarmah, A.K.; Al-Zahrani, S.M. Nano-indentation as a tool for evaluating the rheological threshold in polymer composites. Polym. Test. 2019, 80, 106150. [Google Scholar] [CrossRef]

- Spinelli, G.; Guarini, R.; Ivanov, E.; Calabrese, E.; Raimondo, M.; Longo, R.; Guadagno, L.; Vertuccio, L. Nanoindentation Response of Structural Self-Healing Epoxy Resin: A Hybrid Experimental–Simulation Approach. Polymers 2024, 16, 1849. [Google Scholar] [CrossRef] [PubMed]

- Briscoe, B.J.; Fiori, L.; Pelillo, E. Nanoindentation of polymeric surfaces. J. Phys. D Appl. Phys. 1998, 31, 2395–2405. [Google Scholar] [CrossRef]

- Wang, Y.; Shang, L.; Zhang, P.; Yan, X.; Zhang, K.; Dou, S.; Zhao, J.; Li, Y. Measurement of viscoelastic properties for polymers by nanoindentation. Polym. Test. 2020, 83, 106353. [Google Scholar] [CrossRef]

- Zha, S.; Lan, H.-Q.; Lin, N.; Liu, Y.; Meng, T. Investigating the time- and space-dependent mechanical, physical and chemical properties of aged polyethylene gas pipes using nanoindentation tests. J. Mater. Res. Technol. 2023, 24, 3383–3398. [Google Scholar] [CrossRef]

- Byrne, N.; Ghanei, S.; Espinosa, S.M.; Neave, M. Influence of Hydrogen on Vintage Polyethylene Pipes: Slow Crack Growth Performance and Material Properties. Int. J. Energy Res. 2023, 2023, 1–8. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, B.; Xiang, A.; Jiao, D.; Yu, F.; Zhang, Q.; Zhao, X. Comparative study on the performance of butt fusion-welding processes for nuclear safety class large-diameter thick-walled PE pipes. Nuclear Engineering and Technology. Korean Nucl. Soc. 2024, 56, 4184–4194. [Google Scholar] [CrossRef]

- Shaheer, M.; Troughton, M.; Khamsehnezhad, A.; Song, J. A study of the micro-mechanical properties of butt fusion-welded joints in HDPE pipes using the nanoindentation technique. Weld. World 2017, 61, 819–831. [Google Scholar] [CrossRef]

- Rajaoalison, H.; Zlotkowski, A.; Rambolamanana, G. Mechanical Properties of Sandstone using non-Destructive Method. J. Min. Inst. 2020, 241, 113–117. [Google Scholar] [CrossRef]

- Mogilner, L.Y.; Syasko, V.A.; Shikhov, A.I. Modeling Defects in Ultrasonic Nondestructive Testing: State-of-the-Art and Prospects. Russ. J. Nondestruct. Test. 2024, 60, 481–500. [Google Scholar] [CrossRef]

- Schipachev, A.M.; Dmitrieva, A.S. Application of the resonant energy separation effect at natural gas reduction points in order to improve the energy efficiency of the gas distribution system. J. Min. Inst. 2021, 248, 253–259. [Google Scholar] [CrossRef]

- Pryakhin, E.I.; Azarov, V.A. Increasing the adhesion of fluoroplastic coatings to steel surfaces of pipes with a view to their use in gas transmission systems. Chernye Met. 2024, 3, 69–75. [Google Scholar] [CrossRef]

- Zha, S.; Lan, H.-Q.; Lin, N.; Meng, T. Degradation and characterization methods for polyethylene gas pipes after natural and accelerated aging. Polym. Degrad. Stab. 2023, 208, 110247. [Google Scholar] [CrossRef]

- Majid, F.; Rhanim, R.; Lahlou, M.; Rhanim, H.; Ezzahi, M.; Elghorba, M. Maintainability and reliability of high density polyethylene pipes through experimental and theoretical models. Procedia Struct. Integr. 2020, 25, 430–437. [Google Scholar] [CrossRef]

- Gogolinskiy, K.V.; Vinogradova, A.A.; Kopylova, T.N.; Povarov, V.G.; Vasilev, E.A.; Shchiptsova, E.K.; Rybkin, D.E.; Kolobov, D.S. Study of physicochemical properties of polyethylene gas pipelines material with a prolonged service life. Int. J. Press. Vessel. Pip. 2022, 200, 104825. [Google Scholar] [CrossRef]

- Palaev, A.G.; Fuming, Z. A Leak Detection Method for Underground Polyethylene Gas Pipelines Using Simulation Software Ansys Fluent. Int. J. Eng. 2024, 37, 1615–1621. [Google Scholar] [CrossRef]

- ISO 6259-1:2015; Thermoplastics Pipes—Determination of Tensile Properties—Part 1: General Test Method. ISO: Geneva, Switzerland, 2015.

