Wearable Nanogenerators: Working Principle and Self-Powered Biosensors Applications

Abstract

1. Introduction

2. Working Principles

2.1. Piezoelectric Nanogenerators (PENGs)

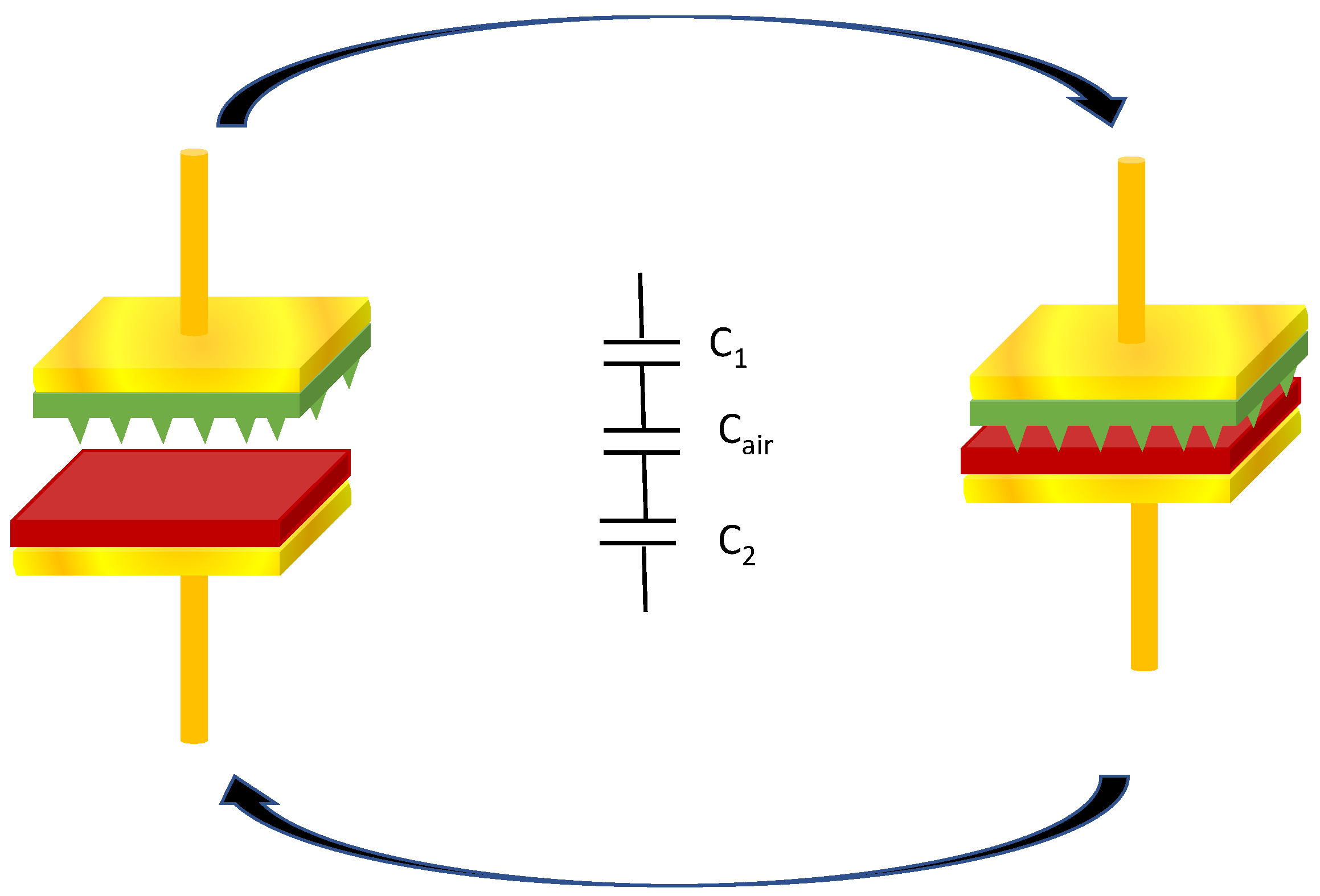

2.2. Triboelectric Nanogenerators (TENGs)

2.3. Hybrid Wearable Nanogenerators

3. Self-Powered Biosensors Based on Nanogenerators

3.1. Glucose Detection

3.2. Thrombin Detection

3.3. SARS-COV-2 Detection

4. Challenges and Future Perspectives

- (i)

- The production of polymeric templates (or materials with corresponding flexibility) with outstanding piezoelectric and triboelectric coefficients;

- (ii)

- The incorporation of energy harvesting systems in all-in-one textile devices with batteries and supercapacitors;

- (iii)

- The incorporation of antigens and specific binders in piezo- and triboelectricity nanogenerators to reach a desirable condition of point-of-care detection of viruses;

- (iv)

- The reduction in the costs for the massive production of energy harvesting and self-powered sensors.

5. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kim, W.G.; Han, J.K.; Tcho, I.W.; Park, J.Y.; Yu, J.M.; Choi, Y.K. Triboelectric Nanogenerator for a Repairable Transistor with Self-Powered Electro-Thermal Annealing. Nano Energy 2020, 76, 105000. [Google Scholar] [CrossRef]

- Miorandi, D.; Sicari, S.; De Pellegrini, F.; Chlamtac, I. Internet of Things: Vision, Applications and Research Challenges. Ad Hoc Netw. 2012, 10, 1497–1516. [Google Scholar] [CrossRef]

- Da Xu, L.; He, W.; Li, S. Internet of Things in Industries: A Survey. IEEE Trans. Ind. Inform. 2014, 10, 2233–2243. [Google Scholar] [CrossRef]

- Wu, Z.; Cheng, T.; Wang, Z.L. Self-Powered Sensors and Systems Based on Nanogenerators. Sensors 2020, 20, 2925. [Google Scholar] [CrossRef]

- Batty, M.; Axhausen, K.W.; Giannotti, F.; Pozdnoukhov, A.; Bazzani, A.; Wachowicz, M.; Ouzounis, G.; Portugali, Y. Smart Cities of the Future. Eur. Phys. J. Spec. Top. 2012, 214, 481–518. [Google Scholar] [CrossRef]

- Zanella, A.; Bui, N.; Castellani, A.; Vangelista, L.; Zorzi, M. Internet of Things for Smart Cities. IEEE Internet Things J. 2014, 1, 22–32. [Google Scholar] [CrossRef]

- Al Mamun, M.A.; Yuce, M.R. Recent Progress in Nanomaterial Enabled Chemical Sensors for Wearable Environmental Monitoring Applications. Adv. Funct. Mater. 2020, 30, 2005703. [Google Scholar] [CrossRef]

