Physical Pretreatments of Lignocellulosic Biomass for Fermentable Sugar Production

Abstract

1. Introduction

2. Lignocellulosic Biomass

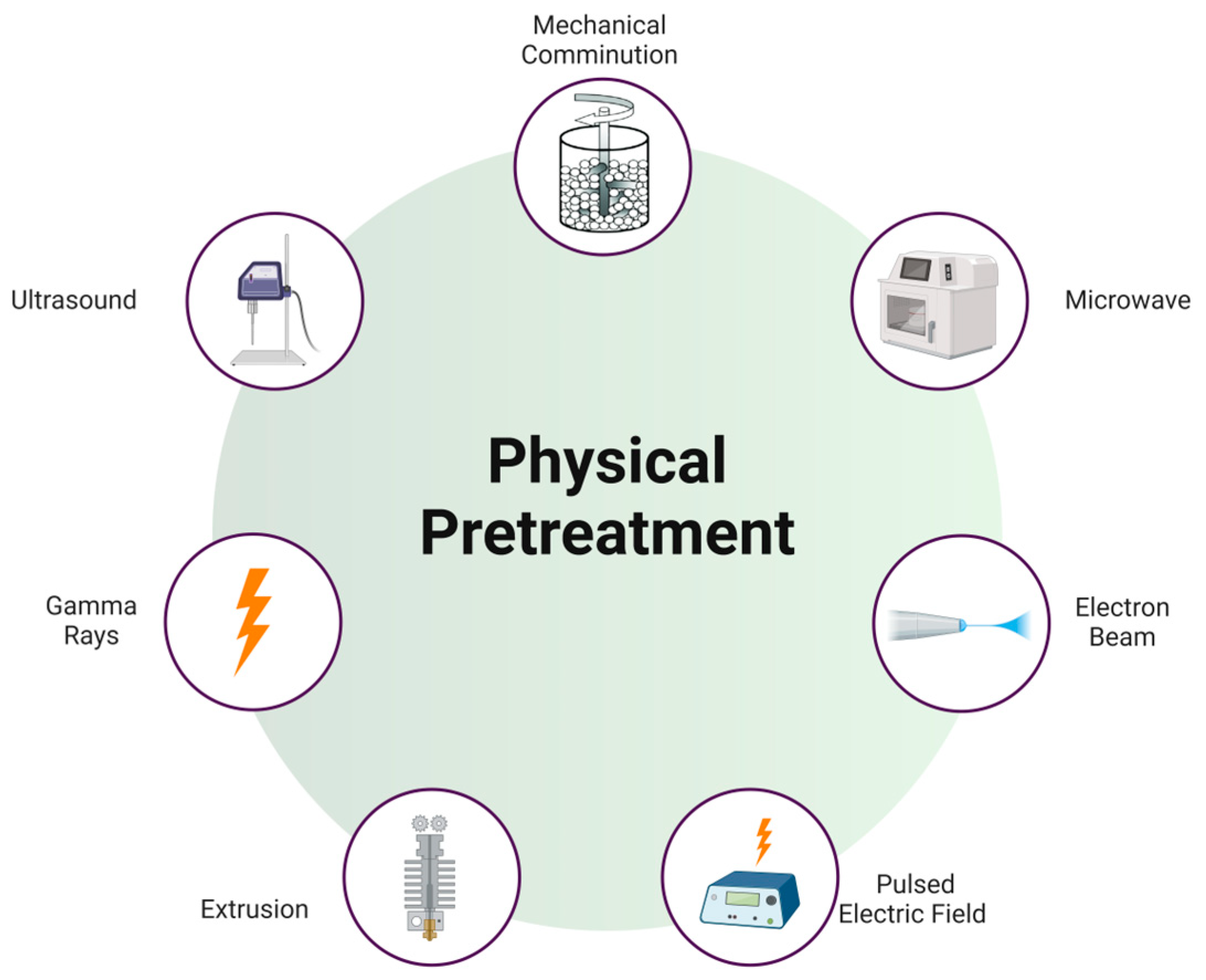

3. Physical Pretreatment

3.1. Mechanical Comminution Pretreatment

3.2. Irradiation Pretreatment

3.2.1. Ultrasound

3.2.2. Microwave

3.2.3. Gamma Rays

3.2.4. Electron Beam

3.3. Extrusion Pretreatment

3.4. Pulsed Electric Field Pretreatment

4. Enzymatic Hydrolysis of Lignocellulosic Biomass After Physical Pretreatment

4.1. Mechanism and Enzymatic Components

4.2. Effect of Pretreatment of Enzymatic Hydrolysis

4.2.1. Mechanical Comminution Pretreatment

4.2.2. Ultrasound Pretreatment

4.2.3. Microwave Pretreatment

4.2.4. Electron Beam Pretreatment

4.2.5. Gamma Rays Pretreatment

4.2.6. Extrusion Pretreatment

4.2.7. Pulsed Electric Field Pretreatment

5. Biomass Final Treatments

5.1. Bioethanol

5.2. Biogas

5.3. Other Products Obtained

6. Energy and Costs Associated with Physical Pretreatment

6.1. Mechanical Comminution

6.2. Ultrasound

6.3. Microwave

6.4. Gamma Radiation

6.5. Electron Beam

6.6. Extrusion

6.7. Pulsed Electric Field (PEF)

7. Conclusions and Critical on Physical Pretreatment

7.1. Common Aspects of Physical Pretreatment Technologies

7.1.1. Structural Modification

7.1.2. Energy Demands

7.1.3. Adaptability to Biomass Variability

7.1.4. Generation of Inhibitors

7.2. Mechanical Comminution

7.3. Ultrasound

7.4. Microwave

7.5. Gamma Rays

7.6. Electron Beam

7.7. Extrusion

7.8. Pulsed Electric Field (PEF)

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhou, Z.; Liu, D.; Zhao, X. Conversion of Lignocellulose to Biofuels and Chemicals via Sugar Platform: An Updated Review on Chemistry and Mechanisms of Acid Hydrolysis of Lignocellulose. Renew. Sustain. Energy Rev. 2021, 146, 111169. [Google Scholar] [CrossRef]

- Cheng, J. Biomass to Renewable Energy Processes Second Edition; CRC Press: Boca Raton, FL, USA, 2017; ISBN 9781315152868. [Google Scholar]

- Singh, N.; Singhania, R.R.; Nigam, P.S.; Dong, C.-D.; Patel, A.K.; Puri, M. Global Status of Lignocellulosic Biorefinery: Challenges and Perspectives. Bioresour. Technol. 2022, 344, 126415. [Google Scholar] [CrossRef] [PubMed]

- Danso, B.; Ali, S.S.; Xie, R.; Sun, J. Valorisation of Wheat Straw and Bioethanol Production by a Novel Xylanase- and Cellulase-Producing Streptomyces Strain Isolated from the Wood-Feeding Termite, Microcerotermes Species. Fuel 2022, 310, 122333. [Google Scholar] [CrossRef]

- Van Putten, R.J.; Van Der Waal, J.C.; De Jong, E.; Rasrendra, C.B.; Heeres, H.J.; De Vries, J.G. Hydroxymethylfurfural, a Versatile Platform Chemical Made from Renewable Resources. Chem. Rev. 2013, 113, 1499–1597. [Google Scholar] [CrossRef] [PubMed]

- Questell-Santiago, Y.M.; Galkin, M.V.; Barta, K.; Luterbacher, J.S. Stabilization Strategies in Biomass Depolymerization Using Chemical Functionalization. Nat. Rev. Chem. 2020, 4, 311–330. [Google Scholar] [CrossRef]

- Sharma, S.; Tsai, M.L.; Sharma, V.; Sun, P.P.; Nargotra, P.; Bajaj, B.K.; Chen, C.W.; Dong, C. Di Environment Friendly Pretreatment Approaches for the Bioconversion of Lignocellulosic Biomass into Biofuels and Value-Added Products. Environments 2023, 10, 6. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, X.; Liu, Q.; Zhang, Q.; Chen, L.; Ma, L. A Review of Conversion of Lignocellulose Biomass to Liquid Transport Fuels by Integrated Refining Strategies. Fuel Process. Technol. 2020, 208, 106485. [Google Scholar] [CrossRef]

- Haldar, D.; Purkait, M.K. A Review on the Environment-Friendly Emerging Techniques for Pretreatment of Lignocellulosic Biomass: Mechanistic Insight and Advancements. Chemosphere 2021, 264, 128523. [Google Scholar] [CrossRef]

- Saini, J.K.; Himanshu; Hemansi; Kaur, A.; Mathur, A. Strategies to Enhance Enzymatic Hydrolysis of Lignocellulosic Biomass for Biorefinery Applications: A Review. Bioresour. Technol. 2022, 360, 127517. [Google Scholar] [CrossRef]

- Guo, H.; Chang, Y.; Lee, D.J. Enzymatic Saccharification of Lignocellulosic Biorefinery: Research Focuses. Bioresour. Technol. 2018, 252, 198–215. [Google Scholar] [CrossRef]