- Song, P.; Trivedi, A.; Siviour, C.R. Tensile testing of polymers: Integration of digital image correlation, infrared thermography and finite element modelling. J. Mech. Phys. Solids. 2023, 171, 105161. [Google Scholar] [CrossRef]

- Gogolinskiy, K.; Gromyka, D.; Kremcheev, E. A Modelling of Cyclic Thermal and Impact Loads on Excavator Bucket. Int. Rev. Mech. Eng. (IREME) 2021, 15, 189–196. [Google Scholar] [CrossRef]

- Afanaseva, O.V.; Putilo, S.Y.; Chirtsov, V.V.; Demidov, A.A. Simulation of the work of structural units of industrial enterprises using the theory of queuing systems. Acad. J. Manuf. Eng. 2024, 22, 115–126. [Google Scholar]

- Sleptsov, A.; Medvedeva, L.; Marinina, O.; Savenok, O. Feasibility Study on the Applicability of Intelligent Well Completion. Processes 2024, 12, 1565. [Google Scholar] [CrossRef]

- Gromyka, D.S.; Utenkova, T.G.; Korotkova, O.Y. Estimation methods of wear mechanisms in cutting heads of mining machines: Review. Min. Informational Anal. Bull. 2021, 2, 75–86. [Google Scholar] [CrossRef]

- Gorbunov, A.E.; Solomenchuk, P.V.; Umanskii, A.S. Modeling a Two-Element Tangential Eddy Current Probe with Active Shielding for Soldered Joint Testing. Russ. J. Nondestruct. Test. 2024, 60, 912–920. [Google Scholar] [CrossRef]

- Louche, H.; Piette-Coudol, F.; Arrieux, R.; Issartel, J. An experimental and modeling study of the thermomechanical behavior of an ABS polymer structural component during an impact test. Int. J. Impact Eng. 2009, 36, 847–861. [Google Scholar] [CrossRef]

- Loseva, E.; Lozovsky, I.; Zhostkov, R. Refining Low Strain Pile Integrity Testing for Minor Flaw Detection with Complex Wavelet Transform. Civ. Eng. J. 2024, 10, 3194–3207. [Google Scholar] [CrossRef]

- Peng, C.; Zeng, F. A molecular simulation study to the deformation Behaviors and the size effect of polyethylene during nanoindentation. Comput. Mater. Sci. 2017, 137, 225–232. [Google Scholar] [CrossRef]

- Hu, E.; Sun, Y.; Zeng, F.; Qu, J. Nanoindentation simulation of PE/POSS under different shapes of indenters. Acta Mech. Solida Sin. 2011, 24, 365–372. [Google Scholar] [CrossRef]

- Li, H.; Chen, J.; Chen, Q.; Liu, M. Determining the constitutive behavior of nonlinear visco-elastic-plastic PMMA thin films using nanoindentation and finite element simulation. Mater. Des. 2021, 197, 109239. [Google Scholar] [CrossRef]

- Balobanov, V.; Verho, T.; Heino, V.; Ronkainen, H.; Pelto, J. Micromechanical performance of high-density polyethylene: Experimental and modeling approaches for HDPE and its alumina-nanocomposites. Polym. Test. 2021, 93, 106936. [Google Scholar] [CrossRef]

- Won, J.; Kim, S.; Kwon, O.M.; Kim, Y.-C.; Kwon, D. Evaluation of tensile yield strength of high-density polyethylene in flat-ended cylindrical indentation: An analytic approach based on the expanding cavity model. J. Mater. Res. 2020, 35, 206–214. [Google Scholar] [CrossRef]

