Towards the Development of a Digital Twin for a Sustainable Mass Customization 4.0 Environment: A Literature Review of Relevant Concepts

Abstract

:1. Introduction

1.1. Industry 4.0 and Mass Customization

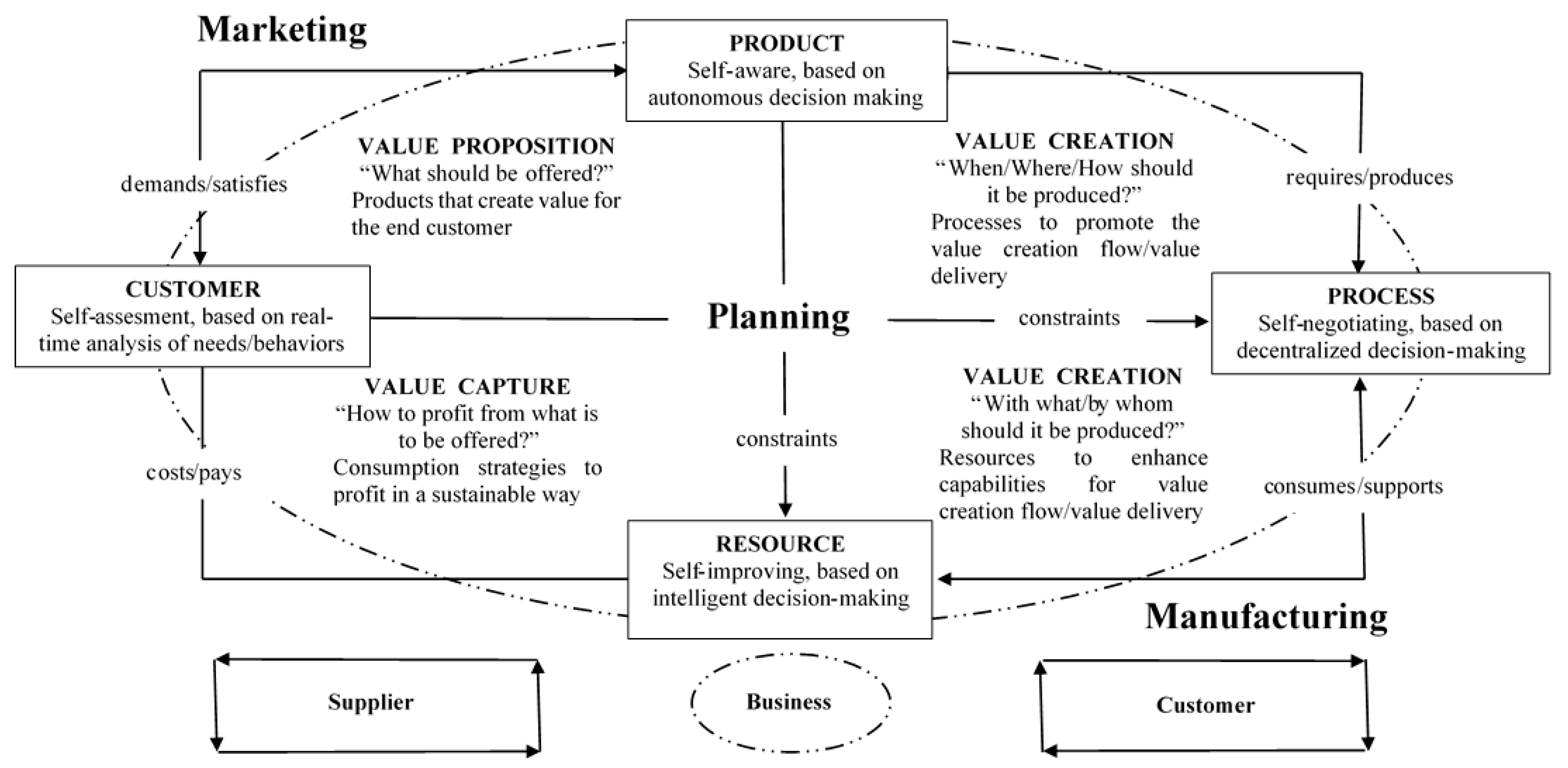

- The need for the development of entirely new business models [38] and their associated business processes. According to [39], a business model focuses on the “what” side of value creation, while a business process model focuses on the “how” side of value creation. As customers are integrated into the value creation process by defining and configuring individual solutions a tool is needed to accomplish this [40]. In the age of Industry 4.0, this refers to:

- The support of a manufacturing environment should be suitable to be scalable at no extra cost [45,46,47]. This scalability refers to the production system reconfiguration that takes place through the integration of plug-and-produce, fully automated, digitized, highly cost efficient, smart new manufacturing units [7]. This calls for the use of new efficient re-configurable manufacturing methods such as the CPS [48], where its real time, production coordination capabilities allows boosting customer satisfaction by economically producing customized products [49,50]. These coordination capabilities come from the efficient processing of a vast amount of information (coming from tightly connected sensors, controllers, manufacturing systems, etc.), that later on is transformed into optimized decisions [51].

1.2. Digital Twins

- Industry 4.0: a DT requires a set of technologies needed for its implementation including, but not limited to, simulation methods, communication protocols, and the core technologies of Industry 4.0 [60], a concept that has emerged as a manufacturing enabler to achieve the desired time-to-market reduction [70];

- Mass customization: the demand for highly individualized products with shorter lifestyles drives modern manufacturing systems to focus on the use of information technology-based manufacturing systems [71], such as the so-called data-driven Digital Twins [58]. A DT of a manufacturing system in the form of a simulation and data model [61] that synchronizes both the physical and digital worlds [72] can be used to address the issue of manufacturing customized products [2], as it makes the deployment of the required flexible and reconfigurable manufacturing system possible [73];

- Sustainability: DTs may be utilized to address these sustainability challenges [10]. For example, social sustainability requires the integration of human skills with technology [76], and the improvement of the environmental and social factors of smart manufacturing may conflict with the economic factor [35]. In [77] the authors depict a sustainable digital twin (SDT) framework for shifting from a static sustainability assessment to a digital twin (DT)-based and Internet of Things (IoT)-enabled dynamic approach;

- Value Creation: within the DT context, the importance of the physical world resides in the fact that it is there where the actual value-creation process takes place [66].

1.3. Digital Twins and Small and Medium-Sized Enterprises

2. Research Gaps

2.1. Sustainability and Manufacturing Efficiency

2.2. Sustainability and Industry 4.0

- Virtual Reality (VR)/Augmented Reality (AR) technologies lead to sustainability via better training and knowledge [124];

2.3. Sustainability and Value Creation

| Sustainability and … | References |

|---|---|

| Manufacturing Efficiency | [4,88,89,90,91,92,93] |

| Mass Customization and Industry 4.0 | [93,96,97,99,100,101,102] |

| Industry 4.0 | [103,104,105,106,107] |

| Smart Manufacturing | [99,108,109,110,111,112,113,114] |

| Virtual/Augmented Reality/Cloud Manufacturing | [115,116,117,118,121,124] |

| Value Creation | [4,126,127,128,129,130,131,132,133] |

2.4. Research Features

- (1)

- The SMC4.0 business environment refers to a business model that reflects the economic benefits of achieving sustainability (in a context of manufacturing efficiency), plus the environmental and social impacts that will guarantee durable competitiveness;

- (2)

- The SMC4.0 manufacturing environment refers to a rapid responsive (quick and profitable), service-oriented (ability to fulfill the demand for highly customized products) manufacturing model.

3. Sustainable Value Creation

3.1. The Sustainable CPPR 4.0 Framework

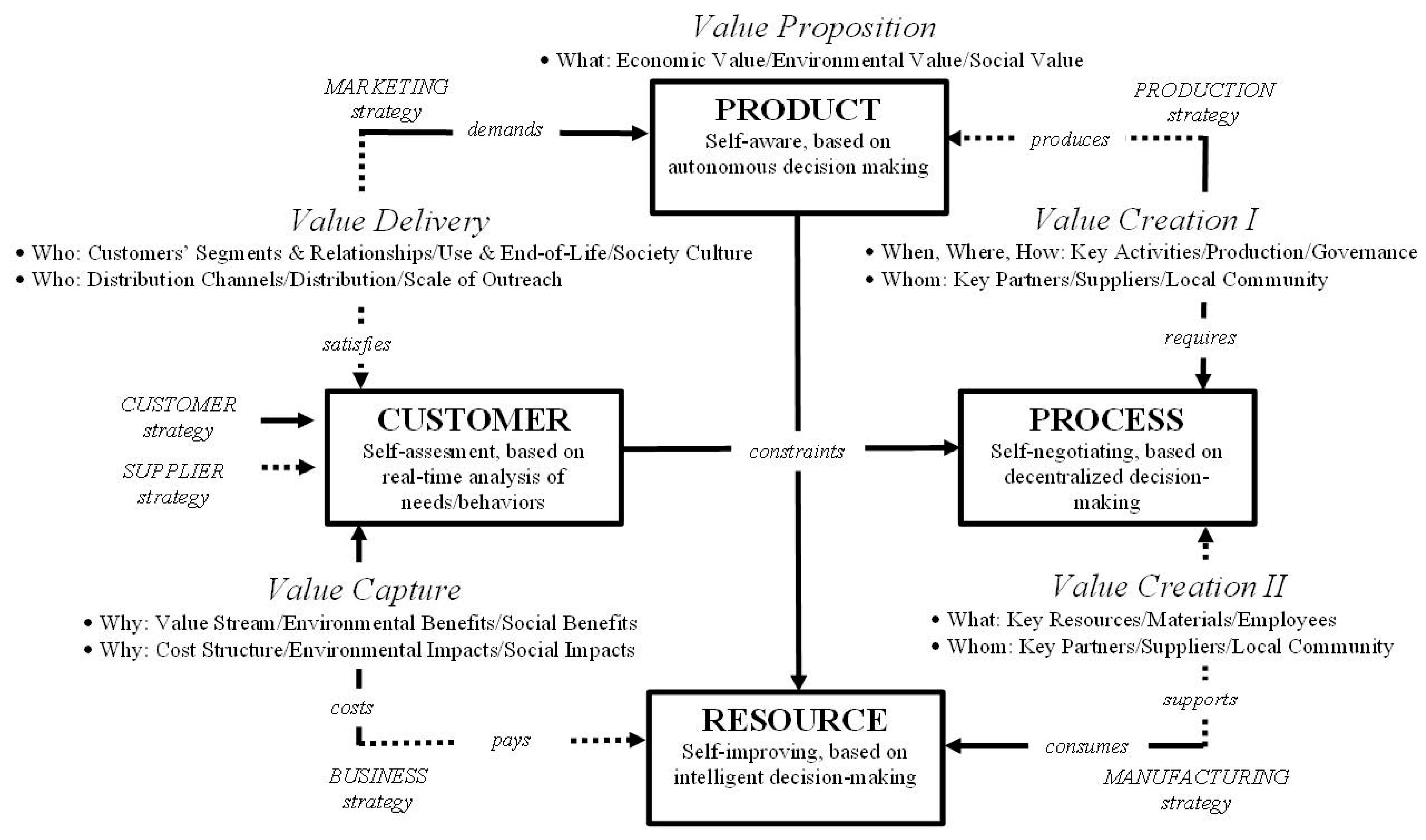

- Each quadrant of the framework presents the questions pertaining to each value domain, i.e., the WHO of value delivery; the WHAT of value proposition; the WHAT/WHEN/WHERE/HOW of value creation; the WHY of value capture;

- The answers to these questions, for each value domain, can be found in Table 2;

- The arrows pointing direction (in Figure 3) indicates the customer (clockwise, solid line) and supplier (counterclockwise, dotted line) standpoint, when reading the framework.