- Mosier, N.; Wyman, C.; Dale, B.; Elander, R.; Lee, Y.Y.; Holtzapple, M.; Ladisch, M. Features of Promising Technologies for Pretreatment of Lignocellulosic Biomass. Bioresour. Technol. 2005, 96, 673–686. [Google Scholar] [CrossRef] [PubMed]

- Mankar, A.R.; Pandey, A.; Modak, A.; Pant, K.K. Pretreatment of Lignocellulosic Biomass: A Review on Recent Advances. Bioresour. Technol. 2021, 334, 125235. [Google Scholar] [CrossRef] [PubMed]

- Yousuf, A.; Sannino, F.; Pirozzi, D. Lignocellulosic Biomass to Liquid Biofuels; Academic Press: Cambridge, MA, USA, 2019; ISBN 978-0-12-815936-1. [Google Scholar]

- Agbor, V.B.; Cicek, N.; Sparling, R.; Berlin, A.; Levin, D.B. Biomass Pretreatment: Fundamentals toward Application. Biotechnol. Adv. 2011, 29, 675–685. [Google Scholar] [CrossRef]

- Zheng, Y.; Shi, J.; Tu, M.; Cheng, Y.S. Principles and Development of Lignocellulosic Biomass Pretreatment for Biofuels. Adv. Bioenergy 2017, 2, 1–68. [Google Scholar] [CrossRef]

- Gupta, A.; Verma, J.P. Sustainable Bio-Ethanol Production from Agro-Residues: A Review. Renew. Sustain. Energy Rev. 2015, 41, 550–567. [Google Scholar] [CrossRef]

- Rezania, S.; Oryani, B.; Cho, J.; Talaiekhozani, A.; Sabbagh, F.; Hashemi, B.; Rupani, P.F.; Mohammadi, A.A. Different Pretreatment Technologies of Lignocellulosic Biomass for Bioethanol Production: An Overview. Energy 2020, 199, 117457. [Google Scholar] [CrossRef]

- Hassan, S.S.; Williams, G.A.; Jaiswal, A.K. Emerging Technologies for the Pretreatment of Lignocellulosic Biomass. Bioresour. Technol. 2018, 262, 310–318. [Google Scholar] [CrossRef] [PubMed]

- Himmel, M.E.; Ding, S.Y.; Johnson, D.K.; Adney, W.S.; Nimlos, M.R.; Brady, J.W.; Foust, T.D. Biomass Recalcitrance: Engineering Plants and Enzymes for Biofuels Production. Science 2007, 315, 804–807. [Google Scholar] [CrossRef] [PubMed]

- Harmsen, P.F.H.; Huijgen, W.; Bermudez, L.; Bakker, R. Literature Review of Physical and Chemical Pretreatment Processes for Lignocellulosic Biomass; Wageningen UR Food & Biobased Research: Wageningen, The Netherlands, 2010; ISBN 9789085857570. [Google Scholar]

- Chen, S.; Zhang, X.; Singh, D.; Yu, H.; Yang, X. Biological Pretreatment of Lignocellulosics: Potential, Progress and Challenges. Biofuels 2010, 1, 177–199. [Google Scholar] [CrossRef]

- Taherzadeh, M.J.; Karimi, K. Pretreatment of Lignocellulosic Wastes to Improve Ethanol and Biogas Production: A Review. Int. J. Mol. Sci. 2008, 9, 1621–1651. [Google Scholar] [CrossRef]

- Ashokkumar, V.; Venkatkarthick, R.; Jayashree, S.; Chuetor, S.; Dharmaraj, S.; Kumar, G.; Chen, W.H.; Ngamcharussrivichai, C. Recent Advances in Lignocellulosic Biomass for Biofuels and Value-Added Bioproducts—A Critical Review. Bioresour. Technol. 2022, 344, 126195. [Google Scholar] [CrossRef]

- Demirbas, A. Biofuels from Agricultural Biomass. Energy Sources Part A Recovery Util. Environ. Eff. 2009, 31, 1573–1582. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, S.; Singh, O.V. Bioconversion of Lignocellulosic Biomass: Biochemical and Molecular Perspectives. J. Ind. Microbiol. Biotechnol. 2008, 35, 377–391. [Google Scholar] [CrossRef] [PubMed]

- Kassaye, S.; Pant, K.K.; Jain, S. Synergistic Effect of Ionic Liquid and Dilute Sulphuric Acid in the Hydrolysis of Microcrystalline Cellulose. Fuel Process. Technol. 2016, 148, 289–294. [Google Scholar] [CrossRef]

- Lee, H.V.; Hamid, S.B.A.; Zain, S.K. Conversion of Lignocellulosic Biomass to Nanocellulose: Structure and Chemical Process. Sci. World J. 2014, 2014, 631013. [Google Scholar] [CrossRef]

- Singhvi, M.S.; Gokhale, D.V. Lignocellulosic Biomass: Hurdles and Challenges in Its Valorization. Appl. Microbiol. Biotechnol. 2019, 103, 9305–9320. [Google Scholar] [CrossRef]

- Velvizhi, G.; Balakumar, K.; Shetti, N.P.; Ahmad, E.; Kishore Pant, K.; Aminabhavi, T.M. Integrated Biorefinery Processes for Conversion of Lignocellulosic Biomass to Value Added Materials: Paving a Path towards Circular Economy. Bioresour. Technol. 2022, 343, 126151. [Google Scholar] [CrossRef]

- Dora, S.; Bhaskar, T.; Singh, R.; Naik, D.V.; Adhikari, D.K. Effective Catalytic Conversion of Cellulose into High Yields of Methyl Glucosides over Sulfonated Carbon Based Catalyst. Bioresour. Technol. 2012, 120, 318–321. [Google Scholar] [CrossRef]

- Zang, G.; Shah, A.; Wan, C. Techno-Economic Analysis of an Integrated Biorefinery Strategy Based on One-Pot Biomass Fractionation and Furfural Production. J. Clean. Prod. 2020, 260, 120837. [Google Scholar] [CrossRef]

- Wang, F.; Ouyang, D.; Zhou, Z.; Page, S.J.; Liu, D.; Zhao, X. Lignocellulosic Biomass as Sustainable Feedstock and Materials for Power Generation and Energy Storage. J. Energy Chem. 2021, 57, 247–280. [Google Scholar] [CrossRef]

- IBGE—Instituto Brasileiro de Geografia e Estatística. Produção Agropecuária. Available online: https://www.ibge.gov.br/explica/producao-agropecuaria/ (accessed on 5 March 2024).

- Jȩdrzejczyk, M.; Soszka, E.; Czapnik, M.; Ruppert, A.M.; Grams, J. Physical and Chemical Pretreatment of Lignocellulosic Biomass. In econd and Third Generation of Feedstocks: The Evolution of Biofuels; Elsevier: Amsterdam, The Netherlands, 2019; pp. 143–196. [Google Scholar] [CrossRef]

- Shah, A.A.; Seehar, T.H.; Sharma, K.; Toor, S.S. Biomass Pretreatment Technologies. In Hydrocarbon Biorefinery: Sustainable Processing of Biomass for Hydrocarbon Biofuels; Elsevier: Amsterdam, The Netherlands, 2022; pp. 203–228. [Google Scholar] [CrossRef]

- Moodley, P.; Trois, C. Lignocellulosic Biorefineries: The Path Forward. In Sustainable Biofuels: Opportunities and Challenges; Academic Press: Cambridge, MA, USA, 2021; pp. 21–42. [Google Scholar] [CrossRef]

- Kumar, P.; Barrett, D.M.; Delwiche, M.J.; Stroeve, P. Methods for Pretreatment of Lignocellulosic Biomass for Efficient Hydrolysis and Biofuel Production. Ind. Eng. Chem. Res. 2009, 48, 3713–3729. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhao, J.; Xu, F.; Li, Y. Pretreatment of Lignocellulosic Biomass for Enhanced Biogas Production. Prog. Energy Combust. Sci. 2014, 42, 35–53. [Google Scholar] [CrossRef]

- Buaban, B.; Inoue, H.; Yano, S.; Tanapongpipat, S.; Ruanglek, V.; Champreda, V.; Pichyangkura, R.; Rengpipat, S.; Eurwilaichitr, L. Bioethanol Production from Ball Milled Bagasse Using an On-Site Produced Fungal Enzyme Cocktail and Xylose-Fermenting Pichia Stipitis. J. Biosci. Bioeng. 2010, 110, 18–25. [Google Scholar] [CrossRef] [PubMed]

- Da Silva, A.S.A.; Inoue, H.; Endo, T.; Yano, S.; Bon, E.P.S. Milling Pretreatment of Sugarcane Bagasse and Straw for Enzymatic Hydrolysis and Ethanol Fermentation. Bioresour. Technol. 2010, 101, 7402–7409. [Google Scholar] [CrossRef]

