A Study on Differences in Educational Method to Periodic Inspection Work of Nuclear Power Plants

Abstract

1. Introduction

1.1. Background

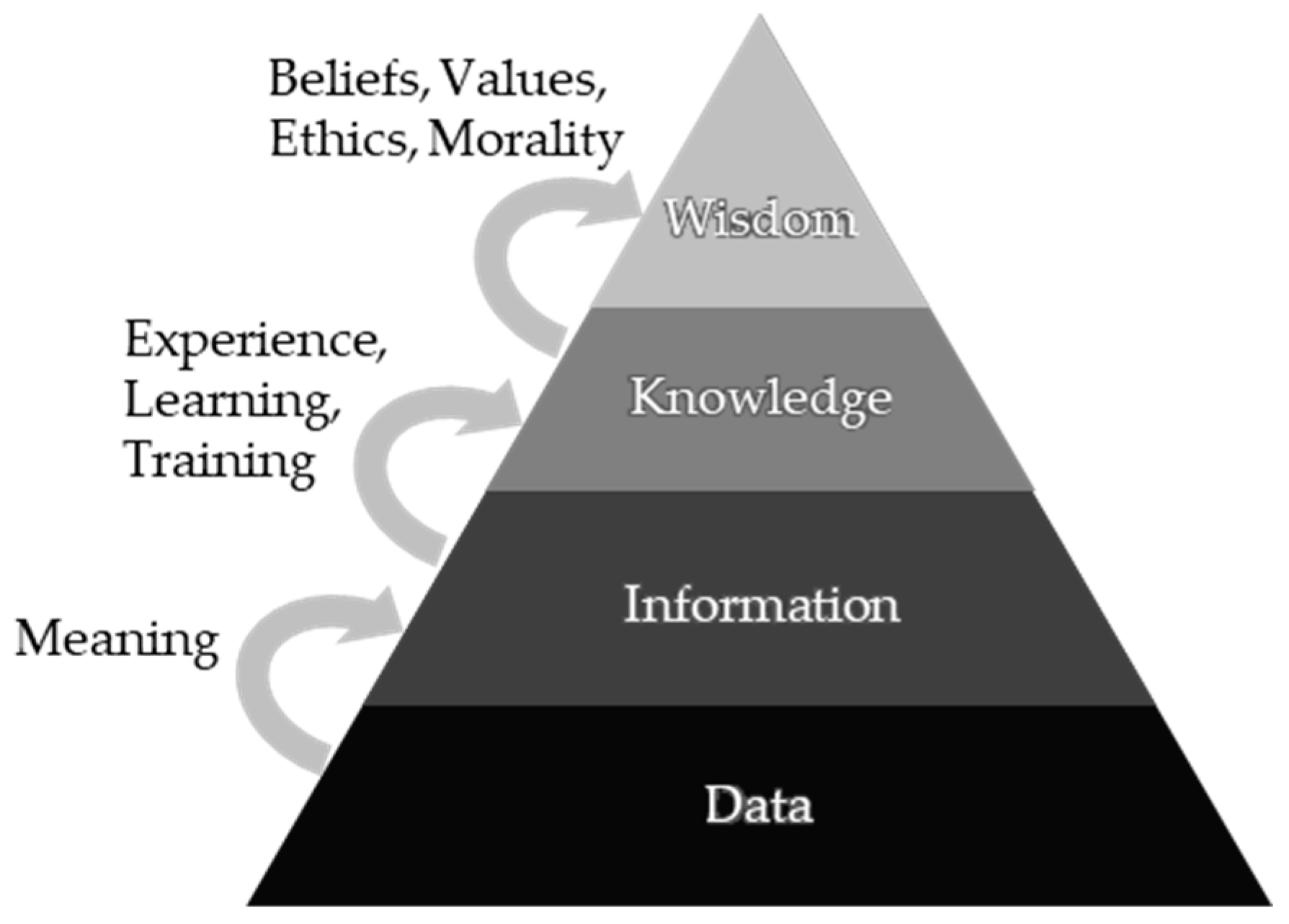

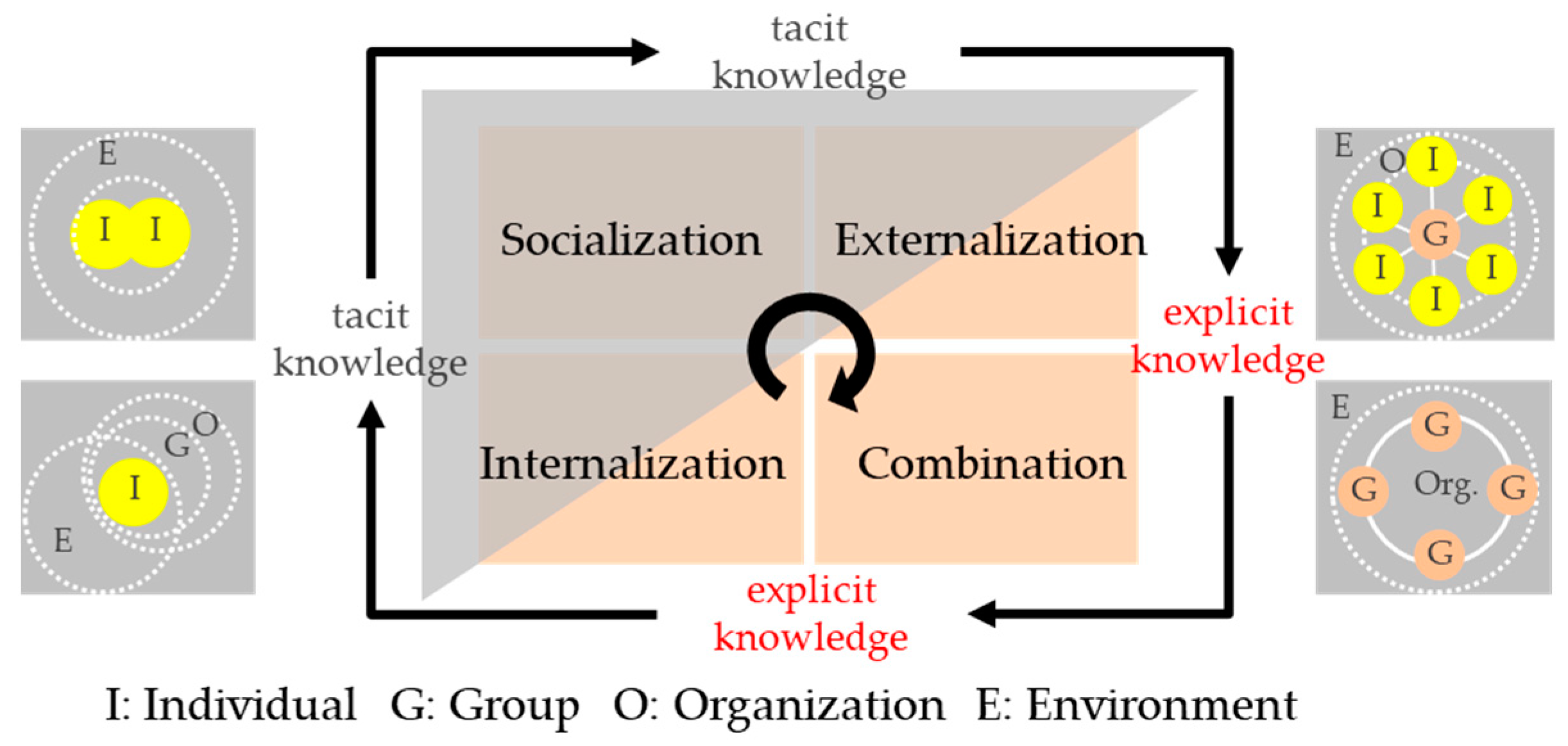

1.2. Knowledge Transfer Process

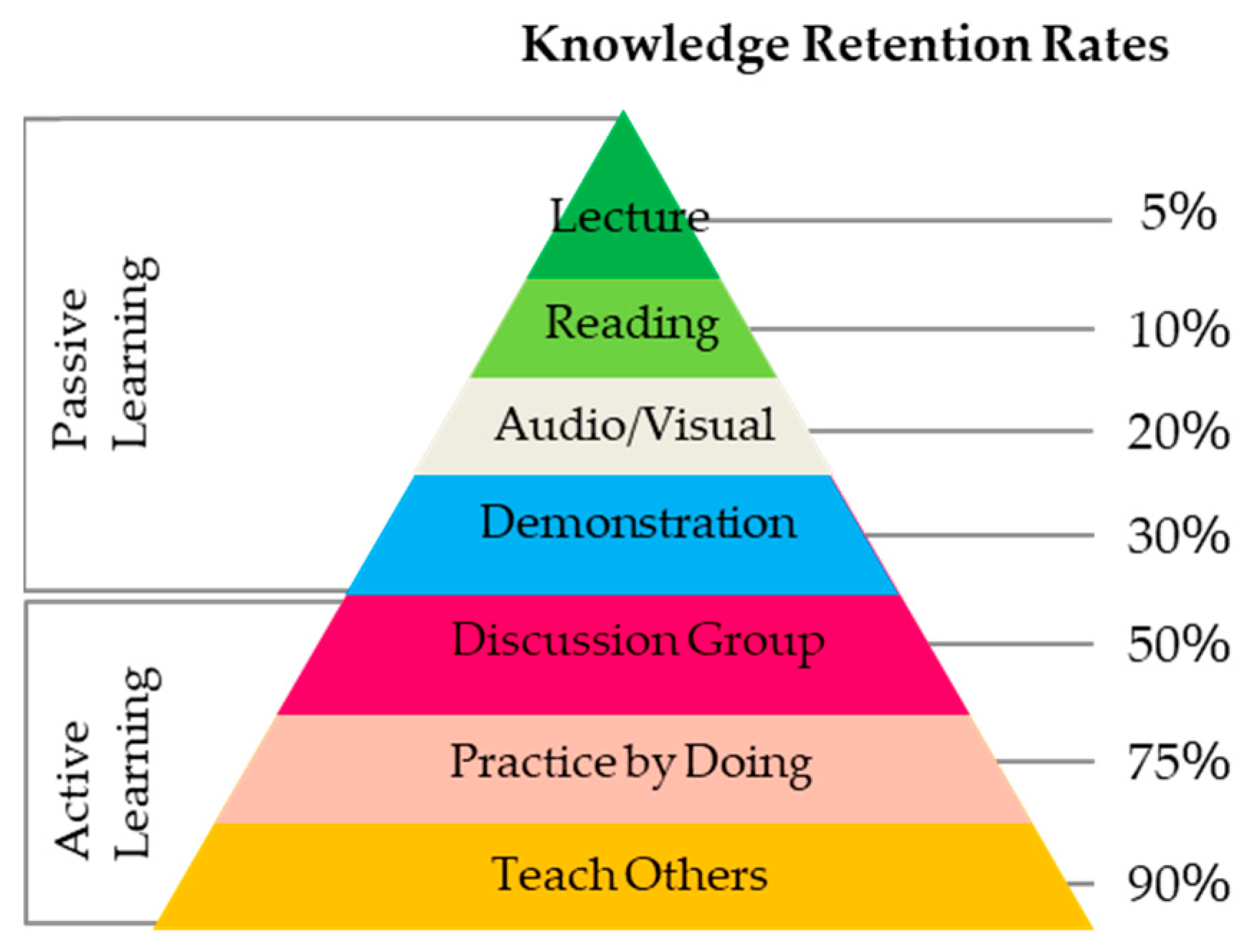

1.3. The Target of This Study in the Knowledge Transfer Process

1.4. Past Research

1.5. Research Objectives

- Development of a VR educational system that enables interactive learning while moving one’s own body as in the field.

- Making VR educational content of the special work, such as periodic inspection, at large-scale nuclear power plants.

- Verification of the differences between VR education and conventional educational methods.

- Suggestion for an educational process to improve the understanding of workers before entering the site.