3.2. The Value Creation Relationships

| Transformation Activities Sequence | Sequence Option # | ||||||

|---|---|---|---|---|---|---|---|

| Product | M1 | M2 | M3 | M4 | M14 | M23 | |

| PA | 1st | 2nd | 1 | ||||

| 1st | 2nd | 2 | |||||

| 1st & 2nd | 3 | ||||||

| PB | 1st | 2nd | 3rd | 1 | |||

| 1st | 2nd | 3rd | 2 | ||||

| 1st | 3rd | 2nd | 3 | ||||

| 1st | 3rd | 2nd | 4 | ||||

| 2nd | 1st & 3rd | 5 | |||||

| 1st & 3rd | 2nd | 6 | |||||

| PC | 1st | 2nd | 3rd | 4th | 1 | ||

| 1st | 2nd | 3rd | 4th | 2 | |||

| 1st | 4th | 2nd & 3rd | 3 | ||||

| 1st | 4th | 2nd & 3rd | 4 | ||||

| 2nd | 3rd | 1st & 4th | 5 | ||||

| 1st & 4th | 2nd & 3rd | 6 | |||||

3.3. The Value Creation Abilities

- Collaboration, the ability to work together by adjusting the individual behavior of the involved partners. This is possible when the means to negotiate common benefits and risks sharing are in place.

- Coordination, the ability to work in a harmonious way when pursuing a goal that is common to all of the involved partners. This is possible when the means to match individual actions with common decision-making processes are in place.

- Cooperation, the ability to work for a common benefit in terms of an objective that is feasible to all of the involved partners. This is possible when the means to align the individual operational levels with the common strategic levels are in place.

- Communication, the ability to share key and relevant information to the rest of the involved partners. In this case, the involved partners refer to the smart products, process, and resources. In the case of information, we propose the definition proposed by [143]:

- Information: data (detected signal that shows a non-random quantified pattern) that have been evaluated to have relevance and used for establishing a course of action to implement defined objectives.

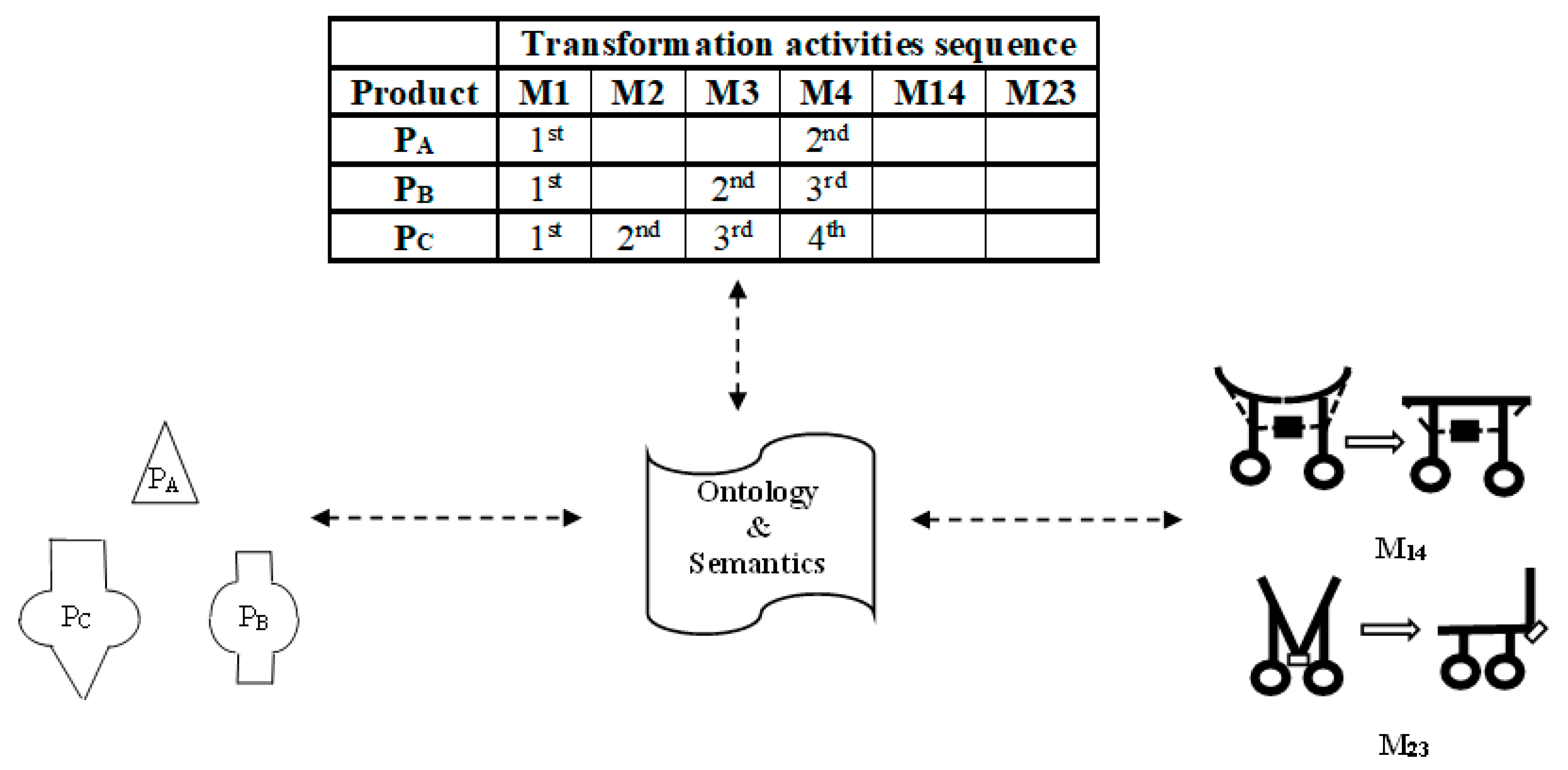

From the DT perspective, this means that there must be a mechanism in place that allows the smart products, processes, and resources “to talk among themselves and understand each other”, with the purpose of establishing a common objective. In Figure 8, the “ontology and semantics” element represents the means through which the DT allows interactions of the elements of the physical world. - Collaboration, the ability to work together by adjusting the individual behavior of the involved partners. This is possible when the means to negotiate common benefits and risks sharing is in place. In the case of behavior, we propose the definition proposed by CIMOSA, the Computer Integrated Manufacturing–Open Systems Architecture [144], when referring to the behavior of a process:

- Behavior: defined by a set of procedural rules that dictate how actions/activities need to be done/executed. This behavior is intended for the achievement of some objective, under some constraints, using some resources. A procedural rule can be in the form of a triggering condition (i.e., a system state) or an event (that is, a solicited request/unsolicited real-world happening which initiates the execution of an action/activity).