- Ho, D.H.; Han, J.; Huang, J.; Choi, Y.Y.; Cheon, S.; Sun, J.; Lei, Y.; Park, G.S.; Wang, Z.L.; Sun, Q.; et al. β-Phase-Preferential Blow-Spun Fabrics for Wearable Triboelectric Nanogenerators and Textile Interactive Interface. Nano Energy 2020, 77, 105262. [Google Scholar] [CrossRef]

- Jiang, L.; Yang, Y.; Chen, Y.; Zhou, Q. Ultrasound-Induced Wireless Energy Harvesting: From Materials Strategies to Functional Applications. Nano Energy 2020, 77, 105131. [Google Scholar] [CrossRef]

- Zou, Y.; Raveendran, V.; Chen, J. Wearable Triboelectric Nanogenerators for Biomechanical Energy Harvesting. Nano Energy 2020, 77, 105303. [Google Scholar] [CrossRef]

- Lin, Z.; Chen, J.; Yang, J. Recent Progress in Triboelectric Nanogenerators as a Renewable and Sustainable Power Source. J. Nanomater. 2016, 2016, 1–24. [Google Scholar] [CrossRef]

- Wang, J.; Li, S.; Yi, F.; Zi, Y.; Lin, J.; Wang, X.; Xu, Y.; Wang, Z.L. Sustainably Powering Wearable Electronics Solely by Biomechanical Energy. Nat. Commun. 2016, 7, 12744. [Google Scholar] [CrossRef] [PubMed]

- Paosangthong, W.; Torah, R.; Beeby, S. Textile-Based Freestanding Triboelectric-Layer Nanogenerator with Alternate Positive and Negative Grating Structure. J. Phys. Conf. Ser. 2019, 1407. [Google Scholar] [CrossRef]

- Li, Z.; Zheng, Q.; Wang, Z.L.; Li, Z. Nanogenerator-Based Self-Powered Sensors for Wearable and Implantable Electronics. Research 2020, 2020, 1–25. [Google Scholar] [CrossRef] [PubMed]

- Shi, B.; Liu, Z.; Zheng, Q.; Meng, J.; Ouyang, H.; Zou, Y.; Jiang, D.; Qu, X.; Yu, M.; Zhao, L.; et al. Body-Integrated Self-Powered System for Wearable and Implantable Applications. ACS Nano 2019, 13, 6017–6024. [Google Scholar] [CrossRef] [PubMed]

- Zou, Y.; Liao, J.; Ouyang, H.; Jiang, D.; Zhao, C.; Li, Z.; Qu, X.; Liu, Z.; Fan, Y.; Shi, B.; et al. A Flexible Self-Arched Biosensor Based on Combination of Piezoelectric and Triboelectric Effects. Appl. Mater. Today 2020, 20, 100699. [Google Scholar] [CrossRef]

- Selvarajan, S.; Alluri, N.R.; Chandrasekhar, A.; Kim, S.J. Unconventional Active Biosensor Made of Piezoelectric BaTiO3 Nanoparticles for Biomolecule Detection. Sens. Actuators B Chem. 2017, 253, 1180–1187. [Google Scholar] [CrossRef]

- Mao, Y.; Yue, W.; Zhao, T.; Shen, M.L.; Liu, B.; Chen, S. A Self-Powered Biosensor for Monitoring Maximal Lactate Steady State in Sport Training. Biosensors 2020, 10, 75. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, S.; Jin, Y.M.; Ouyang, H.; Zou, Y.; Wang, X.X.; Xie, L.X.; Li, Z. Flexible Piezoelectric Nanogenerator in Wearable Self-Powered Active Sensor for Respiration and Healthcare Monitoring. Semicond. Sci. Technol. 2017, 32, 064004. [Google Scholar] [CrossRef]

- Xiong, W.; Hu, K.; Li, Z.; Jiang, Y.; Li, Z.; Li, Z.; Wang, X. A Wearable System Based on Core-Shell Structured Peptide-Co9S8 Supercapacitor and Triboelectric Nanogenerator. Nano Energy 2019, 66, 104149. [Google Scholar] [CrossRef]

- Zhu, Q.; Li, Y.; He, Y.; Guan, M. Piezoelectric Energy Harvesting in Automobiles. Ferroelectrics 2014, 467, 33–41. [Google Scholar] [CrossRef]

- Nilsson, E.; Mateu, L.; Spies, P.; Hagstrom, B. Energy Harvesting from Piezoelectric Textile Fibers. Procedia Eng. 2014, 87, 1569–1572. [Google Scholar] [CrossRef]

- Dakua, I.; Afzulpurkar, N. Piezoelectric Energy Generation and Harvesting at the Nano-Scale: Materials and Devices. Nanomater. Nanotechnol. 2013, 3, 21. [Google Scholar] [CrossRef]

- Sirohi, J.; Mahadik, R. Piezoelectric Wind Energy Harvester for Low-Power Sensors. J. Intell. Mater. Syst. Struct. 2011, 22, 2215–2228. [Google Scholar] [CrossRef]

- You, M.H.; Wang, X.X.; Yan, X.; Zhang, J.; Song, W.Z.; Yu, M.; Fan, Z.Y.; Ramakrishna, S.; Long, Y.Z. A Self-Powered Flexible Hybrid Piezoelectric-Pyroelectric Nanogenerator Based on Non-Woven Nanofiber Membranes. J. Mater. Chem. A 2018, 6, 3500–3509. [Google Scholar] [CrossRef]

- Dong, L.; Jin, C.; Closson, A.B.; Trase, I.; Richards, H.R.; Chen, Z.; Zhang, J.X.J. Cardiac Energy Harvesting and Sensing Based on Piezoelectric and Triboelectric Designs. Nano Energy 2020, 76, 105076. [Google Scholar] [CrossRef]

- Yang, L.; Chi, S.; Dong, S.; Yuan, F.; Wang, Z.; Lei, J.; Bao, L.; Xiang, J.; Wang, J. Preparation and Characterization of a Novel Piezoelectric Nanogenerator Based on Soluble and Meltable Copolyimide for Harvesting Mechanical Energy. Nano Energy 2020, 67, 104220. [Google Scholar] [CrossRef]

- Gong, S.; Zhang, B.; Zhang, J.; Wang, Z.L.; Ren, K. Biocompatible Poly(Lactic Acid)-Based Hybrid Piezoelectric and Electret Nanogenerator for Electronic Skin Applications. Adv. Funct. Mater. 2020, 30, 30. [Google Scholar] [CrossRef]

- Malmonge, L.F.; Malmonge, J.A.; Sakamoto, W.K. Study of Pyroelectric Activity of PZT/PVDF-HFP Composite. Mater. Res. 2003, 6, 469–473. [Google Scholar] [CrossRef]

- Guo, H.-F.; Li, Z.-S.; Dong, S.-W.; Chen, W.-J.; Deng, L.; Wang, Y.-F.; Ying, D.-J. Piezoelectric PU/PVDF Electrospun Scaffolds for Wound Healing Applications. Colloids Surf. B Biointerfaces 2012, 96, 29–36. [Google Scholar] [CrossRef]

