Utilizing Polypropylene Fiber in Sustainable Structural Concrete Mixtures

Abstract

:1. Introduction

2. Methodology and Experimental Set-Up

2.1. Compressive Strength Test

2.2. Direct Compressive Strength Test

2.3. Calculated Compressive Strength Test Using the UPV Values

2.4. The Coefficient of Variation (COV) for PFRC Specimens

3. Discussion of the Results

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Slate, F.O.; Hover, K.C. Microcracking in concrete. In Fracture Mechanics of Concrete: Material Characterization and Testing; Springer: Dordrecht, The Netherlands, 1984; pp. 137–159. [Google Scholar]

- Grzybowski, M.; Shah, S.P. Shrinkage cracking of fiber reinforced concrete. Mater. J. 1990, 87, 138–148. [Google Scholar]

- Ozyurt, N.; Mason, T.O.; Shah, S.P. Non-destructive monitoring of fiber orientation using AC-IS: An industrial-scale application. Cem. Concr. Res. 2006, 36, 1653–1660. [Google Scholar] [CrossRef]

- Raoufi, K.; Weiss, J. The role of fiber reinforcement in mitigating shrinkage cracks in concrete. In Fibrous and Composite Materials for Civil Engineering Applications; Woodhead Publishing: Sawston, UK, 2011; pp. 168–188. [Google Scholar] [CrossRef]

- Pakravan, H.R.; Ozbakkaloglu, T. Synthetic fibers for cementitious composites: A critical and in-depth review of recent advances. Constr. Build. Mater. 2019, 207, 491–518. [Google Scholar] [CrossRef]

- Archana, P.; Nayak, A.; Nayak, S.; Vaddar, H.; Magnur, D. Study of strength of polypropylene fiber reinforced concrete. Int. J. Eng. Res. Technol. (IJERT) 2017, 6, 8–11. [Google Scholar] [CrossRef]

- Dharan, D.; Lal, A. Study the effect of polypropylene fiber in concrete. Int. Res. J. Eng. Technol. (IRJET) 2016, 3, 616–619. Available online: https://www.irjet.net/archives/V3/i6/IRJET-V3I6115.pdf (accessed on 15 January 2019).

- Tiberti, G.; Minelli, F.; Plizzari, G.A.; Vecchio, F.J. Influence of concrete strength on crack development in SFRC members. Cem. Concr. Compos. 2014, 45, 176–185. [Google Scholar] [CrossRef]

- Kayali, O.; Haque, M.N.; Zhu, B. Some characteristics of high strength fiber reinforced lightweight aggregate concrete. Cem. Concr. Compos. 2003, 25, 207–213. [Google Scholar] [CrossRef]

- Pontes, M.F.; Pereira, W.M.; Pituba, J.J.D.C. Numerical analysis on displacements of steel-fiber-reinforced concrete beams. Rev. IBRACON Estrut. Mater. 2020, 13. [Google Scholar] [CrossRef]

- Hsie, M.; Chen, G.; Song, P. Investigating abrasion resistance of steel-polypropylene hybrid fiber-reinforced concrete using statistical experimental design. Int. J. Pavement Res. Technol. 2011, 4, 274. [Google Scholar]

- Lorenzi, A.; Tisbierek, F.T.; Silva, L.C.P. Ultrasonic pulse velocity análysis in concrete specimens. In Proceedings of the IV Conferencia Panamericana de END, Buenos Aires, Argentina, 22–26 October 2007. [Google Scholar]

- Chalioris, C.E.; Panagiotopoulos, T.A. Flexural analysis of steel fibre-reinforced concrete members. Comput. Concr. Int. J. 2018, 22, 11–25. [Google Scholar]

- Zeng, Y.; Zhou, X.; Tang, A.; Sun, P. Mechanical properties of chopped basalt fiber-reinforced lightweight aggregate concrete and chopped polyacrylonitrile fiber reinforced lightweight aggregate concrete. Materials 2020, 13, 1715. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Asteris, P.G.; Naseri, H.; Hajihassani, M.; Kharghani, M.; Chalioris, C.E. On the mechanical characteristics of fiber reinforced polymer concrete. Adv. Concr. Constr. 2021, 12, 271–282. [Google Scholar]

- Designation C192; Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory. American Society for Testing Materials: West Conshohocken, PA, USA, 2016.