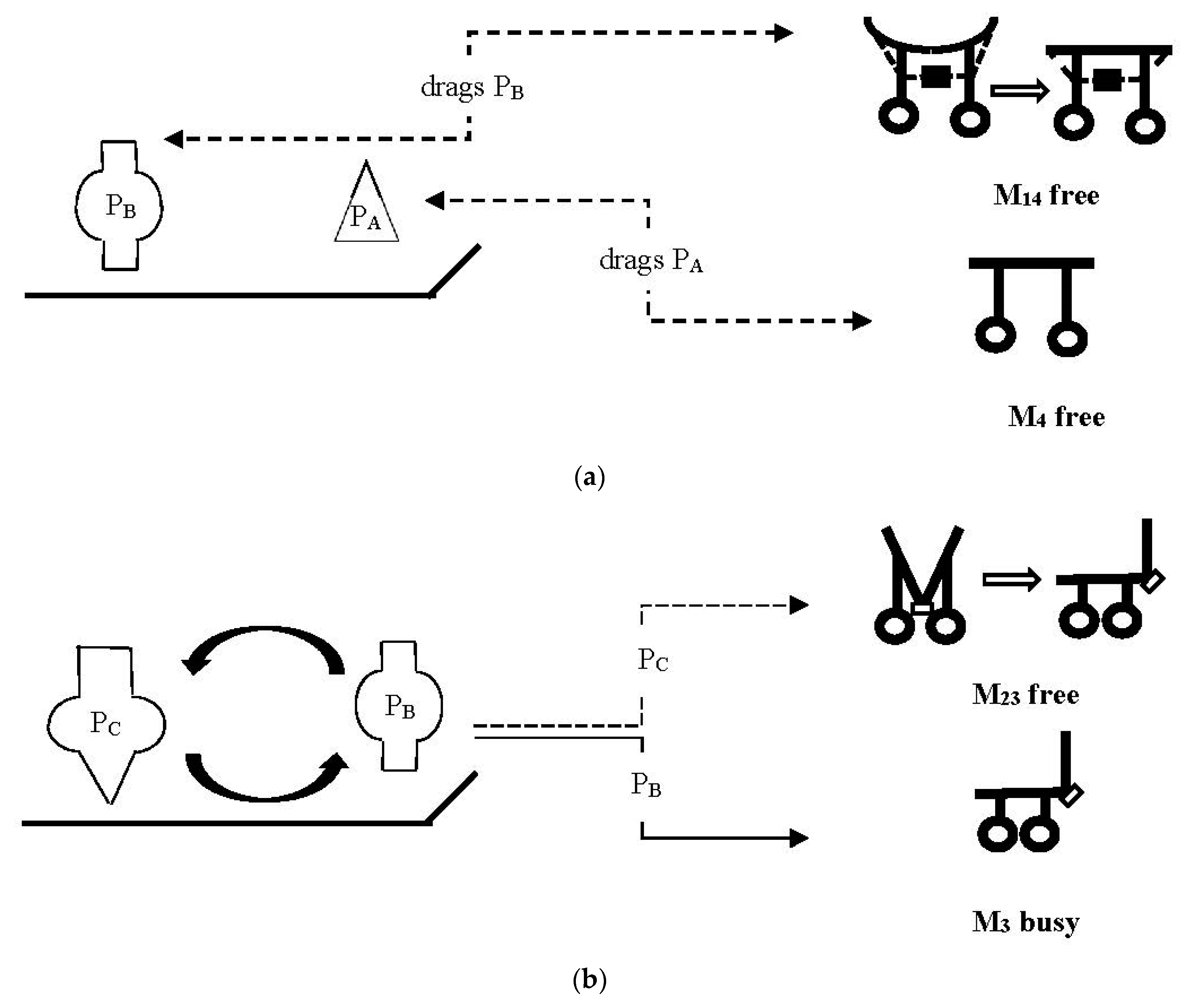

From the DT perspective, this means that there must be a mechanism in place that allows the smart products, processes, and resources “to define” a combined set of procedural rules that “guides” the pursuing of the common objective, within the upper limit of the benefits and the lower limit of the risks (Figure 9). - Coordination, the ability to work in a harmonious way when pursuing an objective that is common to all of the involved partners. This is possible when the means to match individual actions with common decision-making processes are in place. In the case of decision-making, the structure of a GRAI net (Figure 10, Table 6), which is basically a Petri net with special graphical symbols [145], could be used to represent it. From the DT perspective, this means that there must be a mechanism in place that allows the smart products, processes, and resources “to visualize” the impact of the individual decision-making processes, therefore, the next action/activity that needs to be done/executed can be determined properly.

- Cooperation, the ability to work for a common benefit in terms of a goal that is feasible to all of the involved partners. This is possible when the means to fit/integrate the individual contributions with the overall result are in place. From the DT perspective, this means that there must be a mechanism in place that allows the smart products, processes, and resources, “to integrate” their individual contributions, so the placing (where)/timing(when) of the next action/activity that needs to be done/executed can be determined properly.

4. The SMC4.0 Information Flow Model

| Sustainable CPPR 4.0 | Mass Customization Business Processes | Make-to-Order | |||||

|---|---|---|---|---|---|---|---|

| [131] | [147,148] | [146] | [149,150] | [34] | [155] | ||

| Subcycles | Activities | ||||||

| Value Proposition | Design | Product development/design | Development; i.e., product development/design | Step #1: personalization | Design | Design new products | Conduct market research |

| Analyze product technology | |||||||

| Develop prototype | |||||||

| Design new components | |||||||

| Modify standard design to meet customer requirements | |||||||

| Obtain customer approval for new design | |||||||

| Develop bill of material and process plans | |||||||

| Value Capture | Sell | Order taking | Interaction; i.e., order placement | Step #2: purchasing | Order processing | Respond to customer inquiry | |

| Create sales order | Develop specifications | ||||||

| Determine delivery | |||||||

| Determine price | |||||||

| Check customer credit | |||||||

| Receive customer approval | |||||||

| Value Creation | Make/Assembly | Order fulfillment management | Production; i.e., fabrication/assembly | Steps #3 and #4: manufacturing | Production | Production planning and control | |

| Materials management | |||||||

| Fabricate parts | |||||||

| Assemble products | |||||||

| Inspection, testing, rework | |||||||

| Inventory finished products | |||||||

| Value Delivery | N/A | Order fulfillment realization | Logistics; i.e., packing/delivery | Step #5: delivering | Distribution | Ship products to distribution center | |

| Pick products for customer orders | |||||||

| Ship products and invoice customers | |||||||

Managerial Implications

5. Concluding Remarks

5.1. Future Research

- A mechanism for smart products, processes, and resources, “to talk among themselves and understand each other” (Communication);

- A mechanism for smart products, processes, and resources, “to define” a combined set of procedural rules that “guides” the pursuing of the common objective (Collaboration);

- A mechanism for smart products, processes, and resources, “to visualize” the impact of the individual decision-making processes (Coordination);

- A mechanism for smart products, processes, and resources, “to integrate” their individual contributions (Cooperation).

5.2. Conclusions

Funding

Informed Consent Statement

Conflicts of Interest

Appendix A

- From an economic point of view, Industry 4.0 technologies can reduce set-up times, achieve shorter lead times, reduce labor and material costs, increase production flexibility, achieve higher productivity, and enhance customization [166];

- From a social point of view, Industry 4.0 technologies can support employee health and safety, by taking over monotonous and repetitive tasks resulting in higher employee satisfaction and motivation [21].

- Economic sustainability attributes; end poverty (EP), decent work and economic growth (DWEG), industry, innovation, and infrastructure (III), reduced inequalities (RI), and partnerships for the goals (PG).

- Social sustainability attributes; end hunger (EH), good health and well-being (GHW), quality education (QE), gender equality (GE), and peace, justice and strong institutions (PJSI);

- Environmental impact attributes; clean water and sanitation (CWS), affordable and clean energy (ACE), sustainable cities and communities (SCC), responsible consumption and production (RCP), climate action (CA), life below water (LBW), and life on land (LL).

Appendix B

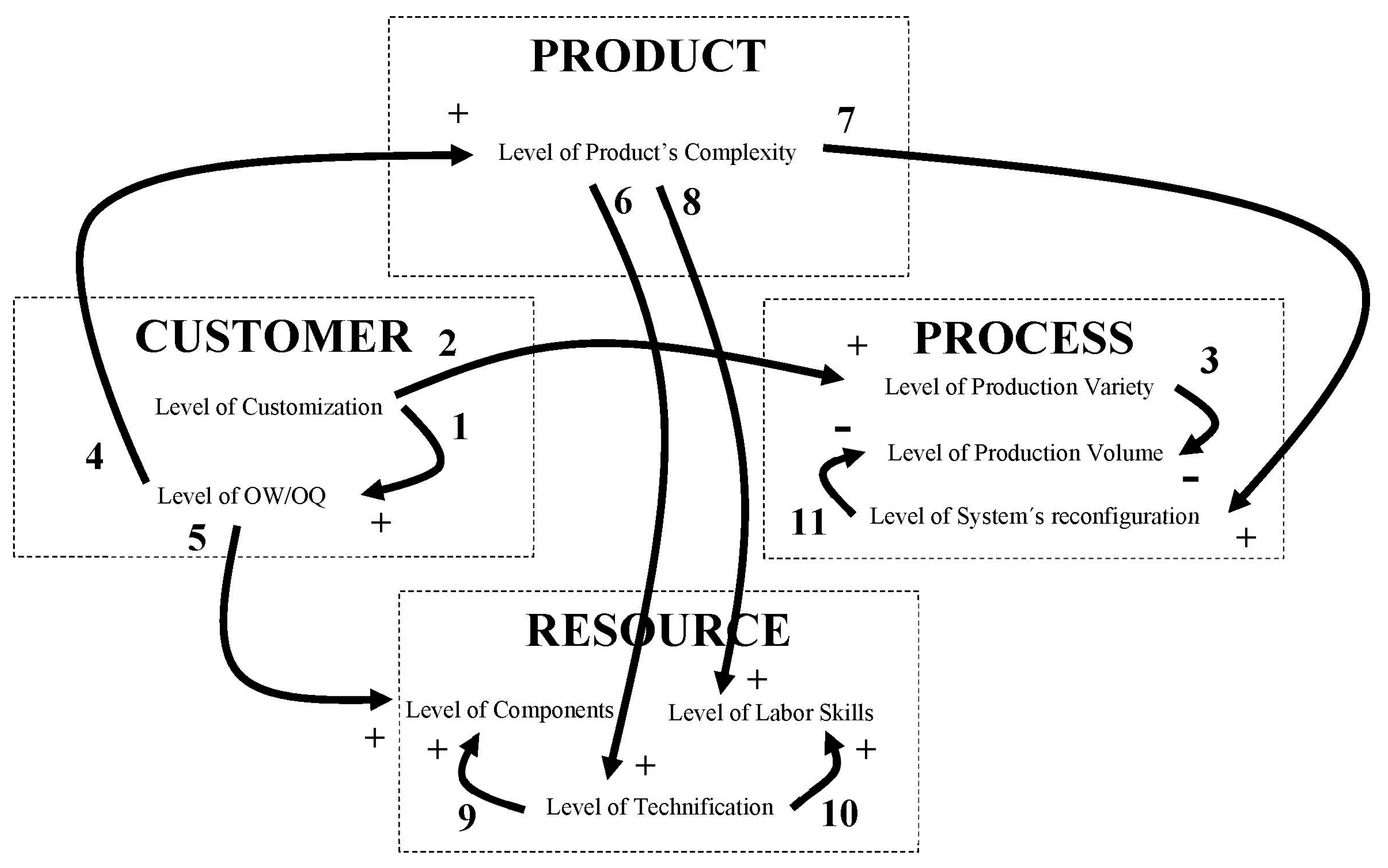

| Mass Customization Structural Elements | Range of Values | Rn * | From | To | Rt ** | |

|---|---|---|---|---|---|---|

| 0 | 1 | |||||

| Level of customization (lc) | Standard product | Personalized product | 1 | lc | lowoq | + |

| Level of OW/OQ (lowoq) | 100% Common features | 100% Unique features | 2 | lc | lpva | + |

| Level of product’s complexity (lpcplx) | Few operations/easy to execute | Lot of operations/hard to execute | 3 | lpva | lpvo | − |

| Level of production variety (lpva) | A small number of models | A large number of models | 4 | lowoq | lpcplx | + |

| Level of production volume (lpvo) | A few units produced | A lot of units produced | 5 | lowoq | lcomp | + |

| Level of system’s reconfiguration (lsr) | Hard-connected workstations/rigid flow | Loose-connected workstations/flexible flow | 6 | lpcplx | ltech | + |

| Level of equipment technification (ltech) | Specialized-use equipment | General-use equipment | 7 | lpcplx | lsr | + |

| Level of labor skill (ls) | Single-task specialist | Multiple-task generalist | 8 | lpcplx | ls | + |

| Level of components (lcomp) | Small number of components | Large number of components | 9 | ltech | lcomp | + |

| Level of customization (lc) | 100% Common features | 100% Unique features | 10 | ltech | ls | + |

| Level of OW/OQ (lowoq) | Few operations/easy to execute | Lot of operations/hard to execute | 11 | lsr | lpvo | − |