- Ponnamma, D.; Chamakh, M.M.; Alahzm, A.M.; Salim, N.; Hameed, N.; Almaadeed, M.A.A. Core-Shell Nanofibers of Polyvinylidene Fluoride-Based Nanocomposites as Piezoelectric Nanogenerators. Polymers 2020, 12, 2344. [Google Scholar] [CrossRef]

- Mago, G.; Kalyon, D.M.; Fisher, F.T. Membranes of Polyvinylidene Fluoride and PVDF Nanocomposites with Carbon Nanotubes via Immersion Precipitation. J. Nanomater. 2008, 2008. [Google Scholar] [CrossRef]

- Li, Y.; Xiong, J.; Lv, J.; Chen, J.; Gao, D.; Zhang, X.; Lee, P.S. Mechanically Interlocked Stretchable Nanofibers for Multifunctional Wearable Triboelectric Nanogenerator. Nano Energy 2020, 78, 105358. [Google Scholar] [CrossRef]

- De A. B. Barbosa, J.; dos Santos, M.R.; de Oliveira, H.P. Electrospun Fibers of Copolymers for the Removal of Ionic Dyes: The Influence of Processing Variables. Fibers Polym. 2018, 19, 94–104. [Google Scholar] [CrossRef]

- Huang, T.; Wang, C.; Yu, H.; Wang, H.; Zhang, Q.; Zhu, M. Human Walking-Driven Wearable All-Fiber Triboelectric Nanogenerator Containing Electrospun Polyvinylidene Fluoride Piezoelectric Nanofibers. Nano Energy 2014, 14, 226–235. [Google Scholar] [CrossRef]

- Zhou, Z.; Zhang, Z.; Zhang, Q.; Yang, H.; Zhu, Y.; Wang, Y.; Chen, L. Controllable Core-Shell BaTiO3@Carbon Nanoparticle-Enabled P(VDF-TrFE) Composites: A Cost-Effective Approach to High-Performance Piezoelectric Nanogenerators. ACS Appl. Mater. Interfaces 2020, 12, 1567–1576. [Google Scholar] [CrossRef]

- Zhang, L.; Gui, J.; Wu, Z.; Li, R.; Wang, Y.; Gong, Z.; Zhao, X.; Sun, C.; Guo, S. Enhanced Performance of Piezoelectric Nanogenerator Based on Aligned Nanofibers and Three-Dimensional Interdigital Electrodes. Nano Energy 2019, 65. [Google Scholar] [CrossRef]

- Zhao, C.; Niu, J.; Zhang, Y.; Li, C.; Hu, P. Coaxially Aligned MWCNTs Improve Performance of Electrospun P(VDF-TrFE)-Based Fibrous Membrane Applied in Wearable Piezoelectric Nanogenerator. Compos. Part B Eng. 2019, 178, 107447. [Google Scholar] [CrossRef]

- Gupta, S.; Bhunia, R.; Fatma, B.; Maurya, D.; Singh, D.; Prateek, P.; Gupta, R.; Priya, S.; Gupta, R.K.; Garg, A. Multifunctional and Flexible Polymeric Nanocomposite Films with Improved Ferroelectric and Piezoelectric Properties for Energy Generation Devices. ACS Appl. Energy Mater. 2019, 2, 6364–6374. [Google Scholar] [CrossRef]

- Ye, S.; Cheng, C.; Chen, X.; Chen, X.; Shao, J.; Zhang, J.; Hu, H.; Tian, H.; Li, X.; Ma, L.; et al. High-Performance Piezoelectric Nanogenerator Based on Microstructured P(VDF-TrFE)/BNNTs Composite for Energy Harvesting and Radiation Protection in Space. Nano Energy 2019, 60, 701–714. [Google Scholar] [CrossRef]

- Siddiqui, S.; Kim, D.I.; Roh, E.; Duy, L.T.; Trung, T.Q.; Nguyen, M.T.; Lee, N.E. A Durable and Stable Piezoelectric Nanogenerator with Nanocomposite Nanofibers Embedded in an Elastomer under High Loading for a Self-Powered Sensor System. Nano Energy 2016, 30, 434–442. [Google Scholar] [CrossRef]

- Siddiqui, S.; Kim, D., II; Duy, L.T.; Nguyen, M.T.; Muhammad, S.; Yoon, W.S.; Lee, N.E. High-Performance Flexible Lead-Free Nanocomposite Piezoelectric Nanogenerator for Biomechanical Energy Harvesting and Storage. Nano Energy 2015, 15, 177–185. [Google Scholar] [CrossRef]

- Ponnamma, D.; Parangusan, H.; Tanvir, A.; AlMa’adeed, M.A.A. Smart and Robust Electrospun Fabrics of Piezoelectric Polymer Nanocomposite for Self-Powering Electronic Textiles. Mater. Des. 2019, 184, 108176. [Google Scholar] [CrossRef]

- Tian, X.; Jiang, X. Poly(Vinylidene Fluoride-Co-Hexafluoropropene) (PVDF-HFP) Membranes for Ethyl Acetate Removal from Water. J. Hazard. Mater. 2008, 153, 128–135. [Google Scholar] [CrossRef]

- Abbrent, S.; Plestil, J.; Hlavata, D.; Lindgren, J.; Tegenfeldt, J.; Wendsjö, Å. Crystallinity and Morphology of PVdF-HFP-Based Gel Electrolytes. Polymer 2001, 42, 1407–1416. [Google Scholar] [CrossRef]

- Cao, J.H.; Zhu, B.K.; Xu, Y.Y. Structure and Ionic Conductivity of Porous Polymer Electrolytes Based on PVDF-HFP Copolymer Membranes. J. Membr. Sci. 2006, 281, 446–453. [Google Scholar] [CrossRef]

- Parangusan, H.; Ponnamma, D.; Al-Maadeed, M.A.A. Stretchable Electrospun PVDF-HFP/Co-ZnO Nanofibers as Piezoelectric Nanogenerators. Sci. Rep. 2018, 8, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Chinya, I.; Pal, A.; Sen, S. Flexible, Hybrid Nanogenerator Based on Zinc Ferrite Nanorods Incorporated Poly(Vinylidene Fluoride-Co-Hexafluoropropylene) Nanocomposite for Versatile Mechanical Energy Harvesting. Mater. Res. Bull. 2019, 118, 110515. [Google Scholar] [CrossRef]

- Chen, C.Y.; Tsai, C.Y.; Xu, M.H.; Wu, C.T.; Huang, C.Y.; Lee, T.H.; Fuh, Y.K. A Fully Encapsulated Piezoelectric-Triboelectric Hybrid Nanogenerator for Energy Harvesting from Biomechanical and Environmental Sources. Express Polym. Lett. 2019, 13, 533–542. [Google Scholar] [CrossRef]

