Thermal Modification of Wood—A Review

Abstract

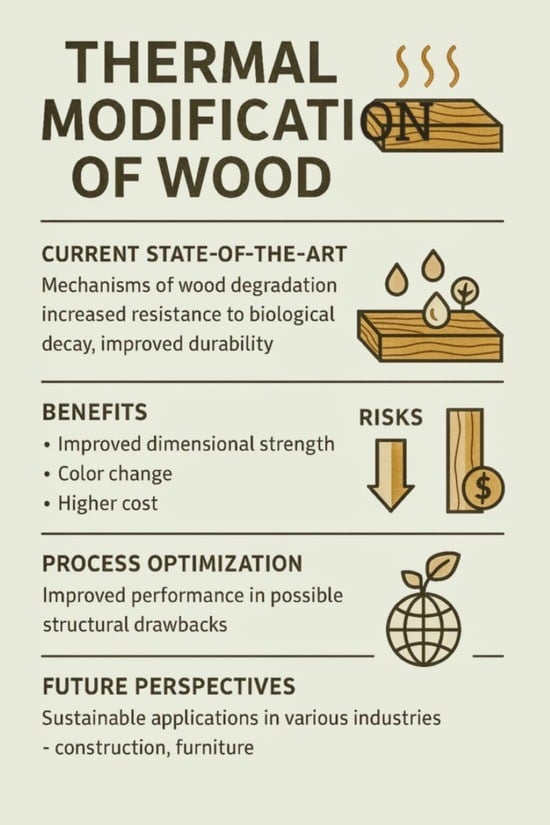

1. Introduction

- (a)

- chemical modification (active and passive modification);

- (b)

- thermally based processes (thermo treatment, thermo–hydrotreatment, thermo–mechanical treatment, thermo–hydro–mechanical treatment);

- (c)

- physical modification (electromagnetic radiation, plasma, and laser);

- (d)

Thermal Wood Modification in Scientific Publications

2. Thermal Modification of Wood—Changes in the Chemical Structure

3. Benefits of Thermal Modification of Wood

4. Risks of Thermal Modification of Wood

5. Prospects of Thermal Modification of Wood

- (a)

- Increased demand for sustainable building materials

- (b)

- Expansion into new markets and applications

- (c)

- Technological improvement

- (d)

- Cost reduction and increased accessibility

- (e)

- Environmental and regulatory support

- (f)

- Research and innovation

The Use of Thermally Modified Wood

- a

- Exterior decking: Due to its stability and resistance to weathering, it is ideal for decks.

- b

- Cladding and siding: Provides a durable and aesthetically pleasing exterior covering for buildings.

- c

- Balconies and railings: Resists moisture and biological attack.

- d

- Windows and doors: Improved stability reduces problems with deformations.

- e

- Garden furniture: Withstands weathering and rot.

- f

- Saunas: Low water absorption and resistance to high temperatures make it a suitable material for saunas.

- g

- Flooring: Both indoors and outdoors, where resistance to moisture is needed.

- h

- Structural elements: In some less stressed structures where stability and durability are important.

- i

- Musical instruments: Its stability and acoustic properties are also utilized in the music industry.

- j

- Interior cladding and panels: For aesthetic appearance and stability.

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sandberg, D.; Kutnar, A.; Mantanis, G. Wood modification technologies—A review. Iforest-Biogeosci. For. 2017, 10, 895. [Google Scholar] [CrossRef]

- Gérardin, P. New alternatives for wood preservation based on thermal and chemical modification of wood—A review. Ann. For. Sci. 2016, 73, 559–570. [Google Scholar] [CrossRef]

- Hill, C.; Altgen, M.; Rautkari, L. Thermal modification of wood—A review: Chemical changes and hygroscopicity. J. Mater. Sci. 2021, 56, 6581–6614. [Google Scholar] [CrossRef]

- Candelier, K.; Dibdiakova, J. A review on life cycle assessments of thermally modified wood. Holzforschung 2021, 75, 199–224. [Google Scholar] [CrossRef]

- Tang, J.; Zhan, T.; Li, Z.; Jiang, J.; Lyu, J. Optimization of dimensional stability and mechanical performance of thermally modified wood using cyclic-gradient thermal treatment. Constr. Build. Mater. 2025, 458, 139596. [Google Scholar] [CrossRef]

