3D printing, or additive manufacturing (AM), is an emerging, digital, and collective advanced manufacturing technology that enables one to build a part in a layer-by-layer approach by adding material instead of cutting it, as opposed to subtractive manufacturing processes such as machining [

1]. The material is fused to an ambient temperature and the material is deposited along a controlled path by G codes generated directly from CAD models. Many additive manufacturing technologies, such as fused deposition modeling (FDM), selective laser sintering, inkjet modeling, and stereo-lithography, are available on the market. Due to its ability to securely produce complex geometrical components in an office-friendly environment, fused deposition modeling (FDM) is the most widely used of these processes. The AM process does not require any tools or dies, which turns AM into a remarkable process for manufacturing various customized parts, with enhancements on a daily basis providing products with better dimensional accuracy, strength, and surface roughness [

2]. The elimination of tooling, fixturing, and intermediate steps in AM enables easier low-volume product manufacturing with wide variety, bringing about a revolutionary change in mass production. This manufacturing paradigm change poses new opportunities and challenges for quality control in AM, such as in situ process monitoring, part-to-part quality prediction, statistical process control, statistical transfer learning, and compensation, as well as challenges related to AM processes, the design of experiments for AM, and model uncertainty quantification [

3].

Product shape accuracy and AM build accuracy prediction have been key concerns in ML4AM (machine learning for AM) due to increased access to AM data. At present, the fully automated and decentralized concept of manufacturing is focused on customers in a more efficient and optimized manner. In manufacturing, the digital manufacturing concepts refer to the application of computer systems to manufacturing products, processes, supply chains, and manufacturing services and enable visibility in real-time manufacturing [

4]. With the integration of Artificial Intelligence (AI), AM has benefited from digital and intelligent manufacturing [

5]. However, with the emergence of Industry 4.0, the concept of DM is changing by keeping focus on the closed-loop control of real-time data utilization as well as networked production facilities in order to provide flexible, resilient, and data-driven production [

6]. The emerging I4.0 technologies—the Internet of Things (IoT), Cyber-Physical Systems, augmented reality, Artificial Intelligence, Blockchain, cloud computing, Big Data and additive manufacturing (AM)—have provided a new environment for manufacturing to become intelligent and digital [

7]. Industry 4.0 defines a production-oriented Cyber-Physical System (CPS) that combines warehousing systems, production facilities, logistics, and even social requirements in order to build global networks of value creation [

8]. This is a technique which can turn the traditional machine-based production system into a digital and Artificial Intelligence-based system that allows machines to organize and interact according to the situation, without the need for human–machine interaction (HMI) to control and direct the production flow [

9]. The production process is unique and authenticated because it offers product and process information in real-time and provides a better approach to existing problems and challenges. This concept is composed of specific manufacturing aspects for the internet and Cyber-Physical Systems. CPS systems enabled in AM help to enhance DM more easily than conventional manufacturing (CM) processes [

10]. CPS systems need to control computation, sensing, and communication, of the physical processes involved for AM. Therefore, CPS methodology for the co-design of real-time control and customized computation systems may make the AM process more accurate and controlled. Moreover, the integration of CPS in the AM-manufactured goods makes the supply chain more robust and flexible [

11]. Industry 4.0 incorporates terms related to communication networks, the internet, manufacturing networks, supply chains, and logistics. This means that the practical transition from traditional production systems to smart factories is also a challenge for researchers [

12]. Regarding the optimal implementation of I4.0, the following three main features can be considered: (1) vertical integration through value networks, (2) horizontal integration and networked manufacturing systems, and (3) end-to-end digital engineering convergence across the entire spectrum of the value chain[

13].

Figure 1 shows a value chain of I4.0 which illustrates the three kinds of features and how they relate [

14]. An efficient ecosystem is formed through horizontal integration of the inter-corporations by affiliated companies. There are many physical and information subsystems operated by a company. One aspect of horizontal integration through value networks is to make one corporation compete with several other similar corporations [

13]. Vertical integration is the key to creating a flexible and changeable production system. A self-organized structure is created by the smart machines through this digitalization and automation that can be continuously reconfigured to match various product types. Vast information is gathered and stored to render the manufacturing process transparent [

15]. In end-to-end engineering integration, a reliable and continuous product model may be reused by convergence at any stage [

16]. Therefore, I4.0 anticipates vertically integrating hierarchical subsystems to transform the traditional factory into a highly reconfigurable and flexible manufacturing system to implement the smart factory. This plays a critical role in supporting customized and small-lot consumer requirements. The smart factory is the critical foundation for the other two types of integration, namely horizontal integration through value networks and end-to-end digital engineering integration.