- Shi, K.; Sun, B.; Huang, X.; Jiang, P. Synergistic Effect of Graphene Nanosheet and BaTiO3 Nanoparticles on Performance Enhancement of Electrospun PVDF Nanofiber Mat for Flexible Piezoelectric Nanogenerators. Nano Energy 2018, 52, 153–162. [Google Scholar] [CrossRef]

- Yu, J.; Hou, X.; Cui, M.; Zhang, N.; Zhang, S.; He, J.; Chou, X. Skin-Conformal BaTiO3/Ecoflex-Based Piezoelectric Nanogenerator for Self-Powered Human Motion Monitoring. Mater. Lett. 2020, 269, 127686. [Google Scholar] [CrossRef]

- Zhang, W.; Yang, H.; Li, L.; Lin, S.; Ji, P.; Hu, C.; Zhang, D.; Xi, Y. Flexible Piezoelectric Nanogenerators Based on a CdS Nanowall for Self-Powered Sensors. Nanotechnology 2020, 31, 385401. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Chen, Y.; Guo, J. ZnO Nanorods Patterned-Textile Using a Novel Hydrothermal Method for Sandwich Structured-Piezoelectric Nanogenerator for Human Energy Harvesting. Phys. E Low-Dimens. Syst. Nanostruct. 2019, 105, 212–218. [Google Scholar] [CrossRef]

- Dai, Q.; Pan, P.; Zhang, R.; Liu, J.; Yang, Z.; Wei, J.; Yuan, Q. A Screen-Printed Piezoelectric Energy Harvester Using Zno Tetrapod Arrays. Mater. Technol. 2018, 52, 231–234. [Google Scholar]

- Wang, Y.; Zhang, X.; Guo, X.; Li, D.; Cui, B.; Wu, K.; Yun, J.; Mao, J.; Xi, L.; Zuo, Y. Hybrid Nanogenerator of BaTiO3 Nanowires and CNTs for Harvesting Energy. J. Mater. Sci. 2018, 53, 13081–13089. [Google Scholar] [CrossRef]

- Jella, V.; Ippili, S.; Yoon, S.-G. Halide (Cl/Br)-Incorporated Organic–Inorganic Metal Trihalide Perovskite Films: Study and Investigation of Dielectric Properties and Mechanical Energy Harvesting Performance. ACS Appl. Electron. Mater. 2020, 2, 2579–2590. [Google Scholar] [CrossRef]

- Fan, F.-R.; Tian, Z.-Q.; Lin Wang, Z. Flexible Triboelectric Generator. Nano Energy 2012, 1, 328–334. [Google Scholar] [CrossRef]

- An, T.; Anaya, D.V.; Gong, S.; Yap, L.W.; Lin, F.; Wang, R.; Yuce, M.R.; Cheng, W. Self-Powered Gold Nanowire Tattoo Triboelectric Sensors for Soft Wearable Human-Machine Interface. Nano Energy 2020, 77, 105295. [Google Scholar] [CrossRef]

- Kim, J.; Cho, H.; Han, M.; Jung, Y.; Kwak, S.S.; Yoon, H.J.; Park, B.; Kim, H.; Kim, H.; Park, J.; et al. Ultrahigh Power Output from Triboelectric Nanogenerator Based on Serrated Electrode via Spark Discharge. Adv. Energy Mater. 2020, 10. [Google Scholar] [CrossRef]

- Ra, Y.; Choi, J.H.; Choi, S.J.; La, M.; Park, S.J.; Kim, M.J.; Choi, D. Cold Rolled Robust Metal Assisted Triboelectric Nanogenerator for Extremely Durable Operation. Extrem. Mech. Lett. 2020, 40, 100910. [Google Scholar] [CrossRef]

- Niu, L.; Miao, X.; Jiang, G.; Wan, A.; Li, Y.; Liu, Q. Biomechanical Energy Harvest Based on Textiles Used in Self-Powering Clothing. J. Eng. Fiber. Fabr. 2020, 15. [Google Scholar] [CrossRef]

- Bayan, S.; Bhattacharya, D.; Mitra, R.K.; Ray, S.K. Two-Dimensional Graphitic Carbon Nitride Nanosheets: A Novel Platform for Flexible, Robust and Optically Active Triboelectric Nanogenerators. Nanoscale 2020, 12, 21334–21343. [Google Scholar] [CrossRef] [PubMed]

- Zou, H.; Guo, L.; Xue, H.; Zhang, Y.; Shen, X.; Liu, X.; Wang, P.; He, X.; Dai, G.; Jiang, P.; et al. Quantifying and Understanding the Triboelectric Series of Inorganic Non-Metallic Materials. Nat. Commun. 2020, 11. [Google Scholar] [CrossRef] [PubMed]

- Yuan, F.; Liu, S.; Zhou, J.; Fan, X.; Wang, S.; Gong, X. A Smart Kevlar-Based Triboelectric Nanogenerator with Enhanced Anti-Impact and Self-Powered Sensing Properties. Smart Mater. Struct. 2020, 29, 125007. [Google Scholar] [CrossRef]

- Salauddin, M.; Rana, S.M.S.; Sharifuzzaman, M.; Rahman, M.T.; Park, C.; Cho, H.; Maharjan, P.; Bhatta, T.; Park, J.Y. A Novel MXene/Ecoflex Nanocomposite-Coated Fabric as a Highly Negative and Stable Friction Layer for High-Output Triboelectric Nanogenerators. Adv. Energy Mater. 2020. [Google Scholar] [CrossRef]

- Sahu, M.; Vivekananthan, V.; Hajra, S.; Abisegapriyan, K.S.; Maria Joseph Raj, N.P.; Kim, S.J. Synergetic Enhancement of Energy Harvesting Performance in Triboelectric Nanogenerator Using Ferroelectric Polarization for Self-Powered IR Signaling and Body Activity Monitoring. J. Mater. Chem. A 2020, 8, 22257–22268. [Google Scholar] [CrossRef]

- Mariappan, V.K.; Krishnamoorthy, K.; Pazhamalai, P.; Natarajan, S.; Sahoo, S.; Nardekar, S.S.; Kim, S.J. Antimonene Dendritic Nanostructures: Dual-Functional Material for High-Performance Energy Storage and Harvesting Devices. Nano Energy 2020, 77, 105248. [Google Scholar] [CrossRef]

- Qu, X.; Ma, X.; Shi, B.; Li, H.; Zheng, L.; Wang, C.; Liu, Z.; Fan, Y.; Chen, X.; Li, Z.; et al. Refreshable Braille Display System Based on Triboelectric Nanogenerator and Dielectric Elastomer. Adv. Funct. Mater. 2020. [Google Scholar] [CrossRef]