References

- Hu, S.J. Evolving paradigms of manufacturing: From mass production to mass customization and personalization. Procedia CIRP 2013, 7, 3–8. [Google Scholar] [CrossRef] [Green Version]

- Aheleroff, S.; Zhong, R.Y.; Xu, X. A Digital Twin Reference for Mass Personalization in Industry 4.0. Procedia Cirp 2020, 93, 228–233. [Google Scholar] [CrossRef]

- Waris, M.M.; Sanin, C.; Szczerbicki, E. Smart Innovation Engineering (SIE): Experience-Based Product Innovation System for Industry 4.0. In Information Systems Architecture and Technology, Proceedings of the 38th International Conference on Information Systems Architecture and Technology–ISAT 2017, Szklarska Poręba, Poland, 17–19 September 2017; Advances in Intelligent Systems and Computing; Wilimowska, Z., Borzemski, L., Światek, J., Eds.; Springer: Cham, Switzerland, 2017; pp. 379–388. [Google Scholar] [CrossRef]

- de Man, J.C.; Strandhagen, J.O. An Industry 4.0 research agenda for sustainable business models. Procedia CIRP 2017, 63, 721–726. [Google Scholar] [CrossRef]

- Efthymiou, K. Manufacturing systems complexity review: Challenges and outlook. Procedia CIRP 2012, 3, 644–649. [Google Scholar] [CrossRef] [Green Version]

- Pfisterer, D.; Radonjic-Simic, M.; Reichwald, J. Business Model Design and Architecture for the Internet of Everything. J. Sens. Actuator Netw. 2016, 5, 7. [Google Scholar] [CrossRef] [Green Version]

- Raza, A.; Haouari, L.; Pero, M.; Absi, N. Impacts of Industry 4.0 on the Specific Case of Mass Customization through Modeling and Simulation Approach. In Customization 4.0; Springer Proceedings in Business and Economics; Hankammer, S., Ed.; Springer International Publishing AG: Cham, Switzerland, 2018. [Google Scholar] [CrossRef]

- Torn, I.A.R.; Vaneker, T.H.J. Mass Personalization with Industry 4.0 by SMEs: A Concept for Collaborative Networks. Procedia Manuf. 2019, 28, 135–141. [Google Scholar] [CrossRef]

- Wang, Y.; Ma, H.S.; Yang, J.H.; Wang, K.S. Industry 4.0: A Way from Mass Customization to Mass Personalization Production. Adv. Manuf. 2017, 5, 311–320. [Google Scholar] [CrossRef]

- Martinez, S.; Mariño, A.; Sanchez, S.; Montes, A.M.; Triana, J.M.; Barbieri, G.; Abolghasem, S.; Vera, J.; Guevara, M. A Digital Twin Demonstrator to enable flexible manufacturing with robotics: A process supervision case study. Prod. Manuf. Res. 2021, 9, 140–156. [Google Scholar] [CrossRef]

- Zawadzki, P.; Zywicki, K. Smart product design and production control for effective mass customization in the industry 4.0 concept. Manag. Prod. Eng. Rev. 2016, 7, 105–112. [Google Scholar] [CrossRef]

- Bednar, S.; Modrak, J.; Soltysova, Z. Assessment of Assembly Process Complexity and Modularity in Mass Customized Manufacturing. In Lecture Notes in Mechanical Engineering, Proceedings of the 5th International Conference on Advanced Manufacturing Engineering and Technologies, Belgrade, Serbia, 5–9 June 2017; Majstorovic, V., Jakovljevic, Z., Eds.; Springer International Publishing AG: Cham, Switzerland, 2017. [Google Scholar] [CrossRef]

- Varnhagen, V.; Schuh, G. Fokus Automobilindustrie: Digitale Wertschöpfungsnetzwerke im Werkzeugbau; Apprimus Verlag: Aachen, Germany, 2013; p. 5. ISBN 978-3-86359-1533. [Google Scholar]

- Sauter, R.; Bode, M.; Kittelberger, D. How Industry 4.0 is Changing How We Manage Value Creation. 2015. Available online: www.horvarth-partners.com (accessed on 17 December 2021).

- Ardito, L.; Petruzzelli, A.M.; Panniello, U.; Garavelli, A.C. Towards Industry 4.0: Mapping digital technologies for supply chain management-marketing integration. Bus. Process Manag. J. 2018, 25, 323–346. [Google Scholar] [CrossRef]

- Schneider, P. Managerial challenges of Industry 4.0: An empirically backed research agenda for a nascent field. Rev. Manag. Sci. 2018, 12, 803–848. [Google Scholar] [CrossRef]

- Foresti, F.; Varvakis, G. Ubiquity and Industry 4.0. Knowledge Management in Digital Change. In Progress in IS; North, K., Ed.; Springer International Publishing AG: Cham, Switzerland, 2018. [Google Scholar] [CrossRef]

- Schumacher, A.; Erolb, S.; Sihn, W. A maturity model for assessing Industry 4.0 readiness and maturity of manufacturing enterprises. Procedia CIRP 2016, 52, 161–166. [Google Scholar] [CrossRef]

- Lin, D.; Lee, C.K.M.; Lau, H.; Yang, Y. Strategic response to Industry 4.0: An empirical investigation on the Chinese automotive industry. Ind. Manag. Data Syst. 2018, 118, 589–605. [Google Scholar] [CrossRef]

- Kusi-Sarpong, S.; Moktadir, A.; Ali, S.M.; Shaikh, A.A. Assessing challenges for implementing Industry 4.0: Implications for process safety and environmental protection. Process Saf. Environ. Prot. 2018, 117, 730–741. [Google Scholar]

- Chukwuekwe, D.O.; Schjølberg, P.; Rødseth, H.; Stuber, A. Reliable, Robust and Resilient Systems: Towards Development of a Predictive Maintenance. In Proceedings of the Euromaintenance 2016 Conference, Athens, Greece, 30 May–1 June 2016; Volume 24. [Google Scholar]

- Müller, J.M.; Maier, L.; Veile, J.; Voigt, K.I. Cooperation Strategies among SMEs for Implementing Industry 4.0. In Digitalization in Supply Chain Management and Logistics: Smart and Digital Solutions for an Industry 4.0 Environment, Proceedings of the Hamburg International Conference of Logistics (HICL); Kersten, W., Blecker, T., Ringle, C.M., Eds.; epubli GmbH: Berlin, Germanny, 2017; ISBN 9783745043280. [Google Scholar]

- Bitkom, E.V.; Vdma, E.V.; Zvei, E.V. Implementation Strategy Industrie 4.0: Report on the results of the Industrie 4.0 Platform; Bitkom e.V. Bundesverband Informationswirtschaft, Telekommunikation und neue Medien e.V.: Berlin, Germany, 2016; ISBN 978-3-00-052211-6. [Google Scholar]

- Tjahjonoa, B.; Espluguesb, C.; Aresc, E.; Pelaezc, G. What does Industry 4.0 mean to Supply Chain? Procedia Manuf. 2017, 13, 1175–1182. [Google Scholar] [CrossRef]

- Ibarra, D.; Ganzarain, J.; Igartua, J.I. Business model innovation through Industry 4.0: A review. Procedia Manuf. 2018, 22, 4–10. [Google Scholar] [CrossRef]

- Junior, J.A.G.; Busso, C.M.; Gobbo, S.C.O.; Carreão, H. Making the links among environmental protection, process safety, and industry 4.0. Process Saf. Environ. Prot. 2018, 117, 372–382. [Google Scholar]

- Židek, K.; Pitel’, J.; Adámek, M.; Lazorík, P.; Hošovský, A. Digital Twin of Experimental Smart Manufacturing Assembly System for Industry 4.0 Concept. Sustainability 2020, 12, 3658. [Google Scholar] [CrossRef]

- Iarovyi, S.; Mohammed, W.M.; Lobov, A.; Ferrer, B.R.; Lastra, J.L.M. Cyber-physical systems for open-knowledge-driven manufacturing execution systems. Proc. IEEE 2016, 104, 1142–1154. [Google Scholar] [CrossRef]

- Thames, L.; Schaefer, D. Industry 4.0: An Overview of Key Benefits, Technologies, and Challenges. In Cybersecurity for Industry 4.0; Springer Series in Advanced Manufacturing; Thames, L., Schaefer, D., Eds.; Springer: Cham, Switzerland, 2017. [Google Scholar] [CrossRef]

- Zhong, R.Y.; Xu, X.; Klotz, E.; Newman, T.S.T.S. Intelligent Manufacturing in the Context of Industry 4.0: A Review. Engineering 2017, 3, 616–630. [Google Scholar] [CrossRef]

- Rodic, B. Industry 4.0 and the new simulation modelling paradigm. Organizacija 2017, 50, 193–207. [Google Scholar] [CrossRef] [Green Version]

- Stump, B.; Badurdeen, F. Integrating lean and other strategies for mass customization manufacturing: A case study. J. Intell. Manuf. 2012, 230, 109–124. [Google Scholar] [CrossRef]

- Gabriel, M.; Pessl, E. Industry 4.0 and Sustainability impacts: Critical discussion of sustainability aspects with a special focus on future of work and ecological consequences. Ann. Fac. Eng. Hunedoar Int. J. Eng. 2016, 14, 131. [Google Scholar]

- Latorre-Biel, J.I.; Faulín, J.; Juan, A.A.; Jiménez-Macías, E. Petri Net Model of a Smart Factory in the Frame of Industry 4.0. IFAC Pap. 2018, 51, 266–271. [Google Scholar] [CrossRef]

- Li, L.; Mao, C.; Sun, H.; Yuan, Y.; Lei, B. Digital Twin Driven Green Performance Evaluation Methodology of Intelligent Manufacturing: Hybrid Model Based on Fuzzy Rough-Sets AHP, Multistage Weight Synthesis, and PROMETHEE II. Complexity 2020, 2020, 3853925. [Google Scholar] [CrossRef]