- Sandberg, D.; Kutnar, A.; Karlsson, O.; Jones, D. Wood Modification Technologies: Principles, Sustainability, and the Need for Innovation; CRC Press: Boca Raton, FL, USA, 2021. [Google Scholar]

- Hill, C.A. Wood Modification: Chemical, Thermal and Other Processes; John Wiley Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- Vainio-Kaila, T.; Rautkari, L.; Nordström, K.; Närhi, M.; Natri, O.; Kairi, M. Effect of extractives and thermal modification on antibacterial properties of Scots pine and Norway spruce. Int. Wood Prod. J. 2013, 4, 248–252. [Google Scholar] [CrossRef]

- De Oliveira Lopes, J.; Cáceres, C.B.; Hernándes, R.E.; Garcia, R.A. Effect of the thermal treatment on the chemical components, sorption, and shrinkage properties of Tectona grandis juvenile wood. Maderas. Cienc. Y Tecnol. 2022, 24. [Google Scholar] [CrossRef]

- Kamperidou, V. Chemical and structural characterization of poplar and black pine wood exposed to short thermal modification. Drv. Ind. 2021, 72, 155–167. [Google Scholar] [CrossRef]

- Kubovský, I.; Kačíková, D.; Kačík, F. Structural changes of oak wood main components caused by thermal modification. Polymers 2020, 12, 485. [Google Scholar] [CrossRef]

- Lourenço, A.; Araújo, S.; Gominho, J.; Pereira, H.; Evtuguin, D. Structural changes in lignin of thermally treated eucalyptus wood. J. Wood Chem. Technol. 2020, 40, 258–268. [Google Scholar] [CrossRef]

- Kačíková, D.; Kubovský, I.; Ulbriková, N.; Kačík, F. The impact of thermal treatment on structural changes of teak and iroko wood lignins. Appl. Sci. 2020, 10, 5021. [Google Scholar] [CrossRef]

- Corleto, R.; Gaff, M.; Niemz, P.; Sethy, A.K.; Todaro, L.; Ditommaso, G.; Macků, J. Effect of thermal modification on properties and milling behaviour of African padauk (Pterocarpus soyauxii Taub.) wood. J. Mater. Res. Technol. 2020, 9, 9315–9327. [Google Scholar] [CrossRef]

- Ditommaso, G.; Gaff, M.; Kačík, F.; Sikora, A.; Sethy, A.; Corleto, R.; Sedlecký, M. Interaction of technical and technological factors on qualitative and energy/ecological/economic indicators in the production and processing of thermally modified merbau wood. J. Clean. Prod. 2020, 252, 119793. [Google Scholar] [CrossRef]

- Kozakiewicz, P.; Drożdżek, M.; Laskowska, A.; Grześkiewicz, M.; Bytner, O.; Radomski, A.; Zawadzki, J. Chemical composition as factor affecting the mechanical properties of thermally modified black poplar (Populus nigra L.). BioResources 2020, 15, 3915. [Google Scholar] [CrossRef]

- Wang, J.; Minami, E.; Asmadi, M.; Kawamoto, H. Effect of delignification on thermal degradation reactivities of hemicellulose and cellulose in wood cell walls. J. Wood Sci. 2020, 67, 19. [Google Scholar] [CrossRef]

- Lengowski, E.C.; Bonfatti Júnior, E.A.; Nisgoski, S.; Bolzon de Muñiz, G.I.; Klock, U. Properties of thermally modified teakwood. Maderas. Cienc. Y Tecnol. 2021, 23. [Google Scholar] [CrossRef]

- Minkah, M.A.; Afrifah, K.A.; Batista, D.C.; Militz, H. Chemical and Mechanical Characterization of Thermally Modified Gmelina arborea Wood: Kemijska in mehanska karakterizacija termično modificiranega lesa vrste Gmelina arborea. Les/Wood 2021, 70, 31–44. [Google Scholar] [CrossRef]

- Zachar, M.; Čabalová, I.; Kačíková, D.; Zacharová, L. The effect of heat flux to the fire-technical and chemical properties of spruce wood (Picea abies L.). Materials 2021, 14, 4989. [Google Scholar] [CrossRef]

- Gaff, M.; Kubovský, I.; Sikora, A.; Kačíková, D.; Li, H.; Kubovský, M.; Kačík, F. Effect of oxidizing thermal modification on the chemical properties and thermal conductivity of Norway spruce (Picea abies L.) wood. Wood Mater. Sci. Eng. 2021, 17, 366–375. [Google Scholar]