- Mohod, M. Performance of Polypropylene Fiber Reinforced Concrete. IOSR J. Mech. Civ. Eng. 2015, 12, 28–36. [Google Scholar] [CrossRef]

- Designation: C597-16; Standard Test Method for Pulse Velocity through Concrete. American Society for Testing Materials: West Conshohocken, PA, USA, 2016.

- Naik, T.; Malhotra, V.; Popovics, J. The Ultrasonic Pulse Velocity Method. In Handbook of Nondestructive Testing of Concrete; CRC Press: Boca Raton, FL, USA, 2004; Chapter 8. [Google Scholar]

- Lin, Y.; Kuo, S.-F.; Hsiao, C.; Lai, C.-P. Investigation of Pulse Velocity- Strength Relationship of hardened Concrete. ACI Mater. J. 2007, 104, 344–350. [Google Scholar] [CrossRef]

- Elvery, R.; Ibrahim, L. Ultrasonic assessment of concrete strength at early ages. Mag. Concr. Res. 1976, 28, 181–190. [Google Scholar] [CrossRef]

- Sandor, P.; Rose, J.; Popovics, J. The behavior of ultrasonic pulse in concrete. Cem. Concr. Res. 1990, 20, 259–270. [Google Scholar] [CrossRef]

- Nash’t, I.; A’bour, S.; Sadoon, A. Finding an unified relationship between crushing strength of concrete and non-destructive tests. In Middle East Nondestructive Testing Conference & Exhibition; Citeseer: Manama, Bahrain, 2005. [Google Scholar]

- Mahure, N.; Vijh, G.; Sharma, P.; Sivakumar, N.; Ratnam, M. Correlation between pulse velocity and compressive strength of concrete. Int. J. Earth Sci. Eng. 2011, 4, 6. Available online: http://ijee.in/publication/ (accessed on 10 May 2022).

- Kheder, G. A two-stage procedure for assessment of in situ concrete strength using combined non-destructive testing. Mater. Struct. 1999, 32, 410–417. [Google Scholar] [CrossRef]

- Suksawang, N.; Wtaife, S.; Alsabbagh, A. Evaluation of Elastic Modulus of Fiber Reinforced concrete. ACI Mater. J. 2018, 115, 239–249. [Google Scholar] [CrossRef] [Green Version]

- Benjamin, J.R.; Cornell, C.A. Probability, Statistics, and Decision for Civil Engineers; McGraw-Hill Publishing Company: New York, NY, USA, 1970. [Google Scholar]

| Properties | Physical | Mechanical | Approximate Cost (USD/kg) | Reference | ||||

|---|---|---|---|---|---|---|---|---|

| Types | Acid/Alkali Resistance | Specific Gravity (kg/m3) | Elongation at Break (%) | Modulus of Elasticity (GPa) | Tensile Strength (MPa) | |||

| Polypropylene (PP) | High | 910 | 15–80 | 1.5–12 | 240–900 | 1–2.5 | [9] | |

| Polyethylene (PE) | High | 920–960 | 4–100 | 5–100 | 80–600 | 2–20 | [10] | |

| Polyvinyl alcohol (PVA) | High | 290–1300 | 6–7 | 20–42.8 | 1000–1600 | 1–15 | [11] | |

| Specific Gravity (SG) | Length (L) (mm) | Filament Diameter (D) (mm) | Tensile Strength (TS) (MPa) | Flexural Strength (FS) (GPa) | Corrosion Resistance | Acid/Alkali Resistance |

|---|---|---|---|---|---|---|

| 0.91 | 19 | 1.52 | 410 | 5.6 | High | Excellent |

| Vf | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0.10% | 0.25% | 0.50% | 0.75% | 1.0% | 1.5% | 1.5% | 1.5% | 1.5% | ||

| Curing in Water | Set A (28 days) | A-1 | A-2 | A-3 | A-4 | A-5 | A-6 | A-6 | A-6 | A-6 |

| Set B (7 days) * | B-1 | B-2 | B-3 | B-4 | B-V | B-6 | B-6 | B-6 | B-6 | |

| Set C (44 days) | C-1 | C-2 | C-3 | C-4 | C-5 | C-6 | C-6 | C-VI | C-6 | |

| w/c ratio | 0.32 | 0.40 | 0.50 | 0.60 | ||||||

| PFRC Mix Designation | Cement (C) (kg/m3) | Fine Agg. (FA) (kg/m3) | Coarse Agg. (CA) (kg/m3) | Water (kg/m3) | ProCon F (kg/m3) |

