Abstract

The aim of this study is to examine the effect of the partial replacement of sand by Glass Fiber-Reinforced Polymer (GFRP) waste on the mechanical properties of cement mortars. Compressive and flexural tests were carried out on mortars containing 0, 3, 5, 10, and 15% (by volume) of GFRP waste. It appears that the incorporation of 3% GFRP waste did not significantly affect the mechanical strength. However, further increasing the GFRP waste content led to a reduction in the mechanical strength. The flexural strength seemed less affected than the compressive strength, since the decrease in flexural strength at a 10% replacement was only 37%, while it was 54% for the compressive strength. However, an improvement in the toughness of the mortar with an increase in the substitution rate was observed. The reference sample displayed a flexural toughness of 0.351 N·m, while the mortar incorporating 15% of GFRP exhibited a flexural toughness of 0.642 N·m. The reuse of GFRP waste in cementitious materials, therefore, constitutes an interesting recycling solution.

1. Introduction

Preserving the environment requires the rational and intelligent use of available resources. In this context, the recycling and reuse of materials becomes essential for reducing pressure on natural resources and carbon emissions [1]. Among the materials that need to be recycled and/or reused are Glass Fiber-Reinforced Polymers (GFRPs). These materials consist of glass fibers dispersed in a resin (e.g., polyester). These materials are widely used in several fields, such as construction, renewable energy (e.g., wind turbine blades), and boats. The recyclability of these materials poses several challenges due to the difficulty of separating the glass fibers from the resin matrix. In addition, due to aging and the different treatments that these materials may have undergone during their lifespan, their properties can vary considerably and can lead to very significant degradation, depending on the medium to which the materials were exposed. This is why these materials are generally landfilled or incinerated [2]. Incineration, which is currently the most used, will no longer be possible in order to protect the environment, particularly to reduce greenhouse gases. In addition, a European directive (1999/31/EC) prohibits the landfilling of large composite parts. So, economically and environmentally viable recycling options are needed.

Currently, there are three main recycling methods, including thermal, chemical, and mechanical recycling [2,3,4,5]. There are also some reuse solutions, such as incorporation into thermoplastics, road applications, incineration with energy recovery [6,7], and use as powder or aggregates in cement-based materials [8,9,10,11]. Other reuse solutions could be implemented, such as their addition into the paste backfill intended for use in underground salt mines [12]. The reuse of GFRP waste in cementitious materials is considered an economically and environmentally viable solution [2]. GFRP waste is also used in the cement manufacturing process as a raw material and/or energy source. The size of the GFRP waste is first reduced. The mineral part of the GFRP is used to make the clinker, while the organic polymer matrix is converted into energy to heat the rotary kiln [2].

The field of cementitious materials thus represents an interesting recycling option for GFRP waste. This option currently makes it possible both to treat large volumes of this waste and to reduce the extraction of natural aggregates (especially sand). In addition, cementitious materials that incorporate GFRP waste could present very interesting specific properties [9,10,11,13].

A large number of studies have examined the effects of glass fibers on the behavior of cementitious materials [14,15,16,17,18,19,20,21,22]. These studies have highlighted the beneficial effects of the incorporation of glass fibers into cementitious materials, such as pozzolanic activity, good fire behavior, and the enhancement of toughness [15,16,17].

In recent years, several studies have focused on the reuse of GFRP waste in construction materials [8,9,10,13,21,23,24]. It should be noted that GFRP waste is also incorporated into polymer concrete materials, in which a thermoset polymer entirely replaces the cement paste [11,25,26]. However, this type of “concrete” has a relatively high cost and high sensitivity to creep and shrinkage [11,27,28].

Several studies on the incorporation of GFRP waste into cementitious materials are available [8,9,10,13,21,23,24]. The data vary depending on the particle size of the waste incorporated (fine or coarse) and the substitution rate [2]. Depending on the grinding process, GFRP waste is incorporated in the form of a powder to replace the cement or fine particles of sand, or in the form of a fiber–resin to partially replace the aggregates. Generally, the incorporation of GFRP waste leads to a loss in the workability of the cementitious material. This is attributed to the flocculation of particles (or fibers), which increases water demand [29,30]. However, the effect on the workability strongly depends on the content, size, and morphological properties of the GFRP waste. The workability is generally reduced with a longer fiber length and higher fiber content. Farinha et al. [31] observed that replacing 20% of fine aggregates by weight with GFRP waste (less than 63 µm) in mortars with the same water content improved workability. In fact, GFRP particles absorb less water than the replaced fine aggregates, thereby reducing water demand. Furthermore, the replacement of coarse aggregates with needle-shaped GFRP waste does not significantly affect the workability. In addition, the water to cement ratio (w/c) gradually increases with the GFRP waste content [32].

The effect of GFRP waste on the mechanical properties should consider the type and size of the substituted waste (fine or coarse aggregate replacement, or supplementary cementitious material). When replacing fine aggregates, some results have shown an increase in the compressive strength, while other studies have reported a decrease in the compressive strength. The reduction in the compressive strength may be due to the lower compressive strength of GFRP particles compared to that of natural aggregates, the weaker bonding of GFRP particles/cement paste, the increase in voids, and the heterogeneous distribution of the waste in the material [8,9,10,32]. Moreover, an increase in the compressive strength when GFRP waste is used in powder form has also been reported [11,31]. This positive effect can be explained by the reduction in voids and the chemical effects induced by the fine particles of GFRP waste. GFRP waste powder can thereby induce pozzolanic activity and a nucleation effect, leading to the improvement of the mechanical strength [33,34].

Concerning the flexural strength, according to Ribeiro et al. [11], a partial replacement rate of sand aggregates with GFRP waste, not exceeding 8% by weight, has a positive effect. Farinha et al. [31] reported an increase in the flexural strength of 155% at 365 days; the reference mortar had a flexural strength of 1.94 MPa and the mortar with 50% (by volume) GFRP waste had 4.95 MPa.

Asokan et al. [24] investigated the effect of the replacement of fine aggregates by GFRP waste powder and fiber in concrete and cement composites. The substitution rates ranged from 5 to 50 wt%. The results showed that the compressive strength decreased with the GFRP substitution rate, while the bending strength with 5% of GFRP waste was enhanced compared to that of the reference sample. Moreover, the density of concrete with 50% GFRP waste was reduced by about 12% [24].

