Restriction of RAP% in HMA Based on Aggregate Gradation and Binder Properties

Abstract

:1. Introduction

2. Selection of Virgin Materials for Investigation

3. RAP Material

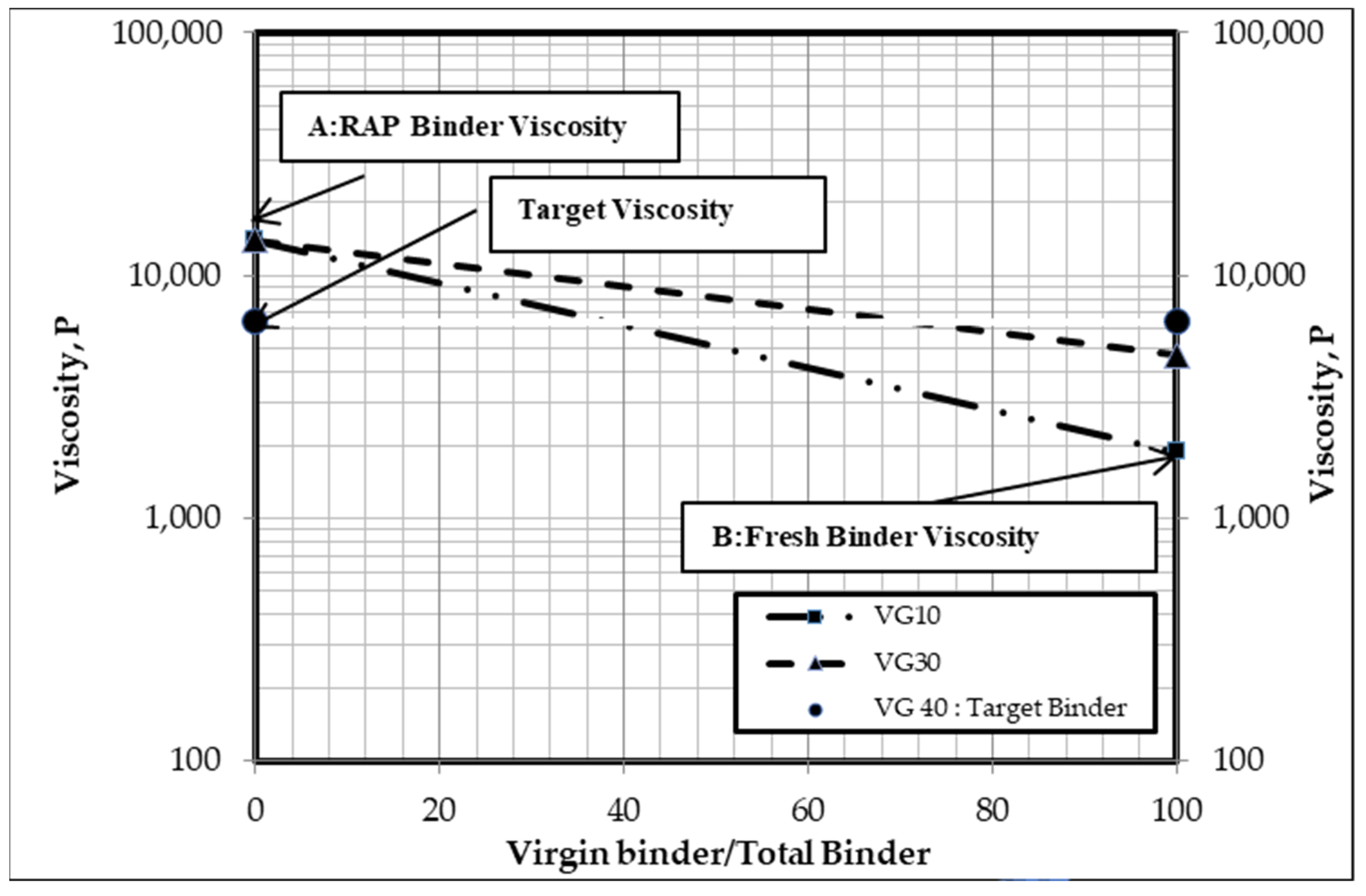

4. Preliminary Evaluation of Binders

- VG10, VG30 and VG40 virgin binders

- RAP binders extracted from six different RAP sources

- Blends of binders extracted from different RAP mixes prepared using Kharagpur RAP in different proportions (10 to 50%) and VG10 and VG30 virgin binders