- Sikora, A.; Hájková, K.; Jurczyková, T. Degradation of chemical components of thermally modified Robinia pseudoacacia L. wood and its effect on the change in mechanical properties. Int. J. Mol. Sci. 2022, 23, 15652. [Google Scholar] [CrossRef]

- Vidholdová, Z.; Kačík, F.; Reinprecht, L.; Kučerová, V.; Luptáková, J. Changes in chemical structure of thermally modified spruce wood due to decaying fungi. J. Fungi 2022, 8, 739. [Google Scholar] [CrossRef] [PubMed]

- Kačík, F.; Kubovský, I.; Bouček, J.; Hrčka, R.; Gaff, M.; Kačíková, D. Colour and chemical changes of black locust wood during heat treatment. Forests 2022, 14, 73. [Google Scholar] [CrossRef]

- Mastouri, A.; Azadfallah, M.; Rezaei, F.; Tarmian, A.; Efhamisisi, D.; Mahmoudkia, M.; Corcione, C.E. Kinetic studies on photo-degradation of thermally-treated spruce wood during natural weathering: Surface performance, lignin and cellulose crystallinity. Constr. Build. Mater. 2023, 392, 131923. [Google Scholar] [CrossRef]

- Gaff, M.; Kubovský, I.; Sikora, A.; Kačíková, D.; Li, H.; Kubovský, M.; Kačík, F. Impact of thermal modification on color and chemical changes of African padauk, merbau, mahogany, and iroko wood species. Rev. Adv. Mater. Sci. 2023, 62, 20220277. [Google Scholar] [CrossRef]

- Gupta, A.; Dutt, B.; Sharma, S. Analysis of chemical properties of thermally treated Pinus roxburghii Sargent wood. BioResources 2023, 18, 4598–4609. [Google Scholar] [CrossRef]

- Gomes, F.D.S.; Reis, M.D.S.; Rupf, A.C.O.; Silvares, P.H.D.S.; Ferreira, J.S.D.S.; Dias, L.D.C.; Batista, D.C. Chemical composition and color of short-rotation teak wood thermally modified in closed and open systems. Appl. Sci. 2023, 13, 13050. [Google Scholar] [CrossRef]

- Liu, S.; Ran, Y.; Cao, J. Comparison on thermally modified beech wood in different mediums: Morphology, chemical change and water-related properties. Ind. Crops Prod. 2024, 209, 117935. [Google Scholar] [CrossRef]

- Grinins, J.; Sosins, G.; Brazdausks, P.; Zicans, J. Chemical composition and mechanical properties of wood after thermal modification in closed process under pressure in nitrogen. Materials 2024, 17, 1468. [Google Scholar] [CrossRef] [PubMed]

- Oberle, A.; Výbohová, E.; Baar, J.; Paschová, Z.; Beránek, Š.; Drobyshev, I.; Čermák, P. Chemical changes in thermally modified, acetylated and melamine formaldehyde resin impregnated beech wood. Holzforschung 2024, 78, 459–469. [Google Scholar] [CrossRef]

- Kačík, F.; Kúdela, J.; Výbohová, E.; Jurczyková, T.; Čabalová, I.; Adamčík, L.; Kačíková, D. Impact of Thermal Treatment and Accelerated Aging on the Chemical Composition, Morphology, and Properties of Spruce Wood. Forests 2025, 16, 180. [Google Scholar] [CrossRef]

- Esteves, B.; Nunes, L.; Lopes, R.; Cruz-Lopes, L. Enhanced Properties of Cryptomeria japonica (Thunb ex Lf) D. Don from the Azores Through Heat-Treatment. Forests 2025, 16, 166. [Google Scholar] [CrossRef]

- Candelier, K.; Hannouz, S.; Thévenon, M.F.; Guibal, D.; Gérardin, P.; Pétrissans, M.; Collet, R. Resistance of thermally modified ash (Fraxinus excelsior L.) wood under steam pressure against rot fungi, soil-inhabiting micro-organisms and termites. Eur. J. Wood Wood Prod. 2017, 75, 249–262. [Google Scholar] [CrossRef]

- Godinho, D.; Lourenço, A.; de Oliveira Araújo, S.; Machado, J.S.; Nunes, L.; Duarte, M.; Gominho, J. Thermally modified wood: Assessing the impact of weathering on mechanical strength and exposure to subterranean termites. Eur. J. Wood Wood Prod. 2025, 83, 40. [Google Scholar] [CrossRef]