Correia et al. [8] examined the substitution of sand by fine GFRP waste (about 96% of the particles measure less than 63 μm) with volume replacement rates ranging from 5 to 20%. For the 5% substitution, the tensile splitting strength and the modulus of elasticity of the concretes were slightly reduced by 2.7% and 3.0%, respectively. The compressive strength decreased by about 19.4%. At higher substitution rates (>5%), the mechanical properties were significantly decreased. It has to be kept in mind that the incorporation of GFRP waste can lead to a workability (or slump) loss that can be overcome with the addition of a superplasticizer or an increase in the water content (water to cement ratio). The increase in substitution rates significantly increases the amount of water needed to maintain the workability [8,24]. This is why concretes containing GFRP waste are often fabricated with an equivalent water to cement ratio.

Tittarelli and Moriconi [10] investigated the possibility of reusing GFRP waste coming directly from a shipyard as a partial aggregate or filler replacement in cement-based composites. The authors specify that a high GFRP replacement rate (15% and 20%) significantly decreases the mortar workability, and a superplasticizer was added (0.25% and 1 wt% of cement) in order to maintain the workability. Tests were performed on cement mortars manufactured by replacing 0%, 10%, 15%, and 20% of the aggregate volume with a GFRP byproduct and on self-compacting concretes (SCC) manufactured through replacing 0%, 25%, and 50% of the calcareous filler volume with GFRP powder. GFRP powder is composed of 20% (v%) glass fibers and 80% (v%) polyester resin. A strong reduction in compressive strength (up to about 25%) was observed both in mortars and self-compacting concretes. The capillary water absorption and drying shrinkage of the GFRP cementitious composites are decreased by about 70% and 50%, respectively, compared to the reference samples without GFRP waste.

Furthermore, it is interesting to note that some studies have reported an improvement in the toughness of cementitious materials incorporating GFRP waste. Overall, the use of recycled GFRP waste in concrete/mortar has contributed to the reduction in crack propagation [29,35,36,37]. This improvement in toughness is very interesting because it can limit the effects of restrained shrinkage. In addition, it is possible to further improve the toughness of the cementitious material and its mechanical properties by improving the dispersion and orientation of the recycled GFRP fibers [37].

All these studies show that the reuse of GFRP waste in cement-based materials can be interesting. Generally, the partial substitution of sand by GFRP waste results in a reduction in the compressive strength, which can be explained in part by the increase in water demand to maintain satisfactory workability. Additionally, it appears that the incorporation of GFRP waste slightly affects the flexural strength [24]. It is even thought that incorporation of GFRP waste could reduce the brittleness of the cementitious material.

The aim of this study is to examine the effect of the partial substitution of sand with GFRP waste from a shipyard on the compressive and flexural strength of cement mortars. Particular focus will be placed on improving the toughness of the mortar with the incorporation of GFRP waste. In addition, the reduction in mechanical strength (notably, the compressive strength) is partly due to the increase in water demand. This work also aims to examine the contribution of an addition of superplasticizer, instead of an increase in the w/c ratio, on the loss of compressive strength.

2. Materials and Methods

Materials

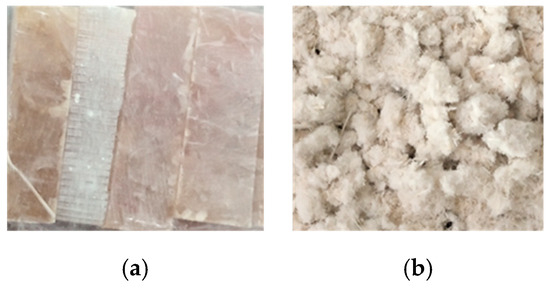

Glass fiber-reinforced polymers coming directly from the deconstruction of out-of-use pleasure boats were used. These composites are mainly composed of glass fibers and polyester resin (Figure 1). Large composite parts were first shredded in an Alpine® grinder (Hosokawa Alpine, Augsburg, Germany) and then ground with a Retsch® SM300 grinder (Haan, Germany) at 1500 rpm, using a 4 mm grid.

Figure 1.

(a) Large parts of composites before grinding; (b) GFRP-based composites after grinding.

An ordinary Portland cement CEM I 52.5R provided by Lafarge Holcim (Teil, France) was used. Its particle size distribution was determined using a laser granulometer (LS 13320 Beckman Coulter, Villepinte, France) (Figure 2). The Blaine fineness of this cement is 0.44 m2/g.

Figure 2.

Particle size distribution of the cement.

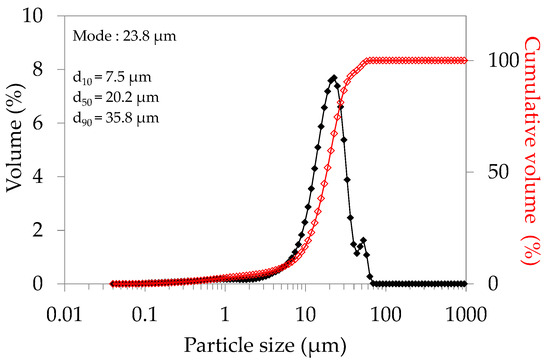

CEN standard sand [38] was chosen. The particle size distributions of the sand and composites were determined according to the NF EN 933-1 standard [39] through vibratory sieving using sieves of 2 mm, 1.6 mm, 1 mm, 0.5 mm, 0.16 mm, and 0.08 mm. Composites particles larger than 2 mm were removed. The particle size distributions are shown in Figure 3. It can be noted that the composites contain more fines particles than standard sand.

Figure 3.

Particle size distribution of the standard sand and composite (GFRP).

The absolute density of the raw materials was measured with a pycnometer (Micromeritics AccuPyc 1330, Micromeritics Instrument Corporation, Norcross, GA, USA). These measurements were performed in triplicate (Table 1).

Table 1.

Absolute density of the raw materials.