2. Materials and Methods

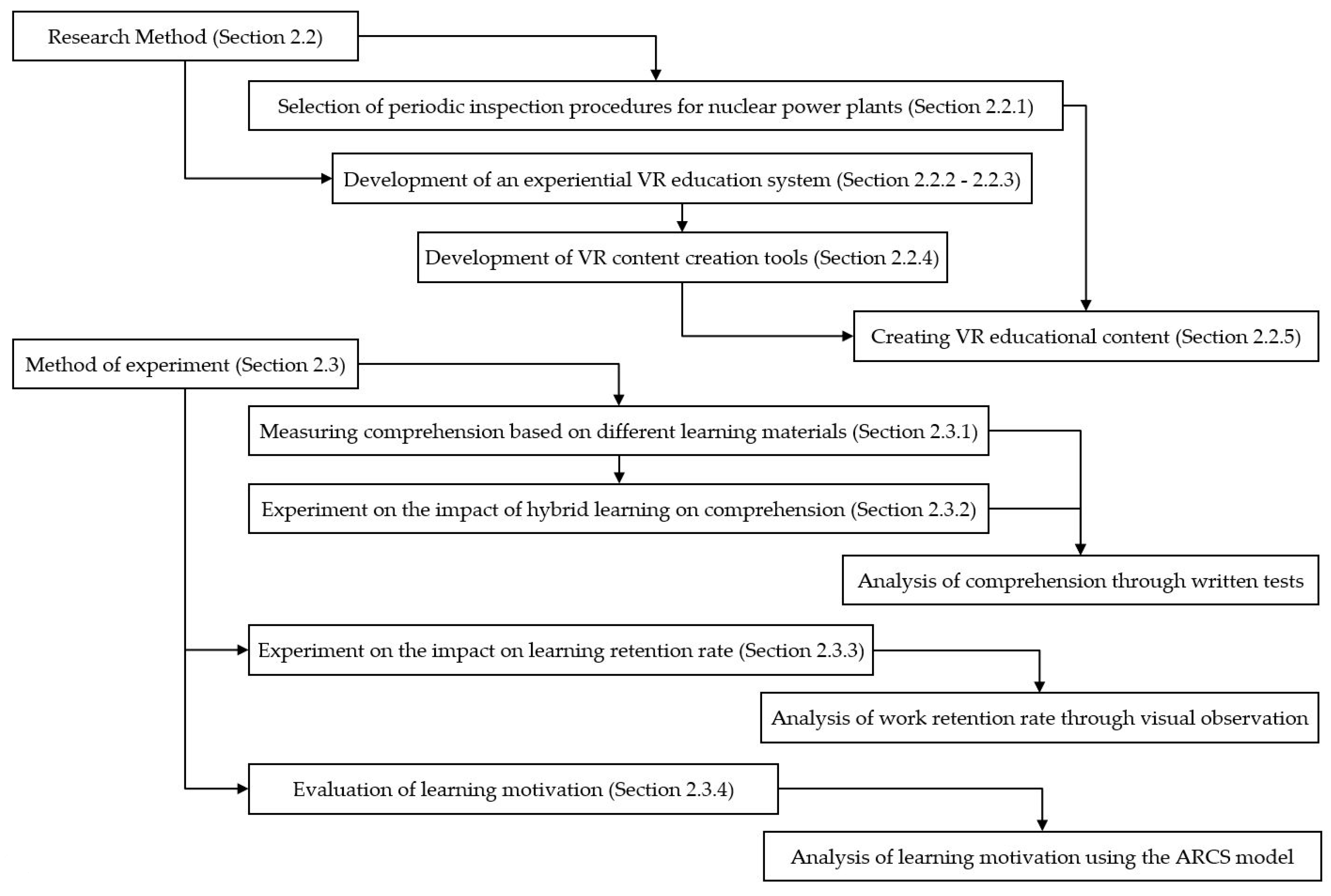

2.1. Research Flowchart

2.2. Research Methods

2.2.1. Outline of the Periodic Inspection Work and the Work Selected for VR

2.2.2. VR System Development Environment

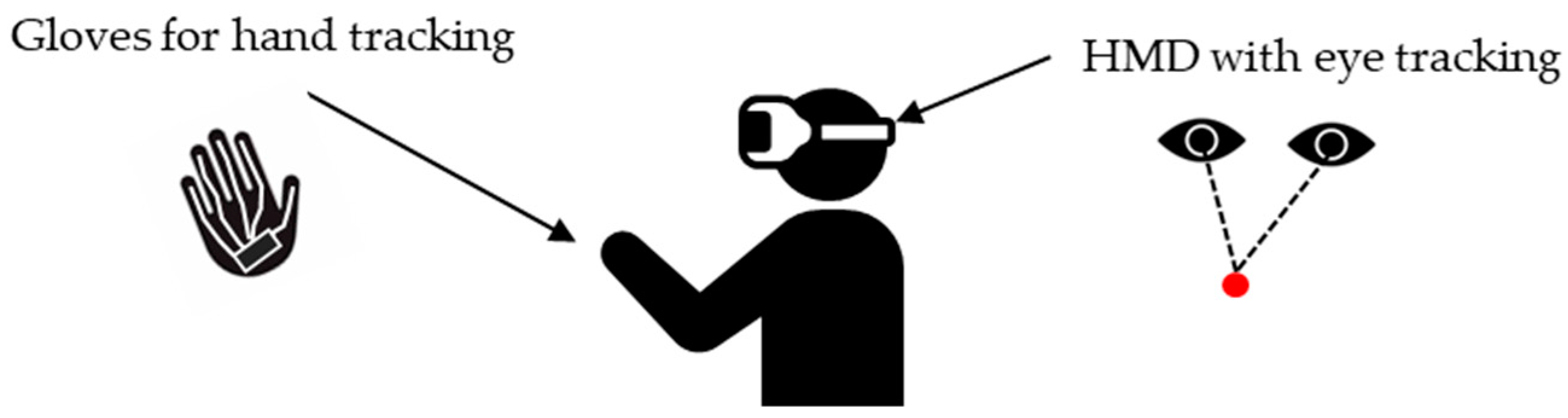

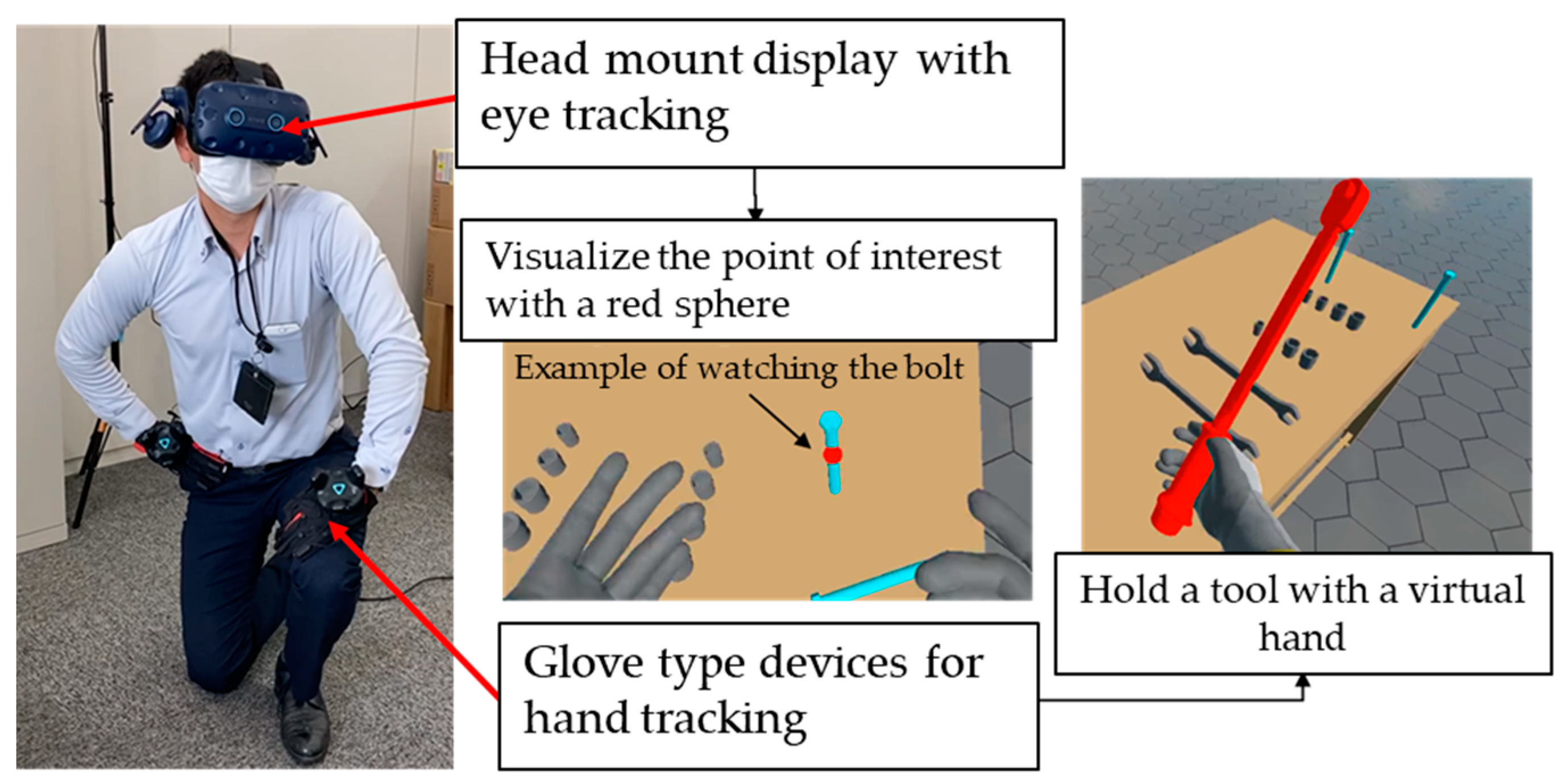

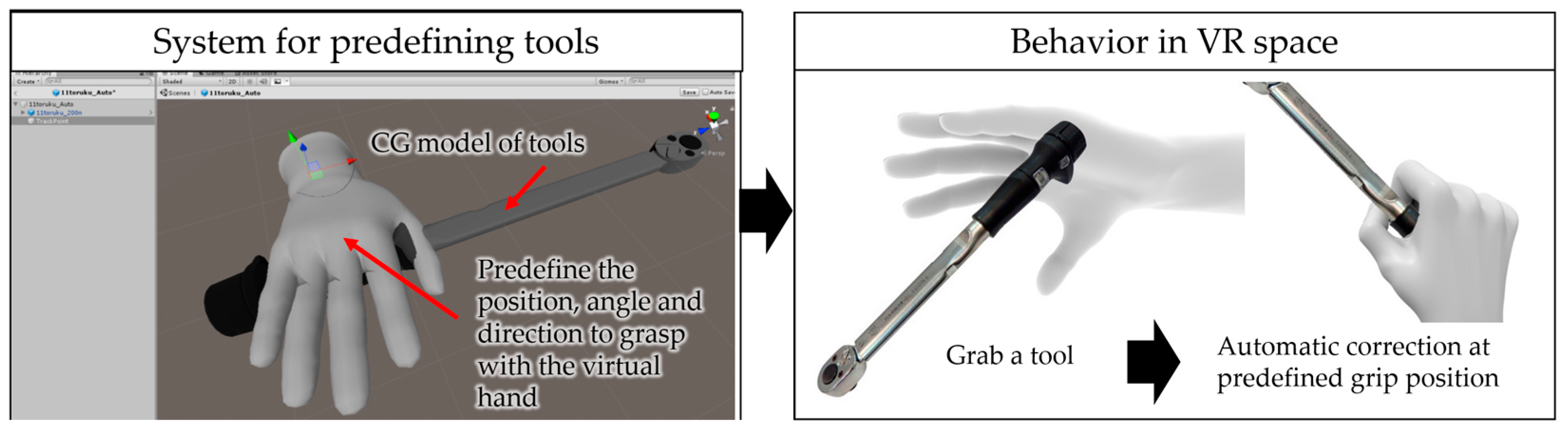

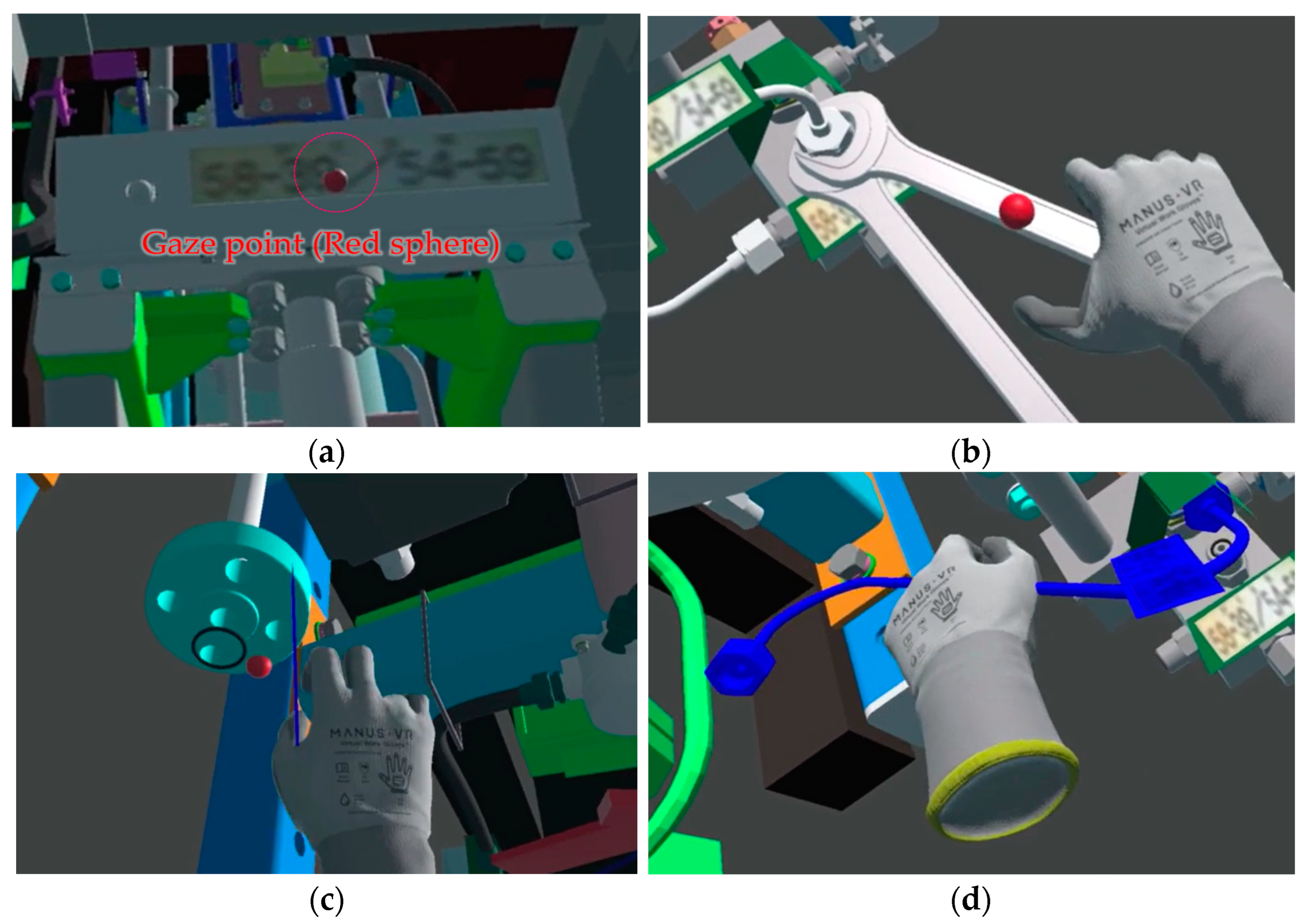

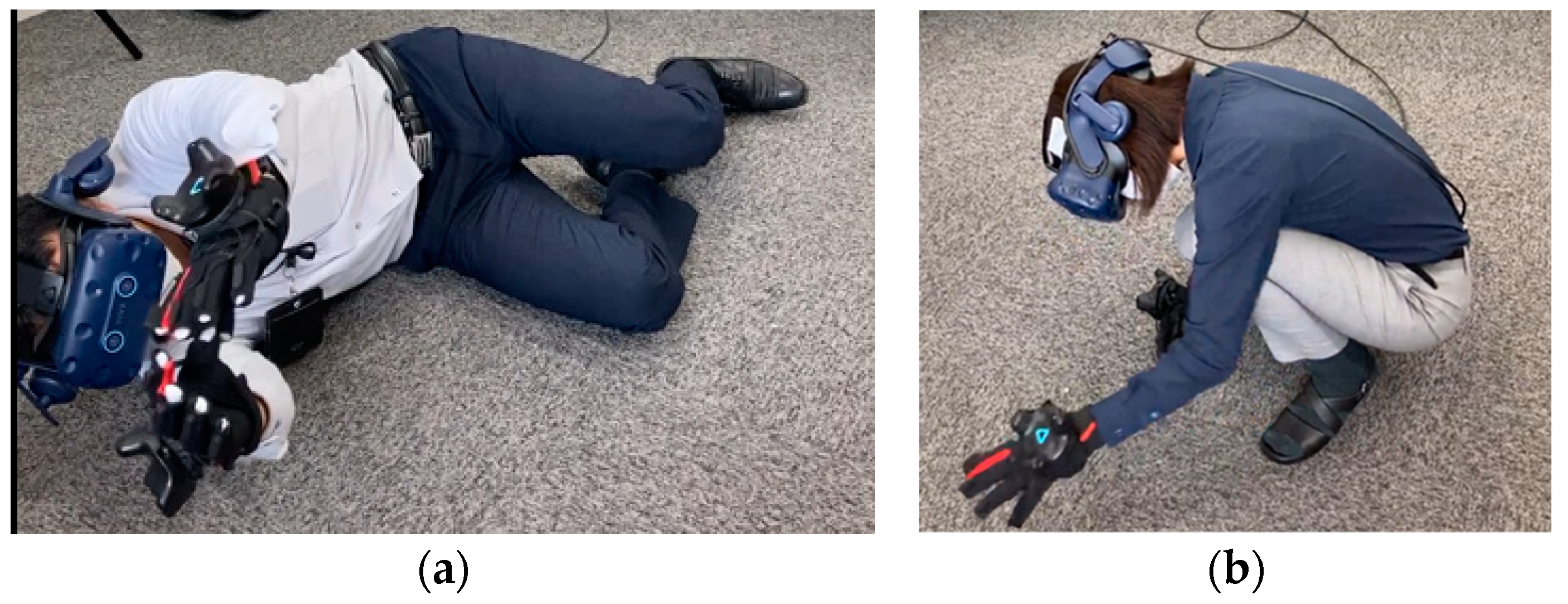

2.2.3. Development of an Experiential VR System for Work Education