- Zeng, M.; Mosier, N.S.; Huang, C.P.; Sherman, D.M.; Ladisch, M.R. Microscopic Examination of Changes of Plant Cell Structure in Corn Stover Due to Hot Water Pretreatment and Enzymatic Hydrolysis. Biotechnol. Bioeng. 2007, 97, 265–278. [Google Scholar] [CrossRef]

- Zhu, J.Y.; Pan, X.; Zalesny, R.S. Pretreatment of Woody Biomass for Biofuel Production: Energy Efficiency, Technologies, and Recalcitrance. Appl. Microbiol. Biotechnol. 2010, 87, 847–857. [Google Scholar] [CrossRef] [PubMed]

- Inoue, H.; Yano, S.; Endo, T.; Sakaki, T.; Sawayama, S. Combining Hot-Compressed Water and Ball Milling Pretreatments to Improve the Efficiency of the Enzymatic Hydrolysis of Eucalyptus. Biotechnol. Biofuels 2008, 1, 2. [Google Scholar] [CrossRef]

- Al-Assaf, S.; Phillips, G.O.; Williams, P.A.; du Plessis, T.A. Application of Ionizing Radiations to Produce New Polysaccharides and Proteins with Enhanced Functionality. Nucl. Instruments Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 2007, 265, 37–43. [Google Scholar] [CrossRef]

- Kassim, M.A.; Khalil, H.P.A.; Serri, N.A.; Kassim, M.H.M.; Syakir, M.I.; Aprila, N.A.S.; Dungani, R.; Kassim, M.A.; Khalil, H.P.A.; Serri, N.A.; et al. Irradiation Pretreatment of Tropical Biomass and Biofiber for Biofuel Production. In Radiation Effects in Materials; IntechOpen: London, UK, 2016. [Google Scholar] [CrossRef]

- Mason, T.J.; Lorimer, J.P. Applied Sonochemistry; Wiley: Hoboken, NJ, USA, 2002. [Google Scholar] [CrossRef]

- Bussemaker, M.J.; Zhang, D. Effect of Ultrasound on Lignocellulosic Biomass as a Pretreatment for Biorefinery and Biofuel Applications. Ind. Eng. Chem. Res. 2013, 52, 3563–3580. [Google Scholar] [CrossRef]

- Zuo, M.; Xiao, R.; Du, F.; Cheng, C.; Rodriguez, R.D.; Ma, L.; Zhu, B.; Qiu, L. Ultrasound-Activated Mechanochemical Reactions for Controllable Biomedical Applications. Smart Mater. Med. 2024, 5, 461–476. [Google Scholar] [CrossRef]

- Zhu, X.; Das, R.S.; Bhavya, M.L.; Garcia-Vaquero, M.; Tiwari, B.K. Acoustic Cavitation for Agri-Food Applications: Mechanism of Action, Design of New Systems, Challenges and Strategies for Scale-Up. Ultrason. Sonochem. 2024, 105, 106850. [Google Scholar] [CrossRef] [PubMed]

- Kunaver, M.; Jasiukaityte, E.; Čuk, N. Ultrasonically Assisted Liquefaction of Lignocellulosic Materials. Bioresour. Technol. 2012, 103, 360–366. [Google Scholar] [CrossRef]

- Ravindran, R.; Jaiswal, A.K. A Comprehensive Review on Pre-Treatment Strategy for Lignocellulosic Food Industry Waste: Challenges and Opportunities. Bioresour. Technol. 2016, 199, 92–102. [Google Scholar] [CrossRef]

- Manickam, S.; Camilla Boffito, D.; Flores, E.M.M.; Leveque, J.M.; Pflieger, R.; Pollet, B.G.; Ashokkumar, M. Ultrasonics and Sonochemistry: Editors’ Perspective. Ultrason. Sonochem. 2023, 99, 106540. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, Y.; Yang, L.; Wu, Z. Effects of Ultrasound Pretreatment on Microstructure and Drying Characteristics of Eucalyptus Urophylla × E. Grandis. BioResources 2018, 13, 5953–5964. [Google Scholar] [CrossRef]

- He, Z.; Qian, J.; Wang, Z.; Yi, S.; Mu, J. Effects of Ultrasound Pretreatment on Eucalyptus Thermal Decomposition Characteristics As Determined by Thermogravimetric, Differential Scanning Calorimetry, and Fourier Transform Infrared Analysis. ACS Omega 2018, 3, 6611–6616. [Google Scholar] [CrossRef] [PubMed]

- He, Z.; Wang, Z.; Zhao, Z.; Yi, S.; Mu, J.; Wang, X. Influence of Ultrasound Pretreatment on Wood Physiochemical Structure. Ultrason. Sonochem. 2017, 34, 136–141. [Google Scholar] [CrossRef]

- Revin, V.; Atykyan, N.; Zakharkin, D. Enzymatic Hydrolysis and Fermentation of Ultradispersed Wood Particles after Ultrasonic Pretreatment. Electron. J. Biotechnol. 2016, 20, 14–19. [Google Scholar] [CrossRef]

- Sharma, V.; Nargotra, P.; Sharma, S.; Bajaj, B.K. Efficacy and Functional Mechanisms of a Novel Combinatorial Pretreatment Approach Based on Deep Eutectic Solvent and Ultrasonic Waves for Bioconversion of Sugarcane Bagasse. Renew. Energy 2021, 163, 1910–1922. [Google Scholar] [CrossRef]

- Candido, R.G.; Mori, N.R.; Gonçalves, A.R. Sugarcane Straw as Feedstock for 2G Ethanol: Evaluation of Pretreatments and Enzymatic Hydrolysis. Ind. Crop. Prod. 2019, 142, 111845. [Google Scholar] [CrossRef]

- Martinez-Jimenez, F.D.; Macie Pinto, M.P.; Mudhoo, A.; De Alencar Neves, T.; Rostagno, M.A.; Forster-Carneiro, T. Influence of Ultrasound Irradiation Pre-Treatment in Biohythane Generation from the Thermophilic Anaerobic Co-Digestion of Sugar Production Residues. J. Environ. Chem. Eng. 2017, 5, 3749–3758. [Google Scholar] [CrossRef]

- Eblaghi, M.; Niakousari, M.; Sarshar, M.; Mesbahi, G.R. Combining Ultrasound with Mild Alkaline Solutions as an Effective Pretreatment to Boost the Release of Sugar Trapped in Sugarcane Bagasse for Bioethanol Production. J. Food Process Eng. 2016, 39, 273–282. [Google Scholar] [CrossRef]

- Liu, C.F.; Sun, R.C.; Qin, M.H.; Zhang, A.P.; Ren, J.L.; Xu, F.; Ye, J.; Wu, S. Bin Chemical Modification of Ultrasound-Pretreated Sugarcane Bagasse with Maleic Anhydride. Ind. Crop. Prod. 2007, 26, 212–219. [Google Scholar] [CrossRef]

- Velmurugan, R.; Muthukumar, K. Utilization of Sugarcane Bagasse for Bioethanol Production: Sono-Assisted Acid Hydrolysis Approach. Bioresour. Technol. 2011, 102, 7119–7123. [Google Scholar] [CrossRef] [PubMed]

- Velmurugan, R.; Muthukumar, K. Sono-Assisted Enzymatic Saccharification of Sugarcane Bagasse for Bioethanol Production. Biochem. Eng. J. 2012, 63, 1–9. [Google Scholar] [CrossRef]

- Ramadoss, G.; Muthukumar, K. Ultrasound Assisted Ammonia Pretreatment of Sugarcane Bagasse for Fermentable Sugar Production. Biochem. Eng. J. 2014, 83, 33–41. [Google Scholar] [CrossRef]

- Li, Q.; Ji, G.S.; Tang, Y.B.; Gu, X.D.; Fei, J.J.; Jiang, H.Q. Ultrasound-Assisted Compatible in Situ Hydrolysis of Sugarcane Bagasse in Cellulase-Aqueous–N-Methylmorpholine-N-Oxide System for Improved Saccharification. Bioresour. Technol. 2012, 107, 251–257. [Google Scholar] [CrossRef]

- Esfahani, M.R.; Azin, M. Pretreatment of Sugarcane Bagasse by Ultrasound Energy and Dilute Acid. Asia-Pac. J. Chem. Eng. 2012, 7, 274–278. [Google Scholar] [CrossRef]

- Velmurugan, R.; Muthukumar, K. Ultrasound-Assisted Alkaline Pretreatment of Sugarcane Bagasse for Fermentable Sugar Production: Optimization through Response Surface Methodology. Bioresour. Technol. 2012, 112, 293–299. [Google Scholar] [CrossRef]

- Sun, J.X.; Xu, F.; Sun, X.F.; Sun, R.C.; Wu, S.B. Comparative Study of Lignins from Ultrasonic Irradiated Sugar-Cane Bagasse. Polym. Int. 2004, 53, 1711–1721. [Google Scholar] [CrossRef]