It is often reported in the literature that the incorporation of composites leads to a significant loss of workability, which can be avoided either by increasing the water content (water to cement ratio) or by incorporating a superplasticizer. In fact, due to flocculation, composites (especially fine fraction <80 µm) can “absorb” or trap part of the mixing water leading to workability loss. In order to assess the workability loss due to the incorporation of composites, yield stress measurements were performed on cement pastes using a rotational rheometer AR 2000EX (TA Instruments, New Castle, DE, USA) equipped with four-blade vane geometry. The yield stresses were measured with the stress growth procedure [40,41,42] in triplicate. The effect of the superplasticizer and water to cement ratio was examined in cement paste with the 15% replacement of cement with the fine fraction of composite (Table 2). Cement pastes were mixed with deionized water at ambient temperature (20 ± 2 °C) in a planetary agitator according to the following sequence: 5 min mixing at 500 rpm, scraping the mixer walls to homogenize the mix (30 s), and 2 min mixing at 1000 rpm. A polycarboxylate-based superplasticizer with a dry extract of 20% was added after 5 min of mixing (delayed addition).

Table 2.

Composition of the cement pastes.

Absorption tests were also carried out on the composites according to the EN 1170-6 standard [43]. So, for mortar composition, an equivalent water to cement (w/c) ratio considering the “absorbed” water is used (Table 3) to achieve the same workability.

Table 3.

Composition of the studied cement mortars.

The mortars were prepared according to the European standard [38]. The composition of the different mortars is shown in Table 3. Due to the difference in density (Table 1), a part of the volume of sand was replaced by composites. Four replacement rates were used: 3, 5, 10, and 15 vol%.

The mixing procedure was carried out according to EN 196-1 standard [38]. First, water and cement were placed into the bowl and mixed at low speed for 30 s. Then, sand was added continuously during the next 30 s, and the mixing was performed at high speed for an additional 30 s. The mixer was then stopped for 90 s. During the first 30 s, the mixer walls were scraped to homogenize the mortar, and the mixing then continued for 60 s at high speed.

For each mortar composition, three specimens were prepared and placed in prismatic molds 40 × 40 × 160 mm3. After 24 h, all the samples were demolded and immersed in water at 20 °C for 28 days.

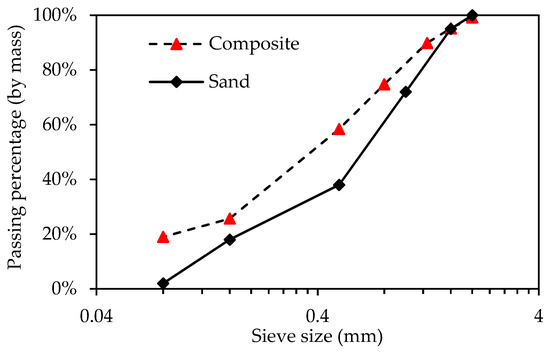

The mechanical tests were carried out in accordance with the NF EN 196-1 standard at 28 days [38]. For each mortar composition, a three-point bending test was performed on three specimens (40 × 40 × 160 mm3) using an MTS machine-100kN (MTS Systems, Créteil, France) equipped with a camera for image acquisition under a displacement rate of 0.5 mm/min (Figure 4a). Fifteen samples were tested using the 3-point bending test.

Figure 4.

Three-point bending test (a) and compression test (b).

The compressive strength was measured on two halves of the prism broken on the bending test using a loading machine 3R RP400E-425kN (Montauban, France) with a loading speed of 2.4 kN/s (Figure 4b). Six specimens were used to determine the compressive strength of each mortar composition.

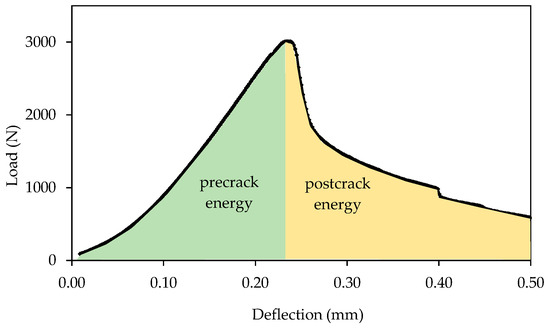

The flexural toughness can be described by the energy under the load-deflection curve up to the final deflection. It is worth pointing out that the final (or design) deflection should be unchangeable for mortar mix once it is specified, while the first crack peak can vary from sample to sample [44]. In this study, the flexural toughness was assessed by calculating the total energy (precrack and postcrack energies) under the load-deflection curve (Figure 5).

Figure 5.

Determination of the flexural toughness.

3. Results and Discussion

3.1. Effect of the Fine Fraction of the Composite on the Workability

Yield stress measurements were performed to examine the effect of the fine fraction of GFRP (less than 80 µm) on the workability of the cement paste. It can be noted that the yield stress is a strong indicator of the workability of cement-based materials and can be directly correlated to the slump [45]. It corresponds to the minimum shear stress required to induce a flow. Figure A1 presents an example of the shear stress–shear strain curves obtained with the stress growth procedure. The yield stress corresponds to the maximum shear strain (peak or plateau).

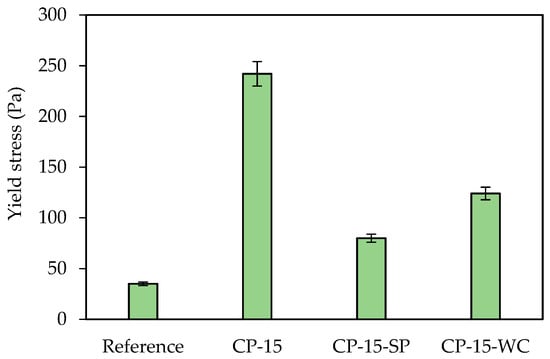

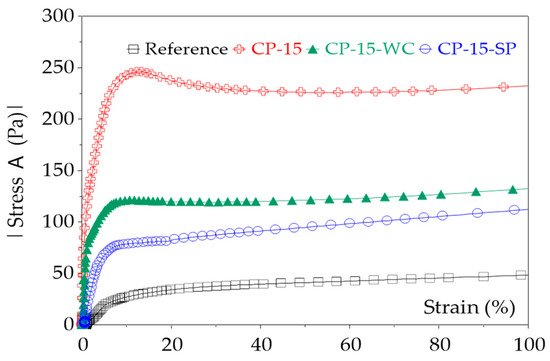

Figure 6 presents the effect of the incorporation of a fine fraction of GFRP on the yield stress of the cement paste. The yield stress of the neat cement paste (reference) was 35 Pa. The substitution of 15% cement with a fine fraction of GFRP led to a significant increase in the yield stress (240 Pa), indicating a loss of workability. In fact, this workability loss is due to the flocculation of the glass fiber/resin particles. So, part of the mixing water is trapped in the composite. Others studies have highlighted this flocculation effect of glass fibers, which increases the water demand [29,30]. The dispersive action of the superplasticizer (CP-15-SP) allowed the yield stress to be decreased (80 Pa). The workability was thus improved by releasing the water trapped in the flocculated particles.