|---|---|---|---|---|---|

| A/B/C-I.32 | 464.0 | 840.5 | 582.7 | 148.2 | 0.96 |

| A/B/C-II.0.32 | 464.0 | 840.5 | 582.7 | 148.2 | 2.24 |

| A/B/C-III.32 | 464.0 | 840.5 | 582.7 | 148.2 | 4.49 |

| A/B/C-IV.32 | 464.0 | 840.5 | 582.7 | 148.2 | 6.73 |

| A/B/C-V.32 | 464.0 | 840.5 | 582.7 | 148.2 | 8.97 |

| A/B/C-VI.32 | 464.0 | 840.5 | 582.7 | 148.2 | 13.46 |

| A/B/C-VI.40 | 464.0 | 840.5 | 582.7 | 185.2 | 13.46 |

| A/B/C-VI.50 | 464.0 | 840.5 | 582.7 | 231.5 | 13.46 |

| A/B/C-VI.60 | 464.0 | 840.5 | 582.7 | 277.8 | 13.46 |

| Eq# | Reference | Equation | Limitation |

|---|---|---|---|

| (2) | Naik, 2004 [19] | Cylindrical Specimens | |

| (3) | Lin, 2007 [20] | CA = 1100 kg/m3 | |

| (4) | Elvery and Ibrahim, 1976 [21] | Temperature (0 °C to 60 °C) | |

| (5) | Sandor et al., 1990 [22] | Age 7 | |

| (6) | Nash’t et al., 2005 [23] | Cubes | |

| (7) | Mahure, 2011 [24] | Grade M15 | |

| (8) | Mahure, 2011 [24] | Grade M20 | |

| (9) | Kheder, 1999 [25] | N/A |

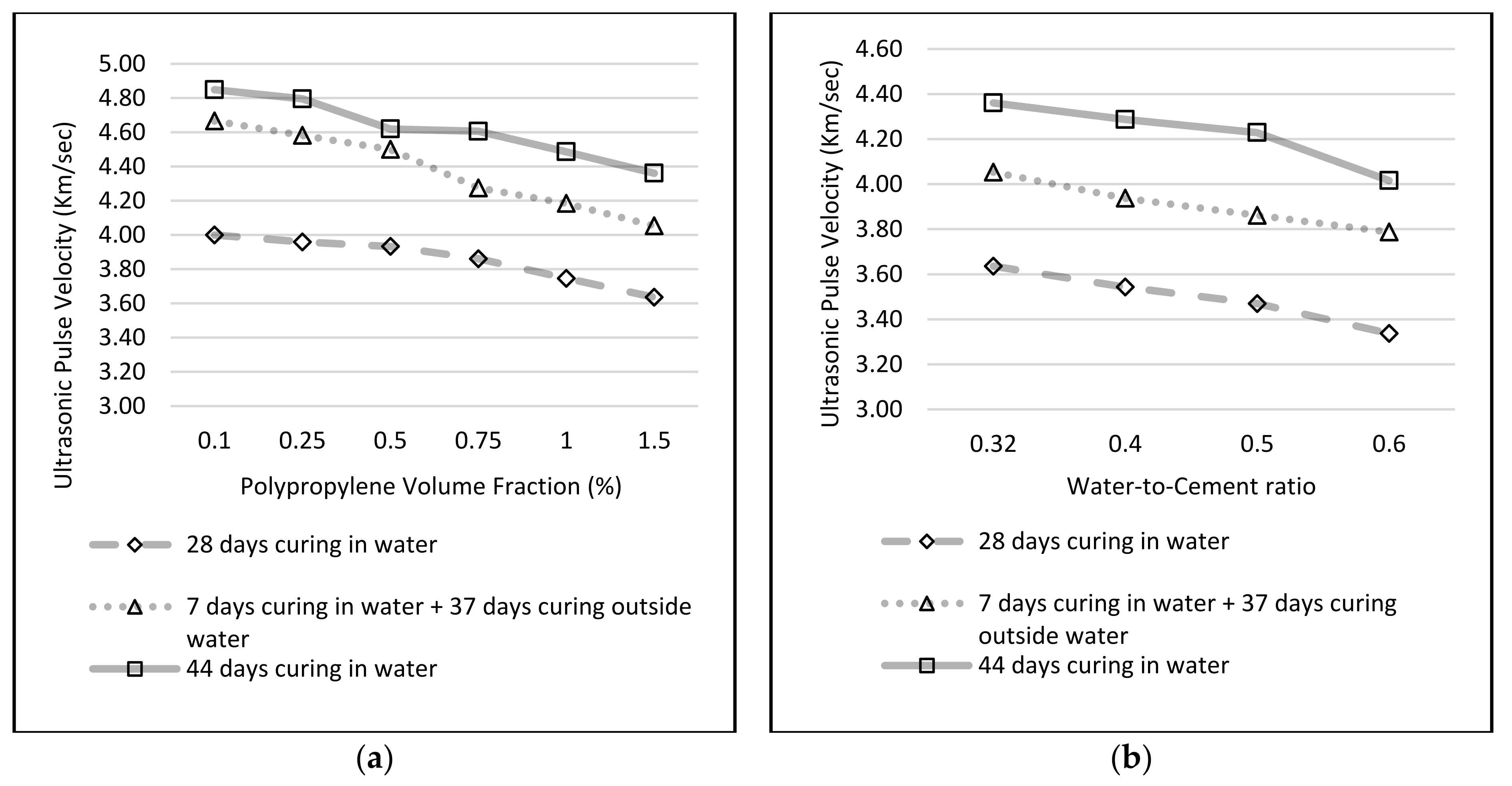

| Ultrasonic Pulse Velocity (km/s) | ||||||||||

| Vf | ||||||||||

| 0.10% | 0.25% | 0.50% | 0.75% | 1.00% | 1.50% | 1.50% | 1.50% | 1.50% | ||