- Pérez-Rodríguez, N.; García-Bernet, D.; Domínguez, J.M. Effects of Enzymatic Hydrolysis and Ultrasounds Pretreatments on Corn Cob and Vine Trimming Shoots for Biogas Production. Bioresour. Technol. 2016, 221, 130–138. [Google Scholar] [CrossRef] [PubMed]

- Yin, J.; Hao, L.; Yu, W.; Wang, E.; Zhao, M.; Xu, Q.; Liu, Y. Enzymatic Hydrolysis Enhancement of Corn Lignocellulose by Supercritical CO2 Combined with Ultrasound Pretreatment. Chin. J. Catal. 2014, 35, 763–769. [Google Scholar] [CrossRef]

- Hu, X.; Xiao, Y.; Niu, K.; Zhao, Y.; Zhang, B.; Hu, B. Functional Ionic Liquids for Hydrolysis of Lignocellulose. Carbohydr. Polym. 2013, 97, 172–176. [Google Scholar] [CrossRef]

- Liu, J.H.; Wang, F.M. Study on Technology of Reducing Sugar Production from Bermuda Grass by Combination of Dilute Acid and Ultrasound. Biotechnology 2015, 14, 274–278. [Google Scholar] [CrossRef]

- Leonelli, C.; Mason, T.J. Microwave and Ultrasonic Processing: Now a Realistic Option for Industry. Chem. Eng. Process. Process Intensif. 2010, 49, 885–900. [Google Scholar] [CrossRef]

- Pellera, F.M.; Gidarakos, E. Microwave Pretreatment of Lignocellulosic Agroindustrial Waste for Methane Production. J. Environ. Chem. Eng. 2017, 5, 352–365. [Google Scholar] [CrossRef]

- Angoy, A.; Brianceau, S.; Chabrier, F.; Ginisty, P.; Jomaa, W.; Rochas, J.F.; Sommier, A.; Valat, M. Microwave Technology for Food Applications. In Green Food Processing Techniques: Preservation, Transformation and Extraction; Academic Press: Cambridge, MA, USA, 2019; pp. 455–498. [Google Scholar] [CrossRef]

- Caballero, B.; Trugo, L.; Finglas, P. Encyclopedia of Food Sciences and Nutrition, 2nd ed.; Caballero, B., Finglas, P., Toldra, F., Eds.; Academic Press: Cambridge, MA, USA, 2003; ISBN 9780080917917. [Google Scholar]

- Hou, A.; Wang, X.; Wu, L. Effect of Microwave Irradiation on the Physical Properties and Morphological Structures of Cotton Cellulose. Carbohydr. Polym. 2008, 74, 934–937. [Google Scholar] [CrossRef]

- Keshwani, D.R.; Cheng, J.J. Microwave-Based Alkali Pretreatment of Switchgrass and Coastal Bermudagrass for Bioethanol Production. Biotechnol. Prog. 2010, 26, 644–652. [Google Scholar] [CrossRef]

- Aguilar-Reynosa, A.; Romaní, A.; Rodríguez-Jasso, R.M.; Aguilar, C.N.; Garrote, G.; Ruiz, H.A. Comparison of Microwave and Conduction-Convection Heating Autohydrolysis Pretreatment for Bioethanol Production. Bioresour. Technol. 2017, 243, 273–283. [Google Scholar] [CrossRef]

- Hu, Z.; Wen, Z. Enhancing Enzymatic Digestibility of Switchgrass by Microwave-Assisted Alkali Pretreatment. Biochem. Eng. J. 2008, 38, 369–378. [Google Scholar] [CrossRef]

- Kostas, E.T.; Beneroso, D.; Robinson, J.P. The Application of Microwave Heating in Bioenergy: A Review on the Microwave Pre-Treatment and Upgrading Technologies for Biomass. Renew. Sustain. Energy Rev. 2017, 77, 12–27. [Google Scholar] [CrossRef]

- Amini, N.; Haritos, V.S.; Tanksale, A. Microwave Assisted Pretreatment of Eucalyptus Sawdust Enhances Enzymatic Saccharification and Maximizes Fermentable Sugar Yield. Renew. Energy 2018, 127, 653–660. [Google Scholar] [CrossRef]

- Bichot, A.; Lerosty, M.; Méchin, V.; Bernet, N.; Delgenès, J.P.; García-Bernet, D. Evaluation of Chemical-Free Microwave Pretreatment on Methane Yield of Two Grass Biomass with Contrasted Parietal Content. Energy Convers. Manag. 2021, 229, 113746. [Google Scholar] [CrossRef]

- Binod, P.; Satyanagalakshmi, K.; Sindhu, R.; Janu, K.U.; Sukumaran, R.K.; Pandey, A. Short Duration Microwave Assisted Pretreatment Enhances the Enzymatic Saccharification and Fermentable Sugar Yield from Sugarcane Bagasse. Renew. Energy 2012, 37, 109–116. [Google Scholar] [CrossRef]

- Boonsombuti, A.; Wanapirom, R.; Luengnaruemitchai, A.; Wongkasemjit, S. The Effect of the Addition of Acetic Acid to Aqueous Ionic Liquid Mixture Using Microwave-Assisted Pretreatment in the Saccharification of Napier Grass. Waste Biomass Valorization 2018, 9, 1795–1804. [Google Scholar] [CrossRef]

- Fonseca, B.C.; Reginatto, V.; López-Linares, J.C.; Lucas, S.; García-Cubero, M.T.; Coca, M. Ideal Conditions of Microwave-Assisted Acid Pretreatment of Sugarcane Straw Allow Fermentative Butyric Acid Production without Detoxification Step. Bioresour. Technol. 2021, 329, 124929. [Google Scholar] [CrossRef]

- Hermiati, E.; Pramasari, D.A.; Ermawar, R.A.; Sondari, D.; Lianawati, A.; Sudiyani, Y.; Adilina, I.B. Microwave Pretreatment of Sugarcane Trash and Oil Palm Empty Fruit Bunch with an Aluminum Sulfate Catalyst for Improvement of Sugar Recovery. Waste Biomass Valorization 2024, 15, 437–453. [Google Scholar] [CrossRef]

- Irmak, S.; Meryemoglu, B.; Sandip, A.; Subbiah, J.; Mitchell, R.B.; Sarath, G. Microwave Pretreatment Effects on Switchgrass and Miscanthus Solubilization in Subcritical Water and Hydrolysate Utilization for Hydrogen Production. Biomass Bioenergy 2018, 108, 48–54. [Google Scholar] [CrossRef]

- Karunanithy, C.; Muthukumarappan, K.; Gibbons, W.R. Sequential Extrusion-Microwave Pretreatment of Switchgrass and Big Bluestem. Bioresour. Technol. 2014, 153, 393–398. [Google Scholar] [CrossRef]

- Kłosowski, G.; Mikulski, D.; Lewandowska, N. Microwave-Assisted Degradation of Biomass with the Use of Acid Catalysis. Catalysts 2020, 10, 641. [Google Scholar] [CrossRef]

- Miranda, I.; Masiero, M.O.; Zamai, T.; Capella, M.; Laluce, C. Improved Pretreatments Applied to the Sugarcane Bagasse and Release of Lignin and Hemicellulose from the Cellulose-Enriched Fractions by Sulfuric Acid Hydrolysis. J. Chem. Technol. Biotechnol. 2016, 91, 476–482. [Google Scholar] [CrossRef]

- Moodley, P.; Gueguim Kana, E.B. Bioethanol Production from Sugarcane Leaf Waste: Effect of Various Optimized Pretreatments and Fermentation Conditions on Process Kinetics. Biotechnol. Rep. 2019, 22, e00329. [Google Scholar] [CrossRef] [PubMed]

- Han, M.X.; Li, D.M.; Feng, Y.J.; Tan, Y.F.; Yuan, Y.X. Microwave Pre-Treatment of Corn Straw and Its Enzymatic Hydrolysis. Adv. Mater. Res. 2013, 641–642, 971–974. [Google Scholar] [CrossRef]

- Rigual, V.; Domínguez, J.C.; Santos, T.M.; Rivas, S.; Alonso, M.V.; Oliet, M.; Rodriguez, F. Autohydrolysis and Microwave Ionic Liquid Pretreatment of Pinus Radiata: Imaging Visualization and Analysis to Understand Enzymatic Digestibility. Ind. Crops Prod. 2019, 134, 328–337. [Google Scholar] [CrossRef]

- Rigual, V.; Santos, T.M.; Domínguez, J.C.; Alonso, M.V.; Oliet, M.; Rodriguez, F. Evaluation of Hardwood and Softwood Fractionation Using Autohydrolysis and Ionic Liquid Microwave Pretreatment. Biomass Bioenergy 2018, 117, 190–197. [Google Scholar] [CrossRef]