- Su, M.; Kim, B. Silk Fibroin-Carbon Nanotube Composites Based Fiber Substrated Wearable Triboelectric Nanogenerator. ACS Appl. Nano Mater. 2020, 3, 9759–9770. [Google Scholar] [CrossRef]

- Pu, X.; Liu, M.; Chen, X.; Sun, J.; Du, C.; Zhang, Y.; Zhai, J.; Hu, W.; Wang, Z.L. Ultrastretchable, Transparent Triboelectric Nanogenerator as Electronic Skin for Biomechanical Energy Harvesting and Tactile Sensing. Sci. Adv. 2017, 3, e1700015. [Google Scholar] [CrossRef]

- He, X.; Zi, Y.; Guo, H.; Zheng, H.; Xi, Y.; Wu, C.; Wang, J.; Zhang, W.; Lu, C.; Wang, Z.L. A Highly Stretchable Fiber-Based Triboelectric Nanogenerator for Self-Powered Wearable Electronics. Adv. Funct. Mater. 2017, 27. [Google Scholar] [CrossRef]

- Pu, X.; Li, L.; Song, H.; Du, C.; Zhao, Z.; Jiang, C.; Cao, G.; Hu, W.; Wang, Z.L. A Self-Charging Power Unit by Integration of a Textile Triboelectric Nanogenerator and a Flexible Lithium-Ion Battery for Wearable Electronics. Adv. Mater. 2015, 27, 2472–2478. [Google Scholar] [CrossRef] [PubMed]

- Park, J.; Kim, D.; Kim, Y.T. Ultra-Stretchable on-Body-Based Soft Triboelectric Nanogenerator for Electronic Skin. Smart Mater. Struct. 2020, 29, 115031. [Google Scholar] [CrossRef]

- Xu, Y.; Min, G.; Gadegaard, N.; Dahiya, R.; Mulvihill, D.M. A Unified Contact Force-Dependent Model for Triboelectric Nanogenerators Accounting for Surface Roughness. Nano Energy 2020, 76, 105067. [Google Scholar] [CrossRef]

- He, T.; Wang, H.; Wang, J.; Tian, X.; Wen, F.; Shi, Q.; Ho, J.S.; Lee, C. Self-Sustainable Wearable Textile Nano-Energy Nano-System (NENS) for Next-Generation Healthcare Applications. Adv. Sci. 2019, 6, 1901437. [Google Scholar] [CrossRef]

- Jiang, Y.; Dong, K.; Li, X.; An, J.; Wu, D.; Peng, X.; Yi, J.; Ning, C.; Cheng, R.; Yu, P.; et al. Stretchable, Washable, and Ultrathin Triboelectric Nanogenerators as Skin-Like Highly Sensitive Self-Powered Haptic Sensors. Adv. Funct. Mater. 2020, 31, 2005584. [Google Scholar] [CrossRef]

- Tayyab, M.; Wang, J.; Wang, J.; Maksutoglu, M.; Yu, H.; Sun, G.; Yildiz, F.; Eginligil, M.; Huang, W. Enhanced Output in Polyvinylidene Fluoride Nanofibers Based Triboelectric Nanogenerator by Using Printer Ink as Nano-Fillers. Nano Energy 2020, 77, 105178. [Google Scholar] [CrossRef]

- Jin, L.; Xiao, X.; Deng, W.; Nashalian, A.; He, D.; Raveendran, V.; Yan, C.; Su, H.; Chu, X.; Yang, T.; et al. Manipulating Relative Permittivity for High-Performance Wearable Triboelectric Nanogenerators. Nano Lett. 2020. [Google Scholar] [CrossRef]

- Wang, N.; Wang, X.-X.; Yan, K.; Song, W.; Fan, Z.; Yu, M.; Long, Y.-Z. Anisotropic Triboelectric Nanogenerator Based on Ordered Electrospinning. ACS Appl. Mater. Interfaces 2020, 12, 46205–46211. [Google Scholar] [CrossRef]

- Park, K.-I.; Jeong, C.K.; Kim, N.K.; Lee, K.J. Stretchable Piezoelectric Nanocomposite Generator. Nano Converg. 2016. [Google Scholar] [CrossRef]

- Dong, S.; Xu, F.; Sheng, Y.; Guo, Z.; Pu, X.; Liu, Y. Seamlessly Knitted Stretchable Comfortable Textile Triboelectric Nanogenerators for E-Textile Power Sources. Nano Energy 2020, 78, 105327. [Google Scholar] [CrossRef]

- Gong, H.; Xu, Z.; Yang, Y.; Xu, Q.; Li, X.; Cheng, X.; Huang, Y.; Zhang, F.; Zhao, J.; Li, S.; et al. Transparent, Stretchable and Degradable Protein Electronic Skin for Biomechanical Energy Scavenging and Wireless Sensing. Biosens. Bioelectron. 2020, 169, 112567. [Google Scholar] [CrossRef] [PubMed]

- Pan, C.; Liu, D.; Ford, M.J.; Majidi, C. Ultrastretchable, Wearable Triboelectric Nanogenerator Based on Sedimented Liquid Metal Elastomer Composite. Adv. Mater. Technol. 2020, 5. [Google Scholar] [CrossRef]

- Bai, Z.; Xu, Y.; Li, J.; Zhu, J.; Gao, C.; Zhang, Y.; Wang, J.; Guo, J. An Eco-Friendly Porous Nanocomposite Fabric-Based Triboelectric Nanogenerator for Efficient Energy Harvesting and Motion Sensing. ACS Appl. Mater. Interfaces 2020, 12, 42880–42890. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Q.; Dong, L.; Zhang, J.; Xu, K.; Zhang, Y.; Shi, H.; Lu, H.; Wu, Y.; Zheng, H.; Wang, Z. All-in-One Hybrid Tribo/Piezoelectric Nanogenerator with the Point Contact and Its Adjustable Charge Transfer by Ferroelectric Polarization. Ceram. Int. 2020, 46, 28277–28284. [Google Scholar] [CrossRef]

- Guo, Y.; Zhang, X.S.; Wang, Y.; Gong, W.; Zhang, Q.; Wang, H.; Brugger, J. All-Fiber Hybrid Piezoelectric-Enhanced Triboelectric Nanogenerator for Wearable Gesture Monitoring. Nano Energy 2018, 48, 152–160. [Google Scholar] [CrossRef]

- Zhu, J.; Zhu, Y.; Wang, X. A Hybrid Piezoelectric and Triboelectric Nanogenerator with PVDF Nanoparticles and Leaf-Shaped Microstructure PTFE Film for Scavenging Mechanical Energy. Adv. Mater. Interfaces 2018, 5. [Google Scholar] [CrossRef]