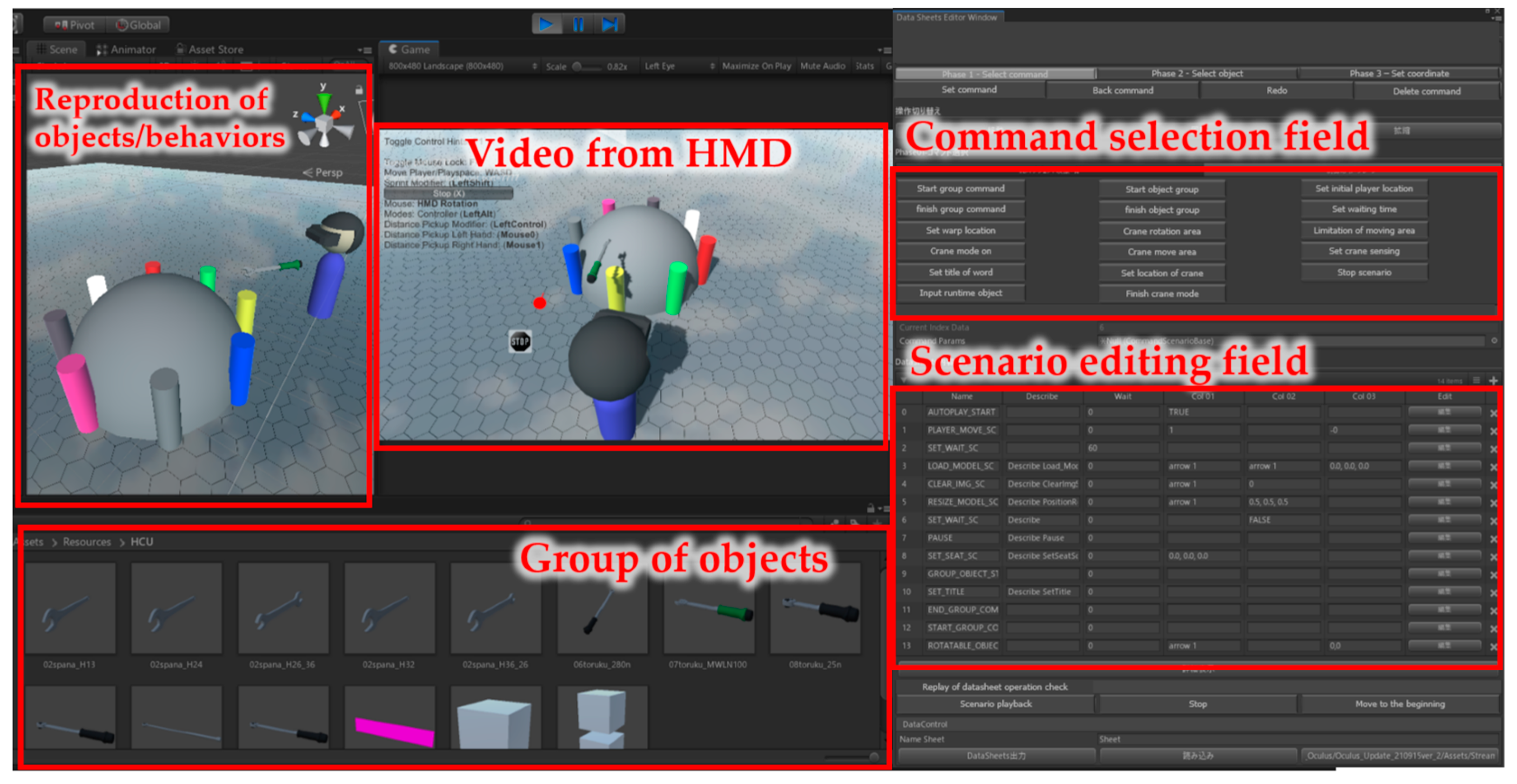

2.2.4. Development of Content Creation Support Tools

2.2.5. Created Content

2.3. Method of the Experiment

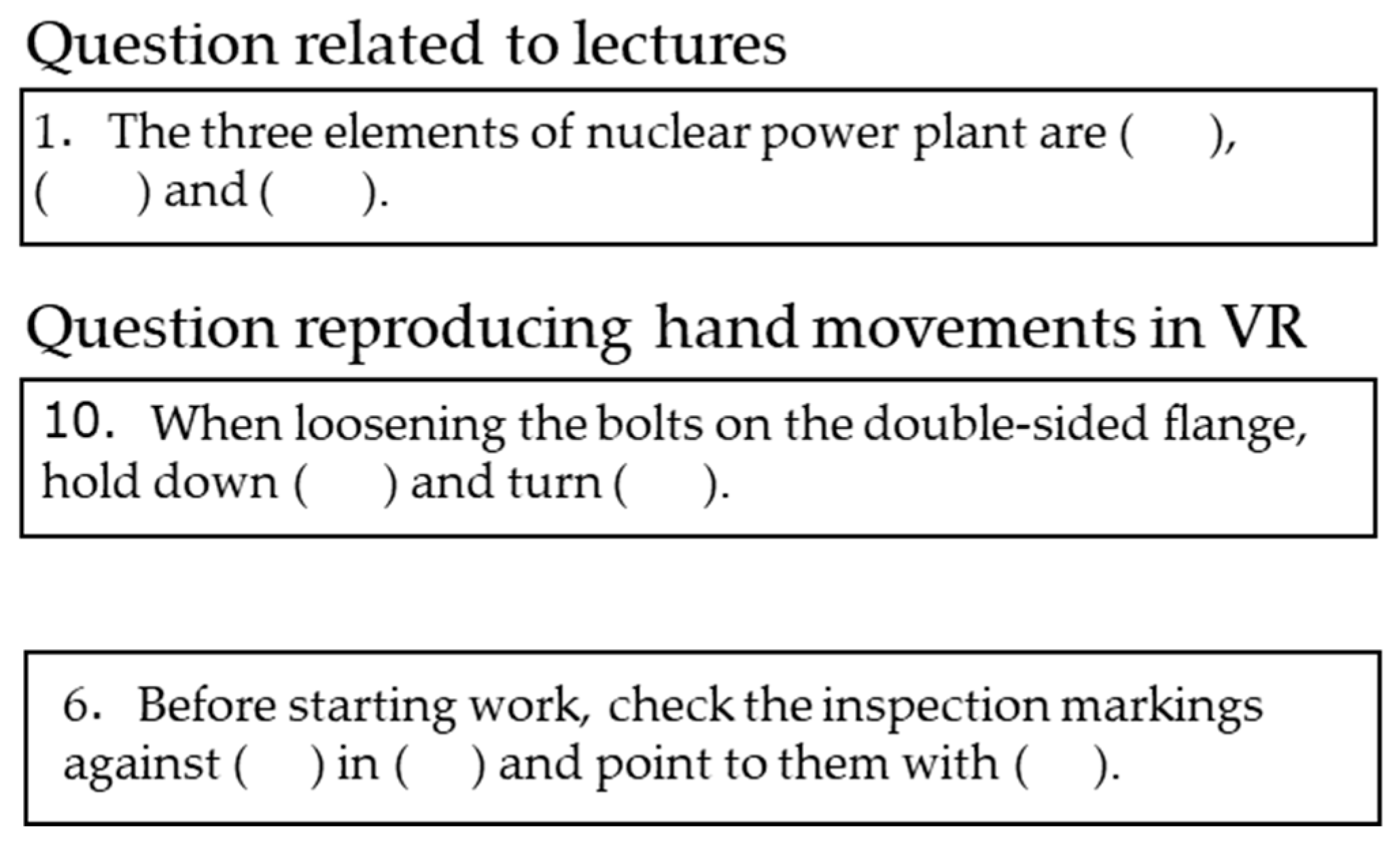

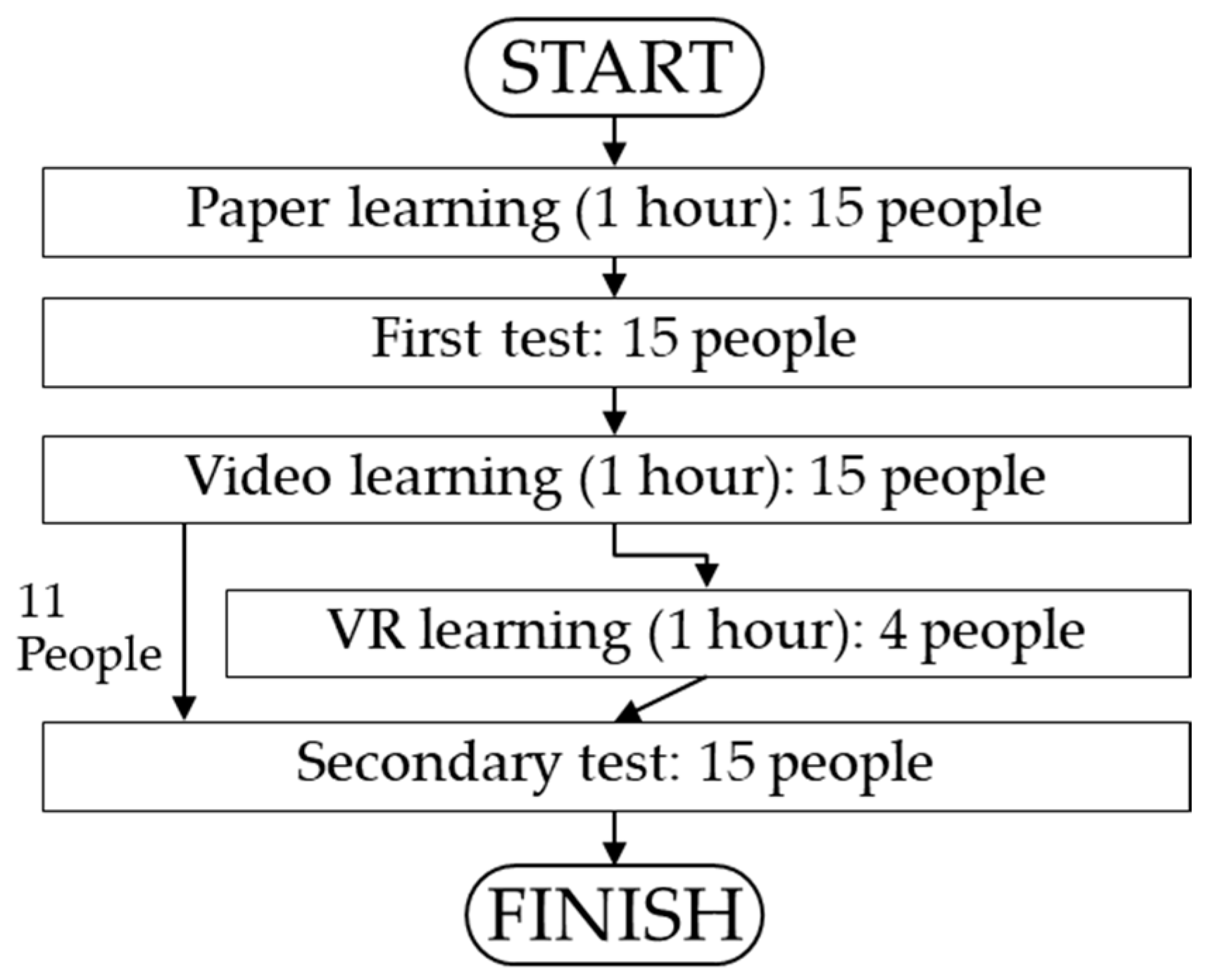

2.3.1. Experiment to Measure Comprehension Using Learning Materials

2.3.2. Experiment to Improve Comprehension by Hybrid Learning

2.3.3. Learning Retention Rate Measurement Experiment

2.3.4. Motivation to Learn Questionnaire

3. Results

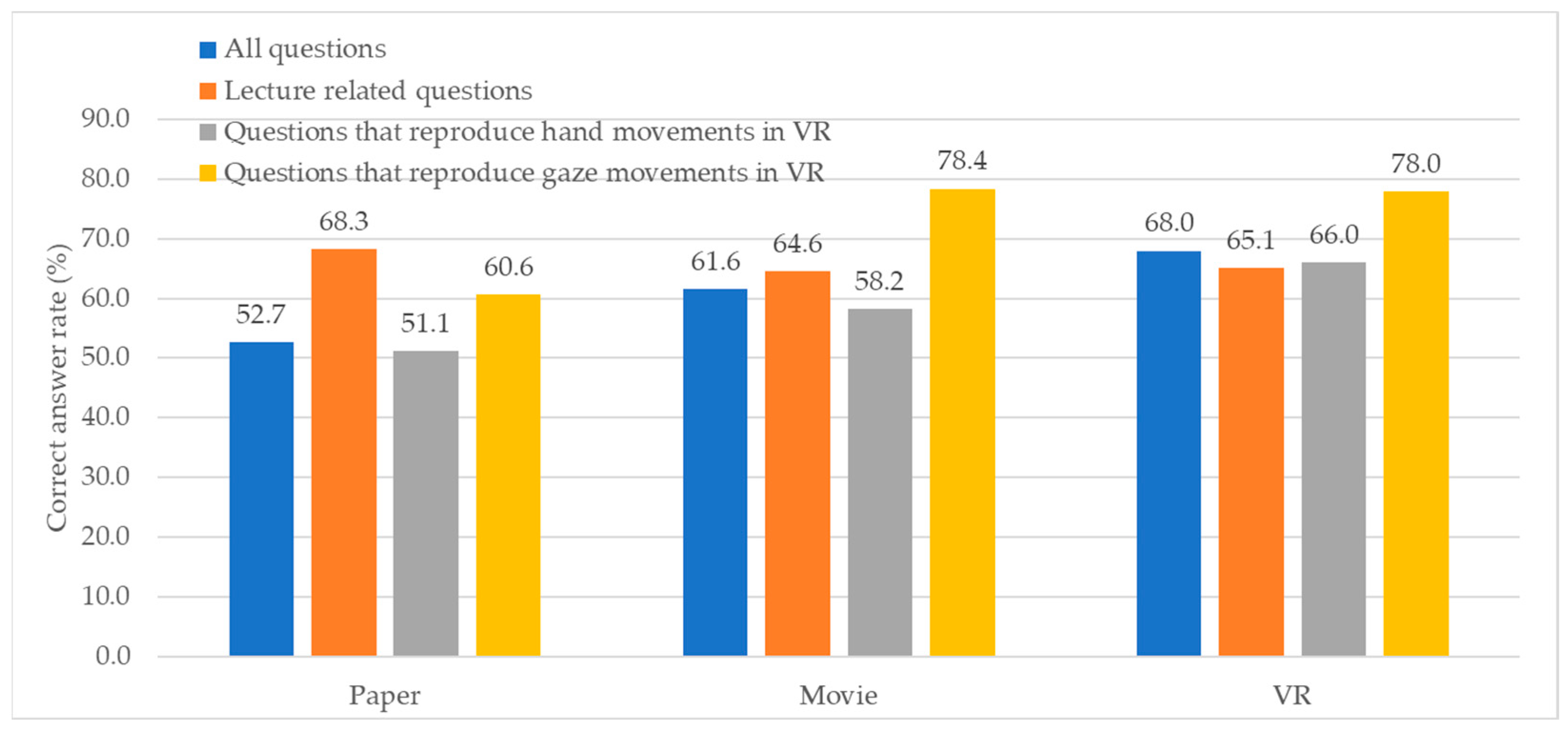