- Zhu, Z.; Rezende, C.A.; Simister, R.; McQueen-Mason, S.J.; Macquarrie, D.J.; Polikarpov, I.; Gomez, L.D. Efficient Sugar Production from Sugarcane Bagasse by Microwave Assisted Acid and Alkali Pretreatment. Biomass Bioenergy 2016, 93, 269–278. [Google Scholar] [CrossRef]

- Sasaki, C.; Takada, R.; Watanabe, T.; Honda, Y.; Karita, S.; Nakamura, Y.; Watanabe, T. Surface Carbohydrate Analysis and Bioethanol Production of Sugarcane Bagasse Pretreated with the White Rot Fungus, Ceriporiopsis Subvermispora and Microwave Hydrothermolysis. Bioresour. Technol. 2011, 102, 9942–9946. [Google Scholar] [CrossRef]

- Wang, C.; Shao, Z.; Qiu, L.; Hao, W.; Qu, Q.; Sun, G. The Solid-State Physicochemical Properties and Biogas Production of the Anaerobic Digestion of Corn Straw Pretreated by Microwave Irradiation. RSC Adv. 2021, 11, 3575–3584. [Google Scholar] [CrossRef]

- Ude, M.U.; Oluka, I. Optimization of Microwave Pretreatment Parameters of Elephant Grass by Response Surface Methodology and Kinetic Study of Its Biomethanation. Biofuels 2022, 13, 863–872. [Google Scholar] [CrossRef]

- Fan, X.; Niemira, B.A. Gamma Ray, Electron Beam, and X-Ray Irradiation. In Food Safety Engineering; Food Engineering Series; Springer: Cham, Switzerland, 2020; pp. 471–492. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, J.; Wu, X.; Wang, K.; Su, X.; Chen, L.; Zhou, H.; Xiong, X. Insights into the Effects of γ-Irradiation on the Microstructure, Thermal Stability and Irradiation-Derived Degradation Components of Microcrystalline Cellulose (MCC). RSC Adv. 2015, 5, 34353–34363. [Google Scholar] [CrossRef]

- Kumar, A.; Kumar, G.A. Modification of Lignin Properties Using Alpha Particles and Gamma-Rays for Diverse Applications. Radiat. Phys. Chem. 2023, 202, 110562. [Google Scholar] [CrossRef]

- Barbara, P.F. Research Needs and Opportunities in Radiation Chemistry Workshop. 1998. Available online: https://www.osti.gov/biblio/1302247 (accessed on 9 March 2024).

- Al Gharib, S.; Mostafavi, M.; Belloni, J. Radiation-Assisted Hydrolysis of Lignocellulosic Biomass. Mechanistic Study. Waste Biomass Valorization 2023, 14, 1113–1122. [Google Scholar] [CrossRef]

- Kapoor, K.; Tyagi, A.K.; Das, M.; Kumar, V. Comparative Analysis of Morphological and Structural Changes in Gamma and Electron Beam Irradiated Sugarcane Bagasse. Cellul. Chem. Technol. 2023, 57, 61–70. [Google Scholar] [CrossRef]

- Wu, X.; Chen, L.; He, W.; Qi, H.; Zhang, Y.; Zhou, Y.; Su, X.; Deng, M.; Wang, K. Characterize the Physicochemical Structure and Enzymatic Efficiency of Agricultural Residues Exposed to γ-Irradiation Pretreatment. Ind. Crop. Prod. 2020, 150, 112228. [Google Scholar] [CrossRef]

- Li, Q.-M.; Li, X.-J.; Jiang, Y.-L.; Xiong, X.-Y.; Hu, Q.-L.; Tan, X.-H.; Wang, K.-Q.; Su, X.-J. Analysis of Degradation Products and Structural Characterization of Giant Reed and Chinese Silvergrass Pretreated by 60Co-γ Irradiation. Ind. Crop. Prod. 2016, 83, 307–315. [Google Scholar] [CrossRef]

- Bak, J.S.; Ko, J.K.; Han, Y.H.; Lee, B.C.; Choi, I.G.; Kim, K.H. Improved Enzymatic Hydrolysis Yield of Rice Straw Using Electron Beam Irradiation Pretreatment. Bioresour. Technol. 2009, 100, 1285–1290. [Google Scholar] [CrossRef]

- Singh, S.V.; Devanandhan, S.; Lakhina, G.S.; Bharuthram, R. Electron Acoustic Solitary Waves in a Magnetized Plasma with Nonthermal Electrons and an Electron Beam. Phys. Plasmas 2016, 23, 82310. [Google Scholar] [CrossRef]

- Jusri, N.A.A.; Azizan, A.; Zain, Z.S.Z.; Rahman, M.F.A. Effect of Electron Beam Irradiation and Ionic Liquid Combined Pretreatment Method on Various Lignocellulosic Biomass. Key Eng. Mater. 2019, 797, 351–358. [Google Scholar] [CrossRef]

- Siwek, M.; Edgecock, T. Application of Electron Beam Water Radiolysis for Sewage Sludge Treatment—A Review. Environ. Sci. Pollut. Res. 2020, 27, 42424–42448. [Google Scholar] [CrossRef]

- Duarte, C.L.; Ribeiro, M.A.; Oikawa, H.; Mori, M.N.; Napolitano, C.M.; Galvão, C.A. Electron Beam Combined with Hydrothermal Treatment for Enhancing the Enzymatic Convertibility of Sugarcane Bagasse. Radiat. Phys. Chem. 2012, 81, 1008–1011. [Google Scholar] [CrossRef]

- Guo, X.; Shu, S.; Zhang, W.; Wang, E.; Hao, J. Synergetic Degradation of Corn Cob with Inorganic Salt (or Hydrogen Peroxide) and Electron Beam Irradiation. ACS Sustain. Chem. Eng. 2016, 4, 1099–1105. [Google Scholar] [CrossRef]

- Rattanawongwiboon, T.; Chanklinhorm, P.; Chutimasakul, T.; Kwamman, T.; Kingkam, W.; Khamlue, R.; Ummartyotin, S. Green Acidic Catalyst from Cellulose Extracted from Sugarcane Bagasse through Pretreatment by Electron Beam Irradiation and Subsequent Sulfonation for Sugar Production. J. Met. Mater. Miner. 2022, 32, 134–142. [Google Scholar] [CrossRef]

- Karthika, K.; Arun, A.B.; Rekha, P.D. Enzymatic Hydrolysis and Characterization of Lignocellulosic Biomass Exposed to Electron Beam Irradiation. Carbohydr. Polym. 2012, 90, 1038–1045. [Google Scholar] [CrossRef] [PubMed]

- Shen, H.; Yu, J.; Bai, J.; Ge, X.; Liang, W.; Ospankulova, G.; Muratkhan, M.; Zhang, G.; Li, W. Electron Beam Irradiation Regulates the Structure and Functionality of Ball-Milled Corn Starch: The Related Mechanism. Carbohydr. Polym. 2022, 297, 120016. [Google Scholar] [CrossRef]

- Duque, A.; Manzanares, P.; Ballesteros, M. Extrusion as a Pretreatment for Lignocellulosic Biomass: Fundamentals and Applications. Renew. Energy 2017, 114, 1427–1441. [Google Scholar] [CrossRef]

- Zheng, J.; Rehmann, L. Extrusion Pretreatment of Lignocellulosic Biomass: A Review. Int. J. Mol. Sci. 2014, 15, 18967–18984. [Google Scholar] [CrossRef]

- Konan, D.; Koffi, E.; Ndao, A.; Peterson, E.C.; Rodrigue, D.; Feng, W.; Konan, D.; Koffi, E.; Ndao, A.; Peterson, E.C.; et al. An Overview of Extrusion as a Pretreatment Method of Lignocellulosic Biomass. Energies 2022, 15, 3002. [Google Scholar] [CrossRef]

- Kuster Moro, M.; Sposina Sobral Teixeira, R.; Sant’Ana da Silva, A.; Duarte Fujimoto, M.; Albuquerque Melo, P.; Resende Secchi, A.; Pinto da Silva Bon, E. Continuous Pretreatment of Sugarcane Biomass Using a Twin-Screw Extruder. Ind. Crop. Prod. 2017, 97, 509–517. [Google Scholar] [CrossRef]

- Doménech, P.; Manzanares, P.; Álvarez, C.; Ballesteros, M.; Duque, A. Comprehensive Study on the Effects of Process Parameters of Alkaline Thermal Pretreatment Followed by Thermomechanical Extrusion in Sugar Liberation from Eucalyptus Grandis Wood. Holzforschung 2021, 75, 250–259. [Google Scholar] [CrossRef]

- Tian, D.; Shen, F.; Yang, G.; Deng, S.; Long, L.; He, J.; Zhang, J.; Huang, C.; Luo, L. Liquid Hot Water Extraction Followed by Mechanical Extrusion as a Chemical-Free Pretreatment Approach for Cellulosic Ethanol Production from Rigid Hardwood. Fuel 2019, 252, 589–597. [Google Scholar] [CrossRef]