- Duarte, S.; Cruz-Machado, V. Exploring Linkages Between Lean and Green Supply Chain and the Industry 4.0. In Proceedings of the Eleventh International Conference on Management Science and Engineering Management, Melbourne, Australia, 1–14 August 2018; Lecture Notes on Multidisciplinary Industrial Engineering. Xu, J., Ed.; Springer International Publishing AG: Cham, Switzerland, 2018. [Google Scholar] [CrossRef]

- Dziurzanski, P.; Swan, J.; Indrusiak, L.S. Value-Based Manufacturing Optimization in Serverless Clouds for Industry 4.0. In Proceedings of the Genetic and Evolutionary Computation Conference, GECCO′18, Kyoto, Japan, 15–19 July 2018. [Google Scholar] [CrossRef] [Green Version]

- Kannan, S.M.; Suri, K.; Cadavid, J.; Barosan, I.; van den Brand, M.; Alferez, M.; Gerard, S. Towards Industry 4.0: Gap Analysis between Current Automotive MES and Industry Standards using Model-Based Requirement Engineering. In Proceedings of the IEEE International Conference on Software Architecture Workshops (ICSAW), Gothenburg, Sweden, 5–7 April 2017. [Google Scholar]

- Singh, P.; Jonkers, H.; Iacob, M.; van Sinderen, M. Modeling Value Creation with Enterprise Architecture. In Proceedings of the 16th International Conference on Enterprise Information Systems (ICEIS-2014), Lisbon, Portugal, 27–30 April 2014; pp. 343–351, ISBN 978-989-758-029-1. [Google Scholar] [CrossRef] [Green Version]

- Boër, C.R.; Pedrazzoli, P.; Bettoni, A.; Sorlini, M. Mass Customization and Sustainability; Springer: London, UK, 2013. [Google Scholar] [CrossRef]

- Tu, M.; Lim, M.K.; Yang, M.F. IoT-based production logistics and supply chain system–Part 2. IoT-based cyber-physical system: A framework and evaluation. Ind. Manag. Data Syst. 2018, 118, 96–125. [Google Scholar] [CrossRef] [Green Version]

- Sievänen, M.; Heiskala, M.; Tiihonen, J.; Paloheimo, K.S.; Siirilä, T. Analyzing service mass customization business models. In Proceedings of the 4th International Conference on Mass Customization and Personalization in Central Europe (MCP-CE 2010), Novi Sad, Serbia, 22–24 September 2010; pp. 72–78. [Google Scholar]

- Schuh, G. Digital Connected Production; Werkzeugmaschinenlabor WZL der RWTH Aachen, Fraunhofer-Institut für Produktionstechnologie: Aachen, Germany, 2017. [Google Scholar]

- Schuh, G.; Boos, W.; Kelzenberg, C. Industrie 4.0: Implement it! In Ein Leitfaden zur Erfolgreichen Implementierung von Industrie 4.0-Lösungen; Werkzeugmaschinenlabor WZL der RWTH: Aachen, Germany, 2018. [Google Scholar]

- Nielsen, K.; Brunø, T.D. Assessment of Process Robustness for Mass Customization. In IFIP International Conference on Advances in Production Management Systems; Prabhu, V., Taisch, M., Kiritsis, D., Eds.; Springer: Berlin, Heidelberg, 2013; Volume 414. [Google Scholar]

- Nielsen, K.; Brunoe, T.D.; Joergensen, K.A.; Taps, S.B.; Brunoe, T.D. (Eds.) Lecture Notes in Production Engineering. In Proceedings of the 7th World Conference on Mass Customization, Personalization, and Co-Creation (MCPC 2014), Aalborg, Denmark, 4–7 February 2014; Springer International Publishing: Cham, Switzerland, 2014. [Google Scholar] [CrossRef]

- Ditlev, T.; Taps, S.B.; Nielsen, K. Chapter 15 Mass Customization in SMEs: Literature Review and Research Directions. In Managing Complexity, Springer Proceedings in Business and Economics; Bellemare, J., Ed.; Springer International Publishing: Cham, Switzerland, 2017. [Google Scholar] [CrossRef]

- Tang, H.; Li, D.; Wang, S.; Dong, Z. CASOA: An Architecture for Agent-Based Manufacturing System in the Context of Industry 4.0. IEEE Access 2017, 6, 2018. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A.; Sokolov, B. A Dynamic Approach to Multi-stage Job Shop Scheduling in an Industry 4.0-Based Flexible Assembly System. In Advances in Production Management Systems. The Path to Intelligent, Collaborative and Sustainable Manufacturing; Lödding, H., Riedel, R., Thoben, K.D., von Cieminski, G., Kiritsis, D., Eds.; Springer: Cham, Switzerland, 2017; Volume 513. [Google Scholar]

- Schröder, C. The Challenges of Industry 4.0 for Small and Medium-sized Enterprises; Wirtschafts-und Sozialpolitik, A., Ed.; Friedrich-Ebert-Stiftung: Berlin/Heidelberg, Germany, 2017; ISBN 978-3-95861-543-4. [Google Scholar]

- Xu, J.; Huang, E.; Hsieh, L.; Lee, L.H.; Jia, Q.S.; Chen, C.H. Simulation optimization in the era of Industrial 4.0 and the Industrial Internet. J. Simul. 2016, 10, 310–320. [Google Scholar] [CrossRef]

- El Saddik, A. Digital Twins: The Convergence of Multimedia Technologies. IEEE MultiMedia 2018, 25, 87–92. [Google Scholar] [CrossRef]

- Stark, R.; Damerau, T. Digital Twin. In CIRP Encyclopedia of Production Engineering; Chatti, S., Tolio, T., Eds.; Springer: Berlin/Heidelberg, Germany, 2019; pp. 1–8. [Google Scholar]

- Rosen, R.; Wichert, V.; Lo, G.; Bettenhausen, K.D. About the Importance of Autonomy and Digital Twins for the Future of Manufacturing. IFAC-Papersonline 2015, 28, 567–572. [Google Scholar] [CrossRef]

- Lu, Y.; Liu, C.; Kevin, I.; Wang, K.; Huang, H.; Xu, X. Digital Twin-driven smart manufacturing: Connotation, reference model, applications and research issues. Robot. Comput. Integr. Manuf. 2020, 61, 101837. [Google Scholar] [CrossRef]

- Zhang, C.; Xu, W.; Liu, J.; Liu, Z.; Zhou, Z.; Pham, D.T. A Reconfigurable Modelling Approach for Digital Twin-based Manufacturing System. Procedia CIRP 2019, 83, 118–125. [Google Scholar] [CrossRef]

- Oks, S.J.; Fritzsche, A.; Moslein, K.M. Engineering cyber-physical systems: An application map-based method. Procedia CIRP 2018, 72, 456–461. [Google Scholar] [CrossRef]

- Göppert, A.; Grahn, L.; Rachner, J.; Grunert, D.; Hort, S.; Schmitt, R.H. Pipeline for ontology-based modeling and automated deployment of digital twins for planning and control of manufacturing systems. J. Intell. Manuf. 2021, 1–20. [Google Scholar] [CrossRef]

- Digital Twin Technology and Simulation: Benefits, Usage and Predictions 2018, 11 November 2017; pp. 1–6. Available online: https://www.i-Scoop.eu (accessed on 22 December 2021).

- Kritzinger, W.; Karner, M.; Traar, G.; Henjes, J.; Sihn, W. Digital twin in manufacturing: A categorical literature review and classification. IFAC-Papersonline 2018, 510, 1016–1022. [Google Scholar] [CrossRef]

- Barni, A.; Pietraroia, D.; Züst, S.; West, S.; Stoll, O. Digital Twin Based Optimization of a Manufacturing Execution System to Handle High Degrees of Customer Specifications. J. Manuf. Mater. Process 2020, 4, 109. [Google Scholar] [CrossRef]

- Biesinger, F.; Meike, D.; Kraß, B.; Weyrich, M. A digital twin for production planning based on cyber-physical systems: A Case Study for a Cyber-Physical System-Based Creation of a Digital Twin. Procedia CIRP 2019, 79, 355–360. [Google Scholar] [CrossRef]

- Cyber-Physical Systems. Driving Force for Innovation in Mobility, Health, Energy and Production; Hellinger, A., Seeger, H., Eds.; National Academy of Science and Engineering: Washington, DC, USA, 2011. [Google Scholar]

- Monostori, L. Cyber-physical production systems: Roots, expectations and R&D challenges. Procedia CIRP 2014, 17, 9–13. [Google Scholar] [CrossRef]

- Samir, S.K.; Khabazzi, M.R.; Maffei, A.; Onori, M.A. Key Performance Indicators in Cyber-Physical Production Systems. Procedia CIRP 2018, 72, 498–502. [Google Scholar] [CrossRef]

- ISO/DIS 23247-1 to 23247-4. Automation Systems and Integration—Digital Twin Framework for Manufacturing; International Organization for Standardization: Geneva, Switzerland, 2020. [Google Scholar]

- Jones, D.; Snider, C.; Nassehi, A.; Yon, J.; Hicks, B. Characterizing the Digital Twin: A systematic literature review. CIRP J. Manuf. Sci. Technol. 2020, 29, 36–52. [Google Scholar] [CrossRef]

- Ding, K.; Chan, F.T.S.; Zhang, X.; Zhou, G.; Zhang, F. Defining a Digital Twin-based Cyber-Physical Production System for autonomous manufacturing in smart shop floors. Int. J. Prod. Res. 2019, 57, 6315–6334. [Google Scholar] [CrossRef] [Green Version]

- Park, K.T.; Lee, J.; Kim, H.J.; Noh, S.D. Digital twin-based cyber physical production system architectural framework for personalized production. Int. J. Adv. Manuf. Technol. 2020, 106, 1787–1810. [Google Scholar] [CrossRef]

- Zhong, R.Y.; Xu, X.; Aheleroff, S. Smart Manufacturing Systems for Industry 4.0: A Conceptual Framework. In Proceedings of the International Conference on Computers and Industrial Engineering, Online, 1 May 2017; pp. 10–31. [Google Scholar]

- Schutzer, K.; Bertazzi, J.A.; Sallati, C.; Anderl, R.; Zancul, E. Contribution to the development of a Digital Twin based on product lifecycle to support the manufacturing process. Procedia CIRP 2019, 84, 82–87. [Google Scholar] [CrossRef]

- Colangelo, E.; Hartleif, S.; Fulga-Beising, B. Informationsmanagement in der Smart Factory. 2019. Available online: https://e-paper.vdi-fachmedien.de/werkstattstechnik/ (accessed on 17 December 2021).

