4.1. Part I: Comparing CHIP to TXM

As it was mentioned earlier in

Section 1, several studies have used X-ray imaging techniques to simplify the ASTM C 1556 test. It has been shown in

Appendix A that XRF gives comparable results to the classic ponding test (ASTM C 1556), and TXM closely matches XRF. Therefore, one may conclude that TXM and the ponding test are comparable. Therefore, the goal of this section is to compare the results of CHIP with TXM. If CHIP and TXM are comparable, then it can be concluded that CHIP and the classic ponding test give comparable results.

Figure 8 shows the concentration profiles of three paste samples with different w/cm ratios after 14 d of ponding for both CHIP and TXM. The TXM results are shown with a solid line, and the CHIP results are shown with a dashed line.

Figure 8 shows the results are very comparable between TXM and CHIP for different w/cm ratios. The average difference in the D

ac is 2.74%, and the maximum difference is 8.6%.

The concentration profiles shown in

Figure 8 show an initial rise in chloride concentration to a maximum point (C

max) within the first layers below the surface (Δx), followed by a gradual decrease in chloride concentration at the lower depths. This phenomenon, which is often referred to in the literature as the “maximum phenomenon”, can be attributed to several reasons [

27,

41,

42,

43,

44,

45,

46]: first, chlorides can be leaching from the cement paste; second, chlorides can move into the outer layer of concrete by convection and not necessarily by diffusion; third, there is variability in microstructure in surface compared to the deeper depths; forth, maximum concentration (C

max) has time-variant characteristics that increase non-linearly with the exposure duration, while the exposure duration has minimal impacts on Δx. In addition, the concentration of the exposure environment is found to be a significant factor influencing both C

max and Δx [

41].

The 12 concrete samples were tested with both CHIP and TXM, and

Figure 9 shows the concentration profiles of the two samples in both methods. The other results can be found in

Appendix E. The higher amount of variability in the concrete samples may be caused by minor differences in the sample loading in the two X-ray machines that could magnify any anomalies in the sample caused by aggregates. Additionally, the diffusion coefficient calculation assumes that the concentration profile has a certain shape. If the results do not meet this shape, then small changes can cause the curve fit to be unstable and produce different results. This is being addressed further for future publications.

To compare the diffusion coefficients obtained by both CHIP and TXM techniques, the results from twenty-four paste samples and twelve concrete samples are presented in

Figure 10. The average percent difference of the measured D

ac between the two measurement methods is 1.02%, with a maximum difference of 16.9%. The 95% prediction intervals are shown with a blue dashed line in

Figure 10. A 95% prediction interval is an estimate of the range where a future observation will fall with a 95% probability. For these data, all of the observations are within the 95% prediction interval. Linear regression was plotted with these data observations in

Figure 10. The slope of the linear regression line is 0.986, which is close to the ideal slope of 1.00, and the R

2 value is 0.99. This shows that linear regression is appropriate for the data. This means that the results of CHIP and TXM are comparable.

4.2. Repeatability of the CHIP Procedure for Concrete

Since concrete is a non-homogenous material and the sample size is limited, it is important to understand the variability of the measurements obtained by CHIP. Two approaches were considered to evaluate the variation of CHIP. The same concrete core was repeatedly scanned to evaluate the reproducibility of CHIP, and then the cores were investigated from different angles.

To evaluate the precision of the CHIP, a concrete sample was loaded, scanned, and removed from the machine. This was repeated three times for each sample. The results are shown in

Figure 11, and the results of all 12 concrete samples are summarized in

Table 5. The results of every single measurement are reported in

Appendix F. Results in

Figure 11 and

Table 5 show the strong repeatability of the experiment by a single user with a standard deviation of 3.07 × 10

−13 m

2/s and a coefficient of variation (COV) of 1.78%. This shows that CHIP can be used to produce highly reproducible measurements of ion penetration for repeat measurements on the same sample at the same orientation.