- Brazil, O.; de Silva, J.P.; Pethica, J.B.; Cross, G.L.W. Extrinsic plastic hardening of polymer thin films in flat punch indentation. Philos. Mag. 2021, 101, 1327–1342. [Google Scholar] [CrossRef]

- Gnatowski, A.; Kijo-Kleczkowska, A.; Chyra, M.; Kwiatkowski, D. Numerical-experimental analysis of polyethylene pipe deformation at different load values. Materials 2021, 14, 160. [Google Scholar] [CrossRef] [PubMed]

- Rueda, F.; Torres, J.; Machado, M.; Frontini, P.; Otegui, J. External pressure induced buckling collapse of high density polyethylene (HDPE) liners: FEM modeling and predictions. Thin-Walled Struct. 2015, 96, 56–63. [Google Scholar] [CrossRef]

- Lamri, A.; Shirinbayan, M.; Pereira, M.; Truffault, L.; Fitoussi, J.; Lamouri, S.; Bakir, F.; Tcharkhtchi, A. Effects of strain rate and temperature on the mechanical behavior of high-density polyethylene. J. Appl. Polym. Sci. 2020, 137, 48778. [Google Scholar] [CrossRef]

- Amjadi, M.; Fatemi, A. Tensile behavior of high-density polyethylene including the effects of processing technique, thickness, temperature, and strain rate. Polymers 2020, 12, 1857. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Luo, W.; Li, M.; Yang, B.; Liu, X. Strain Rate-Dependent Hyperbolic Constitutive Model for Tensile Behavior of PE100 Pipe Material. Polymers 2022, 14, 1357. [Google Scholar] [CrossRef] [PubMed]

- May, D.L.; Gordon, A.P.; Segletes, D.S. The Application of the Norton-Bailey Law for Creep Prediction Through Power Law Regression. Structures and Dynamics. In Proceedings of the ASME Turbo Expo 2013: Turbine Technical Conference and Exposition, San Antonio, TX, USA, 3–7 June 2013; American Society of Mechanical Engineers: New York, NY, USA, 2013; Volume 7A. [Google Scholar] [CrossRef]

- Brathe, L.; Josefson, L. Estimation of Norton-Bailey parameters from creep rupture data. Met. Sci. 1979, 13, 660–664. [Google Scholar] [CrossRef]

- O’Masta, M.R.; Crayton, D.H.; Deshpande, V.S.; Wadley, H.N.G. Mechanisms of penetration in polyethylene reinforced cross-ply laminates. Int. J. Impact Eng. 2015, 86, 249–264. [Google Scholar] [CrossRef]

- Torres, J.P.; Frontini, P.; Machado, M.; Major, Z. Deformation and failure of semicrystalline polymers under dynamic tensile and biaxial impact loading. Int. J. Impact Eng. 2016, 98, 52–61. [Google Scholar] [CrossRef]

- Ginder, R.S.; Nix, W.D.; Pharr, G.M. A simple model for indentation creep. J. Mech. Phys. Solids 2018, 112, 552–562. [Google Scholar] [CrossRef]

- Dean, J.; Bradbury, A.; Aldrich-Smith, G.; Clyne, T. A procedure for extracting primary and secondary creep parameters from nanoindentation data. Mech. Mater. 2013, 65, 124–134. [Google Scholar] [CrossRef]

- Starkova, O.; Gagani, A.I.; Karl, C.W.; Rocha, I.B.C.M.; Burlakovs, J.; Krauklis, A.E. Modelling of environmental ageing of polymers and polymer composites—Durability prediction methods. Polymers 2022, 14, 907. [Google Scholar] [CrossRef]

- Drozdov, A.D.; Høj Jermiin, R.; de Claville Christiansen, J. Lifetime Predictions for High-Density Polyethylene under Creep: Experiments and Modeling. Polymers 2023, 15, 334. [Google Scholar] [CrossRef] [PubMed]

- COMSOL Multiphysics®; v. 6.3.; COMSOL AB: Stockholm, Sweden, 2025; Available online: www.comsol.com (accessed on 11 March 2025).

- ISO 14577-1:2015; Metallic Materials—Instrumented Indentation Test for Hardness and Materials Parameters Part 1: Test Method. ISO: Geneva, Switzerland, 2015.