- Tomak, E.D.; Ermeydan, M.A. Measuring dimensional stability of thermally modified ayous and iroko wood: Comparison of the three test methods. Cellulose 2025, 32, 2581–2597. [Google Scholar] [CrossRef]

- Minkah, M.A.; Afrifah, K.A.; Antwi-Boasiako, C.; Silva, A.P.S.D.; Medeiros, J.R.D.; Paes, J.B.; Militz, H. Biological resistance of thermally modified Gmelina arborea wood. Maderas. Cienc. Y Tecnol. 2024, 26, 3624. [Google Scholar] [CrossRef]

- Paes, J.B.; Brocco, V.F.; Loiola, P.L.; Segundinho, P.G.A.; Silva, M.R.; Juizo, C.G.F. Effect of thermal modification on decay resistance of Corymbia Citriodora and Pinus Taeda wood. J. Trop. For. Sci. 2021, 33, 185–190. [Google Scholar] [CrossRef]

- Sargent, R. Evaluating dimensional stability in modified wood: An experimental comparison of test methods. Forests 2022, 13, 613. [Google Scholar] [CrossRef]

- Okon, K.E.; Ndulue, N.B. Thermal modification of fast-growing Firmiana simplex wood using tin alloy: Evaluation of physical and mechanical properties. Maderas. Cienc. Y Tecnol. 2025, 27, e0325. [Google Scholar] [CrossRef]

- Bytner, O.; Laskowska, A.; Drożdżek, M.; Kozakiewicz, P.; Zawadzki, J. Evaluation of the dimensional stability of black poplar wood modified thermally in nitrogen atmosphere. Materials 2021, 14, 1491. [Google Scholar] [CrossRef]

- Lunguleasa, A.; Spirchez, C. Influence of thermal treatment on properties of ash wood. Forests 2025, 16, 155. [Google Scholar] [CrossRef]

- Tsapko, Y.; Bondarenko, O.; Horbachova, O.; Mazurchuk, S. Research of the process of water absorption by thermally modified wood. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1164, 012030. [Google Scholar] [CrossRef]

- Borůvka, V.; Sedivka, P.; Novák, D.; Turek, J. Haptic and aesthetic properties of heat-treated modified birch wood. Forests 2021, 12, 1081. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, M.; Liu, Y.; Wang, J.; Lei, Y.; Chen, Z.; Yan, L. Evaluation of the colour parameters on hygroscopicity and dimensional stability of thermally modified Populus tomentosa Carr. Ind. Crops Prod. 2023, 205, 117506. [Google Scholar] [CrossRef]

- Herrera-Builes, J.F.; Sepúlveda-Villarroel, V.; Osorio, J.A.; Ananias, R.A. Effect of thermal modification treatment on some physical and mechanical properties of Pinus oocarpa wood. Forests 2021, 12, 249. [Google Scholar] [CrossRef]

- Hrčka, R.; Kučerová, V.; Hýrošová, T.; Hönig, V. Cell wall saturation limit and selected properties of thermally modified oak wood and cellulose. Forests 2020, 11, 640. [Google Scholar] [CrossRef]

- Czajkowski, Ł.; Olek, W.; Weres, J. Effects of heat treatment on thermal properties of European beech wood. Eur. J. Wood Wood Prod. 2020, 78, 425–431. [Google Scholar] [CrossRef]

- Nhacila, F.; Sitoe, E.; Uetimane, E.; Manhica, A.; Egas, A.; Möttönen, V. Effects of thermal modification on physical and mechanical properties of Mozambican Brachystegia spiciformis and Julbernardia globiflora wood. Eur. J. Wood Wood Prod. 2020, 78, 871–878. [Google Scholar] [CrossRef]

- Bytner, O.; Drożdżek, M.; Laskowska, A.; Zawadzki, J. Influence of thermal modification in nitrogen atmosphere on the selected mechanical properties of black poplar wood (Populus nigra L.). Materials 2022, 15, 7949. [Google Scholar] [CrossRef]

- Grinins, J.; Sosins, G.; Irbe, I.; Zicans, J. Weathering resistance of wood following thermal modification in closed process under pressure in nitrogen. Forests 2025, 16, 132. [Google Scholar] [CrossRef]

