Lithium-Sulfur Batteries: Advances and Trends

Abstract

1. Introduction

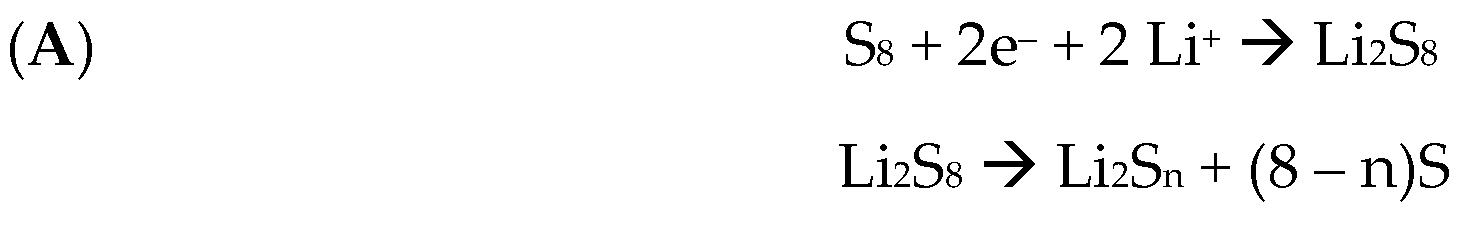

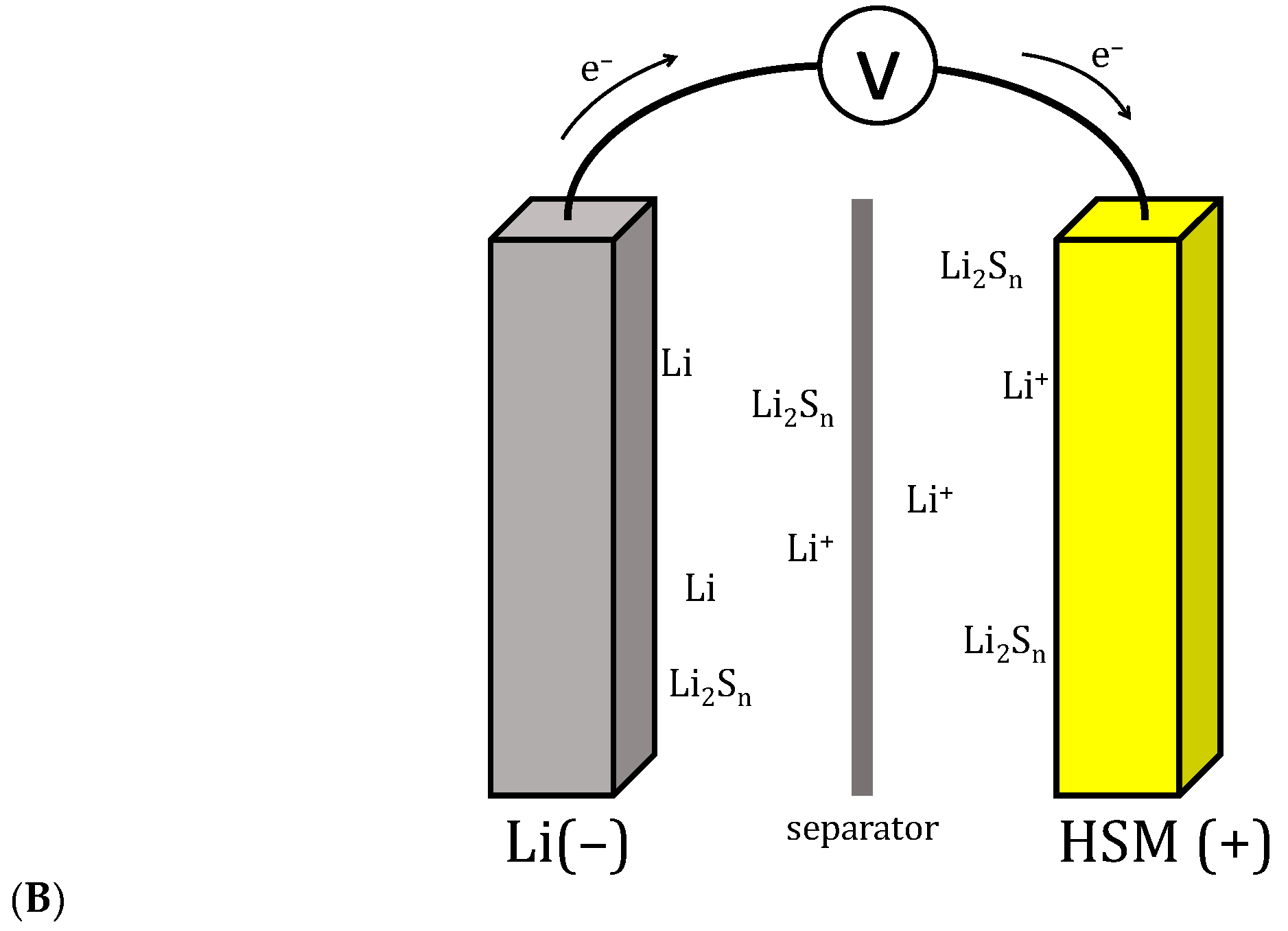

1.1. General Operation of Lithium-Sulfur (Li-S) Batteries

1.2. Summary of Recent Reviews on Li-S Batteries

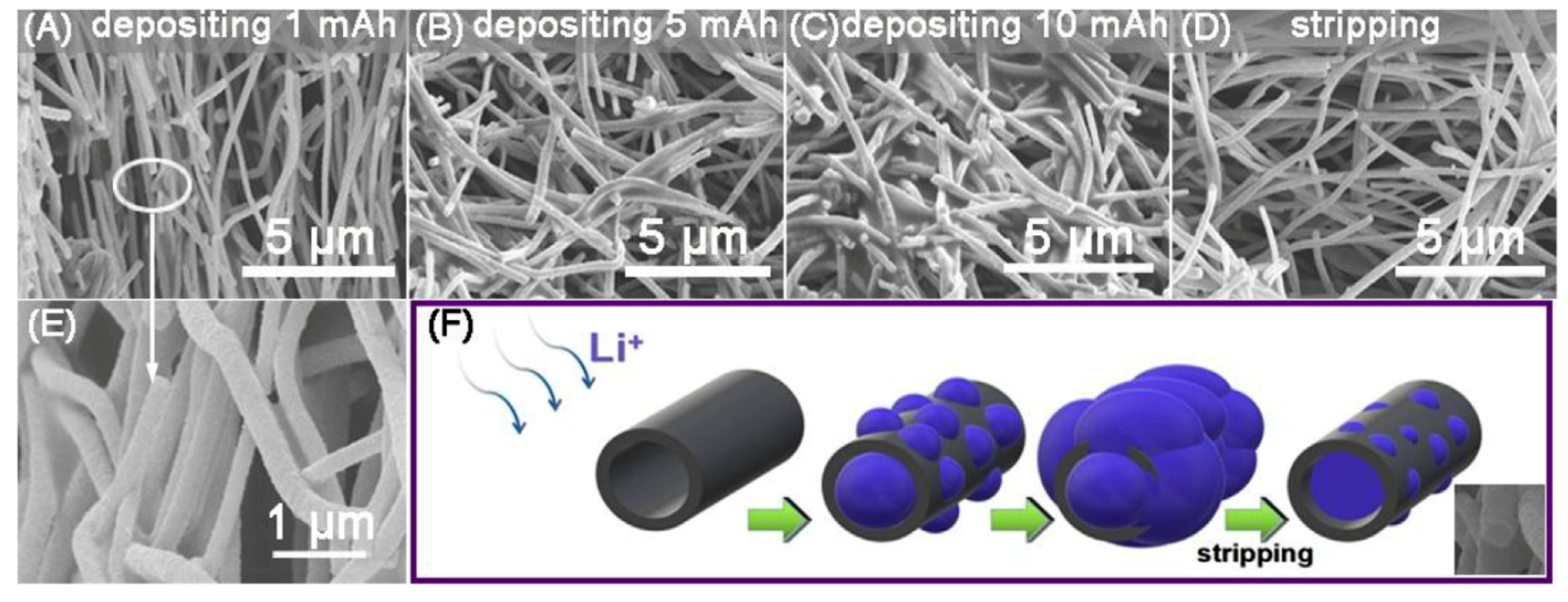

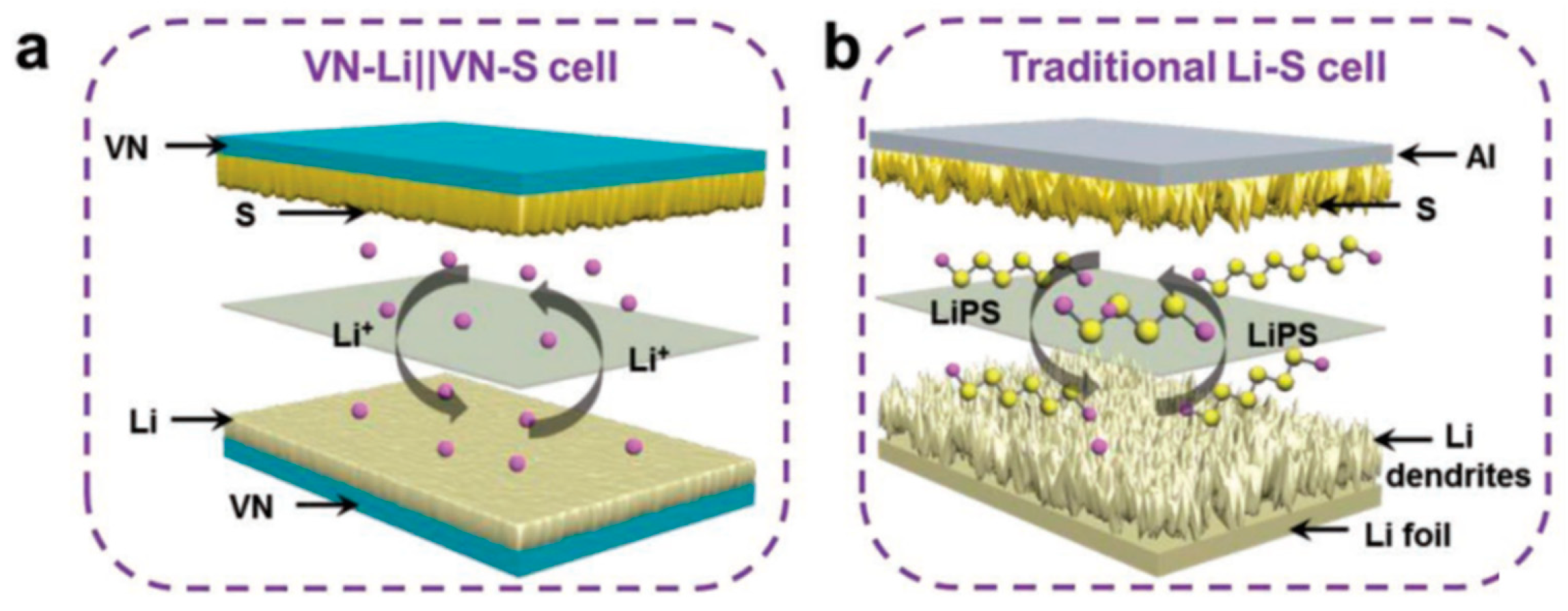

2. Anode and Anode Interface Design

3. Electrolyte Design

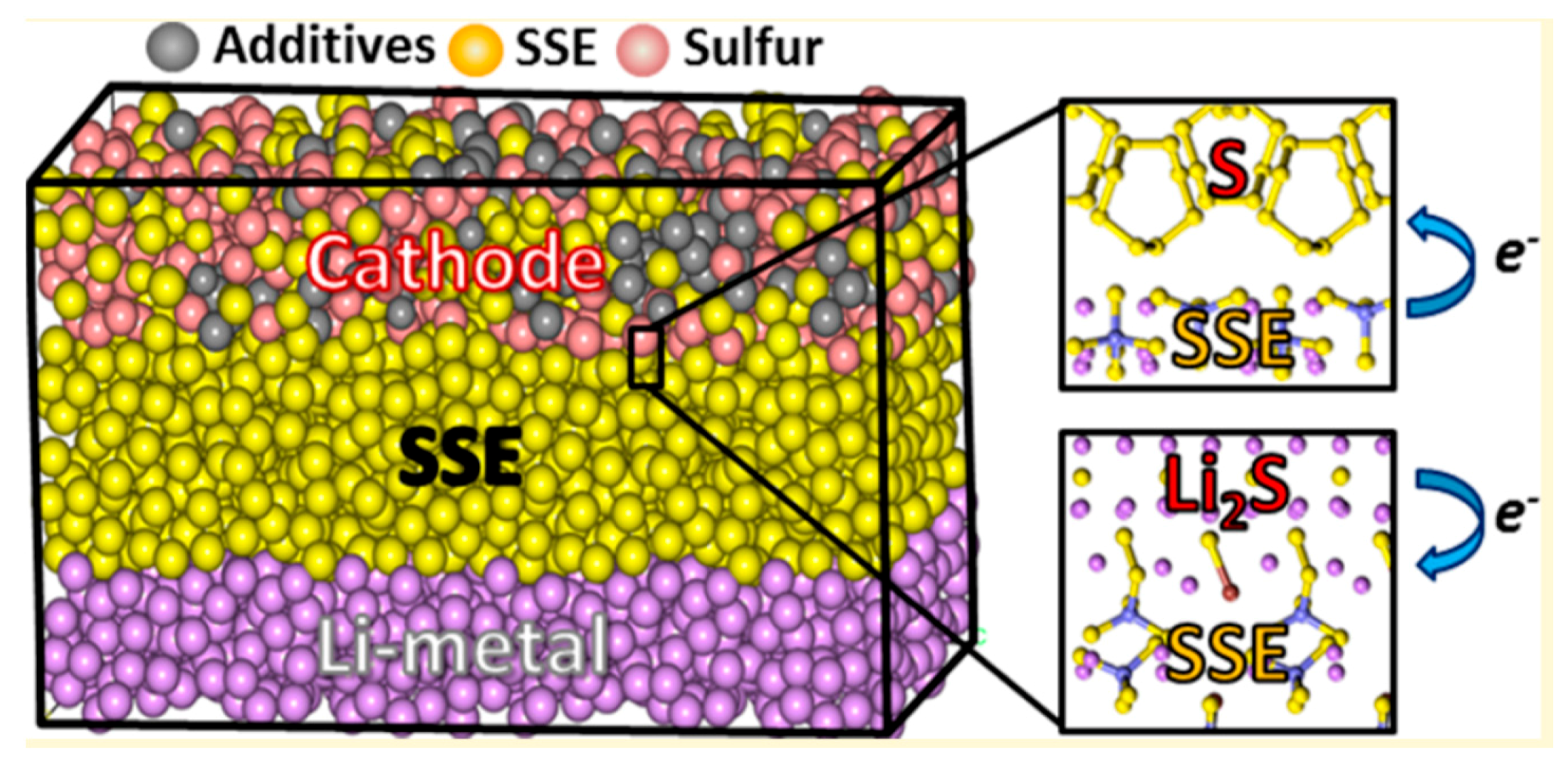

3.1. Solid-State Electrolytes

3.2. Polymer and Gel Electrolytes and Electrolyte Carriers

4. Cathode and Separator Materials