- Peng, C.; Zeng, F.; Yuan, B.; Wang, Y. An MD simulation study to the indentation size effect of polystyrene and polyethylene with various indenter shapes and loading rates. Appl. Surf. Sci. 2019, 492, 579–590. [Google Scholar] [CrossRef]

- Mokhtari, A.; Tala Ighil, N. Identification of the elasto-viscoplastic parameters for a thermoplastic polymer by instrumented indentation. IOP Conf. Ser. Mater. Sci. Eng. 2018, 461, 012057. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 2004, 19, 3–20. [Google Scholar] [CrossRef]

- O’Connor, J.; dos Santos, B.B.; Borges, L.; da Costa, M.F.; Castello, D.A. Computational modeling of viscoplastic polymeric material response during micro-indentation tests. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 1–18. [Google Scholar] [CrossRef]

- Lu, X.; Xu, H.; Zhao, B. Effect of hardening exponent of power-law hardening elastic-plastic substrate on contact behaviors in coated asperity contact. Materials 2018, 11, 1965. [Google Scholar] [CrossRef] [PubMed]

- Clyne, T.W.; Campbell, J.E. Indentation Plastometry. In Testing of the Plastic Deformation of Metals; Cambridge University Press: Cambridge, UK, 2021; pp. 148–191. [Google Scholar] [CrossRef]

- Diana, L.; Safitra, A.G.; Muhammad, G. Tensile Test Simulation for Polymer Composites. Adv. Eng. Res. 2021, 208, 200–206. Available online: https://www.atlantis-press.com/proceedings/icist-20/125964989 (accessed on 11 March 2025). [CrossRef]

- Sedmak, S.; Golubovic, Z.; Murariu, A.; Sedmak, A. Numerical simulation of tensile testing of PE 80 polymer specimens. Therm. Sci. 2018, 22 Pt B, 641–649. [Google Scholar] [CrossRef]

- Nakai, K.; Yokoyama, T. Uniaxial Compressive Response and Constitutive Modeling of Selected Polymers Over a Wide Range of Strain Rates. J. Dyn. Behav. Mater. 2015, 1, 15–27. [Google Scholar] [CrossRef]

- Haward, R.N. Strain hardening of high density polyethylene. J. Polym. Sci. B Polym. Phys. 2007, 45, 1090–1099. [Google Scholar] [CrossRef]

- Vasilyeva, M.; Nagornov, D.; Orlov, G. Research on Dynamic and Mechanical Properties of Magnetoactive Elastomers with High Permeability Magnetic Filling Agent at Complex Magneto-Temperature Exposure. Materials 2021, 14, 2376. [Google Scholar] [CrossRef]

- Van Der Stok, E.; Scholten, F. Strain hardening tests on PE pipe materials. In Proceedings of the Plastic Pipes XVI Conference, Barcelona, Spain, 24–26 September 2012. [Google Scholar]

- Yu, S.; Lu, Y.; Cai, Y. The strain-rate effect of engineering materials and its unified model. Lat. Am. J. Solids Struct. 2013, 10, 833–844. [Google Scholar] [CrossRef]

- Xiao, H.R.; Cai, L.X.; Han, G.Z. Semi-analytical creep model to obtain Norton’s law of materials under flat indentation and its applications. J. Mater. Res. Technol. 2023, 25, 905–911. [Google Scholar] [CrossRef]

- Fusek, M.; Paška, Z.; Rojíček, J.; Fojtík, F. Parameters identification of the Anand material model for 3D printed structures. Materials 2021, 14, 587. [Google Scholar] [CrossRef] [PubMed]

- Sattar, M.; Othman, A.; Kamaruddin, S.; Akhtar, M.; Khan, R. Limitations on the computational analysis of creep failure models: A review. Eng. Fail. Anal. 2022, 134, 105968. [Google Scholar] [CrossRef]

- Ovsik, M.; Maňas, D.; Maňas, M.; Staněk, M.; Kyas, K.; Bednařík, M.; Mizera, A. Microhardness of HDPE influenced by Beta Irradiation. Int. J. Math. Comput. Simul. 2012, 6, 566–574. [Google Scholar]