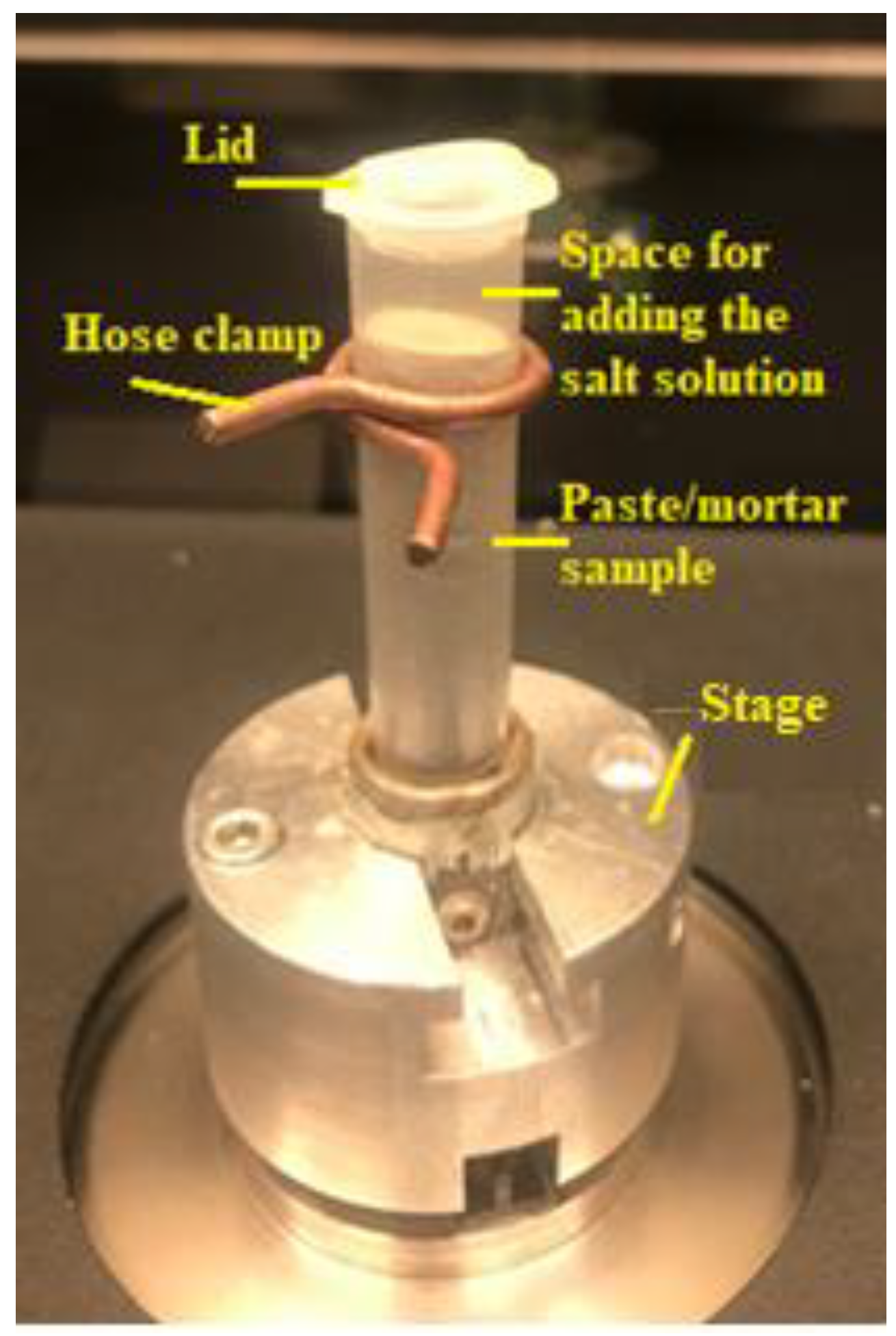

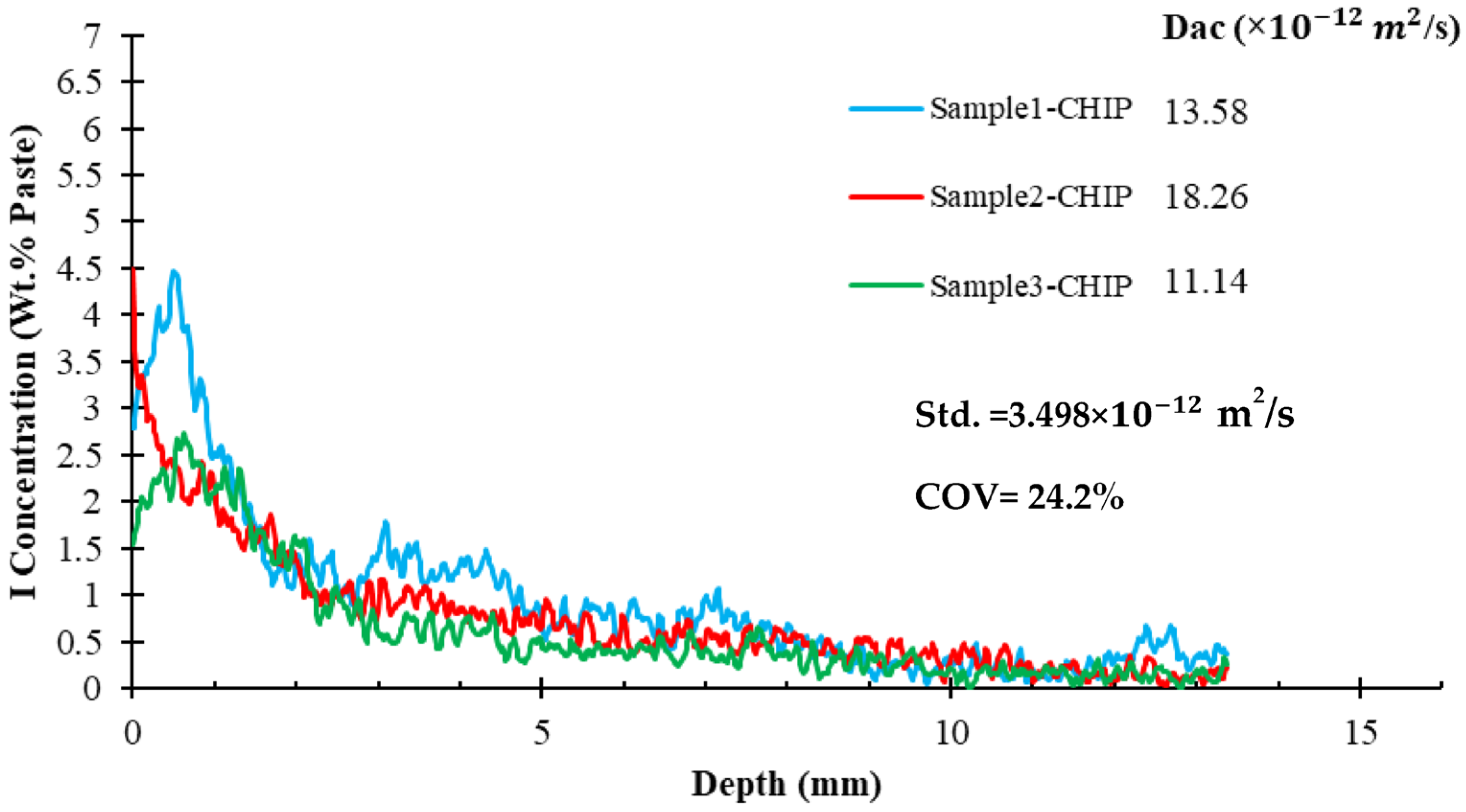

Next, three cores were taken from the same concrete sample, and all three cores were scanned from a single direction. This approach examines the variation of repeat measurements from the same larger sample. The results of this evaluation are shown in

Figure 12. The standard deviation and coefficient of variation (COV) were equal to 3.498 × 10

−12 m

2/s and 24.2%, respectively. The higher variability of the concrete samples compared to the paste samples is likely due to the more inhomogeneous nature of the concrete samples. The COV of 24.2% in CHIP is higher than the COV of 14.2% for the single-laboratory repeatability of ASTM C 1556.

This higher level of variability for CHIP could be caused because the analysis uses a region of 0.88 mm to minimize any cupping artifacts. Since concrete is a composite material, considering only a narrow strip in the center of each radiograph during data analysis may be impacted by variations in the aggregate found in the concrete samples. This means that different samples will have a different distribution of paste and aggregates in the central region of each radiograph at each angle. This will have an impact on the results. For this reason, the authors suggest taking radiographs at different angles of a concrete sample, then calculating the Dac attributed to each angle and reporting the average Dac for each concrete sample. Another solution can be using cubic-cut samples instead of cored samples to eliminate cupping artifacts and then consider a larger area for data analysis.

The discussion above brings up a concern about the importance of scan direction in CHIP. To determine the impact of the direction of scanning on diffusion results for concrete samples, each sample was scanned from the angles of 0°, 60°, and 120°. The results of one sample are shown in

Figure 13, and the results of all tested samples are reported in

Table 6. More details are reported in

Appendix G. The reader must remember that only the center of 0.88 mm of each radiograph was analyzed. This means that these samples will have a different distribution of paste and aggregates in the central region of each radiograph at each angle. This will have an impact on the results. While the concentration profiles in