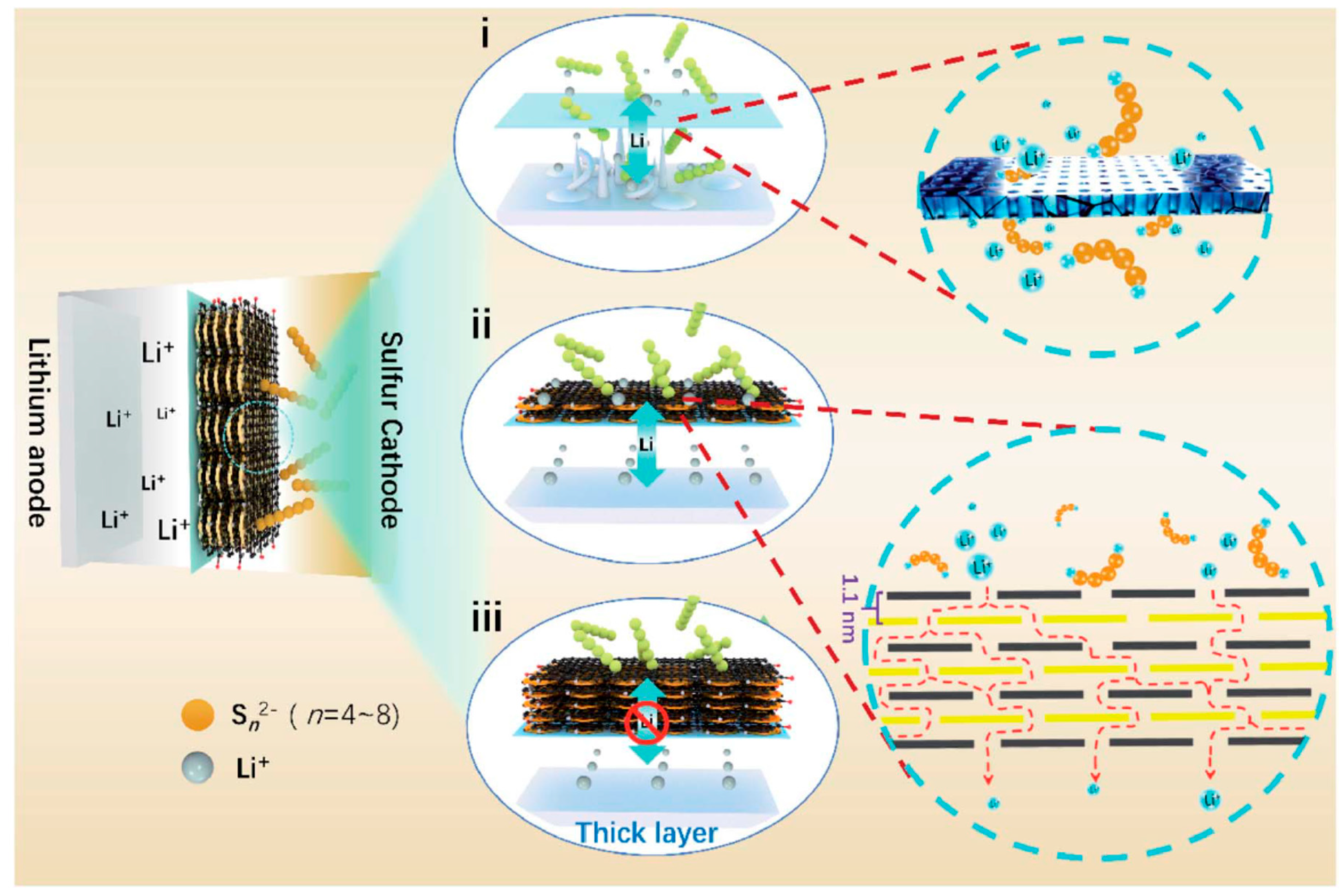

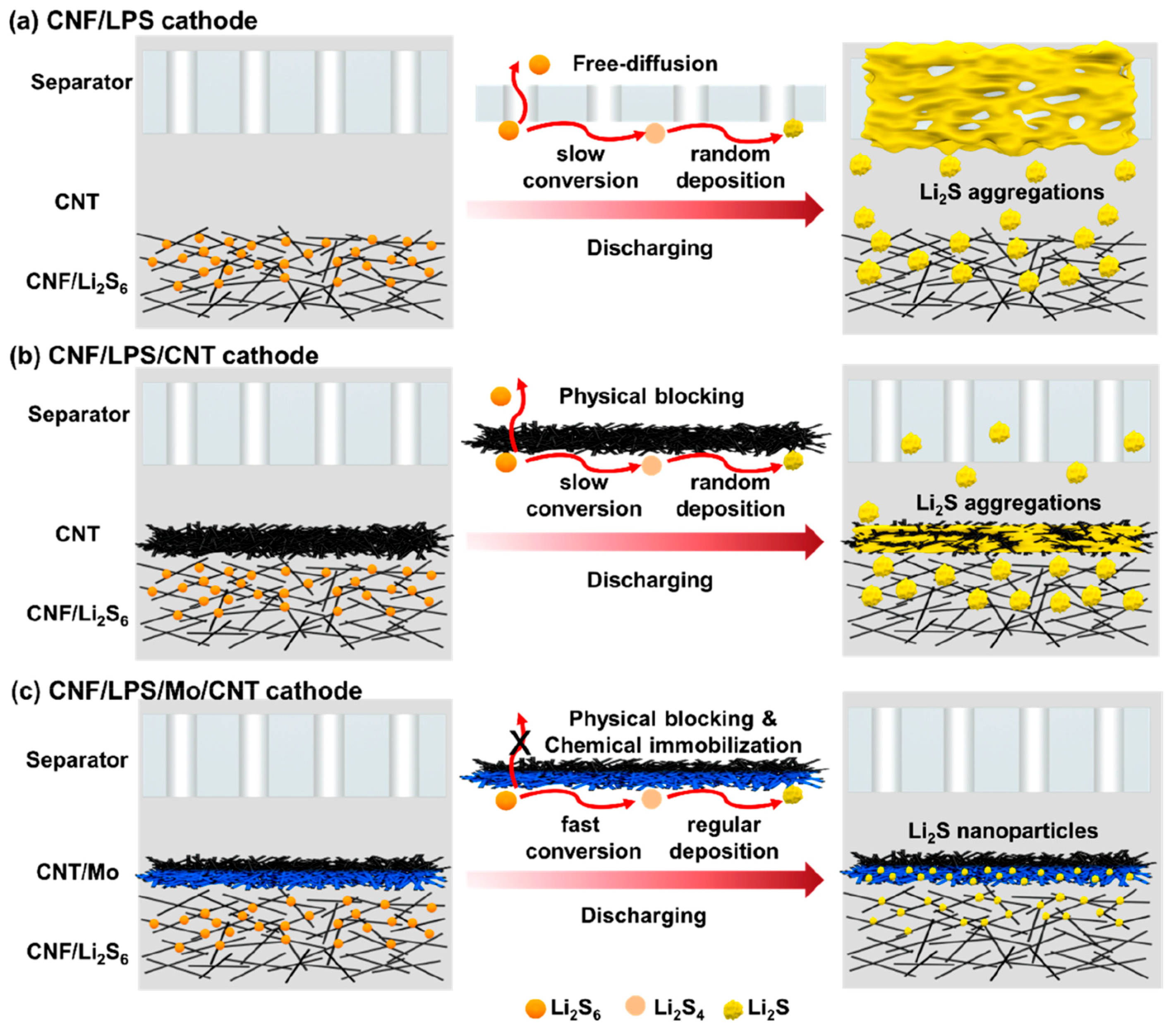

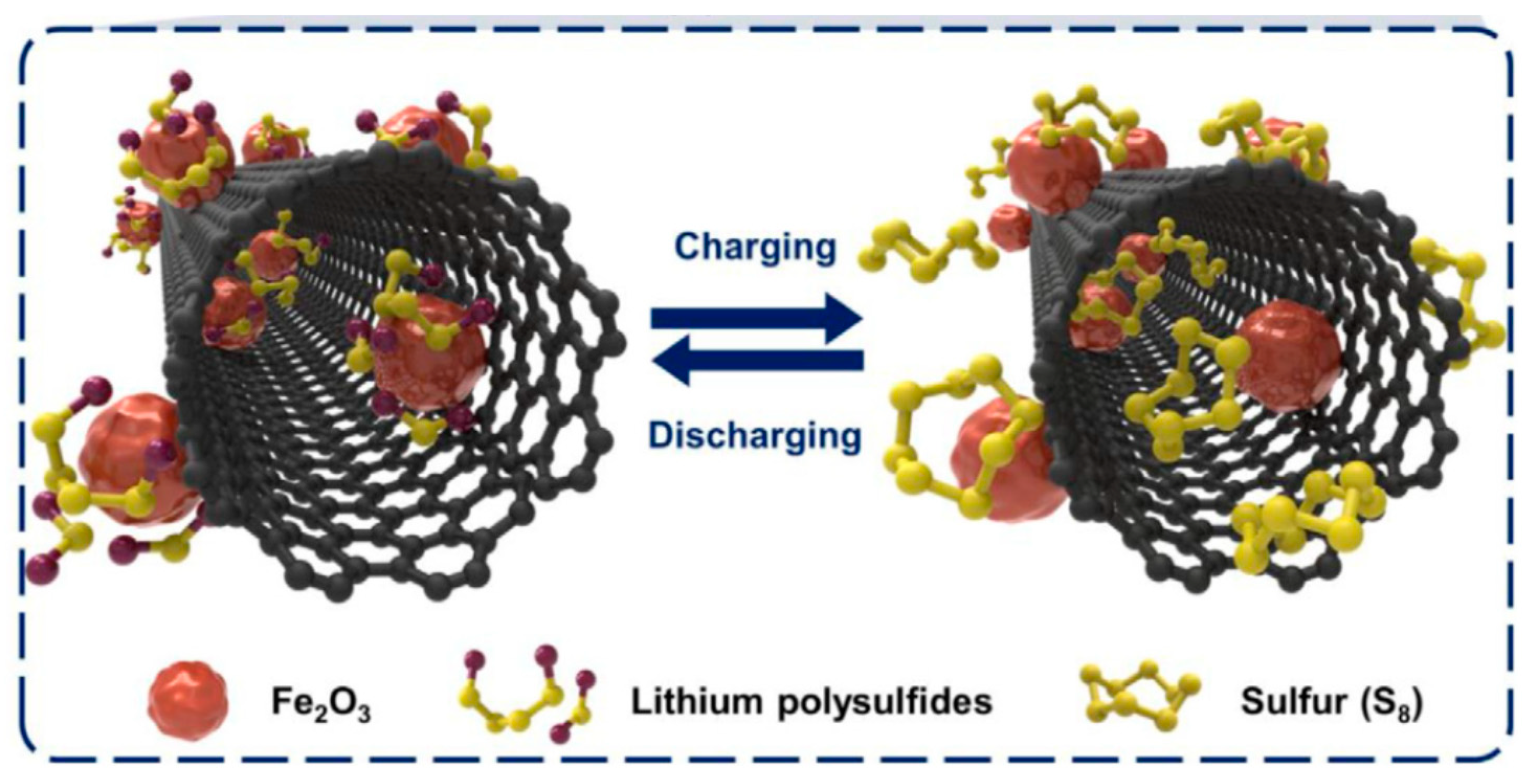

4.1. General Work Employing Graphene and Carbon Cathode Materials

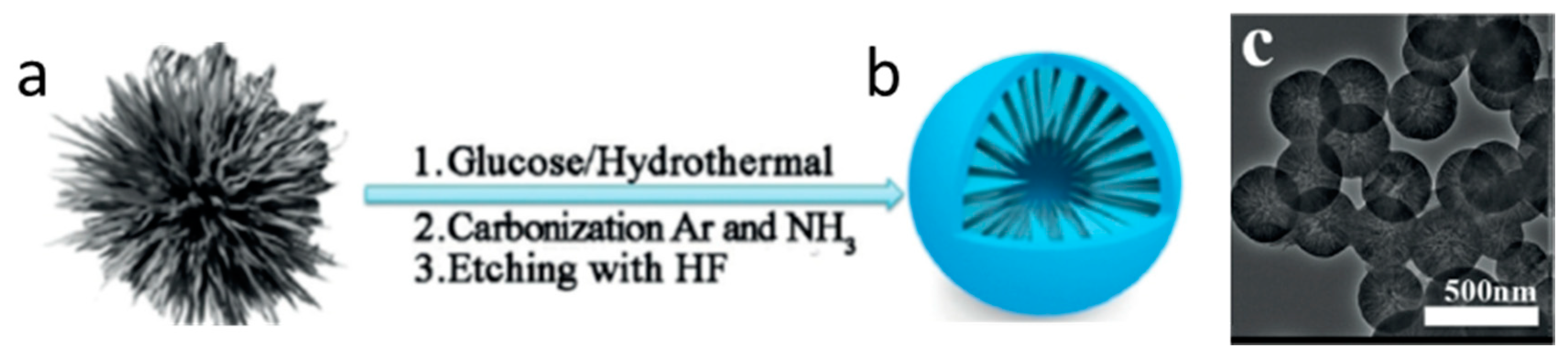

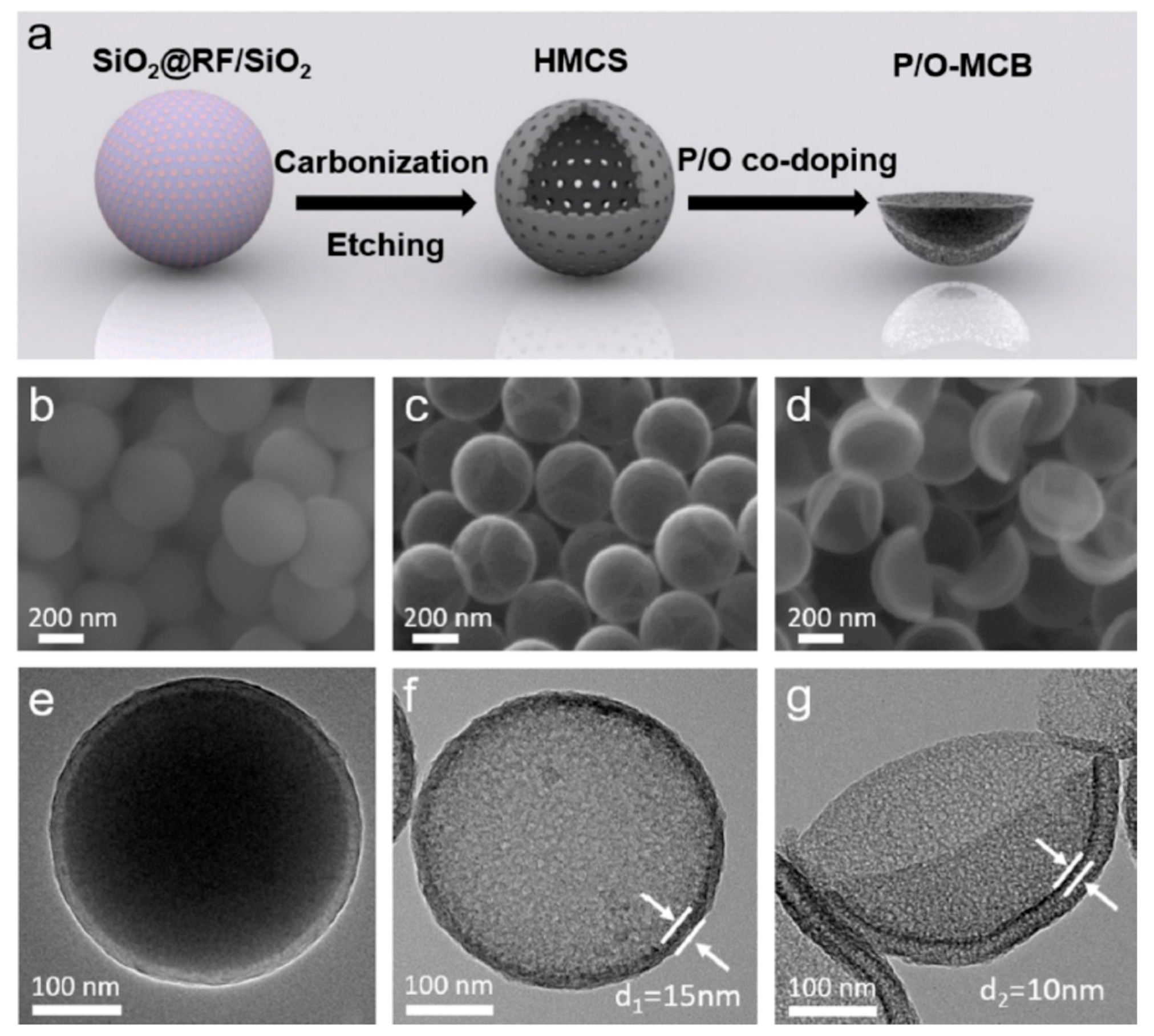

4.2. Heteroatom-Doped Carbon and P-Block Element Materials

4.3. Less Common Allotropic Forms of Carbon and Sulfur

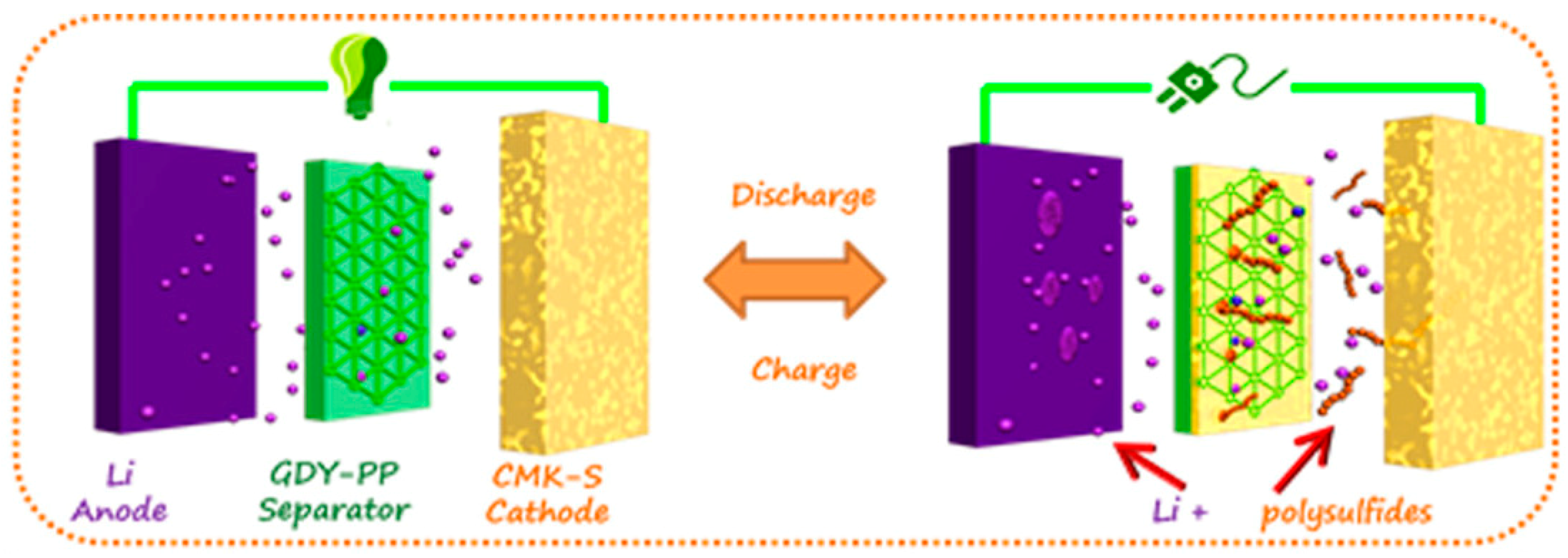

4.4. Semiconducting, Hyperbranched and Inert Polymer Supports and Separators

4.5. Biopolymers in Li-S Batteries

4.6. Metal-Organic Frameworks (MOFs) and Other Open-Pore Scaffolds