Figure 6.

Yield stress of the studied cement pastes.

Furthermore, the workability can also be improved by increasing the water to cement ratio (CP-15-WC). This increase makes it possible to reduce the yield stress (124 Pa) without necessarily deflocculating the particles. The supplement of water just compensates for the water trapped between the particles. However, this increase in the water content is expected to decrease the mechanical strength.

3.2. Effect of the GFRP Waste on the Mechanical Strength

Flexural and compressive tests were performed after 28 days. The results are summarized in Table A1 and Table A2 (Appendix A).

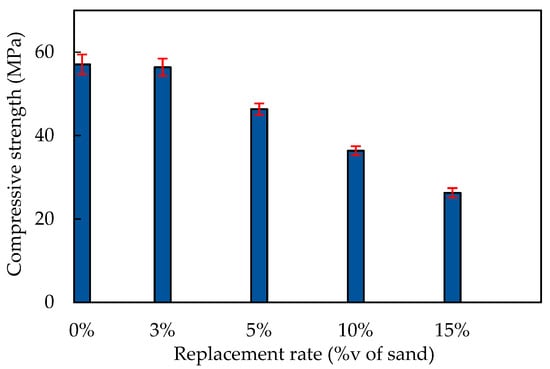

Figure 7 presents the effect of the partial replacement of sand with the composite on the compressive strength. For the control sample without GFRP, the compressive strength was 57 MPa. The substitution of 3% of sand with GFRP slightly affected the compressive strength. Beyond this rate, a significant drop in the compressive strength was observed. It is worth noting that the loss of the compressive strength cannot be only due to the sand replacement but also to the increase in the water content (equivalent w/c).

Figure 7.

Effect of the GFRP on the compressive strength of the cement mortars.

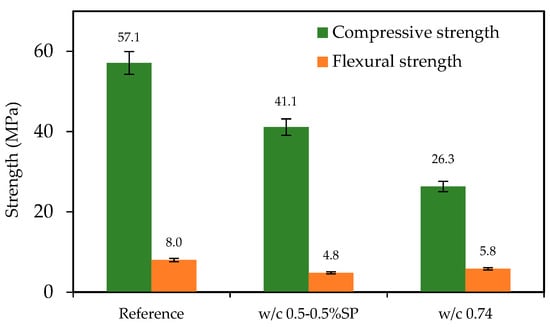

As shown in Figure 8, adding a superplasticizer without changing the water/cement ratio made it possible to limit the loss of the compressive strength. The cement mortar with 15% GFRP and the same w/c ratio as the reference sample (w/c of 0.5), but with 0.5%SP, had a compressive strength of 41.1 MPa, while the cement mortar with the same replacement rate, but with an equivalent w/c of 0.7, displayed a compressive strength of 26.3 MPa. The addition of water, which compensates for the water absorbed to maintain workability, therefore caused a significant loss of compressive strength probably due to an increase in the porosity. The superplasticizer dosage required to maintain the workability with w/c of 0.5 was 0.5% (dry extract). This dosage was too high, and its contribution to reducing the loss of compressive strength was not significant. In addition, the flexural strength did not seem to improve with the addition of the superplasticizer. This is why adjusting w/c ratio appears more suitable than adding a superplasticizer, when a high compressive strength is not required.

Figure 8.

Compressive strength of the cement mortar with 15% GFRP.

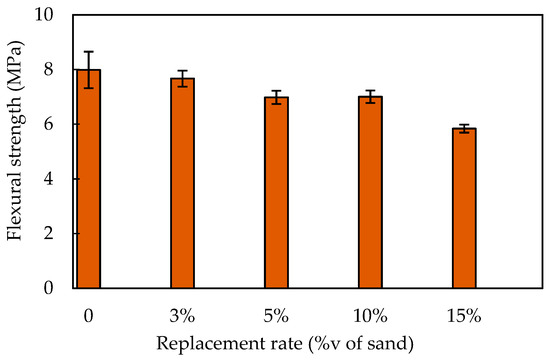

Furthermore, the flexural strength as a function of the replacement rate is shown in Figure 9. It can be noted that the partial substitution of sand with GFRP was accompanied by a reduction in the flexural strength. The reference sample displayed a flexural strength of about 8 MPa, while the cement mortar with 15% composite exhibited a flexural strength of 5.8 MPa.

Figure 9.

Effect of the GFRP on the flexural strength of cement mortars.

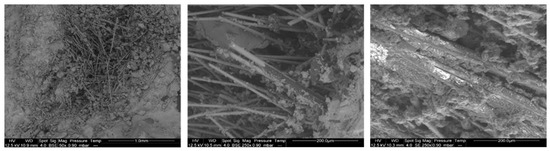

The reduction in the strengths, in particular the compressive strength, can be explained by a poor bonding of the GFRP particles/cement paste, an increase in voids, and a heterogeneous distribution of waste in the mortar [8,9,10,32]. The microstructure of the fractured surface of the cement mortars after the bending test was observed by scanning electron microscopy (SEM Quanta 200 FEG-FEI Company, Hillsboro, OR, USA) (Figure 10). The SEM images highlighted a heterogeneous distribution of fibers, which tended to agglomerate. These agglomerated fibers can trap part of the mixing water, leading to workability loss. In addition, the adhesion of the cement paste to the fibers seems poor, probably due to resin residue.

Figure 10.

SEM observations of the fractured surface of the cement mortar containing 10% GFRP (BSE).