5. Rheological Properties of Binder

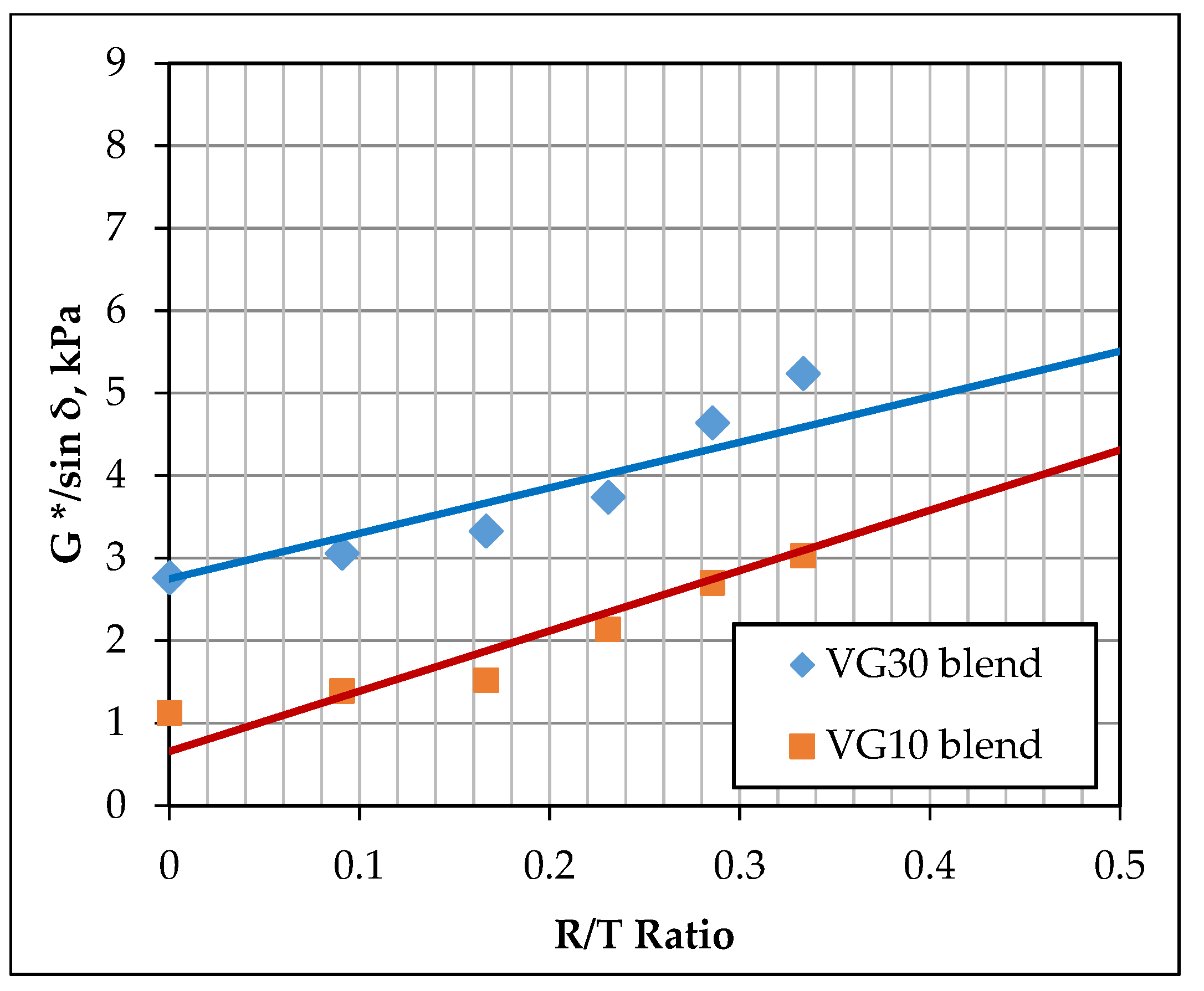

5.1. Binder Rutting Parameter G */sin δ

5.2. Multiple Stress Creep and Recovery Test

5.3. Binder Fatigue Parameter G * sin δ

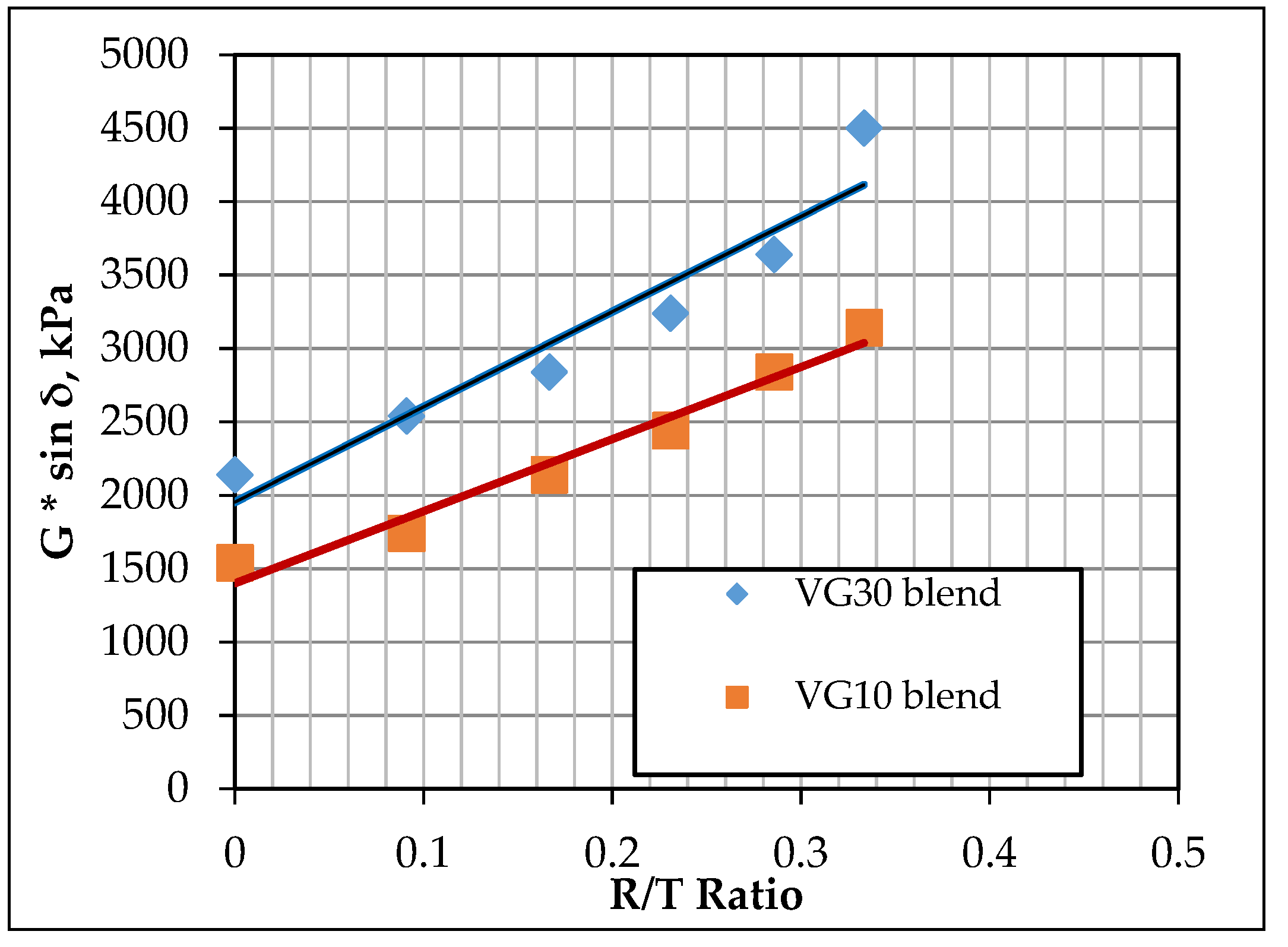

5.4. Linear Amplitude Sweep Test

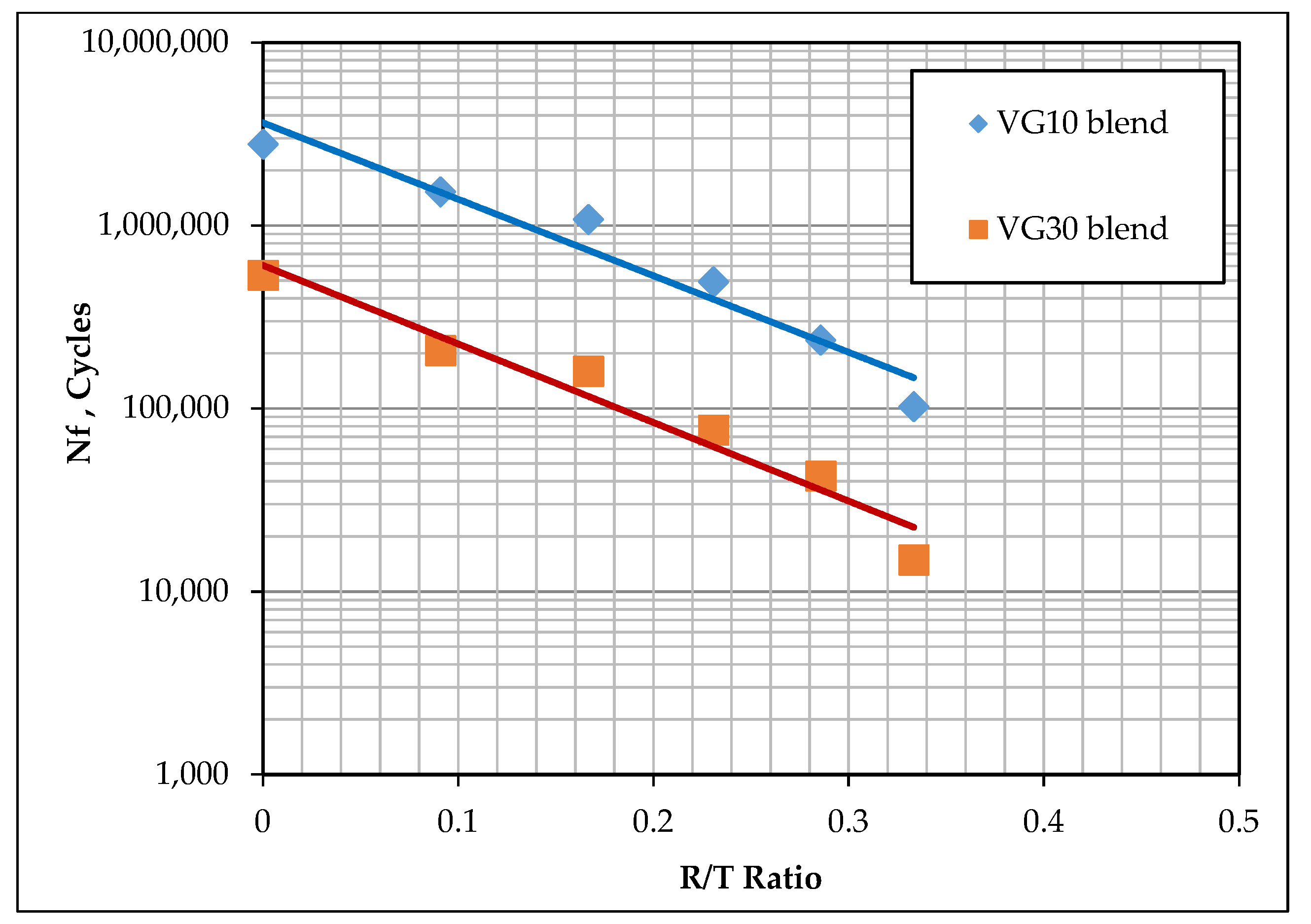

5.5. Viscosity Blending Charts

6. RAP Contents from the Consideration of Equivalence with VG40 Target Binder

7. Restriction of RAP from Aggregate Gradation Consideration

8. Conclusions

- An increase in the RAP binder content in the blend of RAP and virgin binders resulted in the stiffening of the blends in terms of reduced penetration, increase in softening point and increase in complex modulus (G *).

- G */sin δ parameter increased and the non-recoverable creep compliance (Jnr) reduced with an increase in R/T ratio, indicating the beneficial effect of the addition of RAP in improving the rutting performance of the binder.

- The fatigue parameter G * sin δ increased with an increase in the R/T ratio. Similarly, the binder fatigue life, estimated from the LAS test, decreased with an increase in the R/T ratio.