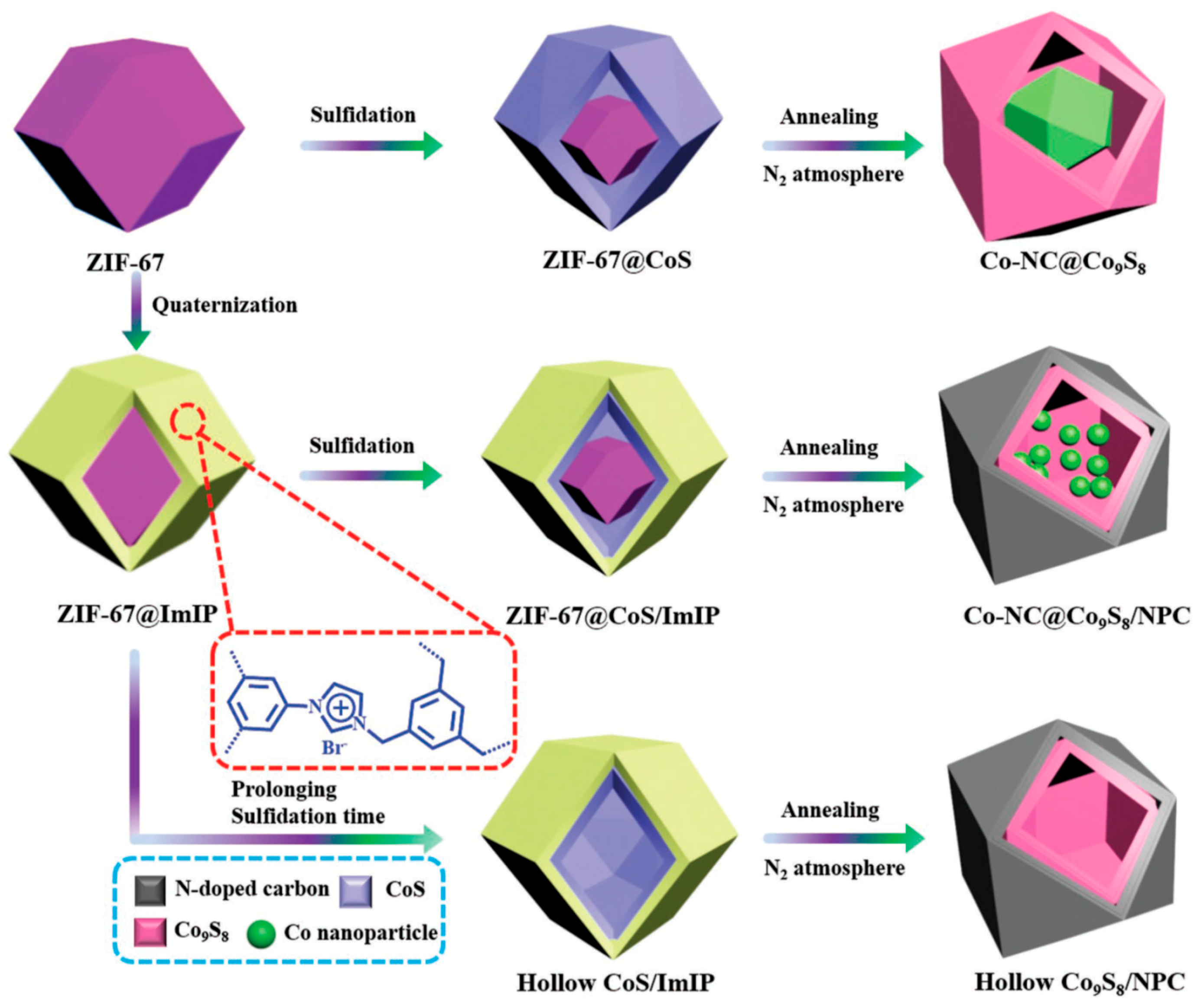

4.7. Systems Employing Metal Sulfides and Phosphides

4.8. Incorporation of Thiols and Organosulfur Compounds

4.9. Rational Design of Catalysts and Hybrid Systems

5. Advances in High Sulfur-Content Material Synthesis

6. Conclusions and Outlook

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yang, H.; Chen, J.; Yang, J.; Wang, J. Prospect of Sulfurized Pyrolyzed Poly(acrylonitrile) (S@pPAN) Cathode Materials for Rechargeable Lithium Batteries. Angew. Chem. 2019, 132, 7374–7386. [Google Scholar] [CrossRef]