- Zhu, J.; Hou, X.; Niu, X.; Guo, X.; Zhang, J.; He, J.; Guo, T.; Chou, X.; Xue, C.; Zhang, W. The D-Arched Piezoelectric-Triboelectric Hybrid Nanogenerator as a Self-Powered Vibration Sensor. Sens. Actuators A Phys. 2017, 263, 317–325. [Google Scholar] [CrossRef]

- Chen, X.; Song, Y.; Su, Z.; Chen, H.; Cheng, X.; Zhang, J.; Han, M.; Zhang, H. Flexible Fiber-Based Hybrid Nanogenerator for Biomechanical Energy Harvesting and Physiological Monitoring. Nano Energy 2017, 38, 43–50. [Google Scholar] [CrossRef]

- Lee, D.W.; Jeong, D.G.; Kim, J.H.; Kim, H.S.; Murillo, G.; Lee, G.H.; Song, H.C.; Jung, J.H. Polarization-Controlled PVDF-Based Hybrid Nanogenerator for an Effective Vibrational Energy Harvesting from Human Foot. Nano Energy 2020, 76, 105066. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, J.; Zhang, Y.; Chen, F.; Wang, H.; Wu, M.; Li, H.; Zhu, Q.; Zheng, H.; Zhang, R. Remarkably Enhanced Hybrid Piezo/Triboelectric Nanogenerator via Rational Modulation of Piezoelectric and Dielectric Properties for Self-Powered Electronics. Appl. Phys. Lett. 2020, 116, 023901. [Google Scholar] [CrossRef]

- Li, M.; Jie, Y.; Shao, L.H.; Guo, Y.; Cao, X.; Wang, N.; Wang, Z.L. All-in-One Cellulose Based Hybrid Tribo/Piezoelectric Nanogenerator. Nano Res. 2019, 12, 1831–1835. [Google Scholar] [CrossRef]

- Rasel, M.S.; Maharjan, P.; Park, J.Y. Hand Clapping Inspired Integrated Multilayer Hybrid Nanogenerator as a Wearable and Universal Power Source for Portable Electronics. Nano Energy 2019, 63, 103816. [Google Scholar] [CrossRef]

- Chowdhury, A.R.; Abdullah, A.M.; Hussain, I.; Lopez, J.; Cantu, D.; Gupta, S.K.; Mao, Y.; Danti, S.; Uddin, M.J. Lithium Doped Zinc Oxide Based Flexible Piezoelectric-Triboelectric Hybrid Nanogenerator. Nano Energy 2019, 61, 327–336. [Google Scholar] [CrossRef]

- Lapčinskis, L.; Mā Lnieks, K.; Linarts, A.; Blū Ms, J.; Šmits, K.N.; Järvekülg, M.; Knite, M.R.; Šutka, A. Hybrid Tribo-Piezo-Electric Nanogenerator with Unprecedented Performance Based on Ferroelectric Composite Contacting Layers. ACS Appl. Energy Mater. 2019, 2, 4027–4032. [Google Scholar] [CrossRef]

- Singh, H.H.; Khare, N. Flexible ZnO-PVDF/PTFE Based Piezo-Tribo Hybrid Nanogenerator. Nano Energy 2018, 51, 216–222. [Google Scholar] [CrossRef]

- Song, J.; Yang, B.; Zeng, W.; Peng, Z.; Lin, S.; Li, J.; Tao, X. Highly Flexible, Large-Area, and Facile Textile-Based Hybrid Nanogenerator with Cascaded Piezoelectric and Triboelectric Units for Mechanical Energy Harvesting. Adv. Mater. Technol. 2018, 3. [Google Scholar] [CrossRef]

- Jo, S.; Kim, I.; Byun, J.; Jayababu, N.; Kim, D. Boosting a Power Performance of a Hybrid Nanogenerator via Frictional Heat Combining a Triboelectricity and Thermoelectricity toward Advanced Smart Sensors. Adv. Mater. Technol. 2020, 6, 2000752. [Google Scholar] [CrossRef]

- Wu, Y.; Kuang, S.; Li, H.; Wang, H.; Yang, R.; Zhai, Y.; Zhu, G.; Wang, Z.L. Triboelectric–Thermoelectric Hybrid Nanogenerator for Harvesting Energy from Ambient Environments. Adv. Mater. Technol. 2018, 3, 1800166. [Google Scholar] [CrossRef]

- Jung, S.; Oh, J.; Yang, U.J.; Lee, S.M.; Lee, J.; Jeong, M.; Cho, Y.; Kim, S.; Baik, J.M.; Yang, C. 3D Cu Ball-Based Hybrid Triboelectric Nanogenerator with Non-Fullerene Organic Photovoltaic Cells for Self-Powering Indoor Electronics. Nano Energy 2020, 77, 105271. [Google Scholar] [CrossRef]

- Cho, Y.; Lee, S.; Hong, J.; Pak, S.; Hou, B.; Lee, Y.W.; Jang, J.E.; Im, H.; Sohn, J.I.; Cha, S.; et al. Sustainable Hybrid Energy Harvester Based on Air Stable Quantum Dot Solar Cells and Triboelectric Nanogenerator. J. Mater. Chem. A 2018, 6, 12440–12446. [Google Scholar] [CrossRef]

- Liu, X.; Li, J.; Fang, Z.; Wang, C.; Shu, L.; Han, J. Ultraviolet-Protecting, Flexible and Stable Photovoltaic-Assisted Piezoelectric Hybrid Unit Nanogenerator for Simultaneously Harvesting Ultraviolet Light and Mechanical Energies. J. Mater. Sci. 2020, 55, 15222–15237. [Google Scholar] [CrossRef]

- Zhong, Y.; Zhao, H.; Guo, Y.; Rui, P.; Shi, S.; Zhang, W.; Liao, Y.; Wang, P.; Wang, Z.L. An Easily Assembled Electromagnetic-Triboelectric Hybrid Nanogenerator Driven by Magnetic Coupling for Fluid Energy Harvesting and Self-Powered Flow Monitoring in a Smart Home/City. Adv. Mater. Technol. 2019, 4. [Google Scholar] [CrossRef]

- Chen, Y.L.; Liu, D.; Wang, S.; Li, Y.F.; Zhang, X.S. Self-Powered Smart Active RFID Tag Integrated with Wearable Hybrid Nanogenerator. Nano Energy 2019, 64. [Google Scholar] [CrossRef]

- Ahmed, R.; Kim, Y.; Mehmood, M.U.; Zeeshan; Shaislamov, U.; Chun, W. Power Generation by a Thermomagnetic Engine by Hybrid Operation of an Electromagnetic Generator and a Triboelectric Nanogenerator. Int. J. Energy Res. 2019, 43, 5852–5863. [Google Scholar] [CrossRef]

- Rodrigues, C.; Gomes, A.; Ghosh, A.; Pereira, A.; Ventura, J. Power-Generating Footwear Based on a Triboelectric-Electromagnetic-Piezoelectric Hybrid Nanogenerator. Nano Energy 2019, 62, 660–666. [Google Scholar] [CrossRef]