- The results indicate that higher RAP contents enhanced rutting resistance and reduced fatigue resistance as expected. However, it is feasible to mix RAP with softer virgin binder to obtain gap graded mixes.

- The maximum permissible proportion RAP in the mix, estimated from aggregate gradation consideration, varied significantly with RAP and target gradation source. In most of the cases, it was found that allowable RAP percentages are lower for the gap gradations compared to those of dense gradations.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Copeland, A. Reclaimed Asphalt Pavement in Asphalt Mixtures: State of the Practice; Report Number FHWA-HRT-11- 021; Turner-Fairbank Highway Research Center: McLean, VA, USA, 2011. [Google Scholar]

- Lee, J.; Denneman, E.; Choi, Y. Maximising the Re-Use of Reclaimed Asphalt Pavement Outcomes of Year Two: RAP Mix Design, AP-T286-15; Austroads: Sydney, Australia, 2015. [Google Scholar]

- White, G.; Jamshidi, A. Extending the use of RAP in airport asphalt resurfacing. In Proceedings of the RILEM International Symposium on Bituminous Materials, Lyon, France, 14–16 December 2020. [Google Scholar]

- Indian Roads Congress (IRC). IRC: 120: Recommended Practice for Recycling of Bituminous Pavements; IRC: New Delhi, India, 2015.

- The Asphalt Institute. MS-2: Asphalt Mix Design Methods, 7th ed.; Manual Series No. 2; The Asphalt Institute: Lexington, KY, USA, 2015. [Google Scholar]

- Ministry of Road Transport and Highways (MoRTH). Specifications for Road and Bridge Works; 5th Revision; Indian Roads Congress: New Delhi, India, 2013.

- European Committee for Standardization. EN 13108-1: Bituminous Mixtures: Material Specifications: Part 1: Asphalt Concrete; European Committee for Standardization: Bruxelles, Belgium, 2006. [Google Scholar]

- European Committee for Standardization. EN 13108-8: Bituminous Mixtures: Material Specifications: Part 8: Reclaimed Asphalt; European Committee for Standardization: Bruxelles, Belgium, 2005. [Google Scholar]

- McDaniel, R.S.; Soleymani, H.; Anderson, R.M.; Turner, P.; Peterson, R. Recommended Use of Reclaimed Asphalt Pavement in the Superpave Mix Design Method. NCHRP Web Document, 30. 2000. Available online: http://onlinepubs.trb.org/onlinepubs/nchrp/nchrp_w30-a.pdf (accessed on 4 August 2021).

- Indian Roads Congress (IRC). IRC: 37: Tentative Guidelines for Design of Flexible Pavements; IRC: New Delhi, India, 2018.

- American Society for Testing and Materials (ASTM). ASTM D3381–18: Standard Specification for Viscosity-Graded Asphalt Binder for Use in Pavement Construction; ASTM: West Conshohocken, PA, USA, 2018. [Google Scholar]

- Indian Roads Congress (IRC). IRC: 111: Specifications for Dense Graded Mixes; IRC: New Delhi, India, 2018.

- Texas Department of Transportation (TxDOT). Standard Specifications for Construction and Maintenance of Highways, Streets and Bridges; TxDOT: Austin, TX, USA, 2004.

- Bharath, G. Performance Characteristics of Bituminous Mixtures Containing Recycled Asphalt Pavement Material. Ph.D. Thesis, Civil Engineering Department, Indian Institute of Technology, Kharagpur, India, 2016. [Google Scholar]

- American Society for Testing and Materials (ASTM). ASTM D36-14: Standard Test Method for Softening Point of Bitumen (Ring-and-Ball Apparatus); ASTM: West Conshohocken, PA, USA, 2014. [Google Scholar]

- American Society for Testing and Materials (ASTM). ASTM D5/D5M–20: Standard Test Method for Penetration of Bituminous Materials; ASTM: West Conshohocken, PA, USA.

- Bureau of Indian Standards (IS). IS: 73: Paving Bitumen-Specification; 4th Revision; IS: New Delhi, India, 2013.