- Xu, J.; Lawson, T.; Fan, H.; Su, D.; Wang, G. Updated Metal Compounds (MOFs, -S, -OH, -N, -C) Used as Cathode Materials for Lithium-Sulfur Batteries. Adv. Energy Mater. 2018, 8, 1702607. [Google Scholar] [CrossRef]

- Xu, G.-L.; Wang, Q.; Fang, J.-C.; Xu, Y.-F.; Li, J.-T.; Huang, L.; Sun, S.-G. Tuning the structure and property of nanostructured cathode materials of lithium ion and lithium sulfur batteries. J. Mater. Chem. A Mater. Energy Sustain. 2014, 2, 19941–19962. [Google Scholar] [CrossRef]

- Su, D.; Zhou, D.; Wang, C.; Wang, G. Toward High Performance Lithium-Sulfur Batteries Based on Li2S Cathodes and Beyond: Status, Challenges, and Perspectives. Adv. Funct. Mater. 2018, 28, 1800154. [Google Scholar] [CrossRef]

- Rehman, S.; Khan, K.; Zhao, Y.; Hou, Y. Nanostructured cathode materials for lithium-sulfur batteries: Progress, challenges and perspectives. J. Mater. Chem. A Mater. Energy Sustain. 2017, 5, 3014–3038. [Google Scholar] [CrossRef]

- Pope, M.A.; Aksay, I.A. Structural Design of Cathodes for Li-S Batteries. Adv. Energy Mater. 2015, 5, 1500124. [Google Scholar] [CrossRef]

- Eftekhari, A.; Kim, D.-W. Cathode materials for lithium-sulfur batteries: A practical perspective. J. Mater. Chem. A Mater. Energy Sustain. 2017, 5, 17734–17776. [Google Scholar] [CrossRef]

- Zhang, S.; Ueno, K.; Dokko, K.; Watanabe, M. Recent Advances in Electrolytes for Lithium-Sulfur Batteries. Adv. Energy Mater. 2015, 5, 1500117. [Google Scholar] [CrossRef]

- Yu, X.; Manthiram, A. Electrode-Electrolyte Interfaces in Lithium-Sulfur Batteries with Liquid or Inorganic Solid Electrolytes. Acc. Chem. Res. 2017, 50, 2653–2660. [Google Scholar] [CrossRef]

- Wang, L.; Ye, Y.; Chen, N.; Huang, Y.; Li, L.; Wu, F.; Chen, R. Development and Challenges of Functional Electrolytes for High-Performance Lithium-Sulfur Batteries. Adv. Funct. Mater. 2018, 28, 1800919. [Google Scholar] [CrossRef]

- Kaiser, M.R.; Chou, S.; Liu, H.-K.; Dou, S.-X.; Wang, C.; Wang, J. Structure-Property Relationships of Organic Electrolytes and Their Effects on Li/S Battery Performance. Adv. Mater. Weinh. Ger. 2017, 29, 1700449. [Google Scholar] [CrossRef] [PubMed]

- Baskoro, F.; Wong, H.Q.; Yen, H.-J. Strategic Structural Design of a Gel Polymer Electrolyte toward a High Efficiency Lithium-Ion Battery. ACS Appl. Energy Mater. 2019, 2, 3937–3971. [Google Scholar] [CrossRef]

- He, Y.; Chang, Z.; Wu, S.; Zhou, H. Effective strategies for long-cycle life lithium-sulfur batteries. J. Mater. Chem. A Mater. Energy Sustain. 2018, 6, 6155–6182. [Google Scholar] [CrossRef]

- Zhao, Y.; Ye, Y.; Wu, F.; Li, Y.; Li, L.; Chen, R. Anode Interface Engineering and Architecture Design for High-Performance Lithium-Sulfur Batteries. Adv. Mater. Weinh. Ger. 2019, 31, 1806532. [Google Scholar] [CrossRef]

- Tao, T.; Lu, S.; Fan, Y.; Lei, W.; Huang, S.; Chen, Y. Anode Improvement in Rechargeable Lithium-Sulfur Batteries. Adv. Mater. Weinh. Ger. 2017, 29, 1700542. [Google Scholar] [CrossRef]

- Lin, D.; Liu, Y.; Cui, Y. Reviving the lithium metal anode for high-energy batteries. Nat. Nanotechnol. 2017, 12, 194–206. [Google Scholar] [CrossRef]

- Cao, R.; Xu, W.; Lv, D.; Xiao, J.; Zhang, J.-G. Anodes for Rechargeable Lithium-Sulfur Batteries. Adv. Energy Mater. 2015, 5, 1402273. [Google Scholar] [CrossRef]

- Zhao, E.; Nie, K.; Yu, X.; Hu, Y.-S.; Wang, F.; Xiao, J.; Li, H.; Huang, X. Advanced Characterization Techniques in Promoting Mechanism Understanding for Lithium-Sulfur Batteries. Adv. Funct. Mater. 2018, 28, 1707543. [Google Scholar] [CrossRef]

- Yan, Y.; Cheng, C.; Zhang, L.; Li, Y.-G.; Lu, J. Deciphering the Reaction Mechanism of Lithium–Sulfur Batteries by In Situ/Operando Synchrotron-Based Characterization Techniques. Adv. Energy Mater. 2019, 9. [Google Scholar] [CrossRef]

- Xu, R.; Lu, J.; Amine, K. Progress in Mechanistic Understanding and Characterization Techniques of Li-S Batteries. Adv. Energy Mater. 2015, 5, 1500408. [Google Scholar] [CrossRef]

- Yue, J.; Yan, M.; Yin, Y.-X.; Guo, Y. Progress of the Interface Design in All-Solid-State Li-S Batteries. Adv. Funct. Mater. 2018, 28, 1707533. [Google Scholar] [CrossRef]

- Liu, Y.; He, P.; Zhou, H. Rechargeable Solid-State Li-Air and Li-S Batteries: Materials, Construction, and Challenges. Adv. Energy Mater. 2017, 8, 1701602. [Google Scholar] [CrossRef]

- Lin, Z.; Liang, C. Lithium–sulfur batteries: From liquid to solid cells. J. Mater. Chem. A 2015, 3, 936–958. [Google Scholar] [CrossRef]

- Lei, D.; Shi, K.; Ye, H.; Wan, Z.; Wang, Y.; Shen, L.; Li, B.; Yang, Q.-H.; Kang, F.; He, Y.-B. Progress and Perspective of Solid-State Lithium-Sulfur Batteries. Adv. Funct. Mater. 2018, 28, 1707570. [Google Scholar] [CrossRef]

- Yun, S.; Park, S.H.; Yeon, J.S.; Park, J.; Jana, M.; Suk, J.; Park, H.S. Materials and Device Constructions for Aqueous Lithium-Sulfur Batteries. Adv. Funct. Mater. 2018, 28. [Google Scholar] [CrossRef]

- Balach, J.; Linnemann, J.; Jaumann, T.; Giebeler, L. Metal-based nanostructured materials for advanced lithium-sulfur batteries. J. Mater. Chem. A Mater. Energy Sustain. 2018, 6, 23127–23168. [Google Scholar] [CrossRef]

- Yuan, H.; Huang, J.-Q.; Peng, H.-J.; Titirici, M.-M.; Xiang, R.; Chen, R.; Liu, Q.; Zhang, Q. A Review of Functional Binders in Lithium-Sulfur Batteries. Adv. Energy Mater. 2018, 8. [Google Scholar] [CrossRef]

- Xiang, Y.; Lia, J.; Lei, J.; Liu, D.; Xie, Z.; Qu, D.; Li, K.; Deng, T.; Tang, H. Advanced Separators for Lithium-Ion and Lithium-Sulfur Batteries: A Review of Recent Progress. ChemSusChem 2016, 9, 3023–3039. [Google Scholar] [CrossRef]

- Ely, T.O.; Kamzabek, D.; Chakraborty, D.; Doherty, M.F. Lithium–Sulfur Batteries: State of the Art and Future Directions. ACS Appl. Energy Mater. 2018, 1, 1783–1814. [Google Scholar] [CrossRef]

- Lochala, J.; Liu, D.; Wu, B.; Robinson, C.; Xiao, J. Research Progress toward the Practical Applications of Lithium–Sulfur Batteries. ACS Appl. Mater. Interfaces 2017, 9, 24407–24421. [Google Scholar] [CrossRef]

- Li, X.; Sun, X. Interface Design and Development of Coating Materials in Lithium-Sulfur Batteries. Adv. Funct. Mater. 2018, 28. [Google Scholar] [CrossRef]

- Kumar, R.; Liu, J.; Hwang, J.-Y.; Sun, Y.-K. Recent research trends in Li–S batteries. J. Mater. Chem. A 2018, 6, 11582–11605. [Google Scholar] [CrossRef]

- Jeong, Y.C.; Kim, J.H.; Nam, S.; Park, C.R.; Yang, S.J. Rational Design of Nanostructured Functional Interlayer/Separator for Advanced Li-S Batteries. Adv. Funct. Mater. 2018, 28, 1707411. [Google Scholar] [CrossRef]

- Guo, Q.; Zheng, Z. Rational Design of Binders for Stable Li-S and Na-S Batteries. Adv. Funct. Mater. 2019, 30, 1907931. [Google Scholar] [CrossRef]

- Fang, R.; Zhao, S.; Sun, Z.; Li, F.; Wang, D.-W.; Cheng, H.-M. More Reliable Lithium-Sulfur Batteries: Status, Solutions and Prospects. Adv. Mater. 2017, 29, 1606823. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Y.; Zheng, S.; Xue, H.; Pang, H. Metal–organic frameworks for lithium–sulfur batteries. J. Mater. Chem. A 2019, 7, 3469–3491. [Google Scholar] [CrossRef]

- Liang, Z.; Qu, C.; Guo, W.; Zou, R.; Xu, Q. Pristine Metal-Organic Frameworks and their Composites for Energy Storage and Conversion. Adv. Mater. 2017, 30, 1702891. [Google Scholar] [CrossRef]

- Yuan, H.; Liu, T.; Liu, Y.; Nai, J.; Wang, Y.; Zhang, W.; Tao, X. A review of biomass materials for advanced lithium–sulfur batteries. Chem. Sci. 2019, 10, 7484–7495. [Google Scholar] [CrossRef]

- Wang, J.; Nie, P.; Ding, B.; Dong, S.; Hao, X.; Dou, H.; Zhang, X. Biomass derived carbon for energy storage devices. J. Mater. Chem. A 2017, 5, 2411–2428. [Google Scholar] [CrossRef]

- Lim, W.-G.; Kim, S.; Jo, C.; Lee, J. A Comprehensive Review of Materials with Catalytic Effects in Li–S Batteries: Enhanced Redox Kinetics. Angew. Chem. Int. Ed. 2019, 58, 18746–18757. [Google Scholar] [CrossRef]

- He, Y.; Zhang, Y.; Ding, F.; Li, X.; Wang, Z.; Lü, Z.; Wang, X.; Liu, Z.; Huang, X. Formation of hollow nanofiber rolls through controllable carbon diffusion for Li metal host. Carbon 2020, 157, 622–630. [Google Scholar] [CrossRef]

- He, J.; Manthiram, A. Long-Life, High-Rate Lithium–Sulfur Cells with a Carbon-Free VN Host as an Efficient Polysulfide Adsorbent and Lithium Dendrite Inhibitor. Adv. Energy Mater. 2019, 10, 1903241. [Google Scholar] [CrossRef]

- Li, S.; Ma, J.; Zeng, Z.; Hu, W.; Zhang, W.; Cheng, S.; Xie, J. Enhancing the kinetics of lithium–sulfur batteries under solid-state conversion by using tellurium as a eutectic accelerator. J. Mater. Chem. A 2020, 8, 3405–3412. [Google Scholar] [CrossRef]

- Guo, R.; Zhang, S.; Wang, J.; Ying, H.; Han, W.-Q. One-Pot Synthesis of a Copolymer Micelle Crosslinked Binder with Multiple Lithium-Ion Diffusion Pathways for Lithium–Sulfur Batteries. ChemSusChem 2020, 13, 819–826. [Google Scholar] [CrossRef] [PubMed]

- Cui, J.; Li, Z.; Li, J.; Li, S.; Liu, J.; Shao, M.; Wei, M. An atomic-confined-space separator for high performance lithium–sulfur batteries. J. Mater. Chem. A 2020, 8, 1896–1903. [Google Scholar] [CrossRef]

- Li, Y.; Wang, C.; Wang, W.; Eng, A.Y.S.; Wan, M.; Fu, L.; Mao, E.; Li, G.; Tang, J.; Seh, Z.W.; et al. Enhanced Chemical Immobilization and Catalytic Conversion of Polysulfide Intermediates Using Metallic Mo Nanoclusters for High-Performance Li–S Batteries. ACS Nano 2019, 14, 1148–1157. [Google Scholar] [CrossRef] [PubMed]

- Chiochan, P.; Kosasang, S.; Ma, N.; Duangdangchote, S.; Suktha, P.; Sawangphruk, M. Confining Li2S6 catholyte in 3D graphene sponge with ultrahigh total pore volume and oxygen-containing groups for lithium-sulfur batteries. Carbon 2020, 158, 244–255. [Google Scholar] [CrossRef]