3.1. Result of Experiment to Measure Comprehension Using Learning Materials

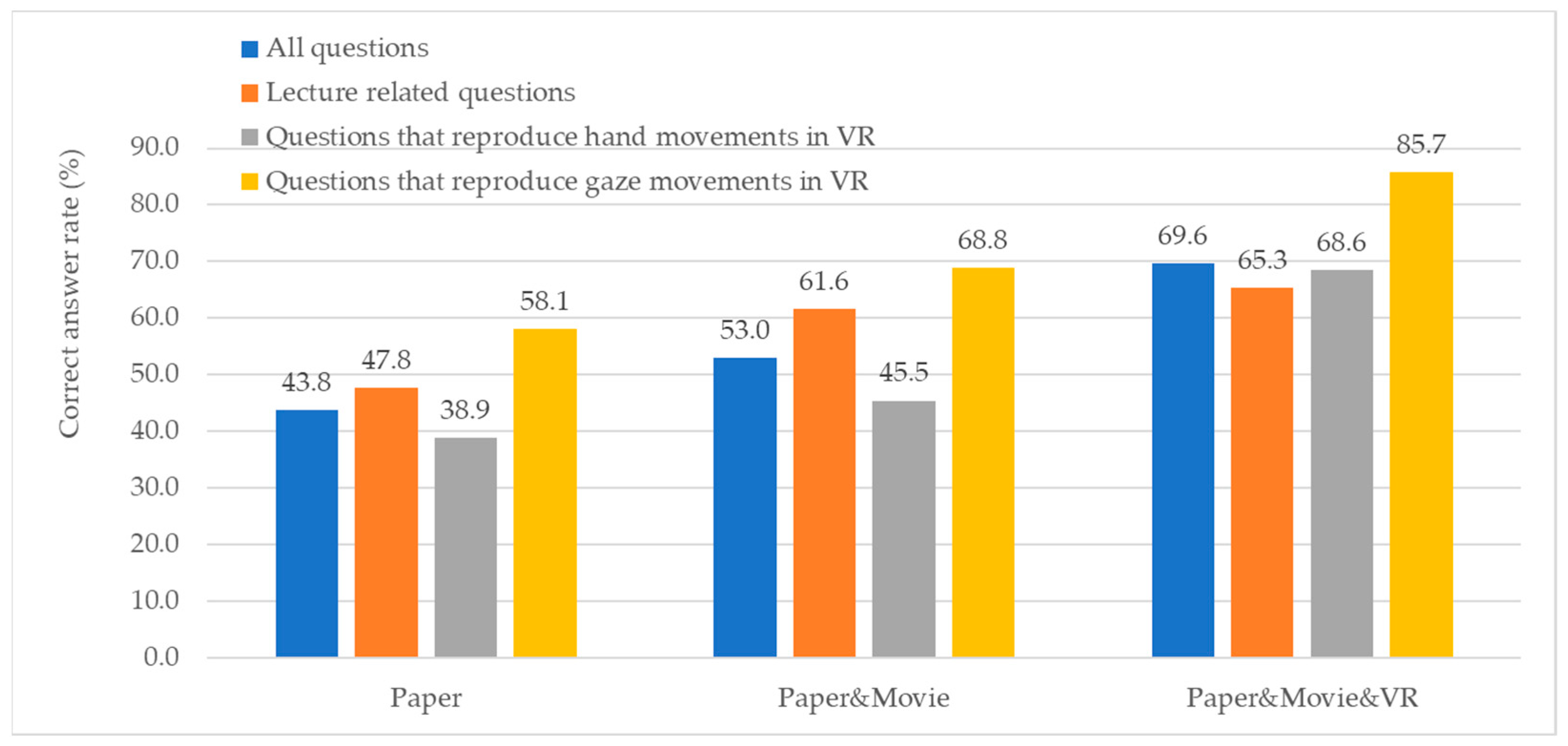

3.2. Result of Experiment to Improve Comprehension Using Hybrid Learning

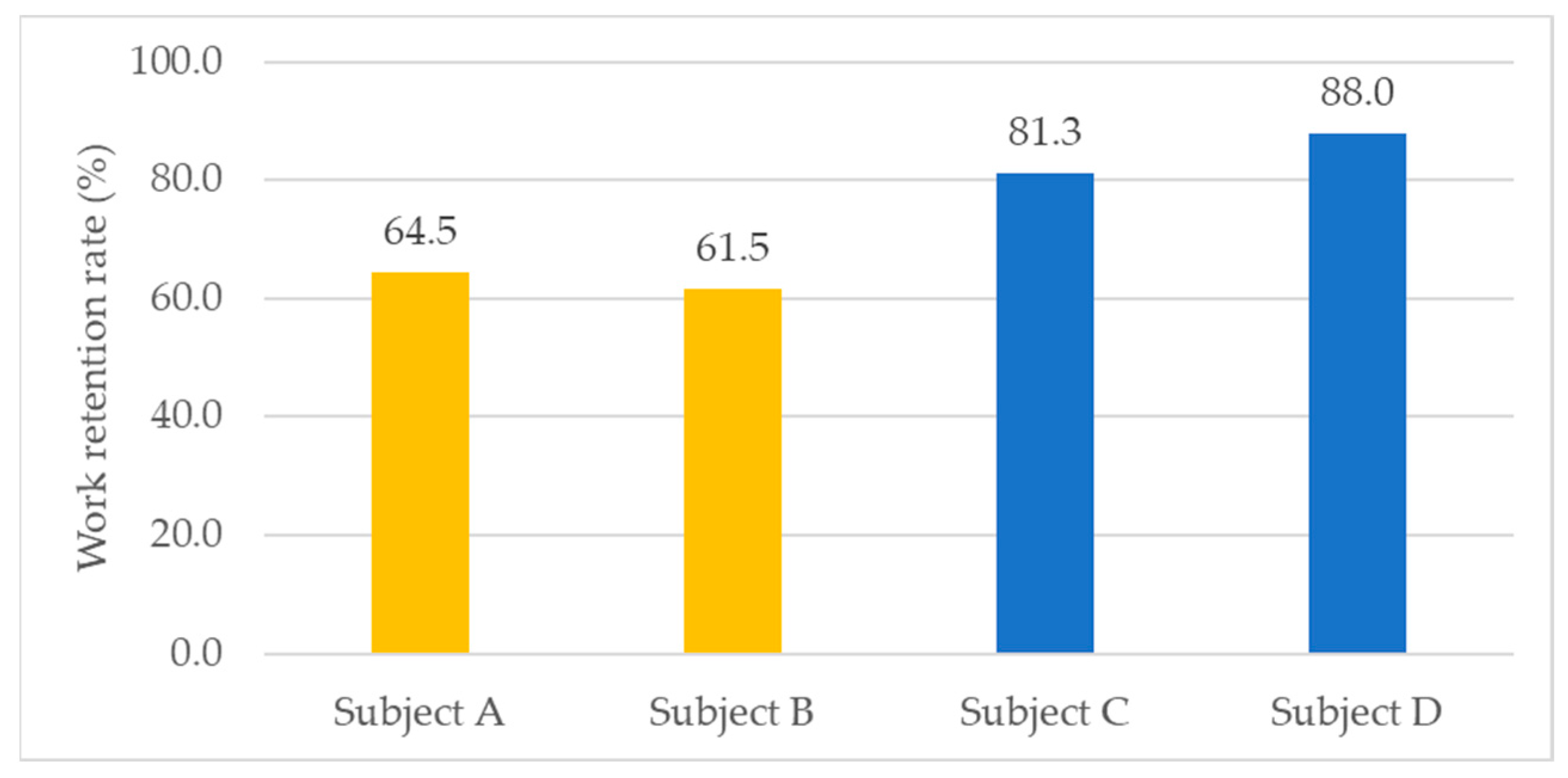

3.3. Result of Learning Retention Rate Measurement Experiment

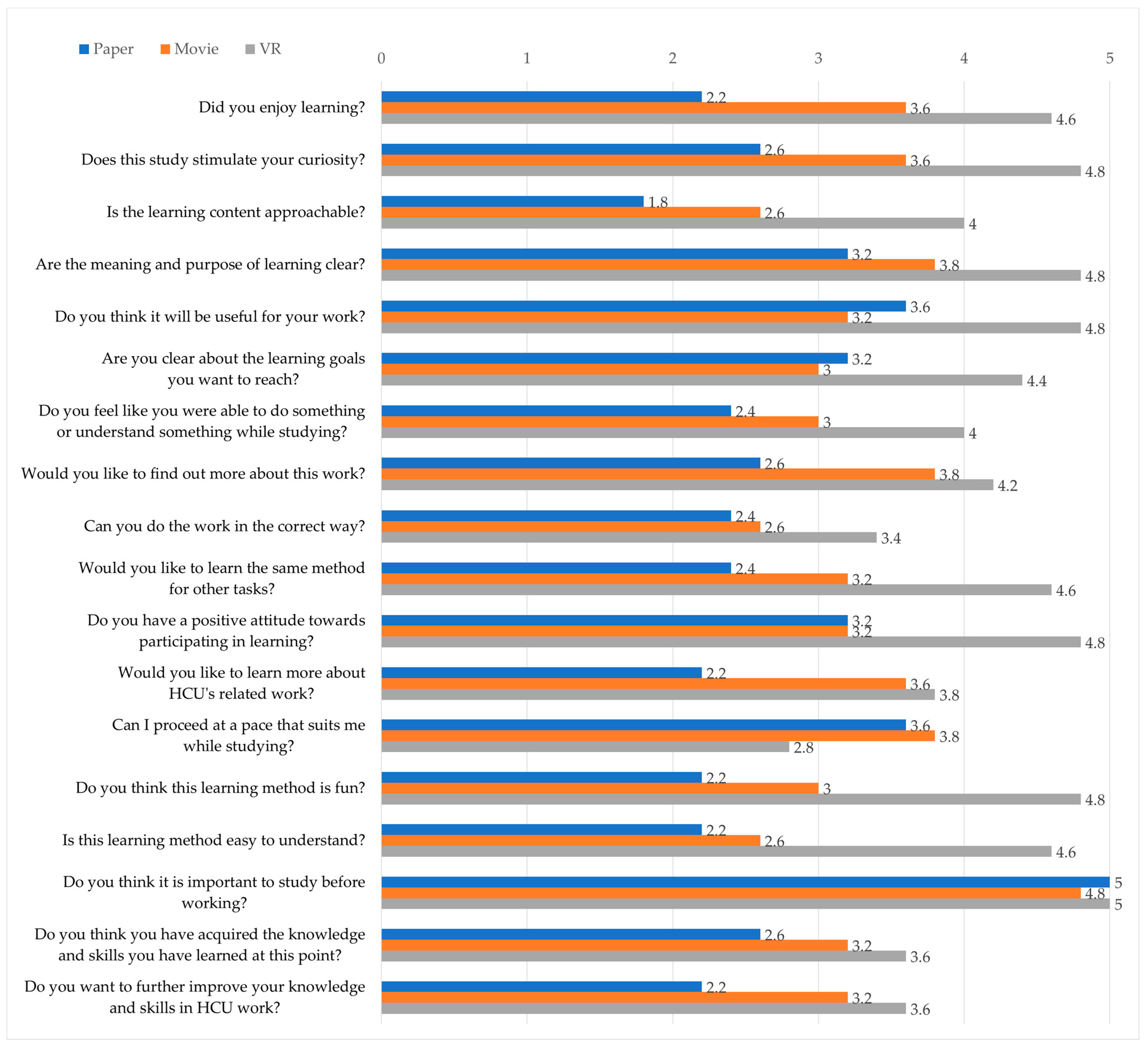

3.4. Result of Motivation to Learn Questionnaire

3.5. Examination of the Experimental Results

4. Discussion

5. Conclusions

- As one of the active learning methods, we developed a VR educational system that enables students to experience interactive work while moving their bodies and compared it with conventional paper and video teaching materials. As a result, VR achieved higher comprehension than the other teaching materials in the comprehension test.

- The results of a comprehension test conducted by learning paper, video, and VR materials in sequence showed that learning all the materials, including VR, in sequence was more effective in improving comprehension compared with learning only paper or paper and video.

- The results of measuring work retention rates at training facilities with and without VR showed that VR learning improved retention rates and affected retention rates in the ancillary tasks more than in the main tasks.

- The results of the evaluation of the characteristics of each material from the experimental results showed that VR is a learning material with no major disadvantages in the inspection work of nuclear power plants and is a learning material with a high overall evaluation value.