- Kousi, N.; Gkournelos, C.; Aivaliotis, S.; Giannoulis, C.; Michalos, G.; Makris, S. Digital twin for adaptation of robots’ behavior in flexible robotic assembly lines. Procedia Manuf. 2019, 28, 121–126. [Google Scholar] [CrossRef]

- Rodionov, N.; Tatarnikova, L. Digital twin technology as a modern approach to quality management. In E3S Web of Conferences; EDP Sciences: Ulis, France, 2021; Volume 284, pp. 4–13. [Google Scholar] [CrossRef]

- Talkhestani, B.A.; Weyrich, M. Digital Twin of manufacturing systems: A case study on increasing the efficiency of reconfiguration. at-Automatisierungstechnik 2020, 68, 435–444. [Google Scholar] [CrossRef]

- Madonna, M.; Monica, L.; Anastasi, S.; di Nardo, M. Evolution of cognitive demand in the human–machine interaction integrated with industry 4.0 technologies. WIT Trans. Built Environ. 2019, 189, 13–19. [Google Scholar] [CrossRef] [Green Version]

- Tagliabue, L.C.; Cecconi, F.R.; Maltese, S.; Rinaldi, S.; Ciribini, A.L.C.; Flammini, A. Leveraging Digital Twin for Sustainability Assessment of an Educational Building. Sustainability 2021, 13, 480. [Google Scholar] [CrossRef]

- Sepasgozar, S.M.E. Differentiating Digital Twin from Digital Shadow: Elucidating a Paradigm Shift to Expedite a Smart, Sustainable Built Environment. Buildings 2021, 11, 151. [Google Scholar] [CrossRef]

- Kamble, S.; Gunasekaran, A.; Parekh, H.; Mani, V.; Belhadi, A.; Sharma, R. Digital twin for sustainable manufacturing supply chains: Current trends, future perspectives, and an implementation framework. Technol. Forecast. Soc. Chang. 2022, 176, 121448. [Google Scholar] [CrossRef]

- Sartal, A.; Bellas, R.; Mejıas, A.M.; Garcıa-Collado, A. The sustainable manufacturing concept, evolution and opportunities within Industry 4.0: A literature review. Adv. Mech. Eng. 2020, 12, 1687814020925232. [Google Scholar] [CrossRef]

- Arnold, C.; Kiel, D.; Voigt, K.I. How the industrial internet of things changes business models in different manufacturing industries. Int. J. Innov. Manag. 2016, 20, 1640015. [Google Scholar] [CrossRef]

- Brunet-Thornton, R.; Martinez, F. Analyzing the Impacts of Industry 4.0 in Modern Business Environments; IGI Global: Hershey, PA, USA, 2018. [Google Scholar]

- Etuk, R.U.; Etuk, G.R.; Baghebo, M. Small and Medium Scale Enterprises (Smes) and Nigeria’s Economic Development. Mediterr. J. Soc. Sci. 2014, 5, 656. [Google Scholar] [CrossRef]

- Ilegbinosa, I.A.; Jumbo, E. Small and Medium Scale Enterprises and Economic Growth in Nigeria: 1975–2012. Int. J. Bus. Manag. 2015, 10, 16. [Google Scholar] [CrossRef] [Green Version]

- Dobrovic, J.; Urbanski, M.; Gallo, P.; Benková, E.; Cabinová, V. Balanced scorecard concept as a tool of strategic management and its usage in the construction industry. Pol. J. Manag. Stud. 2018, 18, 59–72. [Google Scholar] [CrossRef]

- Yasin, A.; Pang, T.Y.; Cheng, C.T.; Miletic, M.A. Roadmap to Integrate Digital Twins for Small and Medium-Sized Enterprises. Appl. Sci. 2021, 11, 9479. [Google Scholar] [CrossRef]

- Fakhimi, M.; Lampros, K.; Stergioulas, N.; Navonil, M. Modelling for sustainable development using the triple-bottom line: Methods, challenges and the need for hybrid M&S. In Proceedings of the 2017 Winter Simulation Conference, Las Vegas, NV, USA, 3–6 December 2017. [Google Scholar]

- Oztemel, E.; Gursev, S. Literature review of Industry 4.0 and related technologies. J. Intell. Manuf. 2020, 31, 127–182. [Google Scholar] [CrossRef]

- Martínez-Olvera, C.; Davizon-Castillo, Y.A. Modeling the supply chain management creation of value: A literature review of relevant concept. In Applications of Contemporary Management Approaches in Supply Chains; IntechOpen Limited: London, UK, 2015; ISBN 978-953-51-2045-2. [Google Scholar]

- Martínez-Olvera, C.; Shunk, D. Comprehensive framework for the development of a supply chain strategy. Int. J. Prod. Res. 2006, 44, 4511–4528. [Google Scholar] [CrossRef]

- Martínez-Olvera, C. Reference model of the manufacturing execution activity in make-to-order environments. Int. J. Prod. Res. 2007, 47, 1635–1659. [Google Scholar] [CrossRef]

- Martínez-Olvera, C. Methodology for realignment of supply-chain structural elements. Int. J. Prod. Econ. 2008, 114, 714–722. [Google Scholar] [CrossRef]

- Ivanov, D. Structural Dynamics and Resilience in Supply Chain Risk Management. In International Series in Operations Research & Management Science; Springer International Publishing AG: Cham, Switzerland, 2018; Volume 265. [Google Scholar] [CrossRef]

- Zipkin, P. The limits of mass customization. MIT Sloan Manag. Rev. 2001, 42, 81–87. [Google Scholar]

- Andersen, A.L.; Larsen, J.K.; Nielsen, K.; Brunoe, T.D.; Ketelsen, C. Exploring Barriers Toward the Development of Changeable and Reconfigurable Manufacturing Systems for Mass-Customized Products: An Industrial Survey. In Customization 4.0, Proceedings of the 9th World Mass Customization & Personalization Conference (MCPC 2017), Aachen, Germany, 20–21 November 2017; Hankammer, S., Nielsen, K., Piller, F.T., Schuh, G., Wang, N., Eds.; Springer International Publishing AG: Cham, Switzerland, 2017. [Google Scholar]

- Blecker, T.; Friedrich, G. Guest Editorial: Mass Customization Manufacturing Systems. IEEE Trans. Eng. Manag. 2007, 54, 4–11. [Google Scholar] [CrossRef]

- Dhungana, D.; Haselböck, A.; Taupe, R. A Marketplace for Smart Production Ecosystems. In Customization 4.0, Proceedings of the 9th World Mass Customization & Personalization Conference (MCPC 2017), Aachen, Germany, 20–21 November 2017; Hankammer, S., Nielsen, K., Piller, F.T., Schuh, G., Wang, N., Eds.; Springer International Publishing AG: Cham, Switzerland, 2017. [Google Scholar]

- Gullander, P.; Davidsson, A.; Dencker, K.; Fasth, Å.; Fässberg, T.; Harlin, U.; Stahre, J. Towards a Production Complexity Model that Supports Operation, Re-balancing and Man-hour Planning. In Proceedings of the 4th Swedish Production Symposium, SPS11, Lund, Sweden, 3–5 May 2011. [Google Scholar]

- Lachenmaier, J.F.; Lasi, H.; Kemper, H.G. Simulation of production processes involving cyber-physical systems. Procedia CIRP 2017, 62, 577–582. [Google Scholar] [CrossRef]

- Mourtzis, D.; Fotia, S.; Boli, N.; Pittaro, P. Product-service system (PSS) complexity metrics within mass customization and Industry 4.0 environment. Int. J. Adv. Manuf. Technol. 2018, 97, 91–103. [Google Scholar] [CrossRef]

- Yao, X.; Zhou, J.; Lin, Y.; Li, Y.; Yu, H.; Liu, Y. Smart manufacturing based on cyber-physical systems and beyond. J. Intell. Manuf. 2019, 30, 2805–2817. [Google Scholar] [CrossRef] [Green Version]

- Bordeleau, F.E.; Mosconi, E.; Santa-Eulalia, L.A. Business Intelligence Value Creation: A Multiple Case Study in Manufacturing SMEs undergoing an Industry 4.0 transformation. In Proceedings of the 51st Hawaii International Conference on System Sciences, Waikoloa, HI, USA, 3–6 January 2018; pp. 3944–3953. [Google Scholar]

- Sun, Y.; Yan, H.; Lu, C.; Bie, R.; Thomas, P. A holistic approach to visualizing business models for the internet of things. Commun. Mob. Comput. 2012, 1, 4. [Google Scholar] [CrossRef] [Green Version]

- Brettel, M.; Friederichsen, N.; Keller, M.; Rosenberg, M. How Virtualization, Decentralization and Network Building Change the Manufacturing Landscape: An Industry 4.0 Perspective. Int. J. Mech. Aerosp. Ind. Mechatron. Eng. 2014, 8, 37–44. [Google Scholar]

- Stock, T.; Seliger, G. Opportunities of sustainable manufacturing in industry 4.0. Procedia CIRP 2016, 40, 536–541. [Google Scholar] [CrossRef] [Green Version]

- Jabbour, A.B.L.S.; Jabbour, C.J.C.; Foropon, C.; Godinho, F. When titans meet–Can industry 4.0 revolutionize the environmentally sustainable manufacturing wave? The role of critical success factors. Technol. Forecast. Soc. Chang. 2018, 132, 18–25. [Google Scholar] [CrossRef]

- Jabbour, A.B.L.S.; Jabbour, C.J.C.; Godinho, F.; Roubaud, D. Industry 4.0 and the circular economy: A proposed research agenda and original roadmap for sustainable operations. Ann. Oper. Res. 2018, 270, 273–286. [Google Scholar]

- Gräßler, A.P.; Pottebaum, J. Creation of a Learning Factory for Cyber Physical Production Systems. Procedia CIRP 2016, 54, 107–112. [Google Scholar] [CrossRef] [Green Version]

- Davis, J.; Edgar, T.; Porter, J.; Bernaden, J.; Sarli, M. Smart manufacturing, manufacturing intelligence and demand-dynamic performance. Comput. Chem. Eng. 2012, 47, 145–156. [Google Scholar] [CrossRef]

- Kang, H.S.; Lee, J.Y.; Choi, S.S.; Kim, H.; Park, J.H.; Son, J.Y.; Kim, B.H.; Noh, S.D. Smart manufacturing: Past research, present findings, and future directions. Int. J. Precis. Eng. Manuf.-Green Technol. 2016, 3, 111–128. [Google Scholar] [CrossRef]