- Shen, G.; Liu, Z.; Lu, A.; Duan, J.; Younus, H.A.; Deng, H.; Wang, X.; Zhang, S. Constructing a 3D compact sulfur host based on carbon-nanotube threaded defective Prussian blue nanocrystals for high performance lithium-sulfur batteries. J. Mater. Chem. A 2020, 8, 1154–1163. [Google Scholar] [CrossRef]

- Lee, J.; Jeon, Y.; Oh, J.; Kim, M.; Lee, L.Y.S.; Piao, Y. γ-Fe2O3 nanoparticles anchored in MWCNT hybrids as efficient sulfur hosts for high-performance lithium-sulfur battery cathode. J. Electroanal. Chem. 2020, 858, 113806. [Google Scholar] [CrossRef]

- Yu, B.; Chen, Y.; Wang, Z.; Chen, D.; Wang, X.; Zhang, W.; He, J.; He, W. 1T-MoS2 nanotubes wrapped with N-doped graphene as highly-efficient absorbent and electrocatalyst for Li–S batteries. J. Power Sources 2020, 447, 227364. [Google Scholar] [CrossRef]

- Yanilmaz, M.; Asiri, A.M.; Zhang, X. Centrifugally spun porous carbon microfibers as interlayer for Li–S batteries. J. Mater. Sci. 2019, 55, 3538–3548. [Google Scholar] [CrossRef]

- Song, J.; Zheng, J.; Zhang, R.; Fu, S.; Zhu, C.; Feng, S.; McEwen, J.-S.; Du, D.; Li, X.; Lin, Y. Enhancing Chemical Interaction of Polysulfide and Carbon through Synergetic Nitrogen and Phosphorus Doping. ACS Sustain. Chem. Eng. 2019, 8, 806–813. [Google Scholar] [CrossRef]

- Yang, J.; Zhao, S.-X.; Zeng, X.; Lu, Y.; Cao, G. Catalytic Interfaces-Enriched Hybrid Hollow Spheres Sulfur Host for Advanced Li–S Batteries. Adv. Mater. Interfaces 2019, 7. [Google Scholar] [CrossRef]

- Li, Z.; Xiao, Z.; Li, P.; Meng, X.; Wang, R. Enhanced Chemisorption and Catalytic Effects toward Polysulfides by Modulating Hollow Nanoarchitectures for Long-Life Lithium–Sulfur Batteries. Small 2019, 16, 1906114. [Google Scholar] [CrossRef] [PubMed]

- Yu, Z.; Liu, M.; Guo, D.; Wang, J.; Chen, X.; Jin, H.; Yang, Z.; Wang, S.; Li, J.; Chen, X.; et al. Radially inwardly aligned hierarchical porous carbon for ultra-long-life lithium-sulfur batteries. Angew. Chem. 2020, 59, 6406–6411. [Google Scholar] [CrossRef] [PubMed]

- Shao, A.-H.; Zhang, Z.; Xiong, D.-G.; Yu, J.; Cai, J.-X.; Yang, Z.-Y. Facile Synthesis of a “Two-in-One” Sulfur Host Featuring Metallic-Cobalt-Embedded N-Doped Carbon Nanotubes for Efficient Lithium-Sulfur Batteries. ACS Appl. Mater. Interfaces 2020, 12, 5968–5978. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Shen, J.; Ji, S.; Xu, X.; Zuo, S.; Liu, Z.; Zhang, D.; Hu, R.; Ouyang, L.; Liu, J.; et al. B,N Codoped Graphitic Nanotubes Loaded with Co Nanoparticles as Superior Sulfur Host for Advanced Li–S Batteries. Small 2020, 16, 1906634. [Google Scholar] [CrossRef]

- Wu, Z.; Yuan, L.; Han, Q.; Lan, Y.; Zhou, Y.; Jiang, X.; Ouyang, X.; Zhu, J.; Wang, X.; Fua, Y. Phosphorous/oxygen co-doped mesoporous carbon bowls as sulfur host for high performance lithium-sulfur batteries. J. Power Sources 2020, 450, 227658. [Google Scholar] [CrossRef]

- Tian, Y.; Li, G.; Zhang, Y.; Luo, D.; Wang, X.; Zhao, Y.; Liu, H.; Ji, P.; Du, X.; Li, J.; et al. Low-Bandgap Se-Deficient Antimony Selenide as a Multifunctional Polysulfide Barrier toward High-Performance Lithium-Sulfur Batteries. Adv. Mater. 2019, 32, e1904876. [Google Scholar] [CrossRef]

- Susarla, S.; Puthirath, A.B.; Tsafack, T.; Salpekar, D.; Babu, G.; Ajayan, P.M. Atomic-Level Alloying of Sulfur and Selenium for Advanced Lithium Batteries. ACS Appl. Mater. Interfaces 2019, 12, 1005–1013. [Google Scholar] [CrossRef]

- Wang, B.; Guo, W.; Fu, Y. Anodized Aluminum Oxide Separators with Aligned Channels for High-Performance Li–S Batteries. ACS Appl. Mater. Interfaces 2020, 12, 5831–5837. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Wang, K.; Yang, Z.; Li, X.; Gao, J.; He, J.; Wang, N.; Wang, H.; Zhang, Y.; Huang, C. Effective Stabilization of Long-Cycle Lithium–Sulfur Batteries Utilizing In Situ Prepared Graphdiyne-Modulated Separators. ACS Sustain. Chem. Eng. 2019, 8, 1741–1750. [Google Scholar] [CrossRef]

- Chung, W.J.; Griebel, J.J.; Kim, E.T.; Yoon, H.; Simmonds, A.G.; Ji, H.J.; Dirlam, P.T.; Glass, R.S.; Wie, J.J.; Nguyen, N.A.; et al. The use of elemental sulfur as an alternative feedstock for polymeric materials. Nat. Chem. 2013, 5, 518–524. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.-J.; Liu, X.; Wu, L.; Dong, W.; Xia, F.-J.; Chen, L.-D.; Zhou, N.; Xia, L.; Hu, Z.-Y.; Liu, J.; et al. A flexible, hierarchically porous PANI/MnO2 network with fast channels and an extraordinary chemical process for stable fast-charging lithium–sulfur batteries. J. Mater. Chem. A 2020, 8, 2741–2751. [Google Scholar] [CrossRef]

- Wei, W.; Li, J.; Wang, Q.; Liu, D.; Niu, J.; Liu, P. Hierarchically Porous SnO2 Nanoparticle-Anchored Polypyrrole Nanotubes as a High-Efficient Sulfur/Polysulfide Trap for High-Performance Lithium–Sulfur Batteries. ACS Appl. Mater. Interfaces 2020, 12, 6362–6370. [Google Scholar] [CrossRef]

- Chen, C.; Xu, H.; Zhang, B.; Jiang, Q.; Zhang, Y.; Li, L.; Lin, Z. Rational design of a mesoporous silica-based cathode for efficient trapping of polysulfides in Li-S batteries. Chem. Commun. 2020, 56, 786–789. [Google Scholar] [CrossRef]

- Liu, X.; Chen, P.; Chen, J.; Zeng, Q.; Wang, Z.; Li, Z.; Zhang, L. A nitrogen-rich hyperbranched polymer as cathode encapsulated material for superior long-cycling lithium-sulfur batteries. Electrochim. Acta 2020, 330, 135337. [Google Scholar] [CrossRef]

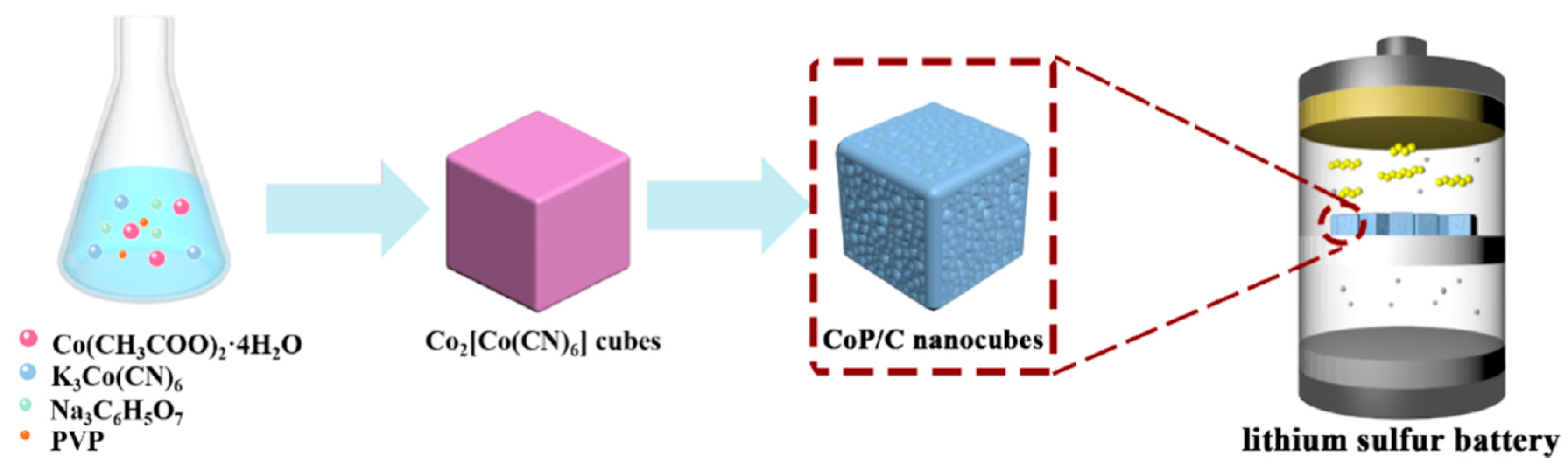

- Lin, J.; Zhang, K.; Zhu, Z.; Zhang, R.; Li, N.; Zhao, C. CoP/C Nanocubes-Modified Separator Suppressing Polysulfide Dissolution for High-Rate and Stable Lithium–Sulfur Batteries. ACS Appl. Mater. Interfaces 2019, 12, 2497–2504. [Google Scholar] [CrossRef]

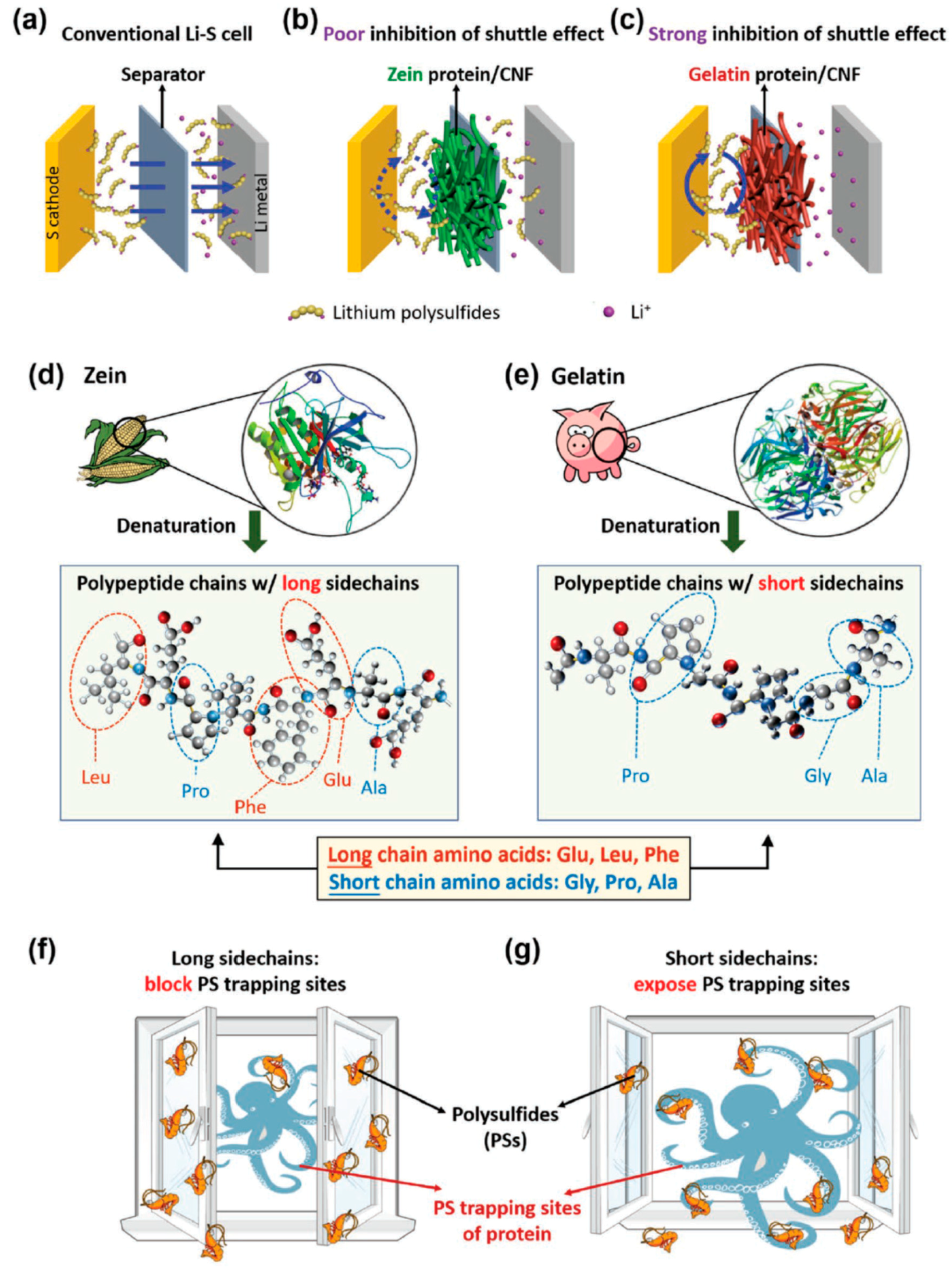

- Chen, M.; Li, C.; Fu, X.; Wei, W.; Fan, X.; Hattori, A.; Chen, Z.; Liu, J.; Zhong, W.-H. Let It Catch: A Short-Branched Protein for Efficiently Capturing Polysulfides in Lithium–Sulfur Batteries. Adv. Energy Mater. 2020, 10. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, W.; Xu, J.; Guo, Z. Advances in Polar Materials for Lithium-Sulfur Batteries. Adv. Funct. Mater. 2018, 28. [Google Scholar] [CrossRef]