| Cu ring in Water | Set A | 4 | 3.96 | 3.76 | 3.06 | 2.81 | 2.71 | 2.73 | 2.69 | 2.58 |

| (28 days) | ||||||||||

| Set B | 5.27 | 4.69 | 3.94 | 3.78 | 3.58 | 3.31 | 3.34 | 3.27 | 3.1 | |

| (7 days) * | ||||||||||

| Set C | 5.79 | 5.22 | 5.09 | 4.93 | 4.69 | 4.36 | 4.2 | 4.02 | 3.41 | |

| (44 days) | ||||||||||

| w/c | 0.32 | 0.4 | 0.5 | 0.6 | ||||||

| Compressive Strength (MPa) | ||||||||||

| Vf | ||||||||||

| 0.10% | 0.25% | 0.50% | 0.75% | 1.00% | 1.50% | 1.50% | 1.50% | 1.50% | ||

| Curing in Water | Set A | 21.8 | 22.5 | 25.1 | 22.8 | 21.2 | 21 | 20.8 | 19.3 | 19.1 |

| (28 days) | ||||||||||

| Set B | 32.3 | 34.9 | 37.1 | 30.1 | 29.2 | 28.6 | 27.5 | 26.9 | 25.2 | |

| (7 days) * | ||||||||||

| Set C | 37.4 | 39.7 | 44.9 | 35.1 | 31.9 | 30.1 | 29.4 | 28.3 | 27.3 | |

| (44 days) | ||||||||||

| w/c | 0.32 | 0.4 | 0.5 | 0.6 | ||||||

| Compressive Strength Considering Size Effect (MPa) | ||||||||||

| Vf | ||||||||||

| 0.10% | 0.25% | 0.50% | 0.75% | 1.00% | 1.50% | 1.50% | 1.50% | 1.50% | ||

| Curing in Water | Set A | 22.5 | 23.2 | 25.9 | 23.5 | 21.9 | 21.7 | 21.5 | 19.9 | 19.7 |

