-

Knowledge Sharing: Key to Sustainable Building Construction Implementation

Knowledge Sharing: Key to Sustainable Building Construction Implementation -

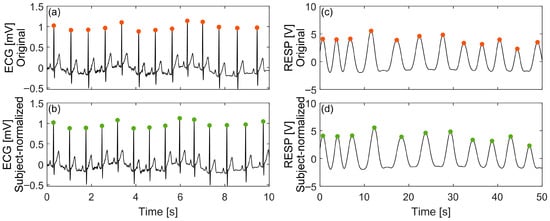

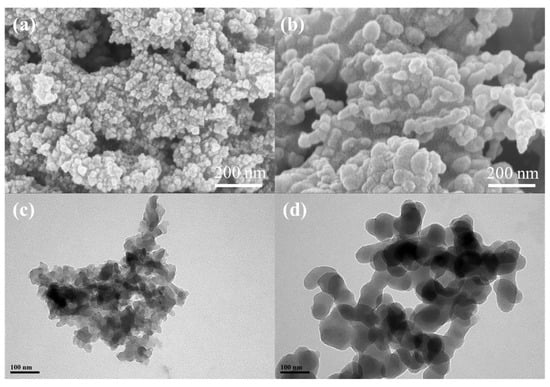

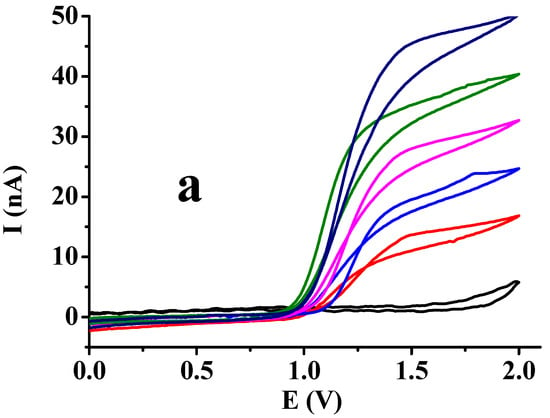

ModuLab: A Modular Sensor Platform for Proof-of-Concept Real-Time Environmental Monitoring

ModuLab: A Modular Sensor Platform for Proof-of-Concept Real-Time Environmental Monitoring -

apex Mk.2/Mk.3: Secure Live Transmission of the First Flight of Trichoplax adhaerens in Space Based on Components Off-the-Shelf

apex Mk.2/Mk.3: Secure Live Transmission of the First Flight of Trichoplax adhaerens in Space Based on Components Off-the-Shelf -

Estimation of Growth Parameters of Eustoma grandiflorum Using Smartphone 3D Scanner

Estimation of Growth Parameters of Eustoma grandiflorum Using Smartphone 3D Scanner

Journal Description

Eng

- Open Access— free for readers, with article processing charges (APC) paid by authors or their institutions.

- High Visibility: indexed within ESCI (Web of Science), Scopus, Ei Compendex, EBSCO and other databases.

- Journal Rank: JCR - Q2 (Engineering, Multidisciplinary) / CiteScore - Q2 (Engineering (miscellaneous))

- Rapid Publication: manuscripts are peer-reviewed and a first decision is provided to authors approximately 19.7 days after submission; acceptance to publication is undertaken in 2.9 days (median values for papers published in this journal in the first half of 2025).

- Recognition of Reviewers: APC discount vouchers, optional signed peer review, and reviewer names published annually in the journal.

Latest Articles

Highly Accessed Articles

Latest Books

E-Mail Alert

News

Topics

Deadline: 31 October 2025

Deadline: 31 December 2025

Deadline: 31 January 2026

Deadline: 28 February 2026

Conferences

Special Issues

Deadline: 31 October 2025

Deadline: 31 December 2025

Deadline: 31 December 2025

Deadline: 31 December 2025