- Wang, Y.; Yu, Y.; Tan, Y.; Li, T.; Chen, Y.; Wang, S.; Sui, K.; Zhang, H.; Luo, Y.; Li, X. Affinity Laminated Chromatography Membrane Built-in Electrodes for Suppressing Polysulfide Shuttling in Lithium–Sulfur Batteries. Adv. Energy Mater. 2019, 10, 1903233. [Google Scholar] [CrossRef]

- Zuoab, Y.; Zhao, M.; Ren, P.; Suab, W.; Zhou, J.; Chen, Y.; Tang, Y.; Chen, Y. An efficient polysulfide trapper of an nitrogen and nickel-decorating amylum scaffold-coated separator for ultrahigh performance in lithium–sulfur batteries. J. Mater. Chem. A 2020, 8, 1238–1246. [Google Scholar] [CrossRef]

- Li, G.; Lu, F.; Dou, X.; Wang, X.; Luo, D.; Sun, H.; Yu, A.; Chen, Z. Polysulfide Regulation by the Zwitterionic Barrier toward Durable Lithium–Sulfur Batteries. J. Am. Chem. Soc. 2020, 142, 3583–3592. [Google Scholar] [CrossRef]

- Li, B.; Xie, M.; Yi, G.; Zhang, C. Biomass-derived activated carbon/sulfur composites as cathode electrodes for Li–S batteries by reducing the oxygen content. RSC Adv. 2020, 10, 2823–2829. [Google Scholar] [CrossRef]

- Razzaq, A.A.; Yuan, X.; Chen, Y.; Hu, J.; Mu, Q.; Ma, Y.; Zhao, X.; Miao, L.; Ahn, J.-H.; Peng, Y.; et al. Anchoring MOF-derived CoS2 on sulfurized polyacrylonitrile nanofibers for high areal capacity lithium–sulfur batteries. J. Mater. Chem. A 2020, 8, 1298–1306. [Google Scholar] [CrossRef]

- Xu, W.; Pang, H.; Zhou, H.; Jian, Z.; Hu, R.; Xing, Y.; Zhang, S. Lychee-like TiO2@TiN dual-function composite material for lithium–sulfur batteries. RSC Adv. 2020, 10, 2670–2676. [Google Scholar] [CrossRef]

- Chen, P.; Wang, Z.; Zhang, B.; Liu, H.; Liu, W.; Zhao, J.; Ma, Z.; Dong, W.; Su, Z. Reduced graphene oxide/TiO2(B) nanocomposite-modified separator as an efficient inhibitor of polysulfide shuttling in Li–S batteries. RSC Adv. 2020, 10, 4538–4544. [Google Scholar] [CrossRef]

- Shen, Z.; Cao, M.; Zhang, Z.; Pu, J.; Zhong, C.; Li, J.; Ma, H.; Li, F.; Zhu, J.; Pan, F.; et al. Efficient Ni 2 Co 4 P 3 Nanowires Catalysts Enhance Ultrahigh-Loading Lithium–Sulfur Conversion in a Microreactor-Like Battery. Adv. Funct. Mater. 2019, 30. [Google Scholar] [CrossRef]

- Yang, Y.; Lei, S.; Song, S.; Sun, W.; Wang, L. Stepwise recycling of valuable metals from Ni-rich cathode material of spent lithium-ion batteries. Waste Manag. 2020, 102, 131–138. [Google Scholar] [CrossRef]

- Thiounn, T.; Smith, R.C. Advances and approaches for chemical recycling of plastic waste. J. Appl. Polym. Sci. 2020, 58, 1347–1364. [Google Scholar] [CrossRef]

- Chalker, J.M.; Worthington, M.J.H.; Lundquist, N.A.; Esdaile, L.J. Synthesis and Applications of Polymers Made by Inverse Vulcanization. Top. Curr. Chem. 2019, 377, 16. [Google Scholar] [CrossRef] [PubMed]

- Lim, J.; Pyun, J.; Char, K. Recent Approaches for the Direct Use of Elemental Sulfur in the Synthesis and Processing of Advanced Materials. Angew. Chem. Int. Ed. 2015, 54, 3249–3258. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Glass, R.S.; Char, K.; Pyun, J.; Pyun, J. Recent advances in the polymerization of elemental sulphur, inverse vulcanization and methods to obtain functional Chalcogenide Hybrid Inorganic/Organic Polymers (CHIPs). Polym. Chem. 2019, 10, 4078–4105. [Google Scholar] [CrossRef]

- Smith, A.D.; Smith, R.C.; Tennyson, A.G. Carbon-Negative Polymer Cements by Copolymerization of Waste Sulfur, Oleic Acid, and Pozzolan Cements. Sustain. Chem. Pharm. 2020, 16, 100249. [Google Scholar] [CrossRef]

- Karunarathna, M.; Smith, R.C. Valorization of Lignin as a Sustainable Component of Structural Materials and Composites: Advances from 2011 to 2019. Sustainability 2020, 12, 734. [Google Scholar] [CrossRef]

- Tang, B.; Wu, H.; Du, X.; Cheng, X.; Liu, X.; Yu, Z.; Yang, J.; Zhang, M.; Zhang, J.; Cui, G. Highly Safe Electrolyte Enabled via Controllable Polysulfide Release and Efficient Conversion for Advanced Lithium–Sulfur Batteries. Small 2020, 16, e1905737. [Google Scholar] [CrossRef]

- E Camacho-Forero, L.; Balbuena, P.B. Elucidating Interfacial Phenomena between Solid-State Electrolytes and the Sulfur-Cathode of Lithium-Sulfur Batteries. ECS Meet. Abstr. 2019, 32, 360–373. [Google Scholar] [CrossRef]

- Xiao, Q.; Deng, C.; Wang, Q.; Zhang, Q.; Yue, Y.; Ren, S. In Situ Cross-Linked Gel Polymer Electrolyte Membranes with Excellent Thermal Stability for Lithium Ion Batteries. ACS Omega 2019, 4, 95–103. Available online: https://pubs.acs.org/doi/full/10.1021/acsomega.8b02255 (accessed on 10 June 2020). [CrossRef]

- Baik, S.; Park, J.H.; Lee, J.W. One-pot conversion of carbon dioxide to CNT-grafted graphene bifunctional for sulfur cathode and thin interlayer of Li–S battery. Electrochim. Acta 2020, 330, 135264. [Google Scholar] [CrossRef]

- Shi, H.; Lv, W.; Zhang, C.; Wang, D.-W.; Ling, G.; He, Y.-B.; Kang, F.; Yang, Q.-H. Functional Carbons Remedy the Shuttling of Polysulfides in Lithium-Sulfur Batteries: Confining, Trapping, Blocking, and Breaking up. Adv. Funct. Mater. 2018, 28. [Google Scholar] [CrossRef]

- Kensy, C.; Härtel, P.; Maschita, J.; Dörfler, S.; Schumm, B.; Abendroth, T.; Althues, H.; Lotsch, B.V.; Kaskel, S. Scalable production of nitrogen-doped carbons for multilayer lithium-sulfur battery cells. Carbon 2020, 161, 190–197. [Google Scholar] [CrossRef]

- Shih, H.-J.; Chang, J.-Y.; Cho, C.-S.; Li, C.-C. Nano-carbon-fiber-penetrated sulfur crystals as potential cathode active material for high-performance lithium–sulfur batteries. Carbon 2020, 159, 401–411. [Google Scholar] [CrossRef]

- Liu, N.; Zhou, G.; Yang, A.; Yu, X.; Shi, F.; Sun, J.; Zhang, J.; Liu, B.; Wu, C.-L.; Tao, X.; et al. Direct electrochemical generation of supercooled sulfur microdroplets well below their melting temperature. Proc. Natl. Acad. Sci. USA 2019, 116, 765–770. [Google Scholar] [CrossRef] [PubMed]

- Yang, A.; Zhou, G.; Kong, X.; Vilá, R.A.; Pei, A.; Wu, Y.; Yu, X.; Zheng, X.; Wu, C.-L.; Liu, B.; et al. Electrochemical generation of liquid and solid sulfur on two-dimensional layered materials with distinct areal capacities. Nat. Nanotechnol. 2020, 15, 231–237. [Google Scholar] [CrossRef] [PubMed]

- Zhao, F.; Li, Y.; Feng, W. Recent Advances in Applying Vulcanization/Inverse Vulcanization Methods to Achieve High-Performance Sulfur-Containing Polymer Cathode Materials for Li-S Batteries. Small Methods 2018, 2, 1–34. [Google Scholar] [CrossRef]

- Liu, X.; Lu, Y.; Zeng, Q.; Chen, P.; Li, Z.; Wen, X.; Wen, W.; Li, Z.; Zhang, L. Trapping of Polysulfides with Sulfur-Rich Poly Ionic Liquid Cathode Materials for Ultralong-Life Lithium–Sulfur Batteries. ChemSusChem 2020, 13, 715–723. [Google Scholar] [CrossRef]

- He, Y.; Matthews, B.; Wang, J.; Song, L.; Wang, X.; Wu, G. Innovation and challenges in materials design for flexible rechargeable batteries: From 1D to 3D. J. Mater. Chem. A 2018, 6, 735–753. [Google Scholar] [CrossRef]

- Peng, H.-J.; Huang, J.-Q.; Zhang, Q. A review of flexible lithium–sulfur and analogous alkali metal–chalcogen rechargeable batteries. Chem. Soc. Rev. 2017, 46, 5237–5288. [Google Scholar] [CrossRef]

- Mukkabla, R.; Ojha, M.; Deepa, M. Poly(N-methylpyrrole) barrier coating and SiO2 fillers based gel electrolyte for safe and reversible Li–S batteries. Electrochim. Acta 2020, 334, 135571. [Google Scholar] [CrossRef]

- Wei, Y.; Li, X.; Xu, Z.; Sun, H.; Zheng, Y.; Peng, L.; Liu, Z.; Gao, C.; Gao, M. Solution processible hyperbranched inverse-vulcanized polymers as new cathode materials in Li–S batteries. Polym. Chem. 2015, 6, 973–982. [Google Scholar] [CrossRef]

- Hua, Z.; Sua, H.; Tua, S.; Xionga, P.; Chenga, M.; Zhaoa, X.; Wanga, L.; Zhua, Y.; Li, F.; Xu, Y. Efficient polysulfide trapping enabled by a polymer adsorbent in lithium-sulfur batteries. Electrochim. Acta 2020, 336, 135693. [Google Scholar] [CrossRef]

- Zhong, Y.; Lin, F.; Wang, M.; Zhang, Y.; Ma, Q.; Lin, J.; Feng, Z.; Wang, H. Metal Organic Framework Derivative Improving Lithium Metal Anode Cycling. Adv. Funct. Mater. 2020, 30, 1907579. [Google Scholar] [CrossRef]

- Wei, L.; Li, W.; Zhao, T.; Zhang, N.; Li, L.; Wu, F.; Chen, R. Cobalt nanoparticles shielded in N-doped carbon nanotubes for high areal capacity Li–S batteries. Chem. Commun. 2020, 56, 3007–3010. [Google Scholar] [CrossRef] [PubMed]

- Yao, S.; Guo, R.; Xie, F.; Wu, Z.; Gao, K.; Zhang, C.; Shen, X.; Li, T.; Qin, S. Electrospun three-dimensional cobalt decorated nitrogen doped carbon nanofibers network as freestanding electrode for lithium/sulfur batteries. Electrochim. Acta 2020, 337, 135765. [Google Scholar] [CrossRef]

- Cai, J.; Song, Y.-Z.; Chen, X.; Sun, Z.; Yi, Y.; Sun, J.; Zhang, Q. MOF-derived conductive carbon nitrides for separator-modified Li–S batteries and flexible supercapacitors. J. Mater. Chem. A 2020, 8, 1757–1766. [Google Scholar] [CrossRef]

- Wang, R.; Yang, J.; Chen, X.; Zhao, Y.; Zhao, W.; Qian, G.; Li, S.; Xiao, Y.; Chen, H.; Ye, Y.; et al. Highly Dispersed Cobalt Clusters in Nitrogen-Doped Porous Carbon Enable Multiple Effects for High-Performance Li–S Battery. Adv. Energy Mater. 2020, 10. [Google Scholar] [CrossRef]