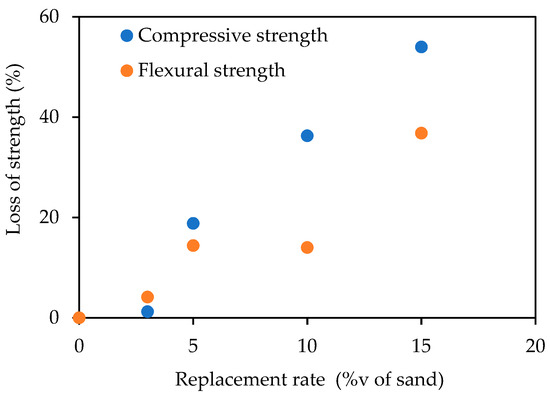

As shown in Figure 11, the compressive strength was more affected by the sand replacement than the flexural strength was. The decrease in the compressive strength in mortar containing 15% GFRP was approximately 54%, while the flexural strength decreased by 37%. Additionally, the decrease in the flexural strength of 10% GFRP mortar was only 14%, while the compressive strength decreased by 37%.

Figure 11.

Loss of the compressive and flexural strength as a function of the replacement rate.

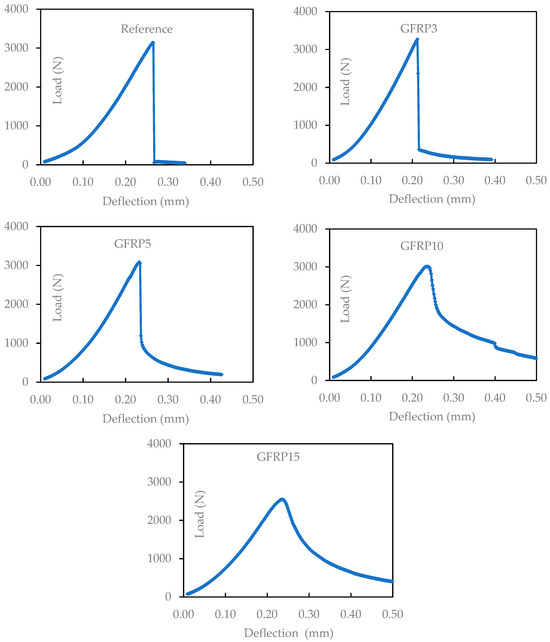

The 3-point bending test allowed the observation of a less sudden and less fragile failure with the incorporation of GFRP. The brittleness of the cement mortar seems to be attenuated with the replacement of sand with GFRP. In fact, at the rupture, the reference mortars split into two halves, while the samples containing the GFRP waste showed crack propagation but did not split into two halves, suggesting that brittleness has improved.

As shown in Figure 12, the incorporation of GFRP affects the shape of the post-peak force–deflection curves. These curves, obtained from three-point bending tests, reveal that the reference mortar displayed a rapid decrease in the load with a rapid propagation of cracks after initiation. This type of curve is characteristic of brittle rupture. For the cement mortars containing GFRP, the load gradually decreased after the peak suggesting an attenuation of brittleness. It is worth noting that some studies have reported an improvement in the toughness of cementitious materials incorporating GFRP waste, which contributes to the reduction in crack propagation, especially due to restrained shrinkage [29,35,36,37].

Figure 12.

Load–deflection curve obtained with a 3-point bending test for different proportions of GFRP within mortars.

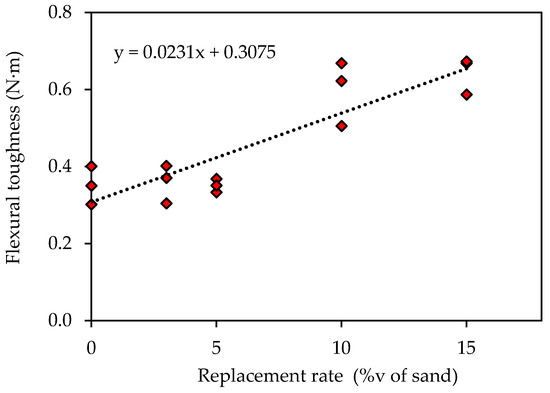

In order to evaluate the attenuation in the brittleness of mortars containing GFRP, a flexural toughness corresponding to the total energy under the loading curve was determined [44]. Figure 13 presents the variation in the flexural toughness as a function of the replacement rate, and Table A3 summarizes the obtained results.

Figure 13.

Flexural toughness as a function of the replacement rate with GFRP waste.

It can be noted that the mortars incorporating GFRP display a higher toughness than the reference mortar. In fact, the rupture of the reference mortar without GFRP is very brittle as soon as the first crack appears. This reference mortar displays a flexural toughness of 0.351 N.m, while the mortar incorporating 15% GFRP has a relatively higher toughness (0.642 N·m), despite the reduction in the flexural strength, indicating a reduction in the brittleness after the initiation of the first crack. Therefore, it seems that the fibers contained in the GFRP help slow down the propagation of cracking. However, it has to be kept in mind that the improvement in the brittleness depends on the degradation of the fibers in the strongly alkaline environment of the cement paste (alkaline hydrolysis) [46,47]. The microstructure of the fractured surface of the cement mortars after the bending test showed the presence of glass fibers in the cement matrix after 28 days (Figure 10). However, it will be necessary to verify the non-degradation of these fibers over longer periods of time.

This improvement in the flexural toughness would make it possible to limit the effects of restrained shrinkage. However, in order to limit the reduction in strengths, an improvement in the dispersion and orientation of the GFRP waste must be carried out. The results obtained in this work are encouraging and clearly show that this waste can be incorporated in cementitious materials.

4. Conclusions

This study aimed to investigate the effect of the incorporation of glass fiber-reinforced polymer waste (GFRP), coming from a shipyard, on the mechanical strength and workability of cement mortars.

The substitution of 3% of sand volume with GFRP waste does not affect the workability and mechanical strengths. However, increasing the GRFP content results in workability loss due to the flocculation of the GFRP particles, which increases the water demand. This workability loss requires an adjustment of the water to cement ratio, but the mechanical strengths are reduced. Adding superplasticizer can improve the workability without increasing the water to cement ratio, but the required dosage is relatively high. Moreover, the addition of the superplasticizer does not significantly limit the loss of strength. The compressive strength appears to be more affected by the incorporation of GFRP waste than the flexural strength. The decrease in the flexural strength of 15% GFRP mortar is only 37%, while the compressive strength decreases by 54%. The decrease in the mechanical strengths can be explained by a poor bonding of the GFRP particles/cement paste, an increase in voids, and a heterogeneous partitioning of waste in the mortar.