- Asphalt Institute. SP-1: Superpave Performance Graded Asphalt Binder Specification and Testing, Asphalt Institute, 3rd ed.; Superpave Series No. 1; Asphalt Institute: Lexington, KY, USA, 2003. [Google Scholar]

- American Society for Testing and Materials (ASTM). ASTM D7175-15: Standard Test Method for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer; ASTM: West Conshohocken, PA, USA, 2015. [Google Scholar]

- American Society for Testing and Materials (ASTM). ASTM D7405-10: Standard Test Method for Multiple Stress Creep and Recovery Test (MSCR) of Asphalt Binder using a Dynamic Shear Rheometer; ASTM: West Conshohocken, PA, USA, 2010. [Google Scholar]

- Roberts, F.L.; Kandhal, P.S.; Lee, D.Y.; Kennedy, T.W. Hot Mix Asphalt Materials, Mixture Design and Construction, 2nd ed.; Lanham, M.D., Ed.; NAPA Research and Education Foundation: Forbes Boulevard, Lanham, USA, 1996. [Google Scholar]

- American Association of State Highway and Transportation Officials (AASHTO). AASHTO TP 101-14: Estimating Damage Tolerance of Asphalt Binders Using the Linear Amplitude Sweep; AASHTO: Washington, DC, USA, 2014.

- The Asphalt Institute. MS-20: Asphalt Hot Mix Recycling, 2nd ed.; Manual Series No -20; The Asphalt Institute: Lexington, KY, USA, 1986. [Google Scholar]

| Property | Limiting Value In | |||||||

|---|---|---|---|---|---|---|---|---|

| Belgium | France | Germany | Ireland | Poland | Portugal | Slovenia | UK | |

| Penetration (1/10 mm) | >10 | >5 | >15 | >15 | 15 | >15 | - | >15 |

| Softening point (°C) | - | <77 | <70 | - | <70 | <70 | <70 | - |

| Sieve Size (mm) | Cumulative % Passing by Weight of Total Aggregate | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| BC | DBM | SMA | Texas Gap | Texas-b | ||||||

| Upper | Lower | Upper | Lower | Upper | Lower | Upper | Lower | Upper | Lower | |

| 37.5 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| 26.5 | 100 | 100 | 100 | 90 | 100 | 100 | 100 | 100 | 100 | 98 |

| 19 | 100 | 90 | 95 | 71 | 100 | 90 | 100 | 98 | 98 | 84 |

| 13.2 | 79 | 59 | 80 | 56 | 70 | 45 | 85 | 72 | ||

| 9.5 | 72 | 52 | 60 | 25 | 70 | 50 | 80 | 60 | ||

| 4.75 | 55 | 35 | 54 | 38 | 28 | 20 | 45 | 30 | 60 | 40 |

| 2.36 | 44 | 28 | 42 | 28 | 24 | 16 | 27 | 17 | 43 | 29 |

| 1.18 | 34 | 20 | 21 | 13 | 27 | 5 | ||||

| 0.6 | 27 | 15 | 18 | 12 | 27 | 5 | 28 | 13 | ||

| 0.3 | 20 | 10 | 21 | 7 | 20 | 10 | 27 | 5 | 20 | 6 |

| 0.15 | 13 | 5 | ||||||||

| 0.075 | 8 | 2 | 8 | 2 | 12 | 8 | 9 | 5 | 7 | 2 |

| Property Evaluated | VG10 | VG30 | VG40 | |||

|---|---|---|---|---|---|---|

| Result | Spec * | Result | Spec * | Result | Spec * | |

| Penetration at 25 °C, 100 g, 5 s, 0.1 mm ASTM D36 [15] | 90 | Min 80 | 68 | Min 45 | 39 | Min 35 |

| Softening Point, °C ASTM D5 [16] | 41 | Min 40 | 48 | Min 47 | 54 | Min 50 |

| Viscosity at 60 °C, Poise ASTM D3381 [10] | 1879 | - | 4689 | - | 6471 | - |

| Parameter | Kharagpur | Ongole | Varanasi | Kolkata | Allahabad | El Paso |

|---|---|---|---|---|---|---|

| Penetration at 25 °C, 100 g, 5 s, 0.1 mm ASTM D5 [16] | 18 | 14 | 14 | 17 | 19 | - |

| Softening Point (R&B), °C, ASTM D36 [15] | 68 | 74 | 75 | 71 | 68 | - |

| Dynamic Viscosity **, P IS: 73 [17] | 13,913 | 34,075 | 36,786 | 17,297 | 12,514 | 16,629 |