| (28 days) | ||||||||||

| Set B | 33.3 | 36 | 38.2 | 31 | 30.1 | 29.5 | 28.4 | 27.8 | 26 | |

| (7 days) * | ||||||||||

| Set C | 38.5 | 41 | 46.3 | 36.2 | 32.9 | 31 | 30.3 | 29.2 | 28.2 | |

| (44 days) | ||||||||||

| w/c | 0.32 | 0.4 | 0.5 | 0.6 | ||||||

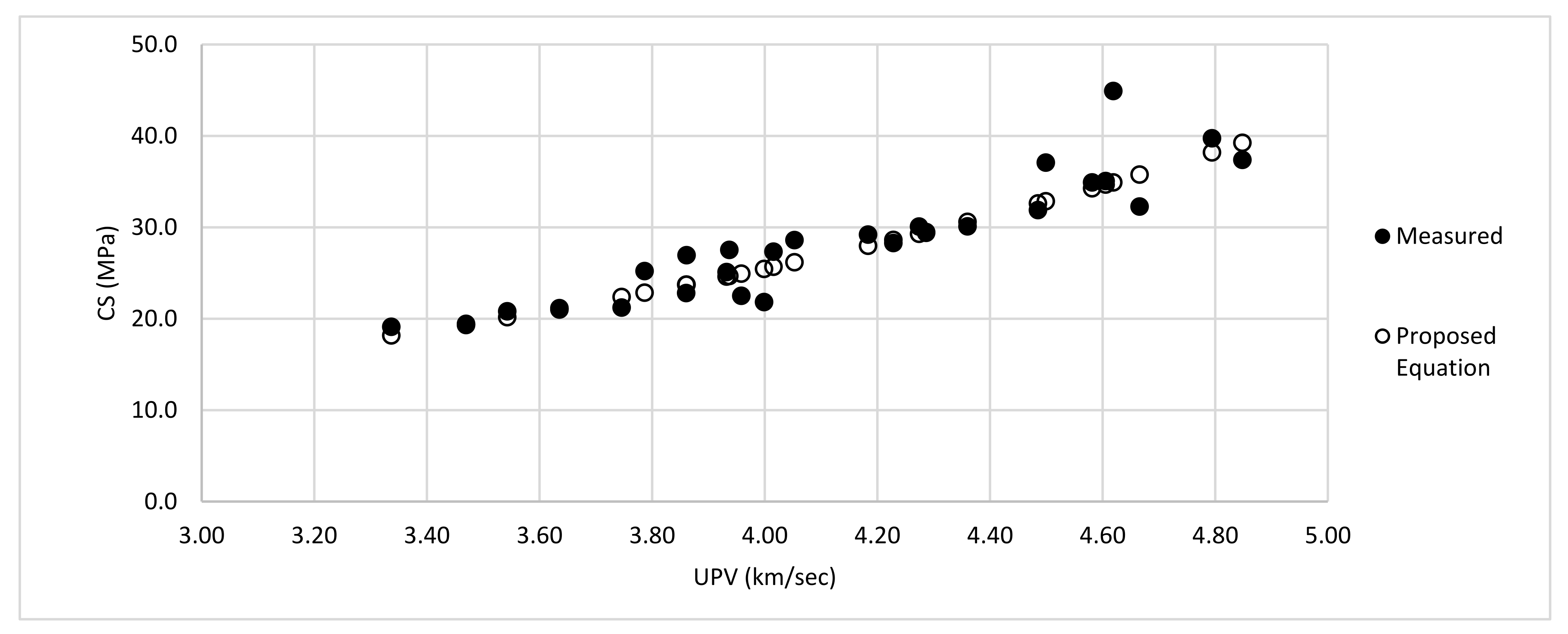

| Equation | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | Proposed Equation (13) |

|---|---|---|---|---|---|---|---|---|---|

| COV | 29.1% | 75.1% | 55.0% | 52.8% | 19.4% | 31.4% | 19.8% | 31.1% | 9.6% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hedjazi, S.; Castillo, D. Utilizing Polypropylene Fiber in Sustainable Structural Concrete Mixtures. CivilEng 2022, 3, 562-572. https://doi.org/10.3390/civileng3030033

Hedjazi S, Castillo D. Utilizing Polypropylene Fiber in Sustainable Structural Concrete Mixtures. CivilEng. 2022; 3(3):562-572. https://doi.org/10.3390/civileng3030033

Chicago/Turabian StyleHedjazi, Saman, and Daniel Castillo. 2022. "Utilizing Polypropylene Fiber in Sustainable Structural Concrete Mixtures" CivilEng 3, no. 3: 562-572. https://doi.org/10.3390/civileng3030033

APA StyleHedjazi, S., & Castillo, D. (2022). Utilizing Polypropylene Fiber in Sustainable Structural Concrete Mixtures. CivilEng, 3(3), 562-572. https://doi.org/10.3390/civileng3030033