Furthermore, it seems that the incorporation of GFRP waste can enhance the flexural toughness, which increases from 0.351 N.m for the reference sample to 0.642 N·m for the sample with 15% GFRP. This improvement in the toughness can be very interesting from a practical point of view, particularly to limit the effect of the restrained shrinkage. The optimization of the dispersion and distribution of GFRP waste should be performed in order to improve the mechanical behavior.

Author Contributions

Conceptualization, Y.E.B., B.F., R.L., D.P. and P.I.; methodology, Y.E.B., B.F., R.L., D.P. and P.I.; validation, Y.E.B., B.F., R.L., D.P. and P.I.; formal analysis, Y.E.B. and B.F.; investigation, Y.E.B. and B.F.; data curation, Y.E.B. and B.F.; writing—original draft preparation, Y.E.B.; writing—review and editing, Y.E.B.; visualization, Y.E.B.; supervision, Y.E.B., R.L., D.P. and P.I. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All the data are available in the Appendix A.

Conflicts of Interest

The authors declare no conflicts of interest.

Appendix A

Figure A1.

Shear stress–shear strain curves of studied cement pastes.

Table A1.

Results of the 3-point bending tests at 28 days.

Table A1.

Results of the 3-point bending tests at 28 days.

| Samples | Stress (MPa) | Strain (%) | Average Stress (MPa) | Average Strain (%) | Standard Deviation |

|---|---|---|---|---|---|

| Ref-1 | 7.35 | 0.64 | 7.98 | 0.63 | 0.67 |

| Ref-2 | 7.92 | 0.66 | |||

| Ref-3 | 8.68 | 0.6 | |||

| GRFP3-1 | 7.55 | 0.64 | 7.67 | 0.59 | 0.29 |

| GRFP3-2 | 7.45 | 0.5 | |||

| GRFP3-3 | 8 | 0.64 | |||

| GRFP5-1 | 7.23 | 0.56 | 6.98 | 0.53 | 0.24 |

| GRFP5-2 | 6.96 | 0.54 | |||

| GRFP5-3 | 6.75 | 0.5 | |||

| GRFP10-1 | 7.04 | 0.56 | 7.00 | 0.56 | 0.23 |

| GRFP10-2 | 7.21 | 0.58 | |||

| GRFP10-3 | 6.76 | 0.54 | |||

| GRFP15-1 | 5.95 | 0.56 | 5.84 | 0.62 | 0.15 |

| GRFP15-2 | 5.67 | 0.52 | |||

| GRFP15-3 | 5.89 | 0.78 |

Table A2.

Results of the compressive tests at 28 days.

Table A2.

Results of the compressive tests at 28 days.

| Mortars | Stress (MPa) | Average Stress (MPa) | Standard Deviation | Incorporation Rate |

|---|---|---|---|---|

| Ref1-1 | 58.22 | 57.07 | 2.37 | 0% |

| Ref1-2 | 59.99 | |||

| Ref 2-1 | x | |||

| Ref 2-2 | 54.02 | |||

| Ref 3-1 | 57.73 | |||

| Ref 3-2 | 55.38 | |||

| GRFP3-1-1 | 54.12 | 56.38 | 2.06 | 3% |

| GRFP3-1-2 | 55 | |||

| GRFP3-2-1 | 54.5 | |||

| GRFP3-2-2 | 58.32 | |||

| GRFP3-3-1 | 58.69 | |||

| GRFP3-3-2 | 57.65 | |||

| GRFP5-1-1 | 47.84 | 46.34 | 1.37 | 5% |

| GRFP5-1-2 | 47.12 | |||

| GRFP5-2-1 | 45.33 | |||

| GRFP5-2-2 | 47.75 | |||

| GRFP5-3-1 | 45.13 | |||

| GRFP5-3-2 | 44.89 | |||

| GRFP10-1-1 | 35.1 | 36.37 | 1.07 | 10% |

| GRFP10-1-2 | 35.98 | |||

| GRFP10-2-1 | 36.51 | |||

| GRFP10-2-2 | 38.33 | |||

| GRFP10-3-1 | 36.29 | |||

| GRFP10-3-2 | 36 | |||

| GRFP15-1-1 | 27.10 | 26.27 | 1.14 | 15% |

| GRFP15-1-2 | 27.57 | |||

| GRFP15-2-1 | 25.87 | |||

| GRFP15-2-2 | 24.35 | |||

| GRFP15-3-1 | 26.72 | |||

| GRFP15-3-2 | 26.03 |

Table A3.

Flexural toughness of the cement mortars.

Table A3.

Flexural toughness of the cement mortars.

| Sample | Load at the First Crack (N) | First Crack Deflection (mm) | Load at the Final Deflection (N) | Final Deflection (mm) | Total Energy * (N·m) | Flexural Toughness (N·m) |

|---|---|---|---|---|---|---|

| Ref-1 | 3040 | 0.26 | 44 | 0.34 | 0.302 | |

| Ref-2 | 3380 | 0.27 | 43 | 0.42 | 0.350 | 0.351 |

| Ref-3 | 3838 | 0.26 | 92 | 0.34 | 0.400 | |

| GRFP3-1 | 3237 | 0.27 | 100 | 0.44 | 0.370 | |

| GRFP3-2 | 3273 | 0.21 | 97 | 0.39 | 0.304 | 0.359 |

| GRFP3-3 | 3497 | 0.26 | 153 | 0.39 | 0.401 | |

| GRFP5-1 | 3083 | 0.23 | 194 | 0.43 | 0.368 | |

| GRFP5-2 | 2882 | 0.23 | 363 | 0.31 | 0.333 | 0.351 |

| GRFP5-3 | 2880 | 0.21 | 298 | 0.34 | 0.351 | |

| GRFP10-1 | 3008 | 0.24 | 436 | 0.59 | 0.668 | |

| GRFP10-2 | 3077 | 0.24 | 420 | 0.46 | 0.505 | 0.598 |

| GRFP10-3 | 2917 | 0.22 | 178 | 0.74 | 0.622 | |

| GRFP15-1 | 2548 | 0.24 | 188 | 0.74 | 0.587 | |

| GRFP15-2 | 2421 | 0.22 | 266 | 0.79 | 0.668 | 0.642 |

| GRFP15-3 | 2529 | 0.32 | 346 | 0.73 | 0.672 |

* Total energy under the load–deflection curve.