- We believe that more effective education can be achieved by appropriately combining various learning methods, such as training facilities and on-the-job training as instructor-led learning, while taking advantage of the advantages of both VR and other learning methods.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Polanyi, M. Personal Knowledge: Towards a Post-Critical Philosophy; University of Chicago Press: Chicago, IL, USA, 1958. [Google Scholar]

- Polanyi, M. The Tacit Dimension; University of Chicago Press: Chicago, IL, USA, 1966. [Google Scholar]

- Hamasaki, K. Survey on maintenance skills required for nuclear power plant periodic inspections. In Proceedings of the Fall meeting of the Atomic Energy Society of Japan, Kochi, Japan, 4 September 2008. [Google Scholar]

- Ackoff, R. From Data to Wisdom. J. Appl. Syst. Anal. 1989, 16, 3–9. [Google Scholar]

- Nonaka, I.; Takeuchi, H. The knowledge Creating Company: How JAPANESE Companies Create the Dynamics of Innovation; Oxford University Press: Oxford, UK, 1995. [Google Scholar]

- Nonaka, I.; Konno, N. The Concept of Ba: Building a Foundation for Knowledge Creation. Calif. Manag. Rev. 1998, 40, 40–54. [Google Scholar] [CrossRef]

- Li, X.; Yi, W.; Chi, H.; Wang, X.; Chan, A.P.C. A critical review of virtual and augmented reality (VR/AR) applications in construction safety. Autom. Constr. 2018, 86, 150–162. [Google Scholar] [CrossRef]

- Eiris, R.; Gheisari, M.; Esmaeili, B. Desktop-based safety training using 360-degree panorama and static virtual reality techniques: A comparative experimental study. Autom. Constr. 2020, 109, 102969. [Google Scholar] [CrossRef]

- Lin, J.; Cao, L.; Li, N. How the completeness of spatial knowledge influences the evacuation behavior of passengers in metro stations: A VR-based experimental study. Autom. Constr. 2020, 113, 103136. [Google Scholar] [CrossRef]

- Shi, Y.; Du, J.; Ahn, C.R.; Ragan, E. Impact assessment of reinforced learning methods on construction workers’ fall risk behavior using virtual reality. Autom. Constr. 2019, 104, 197–214. [Google Scholar] [CrossRef]

- Kang, J.; Jain, N. Merit of Computer Game in Tacit Knowledge Acquisition and Retention. In Proceedings of the 28th International Association for Automation and Robotics in Construction, Seoul, Republic of Korea, 29 June–2 July 2011; pp. 1091–1096. [Google Scholar]

- Shi, Y.; Du, J.; Worthy, D.A. The impact of engineering information formats on learning and execution of construction operations: A virtual reality pipe maintenance experiment. Autom. Constr. 2020, 119, 103367. [Google Scholar] [CrossRef]

- Sampaio, A.Z.; Martins, O.P. The application of virtual reality technology in the construction of bridge: The cantilever and incremental launching methods. Autom. Constr. 2014, 37, 58–67. [Google Scholar] [CrossRef]

- Paes, D.; Arantes, E.; Irizarry, J. Immersive environment for improving the understanding of architectural 3D models: Comparing user spatial perception between immersive and traditional virtual reality systems. Autom. Constr. 2017, 84, 292–303. [Google Scholar] [CrossRef]

- Wang, P.; Wu, P.; Chi, H.L.; Li, X. Adopting lean thinking in virtual reality-based personalized operation training using value stream mapping. Autom. Constr. 2020, 119, 103355. [Google Scholar] [CrossRef]

- Pakarinen, S.; Laarni, J.; Koskinen, H.; Passi, T.; Liinasuo, M.; Salonen, T. Progress in Nuclear Energy. Prog. Nucl. Energy 2024, 169, 105104. [Google Scholar]

- Khoudiakov, M.; Slonimsky, V.; Mitrofanov, S. RBMK Full Scope Simulator Gets Virtual Refuelling Machine; International Atomic Energy Agency, Nuclear Power Engineering Section: Vienna, Austria, 2006; p. 38007637. [Google Scholar]

- Louka, M.N. Augmented and virtual reality research in Halden 1998–2008. In Simulator-Based Human Factors Studies across 25 Years; Springer: Berlin/Heidelberg, Germany, 2010; pp. 287–302. [Google Scholar]

- Masiello, I.; Herault, R.; Mansfeld, M.; Skogqvist, M. Simulation-based VR training for the nuclear sector—A pilot study. Sustainability 2022, 14, 7984. [Google Scholar] [CrossRef]

- Unity Real-Time Development Platform. Available online: https://unity.com/ (accessed on 25 July 2024).

- Unreal Engine: The Most Powerful Real-Time 3D Creation Tool. Available online: https://www.unrealengine.com/ (accessed on 25 July 2024).

- Edger, D. Audio-Visual Methods in Teaching, 3rd ed.; The Dryden Press: New York, NY, USA, 1969. [Google Scholar]

- Weber, S.; Weibel, D.; Mast, F.W. How to Get There When You Are There Already? Defining Presence in Virtual Reality and the Importance of Perceived Realism. Front. Psychol. 2021, 12, 628298. [Google Scholar] [CrossRef] [PubMed]

- Christopher, J.H. Transfer of Training from Virtual Reality Environments; Wichita State University: Wichita, KS, USA, 2005; p. 3189242. [Google Scholar]

- Bowman, D.A.; Kruijff, E.; LaViola, J.J.; Poupyrev, I. An introduction to 3d user interface design. Presence 2001, 10, 96–108. [Google Scholar] [CrossRef]

- Asim, H.; Sebastian, M.; Andrew, P. How good are virtual hands? Influences of input modality on motor tasks in virtual reality. J. Environ. Psychol. 2023, 92, 102137. [Google Scholar]

- Masurovsky, A.; Chojecki, P.; Runde, D.; Lafci, M.; Przewozny, D.; Gaebler, M. Controller-free hand tracking for grab-and-place tasks in immersive virtual reality: Design elements and their empirical study. Multimodal Technol. Interact. 2020, 4, 91. [Google Scholar] [CrossRef]

- Kim, M.; Jeon, C.; Kim, J. A study on immersion and presence of a portable hand haptic system for immersive virtual reality. Sensors 2017, 17, 1141. [Google Scholar] [CrossRef]

- Yousefi, M.V.; Karan, E.P.; Mohammadpour, A.; Asadi, S. Implementing Eye Tracking Technology in the Construction Process. In Proceedings of the 51st ASC Annual International Conference, College Station, TX, USA, 22–25 April 2015. [Google Scholar]

- Jeelani, I.; Han, K.; Albert, A. Automating Analysis of Construction Workers’ Viewing Patterns for Personalized Safety Training and Management. In Proceedings of the 35th International Symposium on Automation and Robotics in Construction, Berlin, Germany, 20–25 July 2018. [Google Scholar]

- Pinheiro, R.B.O.; Pradhananga, N.; Jianuc, R.; Orabi, W. Eye-Tracking Technology for Construction Safety: A Feasibility Study. In Proceedings of the 33th International Symposium on Automation and Robotics in Construction, Auburn, AL, USA, 18–21 July 2016. [Google Scholar]

- Dzeng, R.; Lin, C.; Fang, Y. Using eye-tracker to compare search patterns between experienced and novice workers for site hazard identification. Saf. Sci. 2016, 82, 56–67. [Google Scholar] [CrossRef]

- Hasanzadeh, S.; Esmaeili, B.; Dodd, M.D. Measuring the Impacts of Safety Knowledge on Construction Workers’ Attentional Allocation and Hazard Detection Using Remote Eye-Tracking Technology. J. Manag. Eng. 2017, 33, 04017024. [Google Scholar] [CrossRef]

- Hasanzadeh, S.; Esmaeili, B.; Dodd, M.D. Impact of Construction Workers’ Hazard Identification Skills on Their Visual Attention. J. Constr. Eng. Manag. 2017, 143, 04017070. [Google Scholar] [CrossRef]

- Hasanzadeh, S.; Esmaeili, B.; Dodd, M.D. Measuring Construction Workers’ Real-Time Situation Awareness Using Mobile Eye-Tracking. In Proceedings of the Construction Research Congress, San Juan, Puerto Rico, 31 May–2 June 2016. [Google Scholar]

- Hasanzadeh, S.; Esmaeili, B.; Dodd, M.D. Examining the Relationship between Construction Workers’ Visual Attention and Situation Awareness under Fall and Tripping Hazard Conditions: Using Mobile Eye Tracking. J. Constr. Eng. Manag. 2018, 144, 04018060. [Google Scholar] [CrossRef]

- Jeelani, I.; Han, K.; Albert, A. Automating and scaling personalized safety training using eye-tracking data. Autom. Constr. 2018, 93, 63–77. [Google Scholar] [CrossRef]

- Pfeuffer, K.; Mayer, B.; Mardanbegi, D.; Gellersen, H. Gaze + pinch interaction in virtual reality. In Proceedings of the 5th Symposium on Spatial User Interaction, Brighton, UK, 16–17 October 2017; pp. 99–108. [Google Scholar]

- David, M.; Laure, S.; Joost, B.; Han, H.; Aldo, H. VR training produces more expert-like gaze behaviour in tennis players on-court. J. Vis. 2023, 23, 6007. [Google Scholar]

- Aunnoy, K.M.; Wolfgang, S.; Anil, U.B. Gaze Tracking for Eye-Hand Coordination Training Systems in Virtual Reality. In Proceedings of the Extended Abstracts of the 2020 CHI Conference on Human Factors in Computing Systems, Honolulu, HI, USA, 25–30 April 2020; pp. 1–9. [Google Scholar]

- Alexander, N.; Alexandra, S.; Katarina, S.; Iliya, I.; Siegfried, W. Influence of open-source virtual-reality based gaze training on navigation performance in Retinitis pigmentosa patients in a crossover randomized controlled trial. PLoS ONE 2024, 19, e0291902. [Google Scholar]

- Ye, X.; König, M. Applying Eye Tracking in Virtual Construction Environments to Improve Cognitive Data Collection and Human-Computer Interaction of Site Hazard Identification. In Proceedings of the 39th International Symposium on Automation and Robotics in Construction, Banff, AB, Canada, 21–24 May 2019. [Google Scholar]

- Li, J.; Li, H.; Wang, H.; Umer, W.; Fu, H.; Xing, X. Evaluating the impact of mental fatigue on construction equipment operators’ ability to detect hazards using wearable eye-tracking technology. Autom. Constr. 2019, 105, 102835. [Google Scholar] [CrossRef]

- Takayuki, K.; Masakazu, K. A Solution of Staff Scheduling Problem Considering the Matching between Workers; Research Reports of the Faculty of Engineering Kinki University; Faculty of Engineering, Kinki University: Higashiosaka, Japan, 2013; pp. 27–30. [Google Scholar]