- He, J.; Wen, T.; Qian, S.; Zhang, Z.; Tian, Z.; Zhu, J.; Mu, J.; Hou, X.; Geng, W.; Cho, J.; et al. Triboelectric-Piezoelectric-Electromagnetic Hybrid Nanogenerator for High-Efficient Vibration Energy Harvesting and Self-Powered Wireless Monitoring System. Nano Energy 2018, 43, 326–339. [Google Scholar] [CrossRef]

- Ahmed, R.; Kim, Y.; Zeeshan; Chun, W. Development of a Tree-Shaped Hybrid Nanogenerator Using Flexible Sheets of Photovoltaic and Piezoelectric Films. Energies 2019, 12, 229. [Google Scholar] [CrossRef]

- Santiago-Malagón, S.; Río-Colín, D.; Azizkhani, H.; Aller-Pellitero, M.; Guirado, G.; del Campo, F.J. A Self-Powered Skin-Patch Electrochromic Biosensor. Biosens. Bioelectron. 2021, 175, 112879. [Google Scholar] [CrossRef]

- Han, Q.; Wang, H.; Wu, D.; Wei, Q. Preparation of PbS NPs/RGO/NiO Nanosheet Arrays Heterostructure: Function-Switchable Self-Powered Photoelectrochemical Biosensor for H2O2 and Glucose Monitoring. Biosens. Bioelectron. 2021, 173, 112803. [Google Scholar] [CrossRef]

- Wardak, C.; Paczosa-Bator, B.; Malinowski, S. Application of Cold Plasma Corona Discharge in Preparation of Laccase-Based Biosensors for Dopamine Determination. Mater. Sci. Eng. C 2020, 116, 111199. [Google Scholar] [CrossRef] [PubMed]

- Malinowski, S.; Wardak, C.; Jaroszyńska-Wolińska, J.; Herbert, P.A.F.; Pietrzak, K. New Electrochemical Laccase-Based Biosensor for Dihydroxybenzene Isomers Determination in Real Water Samples. J. Water Process Eng. 2020, 34, 101150. [Google Scholar] [CrossRef]

- Malinowski, S.; Wardak, C.; Pietrzak, K. Effect of Multi-Walled Carbon Nanotubes on Analytical Parameters of Laccase-Based Biosensors Received by Soft Plasma Polymerization Technique. IEEE Sens. J. 2020, 20, 8423–8428. [Google Scholar] [CrossRef]

- Li, X.; Feng, Q.; Lu, K.; Huang, J.; Zhang, Y.; Hou, Y.; Qiao, H.; Li, D.; Wei, Q. Encapsulating Enzyme into Metal-Organic Framework during in-Situ Growth on Cellulose Acetate Nanofibers as Self-Powered Glucose Biosensor. Biosens. Bioelectron. 2021, 171, 112690. [Google Scholar] [CrossRef] [PubMed]

- Wen, F.; He, T.; Liu, H.; Chen, H.Y.; Zhang, T.; Lee, C. Advances in Chemical Sensing Technology for Enabling the Next-Generation Self-Sustainable Integrated Wearable System in the IoT Era. Nano Energy 2020, 78, 105155. [Google Scholar] [CrossRef]

- Shi, B.; Li, Z.; Fan, Y. Implantable Energy-Harvesting Devices. Adv. Mater. 2018, 30, 1801511. [Google Scholar] [CrossRef]

- Zhang, H.; Yang, Y.; Hou, T.C.; Su, Y.; Hu, C.; Wang, Z.L. Triboelectric Nanogenerator Built inside Clothes for Self-Powered Glucose Biosensors. Nano Energy 2013, 2, 1019–1024. [Google Scholar] [CrossRef]

- Xue, X.; Qu, Z.; Fu, Y.; Yu, B.; Xing, L.; Zhang, Y. Self-Powered Electronic-Skin for Detecting Glucose Level in Body Fluid Basing on Piezo-Enzymatic-Reaction Coupling Process. Nano Energy 2016, 26, 148–156. [Google Scholar] [CrossRef]

- Jung, Y.K.; Kim, K.N.; Baik, J.M.; Kim, B.S. Self-Powered Triboelectric Aptasensor for Label-Free Highly Specific Thrombin Detection. Nano Energy 2016, 30, 77–83. [Google Scholar] [CrossRef]

- Collins, C.M.; Yui, S.; Roberts, C.E.S.; Kojic, I. Thrombin Detection Using a Piezoelectric Aptamer-Linked Immunosorbent Assay. Anal. Biochem. 2013, 443, 97–103. [Google Scholar] [CrossRef]

- Antiochia, R. Developments in Biosensors for CoV Detection and Future Trends. Biosens. Bioelectron. 2021, 173, 112777. [Google Scholar] [CrossRef]

- Srivastava, A.K.; Dwivedi, N.; Dhand, C.; Khan, R.; Sathish, N.; Gupta, M.K.; Kumar, R.; Kumar, S. Potential of Graphene-Based Materials to Combat COVID-19: Properties, Perspectives, and Prospects. Mater. Today Chem. 2020, 18, 100385. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Koh, C.S.L.; Lee, Y.H.; Zhang, Y.; Phan-Quang, G.C.; Zhu, C.; Liu, Z.; Chen, Z.; Sim, H.Y.F.; Lay, C.L.; et al. A Wearable Solar-Thermal-Pyroelectric Harvester: Achieving High Power Output Using Modified RGO-PEI and Polarized PVDF. Nano Energy 2020, 73, 104723. [Google Scholar] [CrossRef]

- Oliveira, H.P.; De Sydlik, S.A.; Swager, T.M.; Helinando, P.; de Oliveira, S.A.S.; Timothy, M. Supercapacitors from Free-Standing Polypyrrole/Graphene Nanocomposites. J. Phys. Chem. C 2013, 117, 10270–10276. [Google Scholar] [CrossRef]

- Alcaraz-Espinoza, J.J.; De Melo, C.P.; De Oliveira, H.P. Fabrication of Highly Flexible Hierarchical Polypyrrole/Carbon Nanotube on Eggshell Membranes for Supercapacitors. ACS Omega 2017, 2, 2866–2877. [Google Scholar] [CrossRef] [PubMed]

- Lima, R.M.A.P.; Alcaraz-Espinoza, J.J.; Da Silva, F.A.G.; De Oliveira, H.P. Multifunctional Wearable Electronic Textiles Using Cotton Fibers with Polypyrrole and Carbon Nanotubes. ACS Appl. Mater. Interfaces 2018, 10, 13783–13795. [Google Scholar] [CrossRef]