- Jirouš-Rajković, V.; Miklečić, J. Enhancing weathering resistance of wood—A review. Polymers 2021, 13, 1980. [Google Scholar] [CrossRef]

- Horbachova, O.; Mazurchuk, S.; Lomaha, V.; Buiskykh, N.; Matviichuk, A.; Marchenko, N. Identifying patterns in the resistance of thermally modified ash wood to weathering. East.-Eur. J. Enterp. Technol. 2025, 1, 6–15. [Google Scholar]

- Cirule, D.; Sansonetti, E.; Andersone, I.; Kuka, E.; Andersons, B. Enhancing thermally modified wood stability against discoloration. Coatings 2021, 11, 81. [Google Scholar] [CrossRef]

- Sandberg, D.; Kutnar, A. Thermally modified timber: Recent developments in Europe and North America. Wood Fiber Sci. 2016, 48, 28–39. [Google Scholar]

- Kubojima, Y.; Okano, T.; Ohta, M. Bending strength and toughness of heat-treated wood. J. Wood Sci. 2000, 46, 8–15. [Google Scholar] [CrossRef]

- Nakagawa, T.; Poulin, E.; Rueppel, T.; Chen, Z.; Swinea, J.; O’Brien, M.; Salviato, M. Effects of thermal modification on the flexure properties, fracture energy, and hardness of western hemlock. Wood Sci. Technol. 2024, 58, 109–133. [Google Scholar] [CrossRef]

- Očkajová, A.; Kučerka, M.; Kminiak, R.; Rogoziński, T. Granulometric composition of chips and dust produced from the process of working thermally modified wood. Acta Fac. Xylologiae Zvolen Res Publica Slovaca 2020, 62, 103–111. [Google Scholar]

- Očkajová, A.; Kučerka, M.; Kminiak, R.; Krišťák, Ľ.; Igaz, R.; Réh, R. Occupational exposure to dust produced when milling thermally modified wood. Int. J. Environ. Res. Public Health 2020, 17, 1478. [Google Scholar] [CrossRef]

- Zhang, F.; Zhang, T.; Buck, D.; Bao, Y.; Guo, X. Investigation of surface damage mechanisms in milling heat-treated pine wood. CIRP J. Manuf. Sci. Technol. 2025, 56, 47–60. [Google Scholar] [CrossRef]

- Cui, Y.; Qiu, H.; Ding, T.; Gong, M.; Zhu, N. Study on the morphological characteristics of thermally modified bamboo milling dust. Holzforschung 2025, 79, 69–84. [Google Scholar] [CrossRef]

- De Ligne, L.; Fredriksson, M.; Thygesen, L.G.; Thybring, E.E. Influence of degradation products from thermal wood modification on wood-water interactions. J. Mater. Sci. 2025, 60, 3346–3364. [Google Scholar] [CrossRef]

- Li, T.; Li, G.; Li, J.; Li, X.; Li, M.; Li, Y. Characterization of the odorous constituents and chemical structure of thermally modified rubberwood. Wood Mater. Sci. Eng. 2024, 19, 442–450. [Google Scholar] [CrossRef]

- Liu, Y. Exploratory Thermal Modification of Some West Coast Canadian Wood Species. Ph.D. Dissertation, University of British Columbia, Vancouver, BC, Canada, 2025. [Google Scholar]

- Ajdinaj, D.; Cota, H.; Lato, E.; Quku, D. Surface quality of planed tangential and radial sections of thermally modified Silver fir wood. Maderas. Cienc. Y Tecnol. 2025, 27, e1725. [Google Scholar] [CrossRef]

- Adamčík, L.; Giudice, V.L.; Todaro, L.; Dudiak, M.; Kminiak, R. Surface roughness of thermally modified and unmodified selected wood species after sanding. Eur. J. Wood Wood Prod. 2025, 83, 105. [Google Scholar] [CrossRef]

- Cao, S.; Cheng, S.; Cai, J. Research progress and prospects of wood high-temperature heat treatment technology. BioResources 2022, 17, 3702. [Google Scholar] [CrossRef]

- Cao, S.; Cai, J.; Wu, M.; Zhou, N.; Huang, Z.; Cai, L.; Zhang, Y. Surface properties of poplar wood after heat treatment, resin impregnation, or both modifications. BioResources 2021, 16, 7562–7577. [Google Scholar] [CrossRef]