- Duque, A.; Manzanares, P.; González, A.; Ballesteros, M. Study of the Application of Alkaline Extrusion to the Pretreatment of Eucalyptus Biomass as First Step in a Bioethanol Production Process. Energies 2018, 11, 2961. [Google Scholar] [CrossRef]

- Liang, Y.; Lei, B.; Zhong, H.T.; Feng, Y.H.; Qu, J.P. A Promising Screw-Extrusion Steam Explosion Pretreatment Process: Effects on the Morphological and Structural Features of Eucalyptus Woodchips. RSC Adv. 2016, 6, 109657–109663. [Google Scholar] [CrossRef]

- Lee, S.H.; Inoue, S.; Teramoto, Y.; Endo, T. Enzymatic Saccharification of Woody Biomass Micro/Nanofibrillated by Continuous Extrusion Process II: Effect of Hot-Compressed Water Treatment. Bioresour. Technol. 2010, 101, 9645–9649. [Google Scholar] [CrossRef]

- Karunanithy, C.; Muthukumarappan, K.; Gibbons, W.R. Extrusion Pretreatment of Pine Wood Chips. Appl. Biochem. Biotechnol. 2012, 167, 81–99. [Google Scholar] [CrossRef]

- Fasheun, D.O.; de Oliveira, R.A.; Bon, E.P.S.; da Silva, A.S.A.; Teixeira, R.S.S.; Ferreira-Leitão, V.S. Dry Extrusion Pretreatment of Cassava Starch Aided by Sugarcane Bagasse for Improved Starch Saccharification. Carbohydr. Polym. 2022, 285, 119256. [Google Scholar] [CrossRef]

- Da Silva, A.S.A.; Teixeira, R.S.S.; Endo, T.; Bon, E.P.S.; Lee, S.H. Continuous Pretreatment of Sugarcane Bagasse at High Loading in an Ionic Liquid Using a Twin-Screw Extruder. Green Chem. 2013, 15, 1991–2001. [Google Scholar] [CrossRef]

- Pérez-Rodríguez, N.; García-Bernet, D.; Domínguez, J.M. Extrusion and Enzymatic Hydrolysis as Pretreatments on Corn Cob for Biogas Production. Renew. Energy 2017, 107, 597–603. [Google Scholar] [CrossRef]

- Yoo, J.; Alavi, S.; Vadlani, P.; Behnke, K.C. Soybean Hulls Pretreated Using Thermo-Mechanical Extrusion—Hydrolysis Efficiency, Fermentation Inhibitors, and Ethanol Yield. Appl. Biochem. Biotechnol. 2012, 166, 576–589. [Google Scholar] [CrossRef]

- Yoo, J.; Alavi, S.; Vadlani, P.; Amanor-Boadu, V. Thermo-Mechanical Extrusion Pretreatment for Conversion of Soybean Hulls to Fermentable Sugars. Bioresour. Technol. 2011, 102, 7583–7590. [Google Scholar] [CrossRef]

- Lamsal, B.; Yoo, J.; Brijwani, K.; Alavi, S. Extrusion as a Thermo-Mechanical Pre-Treatment for Lignocellulosic Ethanol. Biomass Bioenergy 2010, 34, 1703–1710. [Google Scholar] [CrossRef]

- Souza, M.F.; Devriendt, N.; Willems, B.; Guisson, R.; Biswas, J.K.; Meers, E. Techno-Economic Feasibility of Extrusion as a Pretreatment Step for Biogas Production from Grass. BioEnergy Res. 2022, 15, 1232–1239. [Google Scholar] [CrossRef]

- Karunanithy, C.; Muthukumarappan, K. A Comparative Study on Torque Requirement during Extrusion Pretreatment of Different Feedstocks. BioEnergy Res. 2012, 5, 263–276. [Google Scholar] [CrossRef]

- Karunanithy, C.; Muthukumarappan, K. Optimizing Extrusion Pretreatment and Big Bluestem Parameters for Enzymatic Hydrolysis to Produce Biofuel Using Response Surface Methodology. Int. J. Agric. Biol. Eng. 2011, 4, 61–74. [Google Scholar]

- Karunanithy, C.; Muthukumarappan, K. Optimization of Alkali Soaking and Extrusion Pretreatment of Prairie Cord Grass for Maximum Sugar Recovery by Enzymatic Hydrolysis. Biochem. Eng. J. 2011, 54, 71–82. [Google Scholar] [CrossRef]

- Karunanithy, C.; Muthukumarappan, K. Influence of Extruder and Feedstock Variables on Torque Requirement during Pretreatment of Different Types of Biomass—A Response Surface Analysis. Biosyst. Eng. 2011, 109, 37–51. [Google Scholar] [CrossRef]

- Weaver, J.C.; Chizmadzhev, Y.A. Theory of Electroporation: A Review. Bioelectrochem. Bioenerg. 1996, 41, 135–160. [Google Scholar] [CrossRef]

- Golberg, A.; Sack, M.; Teissie, J.; Pataro, G.; Pliquett, U.; Saulis, G.; Stefan, T.; Miklavcic, D.; Vorobiev, E.; Frey, W. Energy-Efficient Biomass Processing with Pulsed Electric Fields for Bioeconomy and Sustainable Development. Biotechnol. Biofuels 2016, 9, 94. [Google Scholar] [CrossRef]

- Rocha, C.M.R.; Genisheva, Z.; Ferreira-Santos, P.; Rodrigues, R.; Vicente, A.A.; Teixeira, J.A.; Pereira, R.N. Electric Field-Based Technologies for Valorization of Bioresources. Bioresour. Technol. 2018, 254, 325–339. [Google Scholar] [CrossRef]

- Brahim, M.; Checa Fernandez, B.L.; Regnier, O.; Boussetta, N.; Grimi, N.; Sarazin, C.; Husson, E.; Vorobiev, E.; Brosse, N. Impact of Ultrasounds and High Voltage Electrical Discharges on Physico-Chemical Properties of Rapeseed Straw’s Lignin and Pulps. Bioresour. Technol. 2017, 237, 11–19. [Google Scholar] [CrossRef]

- Barba, F.J.; Brianceau, S.; Turk, M.; Boussetta, N.; Vorobiev, E. Effect of Alternative Physical Treatments (Ultrasounds, Pulsed Electric Fields, and High-Voltage Electrical Discharges) on Selective Recovery of Bio-Compounds from Fermented Grape Pomace. Food Bioprocess Technol. 2015, 8, 1139–1148. [Google Scholar] [CrossRef]

- Vorobiev, E.; Lebovka, N. Pulsed Electric Field in Green Processing and Preservation of Food Products. In Green Food Processing Techniques: Preservation, Transformation and Extraction; Academic Press: Cambridge, MA, USA, 2019; pp. 403–430. [Google Scholar] [CrossRef]

- Kumar, P.; Barrett, D.M.; Delwiche, M.J.; Stroeve, P. Pulsed Electric Field Pretreatment of Switchgrass and Wood Chip Species for Biofuel Production. Ind. Eng. Chem. Res. 2011, 50, 10996–11001. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, L.J.; Jiang, W.; Qian, J.Y. Effect of Pulsed Electric Field on Functional and Structural Properties of Canola Protein by Pretreating Seeds to Elevate Oil Yield. LWT 2017, 84, 73–81. [Google Scholar] [CrossRef]

- Basak, S. The Potential of Pulsed Magnetic Field to Achieve Microbial Inactivation and Enzymatic Stability in Foods: A Concise Critical Review. Futur. Foods 2023, 7, 100230. [Google Scholar] [CrossRef]

- Szwarc, D.; Szwarc, K. Use of a Pulsed Electric Field to Improve the Biogas Potential of Maize Silage. Energies 2020, 14, 119. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, Z.; He, D.; Li, S.; Xu, Y. Optimization of Enzymatic Hydrolysis of Perilla Meal Protein for Hydrolysate with High Hydrolysis Degree and Antioxidant Activity. Molecules 2022, 27, 1079. [Google Scholar] [CrossRef]

- Liu, Y.; Tang, Y.; Gao, H.; Zhang, W.; Jiang, Y.; Xin, F.; Jiang, M. Challenges and Future Perspectives of Promising Biotechnologies for Lignocellulosic Biorefinery. Molecules 2021, 26, 5411. [Google Scholar] [CrossRef]

- Li, X.; Shi, Y.; Kong, W.; Wei, J.; Song, W.; Wang, S. Improving Enzymatic Hydrolysis of Lignocellulosic Biomass by Bio-Coordinated Physicochemical Pretreatment—A Review. Energy Rep. 2022, 8, 696–709. [Google Scholar] [CrossRef]

- Rodionova, M.V.; Bozieva, A.M.; Zharmukhamedov, S.K.; Leong, Y.K.; Lan, J.C.-W.; Veziroglu, A.; Veziroglu, T.N.; Tomo, T.; Chang, J.S.; Allakhverdiev, S.I. A Comprehensive Review on Lignocellulosic Biomass Biorefinery for Sustainable Biofuel Production. Int. J. Hydrogen Energy 2022, 47, 1481–1498. [Google Scholar] [CrossRef]