- Alcaraz-Espinoza, J.J.; de Oliveira, H.P. Flexible Supercapacitors Based on a Ternary Composite of Polyaniline/Polypyrrole/Graphite on Gold Coated Sandpaper. Electrochim. Acta 2018, 274, 200–207. [Google Scholar] [CrossRef]

- Shi, X.; Chen, S.; Zhang, H.; Jiang, J.; Ma, Z.; Gong, S. Portable Self-Charging Power System via Integration of a Flexible Paper-Based Triboelectric Nanogenerator and Supercapacitor. ACS Sustain. Chem. Eng. 2019, 7, 18657–18666. [Google Scholar] [CrossRef]

- Mule, A.R.; Dudem, B.; Patnam, H.; Graham, S.A.; Yu, J.S. Wearable Single-Electrode-Mode Triboelectric Nanogenerator via Conductive Polymer-Coated Textiles for Self-Power Electronics. ACS Sustain. Chem. Eng. 2019, 7, 16450–16458. [Google Scholar] [CrossRef]

- He, H.; Zhang, M.; Zhao, T.; Zeng, H.; Xing, L.; Xue, X. A Self-Powered Gas Sensor Based on PDMS/Ppy Triboelectric-Gas-Sensing Arrays for the Real-Time Monitoring of Automotive Exhaust Gas at Room Temperature. Sci. China Mater. 2019, 62, 1433–1444. [Google Scholar] [CrossRef]

- Shi, Z.; Zhou, H.; Qing, X.; Dai, T.; Lu, Y. Facile Fabrication and Characterization of Poly(Tetrafluoroethylene) @polypyrrole/Nano-Silver Composite Membranes with Conducting and Antibacterial Property. Appl. Surf. Sci. 2012, 258, 6359–6365. [Google Scholar] [CrossRef]

- Kumar, R.; Pandey, A.K.; Singh, R.; Kumar, V. On Nano Polypyrrole and Carbon Nano Tube Reinforced PVDF for 3D Printing Applications: Rheological, Thermal, Electrical, Mechanical, Morphological Characterization. J. Compos. Mater. 2020, 54, 4677–4689. [Google Scholar] [CrossRef]

| Material/Type | d33 Value, pC/N | Ref. |

|---|---|---|

| Pb(Mg1/3Nb2/3) O3-PbTiO3 PMM-PT/(ceramic) | 2000–3000 | [26] |

| Lead zirconia titanate PZT-5H/(ceramic) | 593 | [26] |

| Bulk copolyimide (polymer) | 420 | [27] |

| Poly(tetrafluoroethylene)—PTFE | 200 | [28] |

| BaTiO3/(ceramic) | 190 | [26] |

| Lead zirconia titanate and polyvinylidene fluoride PZT/PVDF/(composite) | 36 | [29] |

| PVDF random fibers/(polymer) | 24.90 | [30] |

| ZnO/(ceramic) | 6–13 | [26] |

| Poly (L-lactic acid) PLLA/(polymer) | 6–12 | [26] |

| Silk/(biomaterial) | d14 = 1.5 | [26] |

| Active Material (Positive) | Active Material (Negative) | Electrode | Voltage | Current | Power | Ref |

|---|---|---|---|---|---|---|

| CNT | Kevlar/shear stiffening gel | - | 41.27 V | - | 212.90 mW | [64] |

| Silver coated fabric | MXene/ecoflex nanocomposite | Ag | 800 V | - | 3.69 mW | [65] |

| Al | BCZT/BiHoO3-PDMS | Al | 300 V | - | 157 mW/m2 | [66] |

| g-C3N4 | Biaxially oriented polypropylene | Al/(PET-ITO) | 10 V | - | - | [62] |

| P4VP | PVDF-HFP | Al | 260 V | 27 mA | 7 mW | [8] |

| Antimonene | Kapton | Al | 18 V | 0.22 mA | 15 mW | [67] |

| Al | Kapton | Al | 3250 V | 44.34 mA | - | [68] |

| CNT/silk layer | PET/ITO | - | 276 V | 9.2 mA | 317.4 mW/cm2 | [69] |

| Nylon fabric | PTFE fabric | Al | 350 V | 5.94 mA | 600 mW | [13] |

| Cold-rolled Al species | Fluorinated ethyelene propylene (FEP) | Al | 180 V | - | 0.36 mW | [60] |

| Hybrid Nanogenerator | Active Material | Potential (V) | Power | Current | Ref |

|---|---|---|---|---|---|

| Triboelectric– Piezoelectric | PTFE–Barium titanate | 45 | - | 10.4 mAcm−2 | [85] |

| Triboelectric– Thermoelectric | Polyimide/PDMS– Bi2Te3 | 30.5 | 24.34 mWm−2 | 1.98 mA | [98] |

| Triboelectric– Piezoelectric | PVDF | - | 127 mW | [90] | |

| Triboelectric– Piezoelectric | Ba (Ti0.8 Zr0.2) O3–(Ba0.838 Ca0.162) (Ti0.9072 Zr0.092) O3 | 45 | - | 2.8 mA | [91] |

| Triboelectric– Piezoelectric | Nitrocellulose/MWCNT–BaTiO3 | 18 | - | 1.6 mAcm−2 | [92] |

| Triboelectric– Piezoelectric– Electromagnetic | Kapton–Nylon–PTFE–Magnet | 30 | - | - | [106] |

| Triboelectric– Piezoelectric | Kapton–PVDF | 560 | 3.7 Wm−2 | - | [93] |

| Triboelectric– Piezoelectric | PDMS–PTFE– PVDF–Li-ZnO–MWCNT | 60.1 | - | 75 mA | [94] |

| Photovoltaic – Piezoelectric | Conventional solar cell–PVDF | 5.071 | 3.42 mW | 1.282 mA | [108] |

| Triboelectric– Piezoelectric | PDMS–MWCNT—PVDF–CNT–BaTiO3 | 161.66 | 2.22 Wm−2 | - | [97] |

| Triboelectric– Piezoelectric | Silk fibroin–PVDF | 500 | 0.31 mWcm−2 | 12 mA | [86] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oliveira, H.P.d. Wearable Nanogenerators: Working Principle and Self-Powered Biosensors Applications. Electrochem 2021, 2, 118-134. https://doi.org/10.3390/electrochem2010010

Oliveira HPd. Wearable Nanogenerators: Working Principle and Self-Powered Biosensors Applications. Electrochem. 2021; 2(1):118-134. https://doi.org/10.3390/electrochem2010010

Chicago/Turabian StyleOliveira, Helinando Pequeno de. 2021. "Wearable Nanogenerators: Working Principle and Self-Powered Biosensors Applications" Electrochem 2, no. 1: 118-134. https://doi.org/10.3390/electrochem2010010

APA StyleOliveira, H. P. d. (2021). Wearable Nanogenerators: Working Principle and Self-Powered Biosensors Applications. Electrochem, 2(1), 118-134. https://doi.org/10.3390/electrochem2010010