References

- Pierrehumbert, R. There is no Plan B for dealing with the climate crisis. Bull. At. Sci. 2019, 75, 215–221. [Google Scholar] [CrossRef]

- Tao, Y.; Hadigheh, S.A.; Wei, Y. Recycling of glass fibre reinforced polymer (GFRP) composite wastes in concrete: A critical review and cost benefit analysis. Structures 2023, 53, 1540–1556. [Google Scholar] [CrossRef]

- Papadakis, N.; Ramírez, C.; Reynolds, N. 16—Designing composite wind turbine blades for disposal, recycling or reuse. In Woodhead Publishing Series in Composites Science and Engineering; Goodship, V.B.T.-M., Recycling and Reuse of Waste Composites, Eds.; Woodhead Publishing: Sawston, UK, 2010; pp. 443–457. [Google Scholar]

- Cousins, D.S.; Suzuki, Y.; Murray, R.E.; Samaniuk, J.R.; Stebner, A.P. Recycling glass fiber thermoplastic composites from wind turbine blades. J. Clean. Prod. 2019, 209, 1252–1263. [Google Scholar] [CrossRef]

- Pickering, S.J. Recycling technologies for thermoset composite materials—Current status. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1206–1215. [Google Scholar] [CrossRef]

- Oliveux, G.; Dandy, L.O.; Leeke, G.A. Current status of recycling of fibre reinforced polymers: Review of technologies, reuse and resulting properties. Prog. Mater. Sci. 2015, 72, 61–99. [Google Scholar] [CrossRef]

- Pickering, S.J.; Kelly, R.M.; Kennerley, J.R.; Rudd, C.D.; Fenwick, N.J. A fluidised-bed process for the recovery of glass fibres from scrap thermoset composites. Compos. Sci. Technol. 2000, 60, 509–523. [Google Scholar] [CrossRef]

- Correia, J.R.; Almeida, N.M.; Figueira, J.R. Recycling of FRP composites: Reusing fine GFRP waste in concrete mixtures. J. Clean. Prod. 2011, 19, 1745–1753. [Google Scholar] [CrossRef]

- Tittarelli, F.; Kawashima, S.; Tregger, N.; Moriconi, G.; Shah, S.P. Effect of GRP by-product addition on plastic and hardened properties of cement mortars. In Proceedings of the 2nd International Conference on Sustainable Construction Materials and Technologies, Ancona, Italy, 28 June 2010; pp. 677–687. [Google Scholar]

- Tittarelli, F.; Moriconi, G. Use of GRP industrial by-products in cement based composites. Cem. Concr. Compos. 2010, 32, 219–225. [Google Scholar] [CrossRef]

- Ribeiro, M.C.S.; Meira-Castro, A.; Silva, F.; Santos, J.; Meixedo, J.; Fiúza, A.; Dinis, M.; Alvim, M. Re-use assessment of thermoset composite wastes as aggregate and filler replacement for concrete-polymer composite materials: A case study regarding GFRP pultrusion wastes. Resour. Conserv. Recycl. 2015, 104, 417–426. [Google Scholar] [CrossRef]

- Korzeniowski, W.; Skrzypkowski, K.; Poborska-Młynarska, K. The Idea of the Recovery of Municipal Solid Waste Incineration (MSWI) Residues in Kłodawa Salt Mine S.A.by Filling the Excavations with Self-Solidifying Mixtures. Arch. Min. Sci. 2018, 63, 553–565. [Google Scholar] [CrossRef] [PubMed]

- Fox, T. Recycling Wind Turbine Blade Composite Material as Aggregate in Concrete. Master’s Thesis, Iowa State University, Ames, IA, USA, 2016. Available online: https://www.imse.iastate.edu/files/2014/03/Fox-Tyler-Recycling-wind-turbine-blade-composite-material-as-aggregate-in-concrete.pdf (accessed on 28 October 2023).

- Chen, X.; Chen, H.; Tan, W. Effect of glass powder on the mechanical and drying shrinkage of glass-fiber-reinforced cementitious composites. Case Stud. Constr. Mater. 2022, 17, e01587. [Google Scholar] [CrossRef]

- Khorami, M.; Ganjian, E.; Mortazavi, A.; Saidani, M.; Olubanwo, A.; Gand, A. Utilisation of waste cardboard and Nano silica fume in the production of fibre cement board reinforced by glass fibres. Constr. Build. Mater. 2017, 152, 746–755. [Google Scholar] [CrossRef]

- Cheng, C.; He, J.; Zhang, J.; Yang, Y. Study on the time-dependent mechanical properties of glass fiber reinforced cement (GRC) with fly ash or slag. Constr. Build. Mater. 2019, 217, 128–136. [Google Scholar] [CrossRef]

- Song, M.; Purnell, P.; Richardson, I. Microstructure of interface between fibre and matrix in 10-year aged GRC modified by calcium sulfoaluminate cement. Cem. Concr. Res. 2015, 76, 20–26. [Google Scholar] [CrossRef]

- Devi, C.; Vijayan, D.S.; Nagalingam, R.; Arvindan, S. A review of the implementations of glass fiber in concrete technology. Mater. Today Proc. 2022, 62, 2010–2015. [Google Scholar] [CrossRef]

- Penacho, P.; De Brito, J.; Veiga, M.R. Physico-mechanical and performance characterization of mortars incorporating fine glass waste aggregate. Cem. Concr. Compos. 2014, 50, 47–59. [Google Scholar] [CrossRef]

- Oliveira, R.; De Brito, J.; Veiga, R. Incorporation of fine glass aggregates in renderings. Constr. Build. Mater. 2013, 44, 329–341. [Google Scholar] [CrossRef]

- Marsh, H.N.; Clarke, L.L. Glass Fiber Reinforced Cement Base Materials; American Concrete Institute, ACI Special Publication: Farmington Hills, MI, USA, 1974; Volume SP-044, pp. 247–264. [Google Scholar]

- Zhang, T.; Zhang, J.; Zhao, Y.; Ai, H. Study on the Performance and Mechanism of Glass Fiber-Reinforced MgO-SiO2-H2O Cement. Materials 2023, 16, 6668. [Google Scholar] [CrossRef]