- Lopes, A.M.; Ferreira Filho, E.X.; Moreira, L.R.S. An Update on Enzymatic Cocktails for Lignocellulose Breakdown. J. Appl. Microbiol. 2018, 125, 632–645. [Google Scholar] [CrossRef]

| Biomass | Operation Type | Specific Parameters | Saccharification Parameters | Main Results | Reference |

|---|---|---|---|---|---|

| Sugarcane bagasse | Ball Milling | Initial size: 1000 µm, 250 rpm, 20 mm balls, up to 240 min | 5% (w/v) pretreated bagasse, 5 FPU/g substrate Acremonium cellulase, 20 U/g xylanase (Optimash BG), 50 mM acetate buffer (pH 5.0), 45 °C, 72 h | Glucose yield: 89.2%, Xylose yield: 77.2%; Significant particle size reduction (not specified) | [40] |

| Corn stover | Grinding (mill) | Initial size: 425–710 µm | 15 FPU/g glucan Spezyme CP, 65 IU/g glucan Novozyme 188; 0.5 M acetate buffer (pH 4.8), 50 °C, 180 rpm | Final particle size: 53–75 µm; Glucose yield: 20.8% | [41] |

| Sugarcane bagasse and straw | Ball Milling | Initial size: 2000 µm, 400 rpm, 15 mm balls, 30–120 min | 15 FPU/g biomass, 5% substrate concentration, pH 5, 45 °C, 72 h | Glucose yield: 78.7% (bagasse, 60 min), 77.6% (straw, 90 min) | [42] |

| Lodgepole pine | Disk Milling | Initial size: 760 to 1520 µm | 15 FPU/g Acremonium cellulase, 0.02 mL Optimash BG, 5 IU Novozyme 188/g of dried biomass; 50 mM acetate buffer (pH 5.0); 45 °C; 48 h | Final particle size: 760 to 1520 µm; Cellulose-to-glucose conversion: 80% | [43] |

| Eucalyptus | Ball Milling | Initial size: 420 µm and 150 µm, 400 rpm, 15 mm balls, 10–120 min | 1–40 FPU Acremonium cellulase, 0.02 mL Optimash BG, 5 IU Novozyme 188/g dry biomass; 50 mM acetate buffer (pH 5.0); 45 °C; 72 h | Glucose yield: 46.8% (20 min), 89.7% (120 min); Xylose yield: 34.3% (20 min), 72.5% (120 min); Total sugar yield: 74% at 200 g/L biomass | [44] |

| Biomass | Pretreatment Parameters | Main Results | Reference |

|---|---|---|---|

| Eucalyptus urophylla × Eucalyptus grandis | Power: 10–500 W; Frequency: 20–25 kHz; Time: 1, 3, and 6 h | Drying rate increased: 5% (1 h), 13% (3 h), 11% (6 h) above 24% moisture; 25% (1 h), 28% (3 h), 23% (6 h) below 24%. Improved permeability. Reduced wood collapse. | [54] |

| Eucalyptus grandis × Eucalyptus urophylla | Frequency: 28 kHz; Time: 0.5, 1, and 1.5 h | Caustic soda solution pretreatment increased reaction rates and reduced thermal decomposition temperatures (309–400 °C). Gas products (CO, H2O, CO2, CH4, CH3COOH) released more at 361 °C than 308 °C. | [55] |

| Eucalyptus grandis × Eucalyptus urophylla | Frequency: 28 kHz; Time: 0.5, 1, and 1.5 h; Temperature: 50 °C | Increased cellulose crystallinity from 31.8% (control) to 35.5% (alkaline pretreatment). Hemicellulose and lignin removal enhanced solvent exposure. | [56] |

| Pinus sylvestris | Frequency: 16.8–9.2 kHz; Time: 25 min | Glucose yield in enzymatic hydrolysis increased 2-fold (35.5 g/L, 61% theoretical). Ethanol yield: 3.11% (v/v) after fermentation. | [57] |

| Sugarcane Bagasse | Power: 40 W; Frequency: 20 kHz; Time: 20 min | Reducing sugar yield: 276.8 mg/g biomass (1.12× DES alone, 1.58× ultrasound alone). Crystallinity index decreased from 64.87% to 52.78%. | [58] |

| Sugarcane Straw | Frequency: 40 kHz; Time: 30 min | Cellulose conversion: Hydrothermal + NaOH: 86.74%; Acid + NaOH: 84.29%. Ultrasound was the least effective for lignin and hemicellulose removal. | [59] |

| Sugarcane Straw | Power: 180 and 800 W; Frequency: 19 kHz; Time: 30 min; Temperature: 75 °C | Methane yield: 80% (v/v) after 40 days with ultrasound bath (PBU). Hydrogen yield decreased with ultrasonic probe (PSU). | [60] |

| Sugarcane Bagasse | Frequency: 35 kHz; Time: 1, 5, 10, and 15 min | Glucan conversion: 50% (26.35 g glucose/100 g biomass). Crystallinity index increased from 53% (raw) to 65% (3% NaOH + ultrasound). Lignin removal: ~50%. Ethanol yield: 5.6 g/L. | [61] |

| Sugarcane Bagasse | Frequency: 40 kHz; Time: 35 min; Temperature: 30 °C | Maximum weight percent gain (WPG): 30.6% with 10 min ultrasound and maleic anhydride (1:1.1 w/w). FT-IR/NMR confirmed maleation at cellulose and hemicellulose. No impact on thermal stability. | [62] |

| Sugarcane Bagasse | Frequency: 24 kHz; Time: 45 and 60 min; Temperature: 50 °C | Maximum glucose yield: 69.06% theoretical; Pentose yield: 81.35%. Maximum ethanol yield: 91.8% theoretical (8.11 g/L). Low inhibitor formation (acetic acid: 0.95 g/L; furfural: 0.1 g/L). | [63] |

| Sugarcane Bagasse | Frequency: 24 kHz; Temperature: 22 °C | Glucose yield: 91.28% theoretical (38.4 g/L). Ethanol yield: 91.22% theoretical (17.9 g/L in 36 h). Lignin removal: 90.6%. Low inhibitor formation. | [64] |

| Sugarcane Bagasse | Frequency: 24 kHz; Time: 15, 30, and 45 min; Temperature: 40, 60, and 80 °C | Cellulose recovery: 95.78%. Delignification: 58.14%. Glucose production: 16.58 g/L. Xylose: 8.21 g/L. Crystallinity index decreased from 68.6% to 48.6%. | [65] |

| Sugarcane Bagasse | Frequency: 45 kHz; Temperature: 90 °C | Cellulose-to-reducing sugar conversion: 95.9% (12 h). Ultrasound-NMMO treated bagasse: 90.4% (24 h). Crystallinity index decreased (TCI: 1.393 → 0.878). Glucose production: 5.2 g/L. | [66] |

| Sugarcane Bagasse | Frequency: 20 kHz; Time: 180 s | Maximum sugar yield: 26.01 g/L (94.49% theoretical). Most influential factors: enzyme use, particle size, acid concentration, ultrasound duration, and power. Optimal acid: 3% (higher led to inhibitors). Optimal ultrasound: 120 W, 180 s. | [67] |

| Sugarcane Bagasse | Frequency: 24 kHz; Temperature: 70 °C | Lignin removal: 82.32%. Maximum reducing sugar yield: 96.27% theoretical. Cellulose recovery: 98.32%. Low inhibitor formation (acetic acid: 0.36 g/L). | [68] |

| Sugarcane Bagasse | Frequency: 20 kHz; Time: 40 min; Temperature: 55 °C | Lignin and hemicellulose increased by 2.2% and 1.3% (compared to non-ultrasound). Extracted lignin had high purity and better solubilization. | [69] |

| Corn Cob | Frequency: 20 kHz | Methane yield increased: 59.8% (VTS), 14.6% (corn cob) after isolated enzymatic hydrolysis. US + Hydrolysis improved methane yield by 41.8% (VTS) and 17.9% (corn cob). | [70] |

| Corn Cob and Corn Stalk | Frequency: 20 kHz; Time: 2 and 8 h; Temperature: 80 °C | Reducing sugar yield: Corn cob (scCO2 + US): 87.0% (+75% vs. control); Corn stalks (scCO2 + US): 30.0% (+13.4% vs. control). Ultrasound disrupted lignin and increased surface area. Ultrasound had a higher effect on corn cob than stalks. | [71] |

| Soybean Straw | Time: 120–250 min; Temperature: 40–80 °C | Maximum reducing sugar yield: 53.27 mg (0.2 g soybean straw), 50.03 mg (0.2 g corn straw). Ultrasound improved biomass interaction with ionic liquids, enhancing cellulose dissolution. | [72] |