- Esteves, B.; Ferreira, H.; Viana, H.; Ferreira, J.; Domingos, I.; Cruz-Lopes, L.; Jones, D.; Nunes, L. Termite resistance, chemical and mechanical characterization of Paulownia tomentosa wood before and after heat treatment. Forests 2021, 12, 1114. [Google Scholar] [CrossRef]

- Järvinen, J.; Ilgın, H.E.; Karjalainen, M. Wood preservation practices and future outlook: Perspectives of experts from Finland. Forests 2022, 13, 1044. [Google Scholar] [CrossRef]

- Aro, M.D. Life-Cycle Assessment of Thermally-Modified Southern Pine Decking. Master’s Thesis, University of Minnesota, Minneapolis, MN, USA, 2018. [Google Scholar]

- Wentzel, M.; González-Prieto, Ó.; Brischke, C.; Militz, H. Physico-mechanical properties of thermally modified Eucalyptus nitens wood for decking applications. Wood Ind./Drv. Ind. 2019, 70, 235–245. [Google Scholar] [CrossRef]

- Humar, M.; Kržišnik, D.; Lesar, B.; Brischke, C. The performance of wood decking after five years of exposure: Verification of the combined effect of wetting ability and durability. Forests 2019, 10, 903. [Google Scholar] [CrossRef]

- Kvietková, M.S.; Dvořák, O.; Kalábová, M.; Šimůnková, K.; Štěrbová, I.; Pastierovič, F.; Lin, C.-F.; Jones, D. The influence of the type of coating on thermally modified wood and the resulting durability of the surface treatment on a facade. J. Build. Eng. 2024, 91, 109629. [Google Scholar] [CrossRef]

- Jones, D.; Sandberg, D. A review of wood modification globally–updated findings from COST FP1407. Interdiscip. Perspect. Built Environ. 2020, 1. [Google Scholar] [CrossRef]

- Jones, D.; Sandberg, D.; Goli, G.; Todaro, L. Wood Modification in Europe: A State-of-the-Art About Processes, Products and Applications; Firenze University Press: Firenze, Italy, 2019; 123p. [Google Scholar]

- Aro, M.D.; Geerts, S.M.; French, S.; Cai, M. Particle size analysis of airborne wood dust produced from sawing thermally modified wood. Eur. J. Wood Wood Prod. 2019, 77, 211–218. [Google Scholar] [CrossRef]

- Ugovšek, A.; Šubic, B.; Starman, J.; Rep, G.; Humar, M.; Lesar, B.; Thaler, N.; Brischke, C.; Meyer-Veltrup, L.; Jones, D.; et al. Short-term performance of wooden windows and facade elements made of thermally modified and non-modified Norway spruce in different natural environments. Wood Mater. Sci. Eng. 2019, 14, 42–47. [Google Scholar] [CrossRef]

- Spear, M.J.; Curling, S.F.; Dimitriou, A.; Ormondroyd, G.A. Review of functional treatments for modified wood. Coatings 2021, 11, 327. [Google Scholar] [CrossRef]

- Godinho, D.; Araújo, S.D.O.; Quilhó, T.; Diamantino, T.; Gominho, J. Thermally modified wood exposed to different weathering conditions: A review. Forests 2021, 12, 1400. [Google Scholar] [CrossRef]

- Tankut, N.; Tankut, A.N.; Zor, M. Mechanical properties of heat-treated wooden material utilized in the construction of outdoor sitting furniture. Turk. J. Agric. For. 2014, 38, 148–158. [Google Scholar] [CrossRef]

- Juizo, C.G.F.; da Rocha, M.P.; Xavier, C.N.; Moraes, A.C.M.; de Oliveira, M.B.; da Silva, J.R.M. Thermal modification of Eucalyptus wood and use for floors of low traffic environments. Floresta 2021, 51, 457–465. [Google Scholar] [CrossRef]

| Wavenumber (cm−1) | Changes | Result and Consequence |

|---|---|---|

| 3420 | slight decrease in the amount of -OH groups | condensation reactions hydrolysis of acetyl groups from hemicelluloses |

| 2940–2840 | slight decreasing of band intensities | changes at the cellulose crystallinity level |

| 1723 | increase in absorbance band shift to lower wavenumbers | increase in carbonyl and carboxyl groups cleavage of β-O-4 linkages |

| 1600–1500 | slight increase and changes | lignin condensation carboxylation of polysaccharides |

| 1420–1460 | slight decrease | degradation of lignin cleavage of methoxyl groups |