Figure 13 showed similar trends, the COV is 22.3%. As shown in

Table 6 the average value of COV for all 12 concrete samples is equal to 23.43%. This is similar to the COV found in

Figure 12 for three different samples from the same concrete cylinder. This means that the variability from three different angles on the same sample is similar to the variability from three different samples from the same mix.

One way to overcome this variability is to take radiographs from an even larger number of angles and use the average concentration to calculate the Dac. Each of these concentration profiles gives a Dac, and this could help determine how homogeneous the sample is from different angles. Larger samples could also be investigated so that more material can be investigated. Additionally, a wider investigation window could be used by accounting for the cupping artifacts in the scan. These are all areas of future work.

4.3. COV and ANOVA Analysis of the CHIP Samples at Different w/cm Ratios

The coefficient of variance (COV) of the 27 paste samples per w/cm of 0.35, 0.40, and 0.45 was calculated as 11.3%. 12.1%, and 16.8%, respectively. The average standard deviation (Std.) and COV for the Dac values calculated for all 81 paste samples (27 samples per each w/cm) tested with CHIP were equal to 1.38 × 10−12 m2/s and 13.4%, respectively. The 95% confidence interval of COV for the paste samples in CHIP showed a lower limit of 7.46% and an upper limit of 19.34%, which shows that all three COV values of the paste samples are not significantly different for the different w/cm ratios. This means that the variation of the measurements for the paste samples does not change significantly at different w/cm ratios.

Another way to determine if the different w/cm ratios are statistically significant, the ANOVA analysis, is shown in

Table 7. By accepting a 5% significance level,

p < 0.05 rejects the null hypothesis. When

p < 0.05, it shows that there is a significant difference between the D

ac of three groups with different w/cm ratios. In other words, CHIP can show that the D

ac of the paste samples changes by changing the w/cm between 0.35, 0.40, and 0.45. It is worth noting that the D

ac values for the tested w/cm are significantly different.