- Li, Y.; Lin, S.; Wang, D.; Gao, T.; Song, J.; Zhou, P.; Xu, Z.; Yang, Z.; Xiao, N.; Guo, S. Single Atom Array Mimic on Ultrathin MOF Nanosheets Boosts the Safety and Life of Lithium–Sulfur Batteries. Adv. Mater. 2020, 32, e1906722. [Google Scholar] [CrossRef]

- Jin, J.; Cai, W.; Cai, J.; Shao, Y.; Song, Y.-Z.; Xia, Z.; Zhang, Q.; Sun, J. MOF-derived hierarchical CoP nanoflakes anchored on vertically erected graphene scaffolds as self-supported and flexible hosts for lithium–sulfur batteries. J. Mater. Chem. A 2020, 8, 3027–3034. [Google Scholar] [CrossRef]

- Wang, C.; Song, H.; Yu, C.; Ullah, Z.; Guan, Z.; Chu, R.; Zhang, Y.; Zhao, L.; Li, Q.; Liu, L. Iron single-atom catalyst anchored on nitrogen-rich MOF-derived carbon nanocage to accelerate polysulfide redox conversion for lithium sulfur batteries. J. Mater. Chem. A 2020, 8, 3421–3430. [Google Scholar] [CrossRef]

- Chen, S.; Ming, Y.; Tan, B.; Chen, S. Carbon-free sulfur-based composite cathode for advanced Lithium-Sulfur batteries: A case study of hierarchical structured CoMn2O4 hollow microspheres as sulfur immobilizer. Electrochim. Acta 2020, 329, 135128. [Google Scholar] [CrossRef]

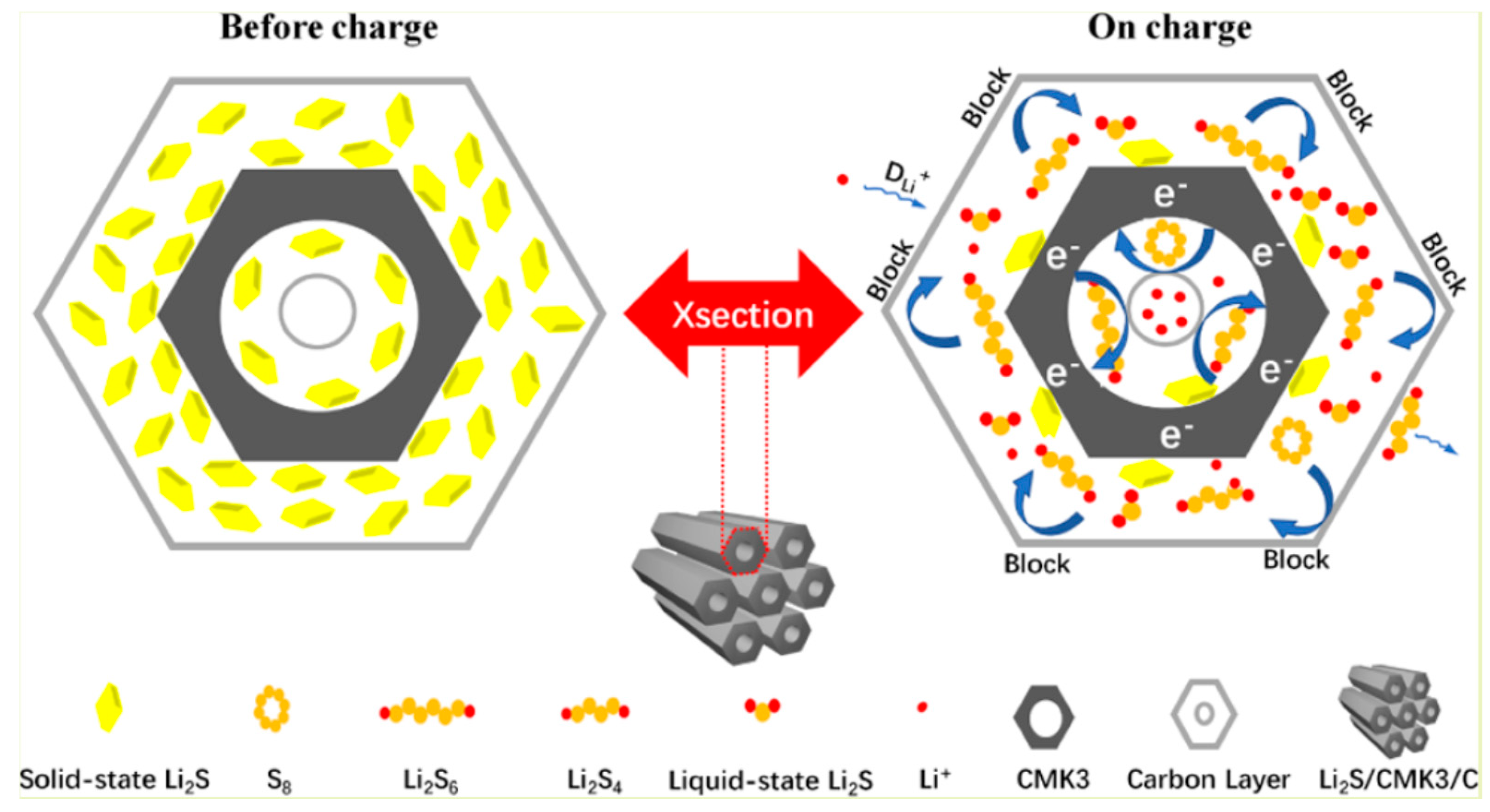

- Liu, H.; Chen, M.; Zeng, P.; Li, X.; Luo, J.; Li, Y.; Xing, T.; Chang, B.; Wang, X.; Luo, Z. Lithium Sulfide-Embedded Three-Dimensional Heterogeneous Micro-/Mesoporous Interwoven Carbon Architecture as the Cathode of Lithium-Sulfur Batteries. ACS Sustain. Chem. Eng. 2020, 8, 351–361. [Google Scholar] [CrossRef]

- Liu, X.; Huang, J.-Q.; Zhang, Q.; Mai, L. Nanostructured Metal Oxides and Sulfides for Lithium-Sulfur Batteries. Adv. Mater. 2017, 29, 1601759. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Jiang, T.; Yang, H.; Lei, D.; Deng, X.; Hao, C.; Zhang, F.; Guo, J. A heterostuctured Co3S4/MnS nanotube array as a catalytic sulfur host for lithium-sulfur batteries. Electrochim. Acta 2020, 330, 135311. [Google Scholar] [CrossRef]

- Guo, D.; Zhang, Z.; Xi, B.; Yu, Z.; Zhou, Z.; Chen, X. Ni3S2 Anchored into N/S co-doped Reduced Graphene Oxide with Highly Pleated Structure as a Sulfur Host for Lithium-Sulfur Batteries. J. Mater. Chem. A Mater. Energy Sustain. 2020, 8, 3834–3844. [Google Scholar] [CrossRef]

- Zhou, L.; Zhuang, Z.; Zhao, H.; Lin, M.; Zhao, D.; Mai, L. Intricate Hollow Structures: Controlled Synthesis and Applications in Energy Storage and Conversion. Adv. Mater. 2017, 29, 1602914. [Google Scholar] [CrossRef]

- Li, W.; Gong, Z.; Yan, X.; Wang, D.; Liu, J.; Guo, X.; Zhang, Z.; Li, G. In situ engineered ZnS–FeS heterostructures in N-doped carbon nanocages accelerating polysulfide redox kinetics for lithium sulfur batteries. J. Mater. Chem. A 2020, 8, 433–442. [Google Scholar] [CrossRef]

- Wang, X.; Zhao, X.; Ma, C.; Yang, Z.; Chen, G.; Wang, L.; Yue, H.; Zhang, D.; Sun, Z. Electrospun carbon nanofibers with MnS sulfiphilic sites as efficient polysulfide barriers for high-performance wide-temperature-range Li–S batteries. J. Mater. Chem. A 2020, 8, 1212–1220. [Google Scholar] [CrossRef]

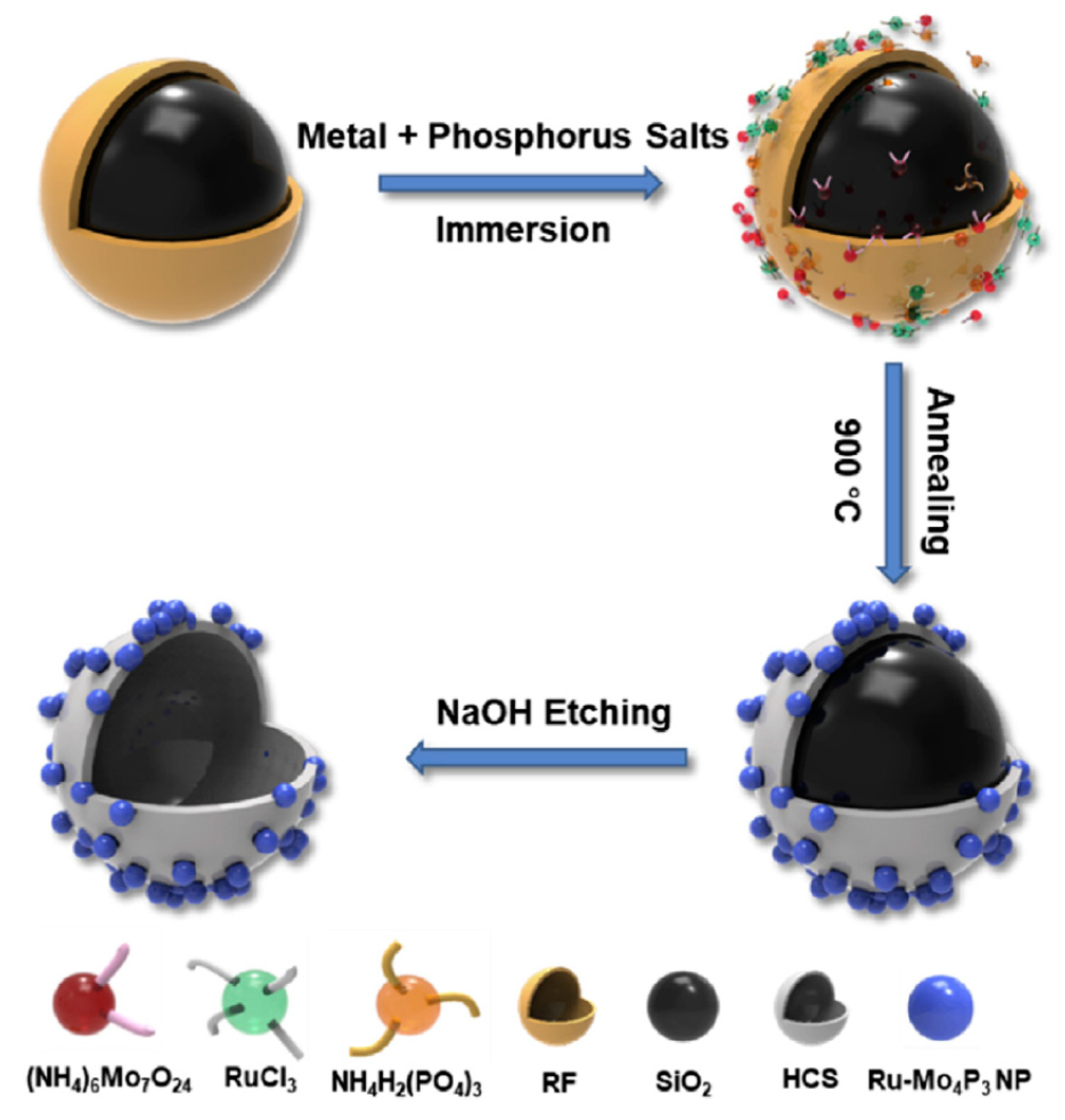

- Ma, F.; Wang, X.; Wang, J.; Tian, Y.; Liang, J.; Fan, Y.; Wang, L.; Wang, T.; Cao, R.; Jiao, S.; et al. Phase-transformed Mo4P3 nanoparticles as efficient catalysts towards lithium polysulfide conversion for lithium–sulfur battery. Electrochim. Acta 2020, 330, 135310. [Google Scholar] [CrossRef]

- Xu, Y.-W.; Zhang, B.-H.; Li, G.-R.; Liu, S.; Gao, X.-P. Covalently Bonded Sulfur Anchored with Thiol-Modified Carbon Nanotube as a Cathode Material for Lithium–Sulfur Batteries. ACS Appl. Energy Mater. 2019, 3, 487–494. [Google Scholar] [CrossRef]

- Phadke, S.; Pires, J.; Korchenko, A.; Anouti, M. How do organic polysulphides improve the performance of Li-S batteries? Electrochim. Acta 2020, 330, 135253. [Google Scholar] [CrossRef]

- Smith, A.D.; McMillen, C.D.; Smith, R.C.; Tennyson, A.G. Copolymers by Inverse Vulcanization of Sulfur with Pure or Technical-Grade Unsaturated Fatty Acids. J. Appl. Polym. Sci. 2020, 58, 438–445. [Google Scholar] [CrossRef]

- Karunarathna, M.S.; Tennyson, A.G.; Smith, R.C. Facile new approach to high sulfur-content materials and preparation of sulfur–lignin copolymers. J. Mater. Chem. A 2020, 8, 548–553. [Google Scholar] [CrossRef]