| 1219–1267 | initial increase decrease slightly in all samples | C-O stretching of guaiacyl and syringyl ring |

| 1190–950 | slight decrease or permanent decrease | degradation of hydroxyl groups demethoxylation of lignin crosslinking |

| Sample | Temperature (°C) | Polydisperzity Index (PDI) | Degree of Polymerization |

|---|---|---|---|

| Lignin fraction | 20 | 2.65 | - |

| 160 | 2.84 | ||

| 180 | 2.80 | ||

| 210 | 2.79 | ||

| Holocellulose fraction | 20 | 4.17 | 1315 |

| 160 | 4.20 | 1151 | |

| 180 | 5.33 | 905 | |

| 210 | 9.48 | 1700 | |

| Cellulose fraction | 20 | 9.81 | 2382 |

| 160 | 10.80 | 2376 | |

| 180 | 11.80 | 2197 | |

| 210 | 9.14 | 1894 |

| Sample | Total Lignin (%) | Syringyl Units (S) Guaiacyl Units (G) p-Hydroxyphenyl Units (H) | Total Carbohydrates (%) | S/G Ratio H:G:S |

|---|---|---|---|---|

| Lignin fraction (E. globulus; untreated) | 91.5 | 72.4 16.1 0.5 | 1.5 | 4.5 1:18:81 |

| Lignin fraction (E. globulus; thermally treated) | 92.7 | 69.3 17.8 2.3 | 2.0 | 3.9 2:20:78 |

| Lignin fraction (E. propinqua; untreated) | 90.4 | 47.2 32.7 4.9 | 1.2 | 1.4 6:39:55 |

| Lignin fraction (E. propinqua; thermally treated) | 94.6 | 52.9 32.5 4.4 | 2.5 | 1.6 5:37:58 |

| Sample | Conditions | KL | DL | S/G Ratio | PDI |

|---|---|---|---|---|---|

| Teak (Tectona grandis) | 160, 180, and 210 °C open system chamber with steam, 3 h | 35.4 * | 8.6 * | 0.9 * | 3.7 * |

| 39.3 | 11.4 | 0.9 | 3.5 | ||

| 39.5 | 15.3 | 0.8 | 3.9 | ||

| 40.5 | 18.3 | 0.6 | 4.0 | ||

| Iroko (Milicia excelsa) | 160, 180, and 210 °C open system chamber with steam, 3 h | 29.0 * | 4.1 * | 0.8 * | 2.0 * |

| 29.0 | 4.5 | 1.0 | 2.1 | ||

| 29.9 | 4.7 | 1.0 | 2.0 | ||

| 36.9 | 7.2 | 0.9 | 2.1 |

| Sample | Conditions | Extractives (%) | Lignin (%) | Hemicelluloses/Cellulose (%) | Ref. |

|---|---|---|---|---|---|

| African padauk | 160, 180, 210 °C | 11.62 * | 33.77 * | 25.72/40.50 * | Corleto et al. [14] |

| ThermoWood | 10.63 | 34.88 | 24.50/41.04 | ||

| Process, | 10.49 | 35.55 | 21.73/40.49 | ||

| 3 h | 9.47 | 39.69 | 9.77/44.38 | ||

| Merbau (Intsia spp.) | 160, 180, 210 °C | 12.30 * | 34.10 * | 17.10/41.40 * | Ditommaso et al. [15] |

| ThermoWood | 9.86 | 33.21 | 15.80/42.80 | ||

| Process, | 7.75 | 35.54 | 9.90/47.20 | ||

| 3 h | 11.89 | 44.67 | 1.70/50.00 | ||

| Black poplar (Populus nigra L.) | Superheated steam 160, 190, 220 °C, 2 h | 1.80 * | 24.12 * | 29.96/52.15 * | Kozakiewicz et al. [16] |

| 2.40 | 23.45 | 28.52/53.20 | |||

| 3.90 | 22.41 | 22.41/54.42 | |||

| 6.40 | 30.76 | 3.58/60.12 |

| Main Topics Discussed | Ref. |

|---|---|

| Effect of delignification on thermal degradation reactivities of hemicellulose and cellulose in wood cell walls | Wang et al. [17] |

| Properties of thermally modified teakwood | Lengowski et al. [18] |

| Chemical and mechanical characterization of thermally modified Gmelina arborea wood | Minkah et al. [19] |