| Binder | Recycled Binder/Total Binder | Penetration (d in mm) | Softening Point (°C) |

|---|---|---|---|

| VG10 | 0 | 90 | 41 |

| VG10-10% RAP | 0.09 | 81 | 43 |

| VG10-20% RAP | 0.16 | 68 | 44 |

| VG10-30% RAP | 0.23 | 64 | 48 |

| VG10-40% RAP | 0.28 | 61 | 56 |

| VG10-50% RAP | 0.33 | 39 | 61 |

| VG30 | 0 | 68 | 48 |

| VG30-10% RAP | 0.09 | 64 | 51 |

| VG30-20% RAP | 0.16 | 54 | 54 |

| VG30-30% RAP | 0.23 | 47 | 57 |

| VG30-40% RAP | 0.28 | 39 | 59 |

| VG30-50% RAP | 0.33 | 29 | 64 |

| Temperature (°C) | G */sin δ (kPa) | |||||

|---|---|---|---|---|---|---|

| Kharagpur | Allahabad | Kolkata | Ongole | Varanasi | El Paso | |

| 64 | 8.4 | 7.58 | 8.12 | 18.8 | 19.4 | 14.78 |

| 70 | 3.84 | 3.37 | 3.75 | 7.65 | 7.85 | 7.92 |

| 76 | 1.8 | 1.64 | 1.98 | 3.4 | 3.43 | 4.26 |

| 82 | 0.92 | 0.86 | 0.9 | 1.56 | 1.61 | 2.36 |

| 88 | 0.56 | 0.49 | 0.29 | 0.79 | 0.7 | 1.3 |

| Temperature (°C) | G */sin δ (kPa) for | |||||

|---|---|---|---|---|---|---|

| VG10 | VG30 | VG40 | ||||

| Un-Aged | RTFO-Aged | Un-Aged | RTFO-Aged | Un-Aged | RTFO-Aged | |

| 46 | 15.49 | 27.40 | 28.6 | 61.8 | 41.2 | 76.66 |

| 52 | 5.71 | 11.61 | 16.19 | 33.29 | 18.01 | 36.07 |

| 58 | 2.22 | 4.55 | 6.79 | 13.06 | 8.78 | 18.01 |

| 64 | 1.06 | 1.74 | 2.91 | 5.27 | 3.733 | 10.18 |

| 70 | 0.53 | 0.85 | 1.33 | 2.29 | 2.43 | 7.69 |

| 76 | 0.27 | 0.42 | 0.65 | 1.09 | 1.33 | 3.82 |

| 82 | 0.16 | 0.22 | 0.34 | 0.55 | 0.76 | 1.15 |

| Binder | R/T Ratio | Jnr (1/kPa) for a Stress Level of | Jnr-diff = (Jnr3200 − Jnr100)/Jnr100 | |

|---|---|---|---|---|

| 100 Pa | 3200 Pa | |||

| VG30 | 0 | 0.297 | 0.3278 | 0.1037 |

| VG30-10% RAP | 0.09 | 0.2476 | 0.2702 | 0.0913 |

| VG30-20% RAP | 0.16 | 0.2211 | 0.2396 | 0.0837 |

| VG30-30% RAP | 0.23 | 0.182 | 0.204 | 0.1209 |

| VG30-40% RAP | 0.28 | 0.16348 | 0.1755 | 0.0735 |

| VG30-50% RAP | 0.33 | 0.1313 | 0.1408 | 0.0724 |

| Binder | R/T Ratio | A | B | Nf (5% Strain) |

|---|---|---|---|---|

| VG10 | 0 | 12,357,742,464 | 5.226 | 2,783,401 |

| VG10-10% RAP | 0.09 | 9,516,625,573 | 5.434 | 1,527,070 |

| VG10-20% RAP | 0.16 | 8,137,621,953 | 5.547 | 1,080,163 |

| VG10-30% RAP | 0.23 | 7,028,025,050 | 5.972 | 493,110 |

| VG10-40% RAP | 0.28 | 3,683,838,642 | 6.138 | 236,365 |

| VG30 | 0 | 5,492,434,229 | 5.744 | 535,644 |

| VG30-10% RAP | 0.09 | 3,920,684,620 | 6.000 | 207,509 |

| VG30-20% RAP | 0.16 | 2,937,455,725 | 6.094 | 160,026 |

| VG30-30% RAP | 0.23 | 1,422,172,502 | 6.102 | 76,295 |

| VG30-40% RAP | 0.28 | 817,174,204.6 | 6.337 | 42,883 |

| VG30-50% RAP | 0.33 | 459,226,299 | 6.361 | 14,932 |

| VG40 | 0 | 3,683,838,642 | 6.419 | 120,092 |

| Mix | Virgin Binder | Recycled Binder % (Recycled Binder/Total Binder) for RAP Obtained from | |||||