- Karunarathna, M.S.; Lauer, M.K.; Tennyson, A.G.; Smith, R.C. Copolymerization of an aryl halide and elemental sulfur as a route to high sulfur content materials. Polym. Chem. 2020, 11, 1621–1628. [Google Scholar] [CrossRef]

- Thiounn, T.; Tennyson, A.G.; Smith, R.C. Durable, acid-resistant copolymers from industrial by-product sulfur and microbially-produced tyrosine. RSC Adv. 2019, 9, 31460–31465. [Google Scholar] [CrossRef]

- Smith, A.D.; Thiounn, T.; Lyles, E.W.; Kibler, E.K.; Smith, R.C.; Tennyson, A.G. Combining agriculture and energy industry waste products to yield recyclable, thermally healable copolymers of elemental sulfur and oleic acid. J. Polym. Sci. Part A Polym. Chem. 2019, 57, 1704–1710. [Google Scholar] [CrossRef]

- Lauer, M.K.; Estrada-Mendoza, T.A.; McMillen, C.D.; Chumanov, G.; Tennyson, A.G.; Smith, R.C. Durable Cellulose–Sulfur Composites Derived from Agricultural and Petrochemical Waste. Adv. Sustain. Syst. 2019, 3, 1900062. [Google Scholar] [CrossRef]

- Karunarathna, M.S.; Lauer, M.K.; Thiounn, T.; Smith, R.C.; Tennyson, A.G. Valorization of waste to yield recyclable composites of elemental sulfur and lignin. J. Mater. Chem. A Mater. Energy Sustain. 2019, 7, 15683–15690. [Google Scholar] [CrossRef]

- Thiounn, T.; Lauer, M.K.; Bedford, M.S.; Smith, R.C.; Tennyson, A.G. Thermally-healable network solids of sulfur-crosslinked poly(4-allyloxystyrene). RSC Adv. 2018, 8, 39074–39082. [Google Scholar] [CrossRef]

- Worthington, M.J.H.; Kucera, R.L.; Chalker, J.M. Green chemistry and polymers made from sulfur. Green Chem. 2017, 19, 2748–2761. [Google Scholar] [CrossRef]

- Zhang, C.; Firestein, K.L.; Fernando, J.F.S.; Siriwardena, D.; Von Treifeldt, J.; Golberg, D. Recent Progress of In Situ Transmission Electron Microscopy for Energy Materials. Adv. Mater. 2019, 32, e1904094. [Google Scholar] [CrossRef]

- Nicotera, I.; Simari, C.; Agostini, M.; Enotiadis, A.; Brutti, S. A Novel Li+-Nafion-Sulfonated Graphene Oxide Membrane as Single Lithium-Ion Conducting Polymer Electrolyte for Lithium Batteries. J. Phys. Chem. C 2019, 123, 27406–27416. [Google Scholar] [CrossRef]

- Jin, Z.-Q.; Xie, K.; Hong, X.; Hu, Z.; Liu, X. Application of lithiated Nafion ionomer film as functional separator for lithium sulfur cells. J. Power Sources 2012, 218, 163–167. [Google Scholar] [CrossRef]

| Entry | Battery Attributes | Coulombic Efficiency (%) | After How Many Cycles? | Charge Density (C) | Discharge Capacity (mAh g−1) | Ref. |

|---|---|---|---|---|---|---|

| 1 | Li@carbon nanofiber anode | 99.6 | 1400 | - | - | [41] |

| 83.6 | 200 | 0.5 | 1.0 | |||

| - | - | 4 | 350 | |||

| 2 | Vanadium nitride support for both cathode and anode | 99.6 | 850 | 4 | - | [42] |

| 3 | Solid state mesoporous carbon/sulfur cathode | - | 200 | 0.1 | 1150 | [43] |

| - | 200 | 0.2 | 727 | |||

| 4 | Sulfur cathode and a gel polymer electrolyte and a layer of pentaerythritol tetrakis divinyl adipate | 85 | 300 | 2 | - | [12] |

| 5 | Carboxylate and sulfonate micelles (affinity for polysulfides) | 96.8 | 100 | 0.5 | 571 | [44] |

| 6 | Ultrathin separator (double hydroxide nanosheets, graphene oxide and a polypropylene) | - | - | 0.2 | 1090 | [45] |

| 7 | Carbon nanofiber layer in cathode, surface terminated with Mo and C nanotubes | - | - | 0.1 | 1401 | [46] |

| 70 | 500 | 1 | - | |||

| (higher cathode loading of 7.64 mg cm−2) | - | 100 | 0.2 | - | ||

| 8 | Li2S6 catholyte is hosted by a carboxyl-modified graphene oxide sponge | 0.1 | 1607 | [47] | ||

| 87 | 200 | 1 | ||||

| 9 | Carbon-nanotubes and Prussian blue nanocrystals as cathode support | 74 | 200 | 0.2 | 1200 to 1457 | [48] |

| 61 | 500 | 0.5 | ||||

| Initial capacity without the C nanotubes | - | - | - | 500 | ||

| 10 | Fe2O3 nanoparticles in multi-walled carbon nanotubes (MWCNTs) cathode | - | 500 | 1 | 545 | [49] |

| 7 | 340 | |||||

| 11 | Three-dimensional porous material of MoS2 nanotubes with n-doped graphene sheets | - | 200 | 0.2 | 1219 | [50] |

| 96.1 | 500 | 1 | ||||

| 12 | Porous interlayer of carbon microfibers | - | - | 1485 | [51] | |

| - | 200 | 0.2 | 615 | |||

| - | - | 1 | 600 | |||

| 13 | Phosphorus and nitrogen co-doped into the carbon | - | - | - | 900 | [52] |

| (sulfur loading of 3.5 mg cm−2) | 84 | 450 | 0.2 | - | ||

| 14 | N-doped carbon hollow spheres SnS2 nanoparticles on exterior (sulfur loading of about 3 mg cm−2) | - | 0.2 | 1344 | [53] | |

| - | 200 | 0.5 | ||||

| 15 | Double-shelled hollow polyhedron of nitrogen-doped carbon nanodots (Co-NC@Co9S8/NPC) | 98.9 | 2000 | 2 | - | [54] |

| (sulfur loading 4.5 mg cm−2) | 500 | |||||

| 16 | Infusion of sulfur into hollow pore carbon structures | 56 | 1000 | - | - | [55] |

| 17 | Nitrogen-doped carbon nanotubes in tandem with metallic cobalt nanoparticles | 60 | 500 | 1 | - | [56] |

| Performance of prior systems using N-doped | 20 | 500 | - | - | ||

| 18 | B,N co-doped C nanotube with Co nanoparticles as sulfur host for cathode | - | 200 | 0.1 | 1160 | [57] |

| 84.8 | 400 | 1 | 1008 | |||

| 19 | Cells with phosphorous/oxygen co-doped into mesoporous carbon bowls (sulfur loading of 5.02 mg cm−2) | - | - | 1 | 897 | [58] |

| 52 | 800 | - | 489 | |||

| 20 | Sb2Se3-x as a polysulfide barrier in sulfur electrochemical conversion | 86.5 | 500 | 1 | - | [59] |

| 21 | Cathode assembly involving co-melting of sulfur and selenium | - | 100 | - | 800 | [60] |

| 22 | Inorganic separators comprising anodized aluminum oxide membranes | 49.6 | 480 | 2 | - | [61] |

| 23 | Graphdiyne nanosheets on polypropylene as a separator | - | - | 0.1 | 1262 | [62] |

| - | 500 | 1 | 412 | |||

| 24 | Poly(sulfur-co-1-vinyl-3-allylimidazolium bromide as a cathode | 90 | 900 | - | - | [63] |

| 25 | MnO2 nanoparticles embedded in polyaniline (PANI) as a scaffold for sulfur cathode | - | 100 | 0.5 | 1195 | [64] |

| - | 500 | 2 | 640 | |||

| 26 | Cathode conductivity using polypyrrole and tin oxide nanoparticles | 75 | 500 | 1 | - | [65] |

| 90 | - | 5 | 383.7 | |||

| 27 | Mesoporous silica framework with polypyrrole having NiO nanoparticles in it | - | 300 | - | 700 | [66] |

| 28 | a polymer-encapsulated sulfur cathode | 74 | 600 | 2 | - | [67] |

| 29 | Polypropylene as a scaffold for a polysulfide-blocking separator layer | - 60 - | - 500 100 | - 1 0.5 | 938 - 601.3 | [68] |

| High sulfur loading (3.2 mg cm−2) | ||||||

| 30 | Gelatin-carbon nanofiber interlayers with high sulfur loading at the cathode (9.4 mg cm−2) | - | 100 | 0.1 | - | [69] |

| 31 | Carbon nanofibers interlayer with konjac glucomannan | - | - | 0.2 | 1286 | [70] |

| 84 | 400 | 1 | - | |||

| 32 | Sodium alginate derivative affinity laminated chromatography membrane layers | - | - | 0.1 | 1492 | [71] |

| 76 | 200 | 0.2 | - | |||

| high-loading electrodes | - | - | 0.05 | 1302 | ||

| 95.2 | 40 | 0.1 | - | |||

| 33 | Separator made of urea and amylose in the presence of nickel chloride with high cathode loading (7 mg cm−2) | 95.7 | 100 | 4 | 714 | [72] |

| 34 | Polymeric zwitterion interlayer | 88 | 1000 | - | - | [73] |

| - | 300 | - | - | |||

| 35 | Oxygen content influence in corncob with sulfur composite cathode | - | - | - | 1504 | [74] |

| - | 200 | 0.3 | 799 | |||

| 36 | Sulfurized polyacrylonitrile with C nanotubes and conductive CoS2 cathode with sulfur loading of (5.9 mg cm−2) | - | - | - | 1322 | [75] |

| 37 | Carbon nitride as components of a metal organic framework (MOF) that served as a separator layer | 88 | 12,000 | 0.2 | 1532.1 | [52] |

| 1.0/2.0 | 1000 | |||||

| 38 | Nitrogen doped into MOF as cathode | 86 | 500 | 1 | - | [52] |

| 5 | 600 | |||||

| 39 | Ultrathin sheets of MOF | 58 | 600 | - | 641 | [52] |

| 40 | MOF utilized carbon cloth, graphene nanocloth, and cobalt phosphide components grown on graphene | - | - | 3 | 930.1 | [52] |

| 85 | 500 | 2 | ||||

| (sulfur at a loading of 2 mg cm−2) (higher sulfur loadings of up to 10.83 mg cm−2) | 0.05 | 813.5 | ||||

| 41 | Nitrogen-rich MOF as cathode with iron nanoparticles | - | - | 0.2 | 1123 | [52] |

| 70 | 500 | - | 605 | |||

| 42 | CoMn2O4 microspheres as sulfur hosts in the cathode | - | - | - | 524.3 | [52] |

| 43 | Lithium sulfide in a three-dimensional mesoporous carbon architecture | - | - | 0.1 | 848 | [52] |

| 400 | 2 | 410 | ||||

| 44 | Hollow spheres of titanium oxide and titanium nitride | 99 | 500 | - | 1254 | [52] |

| 45 | ZIF-67 fiber material (conjunction with cobalt nanoparticles and dicyandiamides) | 100 | 0.1 | 867.44 | [76] | |

| 46 | ZIF-67 framework (Li2S6 containing catholyte current collector) (high sulfur loading of 4.74 mg/cm−2) (sulfur loading 7.11 mg/cm−2) | 300 | 0.2 | 1166 938 910 | [77] | |

| 47 | Co3S4/MnS nanotubes(sulfur loading of 3.2 g cm−2) | 95 | 200 | - | [78,79] | |

| 48 | Ni3S2 fabricated into a N/S-doped reduced graphene oxide | 77 | 1000 | 3 | 1158.6 | [80] |

| 49 | One hollow architecture comprising a combination of zinc sulfide and iron sulfide encapsulated in a nitrogen doped carbon structure | 4 | 718 | [81,82] | ||

| 200 | 0.2 | 822 | ||||

| 50 | MnS-nanofiber interlayer(sulfur loading of 2 mg cm−2) | 400 | 1 | 714 | [83] | |

| 100 | 0.5 | 894 | ||||

| 51 | Ruthenium-Mo4P3 nanoparticles on carbon nanospheres (high sulfur loading of up to 6.6 mg cm−2) | 50 | 0.5 4 | 1178 660 | [84] | |

| 52 | Ni2Co4P3 species (sulfur loading of 25 mg cm−2) | 0.1 | 1223 | [85] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lopez, C.V.; Maladeniya, C.P.; Smith, R.C. Lithium-Sulfur Batteries: Advances and Trends. Electrochem 2020, 1, 226-259. https://doi.org/10.3390/electrochem1030016

Lopez CV, Maladeniya CP, Smith RC. Lithium-Sulfur Batteries: Advances and Trends. Electrochem. 2020; 1(3):226-259. https://doi.org/10.3390/electrochem1030016

Chicago/Turabian StyleLopez, Claudia V., Charini P. Maladeniya, and Rhett C. Smith. 2020. "Lithium-Sulfur Batteries: Advances and Trends" Electrochem 1, no. 3: 226-259. https://doi.org/10.3390/electrochem1030016

APA StyleLopez, C. V., Maladeniya, C. P., & Smith, R. C. (2020). Lithium-Sulfur Batteries: Advances and Trends. Electrochem, 1(3), 226-259. https://doi.org/10.3390/electrochem1030016