- Woo, J.; Shin, S.J.; Seo, W.; Meilanitasari, P. Developing a big data analytics platform for manufacturing systems: Architecture, method, and implementation. Int. J. Adv. Manuf. Technol. 2018, 99, 9–12. [Google Scholar] [CrossRef]

- Yoon, J.S.; Shin, S.J.; Suh, S.H. A conceptual framework for the ubiquitous factory. Int. J. Prod. Res. 2012, 50, 2174–2189. [Google Scholar] [CrossRef]

- Kusiak, A. Smart manufacturing. Int. J. Prod. Res. 2018, 56, 508–517. [Google Scholar] [CrossRef]

- Wang, S.; Wan, J.; Li, D.; Zhang, C. Implementing Smart Factory of Industrie 4.0: An Outlook. Int. J. Distrib. Sens. Netw. 2016, 12, 3159805. [Google Scholar] [CrossRef] [Green Version]

- Hazen, B.; Boone, C.; Farmer, L.A.; Ezell, J. Data quality for data science, predictive analytics, and big data in supply chain management: An introduction to the problem and suggestions for research and applications. Int. J. Prod. 2014, 154, 72–80. [Google Scholar] [CrossRef]

- Hazen, B.T.; Skipper, J.B.; Ezell, J.D.; Boone, C.A. Big data and predictive analytics for supply chain sustainability: A theory-driven research agenda. Comput. Ind. Eng. 2016, 101, 592–598. [Google Scholar] [CrossRef]

- Papadopoulos, T.; Gunasekaran, A.; Dubey, R.; Altay, N.; Childe, S.J.; Wamba, S.F. The role of big data in explaining disaster resilience in supply chains for sustainability. J. Clean. Prod. 2017, 142, 1108–1118. [Google Scholar] [CrossRef] [Green Version]

- Wu, K.J.; Liao, C.J.; Tseng, M.L.; Lim, M.K.; Hu, J.; Tan, K. Toward sustainability: Using big data to explore the decisive attributes of supply chain risks and uncertainties. J. Clean. Prod. 2017, 42, 663–676. [Google Scholar] [CrossRef]

- Jia, S.; Tang, R.; Lv, J. Therblig-based energy demand modeling methodology of machining process to support intelligent manufacturing. J. Intell. Manuf. 2014, 25, 913–931. [Google Scholar] [CrossRef]

- Wang, S.; Liang, W.D.; Cai, X.T. Big data enabled intelligent immune system for energy efficient manufacturing management. J. Clean. Prod. 2018, 195, 507–520. [Google Scholar] [CrossRef]

- Zhang, L.; Mai, J.; Li, B.H.; Tao, F.; Chao, C.; Ren, L.; Huntsinger, R.C. Future Manufacturing Industry with Cloud Manufacturing. In Cloud-Based Design and Manufacturing (CBDM); Schaefer, D., Ed.; Springer International Publishing: Cham, Switzerland, 2014. [Google Scholar] [CrossRef]

- Yao, X.; Lian, Z.; Yang, Y.; Zhang, Y.; Jin, H. Wisdom manufacturing: New humans-computers-things collaborative manufacturing model. Comput. Integr. Manuf. Syst. 2014, 20, 1490–1498. [Google Scholar]

- Yao, X.; Yu, M.; Chen, Y.; Xiang, Z. Connotation, architecture and key technologies of internet of manufacturing things. Comput. Integr. Manuf. Syst. 2014, 20, 1–10. [Google Scholar]

- Mittal, S.; Khan, M.A.; Romero, D.; Wuest, T. Smart manufacturing: Characteristics, technologies and enabling factors. Proc. IMechE Part B J. Eng. Manuf. 2017, 233, 1342–1361. [Google Scholar] [CrossRef]

- Simeone, A. Resource efficiency optimization engine in smart production networks via intelligent cloud manufacturing platforms. Procedia CIRP 2018, 78, 19–24. [Google Scholar] [CrossRef]

- Afuah, A.; Tucci, C.L. Internet Business Models and Strategies; McGraw Hill: Boston, MA, USA, 2003. [Google Scholar]

- Gelbmann, U.; Hammerl, B. Integrative re-use systems as innovative business models for devising sustainable product–service-systems. J. Clean. Prod. 2015, 97, 50–60. [Google Scholar] [CrossRef]

- Osterwalder, A. The Business Model Ontology: A Proposition in a Design Science Approach. Ph.D. Thesis, Universite de Lausanne Ecole des Hautes Etudes Commerciales, Lausanne, Switzerland, 2004. [Google Scholar]

- Prause, G. Sustainable business models and structures for INDUSTRY 4.0. J. Secur. Sustain. Issues 2015, 5, 159–169. [Google Scholar] [CrossRef] [Green Version]

- Stocka, F.T.; Obenaus, M.; Kunz, S.; Kohl, A.H. Industry 4.0 as enabler for a sustainable development: A qualitative assessment of its ecological and social potential. Process Saf. Environ. Prot. 2018, 118, 254–267. [Google Scholar] [CrossRef]

- Martínez-Olvera, C.; Mora-Vargas, J. A Comprehensive Framework for the Analysis of Industry 4.0 Value Domains. Sustainability 2019, 11, 2960. [Google Scholar] [CrossRef] [Green Version]

- Osterwalder, A.; Pigneur, Y.; Clark, T.; Smith, A. Business Model Generation: A Handbook for Visionaries, Game Changers, and Challengers; John Wiley & Sons: Hoboken, NJ, USA, 2010; ISBN 978-0-470-87641-1. [Google Scholar]

- Seliger, G. Sustainability Engineering by Product-Service Systems. In Glocalized Solutions for Sustainability in Manufacturing, Proceedings of the 18th CIRP International Conference on Life Cycle Engineering, Braunschweig, Germany, 2–4 May 2011; Springer: Berlin/Heidelberg, Germany, 2011; pp. 22–28. [Google Scholar]

- Martínez-Olvera, C. An Entropy-Based Formulation for Assessing the Complexity Level of a Mass Customization Industry 4.0 Environment. Math. Probl. Eng. 2020, 2020, 1–19. [Google Scholar] [CrossRef]

- Li, W. Efficiency of Manufacturing Processes Energy and Ecological Perspective, Sustainable Production. In Life Cycle Engineering and Management Series; Herrmann, C., Ed.; Springer: Braunschweig, Germany; Sami Kara: Sydney, Australia, 2015. [Google Scholar] [CrossRef]

- Hsu, C.; Rattner, L.; Pant, S. Manufacturing Information using a Reference Model. Int. J. Oper. Prod. Manag. 1994, 14, 52–72. [Google Scholar]

- Hsu, C.; Rattner, L.; Cho, J.; Yee, L. Core Information Model: A Practical Solution to Costly Integration Problems. Comput. Ind. Eng. 1995, 28, 523–544. [Google Scholar] [CrossRef] [Green Version]

- Fan-Tien, C.; Yang, H.C.; Kuo, T.L.; Feng, C.; Jeng, M.D. Modeling and analysis of equipment managers in manufacturing execution systems for semiconductor packaging. IEEE Trans. Syst. Man Cybern. Part B Cybern. 2000, 30, 772–782. [Google Scholar] [CrossRef] [PubMed]

- Malhotra, R.; Jayaraman, S. An Integrated Framework for Enterprise Modeling. J. Manuf. Syst. 1992, 11, 426–441. [Google Scholar]

- Huff, P.B.; Liles, D. A Comprehensive Enterprise Architecture for Small Manufacturers. In Proceedings of the 2nd Industrial Engineering Research Conference, Los Angeles, CA, USA, 26–28 May 1993. [Google Scholar]

- Cosenz, F.; Rodrigues, V.P.; Rosati, F. Dynamic business modeling for sustainability: Exploring a system dynamics perspective to develop sustainable business models. Bus. Strategy Environ. 2020, 29, 651–664. [Google Scholar] [CrossRef]

- Suh, C.J.; Lee, I.T. An Empirical Study on the Manufacturing Firm’s Strategic Choice for Sustainability in SMEs. Sustainability 2018, 10, 572. [Google Scholar] [CrossRef] [Green Version]

- Meyer, W. Expert Systems in Factory Management: Knowledge-Based CIM; Ellis Horwood Limited: Chichester, UK, 1990; ISBN 0-13-293473-6. [Google Scholar]

- ESPRIT Consortium AMICE. CIMOSA: Open Systems Architecture for CIM. In Research Reports of ESPRIT Project 688; Springer: Berlin/Heidelberg, Germany, 1989; Volume 1. [Google Scholar]

- Pontow, S. Modelling CSP Solution Algorithms with Petri Decision Nets. In Principles and Practice of Constraint Programming-CP98, Proceedings of the 4th International Conference, Pisa, Italy, 26–30 October 1998; Proceedings Lecture Notes in Computer Science; Springer: Berlin/Heidelberg, Germany, 1998; ISBN 3-540-65224-8. [Google Scholar]

- Dean, P.R.; Tu, Y.L.; Xue, D. A framework for generating product production information for mass customization. Int. J. Adv. Manuf. Technol. 2008, 38, 1244–1259. [Google Scholar] [CrossRef]

- Soltysova, Z.; Bednar, S. Complexity management in terms of mass customized manufacturing. Pol. J. Manag. Stud. 2015, 12, 139–149. [Google Scholar]

- Boer, H.E.E.; Nielsen, K.; Brunoe, T.D. Can the SME Successfully Adopt Mass Customization? In Customization 4.0, Proceedings of the 9th World Mass Customization & Personalization Conference (MCPC 2017), Aachen, Germany, 20–21 November 2017; Springer Proceedings in Business and Economics: Berlin, Germany, 2017. [Google Scholar]

- Daaboul, J.; Bernard, A.; Laroche, F. Extended Value Chain Modelling and Simulation for Mass Customization Implementation. In Proceedings of the DET2009 6th International Conference on Digital Enterprise Technology, Hong Kong, China, 14–16 December 2009. [Google Scholar]

- Daaboul, A.; Bernard, A.; Laroche, F. Extended value network modelling and simulation for mass customization implementation. J. Intell. Manuf. 2012, 23, 2427–2439. [Google Scholar] [CrossRef]