- Manaia, J.P.; Pires, F.A.; de Jesus, A.M.; Wu, S. Mechanical response of three semi crystalline polymers under different stress states: Experimental investigation and modelling. Polym. Test. 2020, 81, 106156. [Google Scholar] [CrossRef]

- Pelto, J.; Heino, V.; Karttunen, M.; Rytöluoto, I.; Ronkainen, H. Tribological performance of high density polyethylene (HDPE) composites with low nanofiller loading. Wear 2020, 460–461, 203451. [Google Scholar] [CrossRef]

- Manas, D.; Dobransky, J.; Chvatalova, L. Ultra nano-hardness of surface layer of irradiated high–density polyethylene (HDPE). MATEC Web Conf. 2017, 125, 02044. [Google Scholar] [CrossRef]

- Bai, S.L. Indentation properties of the filler and matrix in polymer composites. J. Mater. Sci. Lett. 2002, 21, 85–88. [Google Scholar] [CrossRef]

- Colak, O.U.; Dusunceli, N. Modeling viscoelastic and viscoplastic behavior of high density polyethylene (HDPE). J. Eng. Mater. Technol. Am. Soc. Mech. Eng. (ASME) 2006, 128, 572–578. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Loading time tl and unloading time tu, s | 35 |

| Hold time th, s | 35 |

| Load P, mN | 50 |

| Material | Poisson’s Ratio ν | Elastic Modulus E, GPa | Density ρ, kg/m3 |

|---|---|---|---|

| Silicon Carbide SiC | 0.17 | 412 | 3210 |

| HDPE PE100 | 0.44 | 1.00 | 950 |

| Value | Hardness HIT, MPa | Elastic Modulus EIT, MPa | Indentation Depth hmax, nm | Recovery Coefficient rc, % |

|---|---|---|---|---|

| Mean | 14.09 | 1083 | 2222 | 76.7 |

| SD | 0.04 | 4 | 9 | 0.5 |

| Method | Hardness HIT, MPa | Elastic Modulus EIT, MPa | Indentation Depth hmax, nm | Recovery Coefficient rc, % |

|---|---|---|---|---|

| FEM | 18.06 | 1078 | 2229 | 63.6 |

| Experiment | 14.09 ± 0.04 | 1083 ± 4 | 2222 ± 9 | 76.7 ± 0.5 |

| Variation | Condition | |||

|---|---|---|---|---|

| A = var n, σref = const | n = var A, σref = const | σref = var A, n = const | Reference Model | |

| var +10% | 17.89 | 13.89 | 19.42 | 18.06 |

| var −10% | 18.29 | 25.30 | 16.89 | |

| Variation | Condition | |||

|---|---|---|---|---|

| A = var n, σref = const | n = var A, σref = const | σref = var A, n = const | Reference Model | |

| var +10% | 1074 | 1145 | 1062 | 1078 |

| var −10% | 1075 | 1036 | 1096 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vinogradova, A.A.; Gogolinskiy, K.V.; Doronin, K.I.; Shchiptsova, E.K.; Melnikova, A.V. HDPE Properties Evaluation via Instrumented Indentation: Experimental and Computer Simulation Approach. Appl. Mech. 2025, 6, 29. https://doi.org/10.3390/applmech6020029

Vinogradova AA, Gogolinskiy KV, Doronin KI, Shchiptsova EK, Melnikova AV. HDPE Properties Evaluation via Instrumented Indentation: Experimental and Computer Simulation Approach. Applied Mechanics. 2025; 6(2):29. https://doi.org/10.3390/applmech6020029

Chicago/Turabian StyleVinogradova, Anna Aleksandrovna, Kirill Valerievich Gogolinskiy, Kirill Igorevich Doronin, Ekaterina Konstantinovna Shchiptsova, and Alena Vadimovna Melnikova. 2025. "HDPE Properties Evaluation via Instrumented Indentation: Experimental and Computer Simulation Approach" Applied Mechanics 6, no. 2: 29. https://doi.org/10.3390/applmech6020029

APA StyleVinogradova, A. A., Gogolinskiy, K. V., Doronin, K. I., Shchiptsova, E. K., & Melnikova, A. V. (2025). HDPE Properties Evaluation via Instrumented Indentation: Experimental and Computer Simulation Approach. Applied Mechanics, 6(2), 29. https://doi.org/10.3390/applmech6020029