|---|---|---|---|---|---|---|---|

| Kharagpur | Allahabad | Kolkata | Ongole | Varanasi | El Paso | ||

| DBM | VG10 | 62 | 59 | 58 | 42 | 40 | 62 |

| VG30 | 30 | 31 | 26 | 17 | 15 | 29 | |

| BC | VG10 | 72 | 68 | 67 | 49 | 47 | 72 |

| VG30 | 35 | 36 | 30 | 19 | 18 | 34 | |

| SMA | VG10 | 85 | 80 | 79 | 57 | 55 | 85 |

| VG30 | 41 | 44 | 35 | 23 | 21 | 41 | |

| Texas-gap | VG10 | 89 | 84 | 82 | 60 | 58 | 89 |

| VG30 | 43 | 45 | 37 | 24 | 22 | 41 | |

| Texas-b | VG10 | 63 | 60 | 60 | 43 | 41 | 64 |

| VG30 | 31 | 32 | 27 | 17 | 16 | 30 | |

| Parameter | Base Binder Type | R/T for Property Equivalent to That of VG40 | Recycled Binder to Total Binder % | |||

|---|---|---|---|---|---|---|

| BC | DBM | SMA | Texas Gap | |||

| Penetration | VG10 | 0.6 | 77 | 67 | 91 | 94 |

| Softening Point | 0.4 | 51 | 45 | 59 | 62 | |

| G */sin δ | 0.42 | 54 | 47 | 62 | 65 | |

| G * sin δ | 0.4 | 51 | 45 | 59 | 62 | |

| Binder fatigue (LAS) | 0.35 | 45 | 39 | 51 | 53 | |

| Penetration | VG30 | 0.41 | 52 | 46 | 61 | 63 |

| Softening Point | 0.19 | 24 | 21 | 26 | 27 | |

| G */sin δ | 0.18 | 23 | 20 | 24 | 26 | |

| G * sin δ | 0.18 | 23 | 20 | 24 | 26 | |

| Binder fatigue (LAS) | 0.16 | 20 | 18 | 21 | 22 | |

| Mix | Type of Gradation | Permissible RAP% for RAP Source | |||||

|---|---|---|---|---|---|---|---|

| Kharagpur | Allahabad | Kolkata | Ongole | Varanasi | El Paso | ||

| DBM | Dense | 46 | 34 | 40 | 36 | 45 | 48 |

| BC | Dense | 43 | 31 | 36 | 33 | 42 | 44 |

| Texas-b | Dense | 45 | 32 | 46 | 51 | 47 | 46 |

| SMA | Gap | 35 | 45 | 16 | 15 | 18 | 21 |

| Texas-gap | Gap | 30 | 36 | 15 | 12 | 16 | 14 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gottumukkala, B.; Kusam, S.R.; Tandon, V.; Muppireddy, A.R.; Mullapudi, R.S. Restriction of RAP% in HMA Based on Aggregate Gradation and Binder Properties. CivilEng 2021, 2, 811-822. https://doi.org/10.3390/civileng2030044

Gottumukkala B, Kusam SR, Tandon V, Muppireddy AR, Mullapudi RS. Restriction of RAP% in HMA Based on Aggregate Gradation and Binder Properties. CivilEng. 2021; 2(3):811-822. https://doi.org/10.3390/civileng2030044

Chicago/Turabian StyleGottumukkala, Bharath, Sudhakar Reddy Kusam, Vivek Tandon, Amaranatha Reddy Muppireddy, and Ramya Sri Mullapudi. 2021. "Restriction of RAP% in HMA Based on Aggregate Gradation and Binder Properties" CivilEng 2, no. 3: 811-822. https://doi.org/10.3390/civileng2030044