- Wang, P.; Wu, H.L.; Ke, L.Y.W.; Li, W.W.; Leung, C.K.Y. Mechanical properties and microstructure of glass fiber reinforced polymer (GFRP) rebars embedded in carbonated reactive MgO-based concrete (RMC). Cem. Concr. Compos. 2023, 142, 105207. [Google Scholar] [CrossRef]

- Asokan, P.; Osmani, M.; Price, A.D.F. Assessing the recycling potential of glass fibre reinforced plastic waste in concrete and cement composites. J. Clean. Prod. 2009, 17, 821–829. [Google Scholar] [CrossRef]

- Ribeiro, M.C.S.; Ferreira, A.J.M.; Marques, A.T. Effect of natural and artificial weathering on the long-term flexural performance of polymer mortars. Mech. Compos. Mater. 2009, 45, 515–526. [Google Scholar] [CrossRef]

- Fowler, D.W. Polymers in concrete: A vision for the 21st century. Cem. Concr. Compos. 1999, 21, 449–452. [Google Scholar] [CrossRef]

- Ribeiro, M.C.S.; Reis, J.M.L.; Ferreira, A.J.M.; Marques, A.T. Thermal expansion of epoxy and polyester polymer mortars—Plain mortars and fibre-reinforced mortars. Polym. Test. 2003, 22, 849–857. [Google Scholar] [CrossRef]

- Tavares, C.M.L.; Ribeiro, M.C.S.; Ferreira, A.J.M.; Guedes, R.M. Creep behaviour of FRP-reinforced polymer concrete. Compos. Struct. 2002, 57, 47–51. [Google Scholar] [CrossRef]

- Mastali, M.; Dalvand, A.; Sattarifard, A.R.; Abdollahnejad, Z. Effect of different lengths and dosages of recycled glass fibres on the fresh and hardened properties of SCC. Mag. Concr. Res. 2018, 70, 1175–1188. [Google Scholar] [CrossRef]

- García, D.; Vegas, I.; Cacho, I. Mechanical recycling of GFRP waste as short-fiber reinforcements in microconcrete. Constr. Build. Mater. 2014, 64, 293–300. [Google Scholar] [CrossRef]

- Farinha, C.B.; de Brito, J.; Veiga, R. Assessment of glass fibre reinforced polymer waste reuse as filler in mortars. J. Clean. Prod. 2019, 210, 1579–1594. [Google Scholar] [CrossRef]

- Oliveira, P.S.; Antunes, M.L.P.; da Cruz, N.C.; Rangel, E.C.; de Azevedo, A.R.G.; Durrant, S.F. Use of waste collected from wind turbine blade production as an eco-friendly ingredient in mortars for civil construction. J. Clean. Prod. 2020, 274, 122948. [Google Scholar] [CrossRef]

- Guo, P.; Meng, W.; Nassif, H.; Gou, H.; Bao, Y. New perspectives on recycling waste glass in manufacturing concrete for sustainable civil infrastructure. Constr. Build. Mater. 2020, 257, 119579. [Google Scholar] [CrossRef]

- Baturkin, D.; Hisseine, O.A.; Masmoudi, R.; Tagnit-Hamou, A.; Massicotte, L. Valorization of recycled FRP materials from wind turbine blades in concrete. Resour. Conserv. Recycl. 2021, 174, 105807. [Google Scholar] [CrossRef]

- Yazdanbakhsh, A.; Bank, L.C.; Rieder, K.-A.; Tian, Y.; Chen, C. Concrete with discrete slender elements from mechanically recycled wind turbine blades. Resour. Conserv. Recycl. 2018, 128, 11–21. [Google Scholar] [CrossRef]

- Rodin, H.; Nassiri, S.; Englund, K.; Fakron, O.; Li, H. Recycled glass fiber reinforced polymer composites incorporated in mortar for improved mechanical performance. Constr. Build. Mater. 2018, 187, 738–751. [Google Scholar] [CrossRef]

- Zhou, B.; Zhang, M.; Wang, L.; Ma, G. Experimental study on mechanical property and microstructure of cement mortar reinforced with elaborately recycled GFRP fiber. Cem. Concr. Compos. 2021, 117, 103908. [Google Scholar] [CrossRef]

- EN 196-1:2016; Methods of Testing Cement - Part 1: Determination of Strength. European Commission: Brussels, Belgium, 2016.

- NF EN 933-1; Tests for Geometrical Properties of Aggregates, Part 1: Determination of Particle Size Distribution-Sieving Method. European Commission: Brussels, Belgium, 2012.

- Mahaut, F.; Chateau, X.; Coussot, P.; Ovarlez, G. Yield stress and elastic modulus of suspensions of noncolloidal particles in yield stress fluids. J. Rheol. 2008, 52, 287–313. [Google Scholar] [CrossRef]

- Perrot, A.; Lecompte, T.; Khelifi, H.; Brumaud, C.; Hot, J.; Roussel, N. Yield stress and bleeding of fresh cement pastes. Cem. Concr. Res. 2012, 42, 937–944. [Google Scholar] [CrossRef]

- El Bitouri, Y.; Azéma, N. Contribution of turbidimetry on the characterization of cement pastes bleeding. Adv. Cem. Res. 2023, 35, 180–190. [Google Scholar] [CrossRef]

- NF EN 1170-6; Test Method for Glass-Fibre Reinforced Cement—Part 6: Determination of the Absorption of Water by Immersion and Determination of the Dry Density. European Commission: Brussels, Belgium, 1998.

- Chen, L. Flexural Toughness of Fibre Reinforced Concrete. Ph.D. Thesis, The University of British Columbia, Vancouver, BC, Canada, 1995. [Google Scholar]

- Roussel, N. Correlation between yield stress and slump: Comparison between numerical simulations and concrete rheometers results. Mater. Struct. 2006, 39, 501–509. [Google Scholar] [CrossRef]

- Arczewska, P.; Polak, M.A.; Penlidis, A. Degradation of glass fiber reinforced polymer (GFRP) bars in concrete environment. Constr. Build. Mater. 2021, 293, 123451. [Google Scholar] [CrossRef]

- Bentur, A.; Ben-Bassat, M.; Schneider, D. Durability of Glass-Fiber-Reinforced Cements with Different Alkali-Resistant Glass Fibers. J. Am. Ceram. Soc. 1985, 68, 203–208. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).