| The effect of heat flux to the fire-technical and chemical properties of spruce wood (Picea abies L.) | Zachar et al. [20] |

| Effect of oxidizing thermal modification on the chemical properties and thermal conductivity of Norway spruce (Picea abies L.) wood | Čabalová et al. [21] |

| Degradation of chemical components of thermally modified Robinia pseudoacacia L. wood and its effect on the change in mechanical properties | Sikora et al. [22] |

| Changes in the chemical structure of thermally modified spruce wood due to decaying fungi | Vidholdová et al. [23] |

| Colour and chemical changes of black locust wood during heat treatment | Kačík et al. [24] |

| Kinetic studies on photo-degradation of thermally-treated spruce wood during natural weathering: Surface performance, lignin and cellulose crystallinity | Mastouri et al. [25] |

| Impact of thermal modification on color and chemical changes of African padauk, merbau, mahogany, and iroko wood species | Gaff et al. [26] |

| Analysis of chemical properties of thermally treated Pinus roxburghii sargent wood. | Gupta et al. [27] |

| Chemical composition and color of short-rotation teak wood thermally modified in closed and open systems | Gomes et al. [28] |

| Conditions | Mw (g/mol) | Mn (g/mol) | PDI | CrI (%) |

|---|---|---|---|---|

| Untreated sample (Fagus Silvatica L.) | 3319 | 2413 | 1.38 | 47.7 |

| Vacuum, 210 °C | 3769 | 2262 | 1.67 | ~48 |

| Nitrogen, 210 °C | 3206 | 1961 | 1.64 | ~48 |

| Steam, 210 °C | 3347 | 1923 | 1.74 | 50.1 |

| Air, 210 °C | 3968 | 2095 | 1.89 | 51.8 |

| Wood Sample | Conditions | Results | Ref. |

|---|---|---|---|

| Iroko (Milicia excelsa) | ThermoWood process 220 °C, 3 h | swelled more quickly insufficient dimensional stability | [36] |

| Ayous (Triplochiton scleroxylon) | ThermoWood process 190 °C, 3 h | swelled more slowly (~ 44%) good dimensional stability | [36] |

| Chinese parasol tree (Firmiana simplex) | tin alloy thermal modification bath 150 and 210 °C 2 and 8 h | significantly improves the dimensional stability of wood (reduction in swelling, water absorption, and density) | [40] |

| Black poplar (Populus nigra L.) | chamber nitrogen atmosphere 160, 190, and 220° 2 h and 6 h | weight loss, lower density lower equilibrium moisture content lower swelling anisotropy | [41] |

| Ash wood (Fraxinus exlecsior L.) | a metal autoclave a steam environment under atmospheric pressure 185 °C, 3 h | improvement of absorbency and swelling values eduction in hydrophilicity by 28.9% more dimensionally stable (21.1%), reduced water affinity | [42] |

| Hornbeam wood | pyrolysis of wood heating 200 °C, 1 to 6 h | reduction of water absorption the environment for development of fungi decreases | [43] |

| Main Topics Discussed | Ref. |

|---|---|

| Study on the morphological characteristics of thermally modified bamboo milling dust | Cui et al. [61] |

| Influence of degradation products from thermal wood modification on wood-water interactions | De Ligne et al. [62] |

| Characterization of the odorous constituents and chemical structure of thermally modified rubberwood | Li et al. [63] |

| Exploratory thermal modification of some West Coast Canadian wood species | Liu et al. [64] |

| Surface quality of planed tangential and radial sections of thermally modified Silver fir wood | Ajdinaj et al. [65] |

| Surface roughness of thermally modified and unmodified selected wood species after sanding | Adamčík et al. [66] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jančíková, V.; Jablonský, M. Thermal Modification of Wood—A Review. Sustain. Chem. 2025, 6, 19. https://doi.org/10.3390/suschem6030019

Jančíková V, Jablonský M. Thermal Modification of Wood—A Review. Sustainable Chemistry. 2025; 6(3):19. https://doi.org/10.3390/suschem6030019

Chicago/Turabian StyleJančíková, Veronika, and Michal Jablonský. 2025. "Thermal Modification of Wood—A Review" Sustainable Chemistry 6, no. 3: 19. https://doi.org/10.3390/suschem6030019

APA StyleJančíková, V., & Jablonský, M. (2025). Thermal Modification of Wood—A Review. Sustainable Chemistry, 6(3), 19. https://doi.org/10.3390/suschem6030019