| Bermuda Grass | Frequency: 40 kHz; Time: 20–100 min; Temperature: 40–80 °C | Maximum reducing sugar yield: 36.89% (optimized). Optimal: 2% acid, 80 °C, solid–liquid ratio 12:1, ultrasound power 80 W, 100 min. Ultrasound reduced biomass crystallinity, increasing cellulose exposure. | [73] |

| Biomass | Specific Parameters | Main Results | Reference |

|---|---|---|---|

| Eucalyptus sawdust | 400 W, 15 min, 180 °C, 2.45 GHz | Sugar release: 3.5× higher vs. LHW; 100% sugar yield after enzymatic hydrolysis. | [83] |

| Corn stalks, Miscanthus | 710 W, 300 W, 800 s (710 W), 180 s (300 W), Pressure (4 bars), 2.45 GHz | No significant increase in methane potential. | [84] |

| Sugarcane bagasse | 600 W, 4 min | Reducing sugar yield: 0.665 g/g (NaOH), 0.83 g/g (NaOH + H2SO4). | [85] |

| Napier grass | 76 min, 147 °C | Maximum fermentable sugar yield: 14.38 g/L. | [86] |

| Sugarcane straw | 1000 W, 2 min, 162 °C | Total sugar yield: 72.2%; Low inhibitor concentration. | [87] |

| Sugarcane trash, Oil Palm EFB | 1200 W, 5 min, 180 °C | Reducing sugar yield: 0.33 g/g (sugarcane trash), 0.19 g/g (OPEFB). | [88] |

| Switchgrass, Miscanthus | 800 W, 10 min, 60–210 °C | Increased subcritical water solubility by 7–10%. | [89] |

| Switchgrass, Big bluestem | 450 W, 2.5 min | Increased total sugar recovery: 59.2% (switchgrass), 68.1% (big bluestem). | [90] |

| Pine chips, Beech chips, Hemp stems | 300 W, 10–20 min, 140–180 °C | Sulfuric acid increased glucose release; nitric acid promoted xylose and galactose release. | [91] |

| Sugarcane bagasse | 820 W, 3 min, NaOH 1% | Cellulose-enriched fractions resulted in the best ethanol yield. | [92] |

| Sugarcane leaf waste | 400 W, 5 min | Lignin removal: 73%. Hemicellulose removal: 62%. Maximum ethanol yield: 31.06 g/L | [93] |

| Corn straw | 640 W, 5 min | 49.25% sugar yield after microwave pretreatment | [94] |

| Pinus radiata | 50–150 °C, 50 min | Glucan digestibility: 79% after autohydrolysis (150 °C) and microwave (120 °C). | [95] |

| Eucalyptus globulus, Pinus radiata | 80–120 °C, 50 min | Glucan digestibility increased: 68 g/100 g (eucalyptus), 78 g/100 g (pine). | [96] |

| Sugarcane bagasse | 320 W, 3–10 min, 170 ± 5 °C | Glucose production: 64% after 7 min with H2SO4. | [97] |

| Sugarcane bagasse | 10–20 min, 180–200 °C | Sugar yield: 44.9 g/100 g bagasse; ethanol yield: 35.8% (holocellulose fraction). | [98] |

| Corn straw | Up to 1600 W, 10 min, 120–210 °C | Methane production increased by 73.08% vs. control. | [99] |

| Elephant grass | 200–600 W, 10–30 min | Lignin reduced to 3.24%, cellulose increased to 38.38%. | [100] |

| Biomass | Pretreatment Parameters | Main Results | Reference |

|---|---|---|---|

| Eucalyptus grandis | Twin-screw extruder, 150 rpm, 100 °C | Increased xylose release: 24.7–27.6 g/100 g (10% NaOH), 36.9–39.7 g/100 g (20% NaOH). | [122] |

| Eucalyptus wood chips | Twin-screw extruder | Maximum cellulose hydrolysis yield: 79.6% after 168 h enzymatic hydrolysis. | [123] |

| Eucalyptus grandis | Twin-screw extruder, 100, 200, 300 rpm; 75, 100, 125 °C; (Liquid-to-solid ratio): Between 0.6 and 1.5. Moisture: 37–60% | Enhanced enzymatic digestibility: glucan (37.6%), xylan (74.6%) release. | [124] |

| Eucalyptus wood chips | Steam explosion through continuous screw extrusion (SESE) | Reduced fiber size, increased surface area, lignin depolymerization/repolymerization. | [125] |

| Eucalyptus wood chips | Twin-screw extruder, 45–120 rpm, ambient temperature | HCW + extrusion significantly increased glucose production. Monosaccharide yield: 39.3% of original wood weight. | [126] |

| Pine wood chips | Single-screw extruder, 100, 150, 200 rpm; 100, 140, 180 °C; Moisture: 25, 35, 45% | Higher screw speed and barrel temperature improved sugar recovery; high moisture reduced recovery. | [127] |

| Sugarcane Bagasse | Twin-screw extruder, 100 rpm, 130 °C, Moisture: 10% | Glucose yield increased by 330%, crystallinity reduced by 78%, improving enzymatic hydrolysis efficiency. | [128] |

| Sugarcane Bagasse and Straw | Twin-screw extruder, 20–150 rpm, 30–150 °C, Moisture: 10–12% | Glucose yield: 68.2% (straw, 7 passes), 36.6% (bagasse, 3 passes). | [121] |

| Sugarcane Bagasse | Twin-screw extruder, 15 rpm, 140 °C, Biomass pre-dried | Glucose yield: 91% (25% bagasse, 2 passes), 76.4% (50% loading). | [129] |

| Corn cob | Twin-screw extruder | Extrusion + NaOH + enzymatic hydrolysis increased methane production by 22.3% vs. raw cob digestion. | [130] |

| Soybean Hulls | Twin-screw extruder, 280, 350, 420 rpm; Barrel adjusted from 40 °C (inlet) to 80 °C (outlet); Moisture: 40%, 45%, 50% | Improved enzymatic hydrolysis: glucose yield increased by 155% vs. untreated biomass. | [131] |

| Soybean Hulls | Twin-screw extruder, 280, 350, 420 rpm; Drum: 80, 110, 140 °C (80 °C most efficient); Moisture: 0.4 | Cellulose-to-glucose conversion: 94.8% (higher than acid: 69.2%, similar to alkali: 93.3%). | [132] |

| Soybean Hulls | Twin-screw extruder, 3.7 Hz (222 rpm); 110 °C; Moisture: 30–35% | Reducing sugars yield: 9–12%. Washing increased yield to 25–36%. | [133] |

| Grass | Twin-screw extruder | Increased biomethane potential (BMP): 11% (fresh grass), 18% (silage). | [134] |

| Switchgrass | Single-screw extruder, Compression ratios: 2:1 and 3:1; 50, 100, 150 rpm; 50, 100, 150 °C; Moisture: 15%, 25%, 35%, 45% | Maximum glucose recovery: 45.2% (15% moisture, 50 rpm, 150 °C, 3:1 compression). | [135] |

| Big bluestem | Single-screw extruder, 20–200 rpm; 45–225 °C; Moisture: 10–50% | Maximum sugar recovery: glucose (71.3%), xylose (78.5%), total sugars (56.9%). | [136] |

| Prairie Cord Grass | Single-screw extruder, 20–200 rpm; 45–225 °C; Moisture: 75–78% | Maximum glucose (86.8%), xylose (84.5%), total sugars (82%) under optimized conditions. | [137] |

| Switchgrass, Prairie Cord Grass, and Big Bluestem | Single-screw extruder, 20–200 rpm; 45–225 °C; Moisture: 10–50% | Sugar recovery: Switchgrass (47.4%, torque: 85–100 Nm), Prairie Cord Grass (56.9%, torque: 27–42 Nm), Big Bluestem (56.9%, torque: 53–84 Nm). | [138] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sant’Ana Júnior, D.B.; Kelbert, M.; Hermes de Araújo, P.H.; de Andrade, C.J. Physical Pretreatments of Lignocellulosic Biomass for Fermentable Sugar Production. Sustain. Chem. 2025, 6, 13. https://doi.org/10.3390/suschem6020013

Sant’Ana Júnior DB, Kelbert M, Hermes de Araújo PH, de Andrade CJ. Physical Pretreatments of Lignocellulosic Biomass for Fermentable Sugar Production. Sustainable Chemistry. 2025; 6(2):13. https://doi.org/10.3390/suschem6020013

Chicago/Turabian StyleSant’Ana Júnior, Damázio Borba, Maikon Kelbert, Pedro Henrique Hermes de Araújo, and Cristiano José de Andrade. 2025. "Physical Pretreatments of Lignocellulosic Biomass for Fermentable Sugar Production" Sustainable Chemistry 6, no. 2: 13. https://doi.org/10.3390/suschem6020013

APA StyleSant’Ana Júnior, D. B., Kelbert, M., Hermes de Araújo, P. H., & de Andrade, C. J. (2025). Physical Pretreatments of Lignocellulosic Biomass for Fermentable Sugar Production. Sustainable Chemistry, 6(2), 13. https://doi.org/10.3390/suschem6020013