- Modrak, V.; Marton, D.; Bednar, S. The Influence of Mass Customization Strategy on Configuration Complexity of Assembly Systems. Procedia CIRP 2015, 33, 538–543. [Google Scholar] [CrossRef] [Green Version]

- Shu, L.; Yang, L. A Modified PSO to Optimize Manufacturers Production and Delivery. JSW 2012, 7, 2325–2332. [Google Scholar] [CrossRef]

- Baykasoglu, A.; Subulan, K.; Güçdemir, H.; Dudaklı, N.; Akyol, D.E. Revenue management for make-to-order manufacturing systems with a real-life application. Eng. Econ. 2019, 65, 27–65. [Google Scholar] [CrossRef]

- Lee, C.H.; Chen, C.H.; Lin, C.; Fan, L.; Zhao, X. Developing a Quick Response Product Configuration System under Industry 4.0 Based on Customer Requirement Modelling and Optimization Method. Appl. Sci. 2019, 9, 5004. [Google Scholar] [CrossRef] [Green Version]

- Miltenburg, J.; Saparling, D. Managing and reducing total cycle time: Models and analysis. Int. J. Prod. Econ. 1996, 46, 89–108. [Google Scholar] [CrossRef] [Green Version]

- Safar, L.; Sopko, J.; Bednar, S.; Poklemba, R. Concept of SME Business Model for Industry 4.0 Environment. TEM J. 2018, 7, 626–637. [Google Scholar] [CrossRef]

- Kiangala, K.S.; Wang, Z. Initiating predictive maintenance for a conveyor motor in a bottling plant using industry 4.0 concepts. Int. J. Adv. Manuf. Technol. 2018, 97, 3251–3271. [Google Scholar] [CrossRef]

- Issa, A.; Hatiboglu, B.; Bildstein, A.; Bauernhans, T. Industrie 4.0 roadmap: Framework for digital transformation based on the concepts of capability maturity and alignment. Procedia CIRP 2018, 72, 973–978. [Google Scholar] [CrossRef]

- Muhammad, I.; Hameed, W.; Haque, A. Influence of Industry 4.0 on the Production and Service Sectors in Pakistan: Evidence from Textile and Logistics Industries. Soc. Sci. 2018, 7, 246. [Google Scholar]

- Muller, J.M.; Kiel, D.; Voigt, K.I. What drives the implementation of Industry 4.0? The role of opportunities and challenges in the context of sustainability. Sustainability 2018, 10, 247. [Google Scholar] [CrossRef] [Green Version]

- Weinert, N.; Chiotellis, S.; Seliger, G. Methodology for planning and operating energy-efficient production systems. CIRP Ann. Manuf. Technol. 2011, 60, 41–44. [Google Scholar] [CrossRef]

- Muller, J.; Dotzauer, V.; Voigt, K. (Eds.) Supply Management Research; Springer: Wiesbaden, Germany, 2017; pp. 165–179. [Google Scholar]

- Tseng, M.L.; Tan, R.R.; Chiu, A.S.F.; Chien, C.F.; Kuo, T.C. Circular economy meets industry 4.0: Can big data drive industrial symbiosis? Resour. Conserv. Recycl. 2018, 131, 146–147. [Google Scholar] [CrossRef]

- Horvath, D.; Szabó, R.Z. Driving forces and barriers of Industry 4.0: Do multinational and small and medium-sized companies have equal opportunities? Technol Forecast. Soc. Chang. 2019, 146, 119–132. [Google Scholar] [CrossRef]

- Sartal, A.; Carou, D.; Dorado-Vicente, R. Facing the challenges of the food industry: Might additive manufacturing be the answer? Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2019, 233, 1902–1906. [Google Scholar] [CrossRef]

- Dalenogare, L.S.; Benitez, G.B.; Ayala, N.F.; Frank, A.G. The expected contribution of Industry 4.0 technologies for industrial performance. Int. J. Prod. Econ. 2018, 204, 383–394. [Google Scholar] [CrossRef]

- Shrouf, F.; Ordieres, J.; Miragliotta, G. Smart factories in Industry 4.0: A review of the concept and of energy management approached in production based on the Internet of Things paradigm. In Proceedings of the 2014 IEEE International Conference on Industrial Engineering and Engineering Management, Selangor Darul Ehsan, Malaysia, 9–12 December 2014; pp. 697–701. [Google Scholar] [CrossRef]

- Sarkis, J.; Zhu, Q. Environmental Sustainability and Production: Taking the Road Less Traveled. Int. J. Prod. Res. 2018, 56, 743–759. [Google Scholar] [CrossRef]

- Robert, K.W.; Parris, T.M.; Leiserowitz, A.A. What is Sustainable Development? Goals, Indicators, Values, and Practice. Environ. Sci. Policy Sustain. Dev. 2005, 47, 8–21. [Google Scholar] [CrossRef]

- Bai, C.; Dallasega, P.; Orzes, G.; Sarkis, J. Industry 4.0 technologies assessment: A sustainability perspective. Int. J. Prod. Econ. 2020, 229, 107776. [Google Scholar] [CrossRef]

- Beltrami, M.; Orzes, G. Industry 4.0 and sustainability: A systematic literature review. In Decision Sciences in a Connected World, Proceedings of the 10th Annual EDSI Conference, Philadelphia, PA, USA, 9 October 2019; Springer Proceedings in Business and Economics: Berlin, Germany, 2019. [Google Scholar]

| VALUE | ECONOMIC | ENVIRONMENTAL | SOCIAL |

|---|---|---|---|

| Proposition | Economic value | Functional value | Social value |

| Creation I | Key Activities | Production | Governance |

| Key Partners | Suppliers | Local Community | |

| Creation II | Key Resources | Materials | Employees |

| Key Partners | Suppliers | Local Community | |

| Delivery | Customers’ Segments & Relationships | Use & End-of-Life Cycle | Society Culture |

| Distribution Channels | Distribution | Scale of Outreach | |

| Capture | Value Stream | Environmental Benefits | Social Benefits. |

| Cost Structure | Environmental Impacts | Social Impacts | |

| Sustainability Indicator | Product Innovation | Emission reduction | Human diversity |

| Risk management Profit | Natural resource management Environmental management | Human rights Labor relations | |

| Cost savings | Environmental assessment | ||

| Eco-Environmental | Energy efficiency | X | |

| Life cycle management | |||

| Socio-Environmental | X | Client safety & health | |

| Global climate change | |||

| Socio-Economic | Customer Ethics | X | Security |

| Product | Transformation Activities Sequence | Sequence Option # | |

|---|---|---|---|

| M4 | M14 | ||

| PA | 2nd (50%) | 1 | |

| 2nd (50%) | 2 | ||

| 1st & 2nd (100%) | 3 | ||

| 1/3 | 2/3 | # sequences fulfilled | |

| PB | 3rd (33.33%) | 1 | |

| 3rd (33.33%) | 2 | ||

| 3rd (33.33%) | 3 | ||

| 3rd (33.33%) | 4 | ||

| 1st & 3rd (66.66%) | 5 | ||

| 1st & 3rd (66.66%) | 6 | ||

| 2/6 | 4/6 | # sequences fulfilled | |

| PC | 4th (25%) | 1 | |

| 4th (25%) | 2 | ||

| 4th (25%) | 3 | ||

| 4th (25%) | 4 | ||

| 1st & 4th (50%) | 5 | ||

| 1st & 4th (50%) | 6 | ||

| 2/6 | 4/6 | # sequences fulfilled | |

| Question Posed | Decision Criteria | |

|---|---|---|

| Smart products | How many transformation activities are left in my manufacturing route? | Select the resource that provides the most of these transformation activities. |

| Smart resource | How many transformation activities can I provide? | Select the product that consumes the most of these transformation activities. |

| Smart process | Which combination of product and resource advances my manufacturing route completion the most? | Select the combination that advances the most manufacturing routes. |

| Elements | Terminology |

|---|---|

| Model m | Structure and parameters describing the Decision problem d. |

| Decision variable dv | A vector of the variables of the Decision problem d. |

| Decision frame d | Set of all solutions Sd of the decision center for a given Decision problem d. |

| Decision center requests r | Restrictions issued/constraints imposed on the solution space by a decision center. |

| Feasible solution Sf | For a given Model m, Decision frame d, and Decision center requests r, a set of all instantiations of Decision variable dv. |

| Evaluation function ef | Function which assigns a real value to each feasible solution sf. |

| Value function vf | Function which combines the values of all Evaluation functions ef, of several Decision objectives do, to define one scalar value for a given Feasible solution sf. |

| Decision objective do | Minimization or maximization of an Evaluation function ef. |

| Decision rule dr | For a given Model m, Decision frame d, Decision center requests r, an algorithm which finds a good Feasible solution Sf with respect to the Decision objective do. |

| Mass Customization Structural Elements [134] | MTO Business Model [155] | ||

|---|---|---|---|

| SUBCYCLES | ACTIVITIES | ||

| Level of customization | Design | Design new products | Conduct market research |

| Level of OW/OQ | Analyze product technology | ||

| Level of product’s complexity | Develop prototype | ||

| Design new components | |||

| Modify standard design to meet customer requirements | |||

| Obtain customer approval for new design | |||

| Develop bill of material and process plans | |||

| Level of production volume | Production | Production planning and control | |

| Level of production variety | Materials management | ||

| Level of technification | Fabricate parts | ||

| Level of labor skill | Assemble products | ||

| Level of system’s reconfiguration | Inspection, testing, rework | ||

| Level of components/raw materials | Inventory finished products | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martínez-Olvera, C. Towards the Development of a Digital Twin for a Sustainable Mass Customization 4.0 Environment: A Literature Review of Relevant Concepts. Automation 2022, 3, 197-222. https://doi.org/10.3390/automation3010010

Martínez-Olvera C. Towards the Development of a Digital Twin for a Sustainable Mass Customization 4.0 Environment: A Literature Review of Relevant Concepts. Automation. 2022; 3(1):197-222. https://doi.org/10.3390/automation3010010

Chicago/Turabian StyleMartínez-Olvera, César. 2022. "Towards the Development of a Digital Twin for a Sustainable Mass Customization 4.0 Environment: A Literature Review of Relevant Concepts" Automation 3, no. 1: 197-222. https://doi.org/10.3390/automation3010010

APA StyleMartínez-Olvera, C. (2022). Towards the Development of a Digital Twin for a Sustainable Mass Customization 4.0 Environment: A Literature Review of Relevant Concepts. Automation, 3(1), 197-222. https://doi.org/10.3390/automation3010010