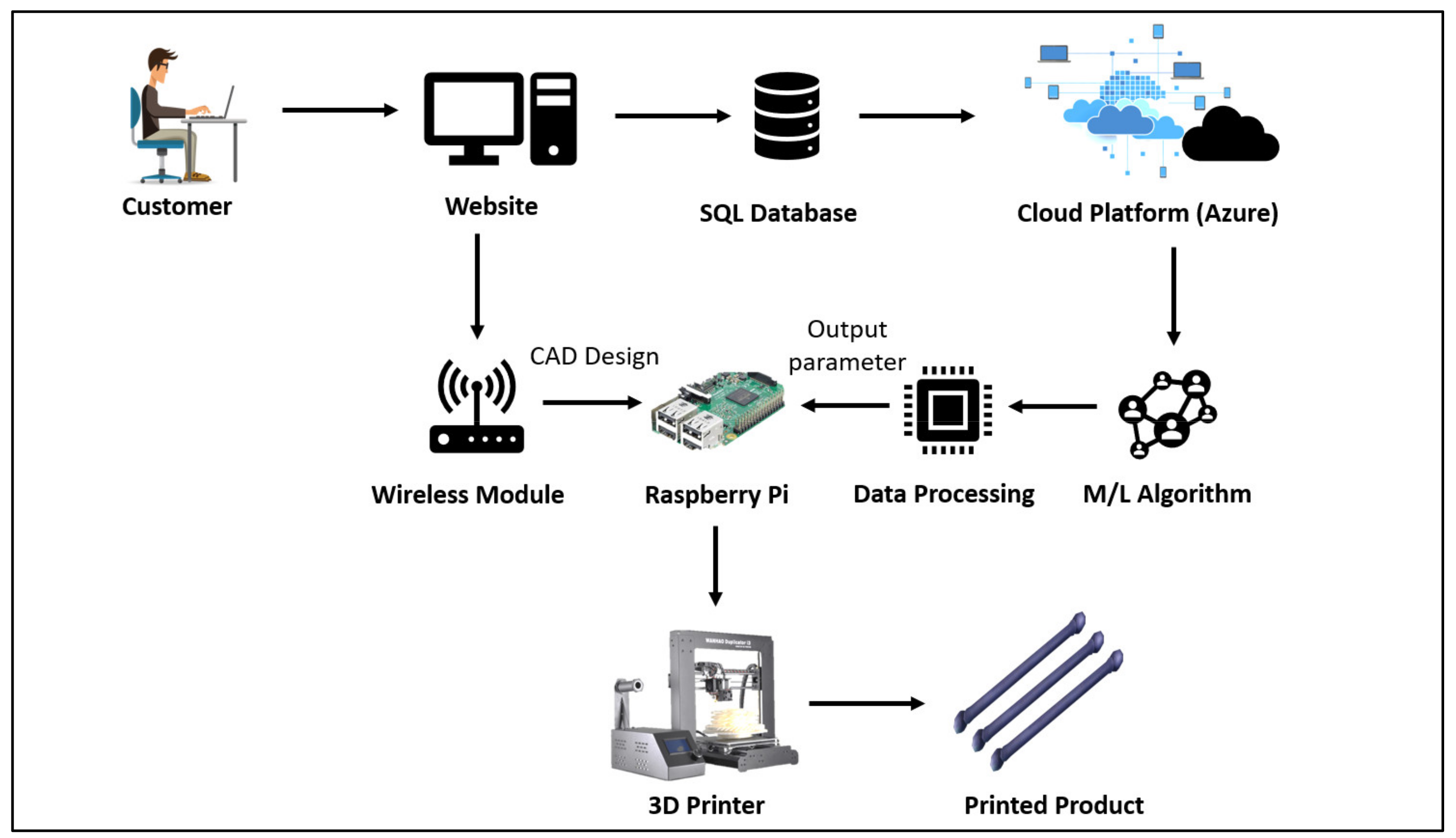

The complete architecture is depicted in

Figure 2, beginning with the data processing pipeline at the device/factory layer and progressing to intelligent, digital, and autonomous applications or dashboards at the application layer.

Figure 2 shows a layer view of the Internet of Things schematic for the I4.0 platform. Machine and production house smart gadgets and tools (such as smartwatches, sensors, glasses, and smartphones) that provide extended human–machine interfaces and functionality. Connecting system layers are used to transform data generated by factory layer devices into information. Aside from that layer, a massive amount of data is gathered in the cyber layer, and data are subsequently analyzed using machine learning algorithms.

This work aims to turn conventional additive manufacturing into intelligent, automatic, and digital AM systems with Industry 4.0. For that purpose, a framework is developed, and a methodological approach is presented in this work. To implement the framework, cloud platform machine learning has been integrated to predict process parameters via a remote CPS system. The methodological approaches have been synthesized in the results section. The study contributes towards developing a system that merges Industry 4.0 technologies for reducing human-to-machine interface and computing the AM process parameters for AM operation. Moreover, this work presents a novel approach for remote access to AM and a user-driven support tool to predict process parameters. Therefore, the framework in this paper can influence the growth of existing AM and considerations for future AM technology for remote locations. The main success of this work lies in the implementation of an Industry 4.0 framework to provide insight to practitioners about the automation and digitization of AM processes.