- Masayuki, O.; Yasuaki, F.; Hiroaki, Y. A Study of Learning Characteristic of Worker in Cell Production. Hum. Eng. 2009, 45, 278–285. [Google Scholar]

- John, M.K. Development and use of the ARCS model of instructional design. J. Instr.-Al Dev. 1987, 10, 2–10. [Google Scholar]

- Sameer, M.A. Hybrid Learning in Higher Education; Indiana State University: Haute, IN, USA, 2014. [Google Scholar]

- Mark, B.U.; William, F.P. Hybrid Teaching: Conceptualization Through Practice for the Post COVID-19 Pandemic Education. Front. Educ. 2022, 7, 924594. [Google Scholar]

- Ma, Z. Hybrid Learning: A New Learning Model that Connects Online and Offline. J. Educ. Educ. Res. 2023, 3, 130–132. [Google Scholar] [CrossRef]

- Lee, B.N. Hybrid and Virtual Learning: Bridging the Educational and Digital Device. Malays. J. Soc. Sci. Humanit. 2023, 8, e002035. [Google Scholar]

- Pamela, C.; Rachel, F. Using Virtual Reality to Support Retrieval Practice in Blended Learning: An Interdisciplinary Professional Development Collaboration between Novice and Expert Teachers. Digital 2023, 3, 251–272. [Google Scholar] [CrossRef]

- Tris, K.; Hao, Z.; Ronnel, B.K. An empirical study on immersive technology in synchronous hybrid learning in design education. Int. J. Technol. Des. Educ. 2024, 34, 1243–1273. [Google Scholar]

- Ismail, I. Effects of Virtual Reality (VR) Video as Asynchronous e-Learning Supplement on Student Learning Outcomes. J. Pengkaj. Ilmu Dan Pembelajaran Mat. Dan IPA IKIP Mataram 2022, 10, 409–416. [Google Scholar] [CrossRef]

| Subject No. | P1 | P2 | P3 | P4 | P5 | M1 | M2 | M3 | M4 | M5 | V1 | V2 | V3 | V4 | V5 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Age | 61 | 46 | 49 | 52 | 47 | 58 | 53 | 27 | 34 | 42 | 40 | 51 | 36 | 23 | 36 |

| Years of field experience | 6 | 0 | 2 | 0 | 0.25 | 5 | 0 | 0 | 1.75 | 0.33 | 0 | 0 | 1 | 0 | 0 |

| Years of employment | 39 | 7 | 25 | 30 | 22 | 38 | 30 | 3 | 9 | 16 | 12 | 26 | 12 | 1 | 12 |

| Levels | Points | Contents | |

|---|---|---|---|

| Work execution level | High | 1.0 | No mistakes/Work complete |

| Middle | 0.5 | There are any mistakes/Work completed | |

| Low | 0 | Work incomplete | |

| Work importance level (weighting) | High | 2.0 | Cause of an accident |

| Middle | 1.5 | Affects quality | |

| Low | 1.0 | Missing work step |

| No. | Questionnaire Contents | Factors |

|---|---|---|

| 1 | Did you enjoy learning? | Attention |

| 2 | Does this study stimulate your curiosity? | Attention |

| 3 | Is the learning content approachable? | Relevance |

| 4 | Are the meaning and purpose of learning clear? | Confidence |

| 5 | Do you think it will be useful for your work? | Satisfaction |

| 6 | Are you clear about the learning goals you want to reach? | Confidence |

| 7 | Do you feel like you were able to do something or understand something while studying? | Satisfaction |

| 8 | Would you like to find out more about this work? | Attention |

| 9 | Can you do the work in the correct way? | Relevance |

| 10 | Would you like to learn the same method for other tasks? | Relevance |

| 11 | Do you have a positive attitude towards participating in learning? | Attention |

| 12 | Would you like to learn more about HCU’s related work? | Confidence |

| 13 | Can I proceed at a pace that suits me while studying? | Relevance |

| 14 | Do you think this learning method is fun? | Attention |

| 15 | Is this learning method easy to understand? | Relevance |

| 16 | Do you think it is important to study before working? | Confidence |

| 17 | Do you think you have acquired the knowledge and skills you have learned at this point? | Satisfaction |

| 18 | Do you want to further improve your knowledge and skills in HCU work? | Confidence |

| Work Step | Work Procedures | High Impact |

|---|---|---|

| Pre-work | Confirm number of people | Yes |

| Check HCU unit | Point to check the HCU location number of the main terminal box | Yes |

| Curing the pressure gauge | Fold the Kim towel into multiple layers | |

| Cover the surface of the pressure gauge with a Kim towel | ||

| Fix the Kim towel to the pressure gauge with flame-retardant tape | ||

| Curing the level switch | Turn around the threaded part and then remove it straight | |

| Cover the terminal side with flame-retardant tape | ||

| Protect the connector side with a plastic bag (use a sponge) | ||

| Tighten the opening of the plastic bag with flame-retardant tape | ||

| Fix the cable to the pillar of the frame (using wire) | Yes | |

| Curing the pressure switch | Turn around the threaded part and then remove it straight | |

| Protect the terminal side with flame-retardant tape | ||

| Protect the connector side with a plastic bag (use a sponge) | ||

| Tighten the opening of the plastic bag with flame-retardant tape | ||

| Fix the cable to the pillar of the frame (using wire) | Yes | |

| Label the instrumentation unit | Create a label for PS/PI/main unit using flame-retardant tape | |

| Paste the label on the PS piping (pasting position) | ||

| Paste the label on the PI piping (pasting position) | ||

| Attach the main body label to the instrumentation block | Yes | |

| Remove PI piping | Remove with priority over PS | Yes |

| Set H26 on the body and H36 on the nut | ||

| Turn H36 without moving H26 | ||

| After removing it, cure both ends of the pipe | ||

| Protect the terminal between the pressure gauge and the instrumentation block | ||

| Store on designated pallet | Yes | |

| Remove PS piping | Set H26 on the body and H36 on the nut | |

| Turn H36 without moving H26 | ||

| After removing it, cure both ends of the pipe | ||

| Protect the terminal between the pressure switch and the instrumentation block | ||

| Store on designated pallet | Yes | |

| Installing a jack | Make sure the jack’s lifting surface is in the lowest position. | Yes |

| Check in advance that the jack’s hydraulic valve is closed | ||

| Place the lifting surface of the jack directly below the instrumentation block | ||

| Carefully raise the lifting surface until it lightly touches the instrumentation block | ||

| Remove the operating handle from the jack | ||

| Removing the instrumentation block | Loosen the two diagonal bolts on the ACC side coupling part | Yes |

| Remove the two diagonal bolts | ||

| Loosen and remove the four bolts on the double-sided flange on the N2 container | ||

| Remove the last bolt while holding the flange of the ACC side coupling part | ||

| Carefully place the flange on the instrumentation block | ||

| Loosen the hydraulic valve and lower the lifting surface to the lowest position | ||

| Pull the jack toward you while holding the instrumentation block | ||

| Curing the instrumentation block | Protect the opening on the ACC side (use it longer to the side) | |

| Remove the O-ring on the ACC piping side with a bamboo skewer | ||

| Store the O-ring in the specified plastic bag | ||

| Protect the opening on the ACC piping side (use it long enough to reach the side) | ||

| Remove the O-ring on the N2 container side with a bamboo skewer | ||

| Store the O-ring in the specified plastic bag | Yes | |

| Cover the opening on the N2 container side with flame-retardant tape | ||

| Store the instrumentation block on the designated pallet | Yes | |

| Tidying up | 4S implementation |

| ARCS Factors | Paper | Movie | VR |

|---|---|---|---|

| Attention | 2.6 | 3.4 | 4.6 |

| Relevance | 2.5 | 3.0 | 3.9 |

| Confidence | 3.2 | 3.7 | 4.3 |

| Satisfaction | 2.9 | 3.1 | 4.1 |

| Average | 2.8 | 3.3 | 4.2 |

| Teaching Materials | Paper | Movie | VR | Group Lecture | Training Facilities | On-Site OJT |

|---|---|---|---|---|---|---|

| Basic knowledge acquisition | 5 | 4 | 3 | 5 | 3 | 2 |

| Understand work procedures | 2 | 4 | 4 | 2 | 5 | 5 |

| Spatial cognition | 1 | 1 | 4 | 1 | 4 | 5 |

| Work experience | 1 | 1 | 4 | 1 | 5 | 5 |

| Cost | 5 | 3 | 2 | 4 | 1 | 1 |

| Understanding/Retention level | 1 | 3 | 4 | 2 | 5 | 5 |

| Repeated learning | 5 | 4 | 3 | 2 | 2 | 1 |

| Learning opportunities/Frequency | 5 | 5 | 4 | 2 | 1 | 1 |

| Willingness to learn | 1 | 3 | 5 | 1 | 4 | 3 |

| Average | 2.9 | 3.1 | 3.7 | 2.2 | 3.3 | 3.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yashiro, Y.; Wang, G.; Hatori, F.; Yabuki, N. A Study on Differences in Educational Method to Periodic Inspection Work of Nuclear Power Plants. CivilEng 2024, 5, 760-784. https://doi.org/10.3390/civileng5030040

Yashiro Y, Wang G, Hatori F, Yabuki N. A Study on Differences in Educational Method to Periodic Inspection Work of Nuclear Power Plants. CivilEng. 2024; 5(3):760-784. https://doi.org/10.3390/civileng5030040

Chicago/Turabian StyleYashiro, Yuichi, Gang Wang, Fumio Hatori, and Nobuyoshi Yabuki. 2024. "A Study on Differences in Educational Method to Periodic Inspection Work of Nuclear Power Plants" CivilEng 5, no. 3: 760-784. https://doi.org/10.3390/civileng5030040

APA StyleYashiro, Y., Wang, G., Hatori, F., & Yabuki, N. (2024). A Study on Differences in Educational Method to Periodic Inspection Work of Nuclear Power Plants. CivilEng, 5(3), 760-784. https://doi.org/10.3390/civileng5030040